Page 1

1

EXCLUSIVE

C.A.I.

R.A.I.

MIX C.S.I.

MIX R.S.I.

EN INSTALLER AND USER MANUAL

ES MANUAL DE INSTALACIÓN Y USO

PT MANUAL PARA INSTALAÇÃO E USO

FR MANUEL D’INSTALLATION ET D’UTILISATION

Page 2

2

English

EXCLUSIVE boiler complies with basic requirements of

the following Directives:

• Gas directive 90/396/EEC

• Yield directive 92/42/EEC

• Electromagnetic compatibility directive 89/336/EEC

• Low-voltage directive 73/23/EEC

Thus, it is EC-marked

La chaudière EXCLUSIVE est conforme aux

prescriptions essentielles des Directives suivantes:

• Directive gaz 90/396/CEE

• Directive rendements 92/42/CEE

• Directive compatibilité électromagnétique 89/336/

CEE

• Directive basse tension 73/23/CEE

et peut donc être estampillée CE

Français

0694

51BP2736 (MIX C.S.I. - MIX R.S.I.)

51BP2679 (C.A.I. - R.A.I.)

Español

La caldera EXCLUSIVE es conforme a los requisitos

esenciales de las siguientes Directivas:

• Directiva gas 90/396/CEE

• Directiva rendimientos 92/42/CEE

• Directiva compatibilidad electromagnética 89/336/

CEE

• Directiva baja tensión 73/23/CEE

y por lo tanto es titular de la marca CE

Portugûes

A caldeira EXCLUSIVE está conforme com os requisitos

essenciais das seguintes Directivas:

• Directiva gás 90/396/CEE

• Directiva rendimentos 92/42/CEE

• Directiva compatibilidade electromagnética 89/336/

CEE

• Directiva baixa tensão 73/23/CEE

é portanto titular de marcação CE

Page 3

3

Installer’s-user’s manual ........................................... 4

Boiler operating elements ................................. 91-92

Hydraulic circuit .................................................. 93-94

Electric diagrams ................................................ 95-98

Circulator residual head ....................................... 102

This handbook contains data and information for both users and installers. In detail:

- the chapters entitled “Installing the boiler, Water connections, Gas connection, Electrical connection, Filling and draining,

Evacuating products of combustion, Technical data, Programming parameters, Gas regulation and conversion” are intended

for installers;

- the chapters entitled “Warnings and safety devices, Switching on and using” are for both users and installers.

The control panel is different between C.A.I.-MIX C.S.I. and R.A.I.-MIX R.S.I. (see detail). Please read, in the booklet, the instructions

referring to your boiler model.

English

The following symbols are used in this manual:

CAUTION = operations requiring special care and adequate preparation

NOT ALLOWED = operations that MUST NOT be performed

C.A.I. - MIX C.S.I. R.A.I. - MIX R.S.I.

Manual para el instalador-usuario ........................ 46

Elementos funcionales de la caldera ..............91-92

Circuito hidráulico .............................................. 93-94

Esquema eléctrico .............................................. 95-98

Altura de carga residual del circulador ................... 102

Este manual contiene datos e informaciones destinados tanto al usuario como al instalador. En especial:

- los capítulos “Instalación de la caldera, Conexiones hidráulicas, Conexión gas, Conexión eléctrica, Llenado y vaciado,

Evacuación productos de la combustión, Datos técnicos, Programación parámetros, Regulación y Transformación gas” son

los que se refieren al instalador;

- los capítulos “Advertencias y seguridades, y Encendido y funcionamiento” son los que se refieren tanto al usuario como al

instalador.

El panel de mando es diferente entre los modelos C.A.I.-MIX C.S.I. y R.A.I.-MIX R.S.I. (ver dibujo). Rogamos consulten el manual

para encontrar las instrucciones relativas a su modelo de caldera.

Español

En algunas partes del manual se utilizan los símbolos:

ATENCIÓN = para acciones que requieren particular atención y una adecuada

preparación

PROHIBIDO = para acciones que NO DEBEN efectuarse nunca

Manuel d’installation-utilisateur ........................... 25

Eléments fonctionnels de la chaudière .......... 91-92

Circuit hydraulique............................................. 93-94

Schéma électrique .............................................. 95-98

Prévalence résiduelle du circulateur .................. 102

Ce manuel contient des données et des informations destinées à l’utilisateur et à l’installateur. Plus précisément:

- les chapitres “Installation de la chaudière, Raccordements hydrauliques, Raccordement du gaz, Branchement électrique,

Remplissage et vidage, Evacuation des produits de la combustion, Données techniques, Configuration des paramètres, Réglage

et Transformation gaz ” s’adressent spécifiquement à l’installateur;

- les chapitres “Avertissements et mesures de sécurité, Allumage et fonctionnement” s’adressent à l’utilisateur et à l’installateur.

Le panneau de commande est différent entre les models C.A.I.-MIX C.S.I. et R.A.I.-MIX R.S.I. (voir dessin). On vous conseille de

consulter le manuel pour les instructions concernantes votre chaudière.

Français

Dans ce manuel nous utilisons parfois les symboles suivants:

ATTENTION = indique les actions demandant une prudence particulière et

une préparation adéquate

INTERDICTION = indique les actions NE DEVANT JAMAIS être exécutées

R.S.I.: DHW functions refer only if a water tank is connected (accessory available

on request).

R.S.I.: Los valores del sanitario son seleccionables sólo en el caso de conexión

con un interacumulador exterior (kit accesorio opcional).

R.S.I.: Les valeurs de la fonction sanitaire sont sélectionnables seulement en cas

de connexion avec un chauffe-eau (accessoire fourni sur demande).

Portugûes

Este livrete inclui dados e informações destinados quer ao usuário quer ao instalador. Especificadamente:

- os capítulos “Instalação da caldeira, Conexões hidráulicas, Conexão gás, Ligação eléctrica,

Enchimento e esvaziamento, Evacuação dos produtos da combustão, Dados técnicos, Programação parâmetros, Regulação

e Transformação gás” são aqueles referidos ao instalador:

- os capítulos “Advertências e seguranças e Ignição e Funcionamento” são aqueles referidos quer ao usuário quer ao instalador.

Os modelos C.A.I.-MIX C.S.I. e R.A.I.-MIX R.S.I. têm os painéis de comando diferentes (veja-se o desenho). Sugerimos consultar

o manual para as instruções relativas ao seu modelo de caldeira.

Manual do instalador-usu

ário ....................................

67

Elementos funcionais da caldeira ...................91-92

Circuito Hidráulico ............................................. 93-94

Diagrama Eléctrico ............................................. 95-98

Altura total de elevação residual

da bomba circuladora ........................................... 102

Em algumas partes do manual são utilizados os símbolos:

ATENÇÃO = para acções que exigirem particular cuidado e preparação

adequada

PROIBIDO = para acções que NÃO SE DEVEM absolutamente executar

R.S.I.: Os valores do circuito sanitário podem ser seleccionados somente com a

ligação a um boiler exterior (kit acessório a pedido).

Page 4

4

Boiler must only be installed by qualified personnel.

Boiler is available in the following models:

Exclusive C.A.I. is a B11BS-type wall-mounted boiler for DHW

production and heating; Exclusive R.A.I. is a B11BS-type wallmounted boiler for heating. This kind of appliance can’t be installed

in bedrooms, bathrooms or in those rooms where a fireplace without

an air intake system should be present.

Exclusive MIX C.S.I. is a C-type wall-mounted boiler for heating

and producing domestic hot water; Exclusive MIX R.S.I. is a C-type

wall-mounted boiler and is able to operate in different conditions:

- CASE A: only heating. The boiler doesn’t supply domestic hot water

- CASE B: only heating with water tank connected, managed by a

thermostat, to prepare domestic hot water

- CASE C: only heating with water tank connected (kit available

upon request), managed by a temperature sensor, to prepare

domestic hot water. Connecting a water tank not supplied by us,

please be sure that the NTC sensor ised has the following

features: 10 kOhm at 25°C, B 3435 ±1%.

Depending on the type of installation selected, it is necessary to set

the parameter “domestic hot water mode”. Refer to page 22 for

description and setting parameter operations.

This type of appliance can be installed in any kind of room as long

as the fumes discharge and the comburent air intake are taken

outside the room.

The following types of fumes outlet are available for this kind of

boiler: C12,C12x; C22; C32,C32x; C42,C42x; C52,C52x (26kW

and 30kW only); C62,C62x; C82,C82x. Installation must comply

with local standards and regulations in force.

For proper installation, we remind you that:

• the boiler must not be installed over a kitchen or any other cooking

equipment

• minimum spaces are to be left in order to allow maintenance

operations: at least 2,5 cm every side and 20 cm under the boiler

• it is forbidden to leave inflammable substances in the room

• suitably insulate heat-sensitive walls (e.g.: in wood).

2.

BOILER INSTALLATION

Model Type Category Power

C.A.I. Combined B11BS 24 kW

C.A.I. Combined B11BS 28 kW

R.A.I. CH only B11BS 28 kW

MIX C.S.I. Combined C 26 kW

MIX C.S.I. Combined C 30 kW

MIX C.S.I. Combined C 35 kW

MIX R.S.I. CH only C 30 kW

MIX R.S.I. CH only C 35 kW

1.

GENERAL SAFETY DEVICES

The boilers produced in our factory are built with care down to

the last component to protect both the user and installer from

eventual accidents. We therefore recommend qualified

personnel that after working on the product they should pay

particular attention to the wiring, especially the bare wires,

that must not be exposed outside the terminal board for any

rason to prevent any contact with the live parts of the wiring.

This instructions manual is integral parts of the product. Make

sure they remain with the boiler, even if it is transferred to

another owner or user or moved to another heating system. In

case of loss or damage, please contact your local Technical

Assistance Service for a new copy.

This boiler may only be installed and serviced by qualified

fitters who satisfy the requirements of local rules. Work must

be done in compliance with regulations in force and

subsequent updates.

The boiler must be serviced at least once a year. This should

be booked in advance with the Technical Assistance Service.

The installer shall instruct the user in the operation of the

boiler and the safety devices.

This boiler may only be used for what it was expressly built to

do. The manufacturer declines all contractual and noncontractual liability for injury to persons or animals or damage

to property deriving from errors made during installation,

adjustment and servicing and from improper use.

This appliance is used to produce hot water and must therefore

be connected to a heating and/or a domestic hot water system,

according to its performance and power.

After removing the packaging, make sure the contents are

undamaged and complete. If this is not the case, contact your dealer.

The safety valve outlet must be connected to a suitable

collection and venting system. The manufacturer declines all

liability for any damage caused by the safety valve.

The safety and automatic adjustment devices on the appliance

must never be modified during its lifetime, except by the maker

or dealer.

If the appliance develops a fault and/or works badly, switch it

off and do not attempt to repair it yourself.

Immediately after installation, inform the user that:

- in the event of leaks, he/she must shut off the water supply and

promptly inform the Technical Assistance Service

- C.A.I.-MIX C.S.I.: he/she must check from time to time to make

sure the

symbol is not lit on the control panel. This symbol

means that the pressure in the water system is incorrect. If

necessary, fill the system as described in the paragraph

“Boiler functions”

- R.A.I.-MIX R.S.I.: must periodically check, on the display, that

the pressure value is between 1 and 1,5 bar; if not fill the

system as described in the paragraph “Boiler functions”

- if the boiler is not planned to be used for a long period, he/

she should call in the Technical Assistance Service to perform

the following operations:

• turn off the main boiler and general system switches

• close the gas and water taps on both the heating (C.A.I.-

MIX C.S.I.-R.A.I.-MIX R.S.I.) and domestic hot water circuits

(C.A.I.-MIX C.S.I. only)

• drain the heating (C.A.I.-MIX C.S.I.-R.A.I.-MIX R.S.I.) and

domestic hot water (C.A.I.-MIX C.S.I. only) circuits to prevent

freezing.

Safety measures:

the boiler should not be used by children or unassisted disabled

people

electrical devices or equipment, such as switches, appliances,

etc., should not be used if there is a smell of gas or fumes. If

there is a gas leak, open all the doors and windows to ventilate the area, turn off the general gas tap and immediately call

the Technical Assistance Service

do not touch the boiler barefoot or if parts of your body are wet

or damp

press the

button until “- -” is shown on the display and

disconnect the electricity supply by turning off the two-position

system switch, before cleaning

it is forbidden to modify the safety or adjustment devices without

the manufacturer’s permission and relative instructions

safety system controlling exhaustion fumes (only C.A.I.

and R.A.I. models): the boiler is equipped with a system

controlling proper exhaustion of combustion products (fume

thermostat), in case of abnormality, this system immediately

stops appliance operation. Press the

button to restore

functionning condition. If abnormality persists, do not perform

any action, but immediately call Technical Service. Device

controlling proper fume exhaustion must never be

deactivated.Use original spare parts only when replacing it.

do not pull, detach or twist the wires from the boiler even if

they are not connected to the power supply

do not block or reduce the size of the ventilation openings in

the room. Only C.A.I. and R.A.I. models: ventilation openings

are necessaries to a right combustion

do not leave inflammable containers or substances in the room

keep packaging out of reach of children

only use appliance for purposes it is devoted to

do not lean any object on the boiler

do not tamper with sealed elements.

Page 5

5

English

7.

FUMES EXHAUSTION

AND BURNING AIR SUCTION (C.A.I.-R.A.I.)

Boiler is equipped with a system controlling proper exhaustion of

combustion products - fume thermostat (12, fig. 82a-82b page 91-

92); in case of abnormality, this system immediately stops appliance

operation. Press the button to restore functionning condition. If

abnormality persists, do not perform any action, but immediately

call Technical Service; technicians will correct fume exhaustion

defect and test operation.

Refer to regulations in force for burnt product exhaustion.

It is compulsory using rigid pipes, junctions between elements must

be tight and all components must be resistant to temperature,

condensates and mechanical stresses.

Device controlling proper fume exhaustion must never be

deactivated. Use original spare parts only when replacing it.

Exhaustion ducts which are not insulated can be dangerous.

Openings for burning air must comply with regulations in force.

If condensates are produced, insulate exhaustion duct.

Fig. 6b shows the top view of boiler with reference measures

for fume outlet distance between centres, from boiler support

plate.

Support plate and integrated pre-installation template are provided

for with the boiler (fig. 2).

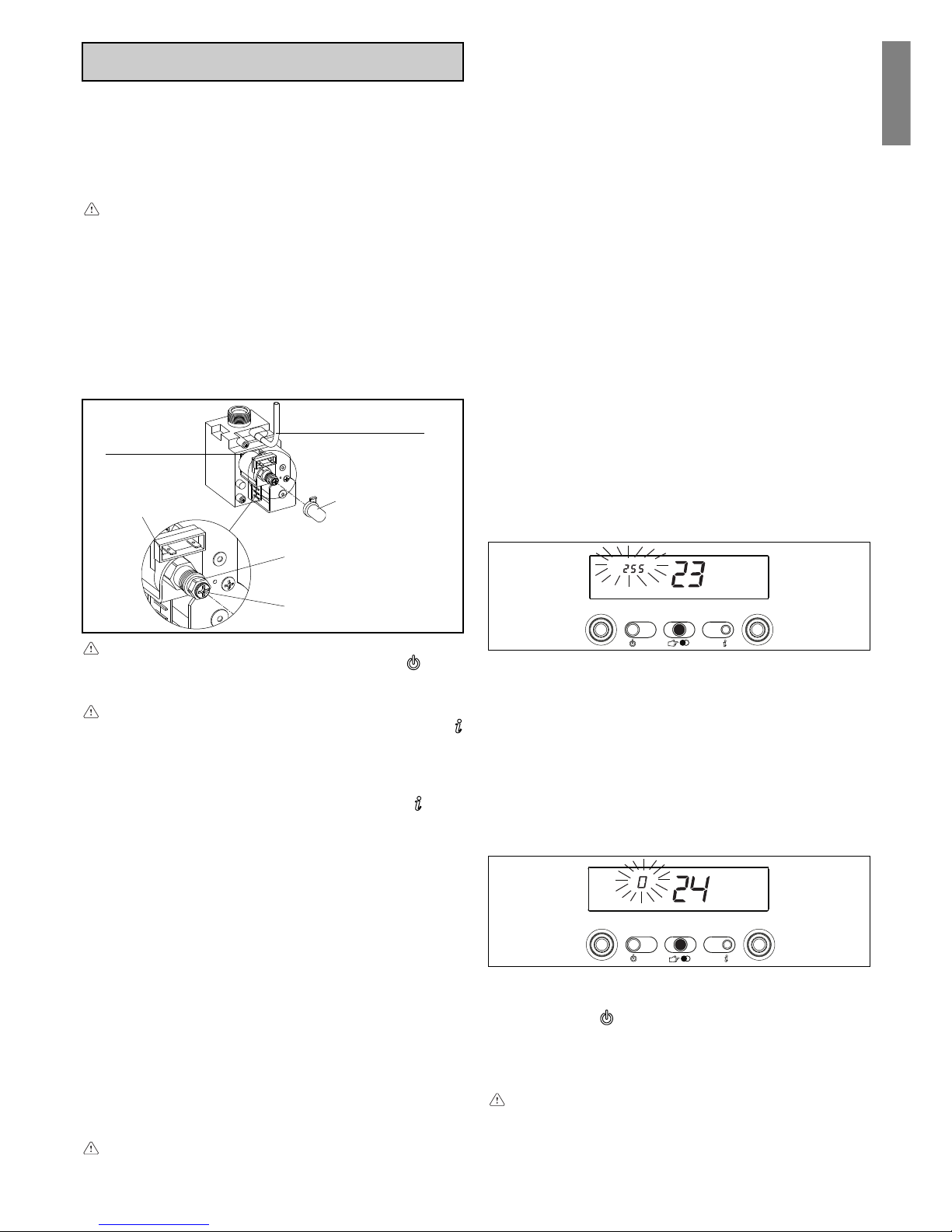

Mounting instructions:

• fix the boiler support plate (F) with the template (G) to the wall

and use a plumb to check that it is perfectly horizontal

• trace out 4 holes (Ø 6 mm) for fixing the boiler support plate (F)

and 2 holes (Ø 4 mm) for fixing the pre-installation template (G)

• make sure all the measurements are correct, then drill holes in

the wall using a drill and point with the diameter given previously

• fix the plate to the wall by the supplied anchor screws

• make hydraulic connections.

After installing the boiler, the screws D

1

(fig. 3a) can be removed.

After installing the boiler and connecting it to the water and gas

supplies, fit the lower cover (A-B, fig. 3b) so that its hooks slip into

the relative slots in the lower part of the boiler. Fix the lower cover

with the screw C (fig. 3c) contained in the documentation envelope

in the boiler.

Before connecting appliance to gas pipe network, check the

following:

• regulations in force are met

• gas type used is the same as set for appliance operation

• pipes are clean.

Gas must be piped externally. If the pipe goes through a wall it

must go through the central opening in the lower part of the

template. It is recommended to install an appropriately sized filter

on the gas line in case gas from the mains contains some small

solid particles. After installation make sure that all the joints have

been made airtight conforming to standard installation practices.

4.

GAS CONNECTION

Position and dimensions of hydraulic connections are specified in

figure 2:

A - CH return 3/4”

B - CH delivery 3/4”

C - gas connection 3/4”

D - DHW outlet 1/2” (C.A.I.-MIX C.S.I. only)

E - DHW inlet 1/2” (C.A.I.-MIX C.S.I. only)

F - Support plate

G - Pre-installation template

If water hardness exceeds 28°Fr, it is recommended to use water

softeners, to prevent any limestone deposit in boiler due to excessively hard water.

3.

HYDRAULIC CONNECTIONS

To access the electrical connections, proceed as follows:

- unscrew the lower cover fixing screw (C, fig. 3c)

- pull the cover towards you and remove (A-B) (fig. 4a)

- loosen the fixing screws (D) and remove the shell (fig. 3a)

- lift up the panel and turn it forwards

- open the terminal board covers making them slide in the direction

of the arrows (fig. 4b: E high voltage connections 230 V, F low

voltage connections, G water tank sensor connections only MIX

R.S.I.-R.A.I.).

Connect the appliance to the mains power supply with a switch

featuring a distance of at least 3,5 mm (EN 60335-1, category III)

between each wire.

The appliance uses alternating current at 230 Volt/50 Hz, has a

power input of 85 W (C.A.I.-R.A.I.), 120 W (26kW MIX C.S.I.), 150

W (30kW MIX C.S.I.-MIX R.S.I.) and 160 W (35kW MIX C.S.I.-MIX

R.S.I.) and complies with EN 60335-1 standard. Connect the boiler

to a safe earth circuit according to current legislation.

Live and neutral (L-N) connections should also be respected.

The boiler can operate with phase-neutral or phase-phase power

supply. For floating power supply, without an earth-bonded

conductor, it is necessary to use an insulation transformer with

secondary anchored to ground.

The earth conductor must be a couple of cm longer than

the others.

5.

ELECTRIC CONNECTION

The central heating system can be filled up once the water mains

have been connected up.

This must be done while the installation is cold by:

• giving two or three turns to the cap of the automatic air vent

valve (A, fig. 5a and 5b) to open it;

• making sure the cold water inlet tap is open (MIX C.S.I. - C.A.I.

only)

• opening the filling tap (C, on the boiler for MIX C.S.I. - C.A.I.,

external for MIX R.S.I. - R.A.I.) until the pressure on the

hydrometer (D) is between 1 and 1,5 bar (blue zone) (fig. 5a and

5b).

Close the filling tap after filling it up.

The boiler is equipped with an efficient air separator so that there

is no need to do anything manually.

The burner only ignites when air venting has finished.

NOTE (MIX C.S.I. - C.A.I. only): even if the boiler is fitted with a

semi-automatic filling system, open tap C to fill the circuit the first

time.

NOTE (MIX R.S.I. - R.A.I. only): manual filling tap is not supplied

with the boiler, foresee one external or verify if external water tank

has one.

Empty the system by:

• switching off the boiler

• connect the rubber hose, supplied standard, to the boiler drain

valve (E, fig. 5a and 5b)

• loosening the valve by hand (E)

• emptying out the lowest parts of the system.

DHW system emptying (MIX C.S.I. - C.A.I. only)

The hot water system must be emptied every time there is risk of

freezing by:

• turning off the tap at the mains

• turning on all the hot and cold taps

• emptying out the lowest parts of the system.

ATTENTION

The safety valve outlet (B) must be connected to a suitable

collection system.

The manufacturer shall not be held liable if the safety valve should

eventually cause flooding.

6.

FILLING AND EMPTYING THE SYSTEM

Gas and/or water pipes may not be used to earth electrical

equipment.

The installer is responsible for making sure that the

appliance has an adequate earthing system; the

manufacturer shall not be held liable for eventual damages

caused by incorrect usage or failing to earth the boiler.

Use the supplied power cable to connect the boiler to the mains

power supply.

Connect the ambient thermostat and/or time clock as shown in the

electrical diagram on page 100.

When replacing the power cable, use a HAR H05V2V2-F cable,

3 x 0,75 mm

2

, Ø max. external 7 mm.

Page 6

6

Refer to regulations in force for exhaustion of combustion products.

Boiler is provided for without fume exhaustion/air suction kit, since

forced draught sealed chamber accessories can be used, as they

better adapt to installation characteristics.

For fume extraction and burning air restoration in boiler, use original pipes or other EC-certified pipes with equivalent characteristics; check connection is correct as shown on instructions fume

accessories provided for with. More appliances can be connected to a

single chimney, provided that all appliances are sealed chamber type.

Boiler is a C-type appliance (sealed chamber) and must be safely

connected to fume exhaustion duct and burning air suction duct,

both getting outside; appliance cannot operate without these ducts.

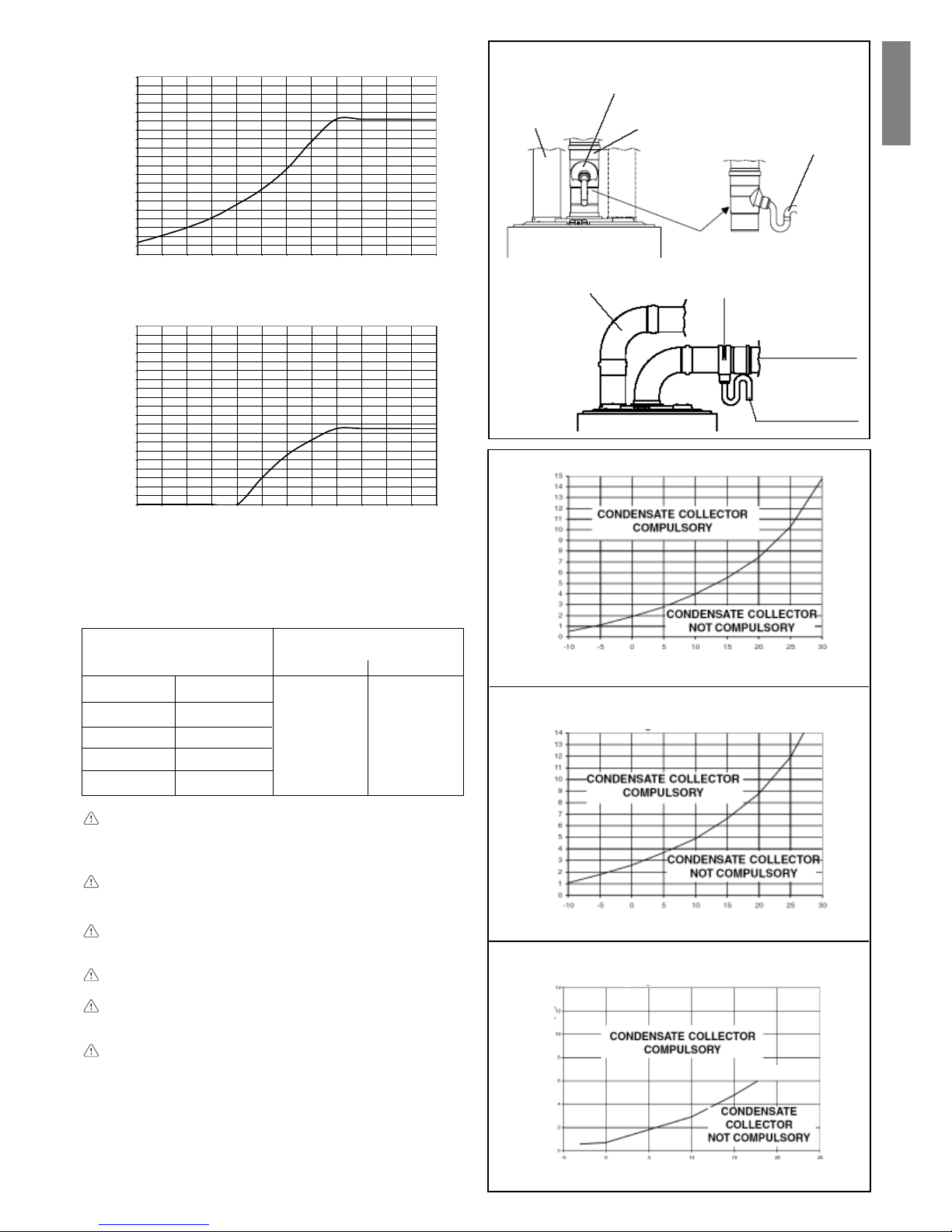

Concentric outlets (ø 60-100)

Concentric ducts may be placed in the most suitable direction for

installation requirements but special care must be taken as regards

the external temperature and the length of the duct.

Consult the graphs to find out whether a condensate collector is

required.

8.

FUMES EXHAUSTION AND BURNING

AIR SUCTION (MIX C.S.I.-MIX R.S.I.)

pressure drop

for each bend (m)

45° 90°

max. linear length

concentric duct ø 60-100 (m)

3,40

26 MIX C.S.I.

0,5 0,85

3,4030 MIX C.S.I.

3,4030 MIX R.S.I.

235 MIX C.S.I.

If the appliance works at temperatures lower than 50 °C (e.g.:

with external probe), the maximum permitted length must be

decreased by 1 metre.

The fumes outlet duct must slope by 1% towards the condensate collector.

The condensate collector can only be applied to the fumes

outlet, within 0.85 m from the boiler; connect the trap of the

condensate collector to a waste water drain.

Uninsulated fumes outlets are potential hazards.

The boiler automatically adapts ventilation according to the type

of installation and the length of the duct. Do not obstruct or narrow

the comburent air inlet duct in any way.

EXHAUSTION CONFIGURATIONS (fig. 7)

Boiler is homologated for the following exhaustion configurations:

C12 Concentric wall exhaustion. Pipes can separately start from

boiler, but outlets must be concentric or close enough to be

subject to similar wind conditions (within 50 cm)

C22 Concentric exhaustion in common chimney (suction and

exhaustion in the same chimney)

C32 Concentric roof exhaustion. Outlets like C12

C42 Exhaustion and suction in common separate chimneys, but

subject to similar wind conditions

C52 Wall or roof separate exhaustion and suction in different

pressure areas. Exhaustion and suction must never be located

on opposite walls

C62 Exhaustion and suction with separately certified and sold

pipes (1856/1)

C82 Single or common chimney exhaustion and wall suction

Maximum length concentric ducts ø 60-100 26 MIX C.S.I.

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

Maximum length concentric ducts ø 60-100

30 MIX C.S.I. - 30 MIX R.S.I.

Maximum length concentric ducts ø 60-100

35 MIX C.S.I. - 35 MIX R.S.I.

EXHAUSTION LENGHT (m)EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

EXTERNAL TEMPERATURE (°C)

Fig. 9

Concentric outlets (ø 80-125)

The boiler is furnished predisposed for connection to concentric

discharge/aspiration ducts and with the air aspiration aperture closed.

The concentric pipes may be oriented in the direction best suited

to the requirements of the premises, respecting the maximum

lengths indicated in the table below.

For installation, follow the instructions provided with the kit.

Execute a Ø 140 mm hole for transit through the wall.

Particular care is required with the external temperature and the

length of the pipe. Refer to the graphics to establish whether the

condensation trap is mandatory or not. In the case of operation at

water temperatures below 60 °C, the use of a condensation trap is

mandatory. In the case of use of condensation trap the fumes

discharge pipe must be inclined by 1% towards the trap.

Connect the condensation trap siphon to a white water outlet pipe.

Non insulated discharge pipes are potential sources of danger.

CONCENTRIC OUTLETS (ø 60-100)

Fig. 8a

Concentric

outlet

Clamp

Condensate

collector

Condensate

drain trap

pressure drop

for each bend (m)

45° 90°

length of ducts

vertical and horizontal (m)

7,626 MIX C.S.I.

1,35 2,2

7,630 MIX C.S.I.

7,630 MIX R.S.I.

4,235 MIX C.S.I.

35 MIX R.S.I.

2

35 MIX R.S.I.

4,2

Page 7

7

English

Twin outlets (ø 80)

Twin ducts can be placed in the most suitable direction for

installation requirements but special care must be taken as regards

the temperature of the installation site and the length of the fumes

duct. To install, follow the instructions supplied with the kit.

In the event of installation with external discharge sections, to

calculate the maximum permitted length without a condensate

collector, refer to the external temperature instead of that of the

installation site of the boiler.

If the appliance works at temperatures lower than 50°C (e.g.:

installations with external probe), the maximum permitted

length without condensate collector must be decreased by

0.85 metres.

The condensate collector can only be applied to the fumes

outlet, within 0.85 m from the boiler; connect the trap of the

condensate collector to a waste water drain.

The fumes outlet duct must slope by 1% towards the condensate collector.

The boiler automatically adapts ventilation according to the

type of installation and the length of the ducts. Do not obstruct

or narrow the ducts in any way.

If the length of the ducts is different from that indicated in the

table to the side:

- for model 26 MIX C.S.I., the sum of the lengths of the inlet

and outlet ducts must be less than 30 metres, but the

length of a single duct must not exceed 18 metres

- for models 30 MIX C.S.I. - MIX R.S.I., the sum of the lengths

of the inlet and outlet ducts must be less than 28 metres,

but the length of a single duct must not exceed 17 metres

- for model 35 MIX C.S.I. - MIX R.S.I., the sum of the lengths

of the inlet and outlet ducts must be less than 12 metres,

but the length of a single duct must not exceed 8 metres.

max. length

twin duct (ø 80) (m)

15 + 1526 MIX C.S.I.

14 + 1430 MIX C.S.I.

14 + 1430 MIX R.S.I.

6 + 635 MIX C.S.I.

pressure drop

for each bend (m)

45°

90°

0,85

0,5

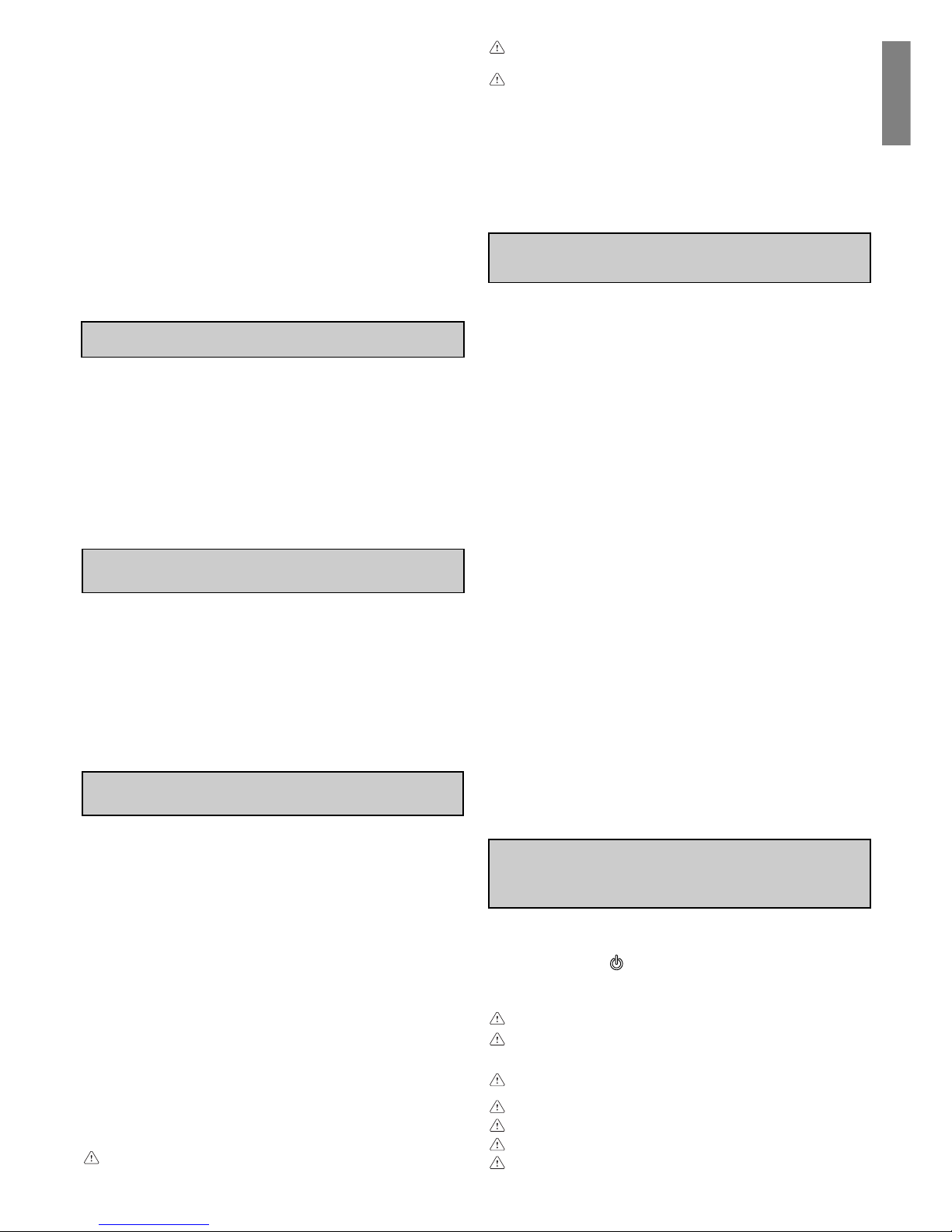

Maximum length twin ducts ø 80 26 MIX C.S.I.

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

Maximum length twin ducts ø 80

30 MIX C.S.I. - 30 MIX R.S.I.

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

Maximum length twin ducts ø 80

35 MIX C.S.I. - 35 MIX R.S.I.

Fig. 10

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

5,5

6,0

6,5

7,0

7,5

8,0

8,5

9,0

9,5

10,0

-30 -25 -20 -15 -10 -5 0 5 10 15 20 2 5 30

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

4,5

5,0

5,5

6,0

6,5

7,0

7,5

8,0

8,5

9,0

9,5

10,0

-30-25-20-15-10-5 0 5 1015202530

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

EXHAUSTION LENGHT (m)

EXTERNAL TEMPERATURE (°C)

26 - 30kW

35kW

TWIN OUTLETS (ø 80)

Condensate

collector

Condensate

collector

Condensate

drain trap

Condensate

drain trap

Air intake

duct

Air intake

duct

Fumes

outlet duct

Fumes

outlet duct

Fig. 8b

CONDENSATE COLLECTOR

COMPULSORY

CONDENSATE COLLECTOR

NOT COMPULSORY

CONDENSATE COLLECTOR

COMPULSORY

CONDENSATE COLLECTOR

NOT COMPULSORY

35 MIX R.S.I.

6 + 6

Page 8

8

99

99

9

..

..

.

TECHNICAL DATA

CH/DHW* nominal heating capacity (Hi) kW 26,70 31,30 28,80 33,20 37,80

kcal/h 22.962 26.918 24.768 28.552 32.508

CH/DHW* nominal heating power kW 24,03 28,30 26,21 30,38 35,31

kcal/h 20.666 24.334 22.539 26.125 30.362

CH reduced heating capacity (Hi) kW 8,30 10,70 8,50 9,80 9,95

kcal/h 7.138 9.202 7.310 8.428 8.557

CH reduced heating power kW 7,05 9,21 7,70 8,86 9,18

kcal/h 6.060 7.923 6.623 7.619 7.898

DHW* reduced heating capacity (Hi) kW 8,30 8,70 8,50 9,80 9,95

kcal/h 7.138 7.482 7.310 8.428 8.557

DHW* reduced heating power kW 7,05 7,49 7,70 8,86 9,18

kcal/h 6.060 6.442 6.623 7.619 7.898

Working efficiency Pn max - Pn min % 90,0-84,9 90,4-86,1 91,0-90,6 91,5-90,4 93,4-92,3

Working efficiency 30% % 89,9 90,3 91,9 92,2 94,5

Electric power W 85 85 120 150 160

Supply voltage V - Hz 230-50 230-50 230-50 230-50 230-50

Protection level IP X5D X5D X5D X5D X5D

Chimney and skirt losses with burner off % 0,07-0,80 0,07-0,80 0,80-0,07 0,80-0,07 0,80-0,07

CH operation

Maximum pressure - temperature bar-°C 3-90 3-90 3-90 3-90 3-90

Minimum pressure for standard working/operating bar 0,25-0,45 0,25-0,45 0,25-0,45 0,25-0,45 0,25-0,45

Selection field of CH water temperature °C 40-80 40-80 40-80 40-80 40-80

Pump: maximum head available for system mbar 30 0 3 00 300 300 340

capacity l/h 1000 1000 1000 1000 1000

Membrane expansion tank l 8 8 8 8 10

Expansion vessel pre-charge (CH) bar 1 1 1 1 1

DHW operation*

Maximum pressure bar 6 6 6 6 6

Minimum pressure bar 0,1 5 0,15 0,1 5 0,15 0,15

Specific capacity following EN625 l/min - - 11,85 14 Hot water quantity: Δt 30° C l/min 11,5 13,5 - - 16,9

DHW minimum capacity l/min 2 2 2 2 2

Selection field of DHW temperature °C 35-60 35-60 35-60 35-60 35-60

Flow regulator l/min 1 0 1 2 1 1 13 15

Gas pressure

Category (extra EC countries) II2H3+ II2H3+ II2H3+ II2H3+ II2H3+

Natural gas pressure (G20) mbar 2 0 20 20 20 20

LPG pressure (G30/G31) mbar 28-30/37 28-30/37 28-30/37 28-30/37 28-30/37

Category (MT) I3B/P I3B/P I3B/P I3B/P I3B/P

LPG pressure (G30/G31) mbar 30 30 30 30 30

Hydraulic connections

CH input-output Ø 3/4” 3/4” 3/4” 3/4” 3/4”

DHW input-output (MIX C.S.I. - C.A.I.) Ø 1/2” 1/2” 1/2” 1/2” 1/2”

Water tank delivery-return (MIX R.S.I. - R.A.I.) Ø - 3/4” - 3/4” 3/4”

Gas input Ø 3/4” 3/4” 3/4” 3/4” 3/4”

Boiler dimensions and weight

Height mm 740 740 740 740 780

Width mm 400 450 400 450 500

Depth mm 332 332 332 332 332

Weight kg 30 33 (C.A.I.) 34 36 (MIX C.S.I.) 43 (MIX C.S.I.)

Weight kg - 32 (R.A.I.) - 35 (MIX R.S.I.) 41 (MIX R.S.I.)

Fan performance

Residual head with 0.85m concentric pipes mbar - - 0,2 0,2 0,2

Residual head of boiler without pipes mbar - - 0,35 0,35 1,15

Flow rates (G20)

Air capacity Nm3/h 46,914 54,996 48,34 54,107 60,724

Fumes capacity Nm3/h 49,591 58,135 51,23 57,44 64,515

Mass flow (max-min) gr/s 16,92-15,01 19,84-17,98 17,45-10,24 19,54-13,64 21,93-13,17

Fume exhaustion pipe

Diameter mm 130 140 - - -

Fume exhaustion and air suction concentric pipe

Diameter mm - - 60-100 60-100 60-100

Max lenght m - - 3,40 3,40 2,00

Loss for a 90°/45° bend m - - 0,85/0,5 0,85/0,5 0,85/0,5

Hole in wall (diameter) mm - - 105 105 105

Diameter mm - - 80-125 80-125 80-125

Max lenght m - - 7,6 7,6 4,2

Loss for a 90°/45° bend m - - 2,2/1,35 2,2/1,35 2,2/1,35

Hole in wall (diameter) mm - - 140 140 140

Fume exhaustion and air suction separated pipe

Diameter mm - - 80 80 80

Max lenght m - - 15+15 14+14 6+6

Loss for a 90°/45° bend m - - 0,8/0,5 0,8/0,5 0,8/0,5

NOx 3 class 2 class 2 class 3 class 3 class

Emission values at maximum and minimum of gas G20 **

Maximum CO s.a. lower than p.p.m. 100 130 100 90 90

CO

2

% 6,40 6,40 6,70 6,90 7,00

NOx s.a. lower than p.p.m. 160 210 190 140 120

Δt fumes °C 113 106 133 132 116

Minimum CO s.a. lower than p.p.m. 130 90 120 100 120

CO

2

% 2,23 2,40 3,35 2,90 3,05

NOx s.a. lower than p.p.m. 100 150 140 110 100

Δt fumes °C 71 70 63 7 2 62

* DHW values refer to MIX C.S.I. - C.A.I. models.

** C.A.I. - R.A.I.: tested with Ø 130 (24kW), Ø 140 (28kW) - lenght 0,5m.

** MIX C.S.I. - MIX R.S.I.: tested with Ø 60-100 concentric - lenght 0,85m - water temperature 80-60°C.

C.A.I.

24kW

C.A.I.

R.A.I.

28kW

MIX C.S.I.

26kW

MIX C.S.I.

MIX R.S.I.

30kW

MIX C.S.I.

MIX R.S.I.

35kW

Page 9

9

English

10.

MULTIGAS TABLE

Parameters Methane Liquid gas

(G20) Butane Propane

(G30) (G31)

C.A.I. - R.A.I.

Lower Wobbe index (15°C-1013 mbar) MJ/m3S 45,67 80,58 70,69

Lower heat value MJ/m3S 34,02 116,09 88

MJ/kgs - 45,65 46,34

Supply nominal pressure (Extra EC countries) mbar 20 28-30 37

(mm H2O) (203,9) (285,5-305,9) (377,3)

Supply nominal pressure (MT) mbar 30

(mm H2O) (305,9)

Supply minimum pressure mbar 13,5

(mm H2O) (137,7) -

24 kW C.A.I.

Main burner (12 nozzles) Ø mm 1,3 0,77 0,77

CH maximum gas capacity Sm3/h 2,82 - -

kg/h - 2,10 2,07

DHW maximum gas capacity Sm3/h 2,82 - -

kg/h - 2,10 2,07

CH minimum gas capacity Sm3/h 0,88 - -

kg/h - 0,65 0,64

DHW minimum gas capacity Sm3/h 0,88 - -

kg/h - 0,65 0,64

Maximum pressure downstrean CH valve mbar 11,80 28,00 36,00

mm H2O 120,33 285,52 367,10

Maximum pressure downstrean DHW valve mbar 11,80 28,00 36,00

mm H2O 120,33 285,52 367,10

Minimum pressure downstrean CH valve mbar 1,30 3,10 4,00

mm H2O 13,26 31,61 40,79

Minimum pressure downstrean DHW valve mbar 1,30 3,10 4,00

mm H2O 13,26 31,61 40,79

28 kW C.A.I. - R.A.I.

Main burner (14 nozzles) Ø mm 1,3 0,77 0,77

CH maximum gas capacity Sm3/h 3,31 - -

kg/h - 2,47 2,43

DHW maximum gas capacity* Sm3/h 3,31 - -

kg/h - 2,47 2,43

CH minimum gas capacity Sm3/h 1,13 - -

kg/h - 0,84 0,83

DHW minimum gas capacity* Sm3/h 0,92 - -

kg/h - 0,69 0,68

Maximum pressure downstrean CH valve mbar 11,90 28,00 35,80

mm H2O 121,35 285,52 365,06

Maximum pressure downstrean DHW valve* mbar 11,90 28,00 35,80

mm H2O 121,35 285,52 365,06

Minimum pressure downstrean CH valve mbar 1,50 3,80 5,30

mm H2O 15,30 38,75 54,05

Minimum pressure downstrean DHW valve* mbar 1,10 2,50 3,30

mm H2O 11,22 25,49 33,65

* DHW values refer to MIX C.S.I. - C.A.I. models.

Page 10

10

Parameters Methane Liquid gas

(G20) Butane Propane

(G30) (G31)

MIX C.S.I. - MIX R.S.I.

Lower Wobbe index (15°C-1013 mbar) MJ/m3S 45,67 80,58 70,69

Lower heat value MJ/m3S 34,02 116,09 88

MJ/kgs - 45,65 46,34

Supply nominal pressure (Extra EC countries) mbar 20 28-30 37

(mm H2O) (203,9) (285,5-305,9) (377,3)

Supply nominal pressure (MT) mbar 30

(mm H2O) (305,9)

Supply minimum pressure mbar 13,5

(mm H2O) (137,7) -

26 kW MIX C.S.I.

Main burner (13 nozzles) Ø mm 1,35 0,78 0,78

CH maximum gas capacity Sm3/h 3,05 - -

kg/h - 2,27 2,24

DHW maximum gas capacity Sm3/h 3,05 - -

kg/h - 2,27 2,24

CH minimum gas capacity Sm3/h 0,90 - -

kg/h - 0,67 0,66

DHW minimum gas capacity Sm3/h 0,90 - -

kg/h - 0,67 0,66

Maximum pressure downstrean CH valve mbar 10,60 27,90 35,50

mm H2O 108,09 284,50 362,00

Maximum pressure downstrean DHW valve mbar 10,60 27,90 35,50

mm H2O 108,09 284,50 362,00

Minimum pressure downstrean CH valve mbar 1,10 2,60 3,60

mm H2O 11,22 26,51 36,71

Minimum pressure downstrean DHW valve mbar 1,10 2,60 3,60

mm H2O 11,22 26,51 36,71

30 kW MIX C.S.I. - MIX R.S.I.

Main burner (15 nozzles) Ø mm 1,35 0,76 0,76

CH maximum gas capacity Sm3/h 3,51 - -

kg/h - 2,62 2,58

DHW maximum gas capacity* Sm3/h 3,51 - -

kg/h - 2,62 2,58

CH minimum gas capacity Sm3/h 1,04 - -

kg/h - 0,77 0,76

DHW minimum gas capacity* Sm3/h 1,04 - -

kg/h - 0,77 0,76

Maximum pressure downstrean CH valve mbar 10,10 27,50 35,40

mm H2O 102,99 280,42 360,98

Maximum pressure downstrean DHW valve* mbar 10,10 27,50 35,40

mm H2O 102,99 280,42 360,98

Minimum pressure downstrean CH valve mbar 1,00 2,80 3,60

mm H2O 10,20 28,55 36,71

Minimum pressure downstrean DHW valve* mbar 1,00 2,80 3,60

mm H2O 10,20 28,55 36,71

35 kW MIX C.S.I. - MIX R.S.I.

Main burner (16 nozzles) Ø mm 1,4 0,8 0,8

CH maximum gas capacity Sm3/h 4,00 - -

kg/h - 2,98 2,94

DHW maximum gas capacity Sm3/h 4,00 - -

kg/h - 2,98 2,94

CH minimum gas capacity Sm3/h 1,05 - -

kg/h - 0,78 0,77

DHW minimum gas capacity Sm3/h 1,05 - -

kg/h - 0,78 0,77

Maximum pressure downstrean CH valve mbar 9,60 27,30 35,40

mm H2O 97,89 278,38 360,98

Maximum pressure downstrean DHW valve mbar 9,60 27,30 35,40

mm H2O 97,89 278,38 360,98

Minimum pressure downstrean CH valve mbar 0,70 2,10 2,80

mm H2O 7,14 21,41 28,55

Minimum pressure downstrean DHW valve mbar 0,70 2,10 2,80

mm H2O 7,14 21,41 28,55

* DHW values refer to MIX C.S.I. - C.A.I. models.

Page 11

11

English

11.

START-UP AND OPERATION

(C.A.I. - MIX C.S.I.)

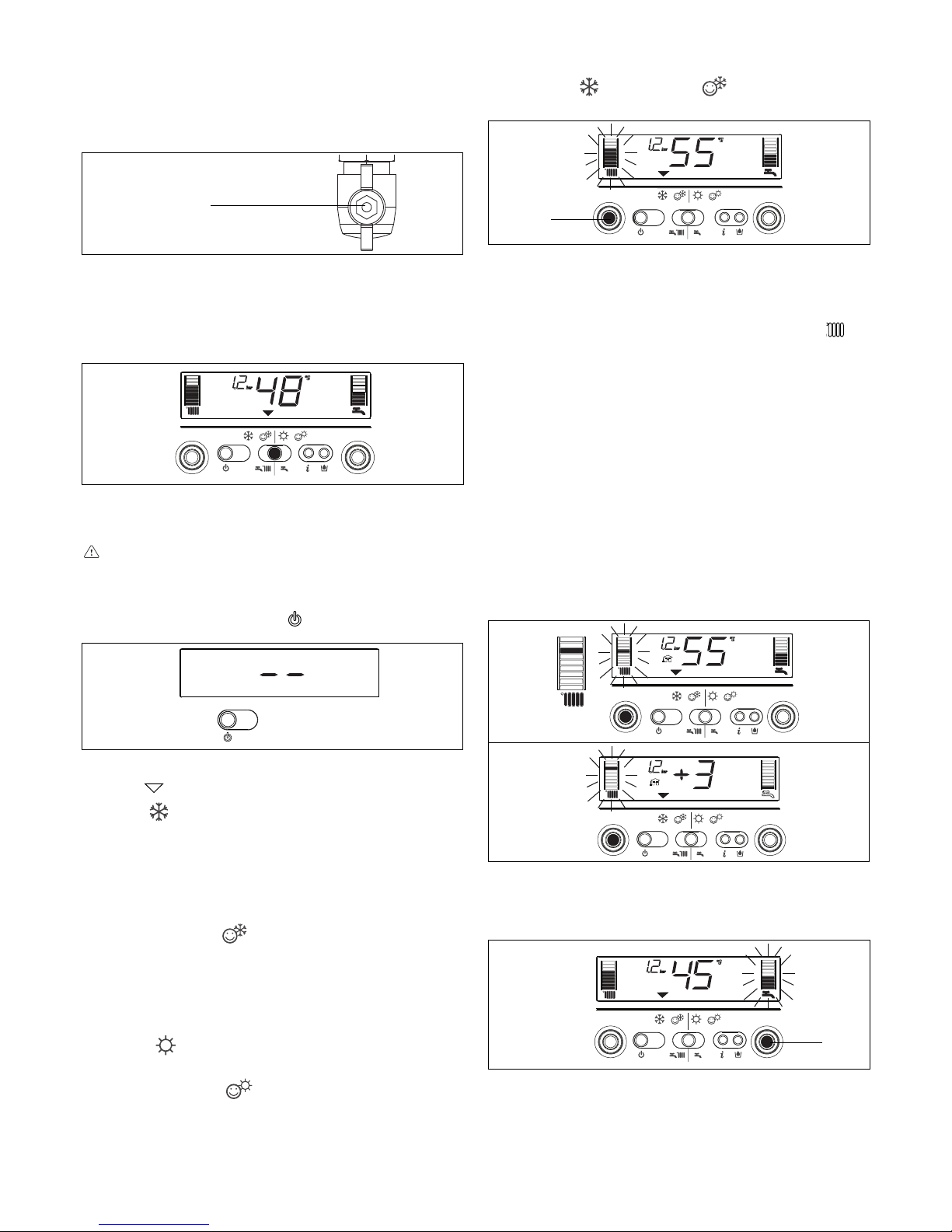

Description of commands

Heating water temperature selector: sets the heating water

temperature.

Domestic hot water temperature selector: sets the domestic

hot water temperature.

Function key:

- ON the boiler is electrically powered and waiting for

operating requests (

- )

- OFF the boiler is electrically powered but will not respond

to operating requests

- RESETresets the boiler following a fault

Operating mode button: allows the most suitable operating

mode to be selected ( winter - winter comfort- summer

- summer comfort).

Info button: shows a sequence of information concerning the

operating status of the machine.

Filling button: pushing it, the boiler automatically fills the system

until the pressure reaches 1 to 1.5 bar.

The boiler produces heating and domestic hot water.

The control panel (fig. 13) contains the main boiler control and

management functions.

Fig. 13

Description of display symbols

graduated heating water temperature scale with heating

function symbol

graduated domestic hot water temperature scale with

domestic hot water function symbol

fault symbol (for details, please see page 15)

reset symbol (for details, please see page 15)

pressure value

external sensor connection

heating/domestic hot water temperature

or

fault symbol (e.g. 10 - no flame)

function selector (turned to the chosen operating mode:

winter - winter comfort- summer - summer

comfort)

burner operating symbol

anti-freeze function active symbol

system filling function symbol

fill symbol

Fig. 14

Domestic

hot water

temperature

selector

Operating

mode button

ON-OFF-RESET

function selector

Filling

button

Heating water

circuit temperature

selector

INFO

button

Page 12

12

Adjusting heating water temperature

Turning the selector A (fig. 18), after having positioned the selector

mode on winter

or winter comfort , it is possible to regulate

the heating water temperature.

Turn clockwise to increase the temperature and anticlockwise to

decrease. The bar segments light up (every 5°C) as the temperature is increased. The selected temperature value appears on the

display. If you enter the S.A.R.A. adjustment field (from 55 to 65 °C)

while selecting the heating water temperature, the symbol

and

the graduated scale start flashing. For details about the S.A.R.A.

function, read page 14. The selected temperature value appears

on the display.

Adjusting heating water temperature with an external sensor

connected

When an external probe is connected, the value of the delivery

temperature is automatically chosen by the system which rapidly

adjusts ambient temperature to the changes in external temperature. Just the central segment of the bar is illuminated (fig. 19).

To increase or decrease the temperature with respect to the value

automatically calculated by the electronic board, turn the heating

water selector clockwise to increase and anticlockwise to decrease.

The bar segments light up (at every comfort level), correction

tolerance lies between - 5 and + 5 comfort levels (fig. 19). When

choosing the level of comfort, the digit area of the display shows

the required level of comfort while the bar shows the matching

segment (fig. 20).

Adjusting domestic hot water temperature

To adjust domestic hot water temperature, turn switch B (fig. 21)

clockwise to increase and anticlockwise to decrease. The bar

segments light up (every 3°C) as the temperature is increased.

The selected temperature value appears on the display.

When choosing the temperature, both for heating and domestic

hot water, the display shows the value being selected. About 4

seconds after the selection has been made, the modification is

memorised and the display returns to the delivery temperature

read by the probe.

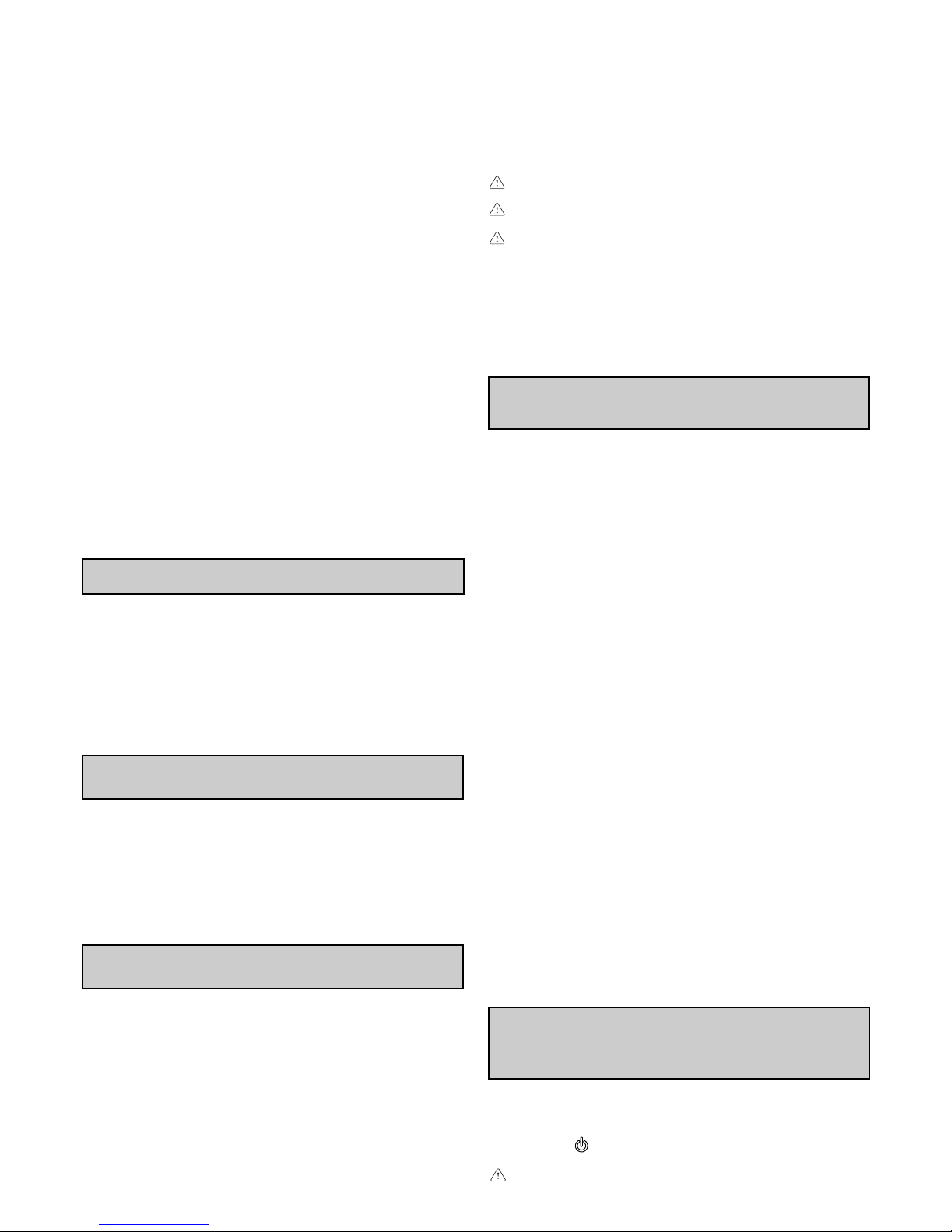

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the

lower part of the boiler

- open the gas tap by turning it anti-clockwise (fig. 15)

- power the boiler.

When powered, the boiler performs a test sequence and a series

of numbers and letters are shown on the display.

If the test is successful the boiler is ready to work about 4 seconds

after the cycle ends.

The display will look like fig. 16.

If the test is unsuccessful, the boiler will not work and a “0” will

flash on the display.

In this case, contact the Technical Assistance Centre.

The boiler turns on in the status it was in before it was switched

off: if the boiler was in the winter comfort mode when it was

switched off, it will turn on again in the winter comfort mode. If it

was in the OFF mode, the display will show two segments in the

central area (fig. 17). Press the

button to enable operation.

- press the function selector until the indicator moves to the required

function

, depending on the kind of operation chosen.

- WINTER

: with the selector in this position, the heating water

and domestic hot water functions are activated.

In this position the S.A.R.A. function is enabled in the heating

mode (see chapter “Boiler functions”). The boiler actives the

temperature stabiliser in order to ensure the continuous

production of domestic hot water, even for small demands or

when the inlet water is already hot. This prevents temperature

oscillations due to the burner switching off/on.

- WINTER COMFORT

: with the selector in this position, as

well as the traditional function of heating water and domestic

hot water, the preheating function is also activated which keeps

the water in the domestic hot water exchanger hot in order to

reduce waiting times. The S.A.R.A. Booster and Domestic hot

water preheating functions are enabled in this position (see

chapter “Boiler functions”).

- SUMMER

: with the selector in this position, just the traditional

domestic hot water function is activated.

- SUMMER COMFORT

: with the selector in this position, the

boiler provides just domestic hot water with a temperature

stabiliser for small deliveries. Ideal at the times of year or in the

areas where the mains water is already warm. In these conditions,

the temperature of the hot water produced by a boiler with just

traditional functions (see SUMMER and WINTER COMFORT)

may be instable.

Fig. 15

open

position

Fig. 16

Fig. 17

Fig. 18

Fig. 21

A

Fig. 19

°C

+ 4/5

+ 3

+ 2

+ 1

0

- 1

- 2

- 3

- 4/5

Fig. 20

B

Page 13

13

English

If this condition occurs it means that the system is incorrectly

pressurised though the boiler will continue to work regularly.

Press the circuit filling button

to start-up the filling sequence.

Press the circuit filling button

a second time to interrupt the

filling sequence. During filling, the drops of the circuit filling

symbol

and the growing pressure value appear on the

display in a cascade sequence (fig. 27).

After filling, the

symbol is displayed for a few moments and then

turns off.

Note

During filling, the boiler does not perform other functions. For

example, if there is a request for domestic hot water, the boiler is

unable to provide it until filling has finished.

Note

If circuit pressure reaches 0.6 bar, the pressure value flashes on

the display (fig. 28b); if it falls below a minimum safety value (0.3

bar), fault code 41 appears on the display (fig. 28a) for a certain

time, following which, if the fault persists, fault code 40 is displayed

(see chapter on “Troubleshooting”).

In the event of fault 40, press

to reset and then to start filling

the circuit. If you have to fill the system several times, contact the

Technical Service Centre to check whether the heating circuit is

watertight (see if there are any leaks).

Information

Press

, the display turns off and just the word InFO appears (fig.

29). Press the button

to view operating information. Press the

button again to move on to the next piece of information. If the

button is not pressed, the system automatically exits the function.

Info list:

Info 0 shows the word InFO (fig. 29)

Info 1 only with the external probe connected, displays external

temperature (e.g. 12 °C) (fig. 30).

The values shown on the display range between - 40 °C

and 40 °C.

Beyond these values the display shows “- -”

Fig. 27

Working the boiler

Adjust the ambient thermostat to the required temperature (approx.

20 °C). If there is a demand for heating water, the boiler starts

and the

symbol is shown on the display (fig. 22). The boiler will

remain working until the set temperatures are reached, after which

it will go on stand-by. In the event of ignition or operating faults,

the boiler will perform a “safety stop”.

The flame symbol

will go out and the fault code and will

be displayed (fig. 23). For a description of faults and how to reset

them, consult chapter “Troubleshooting”.

Switching off

Switching off for short periods

For brief absences press the

button to switch off the boiler. The

display will show two segments in the central area (fig. 17). When

the boiler remains powered with the gas tap open, it is protected

by the following systems:

- anti-freeze (fig. 24): when the temperature of the water in the

boiler falls below safety values, the circulator and the burner

work at minimum power to increase the water temperature to a

safe value (35 °C). The

symbol lights up on the display.

- circulator anti-block: one operating cycle is performed every

24 hours.

Switching off for long periods

For prolonged absences press the

button to switch off the boiler

(fig. 17). The display will show two segments in the central area.

Turn the main switch to “off”.

Turn off the gas tap under the boiler by turning it clockwise (fig. 25).

In this case, the anti-freeze and anti-block systems are disabled.

Empty the water circuit or suitably protect it with a good make

of anti-freeze. Drain the domestic hot water circuit.

Fig. 23

Fig. 22

Fig. 24

Fig. 25

tap

closed

Boiler functions

Semi-automatic filling

The boiler features a semi-automatic filling device which turns on

by pressing the button when the corresponding symbol is

shown on the display (fig. 26).

Fig. 26

Fig. 29

Fig. 28a

Fig. 28b

Fig. 30

Page 14

14

Fig. 34

Fig. 35

Info 2 shows circuit pressure (fig. 31)

Info 3 shows the set heating temperature (fig. 32)

Info 4 shows the set domestic hot water temperature (fig. 33).

S.A.R.A. function

If the “winter” mode is selected, the S.A.R.A. (Automatic Ambient

Adjustment System) function can be activated.

Turn the heating water temperature selector to a temperature

ranging between 55 and 65 °C.

The S.A.R.A. self-adjustment system activates: depending on the

temperature set on the ambient thermostat and the time taken to

reach it, the boiler automatically adjusts the heating water temperature to reduce operating times, thereby increasing operating

comfort and energy saving.

Fig. 31

Fig. 32

Fig. 33

S.A.R.A. BOOSTER function

If the “winter comfort” mode is selected, the S.A.R.A. Booster

function is activated for the heating circuit and reaches the required

ambient temperature more quickly.

DOMESTIC HOT WATER PRE-HEATING function

If the “winter comfort” mode is selected, the domestic hot water

Preheating function is enabled. This function sets out to keep the

domestic hot water contained in the boiler hot, thereby considerably

reducing delivery waiting times.

The

function should be selected to reduce power consumption

in areas where the mains water is not particularly cold.

In this case, the Booster and Preheating functions are not activated.

Troubleshooting

When a fault appears on the display, the flame symbol goes out,

a flashing code is shown and the two symbols

and

appear either together or separately.

For a description of the faults, consult the following table

.

(D) Permanent

(T) Temporary. In this operating status the boiler attempts to eliminate the fault on its own

(°) See NOTE in the next page.

(*) For the “insufficient circuit pressure” fault, proceed with the circuit filling operations described in the “Boiler functions” chapter.

FAULT Alarm Symbol Symbol

ID

FLAME FAILURE BLOCK (D) 10 YES NO

LIMIT THERMOSTAT (D) 20 YES NO

BURNER THERMOSTAT (D) (MIX C.S.I) 21 YES NO

FUMES THERMOSTAT (D) (C.A.I.) 22 YES YES

FUMES OUTLET OR AIR PRESSOSTAT (D) (MIX C.S.I.) 30 YES NO

FUMES OUTLET OR AIR PRESSOSTAT (T) (MIX C.S.I.) 31 NO YES

INSUFFICIENT SYSTEM PRESSURE (D*) 40 YES NO

INSUFFICIENT SYSTEM PRESSURE (T*) 41 NO YES

WATER PRESSURE TRANSDUCER (D) 42 YES YES

FALSE FLAME (D) 50 YES YES

ELECTRONIC BOARD (D) 51-59 YES YES

SANITARY PROBE 1 (T°) 60 NO YES

PRIMARY PROBE (T) 71 NO YES

LOW TEMPERATURE THERMOSTAT (T) 77 YES YES

Page 15

15

English

Resetting faults

Wait for about 10 seconds before resetting operating conditions.

Then proceed as follows:

1) Viewing just the

symbol

If

disappears, it means that an operating fault has been

discovered which the boiler is attempting to solve on its own

(temporary stoppage). If the boiler does not resume normal

operation, two things may happen:

case A (fig. 36)

disappears, the symbol and a different alarm code

appear. In this case, proceed as described in point 2.

case B (fig. 37)

and a different alarm code are displayed together with .

In this case, proceed as described in point 3.

2) Viewing just the

symbol (fig. 38)

Press the

button to reset the appliance. If the boiler starts the

ignition phase and resumes normal operation, it may have

stopped by accident.

If these stoppages should continue, contact the Technical

Assistance Centre.

3) Viewing the

and symbols (fig. 39)

Contact the Technical Assistance Centre.

Note

Fault in domestic hot water circuit sensor - 60: the boiler works

regularly but does not ensure the stability of the hot water temperature which, however, is delivered at a temperature of

approximately 50°C. The fault code is only displayed in standby.

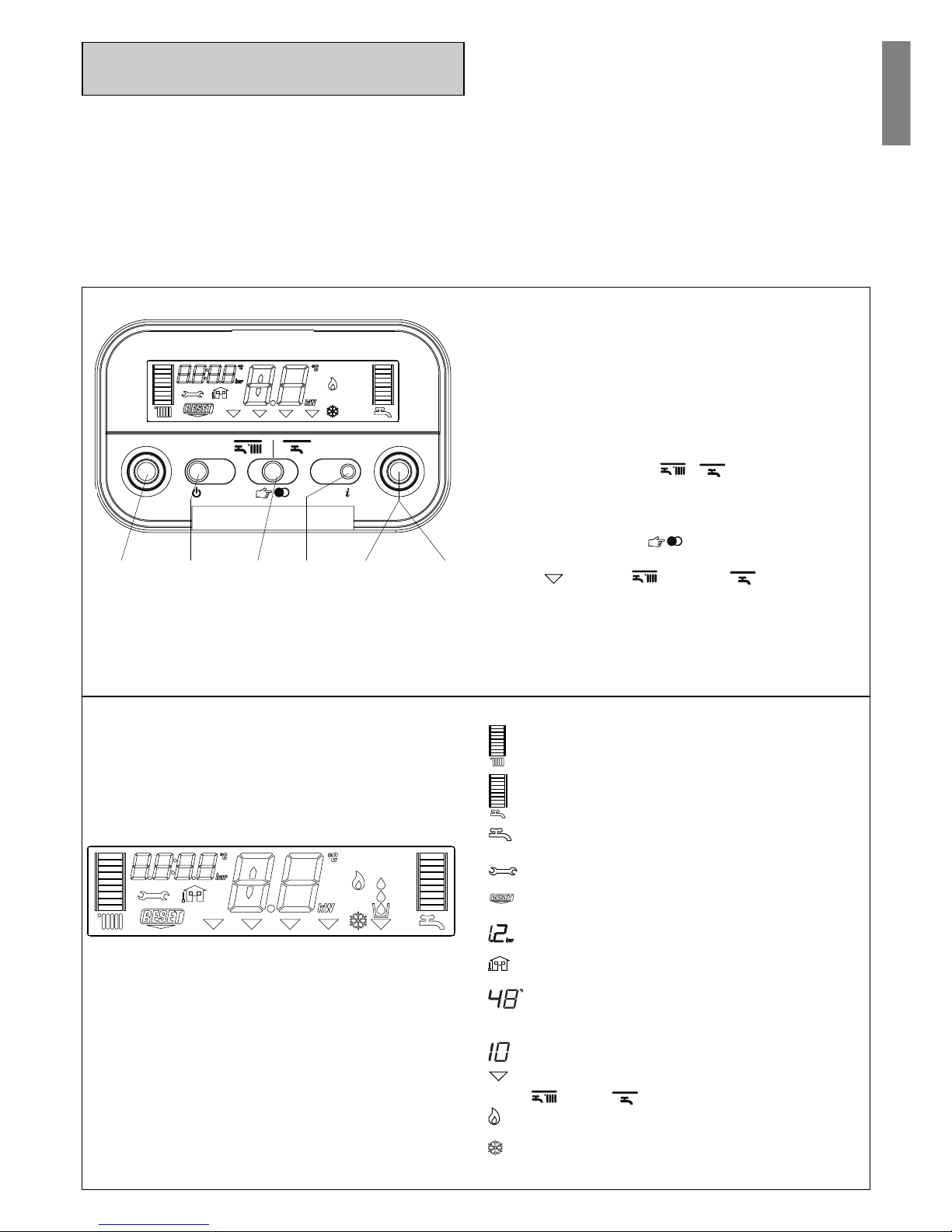

12.

PROGRAMMING PARAMETERS

This boiler incorporates a new generation of electronic boards that, by

setting/modifying operating parameters, allow the boiler to be

personalised to satisfy various system and/or user requirements. The

programmable parameters are shown in the table on the next page.

The parameters must be programmed with the boiler in the

OFF position. To do this, press the

button until the display

shows “- -” (fig. 40).

During parameter modification operations, the “select

functions” button acts as an ENTER (confirm) button, the

button acts as an ESCAPE (escape) button. If no confirmation

is given within 10 seconds, the value is discarded and returns

to the previously set one.

Setting the password

Press and hold down the select functions button and the

button

together for about 10 seconds. The display will look like fig. 41.

Enter the password for accessing the parameter modifications

function by turning the domestic hot water temperature selector to

obtain the required value. The password for accessing the

parameter programming function is located on the back side of

the control panel. Confirm by pressing ENTER.

Modifying parameters

Turn the domestic hot water temperature selector (fig. 42) to

sequentially scroll the two-figure codes of the parameters indicated

in the table. After identifying the parameter you wish to modify,

proceed as follows:

- press ENTER to access the parameter modification function. When

ENTER is pressed, the previously set value starts flashing (fig. 43)

- turn the domestic hot water temperature selector to change the value

- press ENTER to confirm the new value. The digits stop flashing

(fig. 44)

- press ESCAPE to exit.

The boiler returns to the “- -” (OFF) status.

To reset, press the

button (fig. 40).

Fig. 36

Fig. 37

Fig. 38

“temporary

fault”

Fig. 39

Fig. 40

Fig. 41

Fig. 42

Fig. 43

Fig. 44

“temporary

fault”

“permanent

fault”

“permanent

fault”

ENTER

ESCAPE

parameter

value

parameter

number

Page 16

16

CC

CC

C

.A.A

.A.A

.A

.I.I

.I.I

.I

.:.:

.:.:

.:

pr pr

pr pr

pr

ogog

ogog

og

rr

rr

r

aa

aa

a

mmabmmab

mmabmmab

mmab

le parle par

le parle par

le par

aa

aa

a

metersmeters

metersmeters

meters

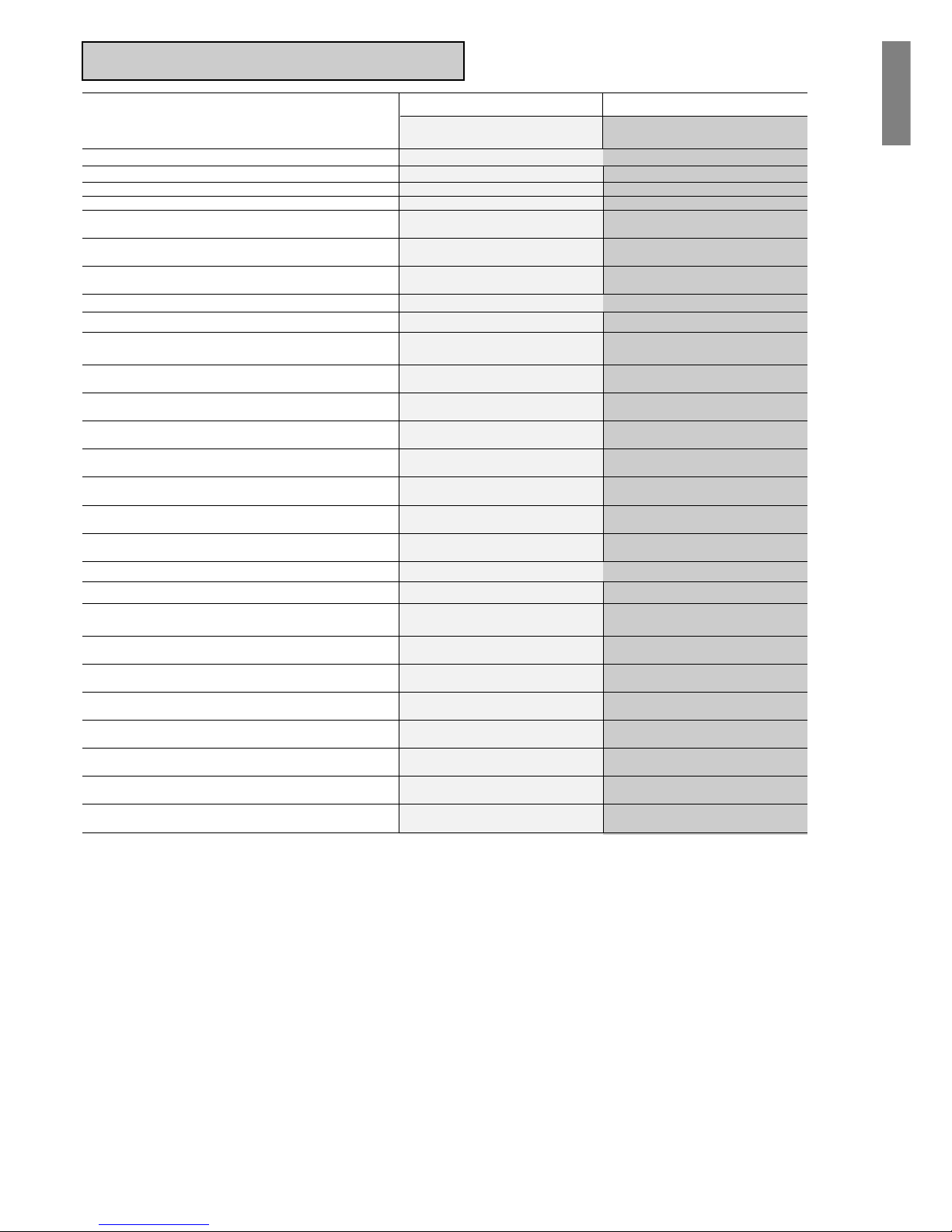

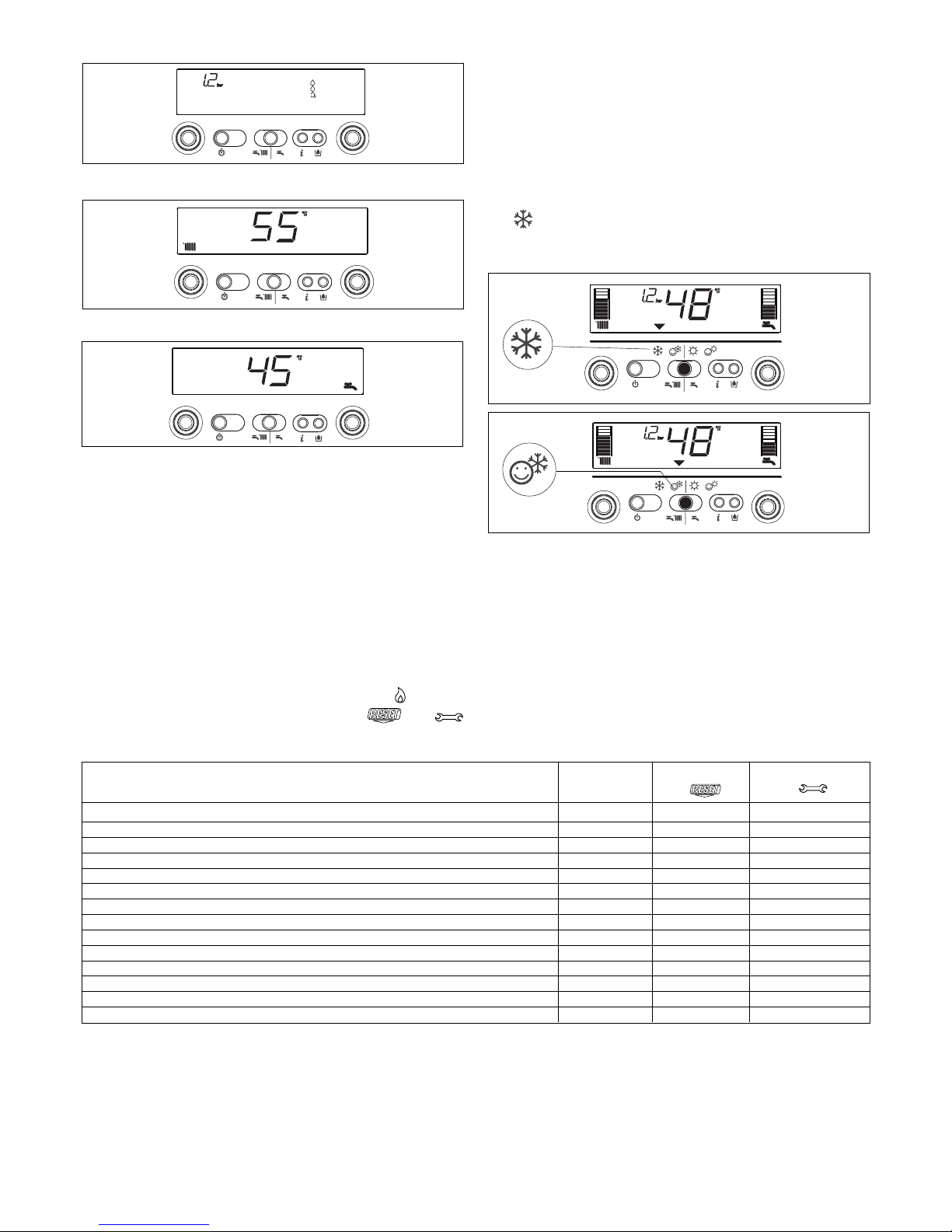

N° DESCRIPTION PARAMETERS UNIT OF MIN MAX DEFAULT PARAMETERS

PAR. MEASURE (setted in factory) (setted by techn. assist. centre)

1 GAS TYPE 1 Methane 1-2

2 LPG

3 Methane France

3 INSULATION LEVEL OF BUILDING (+) (*) min 5 20 5

10 DHW MODE 0 (OFF) 1

1 (Instantaneous)

2 (Mini-tank)

3 (External water-tank with thermostat)

4 (External water-tank with sensor)

11 DHW CIRCUIT MAXIMUM SET-POINT ° C 40 60 60

12 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 60

13 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 80

14 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 5

20 CH MODE 0 (OFF) 1

1 (ON)

2 (zone valves + remote control panel)

21 HEATING CIRCUIT MAXIMUM SET-POINT ° C 40 80 80

22 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 40

28 MAX HEATING POWER REDUCTION TIMER min 0 20 15

29 FORCED HEATING SHUT DOWN TIMER min 0 20 3

30 HEATING TIMER RESET FUNCTION - 0 1 0

40 DHW THERMOSTAT OPERATING MODE 0 (OFF) 1

1 (AUTO)

2 (ON)

41 DHW PREHEATING FUNCTION 0 (OFF) 1

1 (AUTO)

2 (ON)

42 S.A.R.A. FUNCTION 0 (OFF) 1

1 (AUTO)

43 S.A.R.A. BOOSTER FUNCTION 0 (OFF) 1

1 (AUTO)

44 THERMOREGULATION FUNCTION 0 (OFF) 1

1 (AUTO)

45 INCLINATION THERMOREGULATION CURVE (OTC) (*) - 2,5 40 20

48 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 0

50 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

61 DHW ANTIFREEZE FUNCTION TEMPERATURE (ON) °C 0 10 4

62 HEATING ANTIFREEZE FUNC. DELIVERY TEMP. (ON) °C 0 10 6

85 SEMI-AUTOMATIC FILLING 0 (disabled)/1 (enabled) 1

86 AUTOMATIC FILLING PRESSURE (ON) bar 0.4 0.8 0.6

MIX CMIX C

MIX CMIX C

MIX C

.S.S

.S.S

.S

.I.I

.I.I

.I

.:.:

.:.:

.:

pr pr

pr pr

pr

ogog

ogog

og

rr

rr

r

aa

aa

a

mmabmmab

mmabmmab

mmab

le parle par

le parle par

le par

aa

aa

a

metersmeters

metersmeters

meters

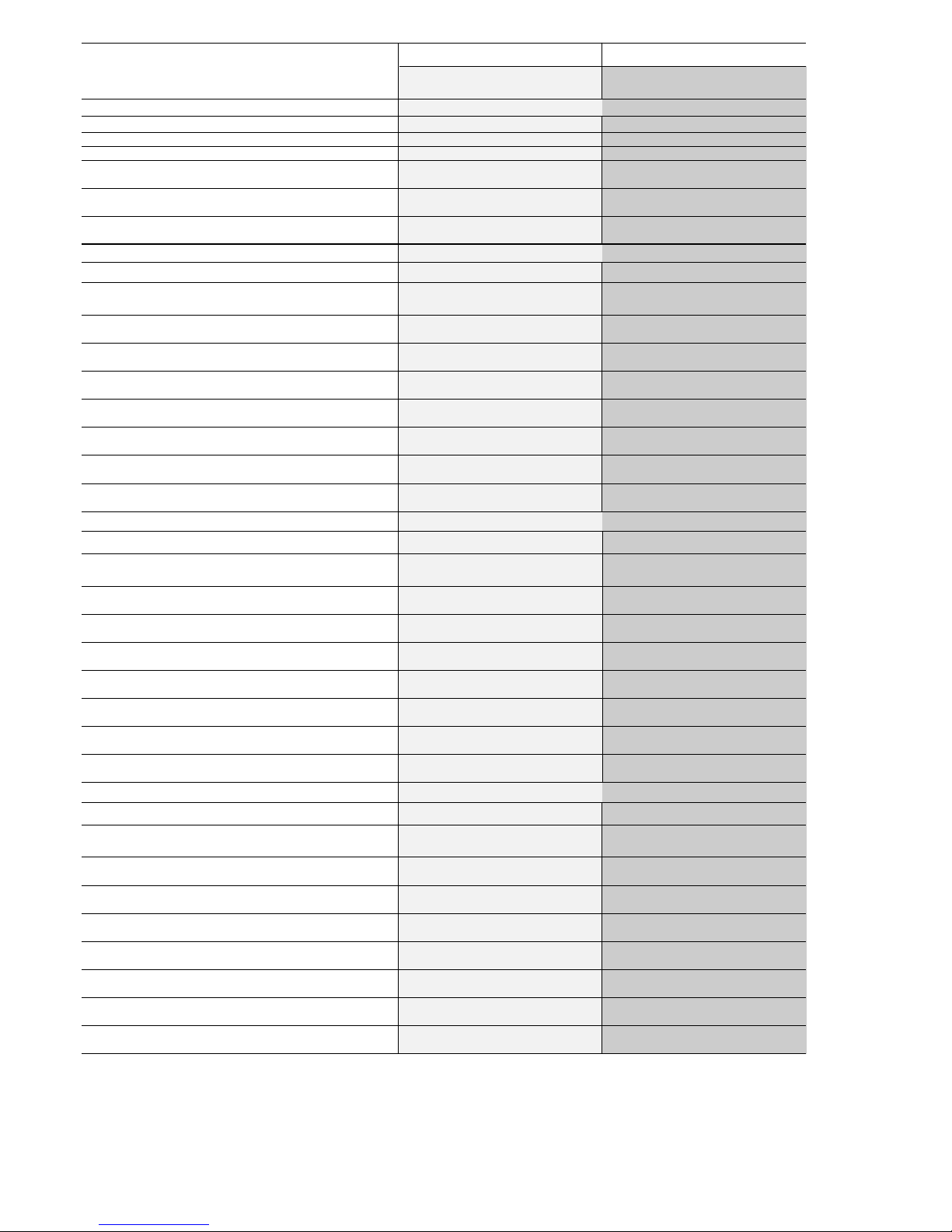

N° DESCRIPTION PARAMETERS UNIT OF MIN MAX DEFAULT PARAMETERS

PAR. MEASURE (setted in factory) (setted by techn. assist. centre)

1 GAS TYPE 1 Methane 1-2

2 LPG

3 Methane France

2 BOILER POWER 26 (26kW) 26-30-34

30 (30kW)

34 (35kW)

3 INSULATION LEVEL OF BUILDING (+) (*) min 5 20 5

10 DHW MODE 0 (OFF) 1

1 (Instantaneous)

2 (Mini-tank)

3 (External water-tank with thermostat)

4 (External water-tank with sensor)

11 DHW CIRCUIT MAXIMUM SET-POINT ° C 40 60 60

12 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 60

13 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 80

14 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 5

20 CH MODE 0 (OFF) 1

1 (ON)

2 (zone valves + remote control panel)

21 HEATING CIRCUIT MAXIMUM SET-POINT ° C 40 80 80

22 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 40

28 MAX HEATING POWER REDUCTION TIMER min 0 20 15

29 FORCED HEATING SHUT DOWN TIMER min 0 20 3

30 HEATING TIMER RESET FUNCTION - 0 1 0

40 DHW THERMOSTAT OPERATING MODE 0 (OFF) 1

1 (AUTO)

2 (ON)

41 DHW PREHEATING FUNCTION 0 (OFF) 1

1 (AUTO)

2 (ON)

42 S.A.R.A. FUNCTION 0 (OFF) 1

1 (AUTO)

43 S.A.R.A. BOOSTER FUNCTION 0 (OFF) 1

1 (AUTO)

44 THERMOREGULATION FUNCTION 0 (OFF) 1

1 (AUTO)

45 INCLINATION THERMOREGULATION CURVE (OTC) (*) - 2,5 40 20

48 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 0

50 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

61 DHW ANTIFREEZE FUNCTION TEMPERATURE (ON) °C 0 10 4

62 HEATING ANTIFREEZE FUNC. DELIVERY TEMP. (ON) °C 0 10 6

85 SEMI-AUTOMATIC FILLING 0 (disabled)/1 (enabled) 1

86 AUTOMATIC FILLING PRESSURE (ON) bar 0.4 0.8 0.6

(*) parameters shown only with external sensor connected and parameter 44 in 1 (AUTO).

(+) for well-insulated buildings select values close to 20, for badly insulated buildings choose values close to 5.

T m. = maximum rated temperature of heating water

T e. = minimum rated external temperature

OTC = 10 x

Tm. - 20

20 - Te.

Parameter 45 “Inclination of thermoregulation curve (OTC)”

The curve must be chosen according to the geographical area and the type

of installation.

Page 17

17

English

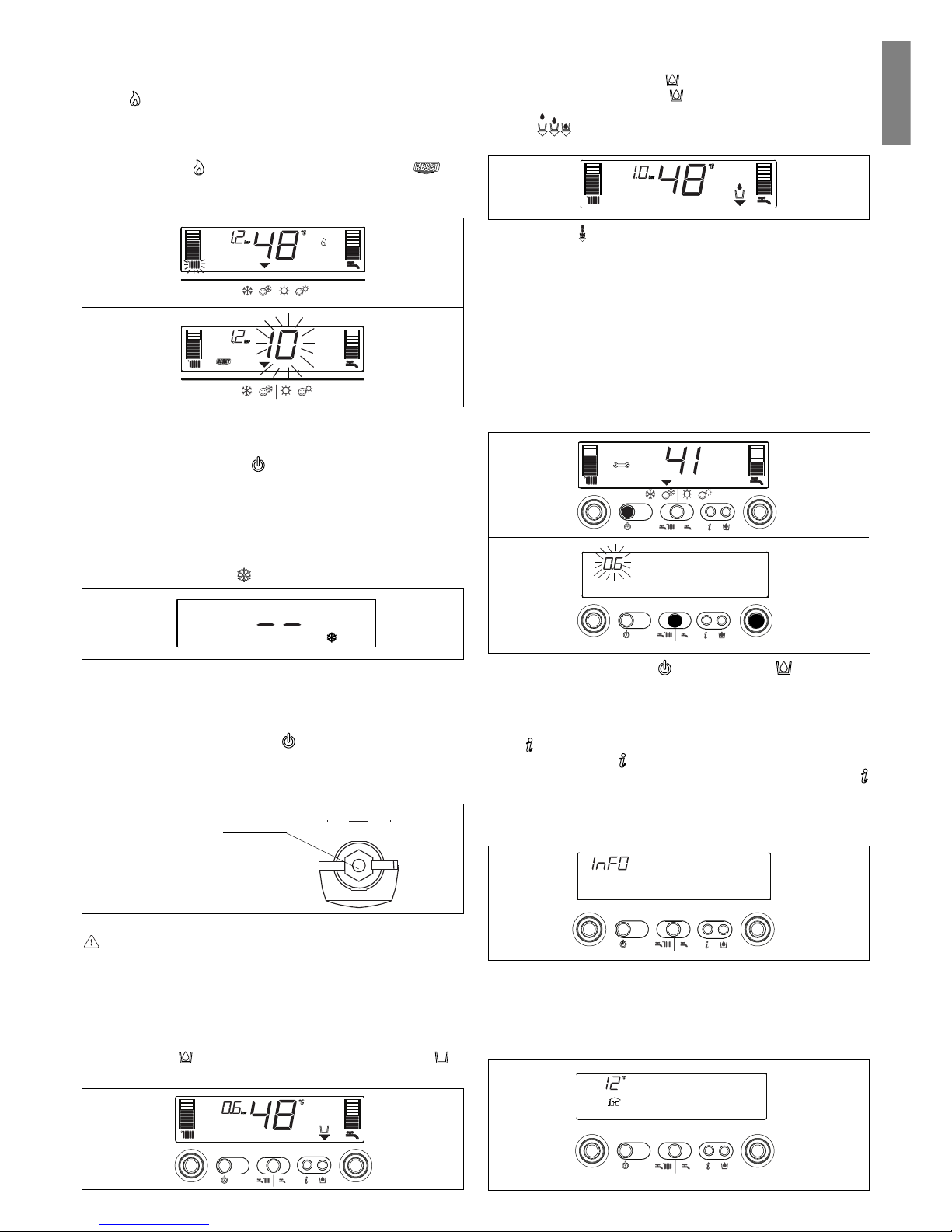

Description of commands

Heating water temperature selector: sets the heating water

temperature.

Domestic hot water temperature selector (C case only): sets

the domestic hot water temperature storaged in the water tank.

Setting parameters selector (cases A, B and C): using in

calibration and programmation phase.

Function key:

- ON the boiler is electrically powered and waiting for

operating requests (

- )

- OFF the boiler is electrically powered but will not respond

to operating requests

- RESETresets the boiler following a fault

Operating mode button:

button allows to choose the

desired operating mode: pressing it, the indicator “function

selector”

moves to: (winter) or (summer, only if

water-tank connected).

Info button: shows a sequence of information concerning the

operating status of the machine.

Fig. 45

Description of display symbols

graduated heating water temperature scale with heating

function symbol

graduated domestic hot water temperature scale (shown

in C case only)

domestic hot water function symbol (shown in B and C

cases)

fault symbol (for details, please see page 21)

reset symbol (for details, please see page 21)

pressure value

external sensor connection

heating/domestic hot water temperature (shown in C case

only)

or

fault symbol (e.g. 10 - no flame)

function selector (turned to the chosen operating mode:

winter or summer (only if water-tank connected)

burner operating symbol

anti-freeze function active symbol

Fig. 46

13.

START-UP AND OPERATION

(R.A.I. - MIX R.S.I.)

This boiler is able to operate in different conditions:

CASE A) only heating

CASE B) only heating with external water tank connected,

managed by a thermostat, to prepare domestic hot

water

CASE C) only heating with external water tank connected,

managed by a temperature sensor (kit available

upon request), to prepare domestic hot water.

Depending on the type of installation selected, it is necessary

to set the parameter “domestic hot water mode”. This operation

must be performed by a Technical Service Centre when

starting-up the boiler.

Domestic hot water

temperature selector

(C case only)

Operating

mode button

ON-OFF-RESET

function selector

INFO

button

Heating water

circuit temperature

selector

Setting

parameters

selector

Page 18

18

Adjusting heating water temperature

Turning the selector A (fig. 52), after having positioned the selector

mode on winter , it is possible to regulate the heating water

temperature.

Turn clockwise to increase the temperature and anticlockwise to

decrease. The bar segments light up (every 5°C) as the temperature is increased. The selected temperature value appears on the

display.

Adjusting heating water temperature with an external sensor

connected

When an external probe is connected, the value of the delivery

temperature is automatically chosen by the system which rapidly

adjusts ambient temperature to the changes in external temperature. Just the central segment of the bar is illuminated (fig. 53).

To increase or decrease the temperature with respect to the value

automatically calculated by the electronic board, turn the heating

water selector clockwise to increase and anticlockwise to decrease.

The bar segments light up (at every comfort level), correction

tolerance lies between - 5 and + 5 comfort levels (fig. 53). When

choosing the level of comfort, the digit area of the display shows

the required level of comfort while the bar shows the matching

segment (fig. 54).

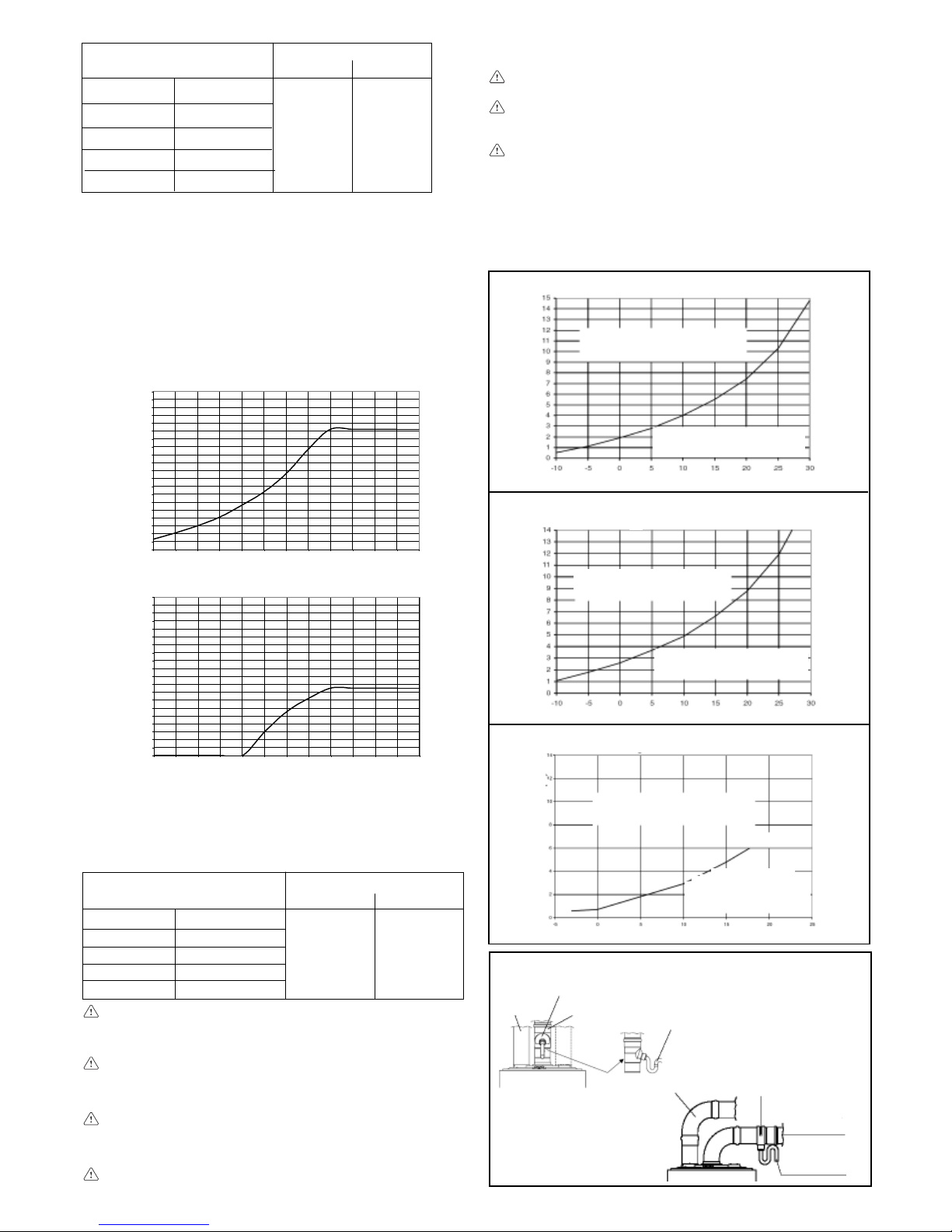

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the

lower part of the boiler

- open the gas tap by turning it anti-clockwise (fig. 47)

- power the boiler.

When powered, the boiler performs a test sequence and a series

of numbers and letters are shown on the display.

If the test is successful the boiler is ready to work about 4 seconds

after the cycle ends.

The display will look like fig. 48.

If the test is unsuccessful, the boiler will not work and a “0” will

flash on the display.

In this case, contact the Technical Assistance Centre.

The boiler turns on in the status it was in before it was switched

off: if the boiler was in the winter mode when it was switched off,

it will turn on again in the winter mode. If it was in the OFF mode,

the display will show two segments in the central area (fig. 49).

Press the

button to enable operation.

Choose the desired operating mode by pressing button,

until the

symbol moves to:

WINTER

SUMMER

WINTER function (fig. 50)

With the selector in this position, the boiler provides hot water for

the heating and, if an external water tank is connected, provides

water to the water tank to allow domestic hot water preparation.

Function S.A.R.A Booster is enabled in this position (see chapter

“Boiler functions”).

SUMMER function (only with external water tank connected,

fig. 51)

With the selector in this position, the boiler provides water to the

water tank with a temperature stabiliser to allow domestic hot water

preparation.

Fig. 47

Fig. 48

Fig. 49

Fig. 52

A

Fig. 53

Fig. 54

open

position

Fig. 50

Fig. 51

°C

+ 4/5

+ 3

+ 2

+ 1

0

- 1

- 2

- 3

- 4/5

Adjusting domestic hot water temperature

CASE A only heating - adjusting not applicable

CASE B only heating + water tank with thermostat: in this

condition every time there is a request from the water

tank thermostat, the boiler supplies hot water to

preparing domestic hot water. During this operation on

the display the icon

flashed.

CASE C only heating + water tank with sensor: to adjust domestic

hot water temperature storaged in the water tank, turn

switch D (fig. 55): clocwise to increase and

anticlockwise to decrease. The bar segments light up

(every 3°C) as the temperature is increased. About 4

seconds after the selection has been made, the

modification is memorised and the display returns to

the delivery temperature read by the sensor.

Page 19

19

English

Fig. 55

D

Working the boiler

Adjust the ambient thermostat to the required temperature (approx.

20 °C). If there is a demand for heating water, the boiler starts

and the

symbol is shown on the display (fig. 56). The boiler will

remain working until the set temperatures are reached, after which

it will go on stand-by. In the event of ignition or operating faults,

the boiler will perform a “safety stop”.

The flame symbol

will go out and the fault code and will

be displayed (fig. 57). For a description of faults and how to reset

them, consult chapter “Troubleshooting”.

Switching off

Switching off for short periods

For brief absences press the

button to switch off the boiler. The

display will show two segments in the central area (fig. 49). When

the boiler remains powered with the gas tap open, it is protected

by the following systems:

- anti-freeze (fig. 58): when the temperature of the water in the

boiler falls below safety values, the circulator and the burner

work at minimum power to increase the water temperature to a

safe value (35 °C). The

symbol lights up on the display.

- circulator anti-block: one operating cycle is performed every

24 hours.

Switching off for long periods

For prolonged absences press the button to switch off the boiler

(fig. 49). The display will show two segments in the central area.

Turn the main switch to “off”.

Turn off the gas tap under the boiler by turning it clockwise (fig. 59).

In this case, the anti-freeze and anti-block systems are disabled.

Empty the water circuit or suitably protect it with a good make

of anti-freeze.

Fig. 56

Fig. 57

Fig. 58

Fig. 59

tap

closed

Boiler functions

Filling the circuit

If circuit pressure reaches 0.6 bar, the pressure value flashes on

the display (fig. 60a); if it falls below a minimum safety value (0.3

bar), fault code 41 appears on the display (fig. 60b) for a certain

time, following which, if the fault persists, fault code 40 is displayed

(see chapter on “Troubleshooting”).

In the event of faul 40 (fig. 61) proceed as follow to restore the

correct pressure value:

- press

button

- open the filling tap external to the boiler, until the pressure shown

in the display is between 1 and 1,5 bar.

If you have to fill the system several times, contact the Technical

Service Centre to check whether the heating circuit is watertight

(see if there are any leaks).

Information

Press , the display turns off and just the word InFO appears (fig.

62). Press the button

to view operating information. Press the

button again to move on to the next piece of information. If the

button is not pressed, the system automatically exits the function.

Info list:

Info 0 shows the word InFO (fig. 62)

Info 1 only with the external probe connected, displays external

temperature (e.g. 12 °C) (fig. 63).

The values shown on the display range between - 40 °C

and 40 °C.

Beyond these values the display shows “- -”

Fig. 60a

Fig. 60b

Fig. 61

Fig. 62

Fig. 63

Page 20

20

Info 2 shows circuit pressure (fig. 64)

Info 3 shows the set heating temperature (fig. 65)

Info 4 shows the setted temperature (only water tank with sensor,

fig. 66).

Fig. 64

Fig. 65

Fig. 66

S.A.R.A. BOOSTER function

If the “winter” mode is selected, the S.A.R.A. Booster function is

activated for the heating circuit. This function allows to reach the

required ambient temperature more quickly.

Depending on the temperature set on the ambient thermostat and

the time taken to reach it, the boiler automatically adjusts the

heating water temperature to reduce operating times, thereby

increasing operating comfort and energy saving.

Fig. 67

Troubleshooting

When a fault appears on the display, the flame symbol goes out,

a flashing code is shown and the two symbols and

appear either together or separately.

For a description of the faults, consult the following table.

(D) Permanent

(T) Temporary. In this operating status the boiler attempts to eliminate the fault on its own

(°) Only with external water tank with sensor. The fault code is shown when the boiler is in stand-by

(*) For the “insufficient circuit pressure” fault, proceed with the circuit filling operations described in the “Boiler functions” chapter.

FAULT Alarm Symbol Symbol

ID

FLAME FAILURE BLOCK (D) 10 YES NO

LIMIT THERMOSTAT (D) 20 YES NO

BURNER THERMOSTAT (D) (MIX R.S.I.) 21 YES NO

FUMES THERMOSTAT (D) (R.A.I.) 22 YES YES

FUMES OUTLET OR AIR PRESSOSTAT (D) (MIX R.S.I.) 30 YES NO

FUMES OUTLET OR AIR PRESSOSTAT (T) (MIX R.S.I.) 31 NO YES

INSUFFICIENT SYSTEM PRESSURE (D*) 40 YES NO

INSUFFICIENT SYSTEM PRESSURE (T*) 41 NO YES

WATER PRESSURE TRANSDUCER (D) 42 YES YES

FALSE FLAME (D) 50 YES YES

ELECTRONIC BOARD (D) 51-59 YES YES

SANITARY PROBE 1 (T°) 60 NO YES

PRIMARY PROBE (T) 71 NO YES

LOW TEMPERATURE THERMOSTAT (T) 77 YES YES

Page 21

21

English

Resetting faults

Wait for about 10 seconds before resetting operating conditions.

Then proceed as follows:

1) Viewing just the

symbol

If

disappears, it means that an operating fault has been

discovered which the boiler is attempting to solve on its own

(temporary stoppage). If the boiler does not resume normal

operation, two things may happen:

case A (fig. 68)

disappears, the symbol and a different alarm code

appear. In this case, proceed as described in point 2.

case B (fig. 69)

and a different alarm code are displayed together with .

In this case, proceed as described in point 3.

2) Viewing just the

symbol (fig. 70)

Press the button to reset the appliance. If the boiler starts the

ignition phase and resumes normal operation, it may have

stopped by accident.

If these stoppages should continue, contact the Technical

Assistance Centre.

3) Viewing the

and symbols (fig. 71)

Contact the Technical Assistance Centre.

Fig. 68

Fig. 69

“temporary

fault”

“temporary

fault”

“permanent

fault”

“permanent

fault”

Fig. 70

Fig. 71

14.

PROGRAMMING PARAMETERS

This boiler incorporates a new generation of electronic boards that, by

setting/modifying operating parameters, allow the boiler to be

personalised to satisfy various system and/or user requirements. The

programmable parameters are shown in the table on the next page.