Beretta HYDRONIC UNIT LE 15 T, HYDRONIC UNIT LE 4, HYDRONIC UNIT LE 12, HYDRONIC UNIT LE 15, HYDRONIC UNIT LE 8 Instructions For Installation Manual

...Page 1

Instructions for installation

Installationsvejledning

HYDRONIC UNIT

LE 4 | LE 6 | LE 8 | LE 12

LE 15 | LE 12 T | LE 15 T

1

EN Instructions for installation

DK Installationsvejledning

Page 2

HYDRONIC UNIT LE

Dear client,

Thank you for choosing a BERETTA product.

Denne manual indeholder de nødvendige informationer for

korrekt installation af varmepumpen.

This booklet provides the information necessary for a correct

and simple installation, without questioning your expertise

and technical competence.

Thank you once again.

CONFORMITY

The appliance complies with the following standards:

2 3

Electromagnetic Compatibility Directive 2004/108/EC and

successive modifications

Machine Directive 2006/42/EC and successive

modifications

Directive ErP 2009/125/EC

At the end of its life, the product should be not

be disposed of as solid urban waste, but rather it

should be handed over to a differentiated waste

collection centre.

KOMPATIBILITET

Dette varmepumpeer produceret i overensstemmelse med

følgende standarder.

El 2004/108/EC

Maskindirektiv 2006/42/EC

ErP 2009/125/EC

Varmepumpen indeholder kølemiddel og skal

derfor ved nedtagning aeveres til en godkendt

indsamlingsvirksomhed, som er godkendt til at

overtage ansvaret for affald.

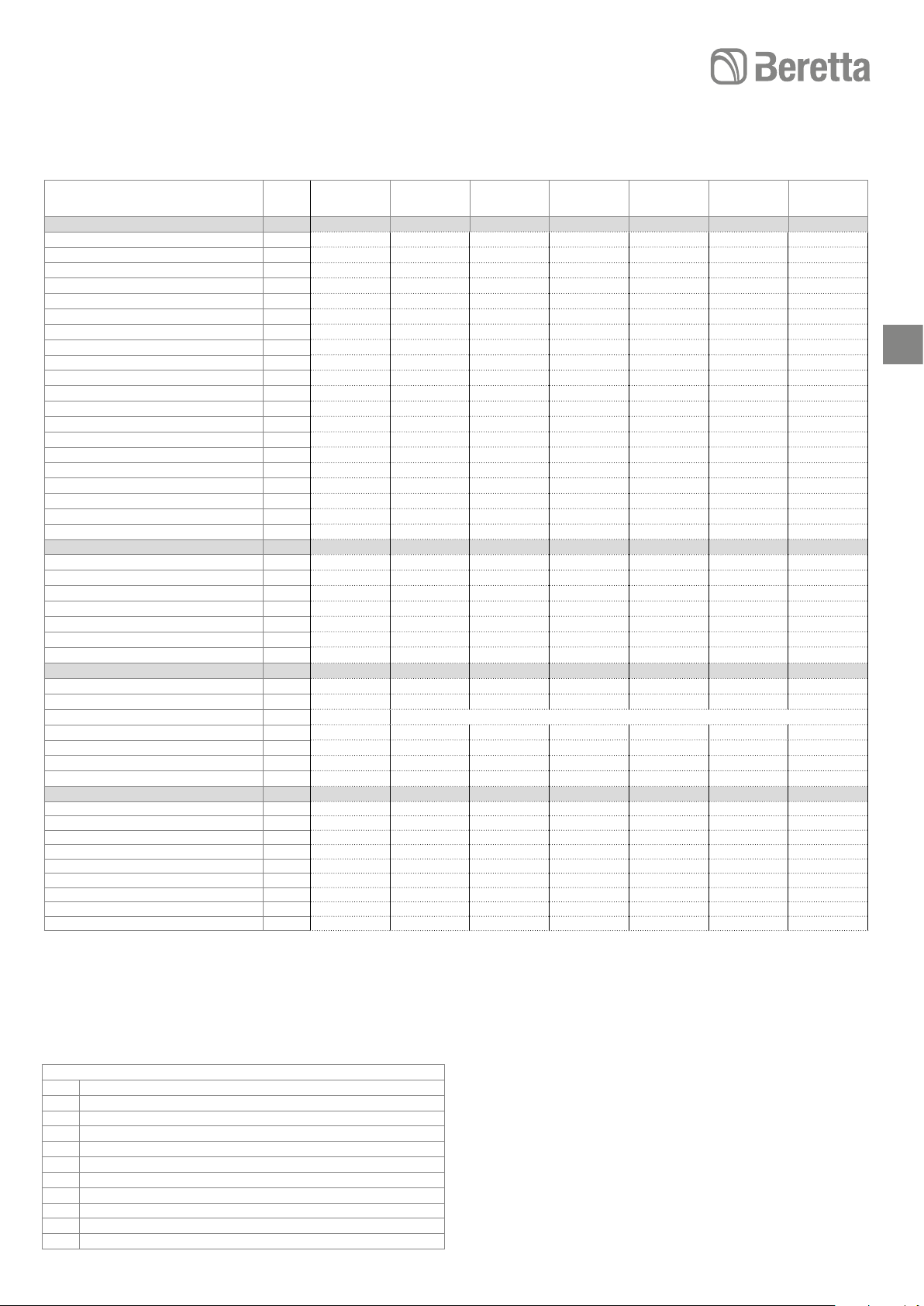

RANGE

Heat pumps Code

HYDRONIC UNIT LE 4 20099402

HYDRONIC UNIT LE 6 20099403

HYDRONIC UNIT LE 8 20099404

HYDRONIC UNIT LE 12 20099405

HYDRONIC UNIT LE 15 20099406

HYDRONIC UNIT LE 12 T 20099407

HYDRONIC UNIT LE 15 T 20099408

MODELLER

Varmepumpe Varenummer

HYDRONIC UNIT LE 4 20099402

HYDRONIC UNIT LE 6 20099403

HYDRONIC UNIT LE 8 20099404

HYDRONIC UNIT LE 12 20099405

HYDRONIC UNIT LE 15 20099406

HYDRONIC UNIT LE 12 T 20099407

HYDRONIC UNIT LE 15 T 20099408

Page 3

HYDRONIC UNIT LE

CONTENTS

GENERAL

General warnings ................................................................................................................................................................. 5

Basic safety rules ................................................................................................................................................................. 6

Description .......................................................................................................................................................................... 7

Identification ........................................................................................................................................................................ 7

Technical Data ..................................................................................................................................................................... 9

Performance based on the climatic zone ............................................................................................................................11

Electrical data ..................................................................................................................................................................... 11

Operating conditions ......................................................................................................................................................... 12

Overall dimensions ........................................................................................................................................................... 13

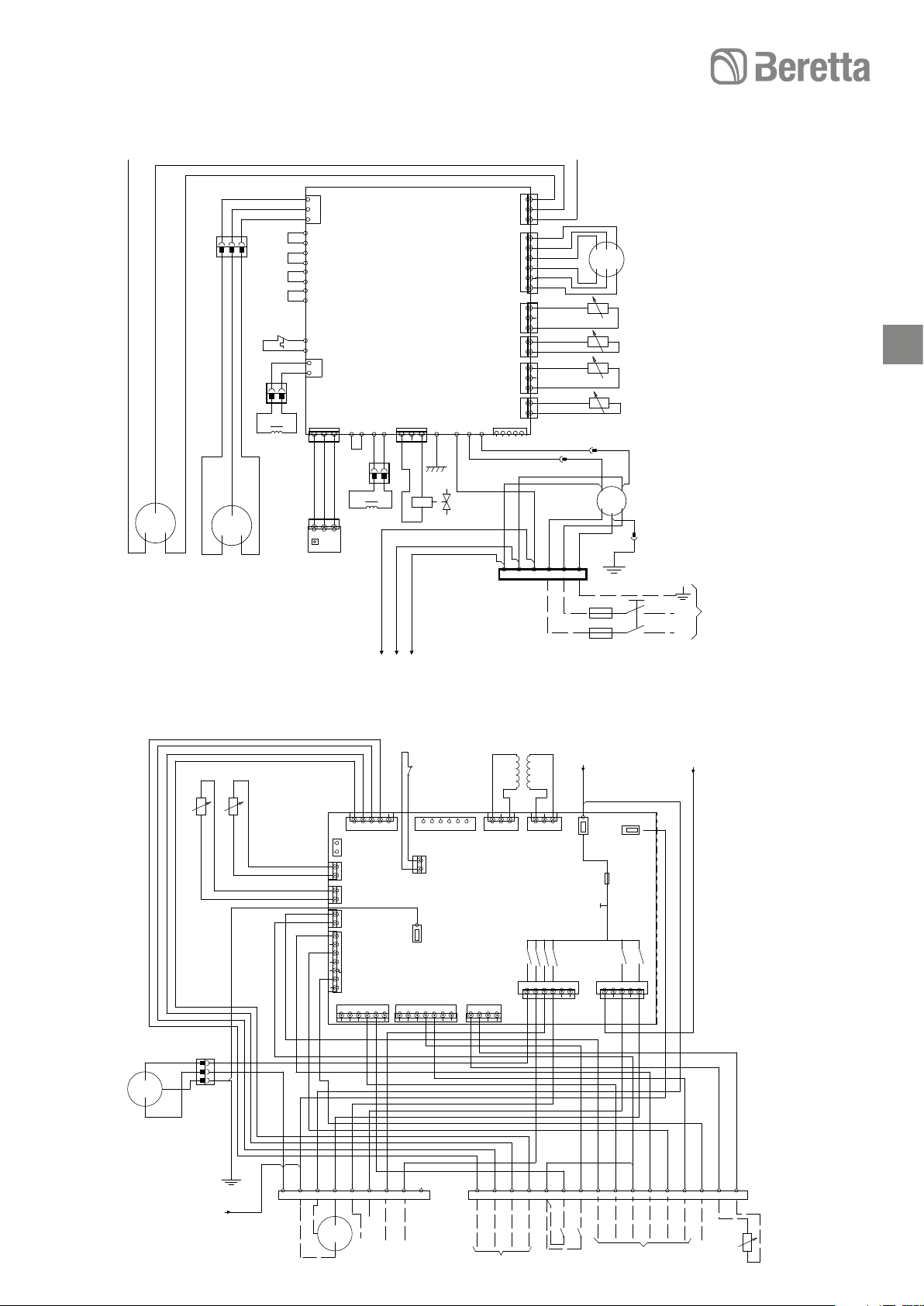

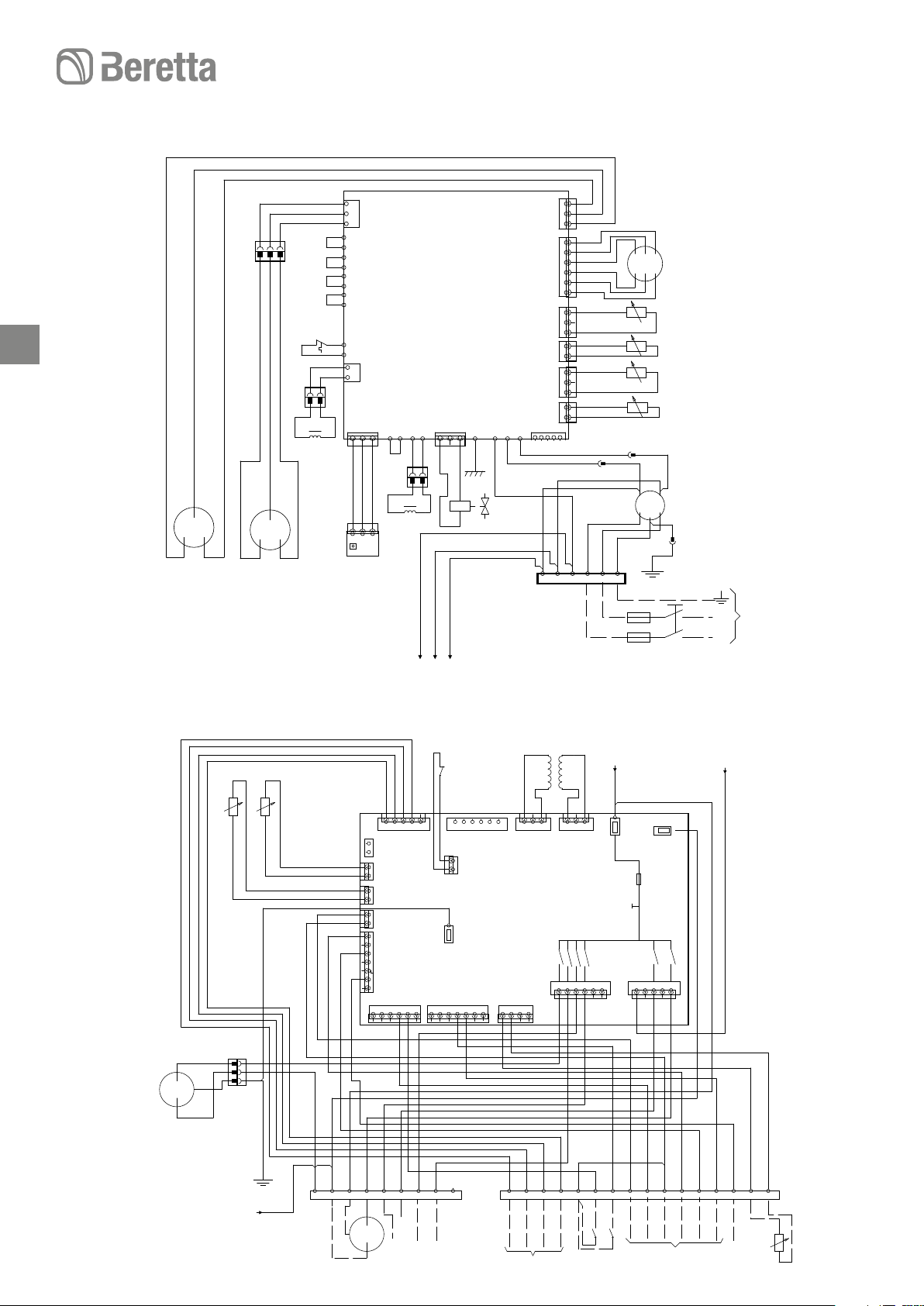

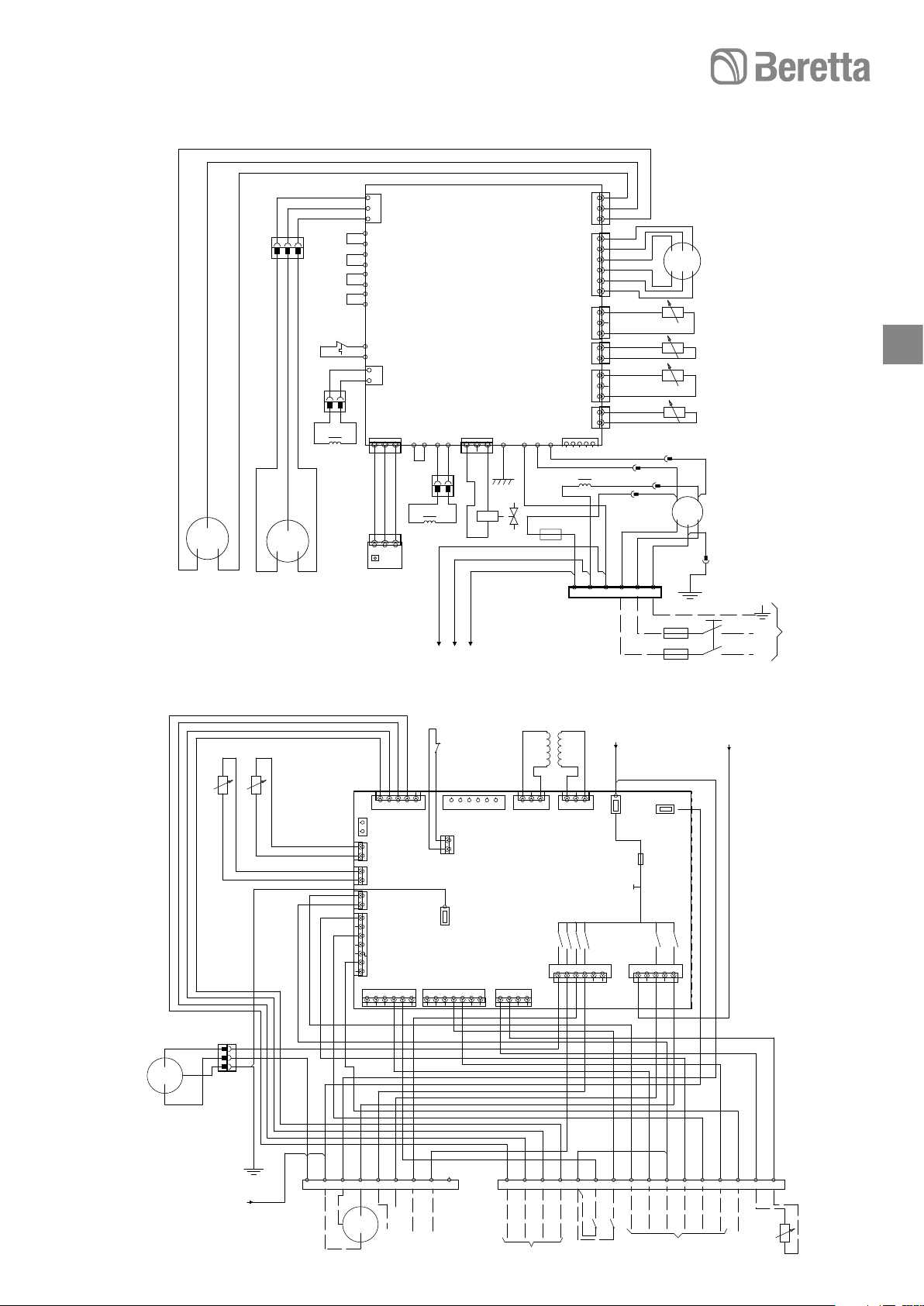

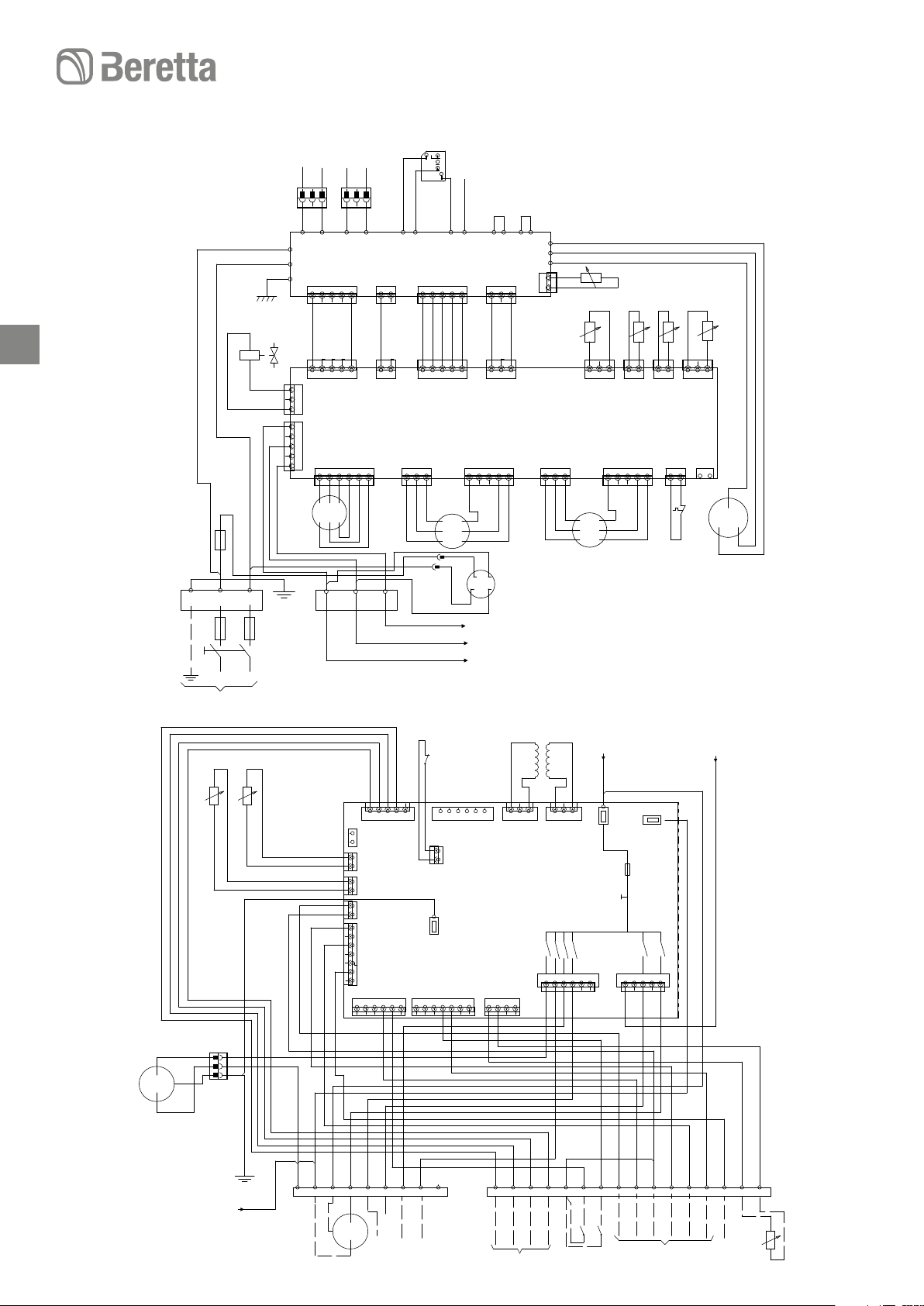

Wiring diagrams ................................................................................................................................................................ 14

Refrigerating circuit diagram .............................................................................................................................................. 21

INSTALLER

Product delivery ................................................................................................................................................................. 22

Handling and transport ...................................................................................................................................................... 22

Access to inner parts ......................................................................................................................................................... 22

Installation ......................................................................................................................................................................... 23

Hydraulic connections ....................................................................................................................................................... 25

Condensate discharge connection .................................................................................................................................... 27

Electrical wiring .................................................................................................................................................................. 27

Control panel ..................................................................................................................................................................... 31

Charging the system .......................................................................................................................................................... 32

Adjustment of the circulation pump.....................................................................................................................................33

3

TECHNICAL ASSISTANCE CENTRE

First commissioning ........................................................................................................................................................... 34

Switching off for lengthy periods ........................................................................................................................................ 34

System drainage ................................................................................................................................................................ 35

Routine maintenance ......................................................................................................................................................... 35

Extraordinary maintenance ................................................................................................................................................ 36

COMMAND

Control panel ..................................................................................................................................................................... 38

Functions .......................................................................................................................................................................... 40

FAULTS

Fault signal ........................................................................................................................................................................ 48

Table of user parameters and functions ............................................................................................................................ 52

Table of installer parameters and functions ....................................................................................................................... 54

Table of factory parameters and functions ......................................................................................................................... 56

In some parts of the booklet, various symbols are used:

WARNING = for actions requiring special care and adequate preparation

DO NOT = for actions that SHOULD ON NO ACCOUNT be carried out

This manual Doc-0092372 Ed. 5 (11/18) is made up of 60 pages

Page 4

HYDRONIC UNIT LE

INDHOLDSFORTEGNELSE

GENERELT

Generelt ................................................................................................................................................................................5

Sikkerhedsregler ................................................................................................................................................................... 6

Beskrivelse ...........................................................................................................................................................................7

Identifikation .........................................................................................................................................................................7

Tekniske data .......................................................................................................................................................................9

4

Ydeevne baseret på klimazone ...........................................................................................................................................11

Elektriske data .................................................................................................................................................................... 11

Drift betingelser ..................................................................................................................................................................12

Dimensioner .......................................................................................................................................................................13

Ledningsdiagram ................................................................................................................................................................ 14

Køle kredsløbs diagram ......................................................................................................................................................21

INSTALLATØR

Levering af produktet .......................................................................................................................................................... 22

Håndtering og transport .....................................................................................................................................................22

Adgang til indre dele ........................................................................................................................................................... 22

Installation ..........................................................................................................................................................................23

Forbindelser til varmeanlæg ................................................................................................................................................ 25

Tilslutning til kondensudledning ..........................................................................................................................................27

El forbindelser ..................................................................................................................................................................... 27

Kontrolpanel .......................................................................................................................................................................31

Udluftning af systemet ........................................................................................................................................................ 32

Justering af cirkulationspumpe ...........................................................................................................................................33

TEKNISK ASSISTANCE

Første opstart ..................................................................................................................................................................... 34

Afbrydelse i længere tid ......................................................................................................................................................34

Tømning af anlægget ..........................................................................................................................................................35

Vedligeholdelse ...................................................................................................................................................................35

Ekstraordinær vedligeholdelse ............................................................................................................................................36

STYRING

Styrepanel ..........................................................................................................................................................................38

Funktioner ..........................................................................................................................................................................40

FEJL

Fejlkoder .............................................................................................................................................................................48

Funktionstabel og brugerparametre ....................................................................................................................................53

Funktionstabel og installatør parametre ...............................................................................................................................57

Fabriksindstillinger og funktioner ......................................................................................................................................... 59

Følgende symboler anvendes i manualen:

ADVARSEL – funktioner, der kræver special viden og omhu.

DO NOT – funktioner, der absolut ikke må udføres

Denne manual Doc-0092372 Ed. 5 (11/18) består af 60 sider

Page 5

HYDRONIC UNIT LE

GENERAL

GENERAL WARNINGS

After removing the packaging, make sure the contents

are complete and undamaged. If necessary contact the

Agency that sold you the appliance.

BERETTA appliances must be installed by authorised compa-

nies in compliance with the DM 37 of 2008 which, at the end

of the job issues the owner with a declaration of conformity

regarding installation, i.e. in compliance with the Standards in

force and the instructions supplied in this booklet.

These appliances should comply with their intended use,

pursuant to their performance characteristics.

BERETTA declines all contractual and non-contractual li-

ability for injury to persons or animal, or damage to property, deriving from errors made during installation, adjustment and maintenance, and from improper use.

In the event of abnormal operation, or leaks of liquids or

refrigerant gases, position the main system switch to “off”

and close the stop taps. Call the BERETTA Technical Assistance Service immediately, or other professionally qualified personnel. Do not try to repair the appliance.

This booklet should be kept safe as it is an integral part of

the equipment and should ALWAYS be kept with it even

when it is sold or given to someone else to use, or transferred to another system. Should the booklet get damaged or gets lost, ask for another copy from the local BERETTA Technical Assistance Centre.

Repairs or maintenance work should be carried out by

the BERETTA Technical Assistance Centre, or by qualified personnel, pursuant to the provisions of this booklet.

Do not modify or tamper with the appliance as dangerous

situations can be created and the appliance manufacturer

will not be liable for any damage caused.

In the installation and/or maintenance operations use ap-

propriate clothing and accident prevention equipment.

The Manufacturer declines all responsibility for the failure

to comply with current safety and accident prevention

standards described below.

Comply with the laws of the nation where the machine is

installed with regard to the use and disposal of the packaging, the products used for cleaning and maintenance,

and the unit's decommissioning.

Pursuant to EC 842/2006 standards regarding certain

fluorinated greenhouse gases, it is mandatory to declare

the total amount of refrigerant present in the installed system. This information can be found on the technical label

attached to the outdoor unit.

This unit contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Maintenance and disposal activities should only be carried out by qualified personnel.

The appliances contain refrigerant gases: handle carefully

to avoid damaging the gas circuit.

GENERELT

GENERELT

Kontroller pakkens indhold efter udpakning.

Produktet skal installeres af en autoriseret installatør i

henhold til DM 37 af 2008.

Varmepumpen må kun anvendes til det, den er udviklet til.

Ukorrekt installation kan forårsage skade på personer, dyr

eller ting. Fabrikanten kan ikke gøres ansvarlig for evt. ska-

de der forårsages p.g.a. ukyndiges indgriben i produktet.

I tilfælde af unormal drift, eller lækager af væsker eller køle-

middeludslip. Sluk på ’OFF’ kontakten på systemet og luk

stophanerne. Tilkald kvalificeret teknisk assistance med

det samme. Forsøg ikke at reparere apparatet selv.

Manualen er en integreret del af udstyret og skal ALTID

være tilgængelig ved service eller reparation, samt ved

evt. salg til anden bruger, eller ved ændring af system.

I henhold til bestemmelserne fra denne manual skal re-

parationer eller vedligeholdelse udføres af kvalificererede

installatører. Der må ikke foretages ændring af apparatet,

da det kan medføre farlige situationer. Fabrikant eller in-

stallatør kan ikke stilles ansvar for disse skader.

Ved installation og/eller vedligeholdelse af drift benyttes

passende tøj og sikkerhedsudstyr. Fabrikanten frasiger

sig ansvar for manglende overholdelse af forebyggelse af

ulykker som beskrevet.

Overholdelse af lovene i det pågældende land, hvor pro-

duktet er installeret, er gældende omkring bortskaffelse af

emballage, produkter til brug for rensning og vedligehol-

delse samt nedlukning af unitten.

I henhold til EC 842/2006 standarder vedrørende specielle

fluor drivhusgasser, er det påbudt at deklarere det totale

brug af kølemiddel i det installerede system. Denne infor-

mation kan findes på den tekniske label som er påsat den

udendørs unit.

Enheden indeholder florerede drivhusgasser under Kyoto

Protocol. Vedligeholdelse og bortskaffelse må kun udføres

af kvalificeret personale.

Varmepumpen indeholder kølemiddel gasser: skal be-

handles forsigtigt for at undgå ødelæggelses af gas kreds-

løbet.

Der skal udføre service på varmepumpen en gang om året

af kvalificeret tekniker.

Der skal udføres frostsikring på vandkredsen (frostvæske).

5

Page 6

HYDRONIC UNIT LE

BASIC SAFETY RULES

This appliance must not be used by children and unaided

disabled persons.

Do not open the access covers to perform any mainte-

nance or cleaning operation before having disconnected

the appliance from the main power supply, by positioning

the master switch at "off".

Do not modify the safety or adjustment devices without

the manufacturer’s authorisation and precise instructions.

Do not climb onto the unit, sit on it and/or rest any type of

6

object on it.

Do not pull, detach or twist the electrical cables coming

from the unit even if it is disconnected from the main pow-

er supply.

Do not spray or throw water directly onto the unit.

Do not dispose of, abandon or leave potentially hazardous

packing material within the reach of children.

It is absolutely forbidden to touch moving parts, get be-

tween them, or insert pointed objects through the grids.

SIKKERHEDSREGLER

Produktet må ikke betjenes af børn eller andre ukyndige.

Kabinettet på varmepumpen må ikke åbnes før strømmen

er slukket på ‘OFF’. Dette gælder ved udførelse af alle former for vedligeholdelse.

Modifikationer på varmepumpen må kun foretages af

autoriseret tekniker.

Unitten må ikke benyttes til at sidde/kravle eller lægge ting

på.

Vrid eller træk aldrig til de elektriske kabler fra varmpum-

pen.

Varmepumpen må ikke udsættes for vand eller vandsprøjt.

Efterlad ikke emballage i nærheden af børn.

Det er totalt forbudt at røre de flytbare dele, gå imellem

dem samt indsætte spidse genstande mellem gitrene.

Page 7

HYDRONIC UNIT LE

DESCRIPTION

Hydronic Unit LE

The product is characterised by:

PAM and PWM modulation DC-INVERTER control, which

allows the compressor to modulate its performance continuously from 30% up to 120%, guaranteeing high energetic standards at any moment.

Pre-painted sheet metal casing.

Revolving ROTARY compressor, for size 4, and TWIN RO-

TARY, for sizes 6-8-12-15, mounted on antivibration support and placed in a special compartment.

Electronically controlled variable speed fan, ensuring an

extremely silent operation.

AISI 316 stainless steel plate heat exchanger, user side,

insulated with closed cell anti-condensation lining.

Exchanger made of copper pipes and louvered aluminium

fins.

Safety devices like sensors, specific automatic switches.

Integrated hydronic module, providing a rapid installation

with the help of a few external components.

Micro-processor electronic control regulating the opera-

tion.

Climate control.

The Hydronic Unit LE appliances are used for the production

of refrigerated water for air conditioning, hot water for heating

and domestic hot water for homes, commercial units and the

like, and are used together with terminal units on small and

medium systems.

Designed for outdoor use, the materials employed have been

chosen for this specific requirement.

BESKRIVELSE

Hydronic Unit LE

PAM og PWN modulerings DC-INVERTER kontrol, der la-

der kompressoren modulere kontinuerligt fra 30% op til

120%. Dette garanterer høj energi-standard til enhver tid.

Pulverlakeret kabinet.

For enhed 4 er en enkel roterende ROTARY-type kom-

pressor og en Roterende TWIN ROTARY-type kompressor for enhed 6-8-12-15. Disse er monteret på antivibrerende konsol og placeret separat.

Elektronisk kontrolleret variabel hastighedsblæser, der

sikrer lydsvag funktion.

AISI 316 varmeveksler rustfri stålplade, bruger side, isole-

ret med antikondenserende foring.

Veksler fremstillet af kobberrør og aluminiums lameller.

Sikkerhedsudstyr så som følere, specifikke automatiske

kontakter.

Mikroprocessor elektronisk kontrol regulerings funktion.

Klima kontrol.

Hydronic Unit LE produkterne er udviklet til nedkøling af vand

til aircondition, opvarmning af vand og varmt brugsvand. Den

anvendes sammen med terminale enheder til små og mellemstore anlæg.

Den er udviklet til udendørs installation og materialerne er

valgt dertil.

7

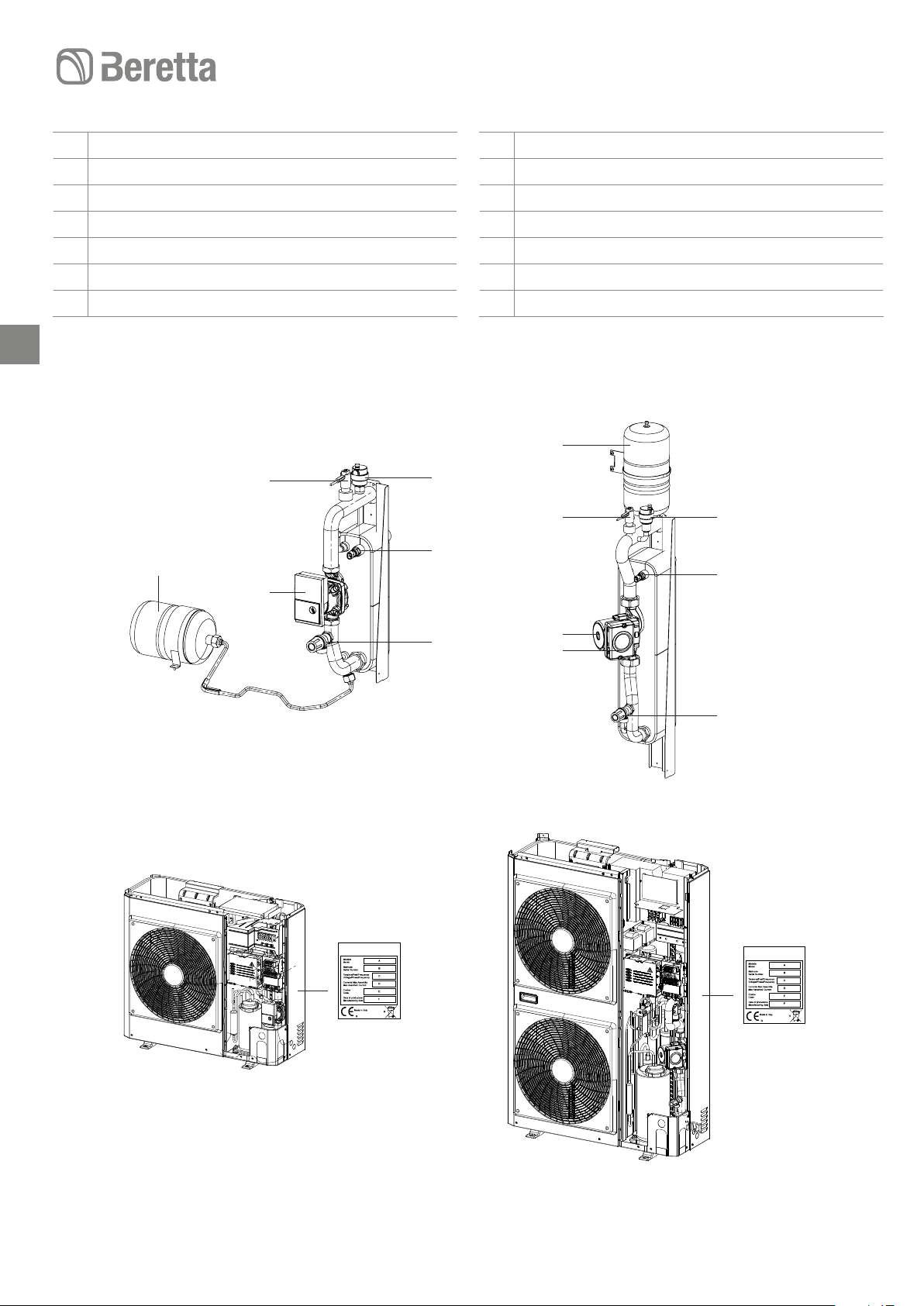

IDENTIFICATION

Technical Tag

The technical label shows all the appliance's technical and

performance data. If it gets lost, ask for a copy from the

BERETTA Technical Assistance Centre.

Tampering, removal, lack of identification labels or any-

thing else which does not permit the safe identification of

the product, makes any installation and maintenance operation difficult.

IDENTIFIKATION

Datapladen viser alle enhedens tekniske data samt ydeev-

ne. Denne label må ikke fjernes.

Hvis labelen mangler vanskeliggøres identifikation, instal-

lation og service af produktet.

Page 8

HYDRONIC UNIT LE

4 - 6 - 812 - 15

1 Automatic air vent valve

2 Temperature probe

3 Safety valve (output 1/2’)

4 Recirculation pump

5 Cap to release pump seizure

6 Flow meter

7 Expansion tank

8

7

1 Automatisk luftudlader

2 Temperatur føler

3 Sikkerhedsventil ½’

4 Cirkulationspumpe

5 Dæksel på pumpe

6 Flowmåler

7 Ekspansionsbeholder

7

6

4

1

6

2

1

2

3

5

4

4 - 6 - 8 12 - 15

3

Page 9

HYDRONIC UNIT LE

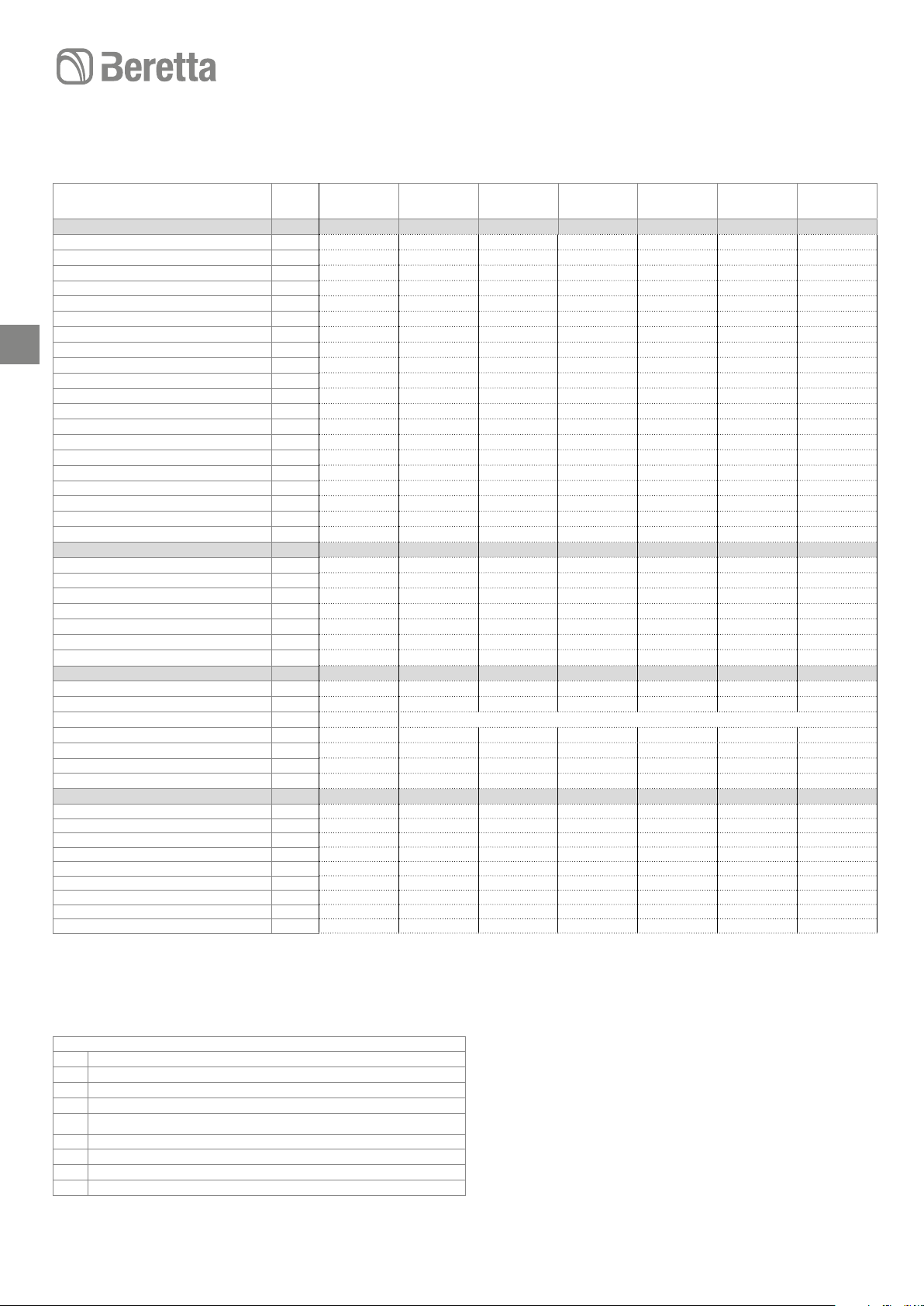

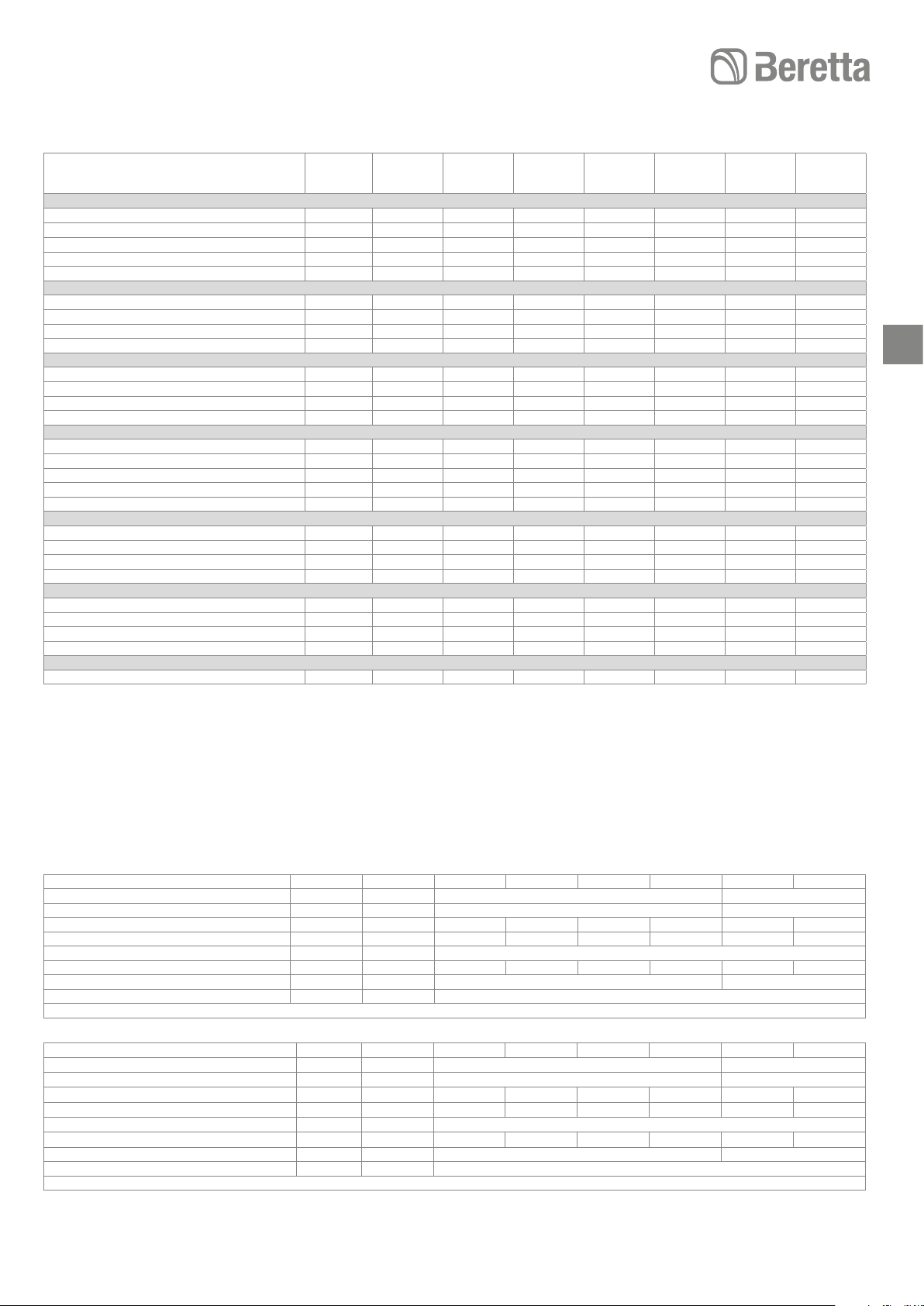

TECHNICAL DATA

Model

Performance in heating mode

Nominal capacity (1) kW

Power consumption (1) kW

COP (1)

Nominal capacity (2) kW

Power consumption (2) kW

COP (2)

Nominal capacity (3) kW

Power consumption (3) kW

COP (3)

Nominal capacity (4) kW

Power consumption (4) kW

COP (4)

Nominal capacity (5) kW

Power consumption (5) kW

COP (5)

Nominal capacity (6) kW

Power consumption (6) kW

COP (6)

Capacity (7)

COP (7)

Performance in cooling mode

Nominal capacity (8) kW

Power consumption (8) kW

EER (8)

Nominal capacity (9) kW

Power consumption (9) kW

EER (9)

ESEER (9)

Generalities

Sound pressure in heating mode dB(A)

Sound pressure in cooling mode dB(A)

Compressor

R410a refrigerant charge ** kg

Empty weight kg

Number of fans n 1 1 1 2 2 2 2

Fan diameter mm 495 495 495 495 495 495 495

Water circuit

Static pressure available kPa

Expansion tank capacity l

Expansion tank pre-charge kPa

System minimum water volume l

System maximum water volume * l

Machine water volume l

Maximum operating pressure kPa

Minimum filling pressure kPa

Hydraulic connections diameter Inches

kW

HYDRONIC

UNIT LE 4

4,07

0,98

4,15

3,87

1,19

3,26

3,5

1,13

3.1

3,4

1,31

2,6

4,1

1,51

2,71

4,27

1,46

2,92

1,06

2,75

4,93

1,17

4,2

3,33

1,10

3,02

4,36

42

44

ROTARY DC INV.

1,195

57

60

2

200

14

65

0,8

300

120

1M

HYDRONIC

UNIT LE 6

5,76 7,16 11,86 14,46 12 15

1,35 1,80 3,00 3,54 2,79 3,57

4,28 3,97 3,95 4,09 4,30 4,20

5,76 7,36 12,91 13,96 11,2 14,5

1,89 2,31 4,26 4,32 3,34 4,39

3,05 3,19 3,03 3,23 3,35 3,30

3,8 4,1 8 10,2 8,55 9,5

1,23 1,31 2,6 3,29 2,69 3,02

3.1 3.1 3.1 3.1 3,17 3,15

3,7 3,9 8 10,2 7,5 9,3

1,42 1,48 3,08 3,92 2,78 3,50

2,6 2,6 2,6 2,6 2,70 2,65

5,4 6,7 11,5 11,7 11,05 12

2,09 2,91 4,64 4,18 3,95 4,21

2,58 2,3 2,48 2,8 2,80 2,85

5,43 7,25 10,87 12,36 11,43 12,17

1,95 2,58 4,05 4,09 3,66 4,08

2,77 2,81 2,68 3,02 3,12 2,98

1,50 1,86 4,68 4,78 4,78 4,78

2,82 2,81 2,70 2,75 2,75 2,75

7,04 7,84 13,54 16,04 13,5 16

1,90 1,96 3,70 4,17 3,25 4,20

3,7 3,99 3,66 3,85 4,15 3,81

4,73 5,84 10,24 13,04 10,2 13

1,58 1,96 3,46 4,42 3,40 4,47

3 2,98 2,96 2,95 3 2,91

4,51 4,15 4,22 4,31 4,40 4,31

42 44 47 48 48 48

44 45 48 49 49 49

1,35 1,81 2,45 3,39 3,385 3,385

61 69 104 112 116 116

60 56 70 58 70 55

2 2 3 3 3 3

200 200 200 200 200 200

21 28 42 49 42 49

65 65 95 95 95 95

0,8 1,0 2,3 2,3 2,3 2,3

300 300 300 300 300 300

120 120 120 120 120 120

1M 1 M 1 M 1 M

HYDRONIC

UNIT LE 8

HYDRONIC

UNIT LE 12

TWIN ROTARY DC INVERTER

HYDRONIC

UNIT LE 15

HYDRONIC UNIT

LE 12 T

1M 1M

HYDRONIC

UNIT LE

* For greater water volumes it is necessary to provide an additional expansion tank

** The value of the refrigerant charge is indicative. The correct value is indicated on the technical data plate.

15 T

9

Reference conditions

Note / Note

1 outdoor temperature d.b. + 7 °C / w.b. + 6°C, water 35 - 30 °C.

2 outdoor temperature + 7 °C / w.b. + 6°C, water 45 - 40 °C.

3 outdoor temperature d.b. + 2 °C / w.b. +1°C, water 35 - 30 °C.

4 outdoor temperature d.b. + 2 °C / w.b. +1°C, water 45 - 40 °C.

5 outdoor temperature d.b. + 7 °C / w.b. + 6°C, water 55 °C.

6

outdoor temperature d.b. + 7 °C / d.b. + 6°C, water 47 - 55 °C.

7 outdoor temperature -7 °C, water 35 °C (with rated water flow)

8 outdoor temperature d.b. +35 °C / w.b. +24°C, water 18 - 23 °C.

9 outdoor temperature d.b. +35 °C, water 7 - 12 °C.

d.b. dry bulb

w.b. wet bulb

EN 14511

Sound pressure measured in a hemispheric field 4 metres

in front of the fan.

Unit performances have been provided in reference to

Directive UNI EN 14511:2011.

Fouling factor: 0.18 x 10-4 (m² K)/W.

Page 10

TEKNISKE DATA

HYDRONIC UNIT LE

Model

Varmefunktion

Nominel ydelse (1) kW

El forbrug (1) kW

COP (1)

Nominel ydelse (2) kW

El forbrug (2) kW

COP (2)

Nominel ydelse (3) kW

10

El forbrug (3) kW

COP (3)

Nominel ydelse (4) kW

Elforbrug (4) kW

COP (4)

Nominel ydelse (5) kW

Elforbrug (5) kW

COP (5)

Nominel ydelse (6) kW

El forbrug (6) kW

COP (6)

Kapacitet (7) kW

COP (7)

Kølefunktion

Nominel ydelse (8) kW

El forbrug (8) kW

EER (8)

Nominel ydelse (9) kW

El forbrug (9) kW

EER (9)

ESEER (9)

Generelt

Lydniveau i varmefunktion dB(A)

Lydniveau i kølefunktion dB(A)

Kompressor

R410a kølemiddel** kg

Netto vægt kg

Antal blæsere Stk 1 1 1 2 2 2 2

Blæser Diameter mm 495 495 495 495 495 495 495

Vandkredsløb

Statisk tilgængelig tryk kPa

Ekspansionsbeholder kapacitet l

Ekspansionsbeholder fortryk kPa

Min vandproduktion l

Max vandproduktion* l

UNIT vandindhold l

Max. arbejdstryk kPa

Min. arbejdstryk kPa

Rørforbindelser Zoll

HYDRONIC

UNIT LE 4

4,07

0,98

4,15

3,87

1,19

3,26

3,5

1,13

3.1

3,4

1,31

2,6

4,1

1,51

2,71

4,27

1,46

2,92

1,06

2,75

4,93

1,17

4,2

3,33

1,10

3,02

4,36

42

44

ROTARY DC INV.

1,195

57

60

2

200

14

65

0,8

300

120

1M

HYDRONIC

UNIT LE 6

5,76 7,16 11,86 14,46 12 15

1,35 1,80 3,00 3,54 2,79 3,57

4,28 3,97 3,95 4,09 4,30 4,20

5,76 7,36 12,91 13,96 11,2 14,5

1,89 2,31 4,26 4,32 3,34 4,39

3,05 3,19 3,03 3,23 3,35 3,30

3,8 4,1 8 10,2 8,55 9,5

1,23 1,31 2,6 3,29 2,69 3,02

3.1 3.1 3.1 3.1 3,17 3,15

3,7 3,9 8 10,2 7,5 9,3

1,42 1,48 3,08 3,92 2,78 3,50

2,6 2,6 2,6 2,6 2,70 2,65

5,4 6,7 11,5 11,7 11,05 12

2,09 2,91 4,64 4,18 3,95 4,21

2,58 2,3 2,48 2,8 2,80 2,85

5,43 7,25 10,87 12,36 11,43 12,17

1,95 2,58 4,05 4,09 3,66 4,08

2,77 2,81 2,68 3,02 3,12 2,98

1,50 1,86 4,68 4,78 4,78 4,78

2,82 2,81 2,70 2,75 2,75 2,75

7,04 7,84 13,54 16,04 13,5 16

1,90 1,96 3,70 4,17 3,25 4,20

3,7 3,99 3,66 3,85 4,15 3,81

4,73 5,84 10,24 13,04 10,2 13

1,58 1,96 3,46 4,42 3,40 4,47

3 2,98 2,96 2,95 3 2,91

4,51 4,15 4,22 4,31 4,40 4,31

42 44 47 48 48 48

44 45 48 49 49 49

1,35 1,81 2,45 3,39 3,385 3,385

61 69 104 112 116 116

60 56 70 58 70 55

2 2 3 3 3 3

200 200 200 200 200 200

21 28 42 49 42 49

65 65 95 95 95 95

0,8 1,0 2,3 2,3 2,3 2,3

300 300 300 300 300 300

120 120 120 120 120 120

1M 1 M 1 M 1 M 1M 1M

HYDRONIC

UNIT LE 8

HYDRONIC

UNIT LE 12

TWIN ROTARY DC INVERTER

HYDRONIC

UNIT LE 15

HYDRONIC UNIT

LE 12 T

* For større vandproduktion er det nødvendigt at tilslutte en ekstra ekspansionstank

** Værdien af kølemiddel er vejledende. Den korrekte værdi vises på datapladen.

HYDRONIC

UNIT LE

15 T

Standard forhold

1 Udetemperatur d.b. +7°C/w.b. +6°C, vand 35 – 30°C

2 Udetemperatur +7°C/w.b. +6°C, vand 45 – 40°C

3 Udetemperatur D.b. +2°C/w.b. +1°C, vand 35 – 30°C

4

Udetemperatur D.b. +2°C/w.b. +1°C, vand 45 – 40°C

5 Udetemperatur D.b. +7°C/w.b. +6°C, vand 55°C

6 Udetemperatur D.b. +35°C/w.b. 24°C, vand 18 – 23°C

7 Udetemperatur D.b. +35°C, vand 7 – 120°C

d.b.

Tør

w.b. Fugtig

Lydniveau målt i hemisfærisk område 4 meter fra blæser.

Funktioner i overensstemmelse med UNI EN 14511:2011.

Forureningsfaktor: 0,18 x 10-4 (m2K)/W.

Page 11

HYDRONIC UNIT LE

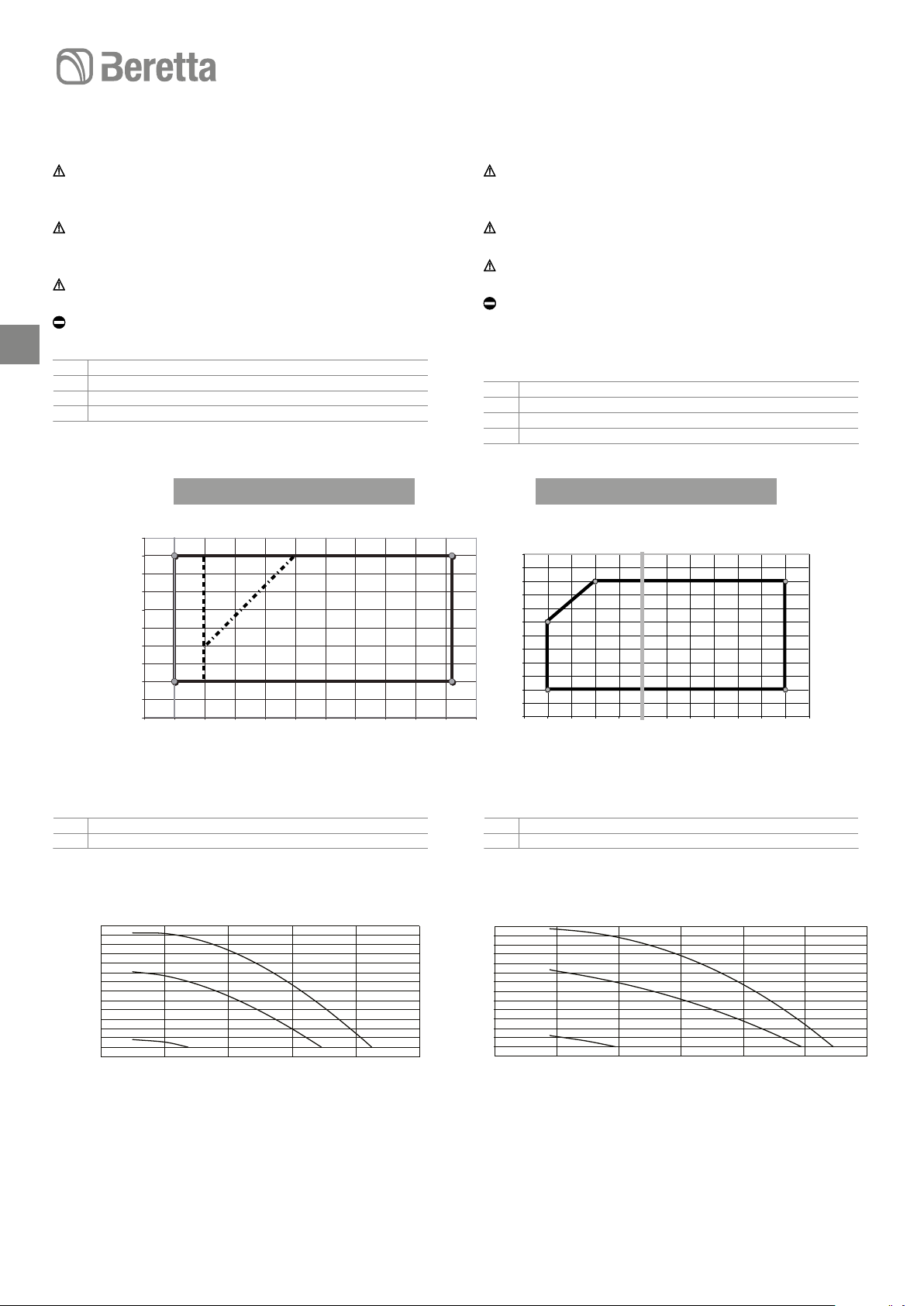

PERFORMANCE BASED ON THE CLIMATIC ZONE LEISTUNGSWERTE IN BEZUG AUF DIE KLIMAZONE

Model / Modell

Temperate zone - Average temperature (47 / 55 °C) - Tempereret zone - Gennemsnitstemperatur (47 / 55°C)

ŋs

SCOP 3,53 3,37 2,84 2,95 3,25 3,47 3,33

Pdesign kW 3,28 4,22 4,65 8,68 9,05 8,38 9,37

Annual consumption * / Årligt forbrug* kW/h 1.900 2.571 3.367 6.077 5.748 4.975 5.806

Energy class / Energi Klasse A++ A++ A+ A+ A++ A++ A++

Cold zone - Average temperature (47 / 55 °C) / Kold zone – gennemsnitstemperatur (47 / 55°C)

ŋs

SCOP 3,23 2,87 2,64 2,72 3,06 3,09 3,11

Pdesign kW 5,16 6,65 6,59 13,67 14,52 13,20 15,05

Annual consumption * / Årligt forbrug* kW/h 3.911 5.431 5.867 11.859 11.188 10.060 11.404

Warm zone - Average temperature (47 / 55 °C) / Varm zone – gennemsnitstemperatur (47 / 55°C)

ŋs

SCOP 4,82 4,60 3,88 4,03 4,44 4,74 4,55

Pdesign kW 3,10 3,79 4,83 8,04 8,38 7,76 8,67

Annual consumption * / Årligt forbrug* kW/h 843 1.085 1.649 2.651 2.508 2.177 2.537

Temperate zone - Low temperature (30 / 35 °C) /Tempereret zone – lavt temperatur 30 / 35°C)

ŋs

SCOP 3,73 3,60 3,03 3,19 3,61 3,78 3,68

Pdesign kW 3,83 4,92 4,56 10,00 10,75 9,76 11,12

Annual consumption * / Årligt forbrug* kW/h 2.015 2.806 3.088 6.467 6.137 5.314 6.230

Energy class / Energi Klasse A+ A+ A A+ A+ A+ A+

Cold zone - Low temperature (30 / 35 °C) / Kold zone – lav temperatur (30 / 35°C)

ŋs

SCOP 3,41 3,07 2,82 2,94 3,40 3,37 3,44

Pdesign 6,03 7,75 6,46 15,75 17,25 15,37 17,86

Annual consumption * / Årligt Forbrug kW/h 4.148 5.927 5.381 12.620 11.945 10.741 12.237

Warm zone - Low temperature (30 / 35 °C) / Varm zone – Lav temperatur (30 / 35°C)

ŋs

SCOP 5,09 4,92 4,14 4,36 4,93 5,16 5,03

Pdesign kW 3,42 4,06 5,09 9,20 9,96 9,04 10,29

Annual consumption * / Årligt forbrug* kW/h 880 1.084 1.624 2.809 2.681 2.327 2.714

Noise level / Lydniveau

Sound power / Lydniveau dB(A) 62 62 64 67 68 68 68

HYDRONIC

UNIT LE 4

138 132 111 115 127 136 130

126 112 103 106 119 121 122

190 181 152 158 175 187 179

146 141 118 125 141 148 144

133 120 110 115 133 132 135

201 194 163 171 194 203 198

HYDRONIC

UNIT LE 6

HYDRONIC

UNIT LE 8

HYDRONIC

UNIT LE 12

HYDRONIC

UNIT LE 15

HYDRONIC

UNIT LE

12 T

HYDRONIC

UNIT LE

15 T

* With backup electric heater * Med elektrisk varme backup

11

ELECTRICAL DATA ELEKTRISKE DATA

Modello

Power supply V- ph - Hz 230 - 1 -50 400 - 3 -50

Allowable voltage range V 207 ÷ 254 373 ÷ 424

Maximum power drawn kW 2 2,3 3,7 5,1 5,1 6,5 6,5

Maximum current drawn A 7,2 11 14 23 20 16 16

Type of fuses gL type

Power supply fuses current A 10- type B 16- type B 16- type B 25 - type D 25 - type D 16- type B 16- type B

Power supply cables mm

Maximum p

Use H03VV-F 4x0.75 mm² cables to connect the remote control to the wires

Model

El tilslutning V- PH - Hz 230 - 1 -50 400 - 3 -50

Volt V 207 ÷ 254 373 ÷ 424

Max. strøm input kW 2 2,3 3,7 5,1 5,1 6,5 6,5

Max. strømforbrug A 7,2 11 14 23 20 16 16

Sikringer Betriebsklasse gL

Sikringer el A 10 - Typ B 16 - Typ B 16 - Typ B 25 - Typ D 25 - Typ D 16 - Typ B 16 - Typ B

Elkabler mm

Max. ekstern. cirkulationspumpe A 2

Benyt H03W-F 4X0,75 mm2 kabler for at forbinde fjernbetjeningen til ledningerne

ump current external circulatio

n A 2

2

2

4 6 8 12 15 12T 15T

H07RN-F 3 x 2.5mm

4 6 8 12 15 12T 15T

H07RN-F 3 x 2.5mm

2

2

H07RN-F 5 x 2.5mm

H07RN-F 5 x 2.5mm

2

2

Page 12

HYDRONIC UNIT LE

OPERATING CONDITIONS

Heat pump optimal operation when producing DHW

should have an outdoor air temperature that does not exceed 30°C.

For outdoor air temperatures exceeding 30°C the domes-

tic hot water production may be limited due to the intervention of machine safety devices.

For technical interventions, see the technical label on the

machine.

It is forbidden to work outside firing rate.

1212

1 Cooling

2 Heating

A Outdoor air temperature (°C)

B Output water temperature (°C)

20

18

16

14

12

10

B

8

6

4

2

0

-5 0510 15 20 25 30 35 40 45 50

006

004

DRIFT BETINGELSER

For optimal funktion af varmepumpen ved produktion af

varmt vand i sommerfunktion, må udetemperaturen ikke

overstige 30°C.

Hvis udetemperaturen overstiger 30°C er varmvandspro-

duktionen begrænset af apparatets sikkerhedsanordning.

For tekniske foranstaltninger henvises til datapladen på

produktet.

Indstillinger udenfor de angivne funktionsområder er ikke

tilladt.

1 Køling

2 Opvarmning

A Udetemperatur (°C)

B Fremløbstemperatur (°C)

1

70

65

60

55

50

B

45

40

35

008-012-015

A

30

25

20

15

10

-25-20 -15-10 -5 0510 15 20 25 30 35

2

A

Flow rate-discharge head diagram

A Flow rate (l/s)

B Available static pressure (kPa)

4 6

75

65

55

45

B

35

25

15

5

0,10,0

0,2 0,3

A

0,4 0,5

Flowmåler

A Flow hastighed (I/s)

B Tilgængelig statisk tryk (kPa)

75

65

55

45

B

35

25

15

5

0,10,0

0,2 0,3

0,4 0,5 0,6

A

Page 13

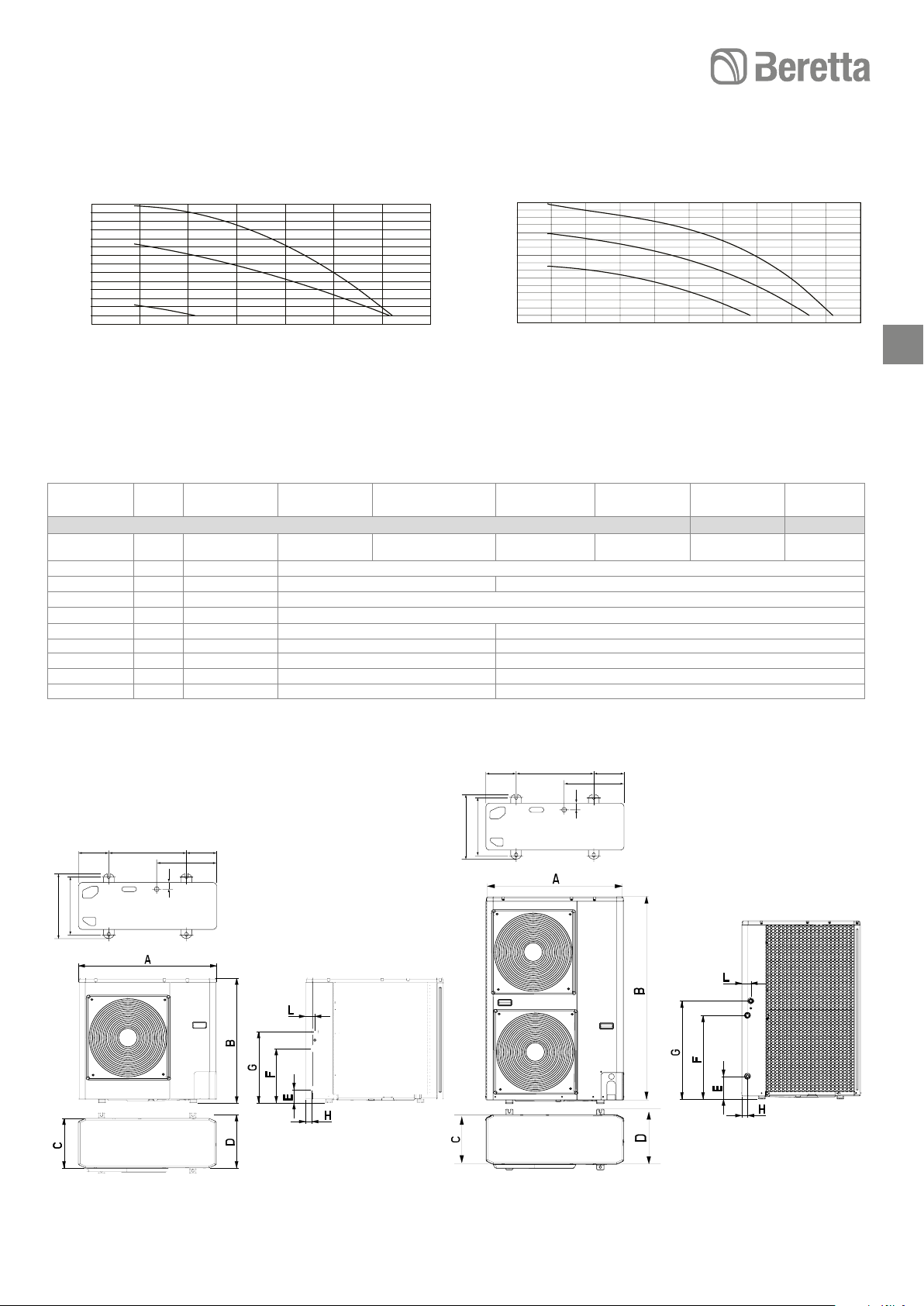

HYDRONIC UNIT LE

41

1

2

3

41

1

2

3

75

65

55

45

B

35

25

15

5

0,10,0

0,2 0,3

8

0,4 0,5 0,6 0,7

A

95

85

75

65

B

55

45

35

25

15

0,10,0

0,2 0,3

0,4 0,5 0,6 0,7 0,8 0,9 1,0

OVERALL DIMENSIONS / DIMENSIONER

Model

Model

Overall dimensions / Dimensioner

Empty weight

Netto vægt

kg 57 61 69 104 112 116 116

A mm 908

B mm 821 1363

C mm 326

D mm 350

E mm 87 174

F mm 356 640

G mm 466 750

H mm 40 44

L mm 60 69

4 6 8 12 15 12 T 15 T

12 - 15

A

139

60015

363

400

54

430

37

400

363

60015

54

430

37

Page 14

HYDRONIC UNIT LE

WIRING DIAGRAMS

- Wiring of the manufacturer

---- Wiring of the installer

CM Compressor motor

FM Fan motor

RV Reversing valve (4 way)

TS Temperature probe low pressure pipe

TO Temperature probe external unit

TD Temperature probe high pressure pipe

TE Temperature probe capacitor pipe

PMV Modulating valve motor

R Reactor

F Fuse

14

LWT Water outlet probe

EWT N.A.

TR Refrigerant sensor

FS Flow meter

TL Temperature probe capacitor pipe 2

C Compressor thermostat

H High pressure switch

RY Relay

T Transformer

PS Water pump motor

E-HTR Electric heater

AD Alarm status and defrost

OAT Outside air probe

LF Frequency Limiting

IS Domestic water input

SV Three-way domestic water valve

Y Yellow

O Orange

R Red

G Grey

A Brown

C Black

V Violet

B Blue

W White

Y/G Yellow Green

LEDNINGSDIAGRAM

- Fabriksmonteret

---- Monteret ved installation

CM Kompressor motor

FM Blæsermotor

RV Omskiftet ventil (4 vejs)

TS Temperaturføler lavtryksrør

TO Temperaturføler ekstern enhed

TD Temperaturføler højtryksrør

TE Temperaturføler kondensafløb

PMV Modulerende blæsermotor

R Reaktor

F Sikring

LWT Fremløbsføler

EWT Anvendes ikke

TR Føler afkøling

FS Flowmeter

TL Temperaturføler kondensafløb 2

C Kompressor termostat

H Højtryks kontakt

RY Relæ

Transformer

T Vandpumpemotor

PS El-varmeelement

E-HTR Alarm status og afrimning

AD Udeføler

OAT Frekvensgrænse

LF Brugsvands input

IS 3-vejs brugsvandsventil

SV Gul

Y Orange

O Rød

R Grå

G Brun

A Sort

C Violet

V Blå

B Hvid

W Gul/grøn

Y/G Gelb-grün

Page 15

HYDRONIC UNIT LE

HYDRONIC UNIT LE 4 POWER/HYDRONIC UNIT LE 4 FORBINDELSESDIAGRAM

CN300

CN700

CN503

CN502

CN501

CN500

1

C

1

3

2

1

1

6

6

5

4

3

2

1

1

3

2

1

1

2

1

1

3

2

1

1

2

1

1

W

N

3 L N PE

7CF

8CF

1PMV

9CF

10CF

11CF

12CF

1TS

1TO

1TD

1TE

15

W

W

C

1FL

U1 U3

L2 N4

Y/G

PE

Y/G

Y/G

N

230V1~50Hz

A

B

R

W

C

3

1 2

1CF

1 2 3

2CM

THERMOSTATFOR

C

W

R

COMPRESSOR

1T

2CF

3CM

W

C

S

1CM

C

R

R

1FM

P04

P05

P06

P25

Y

P24

P23

Y

P22

P21

A

P20

P35

Y

P34

12

P19

P18

P11

P08

2 1

2 1

CN805

1R

3CF

4CF

1

1 2 3

RWC

1 2

1

1MCC1530

P31

P332RP32

V

2 1

5CF

2 1

4CM

3

P30

CN701

6CF

1

1 2 3

1P.C.BOARD

F7 P03 P10 P02

C

1RV

CN806

C

O

1TB

B

C

A

L

/2.10/J4.1

/2.03/J3.1

/2.08/J1.1

HYDRONIC UNIT LE 4 CONTROL / HYDRONIC UNIT LE 4 FORBINDELSESDIAGRAM

1FS

J5.3

J5

J16.4

J16.5

J5.4

J5.5

J16.6

J20.7

7 6 5 4 3 2 1

21CF

1

2

J10.1

J10.2

J10.3

J10.4

J10.5 J10.6

1

J10

22CF

1

1

J17.1

J17

2

J17.2

1PCB

J15.1

J15

J20

1

J20.6

J20.5

1

J20.4

J20.3

J20.2

J20.1

J22.1 J22.2

1 2 3 4

23CF

1LWT

1TR

20CF

1 2 3 4 5

J5.1

J5.2

1

1

J6A.1

J6A

J6A.2

15CF

1

1

J6B.1

2

J6B

O

G

W

Y

Y/G

R

W

R

5CM

13CF

G

Y/G

1PS

2

2

3

3

1

1

A

B

J6B.2

16CF

1

1

J6B.1

2

J6C

J6B.2

17CF

1

1

J18.1

J18

2

J18.2

18CF

7

J11.7

6

J11.6

5

J11

J11.5

4

J11.4

3

J11.3

2

J11.2

1

J11.1

1

J16

1

G

J16.1

J16.2

J16.3

1 2 3 4 5 6

19CF

C

C

A

B

/1.05/J3.1

Y/G

B

B

O

R

G

ALARM+

DFR

/

HUMIDITY

C

EHTR

/

WP

EHS

/

DFR

3TB

N N 18 10 11 12 4 5 16

1SV

A

G

ALARM

2TB

2T

R

A

R

24CF

26CF

3

1 2

1 2

J13.1

J13.2

J13.3

J13

J22.4

1

J7

1

J7.1

1 2 3 4 5 6

25CF

J2.1

J7.2

1

J22

J22.3

J1.1//1.05

B

A

3

J1.1

J1

J2.2

J2.3

J2

J7.3

J7.4 J7.5 J7.6

C

W

C W G Y 13 14 15 7 6 3 2 1 8 21 23 24

1

1

2

2

1LF

REMOTE

1IS

J4

1

27CF

J4.1 J4.2

J4.3 J4.4

1 2 3 4 5

J3

REMOTE

CONTROL

J4.1//1.05

C

J4.5

A

C

O

1OAT

ALARM

INPUT

Page 16

HYDRONIC UNIT LE

HUMIDITY

HYDRONIC UNIT LE 6 Power / HYDRONIC UNIT LE 6 FORBINDELSESDIAGRAM

16

CN300

CN700

CN503

CN502

CN501

CN500

1

C

1

3

2

1

1

6

6

5

4

3

2

1

1

3

2

1

1

2

1

1

3

2

1

1

2

1

1

W

N

3 L N PE

7CF

8CF

1PMV

9CF

10CF

11CF

12CF

1TS

1TO

1TD

1TE

W

W

C

1FL

U1 U3

L2 N4

Y/G

PE

Y/G

Y/G

N

230V1~50Hz

A

B

R

W

C

3

1 2

1CF

1 2 3

2CM

THERMOSTATFOR

C

W

R

COMPRESSOR

1T

2CF

3CM

W

C

S

1CM

C

R

R

1FM

P04

P05

P06

P25

Y

P24

P23

Y

P22

P21

A

P20

P35

Y

P34

12

P19

P18

P11

P08

2 1

2 1

CN805

1R

3CF

4CF

1

1 2 3

RWC

1 2

1

1MCC1530

P31

P332RP32

V

2 1

5CF

2 1

4CM

3

1P.C.BOARD

CN701

1

P30

F7 P03 P10 P02

1 2 3

6CF

C

1RV

CN806

C

O

1TB

B

C

A

L

/2.10/J4.1

/2.03/J3.1

/2.08/J1.1

HYDRONIC UNIT LE 6 CONTROL / HYDRONIC UNIT LE 6 FORBINDELSESDIAGRAM

1FS

J5.2

J16.4

J5.3

J5

J16.5

J5.4

J5.5

J16.6

J20.7

7 6 5 4 3 2 1

21CF

1

2

J10.1

J10.2

J10.3

J10.4

J10.5 J10.6

1

J10

22CF

1

1

J17.1

J17

2

J17.2

1PCB

J15.1

J15

J20

1

J20.6

J20.5

1

J20.4

J20.3

J20.2

J20.1

J22.1 J22.2

23CF

1LWT

1TR

20CF

1 2 3 4 5

J5.1

1

1

J6A.1

J6A

J6A.2

15CF

1

1

J6B.1

2

J6B

O

G

W

Y

Y/G

R

W

R

5CM

13CF

1

1

G

2

2

3

3

Y/G

1PS

A

B

J6B.2

16CF

1

1

J6B.1

2

J6C

J6B.2

17CF

1

1

J18.1

J18

2

J18.2

18CF

7

J11.7

6

J11.6

5

J11

J11.5

4

J11.4

3

J11.3

2

J11.2

1

J11.1

1

J16

1

G

J16.1

J16.2

J16.3

1 2 3 4 5 6

19CF

C

C

A

B

/1.05/J3.1

Y/G

B

B

O

R

G

3TB

N N 18 10 11 12 4 5 16

1SV

C

EHTR

/

WP

ALARM+

EHS

DFR

/

/

DFR

A

G

ALARM

2TB

2T

B

R

A

R

24CF

26CF

3

J13.3

J7

1

25CF

3

1 2

J2.1

J2.2

J2.3

1

J2

J7.1

J7.2

J7.3

J7.4 J7.5 J7.6

1 2 3 4 5 6

1

J22

J22.3

1 2 3 4

1 2

J13.1

J13.2

J13

J22.4

W

C W G Y 13 14 15 7 6 3 2 1 8 21 23 24

REMOTE

1LF

J1.1//1.05

J4.1//1.05

A

J1.1

J1

J3

C

J4

1

J4.1 J4.2

J4.3 J4.4

J4.5

1 2 3 4 5

27CF

A

C

ALARM

INPUT

O

1OAT

C

1

1

2

2

1IS

REMOTE

CONTROL

Page 17

HYDRONIC UNIT LE

HUMIDITY

HYDRONIC UNIT LE 8 POWER / HYDRONIC UNIT LE 8 FORBINDELSESDIAGRAM

R

W

C

3

1 2

40CF

1 2 3

7CM

THERMOSTATFOR

W

6CM

R

S

COMPRESSOR

C

2T

41CF

8CM

C

C

W

R

R

1FM

2 1

2 1

P04

P05

P06

P25

Y

P24

P23

Y

P22

P21

A

P20

P35

Y

P34

12

P19

P18

P11

P08

1P.C.BOARD

CN300

CN700

CN503

CN502

CN501

1

6

1

1

1

1

CN500

CN805

1R

1

1 2 3

42CF

RWC

3

1 2

43CF

1

1MCC1530

P33 P32

V

CN701

1

P31 P30

45CF

2 1

44CF

2 1

9CM

2R

1 2 3

1RV

F7 P03

C

P10 P02

C

O

1 2

C

B

A

/2.10/J4.1

/2.03/J3.1

/2.08/J1.1

1

CN806

1

W

3R

R

1F

R

1TB

N

1

HYDRONIC UNIT LE 8 CONTROL / HYDRONIC UNIT LE 8 FORBINDELSESDIAGRAM

1FS

J5.3

J5

J16.4

12

EHTR

/

WP

J5.4

J5.5

J16.5

J16.6

60CF

C

4

EHS

/

DFR

1

2

J10.1

J10.2

1

61CF

1

1

J17.1

J17

2

J17.2

J15.1

J15

J20

J20.7

J20.6

J20.5

J20.4

J20.3

7 6 5 4 3 2 1

A

G

5

16

ALARM

J10.3

J10.4

J10.5 J10.6

J10

1PCB

1

1

J20.2

J20.1

J22.1CJ22.2

1 2 3 4

62CF

3TB

1LWT

1TR

59CF

1 2 3 4 5

J5.1

J5.2

1

1

J6A.1

J6A

J6A.2

54CF

1

1

J6B.1

2

J6B

O W

G

Y

Y/G

R

W

R

10CM

52CF

1

1

G

1PS

2

2

3

3

Y/G

B

B

Y/G

2TB

N N 18

B

/1.05/J3.1

J6B.2

55CF

1

1

J6B.1

2

J6C

J6B.2

56CF

1

1

J18.1

J18

2

J18.2

57CF

7

J11.7

6

J11.6

5

J11

J11.5

4

J11.4

3

J11.3

2

J11.2

1

J11.1

1

J16

1

J16.1

J16.2

C

1 2 3 4 5 6

58CF

J16.3

C

A

G

B

A

G

O

R

10

11

1SV

ALARM+

DFR

/

3T

R

3

J13.3

A

65CF

1 2

1

J7

1

J7.1

1 2 3 4 5 6

64CF

B

3

J2.1

J2.2

J2.3

J2

J7.2

J7.3

J7.4 J7.5

R

63CF

1 2

J13.1

J13.2

1

J13

J22

J22.3

J22.4

W

W

G

Y

13

REMOTE

46CF

3

2

1

47CF

6

5

4

3

2

1

48CF

3

2

1

49CF

2

1

50CF

3

2

1

51CF

2

1

W

3 L N PE

J1.1//1.05

A

J1.1

J1

J7.6

C

14

15

1

1

2

2

1LF

1IS

A

B

J4

1

66CF

7

C

1FL

Y/G

J4.1 J4.26J4.3

1 2 3 4 5

1PMV

C

J3

J4.43J4.5

REMOTE

CONTROL

W

W

U1 U3

L2 N4

PE

Y/G

2 1 8

1TS

1TO

1TD

1TE

Y/G

A

J4.1//1.05

C

21 23 24

ALARM

INPUT

17

N

L

230V1~50Hz

O

C

1OAT

Page 18

HYDRONIC UNIT LE 12 POWER/HYDRONIC UNIT LE 12 FORBINDELSESDIAGRAM

R

W

C

Y/G

WRW

GCG

O

O

A

PRB

C

W

C

YYB

B

O

O

C

W

R

W

W

C

C

A

R

R

B

1TB

PE

230V1~50Hz

1F

1

2

L

L

1RV

N

N

1CF

1

2

3

2CF

1

2

3

4

5

CN01

CN02

CN03

1P.C.BOARD

2P.C.BOARD

1CM

1 2 3

3CF

1 2 3

P08

1

CN700

1

CN02

4CF

1 2 3 4 5

5CF

1 2 3 4 5

1

1

1PVM

6CF

1 2 3 4 5 6

2TB

1

P09

1

R

CN13

CN01

CN702

2CM

1 2 3

7CF

1 2 3

P12NP13

R

1

8CF

1 2

9CF

1 2

1

CN05

CN04

3

P21

10CF

1 2 3

1

CN303

P24

1

11CF

1 2 3 4 5

12CF

1 2 3 4 5

1

+

1FM

CN800

CN06

P28

J4.1//2.10

J3.1//2.03

J1.1//2.08

P29

13CF

1 2 3 4 5

ED

1

CN302

1

14CF

1 2 3

15CF

1 2

3

1

P19

CN04

CN03

P20 P17 P18

CN600

1

16CF

1 2 3

1

17CF

1

2

CN09

CN10

CN11

CN301

2FM

1TH

1TD

18CF

1 2

3

1

CN600

19CF

1 2 3 4 5

1

CN300

20CF

1 2

1

1TS

CN605

21CF

1 2

1

1TE

CN604

22CF

1 2

THERMOSTAT

FORCOMPRESSOR

1

CN500

1T

1

2

23CF

1 2

3

1

CN601

1TO

1

CN606

3CM

R

C

S

132

4

1FL

18

HYDRONIC UNIT LE

HYDRONIC UNIT LE 12 CONTROL / HYDRONIC UNIT LEE 12 FORBINDELSESDIAGRAM

1FS

J5.3

J5

J16.4

J16.5

12

EHTR

/

WP

J5.4

J5.5

J16.6

J20.7

7 6 5 4 3 2 1

32CF

A

C

G

4

5

EHS

ALARM

/

DFR

J15

J20.6

1

2

33CF

1

1

2

J15.1

J20

J20.5

16

J10.1

J10.2

J10.3

J10

1

J17.1

J17

J17.2

J20.4

J20.3

J20.2

J10.4

1

J20.1

1PCB

J10.5 J10.6

1

J22.1CJ22.2

34CF

4TB

1LWT

O

W

1PS

G

G

Y/G

B

Y

4CM

1

2

3

/1.05/J3.1

1TR

Y/G

24CF

1

2

3

Y/G

B

W

A

3TB

R

B

N N 18

R

G

C

B

26CF

1

2

27CF

1

2

28CF

1

2

29CF

7

6

5

4

3

2

1

1

30CF

R

10

1SV

31CF

1 2 3 4 5

J5.1

J5.2

1

1

J6A.1

J6A

J6A.2

1

J6B.1

J6B

J6B.2

1

J6B.1

J6C

J6B.2

1

J18.1

J18

J18.2

J11.7

J11.6

J11

J11.5

J11.4

J11.3

J11.2

J11.1

1

J16

J16.1

J16.2

J16.3

1 2 3 4 5 6

C

A

O

G

11

ALARM+

DFR

/

HUMIDITY

R

35CF

1

J22

J22.3

1 2 3 4

1 2

J13.1

W

REMOTE

J22.4

J13

R

3

J13.2

J13.3

G

2T

37CF

1

J7

1

36CF

A

1 2

J2.1

J2.2

J2

J7.1

J7.2

J7.3

1 2 3 4 5 6

Y

13

J1.1//1.05

B

A

3

J1.1

J1

J2.3

J3

J4.1//1.05

C

J4

1

J7.4 J7.5

J7.6

J4.1 J4.26J4.3

J4.43J4.5

1 2 3 4 5

38CF

A

C

C

O

W

14

15

7

1

1

2

2

1LF

1IS

REMOTE

CONTROL

2 1 8

21 23 24

ALARM

INPUT

1OAT

Page 19

HYDRONIC UNIT LE

HYDRONIC UNIT LE 15 POWER/HYDRONIC UNIT LE 15 FORBINDELSESDIAGRAM

1R 2R

1CM

1 2

1 2

P05

CONTROLP.C.BOARD

MCC1571

CN701

(WHITE)

1 2 3 4

1 2

11CM

1 2

64CF

P06

P07

CN04

(WHITE)

1 2 3 4 5 6

74CF

10CM

63CF

65CF

1

CN400

1FM

2FM

49C

12

1TL

1TE

2

(WHITE)

CN300

(WHITE)

CN609

(BLUE)

CN610

(YELLOW)

CN604

(WHITE)

CN603

(WHITE)

CN602

(YELLOW)

CN601

(WHITE)

CN600

(WHITE)

72CF

1PCB

SW804

432143214321

ONONON

SW803

SW802

CN710

(WHITE)

1 2 3 4 5 6

SW801

CN704

(BLUE)

3

75CF

1

2

3

66CF

1

2

67CF

1

2

68CF

1TD

1

2

3

69CF

1TO

1

2

70CF

1

2

71CF

1TS

1

2

3

P04

SW800

RY704

73CF

G

1RV

1PMV

R

W

2TB

1 2 3

A

R

W

U V W

CN200

CN201

F01

T25A,250V~

F03

T10A,250V~

P01

C

J4.1//2.10

B

J3.1//2.03

J1.1//2.08

C

CN202

L/F

C

P09

P02

R

1TB

W

L N

N

L

19

230V1~50Hz

HYDRONIC UNIT LE

1LWT

O

G

W

Y

12CM

G

Y/G

1PS

B

/1.07/J3.1

15 CONTROL/HYDRONIC UNIT LE 15 FORBINDELSESDIAGRAM

1FS

J5.3

J5.4

J5

J16.5

J5.5

J16.6

J20.7

7 6 5 4 3 2 1

84CF

A

C

G

4

1

2

J10.1

J10.2

J10.3

J10.4

1

85CF

1

2

J15.1

J15

J20.6

J20.5

5

J10.5 J10.6

J10

1

J17.1

J17

J17.2

2PCB

J20

1

J20.4

16

1

J20.3

J20.2

J20.1

J22.1CJ22.2

1 2 3 4

86CF

4TB

1TR

83CF

1 2 3 4 5

J5.1

J5.2

1

1

J6A.1

J6A

J6A.2

78CF

1

1

J6B.1

2

J6B

J6B.2

79CF

1

1

J6B.1

2

J6C

J6B.2

80CF

1

1

J18.1

J18

2

J18.2

81CF

7

J11.7

6

J11.6

5

J11

Y/G

R

W

R

76CF

1

1

2

2

3

3

A

B

Y/G

3TB

N N 18

B

J11.5

4

J11.4

3

J11.3

2

J11.2

1

J11.1

1

J16

1

G

J16.1

J16.2

J16.3

J16.4

1 2 3 4 5 6

82CF

C

C

A

O

R

G

10

11

12

B

EHTR

/

1SV

WP

ALARM+

EHS

DFR

/

HUMIDITY

ALARM

/

DFR

1T

B

R

A

R

87CF

1

J22

1 2

J22.3

REMOTE

89CF

3

J13.1

J13.2

J13.3

J13

J22.4

W

G

1 2

J2.1

1

J7

1

J7.1

J7.2

1 2 3 4 5 6

88CF

Y

3

J2.2

J2.3

J2

J7.3

J7.4 J7.5

13

J1.1//1.07

J4.1//1.07

A

J1.1

J1

J3

C

J4

1

J7.6

J4.1 J4.26J4.3

J4.43J4.5

1 2 3 4 5

90CF

A

C

C

O

W

14

15

7

1

1

2

2

1LF

1IS

REMOTE

CONTROL

2 1 8

21 23 24

ALARM

INPUT

1OAT

Page 20

HYDRONIC UNIT LE

HUMIDITY

HYDRONIC UNIT LE 12 T/15T Power / Hydronic Unit LE 12 T/15 T Forbindelsesdiagram

POSISTER

1RY

A

3

1

1 2 3 4 5 6

J10.1

J10.2

1

J17.1

J17

J17.2

J20

J20.4

J20.3

CN610

YEL

OPTION

J10.3

R

R

C

15CF

1

1

2

CN02

3

RED

16CF

1

1

2

CN708

3

BLU

1

1

2

CN700

YEL

3

17CF

18CF

1

1

2

CN704

3

BLU

19CF

6

5

4

CN710

3

WHI

2

1

1

14CF

20CF

1

Y

1

CN101

2

WHI

3

B

CN04

CN11

CN12

CN13

20SF

OPTION

1PMV

1T

B

R

40CF

J10.4

J10.5 J10.6

1

J10

42CF

3

1 2

J13.1

J13.2

J13.3

J13

3

1 2

J2.1

J2.2

J2.3

1

J2

A

R

1PCB

J7

1

J7.1

J7.2

J7.3

J7.4 J7.5

J22

1

1

J20.2

J20.1

J22.1CJ22.2

1 2 3 4

39CF

1 2 3 4 5 6

41CF

J22.3

J22.4

W

4TB

W

G

Y

13

REMOTE

R

W

C

G

CN05

CN06

CN07

W

CN20

CN08

CN09

A

3CF

CN50

WHI

1P.C.BOARD

MCC1600

NOISEFILTER

1 2

CN10

CN16

CN17

C

CN18

CN19

8CF

1

1

2

CN23

3

RED

4

CN51

5

BLK

5CF

1 2

R

R

R

W

G

R

G

A

R

R

C

63H

49C

1 2

20

1 2 3 4 5

4CF

(CH56)

1R

G

W

R

1F

10A

250V

R

W

1

2

G

6CF

1

1

CN608

WHI

1CF

1

1

2

CN01

3

WHI

4

5

1 2

1 2

11CF

12CF

1

2P.C.BOARD

MCC1599

CDB

1

CN609

CN690

BLU

GRN

CN802

WHI

R

R

2R

U

W

1TB

PE

L1

L1

L2L2L3

400V3N~50Hz

CN600

CN601

WHI

2TB

1

2

L3

N

N

A

/2.08/J1.1

B

/2.03/J3.1

3

C

/2.10/J4.1

WHI

1

1

1 2 3

1 2

2CF

7CF

1TS

1TE

CN603

CN602

YEL

1

1 2

9CF

1TO

CN604

WHI

WHI

1

1

1 2 3

1 2

10CF

13CF

1TD

1TL

HYDRONIC UNIT LE 12 T/15T Control / Hydronic Unit LE 12 T/15 T Forbindelsesdiagram

1FS

J5.3

J5.4

J5

J16.5

C

EHS

/

DFR

1

2

J5.5

J15

J16.6

J20.7

J20.6

7 6 5 4 3 2 1

37CF

A

G

4

5

ALARM

1

38CF

1

2

J15.1

J20.5

16

1PS

1LWT

O

G

W

Y

G

Y/G

B

2CM

29CF

1

2

3

/1.03/J3.1

1TR

36CF

1 2 3 4 5

J5.1

J5.2

1

30CF

1

1

J6A.1

2

J6A

J6A.2

31CF

1

1

J6B.1

2

J6B

J6B.2

32CF

1

1

J6B.1

2

J6C

J6B.2

33CF

1

1

J18.1

J18

2

J18.2

34CF

7

J11.7

6

J11.6

5

J11

Y/G

R

W

R

J11.5

4

J11.4

3

J11.3

2

J11.2

1

J11.1

1

J16

1

G

J16.1

J16.2

J16.3

J16.4

1 2 3 4 5 6

35CF

C

C

1

2

3

Y/G

A

3TB

B

B

N N 18

A

O

R

G

10

11

12

B

EHTR

/

1SV

WP

ALARM+

DFR

/

21CF 1 2 3 4 5

1IPDUBOARD

MCC1596

COMPRESSOR

CN19

Y

(CH68)

3R

J1

J7.6

C

14

1

2

1LF

1

CN20

Y

C

V

O

J1.1//1.03

A

J1.1

15

1

2

1IS

CN851

RED

22CF

23CF

24CF

1

43CF

CN211

CN212

CN213

(CH78)

4R

1

1

CN502

2

WHI

3

1

1

CN602

2

BLK

1

1

2

3

CN500

4

RED

5

6

7

25CF

R

J4

J4.1 J4.26J4.3

1 2 3 4 5

7

U

V

W

W

1CM

C

26CF 1 2 3 4 5

1

CN504

BLU

CN750

WHI

1

1 2 3

W

1FM

C

J3

J4.43J4.5

REMOTE

CONTROL

R

1

2IPDUBOARD

MCC1597

FAN

CN700

BLU

1

27CF

1 2 3

W

2FM

R

2 1 8

CN505

RED

A

28CF1 2 3 4 5

P501

C

J4.1//1.04

C

21 23 24

ALARM

INPUT

C

C

O

1OAT

Page 21

HYDRONIC UNIT LE

REFRIGERATING CIRCUIT DIAGRAM / KØLE KREDSLØBS DIAGRAM

LWT sensor

LWT føler

Plate heat exchanger / Pladeveksler

Electronic expansion valve

Elektronisk tryksensor

EWT sensor

EWT føler

TR føler

TR sensor

Distributor

21

Fordeler

TE sensor

TO sensor / TO føler

Silencer

Fordamper

4-way valve

TE føler

Veksler

Heat exchanger

Silencer / Fordamper

4-vejs ventil

TS sensor / TS føler

TD sensor / TD føler

Påfyldnings-studs

Charge connection

Rotary compressor

Kompressor

Trykbeholder

Fluid receiver

Page 22

HYDRONIC UNIT LE

600154154

430

400

363

37

1

2

3

INSTALLER

PRODUCT DELIVERY

Preliminary instructions

We recommend the packaging only be removed when the

appliance has been placed at the installation point.

Carefully remove any adhesive strips on the appliance.

Do not dispose of, abandon or leave potentially hazardous

packing material within the reach of children.

22

Composition of the supply

The following are supplied:

Installer's instruction booklet

Warranty certificate

Bar code labels

Control panel

Fair leads (only models 15 - 12/15T)

Condensate discharge pipe

The supplied accessories are inside the electrical panel

HANDLING AND TRANSPORT

Handling should be carried out by suitably equipped qual-

ified personnel, and with equipment appropriate for the

weight of the appliance in compliance with accident pre-

vention regulations.

When being moved, the unit should always be kept in a

vertical position.

The weight of the appliance is out of balance towards the

compressor side.

To lift the unit use pipes with a suitable diameter and thick-

ness for the weight of the appliance.

INSTALLATØR

LEVERING AF PRODUKTET

Foreløbige instruktioner

Placer produktet ved installationsstedet før udpakning.

Fjern omhyggeligt alle strips fra produktet.

Efterlad ikke potentielt farligt indpakningsmaterialer/em-

ballage i børns nærhed.

Indhold

Installations manual

Garanti bevis

Stregkode label

Kontrolpanel

Ledningsholdere (Kun model 15 – 12/15T)

Kondens afløbsrør

-De medfølgende dele er placeret ved el-panelet.

HÅNDTERING OG TRANSPORT

Varmepumpen skal håndteres af uddannede teknikere.

Varmepumpen skal altid håndteres i opret position.

Vægtfordelingen er tungest ved kompressoren.

For at løfte produktet bruges dertil egnede redskaber.

ADGANG TIL INDRE DELE

- Fastgørelsesskruerne løsnes.

- Fjern frontlågen.

ACCESS TO INNER PARTS

- Loosen the fixing screws

- Remove the access panel.

Page 23

HYDRONIC UNIT LE

INSTALLATION

Preliminary instructions

The installation position should be decided by the system

designer or by an expert and should take into account technical requirements and current standards and legislation.

You should avoid:

Positioning in ducts and/or hopper windows.

Obstacles or barriers that cause the recirculation of the

expelled air.

Places with aggressive atmospheres.

Small places where the appliance sound level could be

magnified by reverberations or resonance.

Placement in corners where dust, leaves and other debris

could deposit reducing the efficiency of the appliance by

obstructing the flow of air.

That the air expelled from the appliance enters inhabited

rooms through doors or windows, causing discomfort for

the persons present.

That the air expelled from the unit is met by a head wind.

The units must:

Be positioned on a levelled surface capable of supporting

the weight.

Be positioned on a sufficiently rigid floor slab that does not

transfer vibrations to adjacent or underlying rooms.

It is suggested that a rubber plate be placed between the

unit and the floor or that antivibration supports suitable for

the weight of the unit be used.

The unit must only be installed outdoors.

If several units are placed side by side on the battery side

it is necessary to add up the minimum safety distances.

Provide for lifting the unit off the floor:

20 mm without conveying the condensation dis-

charge

90 - 100 mm to permit the conveyance of the con-

densation discharge

If the unit is installed in areas subject to heavy snowfall,

install at a height at least 200 mm above the usual level of

the snow.

INSTALLATION

Preliminære instruktioner

Producentens afstandskrav skal overholdes og produktet

skal placeres i overensstemmelse med gældende regler

og anvisninger.

Varmepumpen bør ikke placeres:

I servicekanaler og ved vinduesåbninger.

Hvor recirkulation kan forhindres.

Steder med forurenet luft.

Små områder hvor apparatets lydniveau kan forstærkes af

resonans.

I hjørner, hvor støv og blade kan samle sig og forhindre

tilstrækkelig luftafgang.

Hvor luften udledt af apparatets kan trænge ind i rum via

vinduer og andre åbninger.

Hvor varmepumpen kan blive påvirket af vindforhold.

Varmepumpen skal placeres:

På en plan overflade, der kan understøtte varmepumpens

vægt.

Hvor vibrationer fra apparatet ikke forplanter sig andre

rum.

Det anbefales at placere en gummimembran mellem un-

derlaget og unitten eller på anden måde anvende anti vibrations montering i overensstemmelse med varmepum-

pens vægt.

Unitten må kun installeres udendørs.

Hvis der er placeret flere varmepumper side om sides i

kaskade skal sikkerhedsafstanden overholdes.

Afstand fra underlag til varmepumpen:

20 mm uden kondensafløb.

90-100 mm med kondens afløb.

Hvis varmepumpen installeres i områder, hvor der kan

forekomme voldsomme snefald, skal placering foretages

under hensyn til dette.

23

Page 24

HYDRONIC UNIT LE

24

150

500

200

150300

150

1000

200

300

500

1000

150

1000

1000

150 300 300

300

300

200

1000

1000 1500 2000

300

200

Page 25

HYDRONIC UNIT LE

HYDRAULIC CONNECTIONS

Preliminary instructions

The selection and the installation of the components of

the system is referred to the expertise of the installer, who

must operate according to the rules of good technique

and current Legislation.

Make sure that the pipes do not contain stones, rust, de-

bris or other materials that could damage the system.

We suggest a by-pass of the unit be made so that the

pipes can be washed without having to disconnect the

unit.

The connection pipes should be of a suitable diameter

and supported so that their weight does not rest on the

appliance.

It is mandatory:

Install a removable mesh water filter at appliance

inlet in an area accessible for maintenance, with at

least 10 mesh/inch2, to safeguard the appliance from

impurities in the water.

After assembling the system and any repairs, it is es-

sential to clean the entire system thoroughly, taking

particular care with the filter.

To install air venting valves at the highest points of

the piping.

To install flexible elastic joints to connect the pipes.

To prevent the risk of ice forming in the water cir-

cuit, during defrosting operations or the continuous modulation of the frequency of the compressor,

make sure that the amount of water in the circuit

exceeds the minimum required of 3.5 litres/kW.

Systems charged with anti-freeze or subject to special le-

gal provisions require the use of water disconnectors.

Failure to install filters and anti-vibration supports could