Beretta EXCLUSIVE GREEN HE 25 B.S.I., EXCLUSIVE GREEN HE 35 B.S.I. Installer And User Manual

EXCLUSIVE

BOILER

GREEN HE

25 B.S.I.

35 B.S.I.

EN

INSTALLER AND USER MANUAL

ES

MANUAL PARA EL INSTALADOR Y EL USUARIO

HU

BESZERELÉSI ÉS FELHASZNÁLÓI KÉZIKÖNYV

RO

MANUAL DE INSTALARE ŞI UTILIZARE

SL

PRIROČNIK ZA MONTAŽO IN UPORABO

PT

MANUAL DO USUÁRIO-INSTALADOR

FR

MANUEL D'INSTALLATION ET D'UTILISATION

PL

INSTRUKCJA OBSŁUGI, INSTALACJI

I KONSERWACJI KOTŁA GAZOWEGO

2

EXCLUSIVE BOILER GREEN HE B.S.I.

0694

0694BU1240

EXCLUSIVE BOILER GREEN HE B.S.I. boiler complies

with basic requirements of the following Directives: Gas

directive 2009/142/EEC; Yield directive 92/42/EEC; Electromagnetic compatibility directive 2004/108/EEC; Lowvoltage directive 2006/95/EEC; Regulation 677 for condensation boilers. Thus, it is EC-marked

EN

RANGE RATED

This boiler is adjustable to the heat required by the installation; you can in fact set the maximum fl ow rate when the boiler works

on heating. See the “Adjustments” section for calibration.

Once you have set your fl ow rate (PARAMETER 23 for maximum heating), register the value in the special table given here below.

Use this set value as a reference for future controls and adjustments

Output set kW

Date

Fan speed r.p.m.

EN

La caldera EXCLUSIVE GREEN HE B.S.I. cumple con los

requisitos básicos de las siguientes Directivas: Directiva de

gas 2009/142/CEE; Directiva de rendimiento 92/42/CEE;

Directiva Compatibilidad Electromagnética 2004/108/CEE

Directiva Baja Tensión 2006/95/CEE; Norma 677 para calderas de condensación. Por lo tanto, tiene el marcado CE

ES

RANGO DE FUNCIONAMIENTO

Esta caldera se regula al calor requerido por la instalación; de hecho, se puede establecer el caudal máximo cuando la caldera

funciona en calefacción. Ver la sección “Ajustes” para conocer la calibración.

Una vez que se haya establecido el caudal (PARÁMETRO 23 para máxima calefacción), registrar el valor en la siguiente tabla

especial. Utilizar este valor como referencia para controles y ajustes futuros

Salida establecida kW

Fecha

Velocidad del ventilador rpm

ES

EXCLUSIVE BOILER GREEN HE 25 B.S.I. spełnia

podstawowe wymagania następujących dyrektyw

: Urządzenia spalające paliwa gazowe 2009/142/

WE; Sprawność energetyczna kotłów wodnych 92/42/

EWG; Kompatybilność energetyczna 2004/108/EC;

Rozporządzenie dot. niskiego napięcia 2006/95/WE;

Rozporządzenia dot. Kotłów kondensacyjnych EN 677; I w

związku z powyższym posiada znak CE

PL

Centrala EXCLUSIVE BOILER GREEN HE B.S.I. îndeplineşte cerinţele de bază prevăzute de următoarele directive: Directiva pentru gaze 2009/142/CEE; Directiva pentru

randament 92/42/CEE; Directiva de compatibilitate electromagnetică 2004/108/CEE; Directiva de joasă tensiune

2006/95/CEE; Reglementarea 677 pentru centralele cu

condensaţie. Implicit, poartă marcajul CE

RO

EXCLUSIVE BOILER GREEN HE B.S.I. kotel izpolnjuje

bistvene zahteve naslednjih direktiv: Direktiva o plinskih napravah 2009/142/EGS; Direktiva o izkoristkih 92/42/EGS;

Direktiva o elektromagnetni združljivosti 2004/108//ES; Direktiva o nizkonapetostnih napravah 2006/95/EGS; Pravilnik 677 za kondenzacijske kotle. Zato ima oznako CE.

SL

A caldeira EXCLUSIVE BOILER GREEN HE B.S.I. atende

às exigências básicas das seguintes Directivas: Directiva

de gás 2009/142/CEE; Directiva de rendimento 92/42/CEE;

Directiva Compatibilidade Electromagnética 2004/108/

CEE; Directiva Baixa tensão 2006/95/CEE; Regulação 677

para caldeiras de condensação. Desse modo, contém a

marca CE

PT

La CHAUDIÈRE EXCLUSIVE GREEN HE B.S.I. respecte

les conditions requises de base des Directives suivantes :

Directive sur le gaz 2009/142/CEE ; Directive sur le rendement 92/42/CEE ; Directive sur la compatibilité électromagnétique 2004/108/CEE ; Directive basse tension 2006/95/

CEE ; Réglementation 677 pour les chaudières à condensation. Donc, elle est marquée CE.

FR

A EXCLUSIVE BOILER GREEN HE B.S.I. kazán megfe-

lel a következő irányelvek alapvető követelményeinek: Gáz

irányelv 2009/142/EEC; Melegvízkazánokról szóló 92/42/

EGK irányelv; Elektromágneses összeférhetőségről szóló

2004/108/EK irányelv Kisfeszültségű berendezésekről szóló 2006/95/EK irányelv Kondenzációs kazánokra vonatkozó

677 sz. szabályozás. Így rendelkezik CE-jellel

HU

3

EXCLUSIVE BOILER GREEN HE B.S.I.

ZAKRES REGULACJI MOCY

Kocioł ten można dostosować do wymagań systemu centralnego ogrzewania, ponieważ istnieje możliwość obniżenia maksymalnej mocy na c.o. W tym celu należy zapoznać się z rozdziałem Regulacje”

W przypadku zmiany wartości mocy maksymalnej (parametr 23) należy umieścić aktualną wartość w tabeli znajdującej się poniżej.

Jest to bardzo istotne w przypadku wykonywania przeglądów urządzenia.

Nastawiony zakres mocy kotła na c.o. kW

Data

Przy prędkości wentylatora w funkcji c.o. r.p.m.

PL

RANGE RATED

Centrala poate fi reglată la nivelul de căldură necesar în instalaţie; astfel, puteţi seta debitul maxim atunci când centrala

funcţionează pe încălzire. Consultaţi secţiunea „Reglări” pentru calibrare.

După setarea debitului (PARAMETRUL 23 pentru încălzire maximă), înregistraţi valoarea în tabelul special de mai jos.

Utilizaţi această valoare setată ca referinţă pentru controale şi reglări viitoare

Reglare putere termică kW

Data

Turaţie ventilator r.p.m.

RO

RANGE RATED

Ta kotel se regulira glede na potrebe ogrevalnega sistema po toploti; ko kotel deluje v ogrevalnem sistemu, lahko nastavite maksimalno vrednost pretoka. Za umerjanje glejte odsek “Nastavitve”.

Ko ste pretok nastavili (PARAMETER 23 za maksimalno ogrevanje), vrednosti vpišite v posebno tabelo tu spodaj.

Te vrednosti uporabljajte kot referenčne vrednosti med bodočimi pregledi in nastavljanji

Izhodna moč kW

Datum

Hitrost ventilatorja vrt/min

SL

RANGE RATED

Esta caldeira é ajustável ao calor necessário pela instalação; na realidade, é possível ajustar o caudal no máximo quando a caldeira trabalha para aquecer. Consultar a secção “Regulações” para a calibragem.

Uma vez ajustado o seu caudal (PARÂMETRO 23 para aquecimento máximo), registar o valor na tabela especial fornecida aqui

abaixo. Usar esse valor de ajuste como referência para futuros controlos e regulações

Defi nição de potência kW

Data

Velocidade do ventilador r.p.m.

PT

À PUISSANCE AJUSTABLE

La présente chaudière est ajustable à la chaleur requise par l'installation ; vous pouvez en fait régler le débit maximum quand la

chaudière fonctionne en mode chauffage. Voir la section « Réglages » pour le calibrage.

Une fois que vous avez réglé votre débit (PARAMÈTRE 23 pour un chauffage maximum), enregistrez la valeur dans le tableau

spécial indiqué ci-dessous. Utilisez cette valeur de consigne pour référence pour des contrôles et réglages ultérieurs.

Réglage de puissance kW

Date

Vitesse du ventilateur trs/mn

FR

RANGE RATED

Ez a kazán hozzáigazítható a telepítés által megkövetelt hőhöz; beállíthatja a maximális hozamot, amikor a kazán fűtésben dolgozik. Lásd a "Beállítások" c. részt a kalibráláshoz.

Amikor beállította a hozamot (23. PARAMÉTER a maximális fűtéshez), jegyezze fel az értéket az itt alább megadott speciális

táblázatban. Használja ezt a beállított értéket referenciaként a későbbi ellenőrzésekhez és beállításokhoz

Beállított output kW

Dátum

Ventilátor sebesség r.p.m.

HU

4

EXCLUSIVE BOILER GREEN HE B.S.I.

Installer’s - user’s manual 5

Boiler operating elements 160

Hydraulic circuit 162

Electric diagrams 163-167

Circulator residual head 168

The following symbols are used in this manual:

CAUTION = operations requiring special care and ad-

equate preparation

NOT ALLOWED = operations that MUST NOT be per-

formed

EN

Manual de usuario y del instalador 24

Elementos de operación de la caldera 160

Diagramas eléctricos 163-167

Prevalencia residual del circulador 169

En algunas partes del manual se utilizan los símbolos:

ATENCIÓN = para acciones que requieren particular

atención y una adecuada preparación

PROHIBIDO = para acciones que NO DEBEN efectuar-

se nunca

ES

Telepítői-felhasználói kézikönyv 63

A kazán funkcionális alkatrészei 160

Hidraulikus kör 162

Elektromos rajzok 163-167

A keringetőszivattyú maradék emelőnyomása 171

A kézikönyvben az alábbi szimbólumok szerepelnek:

FIGYELEM = megfelelő körültekintést és felkészültséget

igénylő tevékenységek

TILOS = olyan tevékenységek, melyeket szigorúan TI-

LOS végrehajtani

HU

Manual de instalare - utilizare 82

Elementele funcţionale ale centralei 160

Circuit hidraulic 162

Scheme electrice 163-167

Cap rezidual pompă de circulaţie 172

În acest manual sunt utilizate următoarele simboluri:

ATENŢIE = operaţii care necesită o atenţie deosebită şi

o pregătire specifi că

INTERZIS = operaţii care NU TREBUIE efectuate

RO

Priročnik za montažo-uporabo 101

Elementi delovanja kotla 160

Hidravlični sistem 162

Sheme električnih povezav 163-167

Preostala višina črpanja 173

V tem priročniku so uporabljeni naslednji simboli:

POZOR = postopki, ki zahtevajo posebno previdnost in

ustrezno usposobljenost

PREPOVEDANO = postopki, ki se jih NE SME opraviti

SL

Manual do utilizador-instalador 120

Elementos de operação da caldeira 160

Circuito hidráulico 162

Diagramas eléctricos 163-167

Cabeçal residual do circulador 174

Em algumas partes do manual são utilizados os símbolos:

ATENÇÃO = para acções que exigirem particular cuida-

do e preparação adequada

PROIBIDO = para acções que NÃO SE DEVEM absolu-

tamente executar

PT

Manuel de l'installateur - manuel de l'utilisateur 139

Éléments de fonctionnement de la chaudière 160

Circuit hydraulique 162

Schémas électriques 163-167

Hauteur de charge résiduelle 175

Les symboles suivants sont employés dans ce manuel :

PRÉCAUTION = opérations qui exigent un soin particu-

lier et une préparation adéquate.

INTERDICTION = opérations qu'IL NE FAUT PAS réali-

ser.

FR

Instalator / użytkownik instrukcja obsługi 43

Elementy składowe kotła 160

Obiegi hydrauliczne 162

Schematy elektryczne 163-167

Zakres pracy pompy 170

W niektórych częściach instrukcji użyte zostały umowne oznaczenia:

UWAGA = w odniesieniu do czynności wymagających

szczególnej ostrożności oraz odpowiedniego przygotowania

ZABRONIONE = w odniesieniu do czynności, których w

żadnym wypadku NIE MOŻNA wykonywać.

PL

5

EXCLUSIVE BOILER GREEN HE B.S.I.

1- GENERAL SAFETY DEVICES

The boilers produced in our factory are built with care down

to the last component to protect both the user and installer

from eventual accidents. We therefore recommend qualifi ed

personnel that after working on the product they should pay

particular attention to the wiring, especially the bare wires,

that must not be exposed outside the terminal board for any

rason to prevent any contact with the live parts of the wiring.

This instructions manual is integral parts of the product. Make

sure they remain with the boiler, even if it is transferred to

another owner or user or moved to another heating system.

In case of loss or damage, please contact your local Technical

Assistance Service for a new copy.

This boiler may only be installed and serviced by qualifi ed fi t-

ters who satisfy the requirements of local rules. Work must be

done in compliance with regulations in force and subsequent

updates.

The boiler must be serviced at least once a year. This should

be booked in advance with the Technical Assistance Service.

The installer shall instruct the user in the operation of the boil-

er and the safety devices.

This boiler may only be used for what it was expressly built to

do. The manufacturer declines all contractual and non-contractual liability for injury to persons or animals or damage to

property deriving from errors made during installation, adjustment and servicing and from improper use.

This appliance is used to produce hot water and must there-

fore be connected to a heating and/or a domestic hot water

system, according to its performance and power

After removing the packaging, make sure the contents are

undamaged and complete. If this is not the case, contact your

dealer.

We recommend always being careful to control the degree

of wear of the keep-alive anode during ordinary maintenance

jobs.

The safety valve outlet must be connected to a suitable col-

lection and venting system. The manufacturer declines all liability for any damage caused by the safety valve.

The safety and automatic adjustment devices on the appli-

ance must never be modifi ed during its lifetime, except by the

maker or dealer.

If the appliance develops a fault and/or works badly, switch it

off and do not attempt to repair it yourself.

Immediately after installation, inform the user that:

- in the event of leaks, he/she must shut off the water supply

and promptly inform the Technical Assistance Service

- he/she must check from time to time to make sure the

symbol is not lit on the control panel. This symbol means

that the pressure in the water system is incorrect. If necessary, fi ll the system as described in the paragraph “Boiler

functions”

- if the boiler is not planned to be used for a long period, he/

she should call in the Technical Assistance Service to perform the following operations:

- turn off the main boiler and general system switches

- close the gas and water taps on both the heating and domestic hot water circuits

- drain the heating and domestic hot water circuits to prevent

freezing.

Connect the outlet collector to a suitable outlet system (refer

to chapter 6).

Safety measures:

the boiler should not be used by children or unassisted disa-

bled people

electrical devices or equipment, such as switches, applianc-

es, etc., should not be used if there is a smell of gas or fumes.

If there is a gas leak, open all the doors and windows to ventilate the area, turn off the general gas tap and immediately call

the Technical Assistance Service

do not touch the boiler barefoot or if parts of your body are

wet or damp

press the button until “- -” is shown on the display and dis-

connect the electricity supply by turning off the two-position

system switch, before cleaning

it is forbidden to modify the safety or adjustment devices with-

out the manufacturer’s permission and relative instructions

do not pull, detach or twist the wires from the boiler even if

they are not connected to the power supply

do not block or reduce the size of the ventilation openings in

the room

do not leave infl ammable containers or substances in the

room

keep packaging out of reach of children

only use appliance for purposes it is devoted to

do not lean any object on the boiler

do not tamper with sealed elements

it is forbidden to block the condensate outlet.

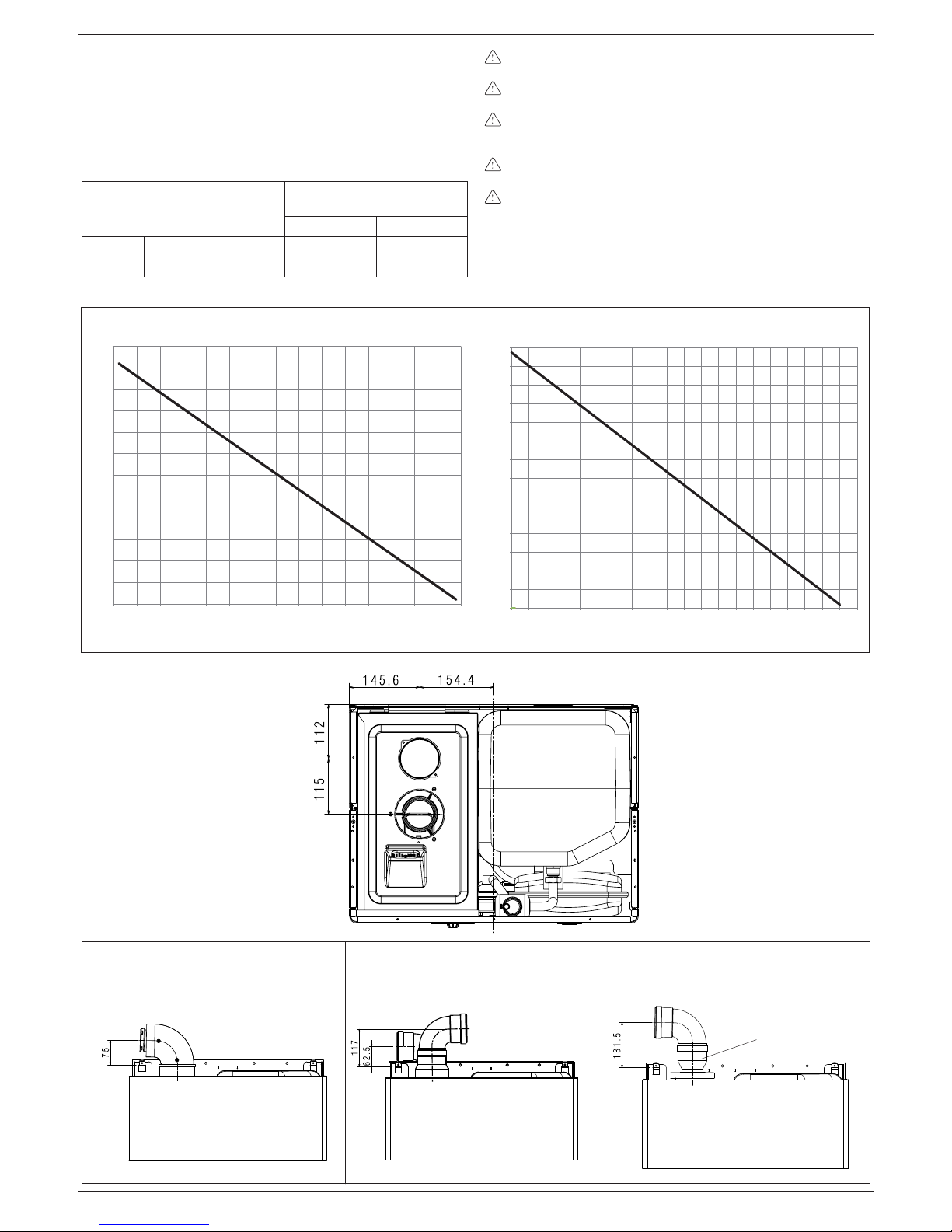

2- BOILER INSTALLATION

Boiler must only be installed by qualifi ed personnel in compliance

with current legislation. Boiler is available in the following models:

Model Type Category Power

B.S.I. Combined C 25 kW - 35 kW

Exclusive Boiler Green HE B.S.I. is a C-type condensation wallmounted boiler for heating and producing domestic hot water,

supplied with a 60 litres inox water tank. Class C appliances can

be installed in any kind of room as long as the fumes discharge

and the comburent air intake are taken outside the room. The following types of fumes outlet are available for this kind of boiler:

B23P; B53P; C13,C13x; C23; C33,C33x; C43,C43x; C53,C53x;

C63,C63x; C83,C83x; C93,C93x. Installation must comply with local standards and regulations in force.

For proper installation, we remind you that:

- the boiler must not be installed over a kitchen or any other cooking equipment

- it is forbidden to leave infl ammable substances in the room

- suitably insulate heat-sensitive walls (e.g.: in wood)

- minimum spaces are to be left in order to allow maintenance

operations: at least 2,5 cm every side and 20 cm under the boiler.

Keep the distance of 370 mm from the bottom of the boiler

to the furniture casing: there must be suffi cient space for

dismantling operations if the magnesium anode has to be

cleaned.

Support plate and integrated pre-installation template are provided

for with the boiler (fi g. 2).

Mounting instructions:

- fi x the boiler support plate (F) with the template (G) to the wall

and use a plumb to check that it is perfectly horizontal

- trace out 4 holes (ø 6 mm) for fi xing the boiler support plate (F)

and 2 holes (ø 4 mm) for fi xing the preinstallation template (G)

- make sure all the measurements are correct, then drill holes in

the wall using a drill and point with the diameter given previously

- fi x the plate to the wall by the supplied anchor screws

- make hydraulic connections.

3- HYDRAULIC CONNECTIONS

Position and dimensions of hydraulic connections are specifi ed in

fi gure 2:

A - CH return 3/4”

B - CH delivery 3/4”

C - Gas connection 3/4”

D - DHW outlet 1/2”

E - DHW inlet 1/2”

F - Support plate

G - Pre-installation template

If water hardness exceeds 28°Fr, it is recommended to use water

softeners, to prevent any limestone deposit in boiler due to excessively hard water.

EN

ENGLISH

6

EXCLUSIVE BOILER GREEN HE B.S.I.

4- CLEANING THE SYSTEM AND CHARACTERISTICS

OF HEATING CIRCUI

T WATER

After installing a new system or replacing a boiler, clean the heating system.

To ensure the product works correctly, after cleaning, additivating

and/or chemically treating the system (e.g.: anti-freeze, fi lm-form-

ers, etc.), make sure the characteristics of the water satisfy the

parameters indicated in the table.

Parameters um Water in heating

circuit

Inlet water

PH 7 ÷ 8 Hardness ° F - 15 ÷20

Appearance - limpid

5- INSTALLING THE EXTERNAL PROBE

Install the probe (fi g. 4) in an area of smooth wall; for brick walls

or other irregular surfaces, prepare a smooth contact area if at all

possible.

Remove the upper plastic cover by turning it anti-clockwise.

Identify the wall fi xing point and drill a hole for the 5x25 expansion

grip. Insert the expansion grip into the hole. Remove the card from

its housing. Fix the housing to the wall using the supplied screw.

Attach the bracket and tighten the screw. Loosen the cable grommet screw, push in the probe connection cable and connect it to the

electrical terminal. Remember to fi rmly secure the cable grommet

to prevent humidity from entering. Put the card back into its housing. Close the upper plastic cover by turning it clockwise. Firmly

secure the cable grommet.

Installing and connecting up the external sensor

The sensor must be installed on an external wall of the building

you want to heat, while taking care to comply with the instructions

below:

- It must be fi tted on the facade most often exposed to wind, on a

wall facing NORTH or NORTH-WEST, and taking care to avoid

direct sunlight.

- It must be fi tted about 2/3 up the height of the façade.

- It must not be near any doors, windows, outlets for air ducts, or

near chimneys or other heat sources.

The electrical connection to the external sensor must be formed

using a two-pole cable (not supplied), with a cross-section of 0,5

to 1 mm2 and a maximum length of 30 metres. It is not necessary

to worry about the polarity of the cable for the connection to the

external sensor. Do not form joints in this cable. If a joint has to be

made it must be watertight and adequately protected.

Any conduiting used for the connection cable must be sepa-

rate from the conduits used for the power cables (230 Vac).

6- CONDENSATE COLLECTION

The outlet collector (A, fi g. 5) collects: the condensate water, any

evacuation water from the safety valve and the system outlet water.

The collector must be connected, by means of a rubber pipe,

to a suitable collection and evacuation system in the storm

water outlet and in compliance with current regulations.

The external diameter of the collector is 20 mm: we therefore

suggest using an Ø18-19 mm pipe, to be closed with a suitable clamp (not supplied).

The manufacturer is not responsible for any damage caused

by the lack of a collection system.

The outlet connection line must have a guaranteed seal.

The manufacturer of the boiler is not responsible for any

fl ooding caused by interventions of the safety valve.

7- GAS CONNECTION

Before connecting appliance to gas pipe network, check the following:

- regulations in force are met

- gas type used is the same as set for appliance operation

- pipes are clean.

After installation make sure that all the joints have been made

airtight conforming to standard installation practices.

Gas must be piped externally. If the pipe goes through a wall it must

go through the central opening in the lower part of the template. It

is recommended to install an appropriately sized fi lter on the gas

line in case gas from the mains contains some small solid particles.

8- ELECTRIC CONNECTION

To access the electrical connections, proceed as follows:

- loosen the fi xing screws (A) and remove the shell (fi g. 3)

- lift up the panel and turn it forwards

- open the terminal board covers making them slide in the direc-

tion of the arrows (fi g. 6: B high voltage connections 230 V, C low

voltage connections).

Connect the appliance to the mains electricity supply with a switch

featuring a distance of at least 3,5 mm (EN 60335-1, category III)

between each wire. The appliance uses alternating current at 230

Volt/50 Hz, has a power input of 66W (25 B.S.I.) - 116W (35 B.S.I.)

and complies with EN 60335-1. The appliance must be connected

to an effi cient earth circuit, according to current legislation and by-

laws.

Live and neutral (L-N) connections should also be respected.

The boiler can operate with phase-neutral or phase-phase power

supply. For fl oating power supply, without an earth-bonded conduc-

tor, it is necessary to use an insulation transformer with secondary

anchored to ground.

The earth conductor must be a couple of cm longer than the

others.

Gas and/or water pipes may not be used to earth electrical

equipment.

The installer is responsible for making sure that the appliance

has an adequate earthing system; the manufacturer shall not

be held liable for eventual damages caused by incorrect usage or failing to earth the boiler.

Use the supplied power cable to connect the boiler to the mains

power supply.

Connect the ambient thermostat and/or time clock as shown in the

electrical diagram.

When replacing the power cable, use a HAR H05V2V2-F cable,

3 x 0,75 mm2, Ø max. external 7 mm.

9- FILLING THE SYSTEMS, ELIMINATING THE

AIR AND EMPTYING THE SYSTEMS

The systems can be fi lled up once the water mains have been con-

nected up.

This must be done while the installation is cold by:

DHW system (fi g. 7)

- open the cold water stopcock (H) to fi ll up the water tank

- open the hot water to check the water tank fi lled up and wait until

the water discharge

Heating system (fi g. 7)

- making sure that the drain valve (B) is closed

- giving two or three turns to the cap of the automatic air vent valve

(C) to open it

- opening the fi lling stopcock (I) until the pressure measured by

the hydrometer (D) is about 1,5 bar (blue zone)

- open the manual vent valve (E) and close it again once the system has been vented; if necessary, repeat this operation until no

more air leaves the valve (E)

- close the fi lling stopcock (I)

- each time the electricity supply to the boiler is switched on, an

automatic vent cycle lasting about 2 minutes starts, and the display reads “SF”, and the “functions selectors”

light up in sequence. Press the button to interrupt the automatic venting cycle.

NOTE: air extraction from the boiler takes place automatically,

through two automatic bleeding valves, C and F.

NOTE: the boiler is also equipped with a semi-automatic fi lling sys-

tem. The fi rst system-fi lling operation must be carried out by open-

ing tap I with the boiler turned off.

CH system emptying (fi g. 7)

Before starting to empty it, remove the electrical feeder by positioning the general switch for the system on “off”.

7

EXCLUSIVE BOILER GREEN HE B.S.I.

- Close the interception devices for the thermal system

- Open the automatic air vent valve (C)

- Unscrew the drain valve (B) by hand, keeping the elbow on the

hose in position to prevent it coming out of its seating

- The water from the system is discharged through the outlet col-

lector (A)

- Emptying out the lowest parts of the system.

DHW system emptying (fi g. 7)

The hot water system must be emptied every time there is risk of

freezing by:

- turning off the stopcock at the mains

- unscrew the cap on the hose adapter (G)

- connect a plastic hose to the hose adapter of the storage boiler

drain valve (G)

- open the valve drain device

- turning on all the hot and cold taps

- emptying out the lowest parts of the system.

ATTENTION

The collector must be connected, by means of a rubber pipe, to a

suitable collection and evacuation system in the storm water outlet

and in compliance with current regulations. The external diameter

of the collector is 20 mm: we therefore suggest using an Ø18-19

mm pipe, to be closed with a suitable clamp (not supplied). The

manufacturer is not responsible for any damage caused by the lack

of a collection system.

Suggestions to correctly eliminate air from the heating system

and boiler (Fig. 8)

We recommend carrying out the sequence of operations given below during fi rst installation or with extraordinary maintenance work:

1. Using a CH11 spanner open the manual air vent valve located

above the air box; the tube supplied with the boiler must be connected to the valve to let out the water into an outside container.

2. Open the manual system fi lling stopcock on the water group,

wait until the water starts coming out of the valve;

3. Switch on the boiler leaving the gas cock closed;

4. Use the room thermostat or the remote control panel to activate

request for heat so that the three-way will turn to heating;

5. Activate request for hot water as follows:

instant boilers: turn on a tap for 30” every minute so that the

three-way cycles from heating to domestic hot water and vice

versa about ten times (here the boiler will go into alarm as it

lacks gas and has to be reset every time this happens).

Heating only boilers connected to an external water tank:

use the water tank thermostat;

6. Continue the sequence until water only comes out of the manual

air vent valve and the fl ow of air has fi nished; close the manual

air vent valve at this point;

7. Make sure the system is at the correct pressure (1 bar is ideal);

8. Close the manual system fi lling stopcock on the water group;

9. Open the gas cock and ignite the boiler.

10- FUMES EXHAUSTION AND BURNING AIR

SUCTION

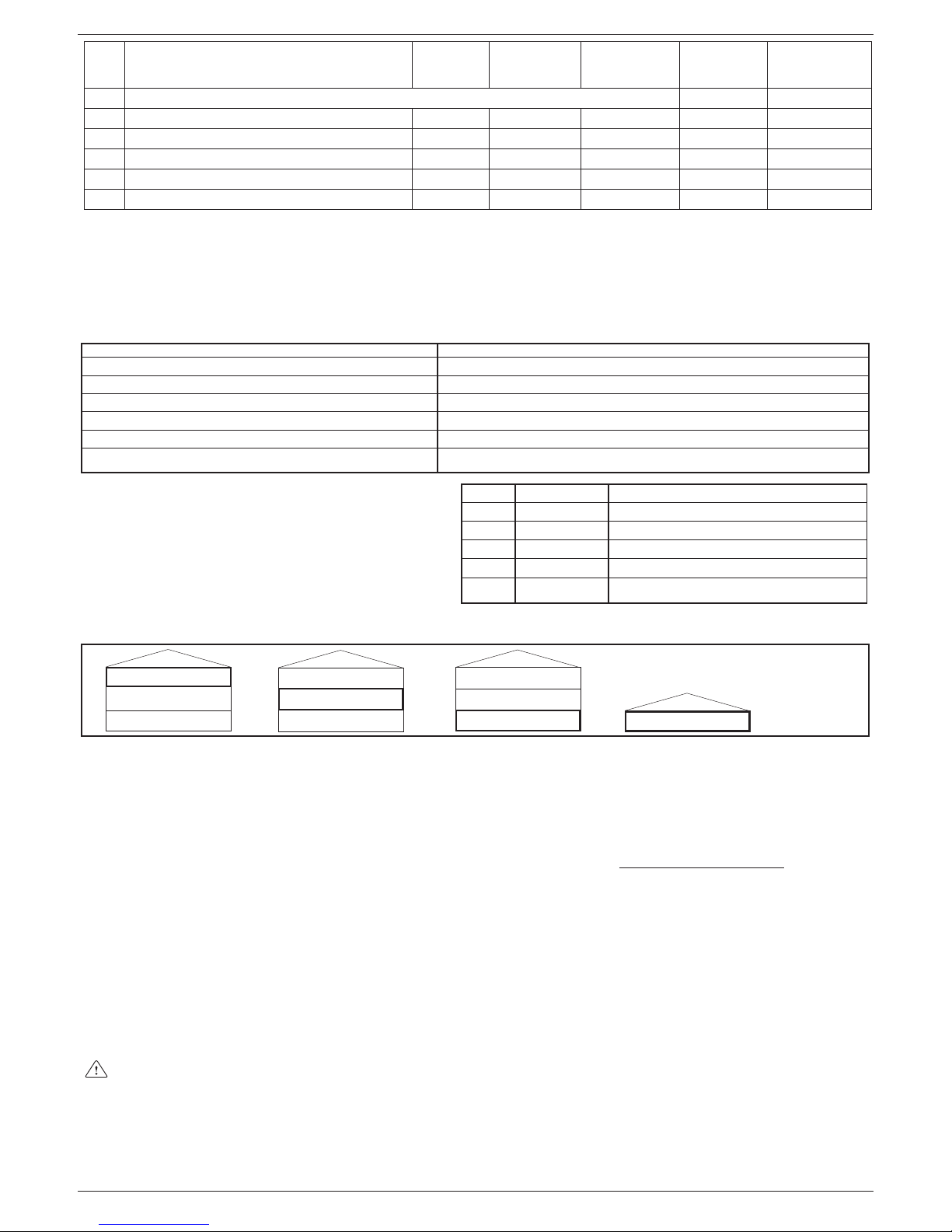

EXHAUSTION CONFIGURATIONS (fi g. 9)

Boiler is homologated for the following exhaustion confi gurations:

B23P-B53P Suction in room and discharge outside

C13-C13x Concentric wall exhaustion. Pipes can separately start

from boiler, but outlets must be concentric or close enough to be

subject to similar wind conditions (within 50 cm).

C23-C23x Concentric exhaustion in common chimney (suction and

exhaustion in the same chimney).

C33-C33x Concentric roof exhaustion. Outlets like C13.

C43-C43x Exhaustion and suction in common separate chimneys,

but subject to similar wind conditions.

C53-C53x Wall or roof separate exhaustion and suction in different

pressure areas. Exhaustion and suction must never be located on

opposite walls.

C63-C63x Exhaustion and suction with separately certifi ed and

sold pipes (1856/1).

C83-C83x Single or common chimney exhaustion and wall suction.

C93-C93x Discharge on roof (similar to C33) and air suction from a

single existing smoke pipe

Refer to regulations in force for exhaustion of combustion products.

Boiler is provided for without fume exhaustion/air suction kit, since

forced draught sealed chamber accessories can be used, as they

better adapt to installation characteristics. For fume extraction and

burning air restoration in boiler, use original pipes or other EC-certifi ed pipes with equivalent characteristics; check connection is cor-

rect as shown on instructions fume accessories provided for with.

More appliances can be connected to a single chimney, provided

that all appliances are sealed chamber type.

“FORCED OPEN” INSTALLATION

(TYPE B23P-B53P, intake inside and outlet outside)

Fumes outlet duct ø 80 mm - fi g. 13

The fumes outlet duct can be aimed in the most suitable direction

for installation needs.

To install follow the instructions supplied with the kit.

In this confi guration, the boiler is connected to the ø 80 mm fumes

outlet duct by means of a ø 60-80 mm adaptor.

In this case, the combustion supporting air is taken from the

room in which the boiler is installed, which must be a suitable

and ventilated technical room.

Non-insulated fumes outlet ducts are potential sources of

danger.

Provision must be made for a 1% slope of the fumes outlet

duct towards the boiler.

max length fumes

outlet duct ø 80 (m)

pressure drop

for each bend (m)

45° 90°

25 B.S.I. 50

1 1,5

35 B.S.I. 60

INSTALLATION “SEALED” (TYPE C)

Boiler is a C-type appliance (sealed chamber) and must be safely

connected to fume exhaustion duct and burning air suction duct,

both getting outside; appliance cannot operate without these ducts.

Concentric outlets (ø 60-100) - Fig. 11

Concentric ducts may be placed in the most suitable direction for

installation requirements but special care must be taken as regards

the external temperature and the length of the duct.

Horizontal

max. linear length

concentric duct ø 60-100 (m)

pressure drop

for each bend (m)

7,85

45° 90°

1,3 1,6

Vertical

max. linear length

concentric duct ø 60-100 (m)

pressure drop

for each bend (m)

8,85

45° 90°

1,3 1,6

Rectilinear length means without bends, outlet ends and con-

nections.

The fumes outlet duct must slope by 1% towards the conden-

sate collector.

Uninsulated fumes outlets are potential hazards.

The boiler automatically adapts ventilation according to the

type of installation and the length of the duct.

Do not obstruct or narrow the comburent air inlet duct in any way.

To install follow the instructions supplied with the kit.

Concentric outlets (ø 80-125 mm)

For this installation it is necessary to install the suitable adaptor kit.

Ducts may be placed in the most suitable direction for installation requirements. For the installation process, follow the instructions supplied with the kit for the specifi c accessory for condensation boilers.

max. linear length

concentric duct ø 80-125 (m)

pressure drop

for each bend (m)

14,85

45° 90°

1 1,5

8

EXCLUSIVE BOILER GREEN HE B.S.I.

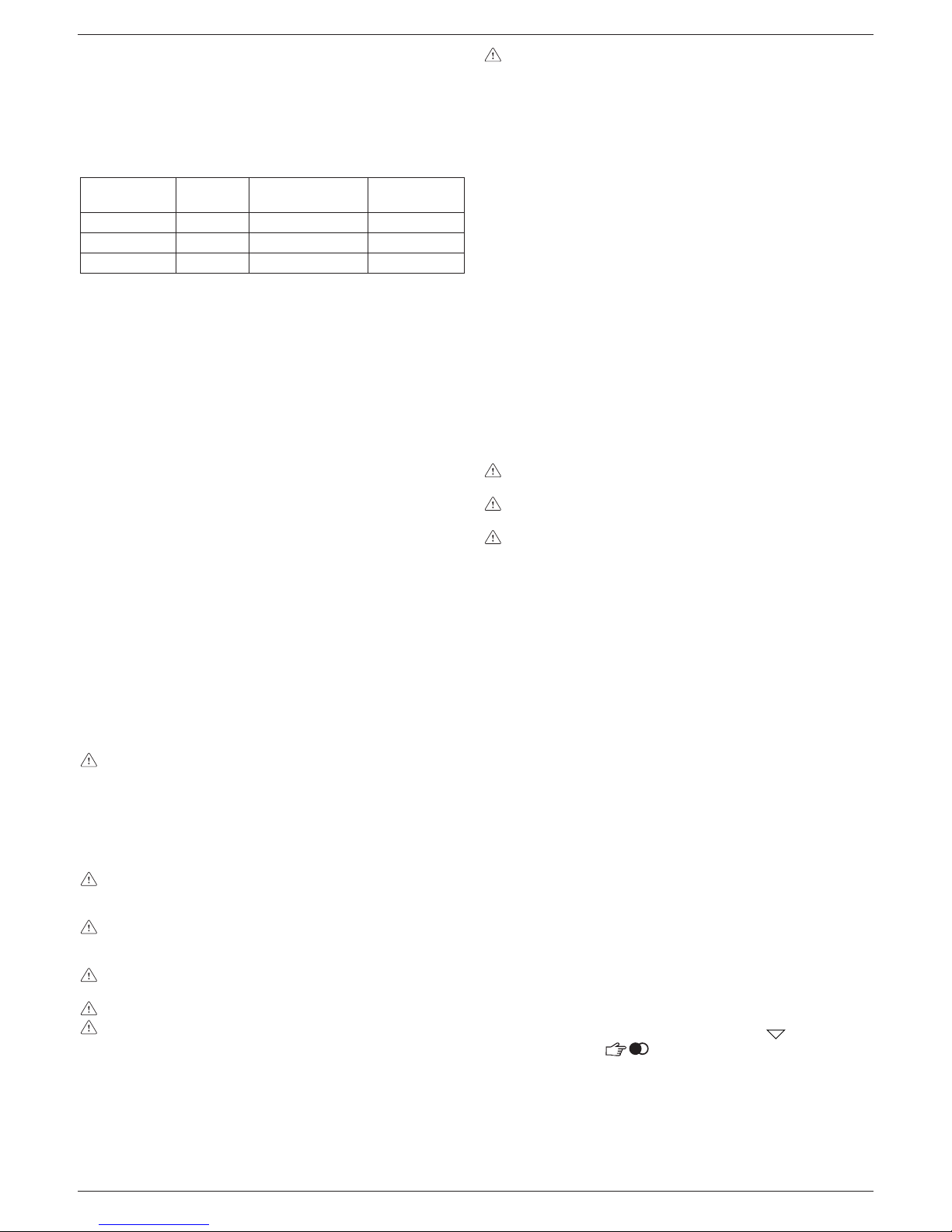

CONCENTRIC DUCT

FOR FUMES OUTLET/AIR INTAKE

SPLIT DUCTS

FOR FUMES OUTLET/AIR INTAKE

FUMES DUCT FOR INTAKE

IN ENVIRONMENTS

adaptor

Ø 60-80

LENGTH OF THE INTAKE DUCT (m)

EXHAUSTION LENGHT (m)

10

11

12 13

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

0

5

10

15

20

25

30

35

40

45

50

55

60

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

EXCLUSIVE BOILER GREEN HE 25 B.S.I.

EXCLUSIVE BOILER GREEN HE 35 B.S.I.

LENGTH OF THE INTAKE DUCT (m)

EXHAUSTION LENGHT (m)

Twin outlets (ø 80) - fi g. 12

The split duct can be aimed in the most suitable direction for installation needs. The combustion-supporting air intake duct must be

connected to the entrance after having removed the closing cap,

attached with three screws, and having attached a suitable adaptor.

The fumes outlet duct must be connected to the fumes outlet after

having installed a suitable adaptor.

For the installation process, follow the instructions supplied with

the kit for the specifi c accessory for condensation boilers.

max. linear length

twin duct ø 80 (m)

pressure drop

for each bend (m)

45° 90°

25 B.S.I. 32+32

1 1,5

35 B.S.I. 40+40

Rectilinear length means without bends, outlet ends and

connections.

The fumes outlet duct must slope by 1% towards the conden-

sate collector.

The boiler automatically adapts ventilation according to the

type of installation and the length of the duct. Do not obstruct

or narrow the comburent air inlet duct in any way.

For an indication of the maximum lengths of every single

pipe, refer to the graphs.

Using longer ducts causes a loss in the power of the boiler.

9

EXCLUSIVE BOILER GREEN HE B.S.I.

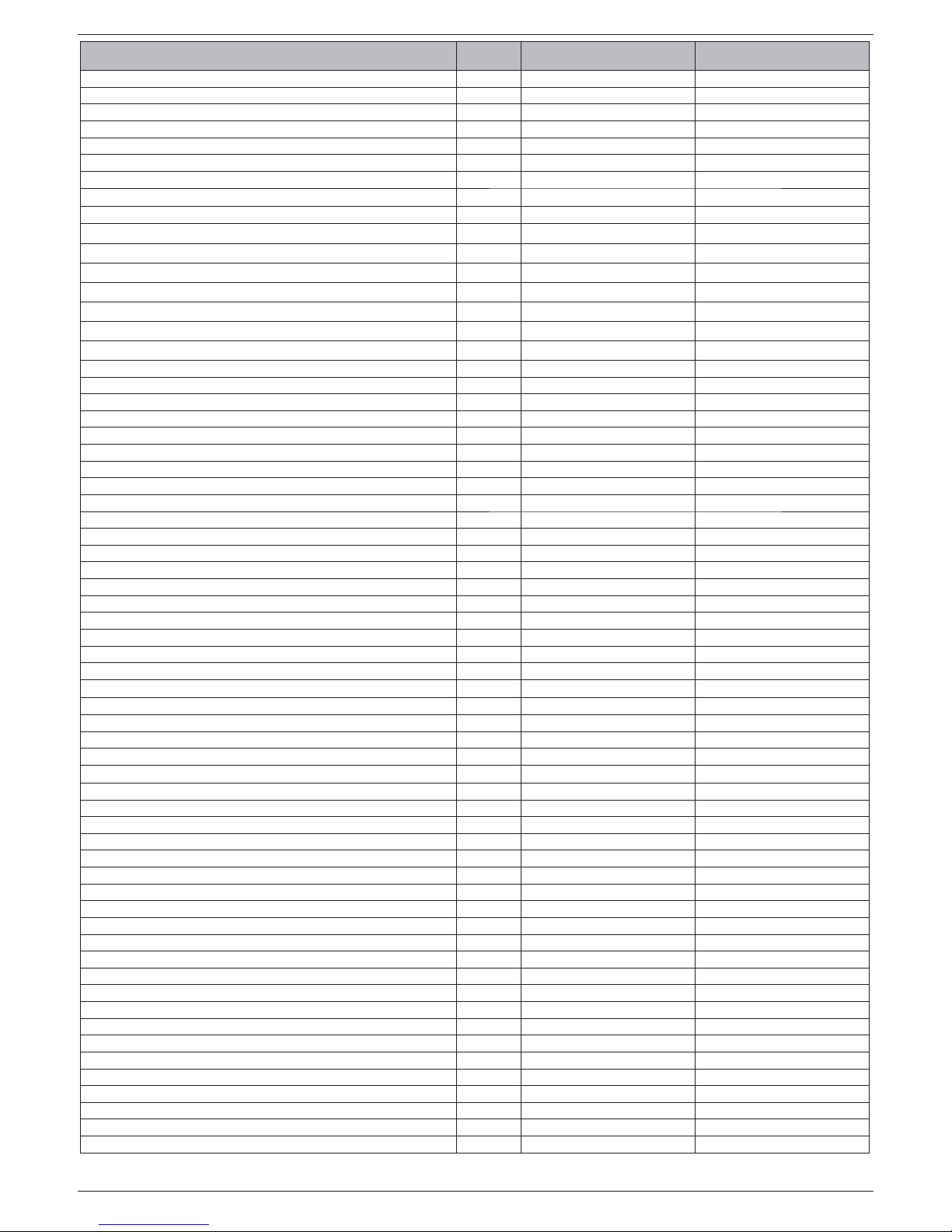

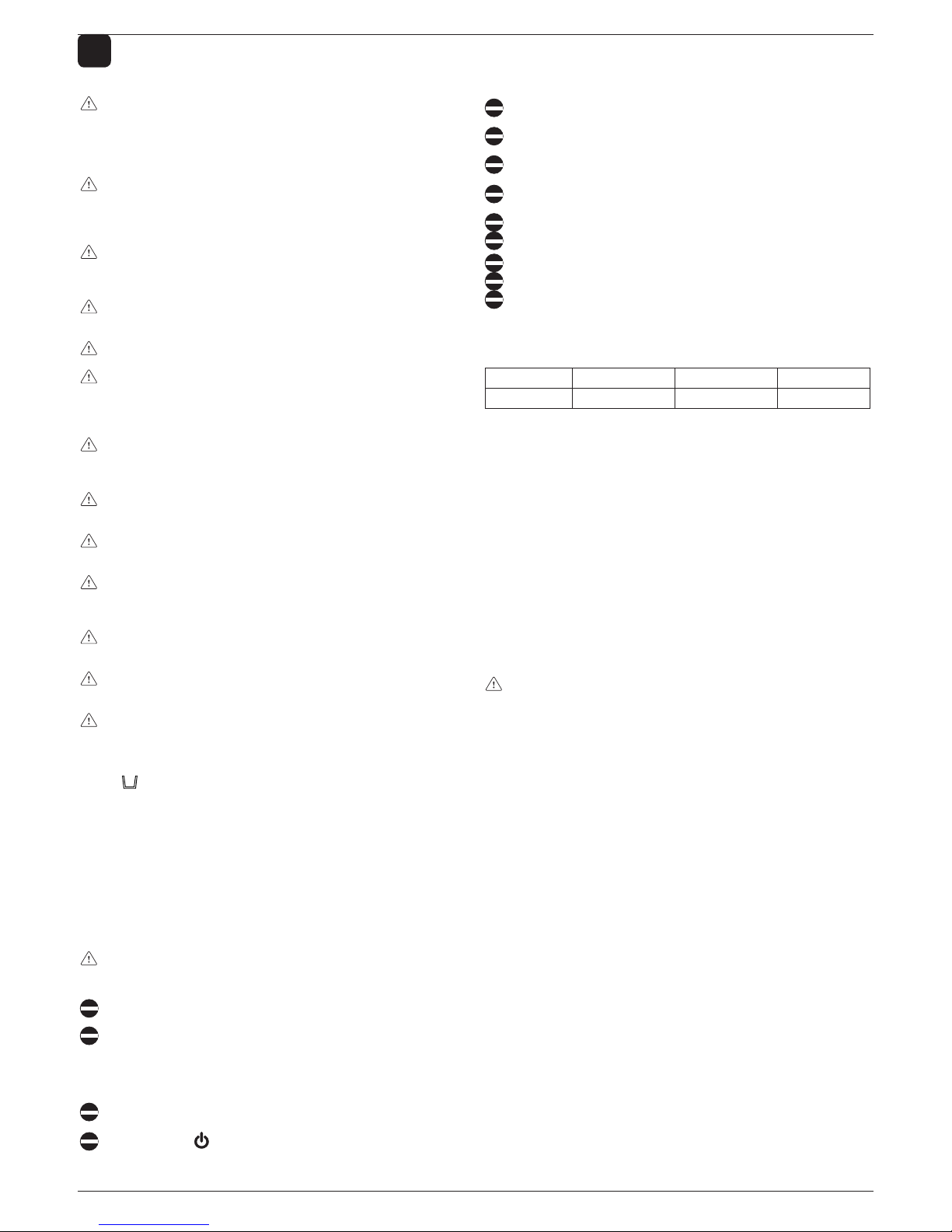

DESCRIPTION

EXCLUSIVE BOILER GREEN HE

25 B.S.I.

EXCLUSIVE BOILER GREEN HE

35 B.S.I.

Heating Heat input kW 25,00 34,60

kcal/h 21.500 29.756

Maximum heat output (80/60°) kW 24,38 33,74

kcal/h 20.963 29.012

Maximum heat output (50/30°) kW 26,20 36,50

kcal/h 22.532 31.393

Minimum heat input (G20/G31) kW 2,50/4,50 3,50/6,20

kcal/h 2.150/3.870 3.010/5.332

Minimum heat output (80°/60°) (G20/G31) kW 2,49/4,47 3,41/6,04

kcal/h 2.144/3.847 2.929/5.193

Minimum heat output (50°/30°) (G20/G31) kW 2,69/4,82 3,71/6,57

kcal/h 2.309/4.145 3.188/5.647

Nominal Range Rated heat output (Qn) kW 25,00 34,60

kcal/h 21.500 29.756

Minimum Range Rated heat output (Qm) (G20/G31) kW 2,50/4,50 3,50/6,20

kcal/h 2.150/3.870 3.010/5.332

DHW Heat input kW 25,00 34,60

kcal/h 21.500 29.756

Maximum heat output (*) kW 25,00 34,60

kcal/h 21.500 29.756

Minimum heat input (G20/G31) kW 2,50/4,50 3,50/6,20

kcal/h 2.150/3.870 3.010/5.332

Minimum heat output (*) (G20/G31) kW 2,50/4,50 3,50/6,20

kcal/h 2.150/3.870 3.010/5.332

(*) average value of various DHW operating conditions

Useful effi ciency (Pn max - Pn min) % 97,5 - 99,7 (G31= 99,4) 97,5 - 97,3 (G31= 97,4)

Effi ciency 30% (47° return) % 102,8 103,1

Combustion performance % 97,8 97,7

Useful effi ciency Pn max - Pn min (50°/30°) % 104,8 - 107,4 (G31= 107,1) 105,5 - 105,9 (G31= 105,9)

Useful effi ciency 30% (30° return) % 109,4 108

Average Range Rated effi ciency Pn (80°/60°) % 98,1 97,6

Average Range Rated effi ciency Pn (50°/30°) % 105,2 106,1

Electric power W

66 116

Category II2H3P II2H3P

Country of destination -Power supply voltage V - Hz 230-50 230-50

Degree of Protection IP X5D X5D

Pressure drops on fl ue with burner on % 2,16 2,30

Pressure drops on fl ue with burner off % 0,10 0,08

Heating operation

Pressure - maximum temperature bar - °C 3 - 90 3 - 90

Minimum pressure for standard operation bar 0,25 - 0,45 0,25 - 0,45

Selection fi eld of heating water temperature °C 20 - 80 20 - 80

Pump: maximum head available mbar 127 320

for system capacity l/h 800 1.000

Membrane expansion tank l 10 10

Expansion tank pre-charge bar 1 1

DHW operation

Maximum pressure bar 8 8

Minimum pressure bar - 0,15

Hot water quantity with ∆t 25°C l/min 14,3 19,8

with ∆t 30°C l/min 11,9 16,5

with ∆t 35°C l/min 10,2 14,2

DHW minimum output l/min - 2

Selection fi eld of DHW temperature °C 35 - 60 35 - 60

Flow regulator l/min 15 15

Gas pressure

Methane gas nominal pressure (G20) mbar 20 20

LPG liquid gas nominal pressure (G31) mbar 37 37

Hydraulic connections

Heating input - output Ø 3/4” 3/4”

DHW input-output Ø 1/2” 1/2”

Gas input Ø 3/4” 3/4”

10

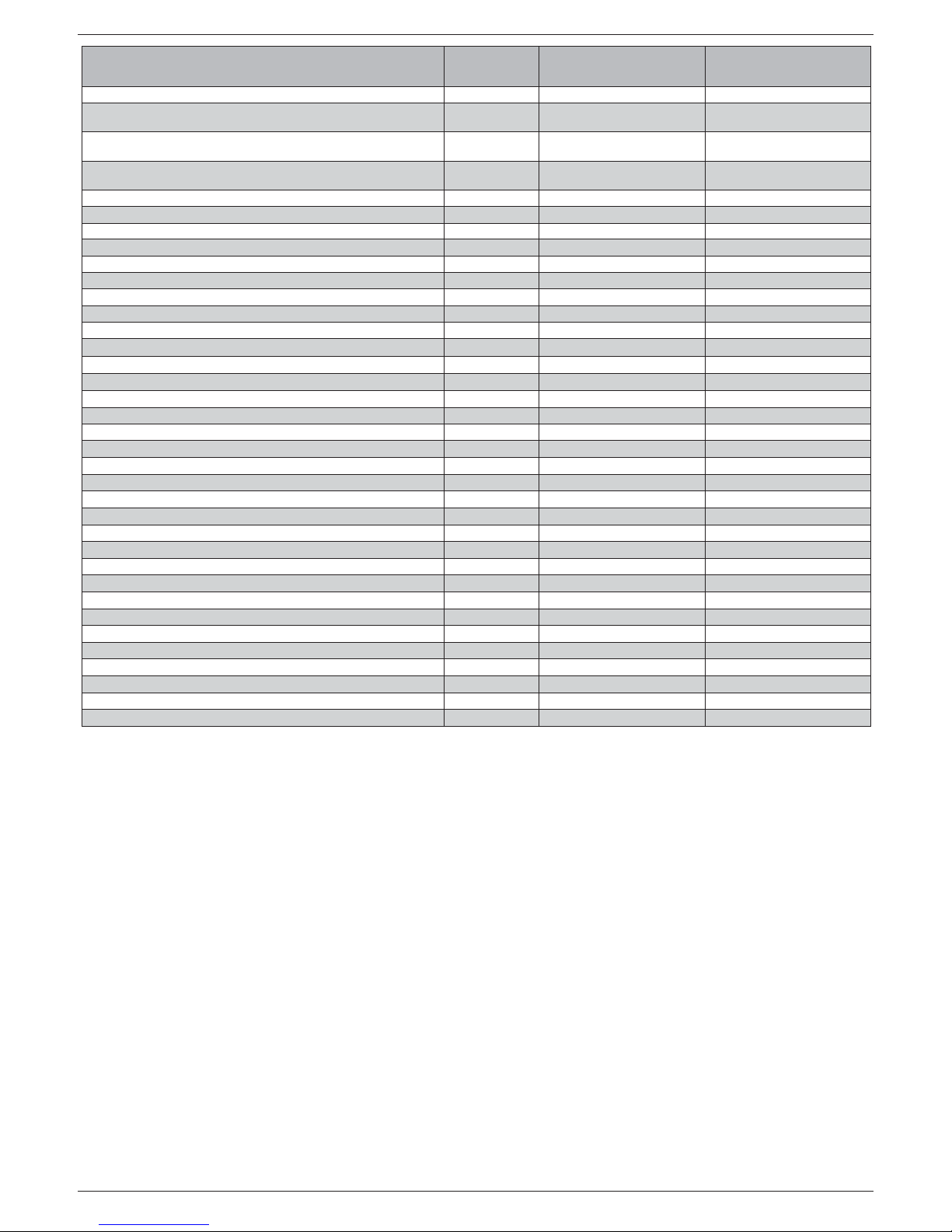

EXCLUSIVE BOILER GREEN HE B.S.I.

DESCRIPTION

EXCLUSIVE BOILER GREEN HE

25 B.S.I.

EXCLUSIVE BOILER GREEN HE

35 B.S.I.

Boiler dimensions

Height mm 940 940

Width mm 600 600

Depth of housing mm 450 450

Boiler weight kg 65 72

Flow rate (G20)

Air capacity Nm3/h 31,135 43,090

Flue gas capacity Nm3/h 33,642 46,561

Mass fl ow of fl ue gas (max-min) gr/s 11,282-1,070 15,614 - 1,498

Flow rate (G31)

Air capacity Nm3/h 31,752 43,945

Flue gas capacity Nm3/h 32,721 45,286

Mass fl ow of fl ue gas (max-min) gr/s 11,046-1,988 15,288 - 2,740

Fan performance

Residual head of boiler without pipes Pa 98 199

Residual head of concentric pipes 0,85 m Pa 40 60

Residual head of separate pipes 0,5 m Pa 90 195

Concentric fl ue gas discharge pipes

Diameter mm 60-100 60-100

Maximum length m 7,85 7,85

Drop due to insertion of a 45°/90° bend m 1,3/1,6 1,3/1,6

Hole in wall (diameter) mm 105 105

Concentric fl ue gas discharge pipes

Diameter mm 80-125 80-125

Maximum length m 14,85 14,85

Drop due to insertion of a 45°/90° bend m 1/1,5 1/1,5

Hole in wall (diameter) mm 130 130

Separate fl ue gas discharge pipes

Diameter mm 80 80

Maximum length m 32+32 40+40

Losses for a 45°/90° bend m

1/1,5 1/1,5

Installation B23P–B53P

Diameter mm 80 80

Maximum length of drainage pipe m 50 60

NOx class 55

Emission values at max. and min. rate of gas G20*

Maximum - Minimum CO s.a. less than ppm 180 - 5 180 - 10

CO

2

% 9 - 9,5 9 - 9,5

NOx s.a. lower than ppm 45 - 10 35 - 15

Flue gas temperature °C 76 - 59 74 - 62

* Check performed with concentric pipe ø 60-100, length 0,85m - water temperature 80-60°C

EXCLUSIVE BOILER GREEN HE

25 B.S.I.

EXCLUSIVE BOILER GREEN HE

35 B.S.I.

Water tank type Inox Inox

Water tank disposition vertical vertical

Exchanger disposition vertical vertical

DHW contents l 60 60

Coil contents l 3,87 3,87

Exchange surface m

2

0,707 0,707

Selection fi eld of DHW temperature °C 35 - 60 35 - 60

Flow regulator l/min 15 15

Hot water quantity drawn in 10’ with Δt 30 °C l 202 202

Water tank maximum pressure bar 8 8

11

EXCLUSIVE BOILER GREEN HE B.S.I.

DESCRIPTION Methane gas (G20) Propane (G31)

Lower Wobbe index (at 15°C-1013 mbar) MJ/m3S 45,67 70,69

Net Calorifi c Value

MJ/m

3

S

MJ/KgS

34,02

-

88

46,34

Supply nominal pressure

mbar

mm W.C.

20

203,9

37

377,3

Supply minimum pressure

mbar

mm W.C.

10

102

-

Exclusive Boiler Green HE 25 B.S.I.

Burner: diameter of nozzles - lenght mm - mm 63 - 130 63 - 130

Diaphragm: number of holes - diameter of holes n° - mm 2 - 3,65 2 - 2,95

Heating maximum gas capacity Sm

3

/h 2,64

kg/h 1,94

DHW maximum gas capacity Sm3/h 2,64

kg/h 1,94

Heating minimum gas capacity Sm

3

/h 0,26

kg/h 0,35

DHW minimum gas capacity Sm

3

/h 0,26

kg/h 0,35

Numbers of fan revolutions at slow start revs/min 3.700 3.700

Maximum number of fan revolutions (CH) revs/min 6.000 6.000

Maximum number of fan revolutions (DHW) revs/min 6.000 6.000

Minimum number of fan revolutions (CH) revs/min 1.200 1.900

Minimum number of fan revolutions (DHW) revs/min 1.200 1.900

Exclusive Boiler Green HE 35 B.S.I.

Burner: diameter of nozzles - lenght mm - mm 63 - 140 63 - 140

Diaphragm: number of holes - diameter of holes n° - mm 2 - 3,8 2 - 3,05

Heating maximum gas capacity Sm

3

/h 3,66

kg/h 2,69

DHW maximum gas capacity Sm3/h 3,66

kg/h 2,69

Heating minimum gas capacity Sm

3

/h 0,37

kg/h 0,48

DHW minimum gas capacity Sm

3

/h 0,37

kg/h 0,48

Numbers of fan revolutions at slow start revs/min 3.300 3.300

Maximum number of fan revolutions (CH) revs/min 6.000 5.900

Maximum number of fan revolutions (DHW) revs/min 6.000 5.900

Minimum number of fan revolutions (CH) revs/min 1.200 1.900

Minimum number of fan revolutions (DHW) revs/min 1.200 1.900

12

EXCLUSIVE BOILER GREEN HE B.S.I.

Description of commands

Heating water temperature selector: sets the heating water

temperature.

Domestic hot water temperature selector: sets the domestic

hot water temperature storaged in the water tank.

Setting parameters selector: using in calibration and program-

mation phase.

Function key:

- ON the boiler is electrically powered and waiting for operating requests (

- )

- OFF the boiler is electrically powered but will not respond to

operating requests

- RESET resets the boiler following a fault

Operating mode button:

button allows to choose the

desired operating mode: (winter) or (summer).

Info button: shows a sequence of information concerning the

operating status of the machine.

Filling button: pushing it, the boiler automatically fi lls the system

until the pressure reaches 1 to 1.5 bar.

Description of display symbols

15

14

graduated heating water temperature scale with

heating function symbol

graduated domestic hot water temperature scale with

domestic hot water function symbol

domestic hot water function symbol

fault symbol

reset symbol

pressure value

external sensor connection

heating/domestic hot water temperature

or

fault symbol (e.g. 10 - no fl ame)

function selector (turned to the chosen operating mode:

winter or summer)

burner operating symbol

anti-freeze function active symbol

system fi lling function symbol

fi ll symbol

Domestic

hot water

temperature

selector

Operating

mode button

ON-OFF-RESET

function selector

Filling

button

Heating

water circuit

temperature

selector

INFO

button

Setting

parameters

selector

12 - START-UP AND OPERATION

The boiler produces heating and domestic hot water.

The control panel (fi g. 14) contains the main boiler control and ma-

nagement functions.

13

EXCLUSIVE BOILER GREEN HE B.S.I.

Switching on

Switch on the boiler as follows:

- access the gas tap through the slots in the cover located in the

lower part of the boiler

- open the gas tap by turning it anti-clockwise (fi g. 16)

- power the boiler.

Each time the power supply is switched on the boiler carries out

an automatic venting cycle that lasts about 2 minutes. The display

reads “SF” (fi g. 17) and the “function selectors”

light up in

sequence. Press the

button to interrupt the automatic

venting cycle.

If the check is concluded correctly, once the automatic venting cycle

has been completed the boiler is ready to work.

The boiler turns on in the status it was in before it was switched

off: if the boiler was in the winter mode when it was switched

off, it will turn on again in the winter mode. If it was in the OFF

mode, the display will show two segments in the central area

(fi g. 18). Press the button to enable operation.

Choose the desired operating mode by pressing

button,

until the symbol moves to:

WINTER

SUMMER

WINTER function (fi g. 19)

With the selector in this position, the boiler provides hot water for

the heating and provides water to the water tank to allow domestic

hot water preparation. Function S.A.R.A is enabled in this position

(see chapter “Boiler functions”).

SUMMER function (fi g. 20)

With the selector in this position, the boiler provides water to the

water tank with a temperature stabiliser to allow domestic hot water

preparation.

16

17

18

19

Adjusting heating water temperature

Turning the selector A (fi g. 21), after having positioned the selector

mode on winter

, it is possible to regulate the heating water

temperature.

Turn clockwise to increase the temperature and anticlockwise to

decrease. The bar segments light up (every 5°C) as the temperature

is increased. The selected temperature value appears on the display.

Adjusting heating water temperature with an external sensor

connected

When an external probe is connected, the value of the delivery

temperature is automatically chosen by the system which rapidly

adjusts ambient temperature to the changes in external temperature.

Just the central segment of the bar is illuminated (fi g. 22).

To increase or decrease the temperature with respect to the value

automatically calculated by the electronic board, turn the heating

water selector clockwise to increase and anticlockwise to decrease.

The bar segments light up (at every comfort level), correction tolerance lies between - 5 and + 5 comfort levels (fi g. 22). When choosing

the level of comfort, the digit area of the display shows the required

level of comfort while the bar shows the matching segment (fi g. 23).

Adjusting domestic hot water temperature

To adjust domestic hot water temperature storaged in the water

tank, turn switch B (fi g. 24) clockwise to increase and anticlock-

wise to decrease. The bar segments light up (every 3°C) as the

temperature is increased.

The selected temperature value appears on the display.

When choosing the temperature, both for heating and domestic

hot water, the display shows the value being selected

. . About 4

seconds after the selection has been made, the modifi cation is

memorised and the display returns to the delivery temperature

read by the probe

. .

20

A

21

22

23

°C

+ 4/5

+ 3

+ 2

+ 1

0

- 1

- 2

- 3

- 4/5

open

position

14

EXCLUSIVE BOILER GREEN HE B.S.I.

Working the boiler

Adjust the ambient thermostat to the required temperature (approx.

20 °C). If there is a demand for heating water, the boiler starts

and the symbol is shown on the display (fi g. 25). The boiler

will remain working until the set temperatures are reached, after

which it will go on stand-by. In the event of ignition or operating

faults, the boiler will perform a “safety stop”.

The fl ame symbol

will go out and the fault code and will

be displayed (fi g. 26). For a description of faults and how to reset

them, consult chapter “Troubleshooting”.

Switching off

Switching off for short periods

For brief absences press the

button to switch off the boiler. The

display will show two segments in the central area (fi g. 27). When

the boiler remains powered with the gas tap open, it is protected

by the following systems:

- anti-freeze: when the temperature of the water in the boiler

falls below safety values, the circulator and the burner work

at minimum power to increase the water temperature to a safe

value (35 °C). The symbol lights up on the display (fi g. 27).

- circulator anti-block: one operating cycle is performed every

24 hours.

Switching off for long periods

For prolonged absences press the button to switch off the boiler

(fi g. 27). The display will show two segments in the central area.

Turn the main switch to “off”.

Turn off the gas tap under the boiler by turning it clockwise (fi g. 28).

In this case, the anti-freeze and anti-block systems are disa-

bled.

Empty the water circuit or suitably protect it with a good make

of anti-freeze. Drain the domestic hot water circuit.

24

B

tap

closed

27

28

Boiler functions

Semi-automatic fi lling

The boiler features a semi-automatic fi lling device which turns on

by pressing the button when the corresponding symbol is

shown on the display (fi g. 29).

If this condition occurs it means that the system is incorrectly pressurised though the boiler will continue to work regularly. Press the

circuit fi lling button

to start-up the fi lling sequence.

Press the circuit fi lling button a second time to interrupt the

fi lling sequence. During fi lling, the drops of the circuit fi lling symbol

and the growing pressure value appear on the display in a

cascade sequence (fi g. 30).

After fi lling, the symbol is displayed for a few moments and

then turns off.

Note

During fi lling, the boiler does not perform other functions. For

example, if there is a request for domestic hot water, the boiler is

unable to provide it until fi lling has fi nished.

Note

If circuit pressure reaches 0.6 bar, the pressure value fl ashes

on the display (fi g. 31a); if it falls below a minimum safety value

(0.3 bar), fault code 41 appears on the display (fi g. 31b) for a

certain time, following which, if the fault persists, fault code 40

is displayed (see chapter on “Troubleshooting”).

In the event of fault 40, press

to reset and then to start fi lling

the circuit. After correcting fault 40, the boiler runs an automatic

vent cycle lasting about 2 minutes; the display reads “SF” (fi g.

32) and the “function selectors” light up in sequence. Press

the

button to interrupt the automatic venting

cycle.

If

you have to fi ll the system several times, contact the Technical

Service Centre to check whether the heating circuit is watertight

(see if there are any leaks).

29

30

25

26

31a

31b

32

15

EXCLUSIVE BOILER GREEN HE B.S.I.

Information

Press

, the display turns off and just the word InFO appears (fi g.

33). Press the button to view operating information. Press the

button again to move on to the next piece of information. If the

button is not pressed, the system automatically exits the function.

Info list:

Info 0 shows the word InFO (fi g. 33)

Info 1 only with the external probe connected, displays external

temperature (e.g. 12 °C) (fi g. 34).

The values shown on the display range between - 30 °C

and 35 °C.

Beyond these values the display shows “- -”

Info 2 shows circuit pressure (fi g. 35)

37

38

36

35

34

33

Info 3 shows the set heating temperature (fi g. 36)

Info 4 shows the set domestic hot water temperature (fi g. 37)

Info 5 displays the set heating temperature, in reference to the

second circuit, only if it is connected.

S.A.R.A. function - fi g. 38

If the “winter” mode is selected, the S.A.R.A. (Automatic Ambient

Adjustment System) function can be activated.

Turning the heating water temperature selector to a temperature

ranging between 55 and 65 °C the S.A.R.A. self-adjustment system activates: depending on the temperature set on the ambient

thermostat and the time taken to reach it, the boiler automatically

adjusts the heating water temperature to reduce operating times,

thereby increasing operating comfort and energy saving.

It is possible to display information, which may be useful for the

Technical Assistance Centre, by pressing the button

for 10 sec-

onds: the code “INF2” appears on the display.

INF2

Step Description Display Display

2 digits 4 digits

1 Input probe temperature xx 01 ° C

2 Return probe temperature xx 02 ° C

3 First water tank probe temperature (*) xx 03 ° C

4 Not used in this model xx Cond ° C

5 Fumes probe temperature xx (**) 05

6 Second heating system probe temperature xx 06 ° C

7 Not used in this model xx 07

8 Ventilator speed /100 xx FAN

9 Not used in this model xx 09

10 Not used in this model xx 10

11 Exchanger cleaning counter status bH xxxx

12-19 Historic alarm codes xx HIS0-HIS7

INF2 list

Note (*): if the water tank probe is faulty or disconnected, in the place of the value “- -” is displayed.

(**): if the display also shows the dot (.), the temperature of the fumes probe is 100+displayed value

16

EXCLUSIVE BOILER GREEN HE B.S.I.

Troubleshooting

When a fault appears on the display, the fl ame symbol goes

out, a fl ashing code is shown and the two symbols and

appear either together or separately.

For a description of the faults, consult the following table.

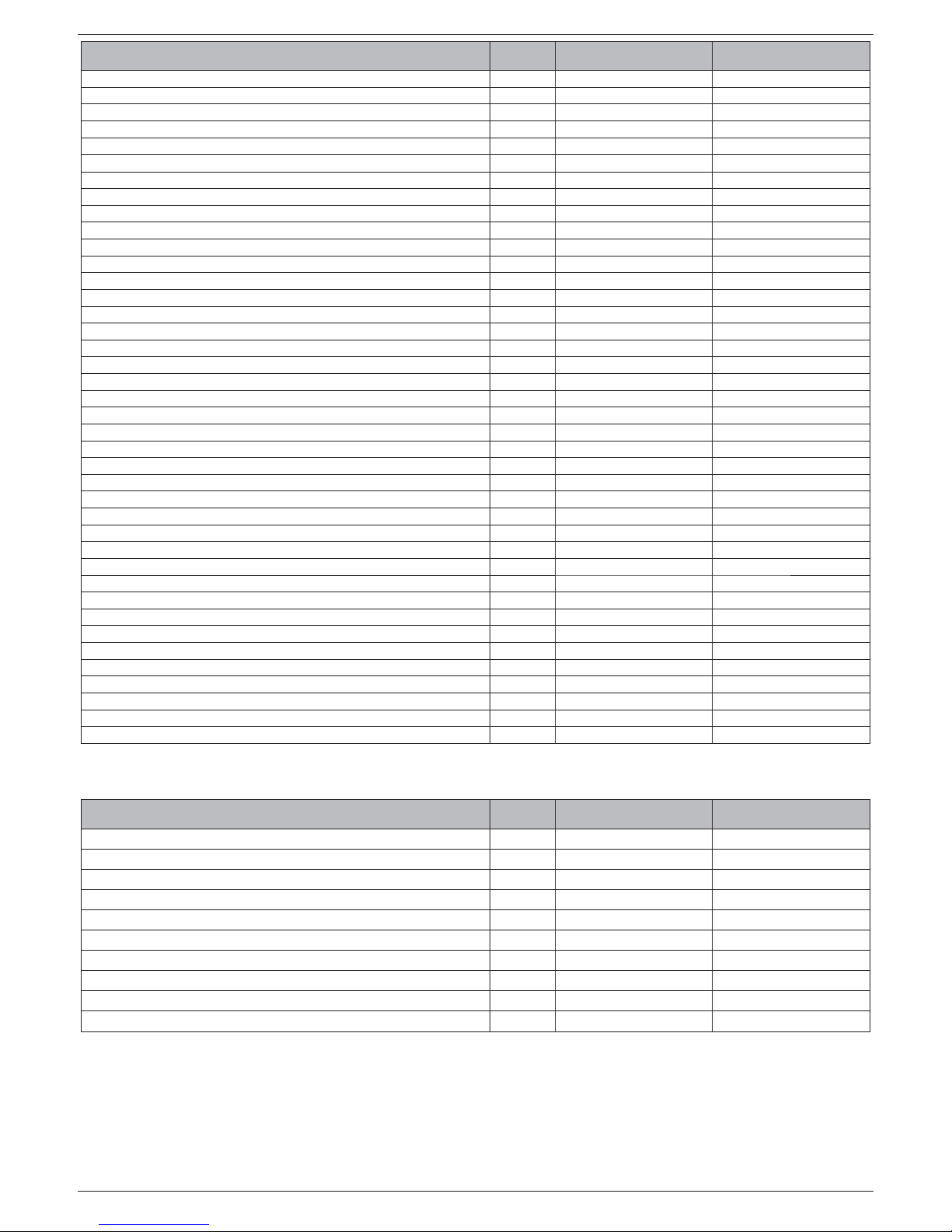

(D) Permanent

(T) Temporary. In this operating status the boiler attempts to eliminate the fault on its own

(°) See NOTE in the next page.

(*) If these two errors occur, check the pressure indicated on the water gauge. If the pressure is insuffi cient (< 0,4 bar, red area), proceed with the fi lling

operations described in the chapter “Filling and emptying the systems”.

If the system’s pressure is suffi cient (> 0,6 bar, blue area) the malfunction is caused by a lack of water circulation. Contact the Technical Assistance.

(-) Call the technical assistance service

FAULT Alarm Symbol Symbol

ID

FLAME FAILURE BLOCK (D) 10 YES NO

PARASITE FLAME (T) 11 NO YES

RE-ATTEMPT IN PROGRESS (T) 12 NO NO

MINIMUM GAS INPUT PRESSURE (T) 13 NO YES

MINIMUM GAS INPUT PRESSURE (D) 14 YES NO

FLAME PRESENT IN STAND-BY FOR NO REASON (D) 15 YES YES

LIMIT THERMOSTAT (D) 20 YES NO

SHORT CIRCUIT FUMES PROBE (D) 21 YES YES

MAXIMUM TEMPERATURE FUMES PROBE (D) 22 YES NO

MAXIMUM TEMPERATURE INPUT PROBE (D) 24 YES NO

MAXIMUM TEMPERATURE INPUT PROBE (T) 25 NO YES

MAXIMUM TEMPERATURE RETURN PROBE (D) 26 YES NO

MAXIMUM TEMPERATURE RETURN PROBE (T) 27 NO YES

RETURN-INPUT PROBE DIFFERENTIAL (D) 28 YES YES

FUMES PROBE OVERTEMPERATURE (D) 29 YES YES

VENTILATOR IN CYCLE (low number of revolutions) (D) 33 YES YES

VENTILATOR (cycle start) (D) 34 YES NO

VENTILATOR (cycle end) (T) 35 NO YES

VENTILATOR IN CYCLE (high number of revolutions) (D) 37 YES YES

INSUFFICIENT SYSTEM PRESSURE (D*) 40 YES NO

INSUFFICIENT SYSTEM PRESSURE (T*) 41 NO YES

WATER PRESSURE TRANSDUCER (D) 42 YES YES

ELECTRONIC BOARD (D) 50-59 YES YES

SANITARY PROBE 1 (T°) 60 NO YES

SHORT CIRCUIT/OPEN PRIMARY PROBE (D) 70 YES YES

MAXIMUM TEMPERATURE INPUT PROBE (T) 71 NO NO

SHORT CIRCUIT/OPEN RETURN PROBE (D) 72 YES YES

LOW TEMPERATURE THERMOSTAT (T) 77 NO YES

INPUT/RETURN DIFFERENTIAL (T) 78 NO YES

INPUT/RETURN DIFFERENTIAL (D) 79 YES NO

SYSTEM ANOMALY (D) 80 YES YES

SYSTEM ANOMALY (T) 81 NO YES

SYSTEM ANOMALY (D) 82 YES YES

SYSTEM ANOMALY (T) 83 NO YES

CLEAN PRIMARY EXCHANGER (-) 91 NO YES

CONDENSATE OR CONDENSATE SENSOR (D) 92 YES NO

CONDENSATE OR CONDENSATE SENSOR (T) 93 NO YES

CONDENSATE SENSOR OR OPEN CIRCUIT (T) 95 NO YES

17

EXCLUSIVE BOILER GREEN HE B.S.I.

Resetting faults

Wait for about 10 seconds before resetting operating conditions.

Then proceed as follows:

1) Viewing just the symbol

If disappears, it means that an operating fault has been

discovered which the boiler is attempting to solve on its own

(temporary stoppage). If the boiler does not resume normal operation, two things may happen:

case A (fi g. 39)

disappears, the symbol and a different alarm code

appear. In this case, proceed as described in point 2.

case B (fi g. 40)

and a different alarm code are displayed together with .

In this case, proceed as described in point 3.

case C - alarm 91 (Call the technical assistance service)

The boiler has a self-diagnosis system which, on the basis of the

hours totalised in particular operating conditions, signals the need

for maintenance or cleaning of the primary exchanger (alarm code

91). After cleaning using the kit supplied as an accessory, reset the

hour counter as follows:

- disconnect the mains power supply

- remove the screws and hooks securing the electrical cover

- remove connector J13 (see wiring diagram)

- power the boiler and wait for alarm 13 to appear on the display

- disconnect the power supply and reconnect connector J13

- put back the electrical cover and restart the boiler

N.B.: perform the counter reset procedure every time the primary

exchanger is thoroughly cleaned or replaced.

2) Viewing just the

symbol (fi g. 41)

Press the button to reset the appliance. If the boiler starts

the ignition phase and resumes normal operation, it may have

stopped by accident.

If these stoppages should continue, contact the Technical Assistance Centre.

3) Viewing the and symbols (fi g. 42)

Contact the Technical Assistance Centre.

Note

Fault in domestic hot water circuit sensor - 60: the boiler

works regularly but does not ensure the stability of the hot water

temperature which, however, is delivered at a temperature of

approximately 50°C. The fault code is only displayed in standby.

“temporary fault”

“permanent fault”

“temporary fault”

“permanent fault”

This boiler incorporates a new generation of electronic boards that,

by setting/modifying operating parameters, allow the boiler to be

personalised to satisfy various system and/or user requirements.

The programmable parameters are shown in the table on the next

page.

The parameters must be programmed with the boiler in the

OFF position. To do this, press the button until the display

shows “- -” (fi g. 43).

During parameter modifi cation operations, the “select functions”

button acts as an ENTER (confi rm) button, the button acts as

an ESCAPE (escape) button. If no confi rmation is given within

10 seconds, the value is discarded and returns to the previously

set one.

Setting the password

Press and hold down the select functions button and the button

together for about 10 seconds. The display will look like fi g. 44.

Enter the password for accessing the parameter modifi cations

function by turning the domestic hot water temperature selector

to obtain the required value. The password for accessing the

parameter programming function is located on the back side of the

control panel. Confi rm by pressing ENTER.

Modifying parameters

Turn the domestic hot water temperature selector (fi g. 45) to

sequentially scroll the two-fi gure codes of the parameters indicated

in the table. After identifying the parameter you wish to modify,

proceed as follows:

- press ENTER to access the parameter modifi cation function.

When ENTER is pressed, the previously set value starts fl ashing

(fi g. 46)

- turn the domestic hot water temperature selector to change the

value

- press ENTER to confi rm the new value. The digits stop fl ashing

- press ESCAPE to exit.

The boiler returns to the “- -” (OFF) status.

To reset, press the

button (fi g. 43).

43

44

45

46

ENTER

ESCAPE

parameter

number

parameter

value

13 - PROGRAMMING PARAMETERS

39

40

41

42

18

EXCLUSIVE BOILER GREEN HE B.S.I.

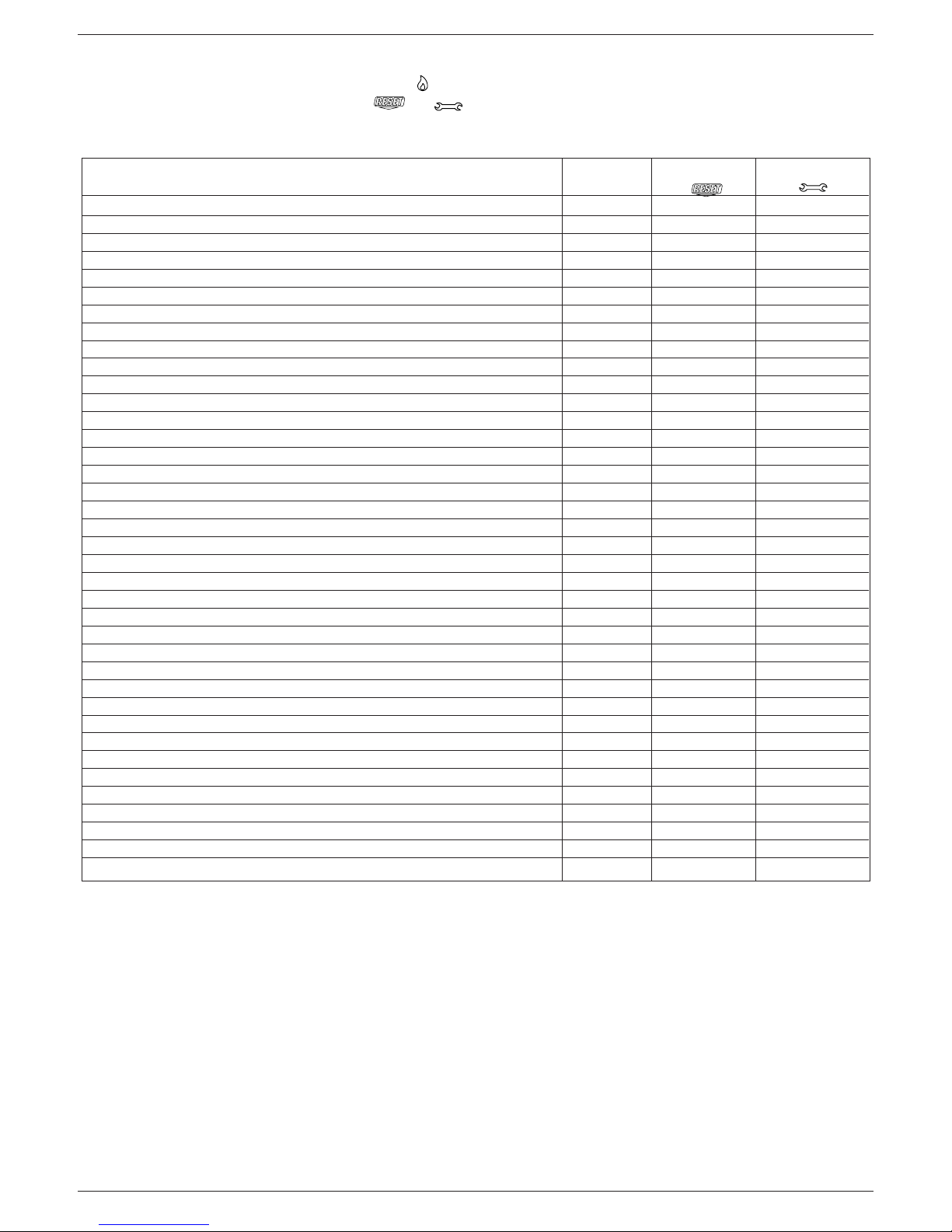

Programmable parameters

N°

PAR.

DESCRIPTION PARAMETERS

UNIT OF

MEASURE

MIN MAX

DEFAULT

(setted in

factory)

PARAMETERS

(setted by techn.

assist. centre)

1 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

2 THIS PARAMETER IS NOT infl uential 10*-16-20*-26-30-34-50*-70* 26 (25kW)

34 (35kW)

3 INSULATION LEVEL OF BUILDING min 5 20 5

10 DHW MODE 0 (OFF)

1 (Instantaneous)

2 (Mini-tank)

3 (External water-tank with thermostat)

4 (External water-tank with sensor)

5 (Integrated water tank)

5

11 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 60

12 WATER TANK MAXIMUM SET-POINT ° C 40 80 60

13 DELIVERY TERMPERATURE EXT. WATER TANK °C 50 85 80

14 DELTA EXTERNAL WATER TANK (ON) °C 0 10 5

20 HEATING MODE 0 (OFF)

1 (ON)

2 (not used)

3 (CONNECT AP)

4 (not used)

5 (not used)

6 (CONNECT AT/BT)

1

21 HEATING CIRCUIT MAXIMUM SET-POINT ° C 40 80 80

22 MINIMUM HEATING SET POINT °C 20 39 20

23 MAXIMUM HEATING VENTILATOR SPEED revs/min G20 G31

25kW 60** 60**

35kW 60** 59**

MAX

24 MINIMUM HEATING VENTILATOR SPEED revs/min G20 G31

25kW 12** 19**

35kW 12** 19**

MIN

25 DIFFERENTIAL HEATING POSITIVE °C 2 10 6

26 DIFFERENTIAL HEATING NEGATIVE °C 2 10 6

28 MAX HEATING POWER REDUCTION TIMER min 0 20 15

29 FORCED HEATING SHUT DOWN TIMER min 0 20 5

30 HEATING TIMER RESET FUNCTION - 0 (NO) 1 (YES) 0

31 MAXIMUM HEATING SET POINT 2CH (II circuit) °C 40 80 45

32 MINIMUM HEATING SET POINT 2CH (II circuit) °C 20 39 25

40 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

41 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

42 S.A.R.A. FUNCTION 0 (OFF)

1 (AUTO)

1

43 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

44 THERMOREGULATION FUNCTION 0 (OFF)

1 (AUTO)

1

45 INCLINATION THERMOREGULATION CURVE (OTC) - 2,5 40 20

46 THERMOREGULATION FUNCTION 2CH 0 (OFF)

1 (AUTO)

1

47 INCLINATION THERMOREGULATION CURVE

(OTC) 2CH

- 2,5 40 10

48 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 50 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 1

51 HEAT REQUEST TYPE CH1 (I circuit) - 0 1 0

52 HEAT REQUEST TYPE CH2 (II circuit) - 0 1 0

61 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 4

62 HEATING ANTIFREEZE FUNC. DELIVERY TEMP.

(ON)

°C 0 10 6

63 WATER TANK ANTIFREEZE FUNC. DELIV. TEMP.

(ON)

°C 0 10 6

65 EXTERNAL SENSOR REACTIVITY 0 (very fast) 255 (very slow) 20

85 SEMI-AUTOMATIC FILLING 0 (disabled)

1 (enabled)

1

86 AUTOMATIC FILLING PRESSURE (ON) bar 0,4 1,0 0,6

19

EXCLUSIVE BOILER GREEN HE B.S.I.

Checking the connection with the external probe

After connecting the external probe to the boiler, use the INFO

function to check that the probe has been automatically recognised

by the temperature control card. Immediately after installation, the

PARAMETER AVAILABLE IN THE PROGRAMMING MODE

TYPE OF BUILDING 3 INSTALLATION AND CALIBRATION & SERVICE

MAXIMUM HEATING SET POINT 21 INSTALLATION

MINIMUM HEATING SET POINT 22 INSTALLATION

ENABLE THERMOREGULATION FUNCTION 44 INSTALLATION

OFFSET TEMPERATURE CURVE 45 INSTALLATION AND CALIBRATION & SERVICE

TYPE OF HEAT REQUEST 51 INSTALLATION

To access the programming mode, consult “Programming

parameters”.

PARAMETER 03. Type of building

In order to calculate delivery temperature, the temperature control

system does not directly use the external temperature value

but considers the heat insulation of the building: in well-lagged

buildings, external temperature variations affect the ambient

temperature less than they do in badly-lagged buildings. Use

parameter 3 to set the heat insulation level of the building according

to the following scheme:

value read by the probe may very well be higher then that measured

by a reference probe.

Enable and optimise the THERMOREGULATION function by setting

the following parameters:

New houses Old houses

Hollow bricks Solid bricks Stones

a 19 14 12 8

b 20 16 15 11

c 19 15 14 9

d 18 12 10 5

types of building

a

b

c

d

PARAMETERS 21 and 22. Maximum and minimum delivery

temperature

These two parameters limit the delivery temperature automatically

produced by the TEMPERATURE CONTROL function. PARAMETER

21 determines MAXIMUM DELIVERY TEMPERATURE (MAXIMUM

HEATING SET POINT) while PARAMETER 22 determines

MINIMUM DELIVERY TEMPERATURE (MINIMUM HEATING SET

POINT).

PARAMETER 45. Choosing the offset temperature curve (graph 1)

The offset heating curve maintains a theoretical ambient

temperature of 20°C at external temperatures ranging from +20°C

to -20°C. The choice of the curve depends on the rated minimum

external temperature (on the geographical area, therefore) and the

rated delivery temperature (on the type of system, therefore) and

must be carefully calculated by the fi tter using the following formula:

PARAMETER 44. Enable thermoregulation function

The connected external temperature probe combined with

PARAMETER 44 provides the following operating modes:

EXTERNAL PROBE CONNECTED and PARAMETER 44 = 0 (OFF)

in this case the TEMPERATURE CONTROL function is disabled

even though the external probe is connected. The temperature read

by the external probe can always be viewed by pressing the INFO

button. The TEMPERATURE CONTROL symbols are not displayed.

EXTERNAL PROBE CONNECTED, PARAMETER 44 = 1 (ON) in

this case the TEMPERATURE CONTROL function is enabled. The

temperature read by the external probe and the TEMPERATURE

CONTROL symbols can be viewed by pressing the INFO button.

The TEMPERATURE CONTROL function cannot be enabled

unless the external probe has been fi tted and connected. In

this case, PARAMETER 44 is ignored and has no effect on

boiler operation.

If, from your calculations, you obtain an intermediate value between

two curves, we suggest choosing the compensation curve closest

to the value obtained.

Example: if the value obtained from the calculations is 8, this is

between curve 7.5 and curve 10. In this case, choose the closest

curve, which is 7.5.

rated delivery T - 20

P. 45 = 10 x

20- rated min. external T

PARAMETER 51. Type of heat request

IF AN AMBIENT THERMOSTAT IS CONNECTED TO THE

BOILER, SET PARAMETER 51 = 0 (graph 2).

The ambient thermostat makes a heat request when its contact

closes, while it stops it when its contact opens. Though delivery

temperature is automatically calculated by the boiler, the user may

manually override it. By modifying HEATING on the user interface,

the HEATING SET POINT will no longer be available but just a

value that can be set from +5 to -5°C as required. Modifi cations to

this value do not directly change delivery temperature but affect the

calculation made to automatically determine its value by modifying

the reference temperature of the system (0 = 20°C).

14 - SETTING THE THERMOREGULATION

N°

PAR.

DESCRIPTION PARAMETERS

UNIT OF

MEASURE

MIN MAX

DEFAULT

(setted in

factory)

PARAMETERS

(setted by techn.

assist. centre)

87 THIS PARAMETER IS NOT USED ON THIS MODEL. DO NOT MODIFY 90 VARIABLE SPEED PUMP - 0 100 41

92 enable post-circulation from dhw to heating - 0 1 0

93 duration of post-circulation from dhw to heating - 1 255 5

94 pump in continual mode ch1 (circuit 1) - 0 1 0

95 pump in continual mode ch2 (circuit 2) - 0 1 0

* Power not available at the moment

** The value is expressed on the display in revs/min/100 (example 3.600 = 36)

Some defaults may be different from what is indicated in the table for updates to the board

20

EXCLUSIVE BOILER GREEN HE B.S.I.

EXTERNAL TEMPERATURE (°C)

THERMOREGULATION CURVES

P21 = MAXIMUM HEATING SET POINT

P22 = MINIMUM HEATING SET POINT

GRAPH 1

DELIVERY TEMPERATURE (°C)

EXTERNAL TEMPERATURE (°C)

TEMPERATURE CURVE CORRECTION

0 C

+ 5 C

- 5 C

10

20

30

40

50

60

70

80

90

-20-15-10-5051015202530

GRAPH 2

10

20

30

40

50

60

70

80

90

-20-15-10-505101520

Curva climatica GIORNO

Curva climatica NOTTE

PARALLEL NIGHT REDUCTION

DELIVERY TEMPERATURE (°C)

EXTERNAL TEMPERATURE (°C)

GRAPH 3

DAY

temperature curve

NIGHT

temperature curve

DELIVERY TEMPERATURE (°C)

CONNECT AT/BT

In case of using CONNECT AT/BT, accessory supplied on request,

the boiler gives the possibility to choose 2 thermoregulation curves:

- OTC 1 CH (parameter 45) for a direct system

- OTC 2 CH (parameter 47) for a mixed system.

Even in case of second circuit (2CH) the curve depends on the

external minimum project temperature (on the geographical area,

therefore) and on the delivey project temperature (on the type of

system, therefore); the installer must to put attention to calculate

it using the following formula:

Parameters 31 and 32 give the possibility to defi ne the maximum

and the minimum central heating set-point of the second circuit.

To correct the curve in this confi guration, please refer to the

instructions supplied with the accessory.

rated delivery T - 20

20- rated min. external T

P. 47 = 10 x

DHW operation

CH operation

Qn nominal capacity

Pn nominal power

IP protection level

P. min minimum pressure

Pmw DHW maximum pressure

Pms CH maximum pressure

T temperature

η working effi ciency

D specifi c capacity

NOx NOx value class

15 - SERIAL NUMBER PLATE

20

30

40

50

60

70

80

90

100

-20-15-10-505101520

32,5 25

17,5

10

2,5

P. 21

P. 22

20

30

27,5

22,535

37,5

40

5

7,5

15

12,5

IF A PROGRAMMABLE TIMER IS CONNECTED TO THE

BOILER, SET PARAMETER 51 = 1 (graph 3).

When the contact is closed, the heat request is made by the

delivery probe on the basis of the external temperature in order

to maintain the rated ambient temperature at the DAY level (20

°C). When the contact opens, it does not stop the heat request but

reduces (parallel shift) the temperature curve to the NIGHT level

(16 °C). Though delivery temperature is automatically calculated

by the boiler, the user may manually override it.

By modifying HEATING on the user interface, the HEATING SET

POINT will no longer be available but just a value that can be set

from +5 to –5°C as required.

Modifications to this value do not directly change delivery

temperature but affect the calculation made to automatically

determine its value by modifying the reference temperature of the

system (0 = 20 °C for DAY level; 16 °C for NIGHT level).

21

EXCLUSIVE BOILER GREEN HE B.S.I.

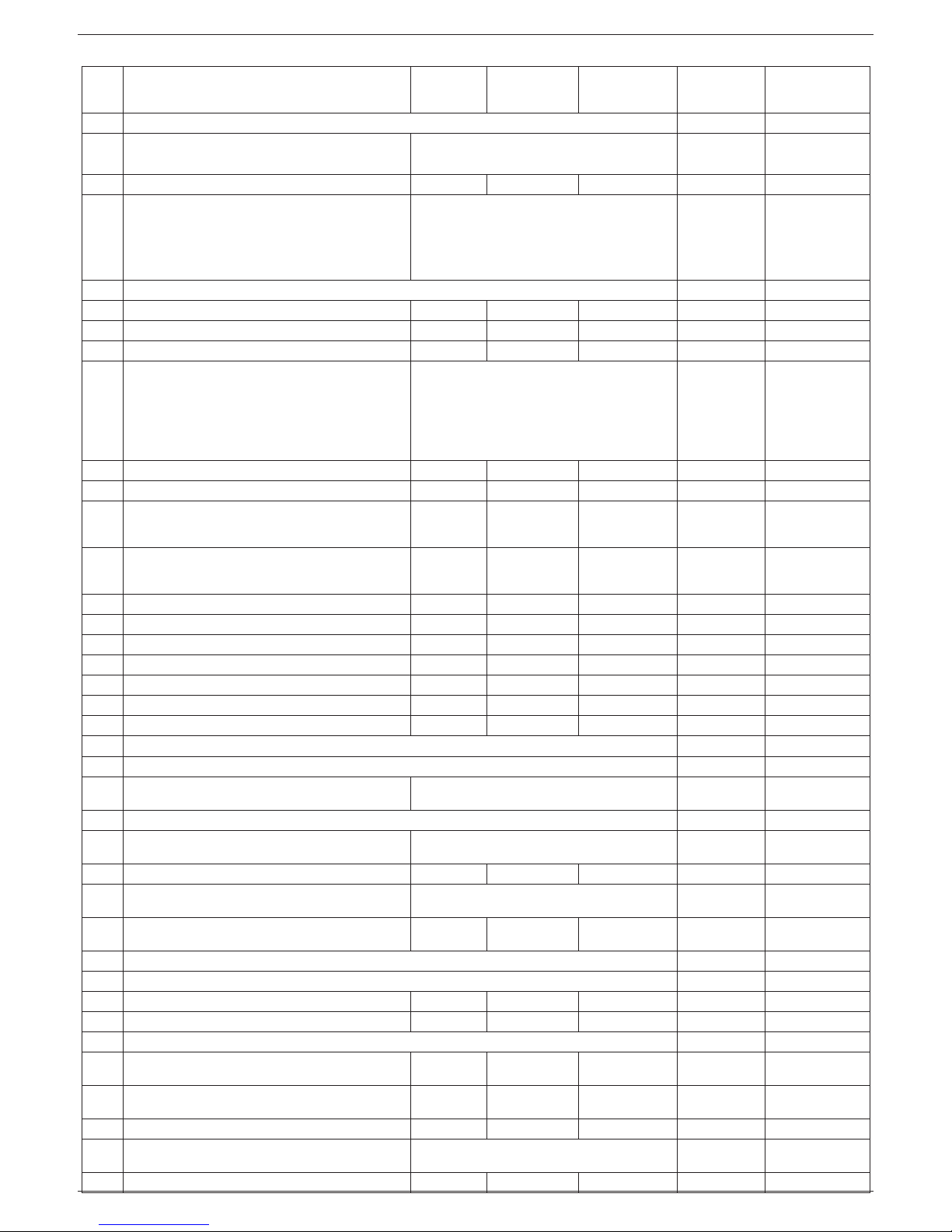

table 1

MAXIMUM NUMBER OF

FAN REVOLUTIONS

G20 G31

25 B.S.I. 60 60 revs/min

35 B.S.I. 60 59 revs/min

MINIMUM VENTILATOR SPEED (P. LP)

- Select parameter LP

- Press the ENTER button, then modify the value of the parameter

by turning the sanitary water temperature selector. The minimum

speed of the fan is linked with the type of gas and the power of

the boiler, table 2

- Turn the sanitary water temperature selector in order to adjust the

set value

- Confi rm the new value you have set by pressing ENTER.

The value indicated on the display is expressed in revs min/100

(example 3600 = 36).

The value set during this operation automatically modifi es the maxi-

mum value of parameter 24.

table 2

MINIMUM NUMBER OF

FAN REVOLUTIONS

G20 G31

25 B.S.I. 12 19 revs/min

35 B.S.I. 12 19 revs/min

VENTILATOR IGNITION SPEED (P. SP)

- Select parameter SP

- Press the ENTER button, then modify the value of the parameter

by turning the sanitary water temperature selector. The standard

slow start value is 3700 revs/min (25 B.S.I.), 3300 revs/min (35

B.S.I.)

- Confi rm the new value you have set by pressing ENTER.

MAXIMUM POWER ADJUSTMENT (P. HH)

- Turn the boiler OFF

- Select the parameter HH and wait for the boiler to come on

- Check that the maximum CO

2

reading on the analyser (see

paragraph “Checking combustion parameters”, page 20)

corresponds with the values indicated in table 3.

If the CO

2

proves to comply with the values in the table, proceed to

adjust the next parameter (LL - adjusting the minimum), if different

modify the value by turning the

maximum power adjustment screw with a screwdriver (clockwise to

decrease) until you obtain a value contained in table 3.

The boiler has already been factory adjusted by the manufacturer.

If a new adjustment is required, for example, after extraordinary

maintenance, replacing the gas valve or converting from natural

gas to LPG, proceed as follows.

Maximum and minimum power, minimum and maximum

heating, must be adjusted in the indicated sequence by

qualifi ed staff.

- Loosen the two fi xing screws (A) and remove the shell (fi g. 3)

- Lift up the panel and turn it forwards

- Loosen the pressure tap screw downline from the gas valve by

about two turns and connect the pressure gauge to it

CALIBRATION & SERVICE operations must be performed with

the boiler in the OFF position. To do this, press the

button

until the display shows “- -” (fi g. 43).

During parameter modifi cation operations, the “select functions”

button acts as an ENTER (confi rm) button, the button acts

as an ESCAPE button. If no confi rmation is given within 10

seconds, the value is discarded and returns to the previously

set one.

Setting the password

Press and hold down the operating mode button and the button

together for about 10 seconds. The display will look like fi g. 44.

Enter the password for accessing the parameter modifi cations

function by turning the domestic hot water temperature selector to

the required value.

The password is located on the back side of the control panel.

Confi rm by pressing ENTER.

Calibration phases

Turn the domestic hot water selector to sequentially scroll the

CALIBRATION & SERVICE phases:

- 1 gas type

- 2 boiler power (do not modify this parameter)

- 10 domestic hot water mode (do not modify this parameter)

- 3 insulation level of building (only if external sensor is

connected)

- 45 inclination of thermoregulation curve (OTC), only if external