Beretta EXCLUSIVE GREEN RSI 16, EXCLUSIVE GREEN CSI 35, EXCLUSIVE GREEN CSI 25, EXCLUSIVE GREEN RSI 35, EXCLUSIVE GREEN RSI 25 User Manual

Page 1

EXCLUSIVE

GREEN

C.S.I. - R.S.I.

EN INSTALLER AND USER MANUAL

ES MANUAL DE INSTALACIÓN Y USO

PT MANUAL PARA INSTALAÇÃO E USO

HU TELEPÍTŐI ÉS FELHASZNÁLÓI KÉZIKÖNYV

RO MANUAL DE INSTALARE SI UTILIZARE

DK INSTALLATIONS- OG BRUGERVEJLEDNING

Page 2

2

EXCLUSIVE GREEN C.S.I. - R.S.I.

0694

BQ0479

EN

EXCLUSIVE GREEN boiler complies with basic requirements of the

following Directives: Gas directive 90/396/EEC; Yield directive 92/42/EEC;

Electromagnetic compatibility directive 89/336/EEC; Low-voltage directive

73/23/EEC; Regulation 677 for condensation boilers. Thus, it is ECmarked.

ES

La caldera EXCLUSIVE GREEN es conforme a los requisitos esenciales

de las siguientes Directivas: Directiva gas 90/396/CEE; Directiva

rendimientos 92/42/CEE; Directiva compatibilidad electromagnética 89/

336/CEE; Directiva baja tensión 73/23/CEE; Normativa calderas de

condensación 677. Y por lo tanto es titular de la marca CE.

PT

A caldeira EXCLUSIVE GREEN está conforme com os requisitos

essenciais das seguintes Directivas: Directiva gás 90/396/CEE; Directiva

rendimentos 92/42/CEE; Directiva compatibilidade electromagnética 89/

336/CEE; Directiva baixa tensão 73/23/CEE; Normativa s de condensação

677. É portanto titular de marcação CE.

HU

Az EXCLUSIVE GREEN kazán teljesíti az alábbi irányelvek lényegi

követelményeit: 90/396/EGK sz. gáz irányelv; 92/42/EGK sz. irányelv a

vízmelegítő kazánokról; 89/336/EGK sz. irányelv az elektromágneses

összeférhetőségről; 73/23/EGK sz. irányelv a kisfeszültségű

berendezésekről; Kondenzációs kazánokra vonatkozó 677 sz. szabvány.

Így jogosan viseli a CE-jelet.

RO

Centrala EXCLUSIVE GREEN este fabricata in conformitate cu cerintele

urmatoarelor Directive: Directiva gaz 90/396/EEC; Directiva eficienta 92/42/

EEC; Directiva compatibilitate electromagnetica 89/336/EEC; Directiva

voltaj redus 73/23/EEC; Regulamentul 677 referitor la boilerele cu

condensare. Prin urmare, este marcat cu simbolul CE.

DK

EXCLUSIVE GREEN kedlen opfylder kravene i følgende direktiver: Gas

direktiv 90/396/EEC;Yield direktiv 92/42/EEC;El direktiv 89/336/EEC;Lavvolt direktiv 73/23/EEC;Regulation 677 af kondenserende kedler. Kedlen er

EC-mærket.

EN

Installer’s-user’s manual ............................................................................ 4

Boiler operating elements ...................................................................... 121

Hydraulic circuit ...................................................................................... 122

Electric diagrams ................................................................................... 124

Circulator residual head ......................................................................... 131

ES

Manual para el instalador-usuario............................................................ 24

Elementos funcionales de la caldera ..................................................... 121

Circuito hidráulico .................................................................................. 122

Esquema eléctrico ................................................................................. 124

Altura de carga residual del circulador .................................................. 131

PT

Manual do instalador-usuário ................................................................... 44

Elementos funcionais da caldeira .......................................................... 121

Circuito Hidráulico .................................................................................. 122

Diagrama Eléctrico ................................................................................. 124

Altura total de elevação residual da bomba circuladora ........................ 131

HU

Telepítői kézikönyv-felhasználói kézikönyv .............................................. 64

A kazán funkcionális alkatrészei ............................................................ 121

Vízkeringetés ......................................................................................... 122

Villamos kapcsolási rajz ......................................................................... 124

A keringető szivattyú maradék emelőnyomása ..................................... 131

RO

Manual instalator-utilizator ...................................................................... 84

Elemenetele functionale ale centralei .................................................... 121

Circuit hidraulic ...................................................................................... 122

Scheme electrice ................................................................................... 124

Presiune reziduala circulator ................................................................. 131

DK

Installations- og brugervejledning .......................................................... 104

Kedelfunktioner ...................................................................................... 121

Hydrauisk kredsløb ................................................................................ 122

El diagrammer ........................................................................................ 124

Pumpe .................................................................................................... 131

Page 3

3

EXCLUSIVE GREEN C.S.I. - R.S.I.

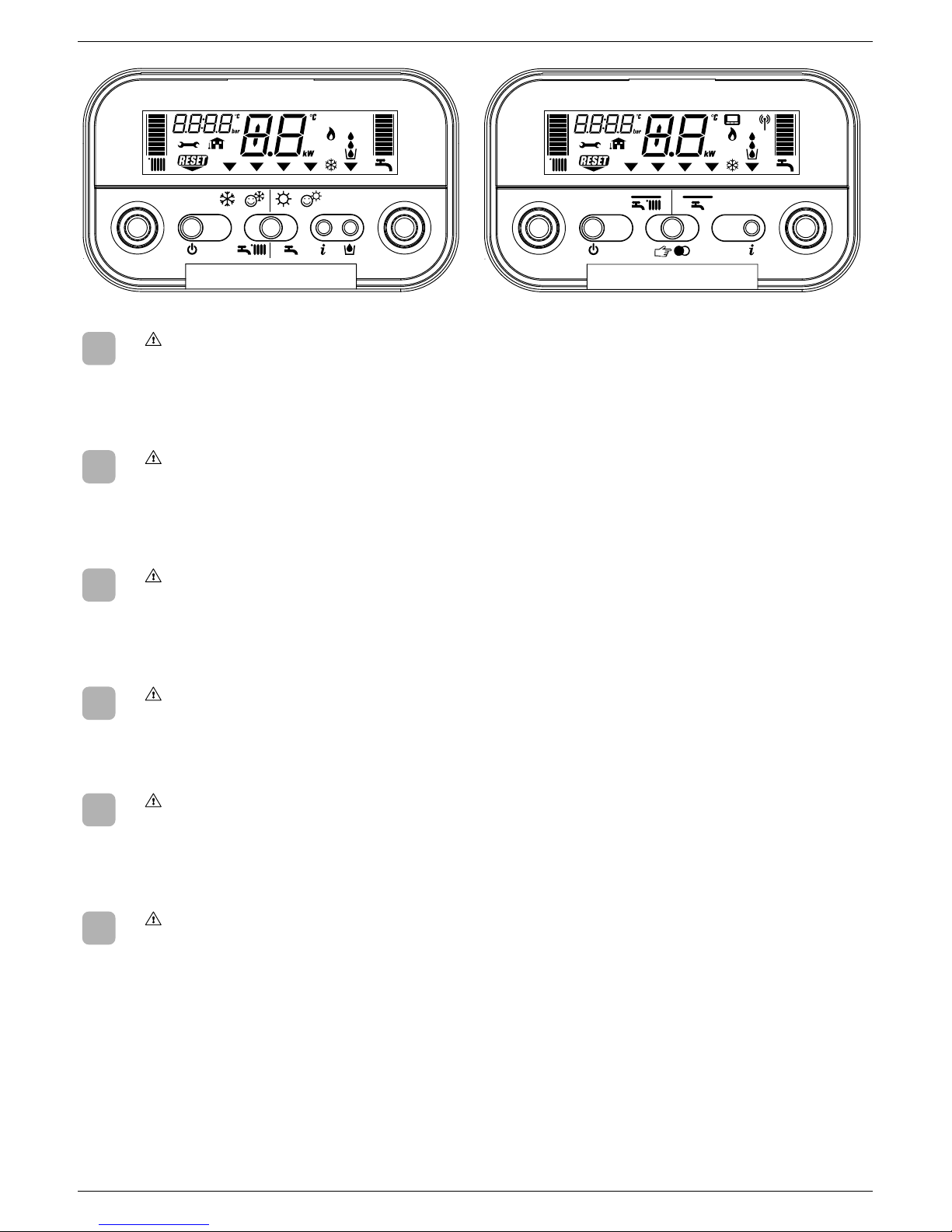

EXCLUSIVE GREEN C.S.I. EXCLUSIVE GREEN R.S.I.

This handbook contains data and information for both users and installers. In detail:

• The chapters entitled “Installing the boiler, Water connections, Gas connection, Electrical connection, Filling and draining, Evacuating products of

combustion, Technical data, Programming parameters, Gas regulation and conversion” are intended for installers;

• The chapters entitled “Warnings and safety devices, Switching on and using” are for both users and installers.

The control panel is different between GREEN C.S.I. and GREEN R.S.I. (see detail). Please read, in the booklet, the instructions referring to your boiler

model.

EN

Este manual contiene datos e informaciones destinados tanto al usuario como al instalador. En especial:

• Los capítulos “Instalación de la caldera, Conexiones hidráulicas, Conexión gas, Conexión eléctrica, Llenado y vaciado, Evacuación productos de la

combustión, Datos técnicos, Programación parámetros, Regulación y Transformación gas” son los que se refieren al instalador;

• Los capítulos “Advertencias y seguridades, y Encendido y funcionamiento” son los que se refieren tanto al usuario como al instalador.

El panel de mando es diferente entre los modelos GREEN C.S.I. y GREEN R.S.I. (ver dibujo). Rogamos consulten el manual para encontrar las

instrucciones relativas a su modelo de caldera.

ES

Este livrete inclui dados e informações destinados quer ao usuário quer ao instalador. Especificadamente:

• Os capítulos “Instalação da caldeira, Conexões hidráulicas, Conexão gás, Ligação eléctrica, Enchimento e esvaziamento, Evacuação dos produtos da

combustão, Dados técnicos, Programação parâmetros, Regulação e Transformação gás” são aqueles referidos ao instalador:

• Os capítulos “Advertências e seguranças e Ignição e Funcionamento” são aqueles referidos quer ao usuário quer ao instalador.

Os modelos GREEN C.S.I. e GREEN R.S.I. têm os painéis de comando diferentes (veja-se o desenho). Sugerimos consultar o manual para as

instruções relativas ao seu modelo de caldeira.

PT

Jelen kézikönyv mind a felhasználó mind a telepítő számára tartalmaz információkat. Pontosabban:

• A telepítő részére szánt fejezetek “A kazán telepítése, Vízbekötések, Gázbekötés, Elektromos bekötés, Feltöltés és a berendezés víztelenítése,

Égéstermék elvezetés, Műszaki adatok, Paraméterek programozása, Gázbeállítások és gáztípusváltás”;

• A telepítő és a felhasználó részére egyaránt szánt fejezetek az “Általános tudnivalók és biztonsági előírások, Begyújtás és működés”.

A GREEN C.S.I. és GREEN R.S.I. (lásd rajzon) modellek vezérlőpaneljei különbözőek. Kérjük, olvassa el az Ön kazánjára vonatkozó kezelési utasítást.

HU

Acest manual contine date si informatii atat pentru utilizator cat si pentru instalator. Si anume:

• Capitolele intitulate “Instalarea cazanului, Conectare la reteaua de apa, Conectare la reteaua de gaz, Conexiuni electrice, Umplerea si golirea instalatiei,

Evacuarea produselor de ardere, Date tehnice, Programarea parametrilor, Reglare si conversie gaz” sunt dedicate instalatorilor;

• Capitolele intitulate “Avertizari si masuri de siguranta, Pornire si utilizare” sunt dedicate atat instalatorilor cat si utilizatorilor.

Panoul de comanda difera intre modelele GREEN C.S.I. si GREEN R.S.I. (vezi detalii). Va rugam sa cititi din manual instructiunle specifice modelului

dumneavoastra.

RO

Denne vejledning indeholder oplysninger til både installatør og bruger.

• Afsnit: ‚Installation af kedlen, Rør-forbindelser, Gas tilslutning, El-forbindelser, Påfyldning og aftapning, Aftræk, Tekniske data, Indstilling af parametre,

Omstilling mellem gasarter‘ henvender sig til installatører og servicefirmaer;

• Afsnit: ‚Sikkerhed, opstart og funktion‘ henvender sig sig til både bruger og installatør.

Kontrolpanelet på GREEN R.S.I. er forskellige. Gennemlæs vejledningen til den valgte model.

DK

Page 4

4

EXCLUSIVE GREEN C.S.I. - R.S.I.

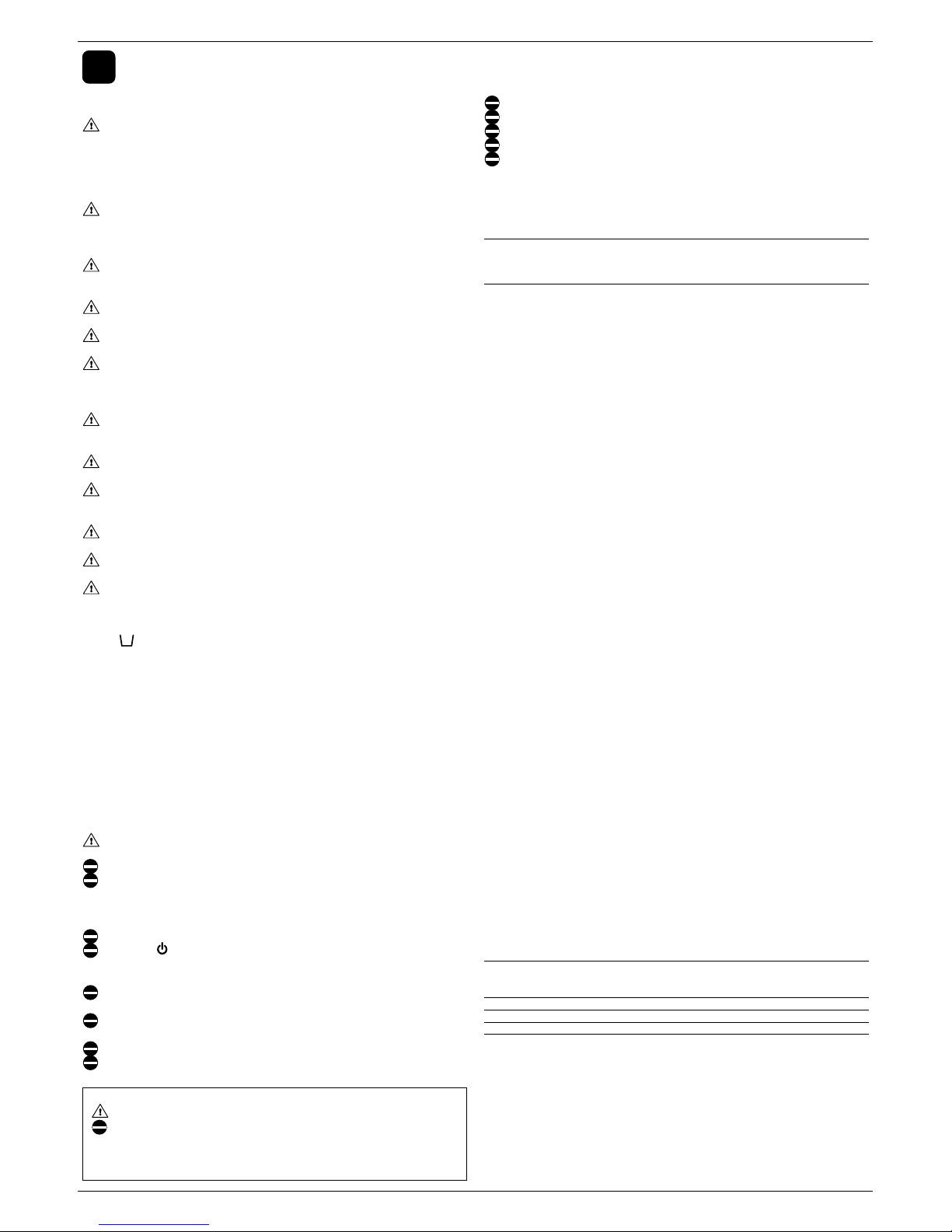

1 - GENERAL SAFETY DEVICES

The boilers produced in our factory are built with care down to the last

component to protect both the user and installer from eventual accidents.

We therefore recommend qualified personnel that after working on the

product they should pay particular attention to the wiring, especially the

bare wires, that must not be exposed outside the terminal board for any

rason to prevent any contact with the live parts of the wiring.

This instructions manual is integral parts of the product. Make sure they

remain with the boiler, even if it is transferred to another owner or user or

moved to another heating system. In case of loss or damage, please contact

your local Technical Assistance Service for a new copy.

This boiler may only be installed and serviced by qualified fitters who satisfy

the requirements of local rules. Work must be done in compliance with

regulations in force and subsequent updates.

The boiler must be serviced at least once a year. This should be booked in

advance with the Technical Assistance Service.

The installer shall instruct the user in the operation of the boiler and the

safety devices.

This boiler may only be used for what it was expressly built to do. The

manufacturer declines all contractual and non-contractual liability for injury

to persons or animals or damage to property deriving from errors made

during installation, adjustment and servicing and from improper use.

This appliance is used to produce hot water and must therefore be

connected to a heating and/or a domestic hot water system, according to

its performance and power.

After removing the packaging, make sure the contents are undamaged

and complete. If this is not the case, contact your dealer.

The safety valve outlet must be connected to a suitable collection and

venting system. The manufacturer declines all liability for any damage

caused by the safety valve.

The safety and automatic adjustment devices on the appliance must never

be modified during its lifetime, except by the maker or dealer.

If the appliance develops a fault and/or works badly, switch it off and do not

attempt to repair it yourself.

Immediately after installation, inform the user that:

- in the event of leaks, he/she must shut off the water supply and promptly

inform the Technical Assistance Service

- GREEN C.S.I.: he/she must check from time to time to make sure the

symbol is not lit on the control panel. This symbol means that the

pressure in the water system is incorrect. If necessary, fill the system

as described in the paragraph “Boiler functions”

- GREEN R.S.I.: must periodically check, on the display, that the pressure

value is between 1 and 1,5 bar; if not fill the system as described in the

paragraph “Boiler functions”

- if the boiler is not planned to be used for a long period, he/she should

call in the Technical Assistance Service to perform the following

operations:

- turn off the main boiler and general system switches

- close the gas and water taps on both the heating (GREEN C.S.I.-

GREEN R.S.I.) and domestic hot water circuits (GREEN C.S.I. only)

- drain the heating (GREEN C.S.I.-GREEN R.S.I.) and domestic hot

water (GREEN C.S.I. only) circuits to prevent freezing.

Connect the outlet collector to a suitable outlet system (refer to chapter 5).

Safety measures:

the boiler should not be used by children or unassisted disabled people

electrical devices or equipment, such as switches, appliances, etc., should

not be used if there is a smell of gas or fumes. If there is a gas leak, open

all the doors and windows to ventilate the area, turn off the general gas tap

and immediately call the Technical Assistance Service

do not touch the boiler barefoot or if parts of your body are wet or damp

press the button until “- -” is shown on the display and disconnect the

electricity supply by turning off the two-position system switch, before

cleaning

it is forbidden to modify the safety or adjustment devices without the

manufacturer’s permission and relative instructions

do not pull, detach or twist the wires from the boiler even if they are not

connected to the power supply

do not block or reduce the size of the ventilation openings in the room

do not leave inflammable containers or substances in the room

EN

ENGLISH

The following symbols are used in this manual:

CAUTION = operations requiring special care and adequate preparation

NOT ALLOWED = operations that MUST NOT be performed

R.S.I.: DHW functions refer only if a water tank is connected (accessory

available on request).

keep packaging out of reach of children

only use appliance for purposes it is devoted to

do not lean any object on the boiler

do not tamper with sealed elements

it is forbidden to block the condensate outlet.

2 - BOILER INSTALLATION

Boiler must only be installed by qualified personnel.

Boiler is available in the following models:

Type

combined

CH only

Category

C

C

Model

C.S.I.

R.S.I.

Power

25-35 kW

16-25-35 kW

Inlet

water

15÷20

limpid

Water in

heating

circuit

7÷8

-

-

um

°F

Parameters

PH

Hardness

Appearance

Exclusive GREEN C.S.I. is a C-type condensation wall-mounted boiler for

heating and producing domestic hot water; Exclusive GREEN R.S.I. is a Ctype condensation wall-mounted boiler and is able to operate in different

conditions:

- CASE A: only heating. The boiler doesn’t supply domestic hot water

- CASE B: only heating with water tank connected, managed by a thermostat,

to prepare domestic hot water

- CASE C: only heating with water tank connected (kit available upon request),

managed by a temperature sensor, to prepare domestic hot water. Connecting

a water tank not supplied by us, please be sure that the NTC sensor ised has

the following features: 10 kOhm at 25°C, B 3435 ±1%.

Depending on the type of installation selected, it is necessary to set the parameter

“domestic hot water mode”. Refer to page 19 for description and setting

parameter operations.

This type of appliance can be installed in any kind of room as long as the fumes

discharge and the comburent air intake are taken outside the room.

The following types of fumes outlet are available for this kind of boiler: B23P;

B53P; C13,C13x; C23; C33,C33x; C43,C43x; C53,C53x; C63,C63x; C83,C83x.

Installation must comply with local standards and regulations in force.

For proper installation, we remind you that:

- the boiler must not be installed over a kitchen or any other cooking equipment

- minimum spaces are to be left in order to allow maintenance operations: at

least 2,5 cm every side and 20 cm under the boiler

- it is forbidden to leave inflammable substances in the room

- suitably insulate heat-sensitive walls (e.g.: in wood).

Support plate and integrated pre-installation template are provided for with the

boiler (

Fig. 1.1).

Mounting instructions:

- fix the boiler support plate (F) with the template (G) to the wall and use a

plumb to check that it is perfectly horizontal

- trace out 4 holes (Ø 6 mm) for fixing the boiler support plate (F) and 2 holes

(Ø 4 mm) for fixing the pre-installation template (G)

- make sure all the measurements are correct, then drill holes in the wall using

a drill and point with the diameter given previously

- fix the plate to the wall by the supplied anchor screws

- make hydraulic connections.

After installing the boiler, the screws D1 (

Fig. 1.2) can be removed. After installing

the boiler and connecting it to the water and gas supplies, fit the lower cover (A-

B, Fig. 1.3) so that its hooks slip into the relative slots in the lower part of the

boiler. Fix the lower cover with the screw C (

Fig. 1.4) contained in the

documentation envelope in the boiler.

Cleaning the system and characteristics of heating circuit water

After installing a new system or replacing a boiler, clean the heating system. To

ensure the product works correctly, after cleaning, additivating and/or chemically

treating the system (e.g.: anti-freeze, film-formers, etc.), make sure the

characteristics of the water satisfy the parameters indicated in the table.

Page 5

5

ENGLISH

3 - HYDRAULIC CONNECTIONS

Position and dimensions of hydraulic connections are specified in figure 1.1:

A - CH return 3/4”

B - CH delivery 3/4”

C - Gas connection 3/4”

D - DHW outlet 1/2” (GREEN C.S.I. only)

E - DHW inlet 1/2” (GREEN C.S.I. only)

F - Support plate

G - Pre-installation template

If water hardness exceeds 28°Fr, it is recommended to use water softeners, to

prevent any limestone deposit in boiler due to excessively hard water.

4 - INSTALLING THE EXTERNAL PROBE

The correct position of the external probe is essential for the climatic control

function to run properly.

The probe must be installed outside the building to be heated, at about 2/3 of

the height of the NORTHERN or NORTHWESTERN face, far from flue pipes,

doors, windows and sunny areas.

Attaching the external probe to the wall

(Fig. 1.6)

- To access the terminal board and anchor holes, unscrew the plastic probe

cover from the housing by rotating it anticlockwise

- Mark the points where the holes will be drilled using the probe housing as a

template

- Remove the box and drill holes for 5x25 expansion grips

- Fix the housing to the wall using the two supplied expansion grips

- Unscrew the cable-holding nut, insert the bipolar cable (with a cross section

between 0,5 and 1mm

2

, not supplied) for the connection between the probe

and the boiler

- For the electrical connection between the external probe and the boiler, refer

to the chapter “Electric connection”

- Tighten the cable-holding nut properly and close the cover of the protective

box.

The probe must be positioned on a smooth surface. In the case of a brick

wall or a wall with an irregular surface, provision must be made for a smooth

contact surface.

The maximum length of the connection between the external probe and

the boiler is 30 m.

The connection cable between the probe and the boiler must not have

connections. If these prove to be necessary, they must be made watertight

and suitably protected.

Any ducts for the connection cable must be separate from other power

lines (230 V.a.C.).

5 - CONDENSATE COLLECTION

The outlet collector (A, Fig. 1.7) collects: the condensate water, any evacuation

water from the safety valve and the system outlet water.

The collector must be connected, by means of a rubber pipe (not supplied),

to a suitable collection and evacuation system in the storm water outlet

and in compliance with current regulations.

The external diameter of the collector is 20 mm: we therefore suggest

using an Ø 18-19 mm pipe, to be closed with a suitable clamp (not supplied).

The manufacturer is not responsible for any damage caused by the lack of

a collection system.

The outlet connection line must have a guaranteed seal.

The manufacturer of the boiler is not responsible for any flooding caused

by interventions of the safety valve.

6 - GAS CONNECTION

Before connecting appliance to gas pipe network, check the following:

- regulations in force are met

- gas type used is the same as set for appliance operation

- pipes are clean.

Gas must be piped externally. If the pipe goes through a wall it must go through

the central opening in the lower part of the template. It is recommended to

install an appropriately sized filter on the gas line in case gas from the mains

contains some small solid particles. After installation make sure that all the

joints have been made airtight conforming to standard installation practices.

7 - ELECTRIC CONNECTION

To access the electrical connections, proceed as follows:

- unscrew the lower cover fixing screw (C, Fig. 1.4)

- pull the cover towards you and remove (A-B) (Fig. 1.5)

- loosen the fixing screws (D) and remove the shell (

Fig. 1.2)

- lift up the panel and turn it forwards

- open the terminal board covers making them slide in the direction of the

arrows (Fig. 1.8: E high voltage connections 230 V, F low voltage connections,

G water tank sensor connections only GREEN R.S.I.).

Connect the appliance to the mains power supply with a switch featuring a

distance of at least 3,5 mm (EN 60335-1, category III) between each wire. The

appliance uses alternating current at 230 Volt/50 Hz, has a power input of 130

W (16kW R.S.I. - 25kW C.S.I. - 25kW R.S.I.) and 175 W (35kW R.S.I. - 35kW

C.S.I.) and complies with EN 60335-1 standard. Connect the boiler to a safe

earth circuit according to current legislation.

Live and neutral (L-N) connections should also be respected.

The boiler can operate with phase-neutral or phase-phase power supply. For

floating power supply, without an earth-bonded conductor, it is necessary to

use an insulation transformer with secondary anchored to ground.

The earth conductor must be a couple of cm longer than the others.

Gas and/or water pipes may not be used to earth electrical equipment.

The installer is responsible for making sure that the appliance has an

adequate earthing system; the manufacturer shall not be held liable for

eventual damages caused by incorrect usage or failing to earth the boiler.

Use the supplied power cable to connect the boiler to the mains power supply.

Connect the ambient thermostat and/or time clock as shown in the electrical

diagram on page

125.

When replacing the power cable, use a HAR H05V2V2-F cable, 3 x 0,75

mm

2

, Ø max. external 7 mm.

8 - FILLING AND EMPTYING THE SYSTEM

The central heating system can be filled up once the water mains have been

connected up.

This must be done while the installation is cold by:

- giving two or three turns to the cap of the automatic air vent valve (A,

Fig. 1.9)

to open it;

- making sure the cold water inlet tap is open (B, Fig. 1.9) (GREEN C.S.I.

only)

- opening the filling tap (C, on the boiler for GREEN C.S.I., external for GREEN

R.S.I.) until the pressure on the hydrometer (D) is between 1 and 1,5 bar

(blue zone) (

Fig. 1.9).

Close the filling tap after filling it up.

The boiler is equipped with an efficient air separator so that there is no need to

do anything manually.

The burner only ignites when air venting has finished.

NOTE: air extraction from the boiler takes place automatically, through two

automatic bleeding valves, A and E.

The first is situated on the pump, while the second is inside the air chamber.

NOTE (GREEN C.S.I. only): the boiler is also equipped with a semi-automatic

filling system. The first system-filling operation must be carried out by opening

tap C with the boiler turned off.

NOTE (GREEN R.S.I. only): manual filling tap is not supplied with the boiler,

foresee one external or verify if external water tank has one.

Before starting to empty it, remove the electrical feeder by positioning the general

switch for the system on “off”.

- Close the interception devices for the thermal system

- Loosen the system outlet valve (F) manually

- The water from the system is discharged through the outlet collector (G).

DHW system emptying (GREEN C.S.I. only)

The hot water system must be emptied every time there is risk of freezing by:

- turning off the tap at the mains

- turning on all the hot and cold taps

- emptying out the lowest parts of the system.

ATTENTION

The collector must be connected, by means of a rubber pipe (not supplied), to

a suitable collection and evacuation system in the storm water outlet and in

compliance with current regulations. The external diameter of the collector is

20 mm: we therefore suggest using an Ø18-19 mm pipe, to be closed with a

suitable clamp (not supplied). The manufacturer is not responsible for any

damage caused by the lack of a collection system.

Page 6

6

EXCLUSIVE GREEN C.S.I. - R.S.I.

INSTALLATION “SEALED” (TYPE C)

Boiler is a C-type appliance (sealed chamber) and must be safely connected to

fume exhaustion duct and burning air suction duct, both getting outside;

appliance cannot operate without these ducts.

Concentric outlets (Ø 60-100)

(Fig. 1.14)

Concentric ducts may be placed in the most suitable direction for installation

requirements but special care must be taken as regards the external temperature and the length of the duct.

Rectilinear length means without bends, outlet ends and connections.

The fumes outlet duct must slope by 1% towards the condensate collector.

Uninsulated fumes outlets are potential hazards.

The boiler automatically adapts ventilation according to the type of

installation and the length of the duct.

Do not obstruct or narrow the comburent air inlet duct in any way.

To install follow the instructions supplied with the kit.

Max length fumes

outlet duct Ø 80 mm

48 m

48 m

60 m

Pressure drop for each

bend (45°/90°) [m]

0,5 / 0,8

16 R.S.I.

25 C.S.I.-R.S.I.

35 C.S.I.-R.S.I.

Max linear length concentric

duct Ø 60-100 mm

7,80 m

7,80 m

7,80 m

Pressure drop for each

bend (45°/90°) [m]

0,5 / 0,8

16 R.S.I.

25 C.S.I.-R.S.I.

35 C.S.I.-R.S.I.

Horizontal

Max linear length concentric

duct Ø 60-100 mm

8,80 m

8,80 m

8,80 m

Pressure drop for each

bend (45°/90°) [m]

0,5 / 0,8

16 R.S.I.

25 C.S.I.-R.S.I.

35 C.S.I.-R.S.I.

Vertical

Max linear length concentric

duct Ø 80-125 mm

17 m

17 m

28 m

Pressure drop for each

bend (45°/90°) [m]

0,5 / 0,9

16 R.S.I.

25 C.S.I.-R.S.I.

35 C.S.I.-R.S.I.

Twin outlets (Ø 80) (Fig. 1.15)

The split duct can be aimed in the most suitable direction for installation needs.

The combustion-supporting air intake duct must be connected to the entrance

after having removed the closing cap, attached with three screws, and having

attached a suitable adaptor.

The fumes outlet duct must be connected to the fumes outlet after having

installed a suitable adaptor.

For the installation process, follow the instructions supplied with the kit for the

specific accessory for condensation boilers.

The fumes outlet duct must slope by 1% towards the condensate collector.

The boiler automatically adapts ventilation according to the type of installation and the length of the duct. Do not obstruct or narrow the comburent

air inlet duct in any way.

For an indication of the maximum lengths of every single pipe, refer to the

graphs (Fig. 1.16).

Using longer ducts causes a loss in the power of the boiler.

Max length

twin duct Ø 80 mm

40 + 40 m

40 + 40 m

50 + 50 m

Pressure drop for each

bend (45°/90°) [m]

0,5 / 0,8

16 R.S.I.

25 C.S.I.-R.S.I.

35 C.S.I.-R.S.I.

Rectilinear length means without bends, outlet ends and connections.

Suggestions to correctly eliminate air from the heating system and

boiler (Fig. 8.2)

We recommend carrying out the sequence of operations given below during

first installation or with extraordinary maintenance work:

1. Using a CH11 spanner open the manual air vent valve located above the air

box; the tube supplied with the boiler must be connected to the valve to let

out the water into an outside container.

2. Open the manual system filling stopcock on the water group, wait until the

water starts coming out of the valve;

3. Switch on the boiler leaving the gas cock closed;

4. Use the room thermostat or the remote control panel to activate request for

heat so that the three-way will turn to heating;

5. Turn on a tap to activate request for hot water (for instantaneous boilers

only; use the water heater thermostat for boilers just for heating connected

to an external water heater) for an interval of 30” every minute to make the

three-way cycle from heating to hot water and vice versa about ten times

(the boiler will be go into alarm as there is no gas under these circumstances,

it must therefore be reset every time this happens);

6. Continue the sequence until water only comes out of the manual air vent

valve and the flow of air has finished; close the manual air vent valve at this

point;

7. Make sure the system is at the correct pressure (1 bar is ideal);

8. Close the manual system filling stopcock on the water group;

9. Open the gas cock and ignite the boiler.

9 - FUMES EXHAUSTION AND BURNING AIR SUCTION

EXHAUSTION CONFIGURATIONS (Fig. 1.11-1.12)

Boiler is homologated for the following exhaustion configurations:

B23P-B53P - Suction in room and discharge outside

C13 - Concentric wall exhaustion. Pipes can separately start from boiler, but

outlets must be concentric or close enough to be subject to similar wind

conditions (within 50 cm)

C23 - Concentric exhaustion in common chimney (suction and exhaustion in

the same chimney)

C33 - Concentric roof exhaustion. Outlets like C13

C43 - Exhaustion and suction in common separate chimneys, but subject to

similar wind conditions

C53 - Wall or roof separate exhaustion and suction in different pressure areas.

Exhaustion and suction must never be located on opposite walls

C63 - Exhaustion and suction with separately certified and sold pipes (1856/1)

C83 - Single or common chimney exhaustion and wall suction

Refer to regulations in force for exhaustion of combustion products.

Boiler is provided for without fume exhaustion/air suction kit, since forced draught

sealed chamber accessories can be used, as they better adapt to installation

characteristics.

For fume extraction and burning air restoration in boiler, use original pipes or

other EC-certified pipes with equivalent characteristics; check connection is

correct as shown on instructions fume accessories provided for with. More

appliances can be connected to a single chimney, provided that all appliances

are sealed chamber type.

“FORCED OPEN” INSTALLATION (TYPE B23P-B53P, intake inside and

outlet outside) - Fumes outlet duct Ø 80 mm

(Fig. 1.13)

The fumes outlet duct can be aimed in the most suitable direction for installation

needs. To install follow the instructions supplied with the kit.

In this configuration, the boiler is connected to the Ø 80 mm fumes outlet

duct by means of a Ø 60-80 mm adaptor.

In this case, the combustion supporting air is taken from the room in which

the boiler is installed, which must be a suitable and ventilated technical

room.

Non-insulated fumes outlet ducts are potential sources of danger.

Provision must be made for a 1% slope of the fumes outlet duct towards

the boiler.

Concentric outlets (Ø 80-125)

(Fig. 1.14)

For this installation it is necessary to install the suitable adaptor kit. Ducts may

be placed in the most suitable direction for installation requirements. For the

installation process, follow the instructions supplied with the kit for the specific

accessory for condensation boilers.

Page 7

7

ENGLISH

10 - TECHNICAL DATA

CH Nominal thermal flow rate

Nominal thermal power (80°/60°)

Nominal thermal power (50°/30°)

Reduced thermal flow rate

Reduced thermal power (80°/60°)

Reduced thermal power (50°/30°)

DHW* Nominal thermal flow rate

Maximum thermal power**

Reduced thermal flow rate**

Minimum thermal power**

Working efficiency Pn max - Pn min (80-60°)

Working efficiency 30% (47° return)

Combustion efficiency

Working efficiency Pn max - Pn min (50-30°)

Working efficiency 30% (30° return)

Electric power

Category

Supply voltage

Protection level

Chimney and skirt losses with burner off

CH operation

Maximum pressure - temperature

Minimum pressure for standard working/operating

Selection field of CH water temperature

Pump maximum head available for system

capacity

Membrane expansion tank

Expansion vessel pre-charge (CH)

DHW operation*

Maximum pressure

Minimum pressure

Hot water quantity ∆t 25° C

∆t 30° C

∆t 35° C

DHW minimum capacity

Selection field of DHW temperature

Flow regulator

Gas pressure

Natural gas pressure (G20)

LPG pressure (G31)

Hydraulic connections

CH input-output

DHW input-output (GREEN C.S.I.)

Water tank delivery-return (GREEN R.S.I.)

Gas input

Boiler dimensions and weight

Height

Width

Depth

Weight

Fan performance

Fan residual head, pipes 0,5 + bend 90° (intake+discharge)

Flow rates (G20)

Air capacity

Fumes capacity

Mass flow (max-min)

Fume exhaustion and air suction concentric pipe

Diameter

Max lenght

Loss for a 90°/45° bend

Hole in wall (diameter)

Diameter

Max lenght

Fume exhaustion and air suction separated pipe

Diameter

Max lenght

Loss for a 90°/45° bend

Forced open installation (B23P-B53P)

Diameter

Max lenght

Loss for a 90°/45° bend

Nox

Emission values at maximum and minimum of gas G20 ****

Maximum CO s.a. lower than

CO

2

NOx s.a. lower than

∆t fumes

Minimum CO s.a. lower than

CO

2

NOx s.a. lower than

∆t fumes

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

kW

kcal/h

%

%

%

%

%

W

V - Hz

IP

%

bar

bar

°C

mbar

l/h

l

bar

bar

bar

l/min

l/min

l/min

l/min

°C

l/min

mbar

mbar

Ø

Ø

Ø

Ø

mm

mm

mm

kg

Pa

Nm

3

/h

Nm

3

/h

gr/s

mm

m

m

mm

mm

m

mm

m

m

mm

m

m

class

p.p.m.

%

p.p.m.

°C

p.p.m.

%

p.p.m.

°C

25

21500

24.43

21006

26.13

22468

6

5160

5.86

5041

6.44

5537

25

21500

25

21500

6

5160

6

5160

97.7-97.7

101.2

97.9

104.5-107.3

107.1

130

II2H3P

230-50

X5D

0.10-0.80

3-90

0.25-0.45

20-80

300

1000

10

1

6

0.15

14.3

12

10.2

2

35-60

10

20

37

3/4"

1/2"

3/4"

845

453

358

44

110

31.237

34

11.32-2.72

60-100

7.8

0.85/0.5

105

80-125

17***

80

40+40

0.8/0.5

80

48

0.8/0.5

5

180

9

50

34

40

9.3

40

28

C.S.I. 25 kW

34.6

29756

33.74

29012

36.75

31601

7

6020

6.88

5918

7.55

6490

34.6

29756

34.6

29756

7

6020

7

6020

97.5-98.3

102.1

97.8

106.2-107.8

108.6

175

II2H3P

230-50

X5D

0.10-0.80

3-90

0.25-0.45

20-80

300

1000

10

1

6

0.15

19.8

16.5

14.2

2

35-60

14

20

37

3/4"

1/2"

3/4"

845

453

359

47

195

43.231

46.701

015.67-3.17

60-100

7.8

0.85/0.5

105

80-125

28***

80

50+50

0.8/0.5

80

60

0.8/0.5

5

250

9

70

54

40

9

60

36

C.S.I. 35 kW

16

13760

15.6

13416

16.8

14434

3.5

3010

3.4

2890

3.7

3148

-

-

-

-

-

-

-

-

97.5-96.0

101.1

97.6

104.9-104.6

107.8

130

II2H3P

230-50

X5D

0.10-0.80

3-90

0.25-0.45

20-80

300

1000

10

1

-

-

-

-

-

-

-

-

20

37

3/4"

3/4"

3/4"

845

453

358

43

57

20.446

22.05

7.41-1.62

60-100

7.8

0.85/0.5

105

80-125

17***

80

40+40

0.8/0.5

80

48

0.8/0.5

5

91

8.8

16

50

10

8.8

15

39

R.S.I. 16 kW

25

21500

24.43

21006

26.13

22468

6

5160

5.86

5041

6.44

5537

-

-

-

-

-

-

-

-

97.7-97.7

101.2

97.9

104.5-107.3

107.1

130

II2H3P

230-50

X5D

0.10-0.80

3-90

0.25-0.45

20-80

300

1000

10

1

-

-

-

-

-

-

-

-

20

37

3/4"

3/4"

3/4"

845

453

358

41

110

31.237

33.744

11.32-2.72

60-100

7.8

0.85/0.5

105

80-125

17***

80

40+40

0.8/0.5

80

48

0.8/0.5

5

180

9

50

34

40

9.3

40

28

R.S.I. 25 kW

34.6

29756

33.74

29012

36.75

31601

7

6020

6.88

5918

7.55

6490

-

-

-

-

-

-

-

-

97.5-98.3

102.1

97.8

106.2-107.8

108.6

175

II2H3P

230-50

X5D

0.10-0.80

3-90

0.25-0.45

20-80

300

1000

10

1

-

-

-

-

-

-

-

-

20

37

3/4"

3/4"

3/4"

845

453

359

43

195

43.231

46.701

15.67-3.17

60-100

7.8

0.85/0.5

105

80-125

28***

80

50+50

0.8/0.5

80

60

0.8/0.5

5

250

9

70

54

40

9

60

36

R.S.I. 35 kW

* DHW values refer to GREEN C.S.I. models.

** Average value among various sanitary running conditions.

*** Estimated with one 90° bend; 16 extensions of 1 meter and a horizontal exhaust of 1 meter (16kW and 25kW),

27 extensions of 1 meter and a horizontal exhaust of 1 meter (35kW).

**** Tested with Ø60-100 concentric - lenght 0,85m - water temperature 80-60°C.

Page 8

8

EXCLUSIVE GREEN C.S.I. - R.S.I.

11 - MULTIGAS TABLE

Lower Wobbe index (15°C-1013 mbar)

Lower heat value

Supply nominal pressure

Supply minimum pressure

EXCLUSIVE GREEN C.S.I. 25 kW

Number of main burner nozzles

Burner diameter

Gas diaphragm

Burner length

CH maximum gas capacity

DHW maximum gas capacity

CH minimum gas capacity

DHW minimum gas capacity

Numbers of fan revolutions at slow start

Maximum number of fan revolutions

Minimum number of fan revolutions

EXCLUSIVE GREEN C.S.I. 35 kW

Number of main burner nozzles

Burner diameter

Gas diaphragm

Burner length

CH maximum gas capacity

DHW maximum gas capacity

CH minimum gas capacity

DHW minimum gas capacity

Numbers of fan revolutions at slow start

Maximum number of fan revolutions

Minimum number of fan revolutions

EXCLUSIVE GREEN R.S.I. 16 kW

Number of main burner nozzles

Burner diameter

Gas diaphragm

Burner length

CH maximum gas capacity

CH minimum gas capacity

Numbers of fan revolutions at slow start

Maximum number of fan revolutions

Minimum number of fan revolutions

EXCLUSIVE GREEN R.S.I. 25 kW

Number of main burner nozzles

Burner diameter

Gas diaphragm

Burner length

CH maximum gas capacity

CH minimum gas capacity

Numbers of fan revolutions at slow start

Maximum number of fan revolutions

Minimum number of fan revolutions

EXCLUSIVE GREEN R.S.I. 35 kW

Number of main burner nozzles

Burner diameter

Gas diaphragm

Burner length

CH maximum gas capacity

CH minimum gas capacity

Numbers of fan revolutions at slow start

Maximum number of fan revolutions

Minimum number of fan revolutions

MJ/m

3

S

MJ/m

3

S (MJ/kgS)

mbar (mm H

2O)

mbar (mm H

2O)

n.

Ø mm

mm

mm

Sm

3

/h

kg/h

Sm

3

/h

kg/h

Sm

3

/h

kg/h

Sm

3

/h

kg/h

revs/min

revs/min

revs/min

n.

Ø mm

mm

mm

Sm

3

/h

kg/h

Sm

3

/h

kg/h

Sm

3

/h

kg/h

Sm

3

/h

kg/h

revs/min

revs/min

revs/min

n.

Ø mm

mm

mm

Sm

3

/h

kg/h

Sm

3

/h

kg/h

revs/min

revs/min

revs/min

n.

Ø mm

mm

mm

Sm

3

/h

kg/h

Sm

3

/h

kg/h

revs/min

revs/min

revs/min

n.

Ø mm

mm

mm

Sm

3

/h

kg/h

Sm

3

/h

kg/h

revs/min

revs/min

revs/min

G20

45,67

34,02 (-)

20 (204)

10 (102.0)

1

70

6.7

120

2.65

-

2.65

-

0.63

-

0.63

3700

4900

1400

1

70

7

120

3.66

-

3.66

-

0.74

-

0.74

3700

6000

1400

1

70

4.7

90

1.69

-

0.37

3700

4800

1400

1

70

6.7

120

2.65

-

0.63

3700

4900

1400

1

70

7

120

3.66

-

0.74

3700

6000

1400

G31

70,69

88 (46,34)

37 (377)

-

1

70

4.7

120

-

1.94

-

1.94

-

0.47

-

0.47

3700

5100

1400

1

70

5

120

-

2.69

-

2.69

-

0.54

-

0.54

3700

6000

1400

1

70

3.6

90

-

1.24

-

0.27

3700

4800

1400

1

70

4.7

120

-

1.94

-

0.47

3700

5100

1400

1

70

5

120

-

2.69

-

0.54

3700

6000

1400

Page 9

9

ENGLISH

Heating water temperature selector: sets the heating water temperature.

Domestic hot water temperature selector: sets the domestic hot water tem-

perature.

Function key:

ON - the boiler is electrically powered and waiting for operating requests (

- )

OFF - the boiler is electrically powered but will not respond to operating requests

RESET - resets the boiler following a fault

Operating mode button: allows the most suitable operating mode to be selected

(

winter - winter comfort- summer - summer comfort).

Info button: shows a sequence of information concerning the operating status

of the machine.

Filling button: pushing it, the boiler automatically fills the system until the

pressure reaches 1 to 1.5 bar.

graduated heating water temperature scale with heating function symbol

graduated domestic hot water temperature scale with domestic hot water

function symbol

fault symbol (for details, please see page 15)

reset symbol (for details, please see page 15)

pressure value

external sensor connection

heating/domestic hot water temperature

or

fault symbol (e.g. 10 - no flame)

function selector (turned to the chosen operating mode: winter winter comfort- summer - summer comfort)

burner operating symbol

anti-freeze function active symbol

system filling function symbol

fill symbol

12 - START-UP AND OPERATION (GREEN C.S.I.)

The boiler produces heating and domestic hot water. The control panel contains the main boiler control and management functions.

Description of commands Description of display symbols

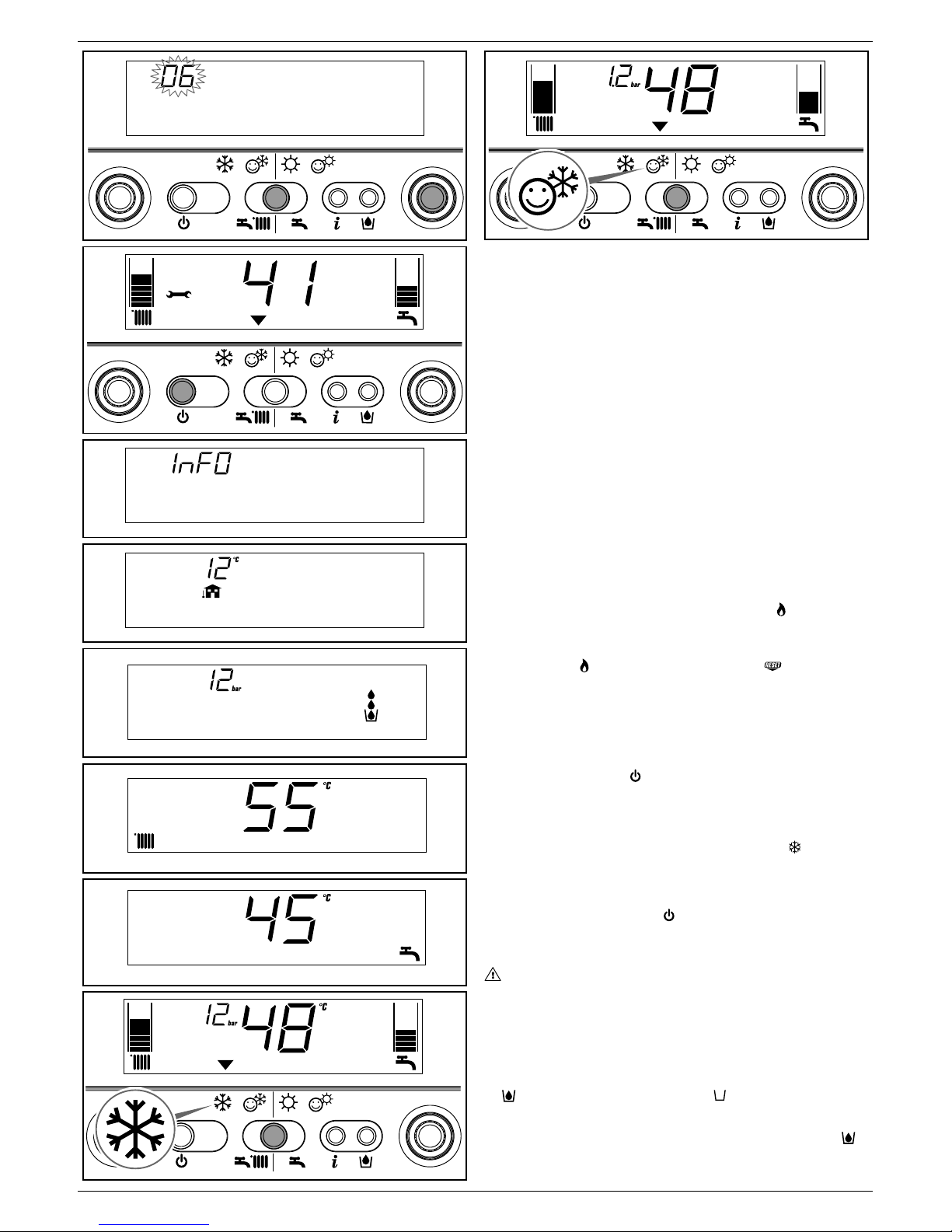

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the lower part of

the boiler

- open the gas tap by turning it anti-clockwise (

Fig. 1)

- power the boiler.

When powered, the boiler performs a test sequence and a series of numbers

and letters are shown on the display.

If the test is successful the boiler is ready to work about 4 seconds after the

cycle ends.

The display will look like

Fig. 2.

If the test is unsuccessful, the boiler will not work and a “0” will flash on the

display.

In this case, contact the Technical Assistance Centre.

The boiler turns on in the status it was in before it was switched off: if the

boiler was in the winter comfort mode when it was switched off, it will turn

on again in the winter comfort mode. If it was in the OFF mode, the display

will show two segments in the central area (

Fig. 3). Press the

button to

enable operation.

- press the function selector until the indicator moves to the required function

, depending on the kind of operation chosen.

- WINTER

: with the selector in this position, the heating water and domestic

hot water functions are activated.

In this position the S.A.R.A. function is enabled in the heating mode (see

chapter “Boiler functions”). The boiler actives the temperature stabiliser in

order to ensure the continuous production of domestic hot water, even for

small demands or when the inlet water is already hot. This prevents temperature oscillations due to the burner switching off/on.

- WINTER COMFORT

: with the selector in this position, as well as the

traditional function of heating water and domestic hot water, the preheating

function is also activated which keeps the water in the domestic hot water

exchanger hot in order to reduce waiting times. The S.A.R.A. Booster and

Domestic hot water preheating functions are enabled in this position (see

chapter “Boiler functions”).

- SUMMER

: with the selector in this position, just the traditional domestic

hot water function is activated.

- SUMMER COMFORT

: with the selector in this position, the boiler

provides just domestic hot water with a temperature stabiliser for small

deliveries. Ideal at the times of year or in the areas where the mains water is

already warm. In these conditions, the temperature of the hot water produced

by a boiler with just traditional functions (see SUMMER and WINTER COMFORT) may be instable.

Adjusting heating water temperature

Turning the selector A (

Fig. 4), after having positioned the selector mode on

winter or winter comfort , it is possible to regulate the heating water

temperature.

Turn clockwise to increase the temperature and anticlockwise to decrease.

The bar segments light up (every 5°C) as the temperature is increased. The

selected temperature value appears on the display. If you enter the S.A.R.A.

adjustment field (from 55 to 65°C) while selecting the heating water temperatu-

re, the symbol

and the graduated scale start flashing. For details about the

S.A.R.A. function, read page 12. The selected temperature value appears on

the display.

Domestic hot water

temperature selector

Operating mode button

ON-OFF-RESET

function selector

Filling button

Heating water circuit

temperature selector

INFO button

Page 10

10

EXCLUSIVE GREEN C.S.I. - R.S.I.

Open position

1

2

3

4

A

+4/5˚C

+3˚C

+2˚C

+1˚C

0˚C

-1˚C

-2˚C

-3˚C

-4/5˚C

5

6

7

B

8

9

10

Tap closed

11

12

13

Page 11

11

ENGLISH

14

15

17

16

18

19

20

21

22

Adjusting heating water temperature with an external sensor

connected

When an external probe is connected, the value of the delivery temperature is

automatically chosen by the system which rapidly adjusts ambient temperature

to the changes in external temperature. Just the central segment of the bar is

illuminated (

Fig. 5).

To increase or decrease the temperature with respect to the value automatically

calculated by the electronic board, turn the heating water selector clockwise to

increase and anticlockwise to decrease. The bar segments light up (at every

comfort level), correction tolerance lies between - 5 and + 5 comfort levels (

Fig.

5). When choosing the level of comfort, the digit area of the display shows the

required level of comfort while the bar shows the matching segment (Fig. 6).

Adjusting domestic hot water temperature

To adjust domestic hot water temperature, turn switch B (

Fig. 7) clockwise to

increase and anticlockwise to decrease. The bar segments light up (every 3°C)

as the temperature is increased.

The selected temperature value appears on the display.

When choosing the temperature, both for heating and domestic hot water, the

display shows the value being selected. About 4 seconds after the selection

has been made, the modification is memorised and the display returns to the

delivery temperature read by the probe.

Working the boiler

Adjust the ambient thermostat to the required temperature (approx. 20°C). If

there is a demand for heating water, the boiler starts and the

symbol is shown

on the display (Fig. 8). The boiler will remain working until the set temperatures

are reached, after which it will go on stand-by. In the event of ignition or operating

faults, the boiler will perform a “safety stop”.

The flame symbol

will go out and the fault code and will be displayed

(Fig. 9). For a description of faults and how to reset them, consult chapter

“Troubleshooting”.

Switching off

Switching off for short periods

For brief absences press the

button to switch off the boiler. The display will

show two segments in the central area (Fig. 3). When the boiler remains powered

with the gas tap open, it is protected by the following systems:

- anti-freeze (

Fig. 10): when the temperature of the water in the boiler falls

below safety values, the circulator and the burner work at minimum power to

increase the water temperature to a safe value (35°C). The

symbol lights

up on the display.

- circulator anti-block: one operating cycle is performed every 24 hours.

Switching off for long periods

For prolonged absences press the

button to switch off the boiler (Fig. 3).

The display will show two segments in the central area. Turn the main switch to

“off”.

Turn off the gas tap under the boiler by turning it clockwise (

Fig. 11).

In this case, the anti-freeze and anti-block systems are disabled. Empty

the water circuit or suitably protect it with a good make of anti-freeze.

Drain the domestic hot water circuit.

Boiler functions

Semi-automatic filling

The boiler features a semi-automatic filling device which turns on by pressing

the

button when the corresponding symbol is shown on the display (Fig.

12).

If this condition occurs it means that the system is incorrectly pressurised though

the boiler will continue to work regularly. Press the circuit filling button

to

start-up the filling sequence.

Page 12

12

EXCLUSIVE GREEN C.S.I. - R.S.I.

Press the circuit filling button a second time to interrupt the filling sequence.

During filling, the drops of the circuit filling symbol

and the growing pressure

value appear on the display in a cascade sequence (Fig. 13).

After filling, the

symbol is displayed for a few moments and then turns off.

Note

During filling, the boiler does not perform other functions. For example, if there

is a request for domestic hot water, the boiler is unable to provide it until filling

has finished.

Note

If circuit pressure reaches 0.6 bar, the pressure value flashes on the display

(

Fig. 14); if it falls below a minimum safety value (0.3 bar), fault code 41 appears

on the display (Fig. 15) for a certain time, following which, if the fault persists,

fault code 40 is displayed (see chapter on “Troubleshooting”).

In the event of fault 40, press

to reset and then to start filling the circuit.

If you have to fill the system several times, contact the Technical Service Centre

to check whether the heating circuit is watertight (see if there are any leaks).

Information

Press

, the display turns off and just the word InFO appears (Fig. 16). Press

the button

to view operating information. Press the button again to move on to

the next piece of information. If the

button is not pressed, the system

automatically exits the function.

Info list:

Info 0 - shows the word InFO (Fig. 16)

Info 1 - only with the external probe connected, displays external temperature

(e.g. 12°C) (Fig. 17).

The values shown on the display range between - 30°C and 35°C.

Beyond these values the display shows “- -”.

Info 2 - shows circuit pressure (

Fig. 18)

Info 3 - shows the set heating temperature (Fig. 19)

Info 4 - shows the set domestic hot water temperature (

Fig. 20)

Info 5 - displays the set heating temperature, in reference to the second circuit,

only if it is connected.

S.A.R.A. function (

Fig. 21)

If the “winter” mode is selected, the S.A.R.A. (Automatic Ambient Adjustment

System) function can be activated.

Turn the heating water temperature selector to a temperature ranging between

55 and 65°C.

The S.A.R.A. self-adjustment system activates: depending on the temperature

set on the ambient thermostat and the time taken to reach it, the boiler

automatically adjusts the heating water temperature to reduce operating times,

thereby increasing operating comfort and energy saving.

S.A.R.A. BOOSTER function (

Fig. 22)

If the “winter comfort” mode is selected, the S.A.R.A. Booster function is activated

for the heating circuit and reaches the required ambient temperature more

quickly.

DOMESTIC HOT WATER PRE-HEATING function (

Fig. 22)

If the “winter comfort” mode is selected, the domestic hot water Preheating

function is enabled. This function sets out to keep the domestic hot water

contained in the boiler hot, thereby considerably reducing delivery waiting times.

The

function should be selected to reduce power consumption in areas

where the mains water is not particularly cold.

In this case, the Booster and Preheating functions are not activated.

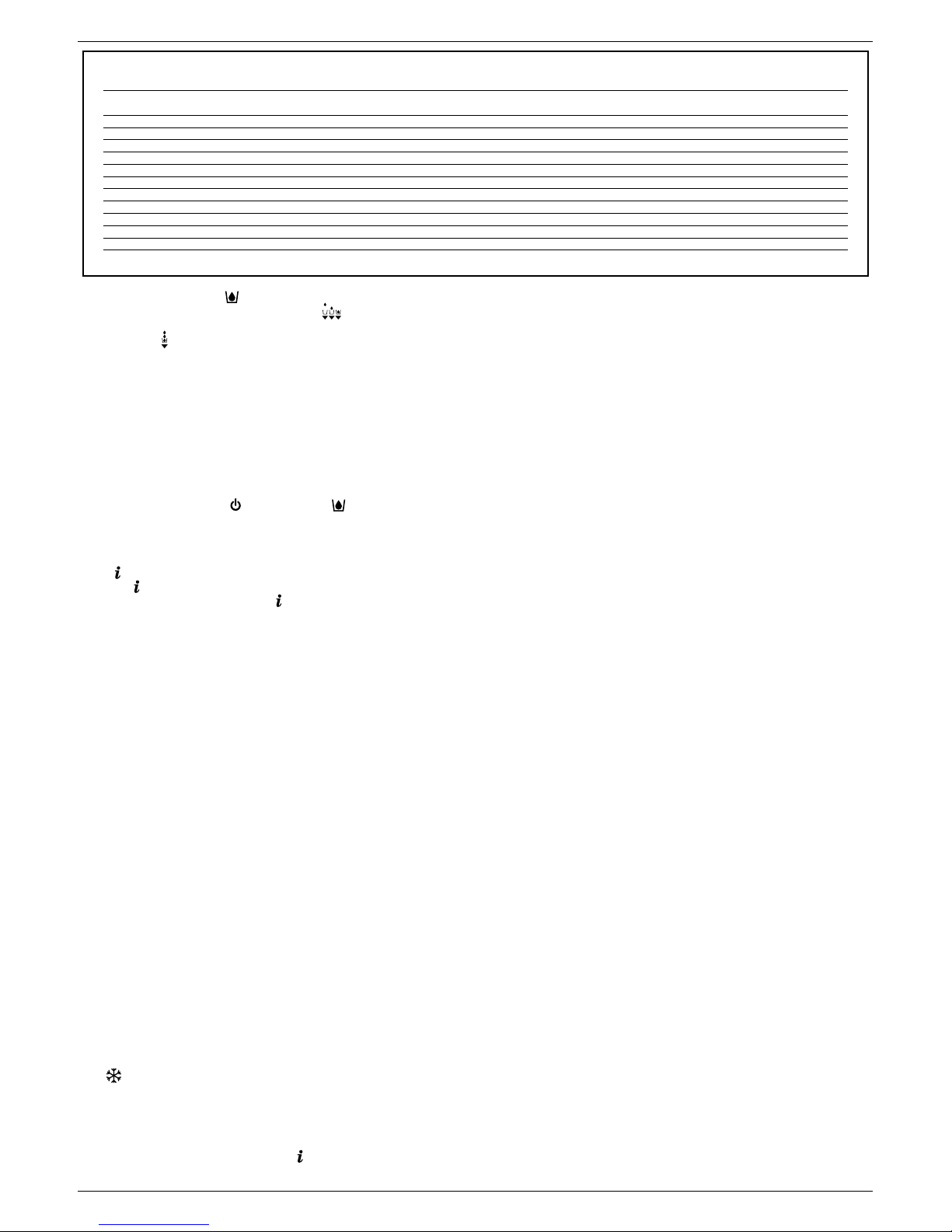

INF2 (

Fig. 23)

It is possible to display information, which may be useful for the Technical

Assistance Centre, by pressing the button

for 10 seconds: the code “INF2”

appears on the display.

Step

1

2

3

4

5

6

7

8

9

10

11-18

Description

Input probe temperature

Return probe temperature

First sanitary probe temperature (*)

Not used in this model

Not used in this model

Second heating system probe temperature

Not used in this model

Ventilator speed /100

Not used in this model

Not used in this model

Historic alarm codes

Display

2 digits

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

Display

4 digits

01

02

03

Cond

05

06

07

FAN

09

10

HIS0-HIS7

°C

°C

°C

°C

°C

Note (*): if the SAN probe is faulty or disconnected, in the place of the value “- -” is displayed.

INF2 list

23

Page 13

13

ENGLISH

graduated heating water temperature scale with heating function symbol

graduated domestic hot water temperature scale (shown in C case only)

domestic hot water function symbol (shown in B and C cases)

fault symbol (for details, please see page 22)

reset symbol (for details, please see page 22)

pressure value

external sensor connection

heating/domestic hot water temperature (shown in C case only)

or

fault symbol (e.g. 10 - no flame)

function selector (turned to the chosen operating mode: winter or

summer (only if water-tank connected)

burner operating symbol

anti-freeze function active symbol

13 - START-UP AND OPERATION (GREEN R.S.I.)

This boiler is able to operate in different conditions:

CASE A - only heating

CASE B - only heating with external water tank connected, managed by a thermostat, to prepare domestic hot water

CASE C - only heating with external water tank connected, managed by a temperature sensor (kit available upon request), to prepare domestic hot water.

Depending on the type of installation selected, it is necessary to set the parameter “domestic hot water mode”. This operation must be performed by a Technical

Service Centre when starting-up the boiler.

Description of commands Description of display symbols

Heating water temperature selector: sets the heating water temperature.

Domestic hot water temperature selector (C case only): sets the

domestic hot water temperature storaged in the water tank.

Setting parameters selector (cases A, B and C): using in calibration and

programmation phase.

Function key:

ON - the boiler is electrically powered and waiting for operating requests

(

- )

OFF - the boiler is electrically powered but will not respond to operating

requests

RESET - resets the boiler following a fault

Operating mode button:

button allows to choose the desired

operating mode: pressing it, the indicator “function selector”

moves to:

(winter) or (summer, only if water-tank connected).

Info button: shows a sequence of information concerning the operating

status of the machine.

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the lower part of

the boiler

- open the gas tap by turning it anti-clockwise (

Fig. 1)

- power the boiler.

When powered, the boiler performs a test sequence and a series of numbers

and letters are shown on the display.

If the test is successful the boiler is ready to work about 4 seconds after the

cycle ends.

The display will look like

Fig. 2.

If the test is unsuccessful, the boiler will not work and a “0” will flash on the

display.

In this case, contact the Technical Assistance Centre.

The boiler turns on in the status it was in before it was switched off: if the

boiler was in the winter mode when it was switched off, it will turn on again

in the winter mode. If it was in the OFF mode, the display will show two

segments in the central area (

Fig. 3). Press the

button to enable

operation.

Choose the desired operating mode by pressing

button, until the

symbol moves to:

WINTER

SUMMER

WINTER function (Fig. 4)

With the selector in this position, the boiler provides hot water for the heating

and, if an external water tank is connected, provides water to the water tank to

allow domestic hot water preparation. Function S.A.R.A Booster is enabled in

this position (see chapter “Boiler functions”).

SUMMER function (only with external water tank connected,

Fig. 5)

With the selector in this position, the boiler provides water to the water tank with

a temperature stabiliser to allow domestic hot water preparation.

Adjusting heating water temperature

Turning the selector A (

Fig. 6), after having positioned the selector mode on

winter

, it is possible to regulate the heating water temperature.

Turn clockwise to increase the temperature and anticlockwise to decrease.

Setting parameters

selector

Operating mode button

ON-OFF-RESET

function selector

Domestic hot water

temperature selector

(C case only)

Heating water circuit

temperature selector

INFO button

Page 14

14

EXCLUSIVE GREEN C.S.I. - R.S.I.

Open position

1

2

3

4

5

6

A

+4/5˚C

+3˚C

+2˚C

+1˚C

0˚C

-1˚C

-2˚C

-3˚C

-4/5˚C

7

9

D

11

10

8

Page 15

15

ENGLISH

12

Tap closed

13

14

15

16

18

17

20

21

19

22

The bar segments light up (every 5°C) as the temperature is increased. The

selected temperature value appears on the display.

Adjusting heating water temperature with an external sensor

connected

When an external probe is connected, the value of the delivery temperature is

automatically chosen by the system which rapidly adjusts ambient temperature

to the changes in external temperature. Just the central segment of the bar is

illuminated (

Fig. 7).

To increase or decrease the temperature with respect to the value automatically

calculated by the electronic board, turn the heating water selector clockwise to

increase and anticlockwise to decrease. The bar segments light up (at every

comfort level), correction tolerance lies between - 5 and + 5 comfort levels (

Fig.

7). When choosing the level of comfort, the digit area of the display shows the

required level of comfort while the bar shows the matching segment (Fig. 8).

Adjusting domestic hot water temperature

CASE A - only heating - adjusting not applicable

CASE B - only heating + water tank with thermostat: in this condition every time

there is a request from the water tank thermostat, the boiler supplies hot water

to preparing domestic hot water. During this operation on the display the icon

flashed.

CASE C - only heating + water tank with sensor: to adjust domestic hot water

temperature storaged in the water tank, turn switch D (Fig. 9): clocwise to

increase and anticlockwise to decrease. The bar segments light up (every 3°C)

as the temperature is increased. About 4 seconds after the selection has been

made, the modification is memorised and the display returns to the delivery

temperature read by the sensor.

Working the boiler

Adjust the ambient thermostat to the required temperature (approx. 20°C). If

there is a demand for heating water, the boiler starts and the

symbol is shown

on the display (Fig. 10). The boiler will remain working until the set temperatures

are reached, after which it will go on stand-by. In the event of ignition or operating

faults, the boiler will perform a “safety stop”.

The flame symbol

will go out and the fault code and will be displayed

(Fig. 11). For a description of faults and how to reset them, consult chapter

“Troubleshooting”.

Switching off

Switching off for short periods

For brief absences press the

button to switch off the boiler. The display will

show two segments in the central area (Fig. 12). When the boiler remains

powered with the gas tap open, it is protected by the following systems:

- anti-freeze (

Fig. 3): when the temperature of the water in the boiler falls below

safety values, the circulator and the burner work at minimum power to increase

the water temperature to a safe value (35°C). The

symbol lights up on the

display.

- circulator anti-block: one operating cycle is performed every 24 hours.

Page 16

16

EXCLUSIVE GREEN C.S.I. - R.S.I.

Switching off for long periods

For prolonged absences press the

button to switch off the boiler (Fig. 3).

The display will show two segments in the central area. Turn the main switch to

“off”.

Turn off the gas tap under the boiler by turning it clockwise (

Fig. 13).

In this case, the anti-freeze and anti-block systems are disabled. Empty

the water circuit or suitably protect it with a good make of anti-freeze.

Boiler functions

Filling the circuit

If circuit pressure reaches 0.6 bar, the pressure value flashes on the display

(Fig. 14); if it falls below a minimum safety value (0.3 bar), fault code 41 appears

on the display (Fig. 15) for a certain time, following which, if the fault persists,

fault code 40 is displayed (see chapter on “Troubleshooting”).

In the event of faul 40 (

Fig. 16) proceed as follow to restore the correct pressure

value:

- press

button

- open the filling tap external to the boiler, until the pressure shown in the

display is between 1 and 1,5 bar.

If you have to fill the system several times, contact the Technical Service Centre

to check whether the heating circuit is watertight (see if there are any leaks).

Information

Press

, the display turns off and just the word InFO appears (Fig. 17). Press

the button

to view operating information. Press the button again to move on to

the next piece of information. If the button is not pressed, the system

automatically exits the function.

Info list:

Info 0 - shows the word InFO (

Fig. 17)

Info 1 - only with the external probe connected, displays external temperature

(e.g. 12°C) (Fig. 18). The values shown on the display range between - 30°C

and 35°C. Beyond these values the display shows “- -”

Info 2 - shows circuit pressure (

Fig. 19)

Info 3 - shows the set heating temperature (Fig. 20)

Info 4 - shows the setted temperature (only water tank with sensor, Fig. 21)

Info 5 - displays the set heating temperature, in reference to the second circuit,

only if it is connected.

S.A.R.A. BOOSTER function (

Fig. 22)

If the “winter” mode is selected, the S.A.R.A. Booster function is activated for

the heating circuit. This function allows to reach the required ambient temperature more quickly.

Depending on the temperature set on the ambient thermostat and the time taken

to reach it, the boiler automatically adjusts the heating water temperature to

reduce operating times, thereby increasing operating comfort and energy saving.

INF2 (

Fig. 23)

It is possible to display information, which may be useful for the Technical

Assistance Centre, by pressing the button

for 10 seconds: the code “INF2”

appears on the display.

Step

1

2

3

4

5

6

7

8

9

10

11-18

Description

Input probe temperature

Return probe temperature

Sanitary probe temperature:

water tank with thermostat (A and B cases)

water tank with probe (C case)

Not used in this model

Not used in this model

Second heating system probe temperature

Not used in this model

Ventilator speed /100

Not used in this model

Not used in this model

Historic alarm codes

Display

2 digits

xx

xx

-xx

xx

xx

xx

xx

xx

xx

xx

xx

Display

4 digits

01

02

03

03

Cond

05

06

07

FAN

09

10

HIS0-HIS7

°C

°C

°C

°C

°C

°C

INF2 list

23

Page 17

17

ENGLISH

FAULT

FLAME FAILURE BLOCK (D)

PARASITE FLAME (T)

RE-ATTEMPT IN PROGRESS (T)

MINIMUM GAS INPUT PRESSURE (T)

MINIMUM GAS INPUT PRESSURE (D)

FLAME PRESENT IN STAND-BY FOR NO REASON (D)

LIMIT THERMOSTAT/FUME THERMOSTAT (D)

SHORT CIRCUIT FUMES PROBE (D)

MAXIMUM TEMPERATURE FUMES PROBE (D)

MAXIMUM TEMPERATURE INPUT PROBE (D)

MAXIMUM TEMPERATURE INPUT PROBE (T)

MAXIMUM TEMPERATURE RETURN PROBE (D)

MAXIMUM TEMPERATURE RETURN PROBE (T)

RETURN-INPUT PROBE DIFFERENTIAL (D)

FUMES PROBE OPEN (D)

FUMES OUTLET OR AIR PRESSURE SWITCH (cycle start) (D)

FUMES OUTLET OR AIR PRESSURE SWITCH (cycle start) (T)

VENTILATOR IN CYCLE (low number of revolutions) (D)

VENTILATOR (cycle start) (D)

VENTILATOR (cycle end) (T)

FUMES OUTLET OR AIR PRESSURE SWITCH (in cycle) (T)

VENTILATOR IN CYCLE (high number of revolutions) (D)

FUMES OUTLET OR AIR PRESSURE SWITCH (in cycle) (D)

INSUFFICIENT SYSTEM PRESSURE (D*)

INSUFFICIENT SYSTEM PRESSURE (T*)

WATER PRESSURE TRANSDUCER (D)

ELECTRONIC BOARD (D)

SANITARY PROBE 1 (T°)

SHORT CIRCUIT/OPEN PRIMARY PROBE (D)

MAXIMUM TEMPERATURE INPUT PROBE (T)

SHORT CIRCUIT/OPEN RETURN PROBE (D)

LOW TEMPERATURE THERMOSTAT (T)

INPUT/RETURN DIFFERENTIAL (T)

INPUT/RETURN DIFFERENTIAL (D)

SYSTEM ANOMALY (D )

SYSTEM ANOMALY (T)

SYSTEM ANOMALY (D )

SYSTEM ANOMALY (T)

CONDENSATE OR CONDENSATE SENSOR (D)

CONDENSATE OR CONDENSATE SENSOR (T)

CONDENSATE SENSOR OR OPEN CIRCUIT (D)

CONDENSATE SENSOR OR OPEN CIRCUIT (T)

Alarm ID

10

11

12

13

14

15

20

21

22

24

25

26

27

28

29

30

31

33

34

35

36

37

38

40

41

42

50-59

60

70

71

72

77

78

79

80

81

82

83

92

93

94

95

Symbol

YES

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

NO

YES

YES

YES

NO

YES

YES

NO

NO

YES

YES

YES

NO

YES

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

YES

NO

YES

NO

YES

NO

Symbol

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

NO

YES

YES

YES

NO

YES

YES

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

NO

YES

YES

YES

NO

YES

YES

YES

YES

NO

YES

YES

YES

14 - TROUBLESHOOTING

When a fault appears on the display, the flame symbol goes out, a flashing code is shown and the two symbols and appear either together or separately.

For a description of the faults, consult the following table.

(D) - Permanent - (T) - Temporary. In this operating status the boiler attempts to eliminate the fault on its own

(°) C.S.I. - Fault in domestic hot water circuit sensor - 60: the boiler works regularly but does not ensure the stability of the hot water temperature which, however,

is delivered at a temperature of approximately 50°C. The fault code is only displayed in standby. R.S.I. - Only with external water tank with sensor. The fault

code is shown when the boiler is in stand-by.

(*) If these two errors occur, check the pressure indicated on the water gauge. If the pressure is insufficient (< 0,4 bar, red area), proceed with the filling

operations described in the chapter “Filling and emptying the systems”. If the system’s pressure is sufficient (> 0,6 bar, blue area) the malfunction is caused

by a lack of water circulation. Contact the Technical Assistance.

Resetting faults

Wait for about 10 seconds before resetting operating conditions.

Then proceed as follows:

1) Viewing just the

symbol

If

disappears, it means that an operating fault has been discovered which

the boiler is attempting to solve on its own (temporary stoppage). If the boiler

does not resume normal operation, two things may happen:

Case A (

Fig. A)

disappears, the symbol and a different alarm code appear. In this case,

proceed as described in point 2.

Case B (

Fig. B)

and a different alarm code are displayed together with .

In this case, proceed as described in point 3.

2) Viewing just the

symbol (Fig. C)

Press the

button to reset the appliance. If the boiler starts the ignition phase

and resumes normal operation, it may have stopped by accident.