Beretta Exclusive GREEN HE C.S.I. 35 kW, Exclusive GREEN HE R.S.I. 35 kW, Exclusive GREEN HE C.S.I. 25 kW, Exclusive GREEN HE R.S.I. 25 kW Installer And User Manual

Page 1

This manual must remain with the user/appliance

EXCLUSIVE

GREEN HE

C.S.I. - R.S.I.

EN NZINSTALLER AND USER MANUAL NZ Edition 2017-1

ES MANUAL DEL INSTALADOR Y DEL USUARIO

PT MANUAL DO USUARIO E DO INSTALADOR

HU TELEPiTOI ES FELHASZNAL6I KEZIKONYV

RO MANUAL DE INSTALARE SI UTILIZARE

SI NAVODILA ZA VGRADITEV, PRIKLJUCITEV IN UPORABO

PL INSTRUKCJA OBSt.UGI I INSTALACJI KOTt.A GAZOWEGO

Page 2

2

EXCLUSIVE GREEN HE C.S.I. - EXCLUSIVE GREEN HE R.S.I.

RANGE RATED

This boiler can be adapted to the heating requirements of the system, it is possible to change the maximum output in central heating. Refer to chapter "Adjustments"

for calibration.

After setting the desired output (parameter 23 maximum heating) Please note the adjusted setting on the boiler.

ES

RANGE RATED

Esta caldera puede adaptarse a los requisitos de calefacción del sistema, es posible cambiar la potencia máxima en la calefacción central. Para la

calibración, consultar el capítulo “Regulaciones”.

Después de ajustar la potencia deseada (parámetro 23 calefacción máxima) apunte el valor en la tabla de la contraportada de este manual para

futuras referencias.

PT

FAIXA CLASSIFICADA

Esta caldeira pode ser adaptada às especificações de aquecimento do sistema, é possível modificar a saída máxima no aquecimento central.

Consulte o capítulo “Ajustes” para a calibração.

Após definir a saída desejada (parâmetro 23 de aquecimento máximo), relate o valor na tabela na contracapa deste manual, para consultas futuras.

HU RANGE RATED

A bojler a rendszer fűtési igényeihez igazítható. A központi fűtés maximális teljesítménye módosítható. A beállításhoz lásd a “Szabályozás” részt.

A megfelelő teljesítmény (23-as paraméter, maximális fűtés) beállítása után jegyezze fel az értéket a kézikönyv hátsó borítóján lévő táblázatba.

RO

GAMA NOMINALA

Această centrală poate fi adaptată la cerinţele de încălzire ale sistemului; este posibil să modificaţi puterea maximă în încălzirea centrală

Pentru calibrare, consultaţi capitolul “Reglaje”.

După ce setaţi puterea dorită (parametrul 23 încălzire maximă) indicaţi valoarea curentă în tabelul de la sfâr itul acestui manual, pentru referinţe ulterioare.

SL

RANGE RATED

Ta kotel se lahko prilagodi zahtevam sistema po toploti, pri centralnem ogrevanju se mu lahko spremeni največjo moč. Za umerjanje glejte poglavje

“Nastavitve”.

Po nastavitvi želene izhodne moči (parameter 23, največje ogrevanje) vnesite vrednost v tabelo na zadnji ovitek tega priročnika, za nadaljnjo uporabo.

PL

ZAKRES REGULACJI MOCY

Kocioł ten można dostosować do wymagań systemu centralnego ogrzewania, ponieważ istnieje możliwość obniżenia maksymalnej mocy na c.o. W tym

celu należy zapoznać się z rozdziałem Regulacje”

W przypadku zmiany wartości mocy maksymalnej (parametr 23) należy umieścić aktualną wartość w tabeli znajdującej się na końcu niniejszej instrukcji.

Jest to bardzo istotne w przypadku wykonywania przeglądów urządzenia.

SI

SI

PL

EN

PL

PT

ES

HU

RO

EN

ES

PT

HU

RO

This boiler manual contains information and specifications for CSI and RSI models

For New Zealand CSI model only applies

CSI = Combination boiler with on demand DHW

RSI = system boiler N/A

Installation of this appliance requires a certifying Gas fitter

Electrical connections should be by a suitably qualified Electrician

Distributed in NZ by Tradepoint LTD (Heat IQ) Wanganui NZ 063447392

EXCLUSIVE GREEN boiler complies with basic requirements of the

following Directives: Gas directive 2009/142/EEC; Yield directive 92/42/

EEC; Electromagnetic compatibility directive 2004/108/EEC; Low-voltage

directive 2006/95/EEC; Regulation 677 for condensation boilers. Thus, it is

EC-marked.

La caldera EXCLUSIVE GREEN cumple con los requisitos básicos de

las siguientes Directivas: Directiva Gas 2009/142/EEC; Directiva

rendimiento 92/42/EEC; Directiva compatibilidad electromagnética

2004/108/EEC; Directiva baja tensión 2006/95/EEC; Regulación 677 para

calderas de condensación. Por lo tanto, tiene el marcado CE.

A caldeira EXCLUSIVE GREEN é compatível com as especificações

básicas das seguintes Directivas: Directiva de gás 2009/142/EEC; Directiva

de rendimento 92/42/EEC; Directiva de compatibilidade electromagnética

2004/108/EEC; Directiva de baixa tensão 2006/95/EEC; Regulação 677

para caldeiras de condensação. Assim, é marcada com EC.

Az EXCLUSIVE GREEN kazán teljesíti az alábbi irányelvek lényegi

követelményeit: 2009/142/EGK sz. gáz irányelv; 92/42/EGK sz. irányelv a

vízmelegítő kazánokról; 2004/108/EGK sz. irányelv az elektromágneses

összeférhetőségről; 2006/95/EGK sz. irányelv a kisfeszültségű

berendezésekről; Kondenzációs kazánokra vonatkozó 677 sz. szabvány. Így

jogosan viseli a CE-jelet.

Centrala EXCLUSIVE GREEN este fabricata in conformitate cu cerintele

urmatoarelor Directive: Directiva gaz 2009/142/EEC; Directiva eficienta

92/42/EEC; Directiva compatibilitate electromagnetica 2004/108/EEC;

Directiva voltaj redus 2006/95/EEC; Regulamentul 677 referitor la centrale

cu condensare. Prin urmare, este marcat cu simbolul CE.

Kotel EXCLUSIVE GREEN ustreza temeljnim zahtevam Naslednjih Uredb:

Uredba o plinu 2009/142/CEE; Uredba o izkoristkih92/42/CEE; Uredba

o elektromagnetni ustreznosti 2004/108/CEE; Uredba o nizki napetosti

2006/95/CEE; Uredba o kondenzacijskih kotlih 677. Torej nosi oznako CE.

KocioU

EXCLUSIVE GREEN

nast�pujqcych dyrektyw : - Urzqdzenia spalajqce paliwa gazowe

2009/142/EEC; Sprawnosc energetyczna

Kompatybilnosc energetyczna 2004/108/EEC; Niskonapi�ciowe wyroby

elektryczne 2006/95/EEC; Norma

w CE

HE

speUnia

podstawowe wymagania

kotU6w

dotyczqca

kotU6w

wodnych

0694

92/42/EEC;

kondensacyjnych 677;

Installer’s-user’s manual ..................................................................................

Boiler operating elements ................................................................................

Hydraulic circuit ...............................................................................................

Electric diagrams .............................................................................................

l

Installer’s-user’s manual .............................................................................. 28

Boiler operating elements .......................................................................... 172

Hydraulic circuit .................................................................................. 173-174

Electric diagrams ................................................................................ 175-176

Installer’s-user’s manual .............................................................................. 52

Boiler operating elements .......................................................................... 172

Hydraulic circuit .................................................................................. 173-174

Electric diagrams ................................................................................ 175-176

Telepítői kézikönyv-felhasználói kézikönyv ................................................. 76

A kazán funkcionális alkatrészei ................................................................ 172

Vízkeringetés ..................................................................................... 173-174

Villamos kapcsolási rajz ..................................................................... 175-176

Manual instalator-utilizaor ...........................................................................100

Elemenetele functionale ale centralei. ....................................................... 172

Circuit hidraulic .................................................................................... 173-174

Scheme electrice ................................................................................ 175-176

Navodila za vgraditelja-uporabo ................................................................ 124

Sestavni deli kotla ...................................................................................... 172

Hidravlična napeljava ......................................................................... 173-174

Električna shema ..................................................................................... 175-176

lnstrukcja instalacji i uzytkowania .................................................................. 148

Budowa kotU

Obieg hydrauliczny ................................................................................. 173-174

Schematy elektryczne ............................................................................ 175-176

a ............................................................................................

172

Page 3

3

ENGLISH

Model

Type

Category

Power

C.S.I.

combined C

25-35 K7

R.S.I.

CH only C

25-35 K7

ENGLISH NZ edition

1

- GENERAL SAFETY DEVICES

The boilers produced in our factory are built with care down to the last

component to protect both the user and installer from eventual accidents.

We recommend personel working on the appliance

should pay particular attention to the wiring, especially the

connections, that must not be exposed outside the terminal board

to prevent any contact with the live parts of the wiring.

This instruction manual is an integral part of the product. Make sure it

remains with the boiler, even if it is transferred to another owner

or user.

This boiler may only be installed and serviced by qualified fitters who

Have the appropriate NZ Gas and Electrical qualifications

Install must comply with NZ code

The boiler must be serviced at least once a year.

The installer must instruct the user in the operation of the boiler

and its safety devices.

This boiler may only be used for what it was expressly built to do. The

manufacturer declines all contractual and non-contractual liability for

injury to persons or animals or damage to property deriving from errors

made during installation, adjustment and servicing and from improper

use.

If this appliance is used to produce hot water it must be connected

to a heating and/or a domestic hot water system, according to its

performance and power.

After removing the packaging, make sure the contents are undamaged

and complete. If this is not the case, contact your dealer.

The safety valve outlet must be connected to a suitable drain. The

manufacturer declines all liability for any damage caused by the an

incorrect safety valve discharge.

The safety and automatic adjustment devices on the appliance must

never be modified during its lifetime,.

If the appliance develops a fault and/or works badly, switch it off and do

not attempt to repair it yourself.

, inform the user that:

-

in the event of leaks, he/she Must shut off the water supply and

promptly seek professional support.

-

Must check from time to time to make sure

on the control panel. This symbol means that the pressure in the

water system is incorrect. If necessary, fill the system as described

in the paragraph “Boiler functions”

-

GREEN HE R.S.I.: must periodically check, on the display, that the

pressure value is between 1 and 1,5 bar; if not fill the system as

described in the paragraph “Boiler functions”

-

if the boiler is not planned to be used for a long period, he/she

should call in the Technical Assistance Service to perform the following

operations:

-

turn off the main boiler and general system switches

-

close the gas and water taps on both the heating (GREEN HE

C.S.I.-GREEN HE R.S.I.) and domestic hot water circuits (GREEN

HE C.S.I. only)

-

drain the heating (GREEN HE C.S.I.-GREEN R.S.I.) and domestic

hot water (GREEN HE C.S.I. only) circuits to prevent freezing.

the

Connect the outlet collector to a suitable outlet system (refer to chapter 5).

Safety measures:

The boiler should not be used by children or unassisted disabled people

electrical devices or equipment, such as switches, appliances, etc.,

should not be used if there is a smell of gas or fumes. If there is a gas

leak, open all the doors and windows to ventilate the area, turn off the

general gas tap and immediately call the Technical Assistance Service

do not touch the boiler if your hands are wet or damp

Press the button until “- -” is shown on the display and disconnect the

electricity supply by turning off the two-position system switch, before

cleaning

Do not modify the safety or adjustment devices without the

manufacturer’s permission and relative instructions

Do not pull, detach or twist the wires from the boiler even if they are not

connected to the power supply

symbol is not lit

Do not block or reduce the size of the ventilation openings in the room

Do not leave inflammable containers or substances in the room

keep packaging out of reach of children

only use appliance for purposes it is devoted to

Do not lean any object on the boiler

Do not tamper with sealed elements

Do not block the condensate outlet.

2

- BOILER INSTALLATION

Boiler must only be installed by qualified personnel.

Boiler is available in the following models:

Exclusive GREEN HE C.S.I.

is a C-type condensation wall-mounted boiler for heating and producing

on demand domestic hot water;

Exclusive GREEN HE R.S.I.

Some reference is made to this model within the manual.

Exclusive Green HE boilers are fitted with:

-

Smart pumps with auto speed adjusting

-

1- 10 modulation, the boiler is designed to automatically modulate the flow

rate supplied between a maximum and a minimum (see technical data)

-

Range Rated, indicates that the boiler has a device for adapting to the

system’s heat requirements, making it possible to adjust the boiler’s flow

rate to the energy requirements of the building

The following types of fumes outlet are available for this kind of boiler:

B23P; B53P; C13,C13x; C23; C33,C33x; C43,C43x; C53,C53x; C63,C63x;

C83,C83x, C93,C93x.

In B23P configuration (if installed inside), do not install the apparatus in

rooms used as bedrooms, bathrooms, showers or where there are open

vent stacks without own air exchange. The boiler must be installed in an

adequately ventilated room. See the UNI-CIG 7129-7131 and UNI 11071

standards for detailed instructions on installing vent stacks, gas pipes and

to ventilate the room.

In C configuration the boiler can be installed in any type of room and there

are no limits to aeration conditions and size of room.

FOR CORRECT INSTALLATION, WE REMIND YOU THAT:

-

The boiler must not be installed over a stove or any other cooking equi-

pment or within a bathroom.

-

minimum spaces are to be left in order to allow maintenance operations:

at least 5,0 cm every side and 20 cm under the boiler

-

it is forbidden to leave inflammable substances in the room

-

suitably fire line any heat-sensitive walls (e.g.: wood lined).

A support plate and integrated pre-installation template are provided for

with

the boiler (FIG. 1.1).

(PWM = Pulse-width modulation))

Mounting instructions:

-

fix the boiler support plate (F) with the template (G) to the wall and use a

plumb to check that it is perfectly horizontal

-

trace out 4 holes (Ø 6 mm) for fixing the boiler support plate (F) and 2

holes (Ø 4 mm) for fixing the pre-installation template (G)

-

make sure all the measurements are correct, then drill holes in the wall

using a drill and point with the diameter given previously

-

fix the plate to the wall by the supplied anchor screws

-

make hydraulic connections.

After installing the boiler, the screws

after

installing the boiler and connecting it to the water and gas supplies, fit

the

lower cover (

the lower case with the screw C (FIG. 1.4) -

in the boiler.

A-B

, FIG. 1.3) so that its hooks slip into the lower paart of the boiler and fix

D1

(FIG. 1.2) can be removed.

Contained in the documentation envelope

Page 4

4

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

Parameters

um

Water in

heating

circuit

Inlet

water

PH

7÷8

Hardness —& -

15÷20

Appearance

- limpid

Residual head (m.c.a.)

EXTERNAL SENSOR YES

((HEAT REGULATION))

EXTERNAL SENSOR NO

(NO HEAT REGULATION)

HIGH

TEMPERATURE

(

radiators

without

thermostatic

valves)

02/0/24)/.!,

(09o = 41)

T constant

(2≤P90≤40)

LOW

TEMPERATURE

(floor

)

02/0/24)/.!,

(09o = 41)

02/0/24)/.!,

(09o = 41)

HIGH

TEMPERATURE

(radiators

with

thermostatic

valves)

02/0/24)/.!,

(09o = 41)

02/0/24)/.!,

(09o = 41)

Cleaning the system and characteristics of heating circuit water

After installing a new system or replacing a boiler, Flush the system.

To ensure the product works correctly, after cleaning, and/or chemically

treating the system (e.g.: Inhibitors, antifreeze, etc.), make sure the

characteristics of the water satisfy the parameters indicated in the table.

If water hardness exceeds 28 Fr,

we recommend the use of a water softener,

to prevent any limescale deposit in boiler due to excessively hard water.

PUMP DUTY

Exclusive Green HE boilers are fitted with a variable speed circulation unit

that is already connected up in terms of plumbing and electrics, and the

usable performance it provides is shown in the graph.

The boilers are fitted with an anti-blocking system that starts an operating

cycle every 24 hours when not used, irrespective of the position of the function selector.

The “anti-blocking” function is only active when the electrical power

supply to the boiler is on.

Operating the appliance pump without water is forbiden

VARIABLE SPEED CIRCULATION UNIT

The modulating circulating function is only active for the heating function.

When the three way valve switches to DHW the pump works at max speed

unit is set at maximum speed. The modulating circulation function applies

only to the boiler circulation unit and not to circulation units on any external

devices connected to it (e.g. booster circulation unit).

Any of 4 operating modes can be chosen, depending on situations and the

type of plant.

By accessing parameter 90 in the technical menu, one of the following possibilities can be chosen:

1

- VARIABLE SPEED CIRCULATION UNITWITH PROPORTIONAL MODE

(41 <= P90 <= 90)

2

- VARIABLE SPEED CIRCULATION UNIT WITH CONSTANT DT MODE

(2 <= P90 <= 40)

3

- VARIABLE SPEED CIRCULATION UNIT WITH MAXIMUM FIXED

MAXIMUM SPEED MODE (P90 = 1)

4

– EXCEPTIONAL USE OF A STANDARD CIRCULATION UNITWITHOUT

SPEED ADJUSTMENT (P90 = 0)

1

- VARIABLE SPEED CIRCULATION UNITWITH PROPORTIONAL MODE

(41 <= P90 <= 90)

In this mode the boiler’s board determines what flow rate curve to adopt

according to the instantaneous power supplied by the boiler.

The boiler controller breaks down the power range within which the boiler

operates in heating mode into various levels. Depending on the power level

in use when heating, one of the speeds available is selected automatically

according to logic: Max power = HIGH SPEED, Min power = LOW SPEED.

This is used on all types of plants where the machine’s power has been

correctly balanced with the plant’s real needs.

Operationally:

- Access parameter 90

- Set the parameter = 41

Note

: The Parameter 90 = 41 setting is recommended by the manufacturer.

Values exceeding 41 are used in specific cases.

2

- VARIABLE SPEED CIRCULATION UNIT WITH CONSTANT DT MODE

(2 <= P90 <= 40)

In this mode the installer sets the T value to be maintained between the

delivery and return (e.g. if a value of 10 is entered, the circulation unit’s

speed will change to implement a plant flow rate aimed at maintaining the

between the inlet and outlet of the heat exchanger AT 10 Deg C

By periodically sampling values provided by the boiler delivery/return

sensors, the board increases or decreases the circulation unit’s speed and

therefore the plant’s flow rate. If the sampling shows a T value lower than

that set, the speed is reduced until the T increases to the value set. Viceversa if sampling is higher than the value set, the speed is increased.

This is used for direct high temperature plants (typical of replacement),

where the boiler is not thermostatically controlled, and where a calculated

delta T can be set.

When working with a constant delivery temperature and attainment of

stabilising the ambient conditions, the average temperature of the radiators

tends to increase. By keeping T constant, the reduction in the flow rate is

obtained by changing the operating curve, which produces a lower return

temperature that in turn favours high boiler performance and the reduction

of electricity consumption.

Operationally:

-

Access parameter 90

-

Set the parameter at a value between 2 and 40 (normally between 10

and 20).

3

- VARIABLE SPEED CIRCULATION UNIT WITH MAXIMUM FIXED

MAXIMUM SPEED MODE (P90 = 1)

In this mode the modulating circulation unit works constantly at maximum

speed.

It is used on plants with a high load loss in which the boiler’s head must be

used as much as possible in order to guarantee sufficient circulation (plant

flow rate at maximum speed lower than 600 litres per hour).

This is used when bottles of mixture are involved, with high flow rates in

the circuit downstream.

Operationally:

- Access parameter 90

- Set the parameter = 1

4

– EXCEPTIONAL USE OF A STANDARD CIRCULATION UNIT WITH-

OUT SPEED ADJUSTMENT (P90 = 0)

This mode must be used in exceptional cases in which the boiler is to

be used with a traditional circulation unit without a speed adjustment. It

presupposes that the adjustable speed circulation unit has been removed

and replaced with a non-adjustable speed circulation unit.

Warning !!!! The BE06 board connected to connector CN9 must be

removed and replaced with a connector with a jumper to be inserted into

connector CN9. This latter connection is obligatory and if not formed

may cause the system to malfunction.

Operationally:

- Access parameter 90

- Set the Parrameter = o

CONFIGURATIONS RECOMMENDED BY THE MANUFACTURER

6,0

5,8

5,6

5,4

5,2

5,0

4,8

4,6

4,4

4,2

4,0

3,8

3,6

3,4

3,2

3,0

2,8

2,6

2,4

2,2

2,0

1,8

1,6

1,4

1,2

1,0

0,8

0,6

0,4

0,2

0,0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

Plant flow rate (l/h)

Page 5

5

ENGLISH

3

- HYDRAULIC CONNECTIONS

Position and dimensions of hydraulic connections are specified in figure 1.1:

A - CH return 3/4”

B - CH delivery 3/4”

C - Gas connection 3/4”

D -

DHW

outlet

E –

DHW

F - Support plate

G - Pre-installation template

4

- IF INSTALLING AN EXTERNAL Thermoregulation Sensor

The sensor (FIG. 1.6) MUST BE INSTALLED ON AN EXTERNAL WALL of the building

while taking care to comply with the instructions below:

-

It must be fitted on the facade most often exposed to wind, on a wall facing

South or South west (southern Hemisphere).

-

It must be fitted about 2/3 up the height of the façade.

-

It must not be near any doors, windows, outlets for air ducts, or near

chimneys or other heat sources.

The electrical connection to the external sensor must be formed using a twopole cable (not supplied), with a cross-section of 0,5 to 1 mm2 and a maximum

length of 30 metres. It is not necessary to worry about the polarity of the cable

for the connection to the external sensor. Do not form joints in this cable.

If a joint has to be made it must be watertight and adequately protected.

Any conduit used for the connection cable must be separate from the

conduits used for the power cables (230 Vac).

WALL MOUNTING OF THE EXTERNAL SENSOR.

Install the probe in an area of smooth wall; for brick walls or other irregular

surfaces, prepare a smooth contact area if at all possible.

Remove the upper plastic cover by turning it anti-clockwise.

Identify the wall fixing point and drill a hole for the 5x25 expansion grip.

Insert the expansion grip into the hole.

Remove the card from its housing.

& fix to the wkll using the screw supplied

Attach the bracket and tighten the screw.

Loosen the cable grommet screw, push in the probe connection cable and

connect it to the electrical terminal.

inlet

(CSI) ½”

(CSI) ½”

Remember to firmly secure the cable grommet to prevent humidity from

entering.

Put the card back into its housing. Close the upper plastic cover by turning

clockwise , firmly secure the cable grommet

5

- CONDENSATE COLLECTION TRAP

The outlet c

water from the safety valve and the system drain outlet water.

ollector A (FIG. 1.

7)

collects the condensate water any evacuation water , the

The collector must be connected, by means of a discharge pipe (not

sup- plied), to a suitable drain.

The external diameter of the collector hose is 20 mm: we therefore

suggest using an Ø 18-19 mm pipe, to be closed with a suitable

clamp (not supplied).

The manufacturer is not responsible for any damage caused by the lack

of a collection system.

The outlet connection line must have a guaranteed seal.

The manufacturer of the boiler is not responsible for any flooding caused

by interventions of the safety valve.

6

- GAS CONNECTION

Before connecting appliance to gas pipe network, check the following:

-

regulations in force are met

-

gas type used is the same as set for appliance operation

-

pipes are clean.

Gas must be piped externally. If the pipe goes through a wall it must go through

the central opening in the lower part of the template. It is recommended to

install an appropriately sized filter on the gas line in case gas from the mains

contains some small solid particles. After installation make sure that all the

joints have been made airtight conforming to standard installation practices.

7

- ELECTRIC CONNECTION

To access the electrical connections, proceed as follows:

-

unscrew the lower cover fixing screw C, (FIG. 1.4)

-

pull the cover towards you and remove (A-B) (FIG. 1.5)

-

loosen the fixing screws (D) and remove the shell (FIG. 1.2)

-

lift up the panel and turn it forwards

-

open the terminal board covers making them slide in the direction of the

arrows (FIG. 1.8: E high voltage connections 230 V, F low voltage connec-

tions, G water tank sensor connections only ( R.S.I.).

Connect the appliance to the mains power supply with a switch featuring a

distance of at least 3,5 mm (EN 60335-1, category III) between each wire.

The appliance uses alternating current at 230 Volt/50 Hz, has a power input

OF 88 w (25KW CSI.- 25KW RSI).) & 116 w (35KW RSI. - 35KW CSI)

and complies with EN 60335-1 standard. Connect the boiler to a safe earth

circuit according to current legislation.

Live and neutral (L-N) connections should also be respected.

The boiler can operate with phase-neutral or phase –phase power supply. For

floating power supply, without an earth-bonded conductor, it is necessary to

use an insulation transformer with secondary anchored to ground.

The earth conductor must be a couple of cm longer than the others.

Gas and/or water pipes may not be used to earth electrical equipment.

The installer is responsible for making sure that the appliance has an

adequate earth system; the manufacturer shall not be held liable for

eventual damages caused by incorrect usage or failing to earth the

boiler.

Use the supplied power cable to connect the boiler to the mains power

supply.

Connect the ambient thermostat and/or time clock as shown in the electrical

diagrams.

When replacing the power cable, use a HAR H05V2V2-F cable, 3 x 0,75

mm2, Ø max. external 7 mm.

8

- FILLING AND EMPTYING THE SYSTEM

The central heating system can be filled up once the water mains have been

connected.

This must be done while the installation is cold by:

-

Turn the caps of the lower (A) and upper (E) automatic bleed valves two

or three turns; leave A and E valve caps open for continual air venting

(FIG. 1.9);

-

Making sure the cold water inlet tap is open

-

Opening the filling tap (B, on the boiler for until the pressure on the

gauge (C) is between 1 and

Close the filling tap after filling.

The boiler is equipped with an efficient air separator so that there is no need

to do anything manually.

The burner only ignites when air venting has finished.

NOTE: air extraction from the boiler takes place automatically, through two

automatic bleeding valves, A and E.

The first is situated on the pump, while the second is inside the air chamber.

NOTE the boiler is also equipped with a semi-automatic filling system. The

first system-filling operation must be carried out by opening tap B with the

boiler turned off.

1,5 Bar (BLUE ZONE) (FIG. 1.9).

Emptying

Before starting to empty the boiler, isolate power switch for the system (off)

Close the isolation devices for the thermal system

-

Loosen the system outlet valve (D) manually

-

The water from the system is discharged through the outlet collector (F).

DHW system emptying (C.S.I. Combi only)

:

-

turn off the tap at the mains cold inlet

-

turn on all the hot and cold taps

-

empty out the lowest parts of the system.

Page 6

6

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

Max linear length concentric

duct Ø 60-100 mm

Pressure drop for each

bend (45°/90°) [m]

25 C.S.I.-R.S.I.

8,85 m

1,3 / 1,6

35 C.S.I.-R.S.I.

8,85 m

Max length fumes

outlet duct Ø 80 mm

Pressure drop for each

bend (45°/90°) [m]

25 C.S.I.-R.S.I.

50 m

1 / 1,5

35 C.S.I.-R.S.I.

60 m

Max linear length concentric

duct Ø 60-100 mm

Pressure drop for each

bend (45°/90°) [m]

25 C.S.I.-R.S.I.

7,85 m

1,3 / 1,6

35 C.S.I.-R.S.I.

7,85 m

To Purge air from the heating system & boiler (Fig. 1.10)

We recommend carrying out the sequence of

operations below during installation and after

exceptional maintenance

1. Using a spanner open the manual air vent valve located above the air

box; the tube supplied with the boiler must be connected to the valve

to let out the water into a container.

2. Open the manual system filling valve

3.

Switch on the boiler leaving the gas valve closed;

4.

Use the room thermostat or the remote control panel to activate request

INSTALLATION “SEALED” (TYPE C)

This boiler is a C-type appliance (sealed chamber) and must be safely

connected to fume exhaustion duct and burning air suction duct, both

terminating outside; This appliance cannot operate without these ducts.

Concentric outlets (Ø 60-100) (Fig. 1.14)

Concentric ducts may be placed in the most suitable direction for installation

requirements but special care must be taken as regards the and the length

of the Flue.

Horizontal

for heat so that the three-way will turn to heating

5.

Activate request for hot water as follows:

turn on a tap for 30 seconds every minute so that the three-way cycles

from heating to domestic hot water and vice versa about ten times

(here the boiler will go into alarm as it lacks gas and will have to be reset

each time this happens

6.

Continue the sequence until water only comes out of the manual air vent

valve; close the manual air vent valve at this point;

7.

Make sure the system is at the correct pressure (1- 1.2 bar is ideal);

8.

Close the manual system filling valve;

9. Open the gas valve and ignite the boiler

9

- FUMES EXHAUSTION AND BURNING AIR SUCTION

EXHAUSTION CONFIGURATIONS (Fig. 1.11-1.12)

Boiler is homologated for the following exhaustion configurations:

B23P-B53P - Suction in room and discharge outside

C13 - Concentric wall exhaustion. Pipes can separately start from boiler,

but outlets must be concentric or close enough to be subject to similar wind

conditions (within 50 cm)

C23 - Concentric exhaustion in common chimney (suction and exhaustion

in the same chimney)

C33 -

#ONCENTRIC ROOF EXHAUSTION. /UTLETS LIKE #13

C43 - Exhaustion and suction in common separate chimneys, but subject

to similar wind conditions

C53

- 7ALL OR ROOF S

EPARATE EXHAUSTION AND SUCTION IN DIFFERENT PRESSURE AREAS.

Exhaustion and suction must never be located on opposite walls

C63 - Exhaustion and suction with separately certified and sold pipes (1856/1)

C83 - Single or common chimney exhaustion and wall suction

C93 – Exhaust on roof (similar to C33) and air

Vertical

linear length means without bends,

Allow 0.5 m per bend in total length calculation.

The Flue outlet pipe MUST SLOPE BY 1% TOWARDS the condensate collector (boiler)-

CAUTION

Exhaust fume outlets are potential hazards.

The boiler automatically adapts ventilation according to the type of

installation and the length of the duct.

Do not obstruct or narrow the combustion air inlet duct in any way.

To install follow the instructions supplied with the kit.

.

Refer to regulations in force for exhaustion of combustion products.

Boiler is provided for without fume exhaustion/air suction kit, since forced

draught sealed chamber accessories can be used, as they better adapt to

installation characteristics.

&OR FUME EXTRACTION AND BURNING AIR RESTORATION IN BOILER, USE ORIGINAL PIPES OR

other EC-certified pipes with equivalent characteristics; check connection is

correct as shown on instructions fume accessories provided for with. More

appliances can be connected to a single chimney, provided that all appliances

are condensing type.

“FORCED OPEN” INSTALLATION (TYPE B23P-B53P, intake inside

and outlet outside) - Fumes outlet duct Ø 80 mm (Fig. 1.13)

The fumes outlet duct can be aimed in the most suitable direction for instal-

lation needs. To install follow the instructions supplied with the kit.

In this configuration, the boiler is connected to the Ø 80 mm fumes outlet

duct by means of a Ø 60-80 mm adaptor.

In this case, the combustion supporting air is taken from the room in

which the boiler is installed, which must be a suitable and ventilated

technical room.

Non-insulated fumes outlet ducts are potential sources of danger.

0ROVISION MUST BE MADE FOR A 1% SLOPE OF THE FUMES OUTLET DUCT TOWARDS

the boiler.

Page 7

7

ENGLISH

10 - TECHNICAL DATA

C.S.I. 25 kW

C.S.I. 35 kW

R.S.I. 25 kW

R.S.I. 35 kW

CH Nominal thermal flow rate

K7

25,00

34,60

25,00

34,60

kcal/h

21.500

29.756

21.500

29.756

.OMINAL THERMAL POWER (8o—/6o—)

K7

24,38

33,74

24,38

33,74

kcal/h

20.963

29.012

20.963

29.012

.OMINAL THERMAL POWER (5o—/3o—)

K7

26,20

36,50

26,20

36,50

kcal/h

22.532

31.393

22.532

31.393

Reduced thermal flow rate (G20/G31)

K7

2,50/4,50

3,50/6,20

2,50/4,50

3,50/6,20

kcal/h

2.150/3.870

3.010/5.332

2.150/3.870

3.010/5.332

2EDUCED THERMAL POWER (8o—/6o—) ('2o/'31)

K7

2,49/4,47

3,41/6,04

2,49/4,47

3,41/6,04

kcal/h

2.144/3.847

2.929/5.193

2.144/3.847

2.929/5.193

2EDUCED THERMAL POWER (5o—/3o—)('2o/'31)

K7

2,69/4,82

3,71/6,57

2,69/4,82

3,71/6,57

kcal/h

2.309/4.145

3.188/5.647

2.309/4.145

3.188/5.647

Nominal thermal flow rate Range Rated heat (Cn)

K7

25,00

34,60

25,00

34,60

kcal/h

21.500

29.756

21.500

29.756

Minimal thermal flow rate Range Rated (Qm) (G20/G31)

K7

2,50/4,50

3,50/6,20

2,50/4,50

3,50/6,20

kcal/h

2.150/3.870

3.010/5.332

2.150/3.870

3.010/5.332

DHW*

Nominal thermal flow rate

K7

25,00

34,60

-

-

kcal/h

21.500

29.756

-

-

Maximum thermal power**

K7

25,00

34,60

-

-

kcal/h

21.500

29.756

-

-

Reduced thermal flow rate** (G20/G31)

K7

2,50/4,50

3,50/6,20

-

-

kcal/h

2.150/3.870

3.010/5.332

-

-

Minimum thermal power** (G20/G31)

K7

2,50/4,50

3,50/6,20

-

-

kcal/h

2.150/3.870

3.010/5.332

-

-

7ORKING EFlCIENCY 0N MAX

- 0N

MIN (8o-6o—)

%

97,5-99,7 ('31= 99,4)

97,5-97,3 ('31=97,4)

97,5-99,7 ('31= 99,4)

97,5-97,3 ('31=97,4)

7ORKING EFlCIENCY 3o% (47— RETURN)

%

102,8

103,1

102,8

103,1

Combustion efficiency

%

97,8

97,7

97,8

97,7 7OR

KING EFlCIENCY 0N MAX

- 0N

MIN (5o-3o—)

%

1o4,8-1o7,4 ('31= 1o7,1)

1o5,5-1o5,9 ('31=1o5,9)

1o4.8-1o7.4 ('31= 1o7,1)

1o5,5-1o5,9 ('31=1o5,9)

7ORKING EFlCIENCY 3o% (3o— RETURN)

%

109,4

108,0

109,4

108,0

!VER

AGE 2ANGE 2ATED 0N PERFORMANCE (8o—/6o— )

%

98,1

97,6

98,1

97,6

!VER

AGE 2ANGE 2ATED 0N PERFORMANCE (5o—/3o— )

%

105,2

106,1

105,2

106,1

Electric power

7

88

116

88

116

Category

II2H3P

II2H3P

II2H3P

II2H3P

Supply voltage

V - Hz

230-50

230-50

230-50

230-50

Protection level

IP

X5D

X5D

X5D

X5D

Chimney losses with burner off-on

%

0,10-2,16

0,08-2,30

0,10-2,16

0,08-2,30

CH operation

Maximum pressure - temperature

bar

3-90

3-90

3-90

3-90

Minimum pressure for standard working/operating

bar

0,25-0,45

0,25-0,45

0,25-0,45

0,25-0,45

Selection field of CH water temperature

—#

20-80

20-80

20-80

20-80

Pump maximum head available for system

mbar

320

320

320

320

capacity

l/h

1000

1000

1000

1000

Membrane expansion tank

l

10

14

10

10

Expansion vessel pre-charge (CH)

bar

1 1 1

1

DHW operation*

Maximum pressure

bar

6 6 -

-

Minimum pressure

bar

0,20

0,20 -

-

Hot water quantity

T 25— #

l/min

14,3

19,8 -

-

T 3o— #

l/min

11,9

16,5 -

-

T 35— #

l/min

10,2

14,2 -

- $(7 MINIMUM CAPACITY

l/min

2 2 -

-

3ELECTION lELD OF $(7 TEMPERATURE

—#

35-60

35-60 -

-

&LOW REGULATOR

l/min

10

11 -

-

Gas pressure

Natural gas pressure (G20)

mbar

20

20

20

20

LPG pressure (G31)

mbar

37

37

37

37

Hydraulic connections

CH input-output

Ø

3/4”

3/4”

3/4”

3/4”

$(7 INPUT-OUTPUT ('2%%. #.3.).)

Ø

1/2”

1/2” -

- 7

ATER TANK DELIV

ERY-RETURN

('2%%. 2.3

.).)

Ø

- - 3/4”

3/4”

Gas input

Ø

3/4”

3/4”

3/4”

3/4”

Boiler dimensions and weight

Height

mm

845

845

845

845

7IDTH

mm

453

453

453

453

Depth

mm

358

358

358

358 7EIGHT

kg

44

45

44

45

Fan performance

&AN RESIDUAL HEAD WITHOUT PIPES

Pa

98

199

98

199

Flow rates (G20)

Air capacity

Nm3/h

31,135

43,090

31,135

43,090

&UMES CAPACITY

Nm3/h

33,642

46,561

33,642

46,561

Mass flow (max-min)

gr/s

11,282-1,070

15,614-1,498

11,282-1,070

15,614-1,498

Fume exhaustion and air suction concentric pipe

Diameter

mm

60-100

60-100

60-100

60-100

Max lenght

m

7,85

7,85

7,85

7,85

,OSS FOR A 9o—/45— BEND

m

1,6/1,3

1,6/1,3

1,6/1,3

1,6/1,3

Hole in the wall

mm

105

105

105

105

Diameter

mm

80-125

80-125

80-125

80-125

Max lenght

m

14,85

14,85

14,85

14,85

,OSS FOR A 9o—/45— BEND

m

1,5/1

1,5/1

1,5/1

1,5/1

Hole in the wall

mm

130

130

130

130

Fume exhaustion and air suction separated pipe

Diameter

mm

80

80

80

80

Max lenght

m

32+32

40+40

32+32

40+40

,OSS FOR A 9o—/45— BEND

1,5/1

1,5/1

7

Page 8

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

10

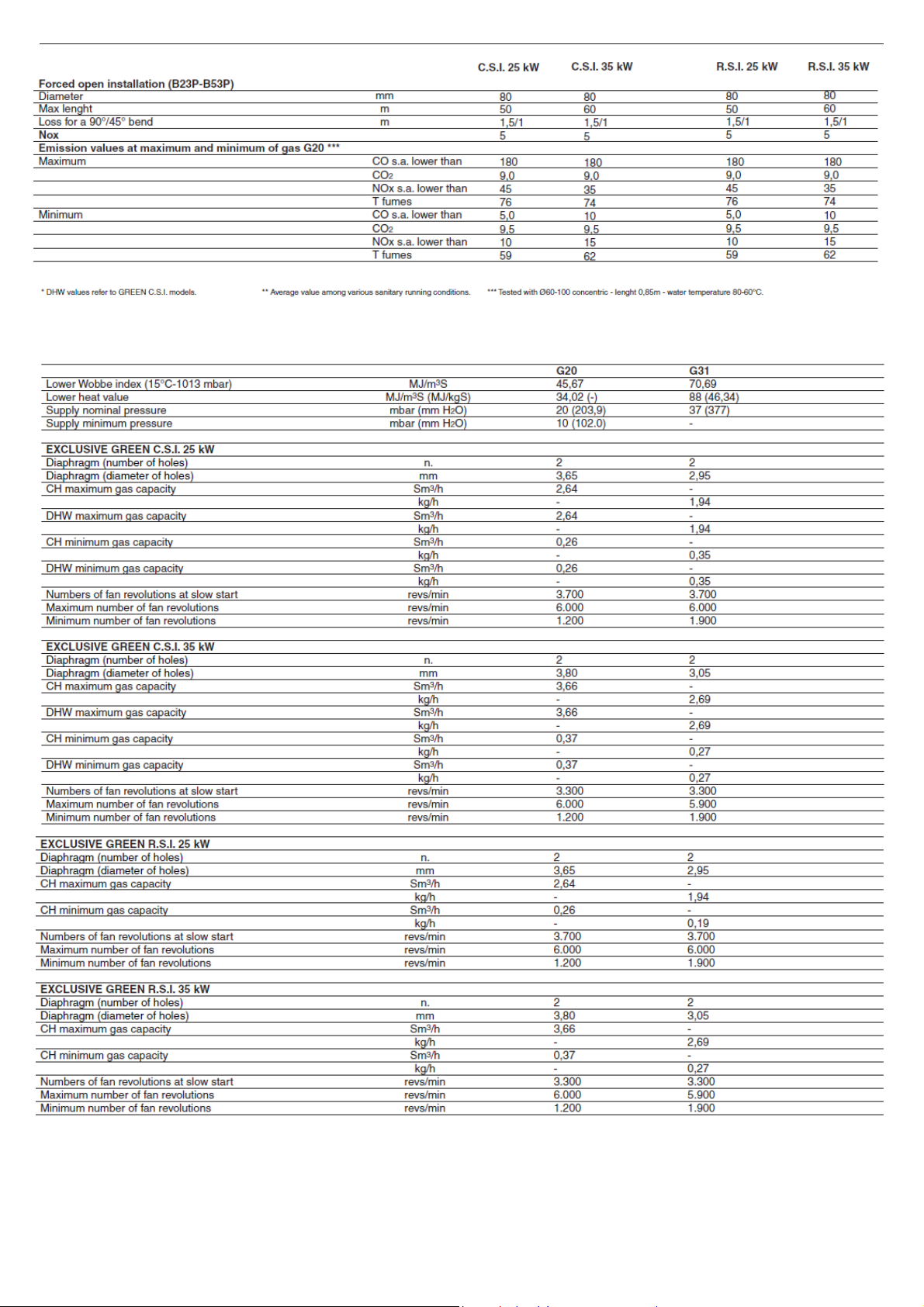

Forced open installation (B23P-B53P)

C.S.I. 25 kW

C.S.I. 35 kW

R.S.I. 25 kW

R.S.I. 35 kW

Diameter

mm

80

80

80

80

Max lenght

m

50

60

50

60

,OSS FOR A 9o—/45— BEND

m

1,5/1

1,5/1

1,5/1

1,5/1

Nox

5

5

5 5

Emission values at maximum and minimum of gas G20 ***

-AXIMUM

#/ S.A.

LOWER THAN

180

180

180

180

#/

2

9,0

9,0

9,0

9,0

./X S.A.

LOWER THAN

45

35

45

35

T fumes

76

74

76

74

-INIMUM

#/ S.A.

LOWER THAN

5,0

10

5,0

10

#/

2

9,5

9,5

9,5

9,5

./X S.A.

LOWER THAN

10

15

10

15

T fumes

59

62

59

62

11 - MULTIGAS TABLE

G20

G31

,OWER 7OBBE INDEX

(15—#-1o13 MBAR)

MJ/m3S

45,67

70,69

Lower heat value

MJ/m3S (MJ/kgS)

34,02 (-)

88 (46,34)

Supply nominal pressure

mbar (mm

H2/)

20 (203,9)

37 (377)

Supply minimum pressure

mbar (mm

H2/)

10 (102.0)

-

EXCLUSIVE GREEN C.S.I. 25 kW

Diaphragm (number of holes)

n.

2 2

Diaphragm (diameter of holes)

mm

3,65

2,95

CH maximum gas capacity

Sm3/h

2,64 -

kg/h

- 1,94

$(7 MAXIMUM GAS CAPACITY

Sm3/h

2,64 -

kg/h

- 1,94

CH minimum gas capacity

Sm3/h

0,26 -

kg/h

- 0,35

$(7 MINIMUM GAS CAPACITY

Sm3/h

0,26 -

kg/h

- 0,35

Numbers of fan revolutions at slow start

revs/min

3.700

3.700

Maximum number of fan revolutions

revs/min

6.000

6.000

Minimum number of fan revolutions

revs/min

1.200

1.900

EXCLUSIVE GREEN C.S.I. 35 kW

Diaphragm (number of holes)

n.

2 2

Diaphragm (diameter of holes)

mm

3,80

3,05

CH maximum gas capacity

Sm3/h

3,66 -

kg/h

- 2,69

$(7 MAXIMUM GAS CAPACITY

Sm3/h

3,66 -

kg/h

- 2,69

CH minimum gas capacity

Sm3/h

0,37 -

kg/h

- 0,27

$(7 MINIMUM GAS CAPACITY

Sm3/h

0,37 -

kg/h

- 0,27

Numbers of fan revolutions at slow start

revs/min

3.300

3.300

Maximum number of fan revolutions

revs/min

6.000

5.900

Minimum number of fan revolutions

revs/min

1.200

1.900

EXCLUSIVE GREEN R.S.I. 25 kW

Diaphragm (number of holes)

n.

2 2

Diaphragm (diameter of holes)

mm

3,65

2,95

CH maximum gas capacity

Sm3/h

2,64 -

kg/h

- 1,94

CH minimum gas capacity

Sm3/h

0,26 -

kg/h

- 0,19

Numbers of fan revolutions at slow start

revs/min

3.700

3.700

Maximum number of fan revolutions

revs/min

6.000

6.000

Minimum number of fan revolutions

revs/min

1.200

1.900

EXCLUSIVE GREEN R.S.I. 35 kW

Diaphragm (number of holes)

n.

2 2

Diaphragm (diameter of holes)

mm

3,80

3,05

CH maximum gas capacity

Sm3/h

3,66 -

kg/h

- 2,69

CH minimum gas capacity

Sm3/h

0,37 -

kg/h

- 0,27

Numbers of fan revolutions at slow start

revs/min

3.300

3.300

Maximum number of fan revolutions

revs/min

6.000

5.900

Minimum number of fan revolutions

revs/min

1.200

1.900

8

* $(7 V

ALUES REFER TO '2%%. #.3.). MODELS

.

** !VER

AGE V

ALUE AMONG VARIOUS SANITARY RUNNING CONDITIONS.

*** 4

ESTED WITH

Œ6o-1oo

CONCENTRIC -

LENGHT o,85M

- WATER TEMPER

ATURE 8o-6o—#

.

Page 9

ENGLISH

11

Heating water circuit

temperature selector

button

/.-/&&-2%3%4 FUN-

ction selector

button

temperature se-

lector

9

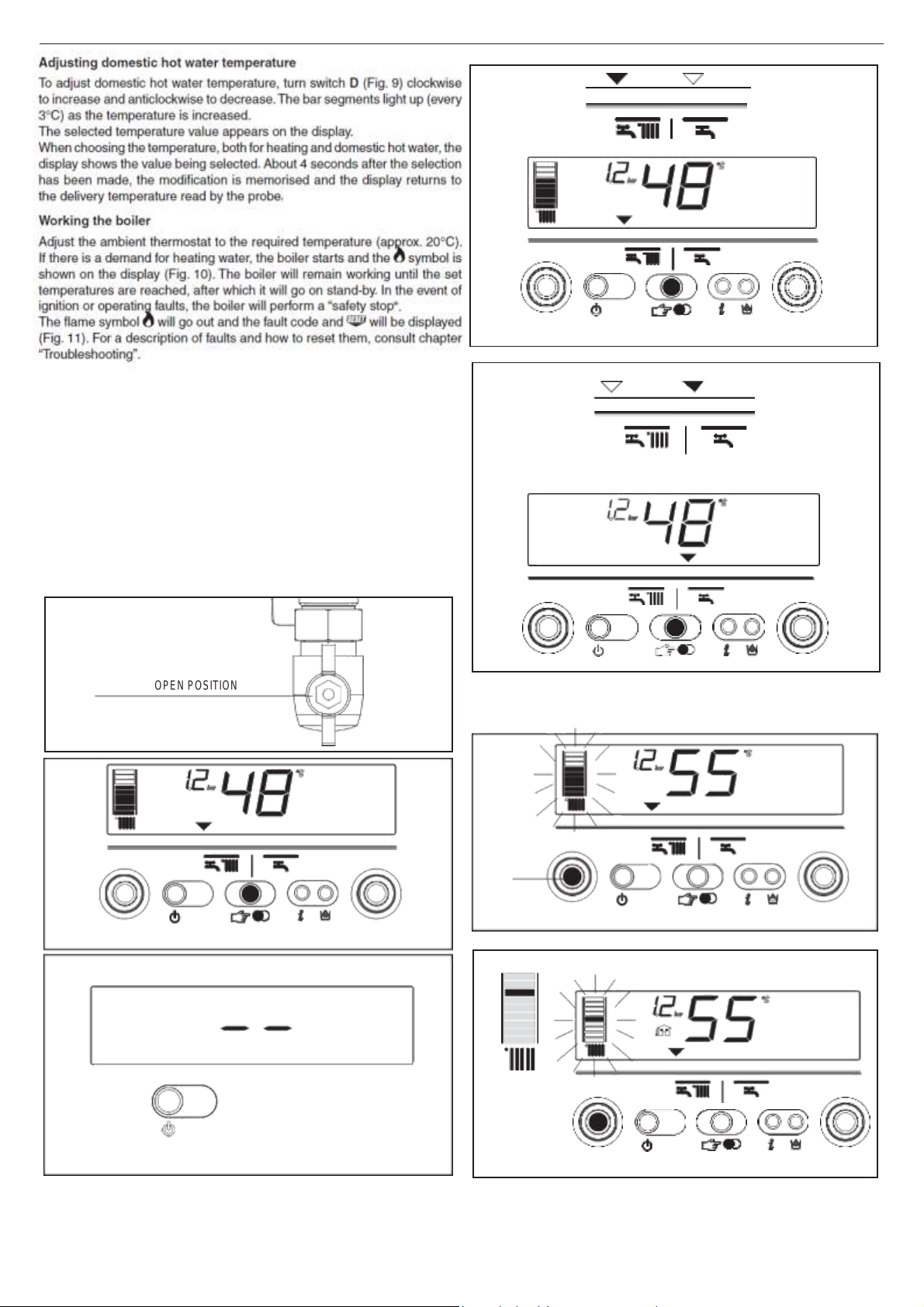

START-UP AND OPERATION (C.S.I. model)

The boiler produces heating and domestic hot water. The control panel contains the main boiler control and management functions.

Description of commands Description of display symbols

graduated heating water temperature scale with heating function symbol

/PERATING MODE BUTTON

Heating water temperature selector: sets the heating water temperature.

Domestic hot water temperature selector: sets the domestic hot water

temperature.

Function key:

/. - THE BOILER IS ELECTRICALLY POWERED AND WAITING FOR OPERATING REQUESTS (

/&& - THE BOILER IS ELECTRICALLY POWERED BUT WILL NOT RESPOND TO OPERATING

requests

RESET - resets the boiler following a fault

Operating mode button: button allows to choose the desired ope-

rating mode: pressing it, the indicator “function selector” moves to:

(winter) or (summer)

Info button: shows a sequence of information concerning the operating

status of the machine.

Filling button: pushing it, the boiler automatically fills the system until the

pressure reaches 1 to 1.5 bar.

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the lower part

of the boiler

- OPEN THE GAS TAP BY TURNING IT ANTI-CLOCKWISE (&IG. 1)

- power the boiler.

7HEN POWERED, THE BOILER PERFORMS A TEST SEQUENCE AND A SERIES OF NUMBERS

and letters are shown on the display.

If the test is successful the boiler is ready to work about 4 seconds after

the cycle ends.

After being powered, the boiler begins an automatic vent cycle lasting ap-

proximately 2 minutes. The display indicates “3&” and the “function selection

indicators” light up in sequence. Press button to interrupt the

automatic vent cycle.

4HE DISPLAY WILL LOOK LIKE &IG. 2.

If the test is unsuccessful, the boiler will not work and a “0” will flash on the

display.

In this case, contact the Technical Assistance Centre.

The boiler turns on in the status it was in before it was switched off: if

the boiler was in the winter mode when it was switched off, it will turn

ON AGAIN IN THE WINTER MODE. )F IT WAS IN THE /&& MODE, THE DISPLAY WILL

SHOW TWO SEGMENTS IN THE CENTRAL AREA (&IG. 3). 0RESS THE button to

enable operation.

Choose the desired operating mode by pressing button, until the

symbol moves to:

WINTER

SUMMER

WINTER function (Fig. 4)

7ITH THE SELECTOR IN THIS POSITION, THE HEATING WATER AND THE DOMESTIC HOT

WATER FUNCTIONS ARE ACTIVATED. &UNCTION 3.!.2.! IS ENABLED IN THIS POSITION

Domestic

hot water

Setting parameters

selector

graduated domestic hot water temperature scale with domestic hot water

function symbol

fault symbol

reset symbol

pressure value

external sensor connection

heating/domestic hot water temperature

or

fault symbol (e.g. 10 - no flame)

function selector (turned to the chosen operating mode:

winter or summer

burner operating symbol

anti-freeze function active symbol

system filling function symbol

fill symbol

(see chapter “Boiler functions”).

SUMMER function (Fig. 5)

7ITH THE SELECTOR IN THIS POSITION, JUST THE TRADITIONAL DOMESTIC HOT WATER

function is activated

Adjusting heating water temperature

Turning the selector A (&IG. 6), AFTER HAVING POSITIONED THE SELECTOR MODE ON

winter

Turn clockwise to increase the temperature and anticlockwise to decrease.

4HE BAR SEGMENTS LIGHT UP (EVERY 5—#) AS THE TEMPERATURE IS INCREASED. 4HE

selected temperature value appears on the display.

)F YOU ENTER THE 3.!.2.!. ADJUSTMENT (FRO

ting water temperature, the symbol and the graduated scale start flashing.

Adjusting heating water temperature with an external sensor

connected

7HEN AN EXTERNAL PROBE IS CONNECTED, THE VALUE OF THE DELIVERY TEMPERATURE

is automatically chosen by the system which rapidly adjusts ambient tem-

perature to the changes in external temperature. Just the central segment

OF THE BAR IS ILLUMINATED (&IG. 7).

To increase or decrease the temperature with respect to the value automa-

tically calculated by the electronic board, turn the heating water selector

clockwise to increase and anticlockwise to decrease. The bar segments

light up (at every comfort level), correction tolerance lies between - 5 and +

5 COMFORT LEVELS (&IG. 7). 7HEN CHOOSING THE LEVEL OF COMFORT, THE DIGIT AREA

of the display shows the required level of comfort while the bar shows the

matcHING SEGMENT (&IG. 8).

, it is possible to regulate the heating water temperature.

M 55 TO 65—#) WHILE SELECTING THE HEA-

Page 10

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

12

4

7

+4/5˚C

+3˚C

+2˚C

+1˚C

0˚C

-1˚C

-2˚C

-3˚C

-4/5˚C

5

1

OPEN POSITION

10

Adjusting domestic hot water temperature

To adjust domestic hot water temperature, turn switch D (&IG. 9) CLOCKWISE

to increase and anticlockwise to decrease. The bar segments light up

3—#) AS THE TEMPERATURE IS INCREASED.

The selected temperature value appears on the display.

7HEN CHOOSING THE TEMPERATURE, BOTH FOR HEATING AND DOMESTIC HOT WATER, THE

display shows the value being selected. About 4 seconds after the selection

has been made, the modification is memorised and the display returns to

the delivery temperature read by the probe.

Working the boiler

Adjust the ambient thermostat to the required temperature (approx. 2o—

#). If there is a demand for heating water, the boiler starts and the symbol

is shown on the display (&IG. 1o). The boiler will remain working until the

set temperatures are reached, after which it will go on stand-by. In the

event of ignition or operating faults, the boiler will perform a “safety stop

The flame symbol will go out and the fault code and will be displayed

(&IG. 11). &OR A DESCRIPTION OF FAULTS AND HOW TO RESET THEM, CONSULT CHAPTER

“Troubleshooting”.

2

3

6

A

Page 11

Page 12

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

12

10

D

11

12a

12b

Tap closed

11

SWITCHING OFF

Switching off for short periods

&OR BRIEF ABSENCES PRESS THE

SHOW TWO SEGMENTS IN THE CENTRAL AREA (&IG. 12A). 7HEN THE BOILER REMAINS

powered with the gas tap open, it is protected by the following systems:

-

anti-freeze: when the temperature of the water in the boiler falls below safety

values, the circulator and the burner work at minimum power to increase

the water temperature to a safe value (35—#). The symbol lights up on

the display.

-

circulator anti-block: one operating cycle is performed every 24 hours.

Switching off for long periods

&OR PROLONGED ABSENCES PRESS THE BUTTON TO SWITCH OFF THE BOILER (&IG.

3). The display will show two segments in the central area. Turn the main

switch to “off”.

4URN OFF THE GAS TAP UNDER THE BOILER BY TURNING IT CLOCKWISE (&IG. 12B).

In this case, the anti-freeze and anti-block systems are disabled. Empty

the water circuit or suitably protect it with a good make of anti-freeze.

button to switch off the boiler. The display will

Page 13

ENGLISH

13

INF2 list

Step

Description

Display

2 digits

Display

4 digits

1 Input probe temperature

xx

01 —#

2 Return probe temperature

xx

02 —#

3 &IRST SANITARY PROBE TEMPERATURE (*)

xx

03 —# 4

Not used in this model

xx

Cond

—# 5

FUMES PROBE TEMPERATURE

xx (**)

05 6

Second heating system probe temperature

xx

06 —# 7

Domestic hot water flow rate (***)

xx

07

l/min

8

Ventilator speed /100

xx

&!. 9

Not used in this model

xx

09

10

Not used in this model

xx

10

11

Exchanger cleaning counter status

bH

xxxx

12-19

Historic alarm codes

xx

HIS0-HIS7

Note (*): if the SAN probe is faulty or disconnected, in the place of the value “- -” is displayed.

(**): if the display also shows the dot (.), the temperature of the fumes probe is 100+displayed value

(***):

IF THE mOW RATE IS

>1o

L/MIN # !

X L/MIN WHERE ! = 1o n " = 11 n # = 12

APPEARS ON THE DISPLAY

13

14

16

12

Boiler functions

Semi-automatic filling

The boiler features a semi-automatic filling device which turns on by pressing

the

button when the corresponding symbol is shown on the display

(&IG. 13).

If this condition occurs it means that the system is incorrectly pressurised

though the boiler will continue to work regularly. Press the circuit filling button

Press the circuit filling button a second time to interrupt the filling sequen-

ce. During filling, the drops of the circuit filling symbol and the growing

pressure value appear on the display in a cascade sequence.

After filling, the symbol is displayed for a few moments and then turns off.

Note

$URING lLLING, THE BOILER DOES NOT PERFORM OTHER FUNCTIONS. &OR EXAMPLE, IF

there is a request for domestic hot water, the boiler is unable to provide it

until filling has finished.

Note

If circuit

(&IG. 14); IF IT FALLS BELOW A MINIMUM SAFETY VALUE (o.3 BAR), FAULT CODE 41

APPEARS ON THE DISPLAY (&IG. 15) FOR A CERTAIN TIME, FOLLOWING WHICH, IF THE

fault persists, fault code 40 is displayed (see chapter on “Troubleshooting”).

In the event of fault 40, press to reset and then to start filling the circuit.

After fault 40 has been resolved, the boiler will carry out an automatic vent

CYCLE LASTING FOR ABOUT 2 MINUTES: THE WORDING h3&v WILL APPEAR ON THE DISPLAY

(&IG. 16) AND THE hFUNCTION SELECTION INDICATORSv will light up in sequence.

Press button to stop the automatic vent cycle.

to start-up the filling sequence.

pressure

reaches 0.6 bar, the

pressure

value flashes on the display

If you have to fill the system several times, contact the Technical Service

Centre to check whether the heating circuit is watertight (see if there are

15

any leaks).

Information

Press , THE DISPLAY TURNS OFF AND JUST THE WORD )N&/ APPEARS (&IG. 17). 0RESS

the button to view operating information. Press the button again to move

on to the next piece of information. If the button is not pressed, the system

automatically exits the function.

INF2

It is possible to display information, which may be useful for the Technical Assistance Centre, by pressing the button

appears on the display.

for 10 seconds: the code “INF2”

Page 14

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

14

21

20

17

18

19

13

Info 0 -

SHOWS THE WORD )N&/ (&IG. 17)

Info 1 - only with the external probe connected, displays external temperature

(E.G. 12—#) (&IG. 18). 4HE VALUES SHOWN ON THE DISPLAY RANGE BETWEEN -

3o—# AND 35—#. "EYOND THESE VALUES THE DISPLAY SHOWS h- -v

Info 2 -

SHOWS CIRCUIT PRESSURE (&IG. 19)

Info 3 -

SHOWS THE SET HEATING TEMPERATURE (&IG. 2o)

Info 4 -

SHOWS THE SETTED TEMPERATURE (ONLY WATER TANK WITH SENSOR, &IG. 21)

Info 5 - displays the set heating temperature, in reference to the second

circuit, only if it is connected.

S.A.R.A. function (Fig. 21)

If the “winter” mode is selected, the S.A.R.A. (Automatic Ambient

Adjustment System) function can be activated.

Turn the heating water temperature selector to a temperature ranging

55 AND 65—#.

The S.A.R.A. self-adjustment system activates: depending on the temperature

set on the ambient thermostat and the time taken to reach it, the boiler au-

tomatically adjusts the heating water temperature to reduce operating times,

thereby increasing operating comfort and energy saving.

21

Page 15

ENGLISH

15

FAULT

Alarm ID

Symbol

Symbol

&,!-% &!),52%

",/#+

($) 10

YES ./

0!2!3)4% &,!-% (4)

11

./ YES

2%-!44%-04 ). 02/'2%33 (4) 12

./ ./

MINIMUM GAS INPUT PRESSURE (T)

13

./ YES

MINIMUM GAS INPUT PRESSURE (D)

14

YES ./

,)-)4 4(%2-/34!4 ($)

20

YES ./

3(/24

#)2#5)4 &5-%3 02/"% ($) 21

YES

YES

-!8)-5-

4%-0%2!452% ).054 02/"% ($)

24

YES ./

-!8)-5-

4%-0%2!452% ).054 02/"% (4)

25

./ YES

-!8)-5-

4%-0%2!452% 2%452. 02/"% ($)

26

YES ./

-!8)-5-

4%-0%2!452% 2%452. 02/"% (4)

27

./ YES

2%452.-).054 02/"% $)&&%2%.4)!, ($)

28

YES

YES

&5-%3 02

/"% /

6%2

4%-0%2!

452% (D)

29

YES

YES

6%.4),!4/2

(CYCLE START)

($)

34

YES ./

6%.4),!4/2 ). #9#,%

(LOW NUMBER OF REVOLUTIONS)

($)

37

YES

YES

).35&&)#)%.4 3934%- 02%3352% ($*)

40

YES ./

).35&&)#)%.4 3934%- 02%3352% (4*)

41

./ YES

7!4%2 02%3352% 42!.3$5#%2 ($) 42

YES

YES

%,%#42/.)#

"/!2$

($) 50-59

YES

YES

3!.)4!29 02/"%

1 (4—)

60

./ YES

3(/24 #)2#5)4//0%. 02)-!29 02/"% ($)

70

YES

YES

-!8)-5-

4%-0%2!452% ).054 02/"% (4)

71

./ ./

3(/24 #)2#5)4//0%. 2%452. 02/"% ($)

72

YES

YES

3%#/.$ 3934%- 7)4(/54 (%!4).' 02/"%

75

./ YES

,/7

4%-0%2!

452% 4(%2-/34!4 (4) 77

./ YES

).054/2%452. $)&&%2%.4)!, (4) 78

./ YES

).054/2%452. $)&&%2%.4)!, ($) 79

YES ./

3934%- !./-!,9

($)

80

YES

YES

3934%- !./-!,9

(4)

81

./ YES

3934%- !./-!,9

($)

82

YES

YES

3934%- !./-!,9

(4)

83

./ YES

CLEAN PRIMARY EXCHANGER (-)

91

./ YES

Temporary

Permanent

14

12

- TROUBLESHOOTING

7HEN A FAULT APPEARS ON THE DISPLAY, THE mAME SYMBOL

SEPAR

ATELY. &OR A

DESCR

IPTION OF THE F

AULTS, CONSULT THE F

goes out, a flashing code is shown and the two symbols and appear either together or

OLLO

WING TABLE.

(D) - Permanent - (T) - Temporary. In this operating status the boiler attempts to eliminate the fault on its own

(°) #.3.). - &AULT IN DOMESTIC HOT WATER CIRCUIT SENSOR - 6o: THE BOILER WORKS REGULARLY BUT DOES NOT ENSURE THE STABILITY OF THE HOT WATER TEMPERATURE WHICH,

HOWEVER, IS DELIVERED AT A TEMPERATURE OF APPROXIMATELY 5o—#. 4HE FAULT CODE IS ONLY DISPLAYED IN STANDBY. 2.3.). - /NLY WITH EXTERNAL WATER TANK

WITH

sensor. The fault code is shown when the boiler is in stand-by.

(*) If these two errors occur, check the pressure indicated on the water gauge. If the pressure is insufficient (< 0,4 bar, red area), proceed with the filling

OPERATIONS DESCRIBED IN THE CHAPTER h&ILLING AND EMPTYING THE SYSTEMSv. )F THE SYSTEM'S PRESSURE IS SUFlCIENT (> o,6 BAR, BLUE AREA) THE MALFUNCTION IS

caused by a lack of water circulation. Contact the Technical Assistance.

If alarm 21 code is temporarily displayed at ignition (with flame burning) this does not indicate a fault. Check the above table if the alarm persists.

Resetting faults

7AIT

FOR

ABOut

Then proceed as follows:

1)

Viewing just the symbol

If disappears, it means that an operating fault has been discovered which

the boiler is attempting to solve on its own (temporary stoppage). If the boiler

does not resume normal operation, two things may happen:

Case A (Fig. A)

disappears, the symbol and a different alarm code appear. In this

case, proceed as described in point 2.

Case B (Fig. B)

and a different alarm code are displayed together with .

In this case, proceed as described in point 3.

Case C

Alarm 91 - Contact the Technical Assistance

The boiler has a self-diagnosis system which, on the basis of the hours to-

talised in particular operating conditions, signals the need for maintenance

or cleaning of the primary exchanger (alarm code 91). After cleaning using

the kit supplied as an accessory, reset the hour counter as follows:

-

disconnect the mains power supply

-

remove the screws and hooks securing the electrical cover

-

remove connector J13 (see wiring diagram)

-

power the boiler and wait for alarm 13 to appear on the display

-

disconnect the power supply and reconnect connector J13

-

put back the electrical cover and restart the boiler

N.B.: perform the counter reset procedure every time the primary exchanger

is thoroughly cleaned or replaced.

10 seconds before resetting operating conditions.

fault

fault

Page 16

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

16

F

G

Temporary

fault

Permanent

fault

15

2)

Viewing just the symbol (Fig. C)

Press the button to reset the appliance. If the boiler starts the ignition

phase and resumes normal operation, it may have stopped by accident.

If these stoppages should continue, contact the Technical Assistance Centre.

3)

Viewing the and symbols (Fig. D)

Contact the Technical Assistance Centre.

Note (C.S.I.)

&AULT IN DOMESTIC HOT WATER CIRCUIT SENSOR - 6o: THE BOILER WORKS REGULARLY BUT

does not ensure the stability of the hot water temperature which, however,

IS DELIVERED AT A TEMPERATURE OF APPROXIMATELY 5o—#. 4HE FAULT CODE IS

ONLY

displayed in standby.

13

- PROGRAMMING PARAMETERS

This boiler incorporates a new generation of electronic boards that, by setting/

modifying operating parameters, allow the boiler to be personalised to satisfy

various system and/or user requirements.The programmable parameters are

shown in the table on the next page.

4HE PARAMETERS MUST BE PROGRAMMED WITH THE BOILER IN THE /&& POSITION.

To do this, press the

During parameter modification operations, the “select functions” button

acts as an ENTER (confirm) button, the button acts as an ESCAPE

(escape) button. If no confirmation is given within 10 seconds, the value

is discarded and returns to the previously set one.

BUTTON UNTIL THE DISPLAY SHOWS h- -v (&IG. %).

Setting the password

Press and hold down the select functions button and the button together

FOR ABOUT 1o SECONDS. 4HE DISPLAY WILL LOOK LIKE &IG. &. %NTER THE PASSWORD FOR

accessing the parameter modifications function by turning the domestic hot

water temperature selector to obtain the required value. The password for

accessing the parameter programming function is located on the back side

of the control panel. Confirm by pressing ENTER.

Modifying parameters

4URN THE DOMESTIC HOT WATER TEMPERATURE SELECTOR (&IG. ') TO SEQUENTIALLY

scroll the two-figure codes of the parameters indicated in the table. After

identifying the parameter you wish to modify, proceed as follows:

- PRESS %.4%2 TO ACCESS THE PARAMETER MODIlCATION FUNCTION. 7HEN %.4%

IS PRESSED, THE PREVIOUSLY SET VALUE STARTS mASHING (&IG.()

-

turn the domestic hot water temperature selector to change the value

-

press ENTER to confirm the new value. The digits stop flashing

-

press ESCAPE to exit.

4HE BOILER RETURNS TO THE h- -v (/&&) STATUS.

To reset, press the

E

BUTTON (&IG. %).

2

Page 17

ENGLISH

23

N.

PARAMETERS DESCRIPTION

PAR.

UNIT OF

MEASURE

MIN

MAX

DEFAULT

(1)

(2)

1

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

1

2

-)./2

0!2!-%4%2

10-16-20-26-30-34-50-70

26 (25K7)-34 (35K7)

3

).35,!4)/.

,%6%,

/& "5),$).'

min

5 20

5

10

$(7 -/$%

1 - Instantaneous

2 - Mini-tank

3 - External water- tank with thermostat

4 - External water- tank with sensor

5 - DS integrated water tank

6 3S integrated water tank

1

11

$(7

#)2#5)4

-!8)-5-

3%4-0/).4

—# 40 60

60

12

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

60

13

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

80

14

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

5

20

(%!4).' -/$%

o - /&&

1 - /.

2 - :ONE VALVES + REMOTE CONTROL PANEL

3 -

#/..%#4 !0

4 - Not used

5 - Not used

6

- #/..%#4 !4/"4

7 2%-/4% #/ .42/,+#/..%#4 !4/"4

8 2%-/4% 0!.%, + :/.% 6!,6%3

1

21

(%!4).'

#)2#5)4

-!8)-5-

3%4-0/).4

—# 40

80

80

22

-).)-5- (%!4).'

3%4

0/).4

C 20

39

20

23

-!8)-5-

(%!4).' 6%.4),!4/2

30%%$

revs/min

G20 G31

25 K7 6o 6o

35 K7 6o 59

MAX

24

-).)-5-

(%!4).' 6%.4),!4/2

30%%$

revs/min

G20 G31

25 K7 12 19

35 K7 12 19

MIN

25

$)&&%2%.4)!,

(%!4).'

0/3)4)6%

—#

2 10

6

26

$)&&%2%.4)!,

(%!4).'

.%'!4)6%

—# 2 10

6

28

-!8 (%!4).'

0/7%2 2%$5#4)/. 4)-%2

min 0

20

15

29

&/2#%$

(%!4).'

3(54

$/7.

4)-%2

min 0

20

5

30

(%!4).'

4)-%2

2%3%4

&5.#4)/.

- o

(./)

1 (YES)

0

31

-!8)-5- (%!4).'

3%4

0/).4

2#(

()) CIRCUIT)

—# 40

80

45

32

-).)-5- (%!4).'

3%4

0/).4

2#(

()) CIRCUIT)

—# 20

39

25

40

$(7 4(%2-/34!4 /0%2!

4).' -/$%

o - /&&

1 - !54/

2 - /.

1

41

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

1

42

3.!.2.!. &5.#4)/.

o - /&&

1 - !54/

1

43

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

1

44

4(%2-/2%'5,!4)/. &5.#4)/.

o - /&&

1 - !54/

1

45

).#,).!4)/. 4(%2-/2%'5,!4)/.

#526%

(/4#)

2,5 40

20

46

4(%2-/2%'5,!4)/. &5.#4)/. 2#(

-

o - /&&

1

- !54/

1

47

).#,).!4)/. 4(%2-/2%'5,!4)/.

#526%

(/4#) 2#(

2,5

40

10

48

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

-

-

50

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

1

51

HEAT REQUEST TYPE CH1 (I circuit)

-

0 1

0

52

HEAT REQUEST TYPE CH2 (II circuit)

-

0 1

0

61

$(7

!.4)&2%%:%

&5.#4)/.

4%-0%2!452%

(/.)

—#

0 10

4

62

(%!4).'

!.4)&2%%:% &5.#. $%,)6%29 4%-0.

(/.)

—#

0 10

6

63

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

6

65

%84%2.!, 3%.3/2 2%!#4)6)49

0 (very fast) 255 (very slow)

20

85

3%-)-!54/-!

4)# &),,).'

0 - Disabled

1 - Enabled

1

86

!54/-!

4)# &),,).' 02%3352% (/.)

bar

0.4 1.0

0.6

87

4()3 0

!2!-%4%2 )3 ./4

53%$ /. 4()3 -/$%,. $/ ./4

-/$)&9

-

90 ADJUSTABLE SPEED PUMP

0 100

41

92 %.!",% 0/34

-#)2#5,!

4)/. &2/-

$(7 4/

(%!

4).'

0 1

0

93 $52!

4)/. /& 0/34

-#)2#5,!

4)/. &2/-

$(7 4/

(%!

4).'

1 255

5

94 05-0

). #/.4).5!,

-/$% #(1 (#)2#5)4 1)

0 1

0

95 05-0

). #/.4).5!,

-/$% #(2 (#)2#5)4 2)

0 1

0

17 16

PROGRAMMABLE PARAMETERS HE C.S.I.

* 4HE VALUE IS EXPRESSED ON THE DISPLAY IN REVS/MIN/1oo (EXAMPLE 3.6oo = 36).

Some default values could be different from the one in the table, dependent on the status of data sheet updating

1

Setted in factory

2

Settede by technical assistan

3

4

5

6

Page 18

EXCLUSIVE GREEN HE C.S.I. - R.S.I.

24

D

17

16 - SETTING THE THERMOREGULATION – OPTIONAL with use of external sensor

Checking the connection with the external probe

!FTER CONNECTING THE EXTERNAL PROBE TO THE BOILER, USE THE ).&/ FUNCTION TO CHECK THAT THE PROBE HAS BEEN AUTOMATICALLY RECOGNISED BY THE TEMPERATURE

control card. Immediately after installation, the value read by the probe may very well be higher then that measured by a reference probe.

%NABLE AND OPTIMISE THE 4(%2-/2%'5,!4)/. FUNCTION BY SETTING THE FOLLOWING PARAMETERS:

PARAMETER

490%

/& "5),$).'

-!8)-5- (%!4).'

-).)-5- (%!4).'

%.!",% 4(%2-/2%'5,!4)/.

&5.#4)/.

/&&3%4 4%-0%2!452% #526%

490% /& (%!4 2%15%34

3%4

3%4

0/).4

0/).4

To access the programming mode, consult “Programming parameters”.

PARAMETER 03. Type of building

3

21

22

44

45

51

In order to calculate delivery temperature, the temperature control system

does not directly use the external temperature value but considers the heat

insulation of the building: in well-lagged buildings, external temperature

variations affect the ambient temperature less than they do in badly-lagged

buildings. Use parameter 3 to set the heat insulation level of the building

according to the following scheme:

Type of building

New Old Hollow Solid

houses houses bricks bricks

A 19 14 12 8

B 20 16 15 11

C 19 15 14 9

D 18 12 10 5

Stones

PARAMETERS 21 and 22. Maximum and minimum delivery

temperature

These two parameters limit the delivery temperature automatically produced

BY THE

4%-0%2!452% #/.42/,

-!8)-5- $%,)6%294%-0%2!452% (-!8)-5- (%!4).' 3%4 0/).4)

while PARAMETER 22 determines MINIMUM DELIVERY TEMPERATURE

(-).)-5- (%!4).'

3%4

PARAMETER 44. Enable thermoregulation function

The connected external temperature probe combined with PARAMETER 44

provides the following operating modes:

%84%2.!, 02/"% #/..%#4%$

CASE THE 4%-0%2!452% #/.42/, FUNCTION IS DISABLED EVEN THOUGH THE

external probe is connected. The temperature read by the external probe

CAN ALWAYS BE VIEWED BY PRESSING THE ).&/ BUTTON. 4HE 4%-0%2!452%

#/.42/, SYMBOLS ARE NOT DISPLAYED.

%84%2.!, 02/"% #/..%#4%$, 0!2!-%4%2

THE 4%-0%2!452% #/.42/, FUNCTION IS ENABLED. 4HE TEMPERATURE READ

BY THE EXTERNAL PROBE AND THE 4%-0%2!452% #/.42/, SYMBOLS CAN BE

VIEWED BY PRESSING THE ).&/ BUTTON.

4HE 4%-0%2!452% #/.42/, FUNCTION CANNOT BE ENABLED UNLESS THE

external probe has been fitted and connected. In this case, PARAMETER

44 is ignored and has no effect on boiler operation.

PARAMETER 45. Choosing the offset temperature curve (graph 1)

The offset heating curve maintains a theoretical ambient temperature of

2o—# AT EXTERNAL TEMPERATURES RANGING FROM +2o—# TO -2o—#. 4HE CHOICE

OF

the curve depends on the rated minimum external temperature (on the ge-

ographical area, therefore) and the rated delivery temperature (on the type

of system, therefore) and must be carefully calculated by the fitter using the

following formula:

0. 45 = 1o X

FUNCTION.

0/).4).

AND

0!2!-%4%2

rated delivery T - 20 20-

rated min. external T

0!2!-%4%2 21

44 = o

44 = 1

(/.)

DETERMINES

(/&&)

IN THIS

IN THIS CASE

AVAILABLE IN THE PROGRAMMING MODE