Page 1

EXCLUSIVE C

Installer and user manual

RO

MANUAL DE INSTALARE SI UTILIZARE

ENESINSTALLER AND USER MANUAL

MANUAL DE INSTALACIÓN Y USO

Page 2

Installer’s-user’s manual 3-28

Boiler operating elements 40

Electric diagrams 41

Hydraulic circuit 42

Circulator residual head 43

EXCLUSIVE boiler complies with basic requirements of the

following Directives:

- Gas directive 2009/142/EC

- Efciencydirective:Article7(2)andAnnexIIIofdirective92/42/

EEC

- Electromagnetic compatibility directive 2014/30/EU

- Low-voltage directive 2014/35/EU

- Directive 2009/125/EC Ecodesign for energy-using appliances

- Directive 2010/30/EU Indication by labelling of the consumption

of energy by energy-related products

- DelegatedRegulation(EU)No.811/2013

- DelegatedRegulation(EU)No.813/2013

- DelegatedRegulation(EU)No.814/2013.

EN

In some parts of the booklet, some symbols are used:

b

WARNING = for actions requiring special care and adequate

preparation.

a

PROHIBITED =foractionsTHATMUSTNOTbeperformed.

Sectiondestinedforuseralso.

Warning

This instructions manual contains data and information for both the user and

theinstaller. Specically,note that the user,for the use of the appliance,

must refer to chapters:

• Warnings and safety

• Maintenance

a

The user must not perform operations on the safety devices,

replacing parts of the product, tamper with or attempt to repair

the appliance. These operations must be entrusted exclusively

professionallyqualiedpersonnel.

b

The manufacturer is not liable for any damage caused by the

non-observance of the above and/or the failure to comply with the

regulations.

RANGE RATED

Thisboilercanbeadaptedtotheheatrequirementsofthesystem,andinfactitispossibletosettherangeratedparameterasshowninthespecic

paragraph.

Putthesetvalueontheadhesivelabelsuppliedand,forsuccessivecontrols,refertothenewvalue.

0476

0476CS1393

Page 3

3

ENGLISH

1 WARNINGS AND SAFETY

b

The boilers manufactured in our factories are checked even in

the smallest details in order to protect users and installers against

possible injury. After working on the product, qualied personnel

must check the electrical wiring, in particular the stripped part of

leads, which must not protrude from the terminal board and avoiding

possible contact with live parts of the leads themselves.

b

This installer and user manual constitutes an integral part of the

product: make sure they are always kept with the appliance, even

if it is transferred to another owner or user, or moved to another

heating system. In case of loss or damage, please contact your local

Technical Assistance Service for a new copy.

b

This boiler may only be installed and serviced by personnel qualied

in accordance with current regulations.

b

The installer must instruct the user about the operation of the

appliance and about essential safety regulations.

b

This boiler must only be used for the application it was designed for.

The manufacturer accepts no liability within or without the contract

for any damage caused to people, animals and property due to

installation, adjustment and maintenance errors or to improper use.

b

After removing the packaging, make sure the content is in good

condition and complete. Otherwise, contact the dealer from whom

you purchased the appliance.

b

The safety valve outlet must be connected to a suitable collection

and venting system. The manufacturer declines all liability for any

damage caused due to any intervention carried out in the safety

valve.

b

The seal of the condensate drainage connection line must be secure,

and the line must be fully protected against the risk of freezing (e.g.

by insulating it).

b

Check that the rain water drainage channel of the ue gases tting

and the relative connection pipe are free of obstructions.

b

Dispose of all the packaging materials in the suitable containers at

the corresponding collection centres.

b

Dispose of waste by being careful not to harm human health and

without employing procedures or methods which may damage the

environment.

b

At the end of its life, the product should be not be disposed of as solid

urban waste, but rather it should be handed over to a differentiated

waste collection centre.

b

During installation, inform the user that:

- in the event of water leaks, the water supply must be shut off and

the Technical Assistance Centre must be contacted immediately

- periodically check that the operating pressure of the hydraulic

system is comprised between 1 and 1.5 bar. If it is not, request

the prompt intervention of the Technical Assistance Centre or else

professionally qualied personnel.

b

If the boiler is not used for a long period of time, it is recommended

to perform the following operations:

- turn the main appliance switch and the main system switch to “off”

- close the fuel and water valves for the heating and domestic hot

water system

- empty the heating and domestic hot water circuits if there is the

risk of freezing

b

Boiler maintenance must be carried out at least once a year; this

should be booked in advance with the Technical Assistance Centre

to ensure the necessary safety standards.

For safety reasons, please remember that:

a

The appliance is not to be used by children or unassisted people with

disabilities.

a

It is forbidden to touch the appliance while barefoot or if parts of your

body are wet.

a

It is forbidden to activate electric devices or appliances such as

switches, household appliances and so on if you notice a smell of

fuel or unburned fuel. In this case:

- ventilate the room by opening the doors and windows;

- close the fuel shut-off device;

- request the prompt intervention of the Technical Assistance Centre

or else professionally qualied personnel.

INSTALLATION MANUAL

EN

ENGLISH

a

Any technical or cleaning operation is forbidden before disconnecting

the appliance from the main power supply by turning the system’s

main switch to “OFF” and the main switch of the boiler to “OFF”.

a

Do not modify the safety or adjustment devices without the

manufacturer’s authorisation and precise instructions.

a

It is prohibited to pull, detach or twist the electrical cables coming

from the appliance even if it is disconnected from the mains power

supply.

a

Avoid blocking or reducing the size of the air vent openings in

the installation room, do not leave inammable containers and

substances in the room where the appliance is installed.

a

Do not leave ammable containers and substances in the room

where the device is installed.

a

It is forbidden to disperse the packaging material in the environment

and leave it within children’s reach as it may be a potential source

of danger. It must be disposed in accordance with the present law.

a

The condensate drain outlet must be turned towards the drain outlet

avoiding the formation of more siphons.

a

Never carry out any work on the gas valve.

2

DESCRIPTION

The EXCLUSIVE boilers have a new ACC (Activate Combustion Control)

system.

This new control system, developed by Beretta, ensures functionality,

efciency and low emissions under any conditions.

The ACC system uses an ionisation sensor immersed in the burner ame,

whose information allows the control board to operate the gas valve that

regulates the fuel.

This sophisticated control system provides the auto-regulation of the

combustion, so there is no need for an initial calibration. The ACC system is

able to adapt the boiler to operate with different gas compositions, different

outlet pipes lengths and different altitudes (within the specied design

limits).

The ACC system can also perform an auto-diagnostic operation that locks

out the burner before the permitted upper emission limit is exceeded.

EXCLUSIVE is a type C condensing wall-hung boiler to be used for heating

and the production of domestic hot water: depending on the fume discharge

accessory used, it is classied in categories B23P;B53P; C13,C13x;

C33,C33x; C43,C43x; C53,C53x; C63,C63x; C83, C83x; C93, C93x.

In B23P conguration (when installed indoors), the appliance cannot

be installed in bedrooms, bathrooms, showers or where there are open

replaces without a proper air ow. The room where the boiler is installed

must have proper ventilation. Detailed requirements for the installation of

the ue, the gas piping and for ventilating the room, can be found in UNI

7129-7131.

In conguration C, the appliance can be installed in any type of room (there

are no limitations due to ventilation conditions or room volume).

3 INSTALLATION

3.1 Cleaning the system and characteristics of the

water

In the case of a new installation or replacement of the boiler, it is necessary

to clean the heating system.

To ensure the device works well, top up the additives and/or chemical

treatments (e.g. anti-freeze liquids, lming agents, etc.) and check the

parameters in the table are within the values indicated.

PARAMETERS UM

HEATING CIRCUIT

WATER

FILLING WATER

pH value 7-8 Hardness °F - 15-20

Appearance - clear

b

Before installation, wash all system piping carefully in order to

remove any residues that may impair the operation of the appliance.

Page 4

4

EXCLUSIVE

b

Under the safety valve, install a water collecting funnel with the

corresponding discharge in the event of leaks due to the overpressure

of the heating system. The domestic hot water circuit does not need a

safety valve, but make sure that the pressure of waterworks does not

exceed 6 bar. In case of doubts, install a pressure reducer.

b

Prior to ignition, make sure that the boiler is designed to operate

with the gas available; this can be checked by the wording on the

packaging and by the adhesive label indicating the gas type.

b

It is very important to highlight that in some cases the ues are under

pressure, so the joints of the various elements must be airtight.

3.2 Installation regulations

The installation must be carried out by qualied personnel, in compliance

with the following reference standards:

- UNI 7129-7131

- CEI 64-8.

Always comply with local standards of the Fire Department, the Gas

Company and with possible municipal dispositions.

POSITION

EXCLUSIVE is a wall-hung boiler for heating and for the production of hot

water. There are two categories, depending on the type of installation:

- B23P-B53P boiler type - forced open installation, with ue gas discharge

pipe and pick-up of combustion air from the installation area. If the

boiler is not installed outdoors, the air intake in the installation area is

compulsory;

- C13,C13x; C33,C33x; C43,C43x; C53,C53x; C63,C63x; C83,C83x,

C93,C93x type boiler: appliance with airtight chamber, with ue gas

discharge pipe and pick-up of combustion air from outside.

It does not require an air intake point in the installation area.

This type MUST be installed using concentric pipes, or other types of

discharge designed for condensing boilers with an airtight chamber.

MINIMUM DISTANCES (g. 6-6a)

To ensure access to the boiler for normal maintenance operations, respect

the minimum installation clearances envisaged.

For correct appliance positioning, bear in mind that:

- it must not be placed above a cooker or other cooking device

- it is forbidden to leave inammable products in the room where the boiler

is installed

- heat-sensitive walls (e.g. wooden walls) must be protected with proper

insulation.

b

In case of installation it is ESSENTIAL to provide the necessary

space for the introduction of the instrument for the combustion

analysis check. In g. 6a is shown a sample drawing where the

distances between boiler and cabinet/niche were obtained using a

300mm length tool.

Longer lengths of tools require more space.

3.3 Elimination of air from the heating circuit and

from the boiler - g. 7

During the initial installation phase, or in the event of extraordinary

maintenance, you are advised to perform the following sequence of

operations:

1. Open by two or three turns the automatic relief valve cap (A) and leave

it open.

2. Open the system lling tap located on the water unit.

3. Switch on the electricity supply to the boiler, leaving the gas tap turned

off.

4. Activate a heat request via the room thermostat or the remote control

panel, so that the 3-way valve goes into heating mode.

5. Activate a request for DHW as follows: open a tap for 30” per minute so

that the three-way valve cycles from heating to DHW and vice versa for

about ten times (in this situation, the boiler will go into alarm due to lack

of gas, therefore reset it whenever this is proposed).

6. Continue the sequence until no more air is felt coming from the air vent

valve.

7. Check the system pressure level is correct (the ideal level is 1 bar).

8. Turn off the system lling tap.

9. Turn on the gas tap and ignite the boiler.

3.4 Positioning the wall-mounted boiler and hydraulic

connections - g. 8-9

The boiler comes as standard with a boiler support plate. The position and

dimension of hydraulic ttings are shown in the detail drawing.

For the assembly, proceed as follows:

- fasten the boiler support plate (F) to the wall and use a spirit level to

make sure it is perfectly horizontal

- mark the 4 holes (ø 6 mm) envisaged for securing the boiler support

plate (F)

- make sure that all measurements are exact, then drill the wall using drill

tips with the diameters indicated above

- x the plate with the built-in template to the wall

- carry out the hydraulic connections.

3.5 Electrical wiring - g. 10-11

Low voltage connections

Carry out the low voltage connections as follows:

- use the external cable box supplied as standard

- unscrew the xing screws of the cover (V)

- carry out the connections as shown in g. 11

b

It is recommended to use wires with section not exceeding

0,5mm2.

b

In case of TA or TBT connection, remove the respective shunts

(g. 12).

- close the box with the screws that were previously removed

- press the two tabs on the sides of the box to place it correctly in its

housing in the boiler sliding upward within the guide rails

- tighten the safety screw (V1).

b

If the low voltage electrical connection box is not connected the

boiler does not ignite.

High voltage connections

The connection to the mains supply must be made via a separation device

with an omnipolar opening of at least 3.5 mm (EN 60335/1 - category 3).

The appliance works with alternating current at 230 Volt/50 Hz, and is in

compliance with Standard EN 60335-1.

It is obligatory to make the connection with a safe ground/earth, in

compliance with current directives.

b

It is the responsibility of the installer to provide suitable grounding

for the appliance; the manufacturer will not be liable for any damage

resulting from an incorrect or absent earth connection.

b

It is also recommended to uphold the phase-neutral connection (L-N).

b

The earth conductor must be a couple of cm longer than the others.

The boiler can operate with a phase-neutral or phase-phase supply.

For power supplies that are not earthed, it is necessary to use an isolating

transformer with earth-anchored secondary.

It is forbidden to use gas and/or water pipes to earth electrical appliances.

Use the power cable supplied to connect the boiler to the mains power

supply.

If the power cable has to be replaced, use a HAR H05V2V2-F cable, 3 x

0.75mm2, Ø max external 7 mm.

3.6 Gas connection

The connection of the gas supply must be carried out in compliance with

current installation standards.

Before carrying out the connection, check that the type of gas is that for

which the appliance is set up.

3.7 Removing the casing

To access the components inside, remove the casing as indicated below:

- locate and unscrew the 2 screws (A - g. 13) that x the casing to the

boiler

- by leveraging the xing clips (C - g. 13), unhook the lower part of the

casing

- lift the casing upwards to release it from the top tabs (B - g. 13), then

remove it.

WARNING

b

The possible damage of the frontal panel involves the replacement

of the same.

b

The noise absorbing panels inside the front and side walls ensure

the airtight seal for the air supply duct in the installation environment.

b

It is therefore ESSENTIAL after the dismantling operations to

correctly reposition the components so as not to compromise the

boiler’s operation.

3.8 Flue gas exhaust and combustion air suction

To evacuate the combustion products, refer to UNI 7129-7131. Always

comply with local standards of the Fire Department, the Gas Company and

with possible municipal dispositions.

The release of combustion products is assured by a centrifugal fan and the

control board constantly checks that it is operating correctly. It is essential

for evacuating fumes and adduction boiler combustion air that only original

pipes are used and that the connection is made correctly as shown in the

instructions provided with the ue gas accessories.

A single ue can be connected to several appliances provided that every

appliance is the condensing type.

Page 5

5

ENGLISH

The boiler is a C-type appliance (with airtight chamber), and must therefore

have a safe connection to the ue gas discharge pipe and to the combustion

air suction pipe; these both carry their contents outside, and are essential

for the operation of the appliance.

Both concentric and twin terminals are available.

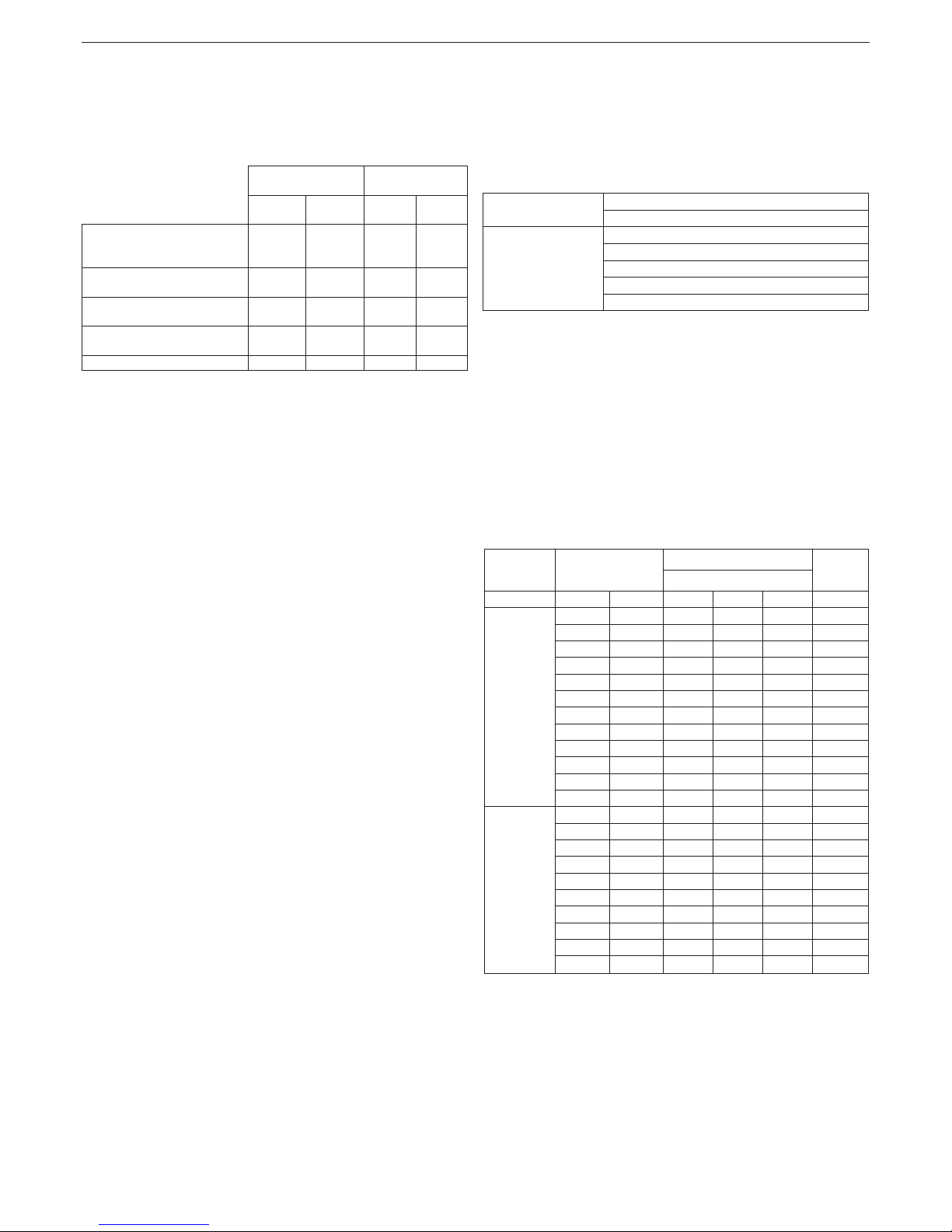

Suction/discharge pipes length table

Maximum straight

length

Pressure drop

25C n 30C n

bend

45°

bend

90°

Flue gases pipe Ø 80 mm

(“forced open” installation)

(type B23P-B53P)

125 m 90 m 1 m 1,5 m

Concentric pipe

Ø 60-100 mm (horizontal)

10 m 10 m 1,3 m 1,6 m

Concentric pipe

Ø 60-100 mm (vertical)

11 m 11 m 1,3 m 1,6 m

Concentric pipe

Ø 80-125 mm

25 m 25 m 1 m 1,5 m

Twin pipe Ø 80 mm 70+70 m 50+50 m 1 m 1,5 m

b

“Straight length” means with terminals and joints but without bends.

b

The boi

ler is supplied without the ue gas outlet/air suction kit, since

it is possible to use the accessories for condensing appliances that

better adapt to the installation characteristics (see catalogue).

b

The maximum lengths of the pipes refer to the ue accessories

available in the catalogue.

b

It is compulsory to use specic pipes.

b

The non insulated ue gas outlet pipes are potential sources of

danger.

b

The use of a longer pipe causes a loss of output of the boiler

b

Make sure the ue gas discharge pipe is tilted 3° towards the boiler.

b

As envisaged by current legislation, the boiler is designed to take

in and dispose of ue gas condensate and/or meteoric water

condensate deriving from the ue gas discharge system using its

own siphon.

b

If a condensate relaunch pump is installed, check the technical

data (provided by the manufacturer) regarding output, to ensure it

operates correctl.

“Forced open” Installation (type B23P/B53P)

In this conguration the boiler is connected to the ø 80 mm ue gases

discharge pipe by means of an adaptor.

- Position the adaptor so that the Ø 60 pipe goes fully into the ue gases

turret of the boiler.

- Once positioned, make sure that the 4 notches (A) on the ange connect

to the groove (B) on the Ø100 of the adaptor.

- Fully tighten the two locking terminals of the ange (C) so the adaptor

itself is restrained.

Concentric pipes (ø 60-100 mm)

- Position the bend so that the Ø 60 pipe goes fully into the ue gases

turret of the boiler.

- Once positioned, make sure that the 4 notches (A) on the ange connect

to the groove (B) on the Ø100 of the bend.

- Fully tighten the two locking terminals of the ange (C) so the bend itself

is restrained.

Twin pipes (ø 80 mm) - see graphs g. 18

The combustion air suction pipe should be selected from the two inputs,

remove the closing plug xed with the screws and x the specic air

deector.

- Position the adaptor on the ue gases pipe so that the Ø 60 pipe goes

fully into the ue gases turret of the boiler

- Once positioned, make sure that the 4 notches (A) on the ange connect

to the groove (B) on the Ø100 of the adaptor.

- Fully tighten the two locking terminals of the ange (C) so the adaptor

itself is restrained.

Concentric pipes (ø 80-125 mm)

- Position the adaptor so that the Ø60 pipe goes fully into the ue turret

of the boiler.

- Once positioned, make sure that the 4 notches (A) on the ange connect

to the groove (B) on the Ø100 of the adaptor.

- Fully tighten the two locking terminals of the ange (C) so the adaptor

itself is restrained.

- Then t the Ø 80-125 adaptor kit on the vertical tting.

Twin pipes ø 80 with ducting Ø50 - Ø60 - Ø80 (g. 15a)

Thanks to the boiler characteristics, a ue gas discharge pipe ø 80 can

be connected to the ducting ranges Ø50 - Ø60 - Ø80.

b

For the ducting, you are advised to make a project calculation in

order to respect the relevant standards in force.

The table shows the standard congurations allowed.

Table of standard pipe configurations (*)

Air suction

1 bend 90° ø 80

4,5m pipe ø 80

Flue gas discharge

1 bend 90° ø 80

4,5m pipe ø 80

Reduction from ø 80 to ø50, from ø 80 to ø 60

Stack base bend 90°, ø 50 or ø 60 or ø 80

For ducting pipe lengths see table

(*) Use ue gas system accessories in plastic (PP) for condensing boilers:

Ø50 and Ø80 H1 class and Ø60 P1 class.

The boilers are factory set to:

25C n: 5.600 r.p.m. (CH) and 7.900 r.p.m. (DHW) and the maximum length

that can be reached is 6m for the ø 50 pipe, 21m for the ø 60 pipe and 115m

for the ø 80 pipe.

30C n: 6.500 r.p.m. (CH) and 7.900 r.p.m. (DHW) and the maximum length

that can be reached is 4m for the ø 50 pipe, 16m for the ø 60 pipe and 83m

for the ø 80 pipe.

Should it be necessary to achieve greater lengths, compensate the pressure drop with an increase in the r.p.m.of the fan, as shown in the adjustments table, to ensure the rated heat input.

b

The minimum calibration is not modied.

Adjustments table

Maximum number

of fan rotations

r.p.m.

Ducting pipes

ΔP at

boiler

output

maximum length (m)

CH DHW Ø 50 Ø 60 Ø 80 Pa

25C n

5.600 7.900 6 21 115 180

5.600 8.000 8 (*) 25 (*) 139 (*) 210

5.700 8.100 10 (*) 32 (*) 175 (*) 255

5.700 8.200 12 (*) 35 (*) 195 (*) 280

5.800 8.300 14 (*) 42 (*) 231 (*) 325

5.900 8.400 17 (*) 48 (*) 263 (*) 365

6.000 8.500 19 (*) 53 (*) 291 (*) 400

6.100 8.600 22 (*) 60 (*) 331 (*) 450

6.200 8.700 24 (*) 66 (*) 363 (*) 490

6.200 8.800 26 (*) 71 (*) 389 (*) 523

6.300 8.900 28 (*) 76 (*) 420 (*) 562

6.400 9.000 31 (*) 82 (*) 452 (*) 601

30C n

6.500 7.900 4 16 83 190

6.600 8.000 5 (*) 19 (*) 103 (*) 225

6.700 8.100 7 (*) 24 (*) 128 (*) 270

6.800 8.200 9 (*) 28 (*) 151 (*) 310

6.900 8.300 11 (*) 33 (*) 174 (*) 350

7.000 8.400 13 (*) 37 (*) 196 (*) 390

7.100 8.500 14 (*) 40 (*) 213 (*) 420

7.200 8.600 16 (*) 44 (*) 236 (*) 460

7.300 8.700 17 (*) 48 (*) 256 (*) 495

7.400 8.800 19 (*) 53 (*) 281 (*) 540

(*) Maximum installable length ONLY with exhaust pipes in H1 class.

Congurations Ø50 or Ø60 or Ø80 show test data veried in the laboratory.

In the case of installations that differ from those indicated in the “standard

conguration” and “adjustments” tables, refer to the equivalent linear

lengths below.

b

In any ca

se, the maximum lengths declared in the booklet are

guaranteed, a

nd it is essential not to exceed them.

Page 6

6

EXCLUSIVE

COMPONENT Ø 50 Linear equivalent in metres Ø80 (m)

Bend 45° Ø 50 12,3

Bend 90° Ø 50 19,6

Extension 0.5m Ø 50 6,1

Extension 1.0m Ø 50 13,5

Extension 2.0m Ø 50 29,5

COMPONENT Ø 60 Linear equivalent in metres Ø80 (m)

Bend 45° Ø 60 5

Bend 90° Ø 60 8

Extension 0.5m Ø 60 2,5

Extension 1.0m Ø 60 5,5

Extension 2.0m Ø 60 12

3.9 Filling the heating system (g. 16)

Note: even if the boiler is tted with a semi-automatic lling device, the

rst lling operation must be carried out by turning the ller tap (B) with the

boiler off.

Once the hydraulic connections have been carried out, ll the heating

system.

This operation must be carried out when the system is cold,carrying out the

following operations:

- open the cap of the lower (A) automatic air vent valve by two or three

turns; to allow a continuous venting of the air, leave the plug of the valve

A open

- make sure the cold water inlet tap is open

- open the lling tap (B) until the pressure indicated by the water pressure

gauge is between 1 and 1.5 bar

- re-close the lling tap.

b

The venting of the boiler takes place automatically via the two

automatic vent valve A positioned on the circulator.

3.10 Draining the heating system (g. 16)

Before starting emptying, switch off the electricity supply by turning off the

main switch of the system.

- Close the heating system’s valves.

- Connect a hose to the system drain valve (C).

- Manually loosen the system drain valve (C).

3.11 Emptying the domestic hot water system

Whenever there is risk of frost, the domestic hot water system must be

emptied in the following way:

- turn off the main water supply tap

- turn on all the hot and cold water taps

- drain the lowest points.

3.12 Circulator settings

Circulator residual discharge head

The boilers is equipped with an already hydraulically and electrically

connected circulator, whose useful available performance is indicated in

the graphs at page 43.

The circulator comes set from the factory with a 6 metre discharge head curve.

The boiler is equipped with an anti-blocking system which starts up an

operation cycle after every 24 hours in standby with the mode selector in

any position.

b

The “antiblocking” function is active only if the boiler is electrically

powered.

a

Operating the circulator without water is strictly forbidden.

If you need to use a different curve you can select the desired level on the

circulator.

Below the main characteristics and the ways to set up their desired operation

are listed.

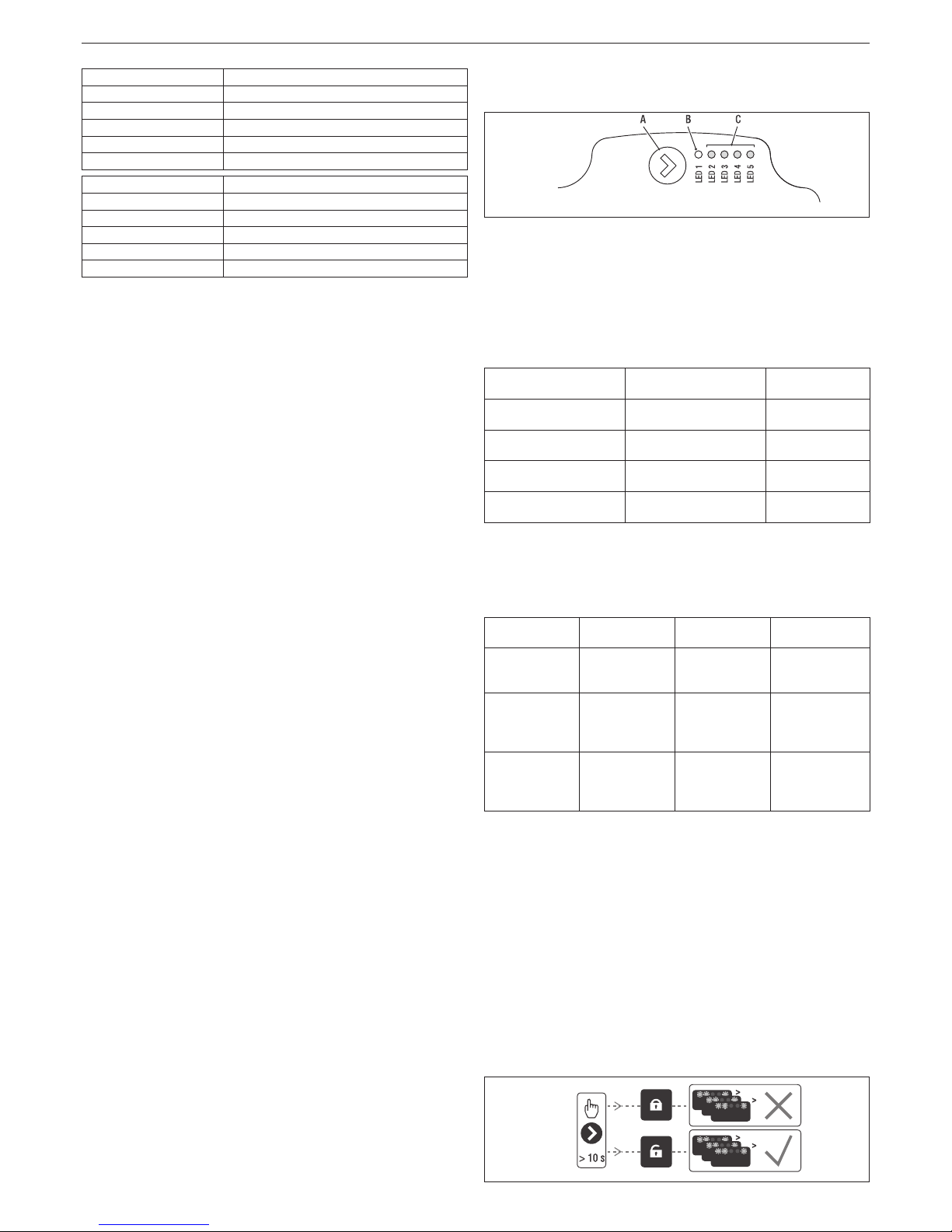

3.12.1 User interface

The user interface is made up of a button (A), a two-coloured red / green

LED (B) and four yellow LEDs (C) arranged in a row.

The user interface allows the operating performance to be viewed (operating

status and alarm status) and it also allows the circulator operating modes

to be set.

The performance, indicated by the LEDs (B) and (C) is always visible during

normal operation of the circulator whereas the settings can be carried out

by pressing the button (A).

3.12.2 Operating status indication

When the circulator is in operation the LED (B) is green. The four yellow

LEDs (C) indicate the electrical energy consumption (P1) as shown in the

following table.

LED status CIRCULATOR status

Consumption in

% of MAX P1 (*)

Green LED on +

1 yellow LED on

Operating at minimum 0~25

Green LED on +

2 yellow LEDs on

Operating at

minimum-medium

25~50

Green LED on +

3 yellow LEDs on

Operating at medium-

maximum

50~75

Green LED on +

4 yellow LEDs on

Operating at maximum 100

(*) For the power (P1) absorbed by the circulator see the indications in the

“Technical Data” table.

3.12.3 Alarm status indication

If the circulator has detected one or more alarms the two-coloured LED (B)

will be red. The four yellow LEDs (C) indicate the type of alarm as shown

in the following table.

LED status

ALARM

description

Status

CIRCULATOR

Possible

SOLUTION

Red LED on +

1 yellow LED

on (LED 5)

The drive shaft

is jammed

Start attempt

every 1.5

seconds

Wait or unjam

the drive shaft

Red LED on +

1 yellow LED

on (LED 4)

Low input

voltage

Warning only.

The circulator

continues to

operate

Check the

input voltage

Red LED on +

1 yellow LED

on (LED 3)

Electrical power

supply fault or

faulty circulator

The circulator

is stopped

Check the

electrical power

supply or replace

the circulator

b

If there a

re several alarms the circulator will display only the alarm

with the highest priority.

3.12.4 Display of active settings

With the circulator powered, press briey on the button (A) to view the active

conguration of the circulator. The LEDs indicate the active settings.

In this phase no variations can be made to the circulator conguration. Two

seconds after the button (A) has been pressed the user interface returns to

the normal operating status display.

3.12.5 Key lock function

The purpose of the key lock function is to prevent accidental modications

to the settings or the improper use of the circulator.

When the key lock function is activated, long-pressing the button (A) is

prevented. This prevents the user from entering the circulator’s operating

modes setting section.

Enabling/disabling the key lock function is achieved by pressing the button

(A) for more than 10 seconds. During this step all of the LEDs (C) will ash

for 1 second.

Page 7

7

ENGLISH

3.12.6 Changing the operating mode

In normal operating conditions the circulator works with the factory settings

or the last settings carried out.

To change the conguration:

Ensure that the key lock function is deactivated.

Press the button (A) for more than 2 seconds until the LEDs begin to ash.

Short-press the button (A) within 10 seconds and the user interface will move

on to display the next settings. The various available settings will appear in

a cyclic sequence.

If the button (A) is not pressed, the last setting will be stored.

A

B

C

A. Operating status display

B. Settings display

C. Settings

Conguración

If the button (A) is pressed you can move back to the “active settings display”

again and check that the LEDs (B) and (C) indicate (for 2 seconds) the last

setting carried out.

If the button (A) is not pressed for more than 2 seconds the user interfaces

switches to the “Operating status display”.

The available settings are shown in gure along with the related representation

of LED (B) and (C).

(*)

LED 1RLED 2GLED 3GLED 4GLED 5

G

(*) Factory set value

R red

G yellow

IM

PORTANT

If the 3 (5 metres) or 4 (4 metres) curves are set the bypass must be replaced

with the one supplied, following the procedure indicated below:

Remove boiler electrical power by setting the system’s main switch to off.

Close the system taps and empty the boiler heating circuit.

Extract the bypass body cover xing spring (D).

Extract the bypass body cover (E).

Replace the bypass valve (F) with the one included.

Ret the bypass body cover and its spring.

D

F

E

Page 8

8

EXCLUSIVE

This icon indicates that the OFF operating status mode has been set. Each ignition request is ignored except for the anti-freeze function. The pump

anti-lock, 3-way valve and anti-freeze function remain active.

This icon indicates that WINTER mode has been selected (HEATING function enabled). If a heating request from the main zone is in progress, the

icon will be flashing.

This icon indicates that the circuit for domestic hot water production is enabled. When a domestic hot water request is in progress, the icon flashes.

The P at the top of the domestic hot water icon indicates that the boiler preheating function is enabled; the P when flashing indicates that a preheating

request is in progress.

When the “central heating programming timing” is enabled this icon indicates that the system heating (main zone) is in AUTOMATIC mode (the

management of the heating requests follows what has been set with the timer).

If the heating function is not enabled during the current time frame, the icon will be crossed out.

When the “central heating programming timing” is enabled this icon indicates that the system heating (main zone) is in MANUAL mode (the

management of the heating requests does not follow what has been set with the programming timing, but it is always active).

OFF This icon indicates that the system (main zone) has been set to off (not active).

This icon indicates that the system is detecting the presence of a flame.

This icon indicates the presence of an anomaly, and is always flashing.

FRI

18/05/2013

12:17

MENU

INFO SET

PLANT

HOT WATER TEMPERATURE

STATE

42

°C

P

1.3

bar

LED

REC10

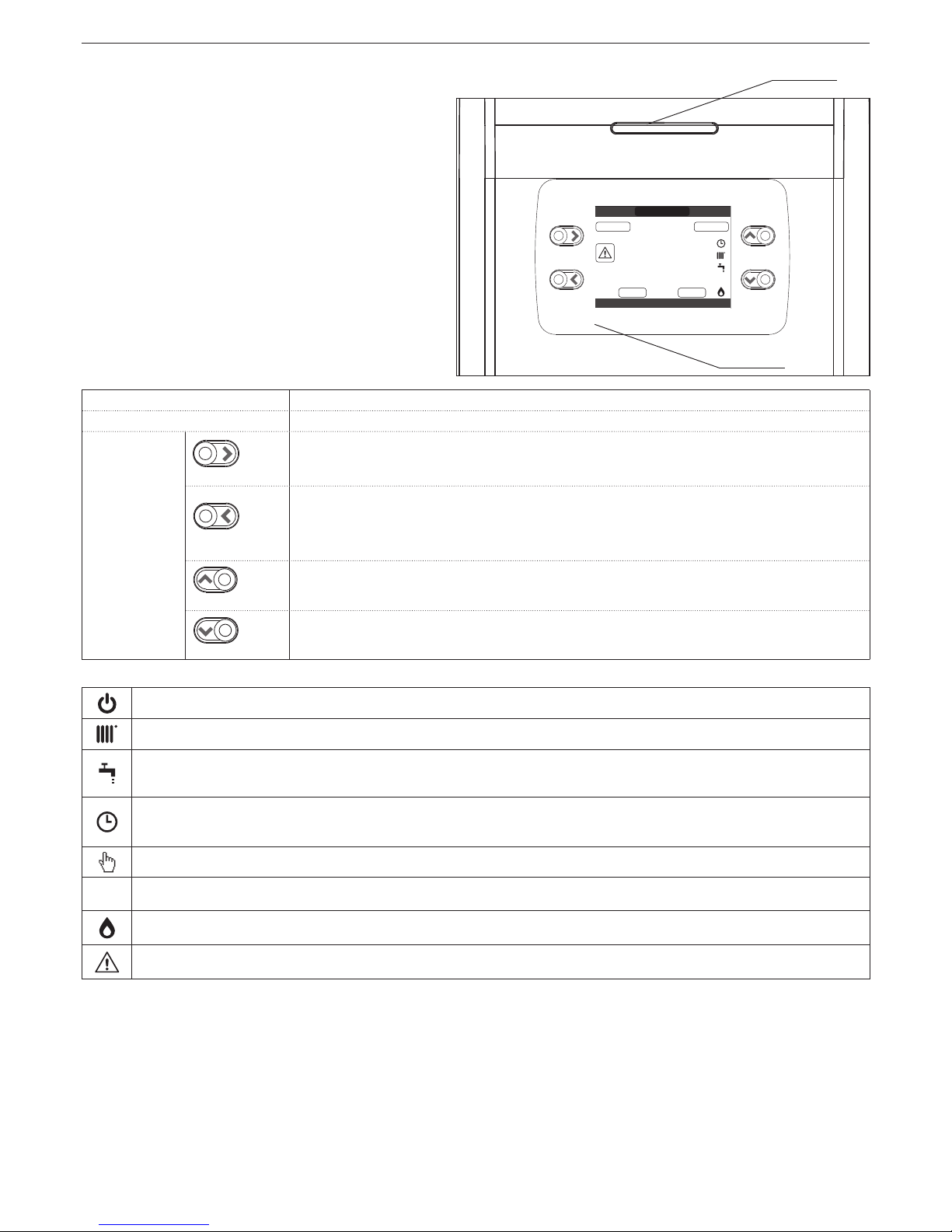

4 CONTROL PANEL (REC10)

The REC10 remote control has the function of machine interface,

displaying the system and providing access to the parameters.

The middle of the main screen displays the temperature of the domestic

hot water probe, unless there is a heat request is in progress, in this

case the delivery temperature of the boiler at that particular time is

displayed.

The value expressed in bar refers to the system’s water pressure.

The top of the screen shows the information regarding the current date

and time, as well as the outdoor temperature, if available.

On the left and right sides are displayed the icons indicating the status

of the system; their meaning is as follows.

Pressing the keys

“up” and “down”

it is possible to choose from among

the following options:

• PLANT: a scrolling message on the display can indicate the temperature

of the domestic hot water probe rather than the flow sensor of the boiler

• STATE (when the SYSTEM SCREEN is selected): to set the status

of the boiler (OFF, SUMMER or WINTER) and, when managed by the

room thermostat, the operating mode of the main area in heating mode

(ON or OFF if the time schedule is disabled, AUTO according to hourly

programming, MANUAL or OFF if programming timing is enabled)

• SET: to establish the heating or hot water setpoint value or for activating

preheating

• INFO: to display the value of the system variables

• MENU: to access the system’s configuration menus

The configuration MENU is organised with a multi-level tree structure. With

the “ok” key you can access the selected submenu, with the

“up” and

“down”

keys it is possible to navigate through the submenus, while the

“back/cancel” key takes you back to the previous level.

An access level has been fixed for each submenu: USER level, always

available; TECHNICAL level, password protected.

Below is a summary of the MENU tree structure of the REC10.

b

Some of the information might not be available on the REC10

depending on the access level, the status of the machine or the

system conguration.

LED

Light signal indicating the operating status of the boiler. Can be red or green (see specific paragraph)

REC10

Boiler control panel

Key area

ok= confirm

back= ret

urn to the previous screen

cancel selection

return to the main screen (press > 2 sec.)

up= allows you to choose between the options PLANT-STATE-SET-INFO-MENU and to

surf through the

submenus

scrolling upwards

down= allows you to choose between the options PLANT-STATE-SET-INFO-MENU and to

surfe through the

submenus

scrolling down

cancel=

Page 9

9

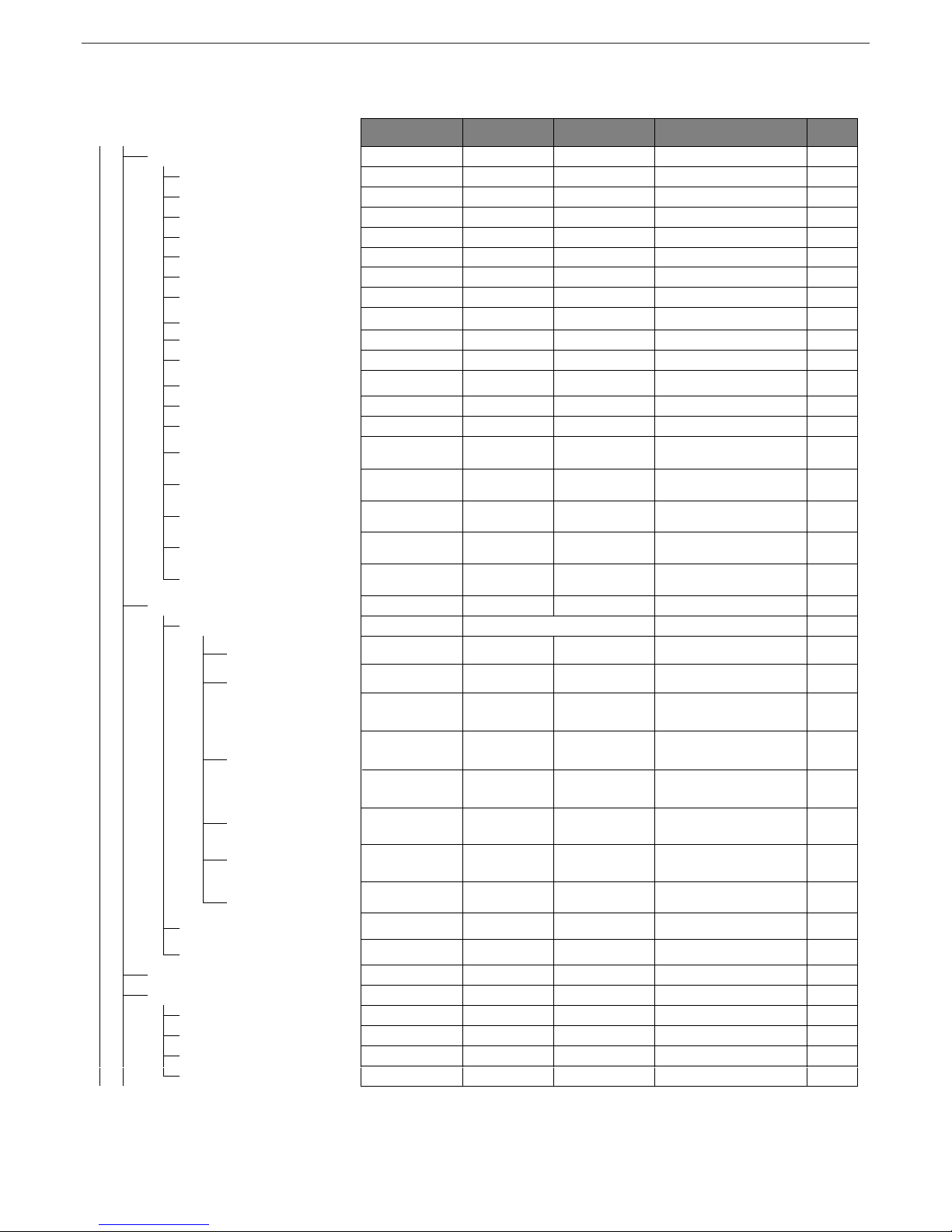

ENGLISH

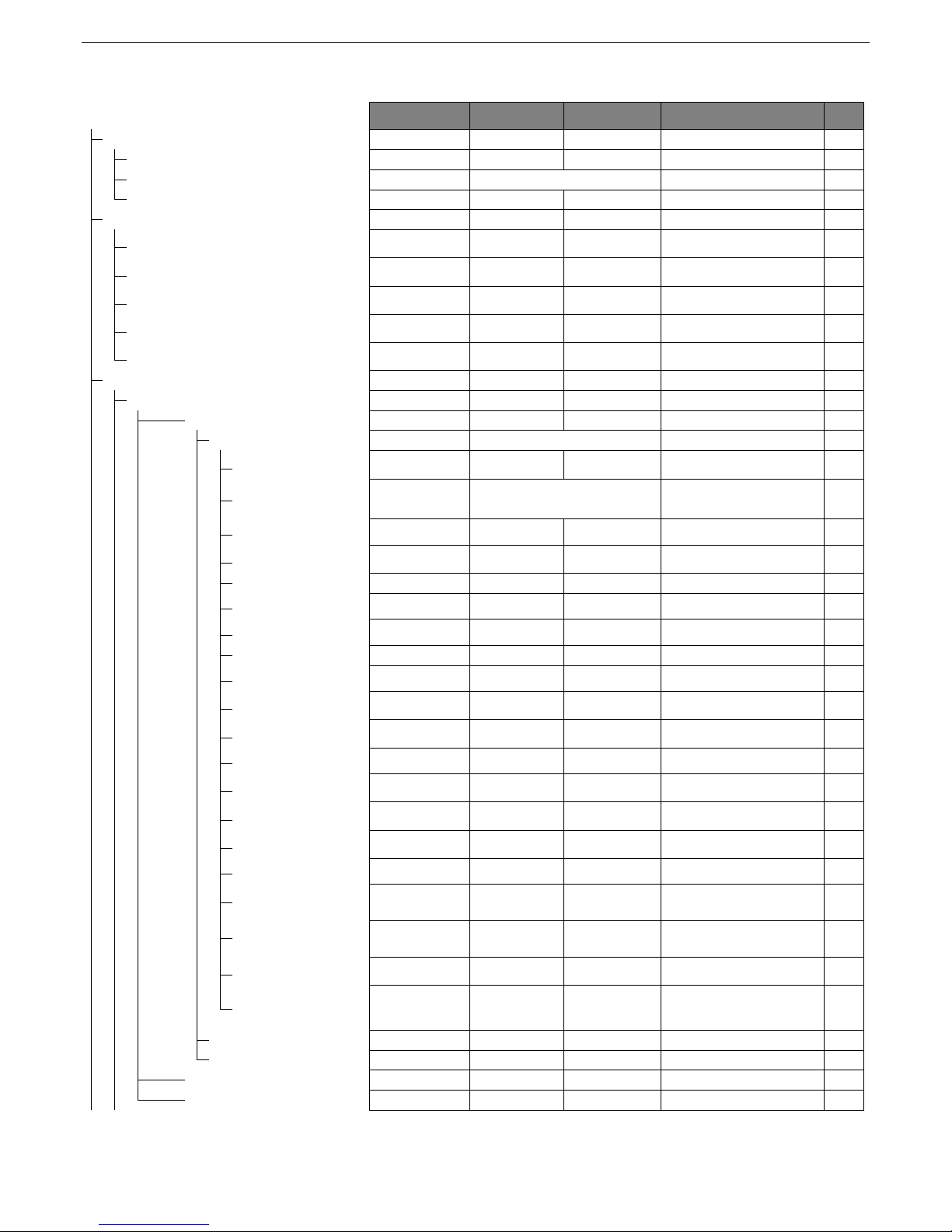

MENU

DEFAULT VALUE

MINIMUM

VALUE

MAXIMUM

VALUE

ACCESS LEVEL

NOTES

SET

VALUE

SETTINGS

USER

TIME & DATE

USER

LANGUAGE

ITALIANO / ENGLISH USER

BACKLIGHT

5 min 1 min 15 min USER

TIME SCHEDULE

USER

MAIN

USER

Only if POR = 1

ZONE1

USER

Only if POR = 1

ZONE2

USER

Only if POR = 1

DHW

USER

DHW HEAT PUMP

USER

TECHNICAL

INSTALLER

INSTALLATION

INSTALLER

ZONES MANAGER

INSTALLER

MODIFY ZONE MAIN MAIN / ZONE1 / ZONE2 INSTALLER

ACTUATION TYPE

ITRF05/AKM ITRF05/AKM BE16

INSTALLER

Only MAIN zone

REQUEST TYPE THERMOSTAT

THERMOSTAT / TEMPERATURE PROBE /

REC10 MASTER / REC10 SLAVE

INSTALLER

BE16 ADDRESS - - 1 6

INSTALLER

Only zones with

ACTUATION = BE16

HYDRAULIC CONF DIRECT ZONE DIRECT ZONE MIXING ZONE

INSTALLER

Only zones with ACTUATION = BE16

ZONE TYPE HIGH TEMP. HIGH TEMP. LOW TEMP. INSTALLER

MIN CH SET

40°C (AT)

20°C (BT)

20°C MAX CH SET INSTALLER

MAX CH SET

80,5°C (AT)

45°C (BT)

MIN CH SET

80,5°C (AT)

45°C

(BT)

INSTALLER

CHANGE NAME

INSTALLER

PI - PROPORTIONAL 5 0 99

SERVICE

Only mixing z ones with A

CTUATION=BE16

PI - INTEGRAL 10 0 99

SERVICE

Only mixing z ones with ACTUATION=BE16

VALVE RUN 120 sec 0 sec 240 sec

SERVICE

Only mixing z ones with ACTUATION=BE16

CLOSING AT POWE R ON 140 sec 0 sec 240 sec

SERVICE

Only mixing z ones with ACTUATION=BE16

OUTLET OVER 55°C 0°C 100°C

SERVICE

Only BT zones with A CTUATION =BE16

OUTLET OVER TEST TIME 0min 0min 240min

SERVICE

Only BT zones with A CTUATION =BE16

OUTLET OVER WAIT TIME 2mi n VALVE RUN 240min

SERVICE

Only BT zones with A CTUATION =BE16

OUTLET OVER REST TIME 2min 0min 240min

SERVICE

Only

BT zones with ACTUATION =BE16

FREEZE PROT TEMP 6°C -20°C 50°C

SERVICE

Only zones with ACTUATION = BE16

FREEZE PROT OFFSET ZONE 5°C 1°C 20°C

SERVICE

Only zones with ACTUATION = BE16

FREEZE PROT T EXT 10°C 0°C 100°C

SERVICE

Only zones with ACTUATION = BE16

POR

0 (1 if REC10

in the AMBIENT)

0 1 INSTALLER

ADD ZONE

INSTALLER

DELETE ZONE

INSTALLER

SENSOR CALIBRATION 0,0°C - 6,0°C 6,0°C INSTALLER

SYSTEM RESET

INSTALLER

FACTORY SET

Page 10

10

EXCLUSIVE

MINIMUM

VALUE

MAXIMUM

VALUE

ACCESS LEVEL

NOTES

SET

VALUE

PARAMETERS

INSTALLER

TIMER OFF CH 3 min 0 m in 20 mi n INSTALLER

HYST ON HIGH TEMP 5°C 2°C 10 °C SERVICE

HYST OFF HIGH TEMP 5°C 2°C 10°C SERVICE

HYST ON LOW TEMP 3°C 2°C 10°C SERVICE

HYST OFF LOW TEMP

3°C 2°C 10°C SERVICE

SP INCR HIGH TEMP

5°C 0°C 10°C SERVICE

SP INCR LOW TEMP

0°C 0°C 6°C SERVICE

INCR COOLING SP

0°C 0°C 10°C SERVICE

PUMP DUTY CYCLE

85 41 100 SERVICE

RESET TIMERS CH

FUNC. NOT ACTIVE FUNC. NOT ACTIVE FUNCTION ACTIVE INSTALLER

DHW THERMOSTAT

RELATED RELATED ABSOLUTE

INSTALLER

Only in insta ntaneous configuration

SLIDING OUTLET

DEACTIVATE FUNC. DEACTIVATE FUNC. ACTIV ATE FUNCTION

INSTALLER

CH DELAY POST-DHW

0 0 1 SERVICE

CH DELAY TIME

6sec 1sec 255sec

SERVICE

If CH DELAY POST-DHW = 1

PRESS TRANSDUCER

1 0 1 SERVICE

LOAD ENABLE

1 0 1

SERVICE

Only if PRESS TRANSDUCER = 1

START LOADING VALUE

0,6 0,4 1

SERVICE

Only if LOAD ENABLE = 1

PREHEATING

0 0 1

INSTALLER

Only if managed by the c ontrol boar d

THERMOREGULATI ON

INSTALLER

CLIMATIC CURVES

MAIN MAIN / ZONE1 / ZONE2 INSTALLER

FIXED SET POINT

80,5 °C (AT)

45 °C (BT)

MIN CH SET MAX CH SET

INSTALLER

If EXTERNAL PROBE NOT connected

NIGHT COMP FUNC. NOT ACTIVE FUNC. NOT ACTIVE FUNCTION ACTIVE

INSTALLER

If EXTERNAL PROBE connected

CURVE SLOPE

2,0 1,0 3,0

INSTALLER

If EXTERNAL PROBE connected,

request type

TA

and zone type

AT

0,4 0,2 0,8

INSTALLER

If EXTERNAL PROBE connected,

request type TA and zone type

BT

2,0 0,1 5,0

INSTALLER

If request type AMBIENT PROBE

or REC10

AMBIENT INFLUE NCE 10 0 20

INSTALLER

If request type AMBIENT PROBE

or REC10

OFFSET 20°C 20°C 40°C

INSTALLER

If request type AMBIENT PROBE

or REC10

COOLING

18°C 4°C 20°C INSTALLER

BUILDING TYPE

5min 5min 20min

INSTALLER

Only i

f EXTERNAL PROBE connected

OUTDOOR REACTIVITY

20 0 255

INSTALLER

Only i

f EXTERNAL PROBE connected

RANGE RATED

MAX CH MIN MAX CH INSTALLER

CALIBRATION

INSTALLER

MIN

INSTALLER

MAX

INSTALLER

RLA

MIN MAX INSTALLER

MAX CH

MIN MAX INSTALLER

DEFAULT VALUE

FACTORY SET

see MULTIGAS TABLE

see MULTIGAS TABLE

see MULTIGAS TABLE

see MULTIGAS TABLE

1500 RPM

3000 RPM

9999 RPM5500 RPM

Page 11

11

ENGLISH

MINIMUM

VALUE

MAXIMUM

VALUE

ACCESS LEVEL

NOTES

SET

VALUE

SWEEPER

INSTALLER

ACTIVATE FUNCTION

INSTALLER

DEACTIVATE FUNCTION

INSTALLER

MAX SPEED MAX

INSTALLER

RANGE RATED SPEED RANGE RATED

INSTALLER

MIN SPEED MIN

INSTALLER

CHANGE FAN SPEED Current speed MIN MAX INSTALLER

ANTI-LEGIONEL LA

WEEKLY FUNCTION

F. NOT ACTIVE / DAILY FUNCTION /

WEEKLY FUNCTION

INSTALLER

VENT CYCLE

ENABLE FUN. ENABLE FUN. DISABLE FUN. SERVICE

DISABLE FUNCTION

SERVICE

ENABLE FUNCTION

SERVICE

STOP FUNCTION

INSTALLER

Only if VENT CYLCE in pro gress

EXHAUST PROBE RESET

INSTALLER

ADD WATER TANK

INSTALLER

Only in insta ntaneous configuration

WATER TANK

INSTALLER

REMOVE WATER TANK

INSTALLER

WATER TANK SETPOINT

50°C 37,5°C 60°C

INSTALLER

Only if HEAT P UMP enabled to DHW

TANK FROST PROTECT

7°C 0°C 10 0°C

SERVICE

Only if HEAT P UMP enabled to DHW

TANK FR PROT OFFSET

5°C 1°C 20°C

SERVICE

Only if HEAT P UMP enabled to DHW

ADD SOLAR PLANT

INSTALLER

Only if solar system is n ot configured

SOLAR

INSTALLER

REMOVE SOLAR PLANT

INSTALLER

T MAX TANK 60°C 10°C 130°C INSTALLER

DELTA T ON PUMP 8°C DELTA T OFF 30°C INSTALLER

DELTA T OFF PUMP 4°C 4°C DELTA T ON INSTALLER

INTEGRATION DELAY 0 min 0 min 199 min INSTALLER

COLLECTOR T MIN (- -) (- -) / -30°C 0°C INSTALLER

COLLECTOR T MAX 110°C COLL. T P ROT 180°C INSTALLER

COLLECTOR T PROT 110° C 80°C. T MAX COLL. INSTALLER

COLLECTOR T AUTH 40°C T LOCK 95°C INSTALLER

COLLECTOR T LOCK 35°C -20°C COLL. T AUTH INSTALLER

PWM COLL PUMP 0 min 0 min 30 min INSTALLER

TANK COOLING FUNC. NOT ACTIVE FUNC. NOT ACTIVE FUNCTION ACTIVE INSTALLER

SOLAR PUMP STATE OFF OFF / ON / AUTO INSTALLER

DEFAULT VALUE

FACTORY SET

Page 12

12

EXCLUSIVE

MINIMUM

VALUE

MAXIMUM

VALUE

ACCESS LEVEL

NOTES

SET

VALUE

ADD HEAT PUMP

INSTALLER

Only if heat pump not configured

HEAT PUMP

INSTALLER

REMOVE HEAT PUMP

INSTALLER

Only if heat pump config ured

USE FREE CONTACTS / USE BUS USE BUS USE BUS USE FREE CONTACTS SERVICE

ENABLE / DISABLE COOLING DEACTIVATE FUNCTION FUNCTION ACTIVE DEACTIVATE FUNCTION INSTALLER

USE FOR DHW / DON'T USE FOR D HW

DHW FUNCTION

NOT ACTIVE

DHW FUNCTION

ACTIVE

DHW FUNCTION

NOT ACTIVE

INSTALLER

ANTI FREEZE DELTA SET 1°C 0°C 6°C SERVICE

ENABLE / DISABLE NIGHT REDUCT DEACTIVATE FUNCTION FUNCTION ACTIVE DEACTIVATE FUNCTION INSTALLER

REDUCED FREQUE NCY 100% 50% 100% SERVICE

MIN OUTDOOR TEMP 5°C -5°C 20°C INSTALLER

MIN DHW OUT TEMP 5°C -5°C 20°C INSTALLER

MIN EMERG OUT T -10°C -20° C 10°C INSTALLER

BOILER INTEGR DELAY

30min

1min

240min

SERVICE

HP INTEGR DELAY

30min

1min

240min

SERVICE

BOILER WAITING

2min

1min

60min

SERVICE

HEAT PUMP WAITING

2min

1min

60min

SERVICE

INTEGRATION OFFSET

5°C

0°C

10°C

SERVICE

WINTER SUMMER DELAY

0h

0h

24h

SERVICE

WARNING VALIDATION

60sec

1sec

300sec

SERVICE

ENABLE CIRC STATE ON/ AUTO

AUTO

ON

AUTO

INSTALLER

DHW HP SETPOINT

60°C

20°C

60°C

SERVICE

DHW OFFSET

10°C

0°C

25°C

SERVICE

ENABLE ALARM HISTORY

SERVICE

ALARM HISTORY

INSTALLER

SCREED HEATING

DEACTIVATE F.

DEACTIVATE F.

ACTIVATE F.

INSTALLER

DEACTIVATE FUNCTION

INSTALLER

ACTIVATE FUNCTION

INSTALLER

FUNCTION SETTIN GS

SERVICE

TFMIN

20°C

15°C

30°C

SERVICE

TFMAX

35°C

30°C

55°C

SERVICE

SYSTEM INFO

SERVICE

DEFAULT VALUE

FACTORY SET

COMBUSTION CHECK

GAS TYPE

COMBUSTION OFFSET

BOILER TYPE

NG

NG/LPG

SERVICE

SERVICE

SERVICE

SERVICE

A

A/B/C

RESTORE

RESTORE

RESET

Page 13

13

ENGLISH

4.1 Access to the technical parameters

Through the REC10 it is possible to access, using the TECHNICAL menu,

a series of parameters that can be programmed to allow you to personalise

the operation of the boiler:

- select MENU on the initial page of the REC10 and press the key

18/05/2013 12:17

INFO SET

30

°C

.3

MENU

FRI

STATE

PLANT

HOT WATER TEMPERATURE

1.3

bar

- keep the keys

and

pressed at the same time to enter the

password menu (about 5 sec)

18/11/2013 12:17

FRI

SETTINGS

MENU

SELECT OPTION

- using the keys and select the value of the password to

access the INSTALLER or SERVICE authorisation level, depending on

the level of the tree menu, then press the key

00

INSERT PASSWORD

- select TECHNICAL with the keys and , confirming the

selection with the key

SETTINGS

TECHNICAL

SELECT OPTION

MENU

- access the desired menu and change/view the parameter concerned

(see the menu tree on page 8).

It is possible to return to the start page at any time by keeping the key

“back/cancel” pressed for at least 2 seconds.

5 COMMISSIONING

5.1 Preliminary checks

First ignition is carried out by competent personnel from an authorised

Technical Assistance Service Beretta.

Before starting up the boiler, check:

- that the data of the supply networks (electricity, water, gas) correspond

to the label data

- that the extraction pipes of the ue gases and the air suction pipes are

working correctly

- that conditions for regular maintenance are guaranteed if the boiler is

placed inside or between items of furniture

- the seal of the fuel adduction system

- that the fuel ow rate corresponds to values required by the boiler

- that the fuel supply system is sized to provide the correct ow rate to

the boiler, and that it has all the safety and control devices required by

current regulations

- that the circulator rotates freely because, especially after long periods of

inactivity, deposits and/or debris can prevent free rotation.

Eventual releasing of the circulator shaft

- Insert a screwdriver in the hole (1) of the circulator.

- Press (a) and turn the n° 2 Phillips screwdriver (b) until the release of

the crankshaft.

Perform this operation with extreme caution to avoid damaging the

components.

a

b

1

5.2 Programming the boiler

- Position the system’s master switch to the “on” position.

- If necessary set the TIME and DATE setting the HOURS, MINUTES,

DAY, MONTH and YEAR with the keys “up” and “down”, confirming

the selection.

-

12 17:

ENTER TIME AND DATE

TIME & DATE

USE THE ARROWS TO MODIFY

18 / 11 / 2013

Note: it is possible to change the TIME and DATE settings, as well as

LANGUAGE and the duration of the back-lighting, also later by entering

the MENU from the main screen and then selecting SETTINGS.

b

Each time that the boiler is powered an automatic venting cycle is

carried out lasting 2 min. To interrupt the vent cycle, carry out the

procedure explained in the section

“5.3 First commissioning”

.

- Set the boiler to OFF from REC10 selecting the STATE menu and

then BOILER.

Page 14

14

EXCLUSIVE

18/05/2013 12:17

MENU

INFO SET

42

°C

1.3

bar

FRI

PLANT

HOT WATER TEMPERATURE

STATE

STATE

BOILER

MAIN ZONE

BOILER

OFF

SUMMER

WINTER

- Through the REC10 it is possible to access, using the TECHNICAL

menu, a series of parameters that can be programmed to allow you to

personalise the operation of the boiler based on the type of system.

- Then set the parameters according to the desired operating modes.

5.2.1 Boiler conguration

- Access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

.

- Select PARAMETERS with the “up” and “down” keys, confirming the

selection.

-

TERMOREGOLAZIONE

PARAMETERS

INSTALLATION

THERMOREGULATION

RANGE RATED

TECHNICAL

INSTALLER

CALIBRATION

Select from among the following options with the “up” and “down”,

keys, confirming the selection.

-

PARAMETERS

INSTALLER

TIMER OFF CH

RESET TIMERS CH

PREHEATING

DHW THERMOSTAT

TIMER OFF CH

This parameter allows you to change the TIMER OFF CH, regarding

the delay time introduced for re-igniting the burner in the face of an off

due to the heating temperature being reached. The factory setting for

this parameter is 3 minutes and can be set to a value between 0 min

and 20 min selecting the desired one with the “up” and “down”, keys

confirming the selection.

-

TIMER OFF CH

3

MIN

RESET TIMERS CH

This parameter allows you to reset the REDUCED HEATING MAXIMUM

OUTPUT TIMING, during which the speed of the fan is limited to 75%

of the maximum heating output that has been set, and the TIMER OFF

CH. The factory setting for this parameter is FUNCTION NON ACTIVE,

select FUNCTION ACTIVE using the keys “up” and “down”, confirming

the selection for resetting the timings.

FUNCTION NOT ACTIVE

RESET TIMERS CH

FUNCTION ACTIVE

INSTALLER

- DOMESTIC HOT WATER THERMOSTAT

This parameter allows you to set the type of DOMESTIC HOT WATER

THERMOSTAT.

The factory setting for this parameter is RELATED, i.e. for domestic hot

water the boiler switches off at setpoint +5°C and restarts at setpoint

+4°C.

To select the ABSOLUTE values, where the boiler for domestic hot water

will still switch off at 65°C and restart at 63°C, use the keys “up” and

“down”.

DHW THERMOSTAT

ABSOLUTE

INSTALLER

RELATED

Page 15

15

ENGLISH

- PREHEATING

Setting PREHEATING = 1 the boiler ’s domestic hot water function

activates. This function keeps the water in the domestic hot water

exchanger hot, to reduce standby times when a request is made. When

the preheating function is enabled the symbol P comes on with a steady

light at the top with respect to the hot water icon. During burner ignition

following a preheating request, the symbol P starts flashing.

To deactivate the preheating function, set the parameter to PREHEATING

= 0, the symbol P switches off.

The function is not active when the boiler is OFF.

TERMOSTATI SAN

PREHEATING

0

5.2.2 Conguration of the zone

It is possible to customise the management of the heating zone by

accessing the ZONES MANAGER menu.

- Access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

.

- In sequence select INSTALLATION, ZONES MANAGER and MODIFY

ZONE with the “up” and “down” keys, confirming the selection.

PARAMETERS

INSTALLATION

THERMOREGULATION

RANGE RATED

TECHNICAL

INSTALLER

CALIBRATION

INSTALL

SENSOR CALIBRATION

INSTALLER

ZONES MANAGER

SYSTEM RESET

ADD ZONE

MODIFY ZONE

DELETE ZONE

INSTALL

INSTALLER

- Select the desired heating zone and then choose from among the options

with the “up” and “down” keys, confirming the selection:

MAIN

INSTALLER

INSTALL

- TYPE OF ACTUATION

Set the parameter in question to ITRF05/AKM (default value)

- TYPE OF HEAT REQUEST

This parameter allows you to specify the type of heat request, it is

possible to choose from among the following options:

THERMOSTAT (factory setting): the heat request is generated with an

ON/OFF thermostat

REC10 MASTER: the heat request is generated by the REC10

MASTER; in this case the REC10 assumes the function of MACHINE

INTERFACE

- TYPE OF ZONE

This parameter allows you to specify the type of zone to be heated, it

is possible to choose from among the following options:

HIGH TEMPERATURE (factory setting):

LOW TEMPERATURE

- MIN SET HEAT

This parameter allows you to specify the minimum heating setpoint that

is possible (range 20°C - 80.5°C, default 40°C for high temperature

systems - range 20°C - 45°C, default 20°C for low temperature

systems)

- MAX SET HEAT

This parameter allows you to specify the maximum heating setpoint that

is possible (range 20°C - 80.5°C, default 80.5°C for high temperature

systems - range 20°C - 45°C, default 45°C for low temperature

systems)

- CHANGING NAME

This parameter allows you to attribute a specific name to the heating

zone

- POR

This parameter allows you to enable the central heating programming

timing for the zone concerned if the heat request is carried out using a

room thermostat

Time schedule not enabled = 0

When the room thermostat contact closes the heat request is always

met without any time band limitation

Time schedule enabled = 1

When the room thermostat contact closes the heat request is enabled

according to the programming timing.

Note: in this case make sure that the operating mode of the zone is set

to AUTO in the STATE menu.

5.2.3 Time band schedule function (room thermostat)

Whenever the heating system is managed by a room thermostat, and

therefore without any time schedule, it is possible to tie the heat requests

coming from the device to programmable time bands by setting the

parameter POR = 1 (see section

“5.2.2 Configuration of the zone”

), in other

cases it is always enabled.

To access this function:

- select MENU on the main page of the REC10 and press “ok”

18/05/2013 12:17

30

°C

.3

1.3

bar

MENU

INFO SET

FRI

HOT WATER TEMPERATURE

STATE

PLANT

MON

Page 16

16

EXCLUSIVE

- using the “up” and “down” keys select PROGRAMME TIMER confirming

the selection

SETTINGS

MENU

SELECT OPTION

TIME SCHEDULE

From this menu it is possible to access the display and adjustment of the

programming timing for the heating functions of the zone. For each day

of the week it is possible to set up to 4 bands, characterised by a starting

time and an end time.

Note: for more details on the use of the programming timing see the USER

MANUAL of the REC10.

MON

18/11/2013 12:17

MAIN

SELECT THE ZONE

SCHEDULE

07:30

11:30

18:00

08:30

13:30

22:30

SELECT

A DAY

START

MAIN

THURSDAY

END

ZONE SCHEDULE

5.2.4 Setting the thermoregulation

Thermoregulation only works with the outdoor temperature sensor

connected and active only for the HEATING function; therefore, once

installed, connect the outdoor temperature sensor to the specific

connections on the boiler terminal board.

This enables the THERMOREGULATION function.

The temperature measured by the outdoor temperature sensor is displayed

on the initial page in the top right, alternating with the display of the time.

When thermoregulation is enabled (outdoor temperature sensor present),

the algorithm for automatically calculating the outlet setpoint depends on

the type of heat request.

In any case, the thermoregulation algorithm will not directly use the outdoor

temperature, but rather a calculated outdoor temperature that takes into

account the building’s insulation: in buildings that are well insulated, the

outdoor temperature variations will have less impact than those that are

poorly insulated by comparison. Enabling THERMOREGULATION occurs

in the following way:

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- select THERMOREGULATION with the “up” and “down” keys,

confirming the selection.

PARAMETERS

THERMOREGULATION

RANGE RATED

TECHNICAL

INSTALLER

CALIBRATION

INSTALLATION

Using the REC10 it is possible to set the value of the following parameters:

BUILDING TYPE

It is indicative of the frequency with which the value of the calculated

outdoor temperature for thermoregulation is updated, a low value for this

value will be used for buildings that have little insulation.

Setting range: [5min - 20min]

Factory setting: [5min]

REACTIVITY EXT SENSOR

It is an indication of the speed with which variations of the measured

outdoor temperature affect the calculated outdoor temperature value for

thermoregulation, low values indicate high speeds.

Setting range: [0 - 255]

Factory setting: [20]

At this point, to change the value of the previous parameters, proceed as

described below:

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- in sequence select THERMOREGULATION and TYPE OF BUILDING

rather than REACTIVITY EXT SENSOR with the “up” and “down” keys,

confirming the selection

- set the desired value with the “up” and “down” keys, confirming the

selection.

Note: The value of the calculated outdoor temperature used by the

thermoregulation algorithm is displayed in the INFO menu under T EXT

FOR THERMOREG.

HEAT REQUEST FROM THERMOSTAT or POR (Programmable Timer)

In this case the outlet setpoint depends on the outdoor temperature for

obtaining a reference ambient temperature of 20°C. There are 2 parameters

that compete to calculate the output setpoint:

- slope of the compensation curve (KT)

- offset on the reference ambient temperature.

SELECTING THE COMPENSATION CURVE- fig. 17

The compensation curve for heating maintains a theoretical temperature of

20°C indoors, when the outdoor temperature is between +20°C and -20°C.

The choice of the curve depends on the minimum outdoor temperature

envisaged (and therefore on the geographical location), and on the delivery

temperature envisaged (and therefore on the type of system). It is carefully

calculated by the installer on the basis of the following formula:

KT = T. outlet envisaged - Tshift

20- min. design external T

Tshift = 30°C standard system

25°C floor installations

If the calculation produces an intermediate value between two curves, you

are advised to choose the compensation curve nearest the value obtained.

Example: if the value obtained from the calculation is 1.3, this is between

curve 1 and curve 1.5. Choose the nearest curve, i.e. 1.5.

The settable KT values are as follows:

standard system: 1.0-3.0

floor system 0.2-0.8.

Using the REC10 it is possible to set the selected thermoregulation curve:

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- in sequence select THERMOREGULATION and CLIMATIC CURVES

with the “up” and “down” keys, confirming the selection

- select the desired heating zone with the “up” and “down” keys,

confirming the selection

- set the desired climatic curve with the “up” and “down” keys, confirming

the selection.

OFFSET ON THE REFERENCE AMBIENT TEMPERATURE - fig. 17

In any event, the user can indirectly modify the value of the HEATING

setpoint inserting an offset on the reference temperature that can vary

within the range -5-+5 (offset 0 = 20°C).

NIGHT COMPENSATION - fig. 17

Whenever a programmable timer is connected to the ROOM THERMOSTAT

input, from the TECHNICAL\THERMOREGULATION\CLIMATIC CURVES\

MAIN the NIGHT COMPENSATION function can be enabled.

In this case, when the CONTACT is CLOSED, the heat request is made

by the flow sensor, on the basis of the outdoor temperature, to obtain a

nominal ambient temperature on DAY level (20°C).

The opening of the contact does not produce a switch-off, but a reduction

(parallel translation) of the climatic curve on NIGHT level (16°C).

Also in this case, the user can indirectly modify the value of the HEATING

setpoint inserting once again an offset on the reference DAY temperature

(20°C) rather than NIGHT (16°C) that can vary within the range [-5 - +5].

5.3 First commissioning

- Position the system’s master switch to the “on” position.

- Open the gas tap to allow fuel to flow.

Page 17

17

ENGLISH

- Adjust the room thermostat to the desired temperature (~20°C) or, if the

system is equipped with a chronothermostat or programmable timer or

REC10 set as an ambient regulator, ensure that the thermostat or timer

is “active” and set correctly (~20°C)

- Then set the boiler for WINTER selecting the STATE menu on the

REC10 and then BOILER, based on the season and the type of operation

selected.

18/05/2013 12:17

MENU

INFO SET

42

°C

1.3

bar

FRI

PLANT

HOT WATER TEMPERATURE

STATE

BOILER

STATE

MAIN ZONE

BOILER

OFF

SUMMER

WINTER

- When there is a heat request and the boiler is igniting, the icon

“ ” appears on the display. The boiler will start up and continue working

until the set temperatures are reached, after which it will then go back

to standby.

b

Each time the boiler is started up an automatic venting cycle is

carried out lasting 2 min. When the vent cycle is in progress, all heat

requests are inhibited and a sliding message at the foot of the page

appears on the main page of the REC10.

In this condition the green and red LEDs light up alternately for 0.1

sec with a pause of 0.5 sec and 1 sec between one ignition and

another.

X17

X14

1

5

6

X6

1

3

1

X3

X7

arancione

E.R.

SW1

9

10

7

8

5

6

1

2

14

15

16

17

arancione (ES)

arancione (ES)

giallo (B)

nero (-)

rosso (+)

arancione (A)

(OT+)

(ES)

(TBT)

(RT)

+

-

A

B

REC

N

L

F= 3.15A F

230 V

M3

F

blu

marrone

TSC2

blu

EA

marrone

giallo/verde

N

F

X6

3

1

2

marrone

X15

blu

V Hv

1

2

1

4

2

3

verde A1)

rosso (A2)

arancione (K2)

bianco(K1)

J1

BE20

C.S.A.

marrone

blu

5

3

1

2

4

X4

combustion analysis button SW1

b

The vent cycle can be interrupted beforehand by removing the cap

from the instrument panel and pressing the combustion analysis

button SW1 or else from the TECHNICAL menu of the REC10 in the

following way:

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- select VENT CYCLE with the “up” and “down” keys, confirming the

selection

TECHNICAL

INSTALLER

CALIBRATION

RANGE RATED

SWEEPER

THERMOREGULATION

VENT CYCLE

- select STOP FUNCTION with the “up” and “down” keys, confirming

the selection.

VENT CYCLE

STOP FUNCTION

INSTALLER

The REC10 will briefly display a wait message after which you will

automatically be taken to the main screen.

18/05/2013 12:17

INFO SET

30

°C

.3

MENU

FRI

STATE

PLANT

HOT WATER TEMPERATURE

1.3

bar

SUMMER : selecting SUMMER operating mode in the STATE menu

and then BOILER, the traditional function of just domestic hot water will be

activated. The REC10 normally displays the temperature of the domestic

hot water supplied by the boiler.

BOILER

OFF

SUMMER

WINTER

WINTER / : selecting WINTER in the STATE menu and then

BOILER, the heating and domestic hot water functions are activated.

REC10 normally displays the domestic hot water temperature unless

there is a heating request in progress, in which case the boiler’s outlet

temperature is displayed.

Page 18

18

EXCLUSIVE

BOILER

OFF

SUMMER

WINTER

5.4 Adjusting the heating water temperature without

an outdoor temperature sensor connected

When there is no outdoor temperature sensor, the boiler operates at

a fixed-point, the HEATING setpoint in this case can be set selecting

SET on the main screen of the REC10 and selecting the desired value

within the range [40°C - 80.5°C] for high temperature systems rather than

[20°C - 45 °C] for low temperature systems.

DHW

SET

PREHEATING

HEATING

5.5 Adjusting the heating water temperature with an

outdoor temperature sensor connected

When an outdoor temperature sensor is installed, the outlet temperature

is automatically selected by the system, which quickly adjusts the ambient

temperature according to the variations in the outdoor temperature. If you

want to change the temperature, raising it or lowering it with respect to that

automatically calculated by the electronic board, it is possible to change the

HEATING setpoint by selecting SET on the main screen of the REC10 and

selecting within the range (-5 - +5) the desired comfort level (see section

“5.2.4 Setting the thermoregulation”

).

Note: when there is an outdoor temperature sensor connected it is still

possible to have the boiler operate at a fixed point setting the values of MIN

SP HEAT and MAX SP HEAT at the desired HEATING setpoint.

5.6 Adjustment of the domestic hot water

temperature

To adjust the domestic hot water temperature (bath, shower, kitchen, etc.),

set the DOMESTIC HOT WATER setpoint selecting SET on the main

screen of the REC10 and selecting the desired value within the range

[37.5°C - 60°C].

SET

HEATING

PREHEATING

DHW

5.7 “Preheating” function

It is possible to access the PREHEATING function selecting SET on the

main screen of the REC10.

Setting PREHEATING = 1 the boiler’s domestic hot water function

activates. This function keeps the water in the domestic hot water

exchanger hot, to reduce standby times when a request is made. When the

preheating function is enabled, the symbol P comes on with a steady light

at the top with respect to the hot water icon. During burner ignition following

a preheating request, the symbol P starts flashing.

To deactivate the preheating function, set the parameter to PREHEATING = 0,

the symbol “P” switches off.

The function is not active when the boiler is OFF.

SET

HEATING

DHW

PREHEATING

5.8 Boiler start-up

If there is a room thermostat or a programming timer, or the REC10

MASTER is set as an ambient regulator, it is necessary that these are on

and that they have been adjusted to a temperature higher than the ambient

temperature so that the boiler switches on.

The boiler will be in standby until the burner switches on following a heat

request.

The display shows “ ” to indicate the presence of a ame.

18/05/2013 12:17

MENU

INFO SET

42

°C

1.3

bar

FRI

PLANT

HOT WATER TEMPERATURE

STATE

The boiler will be in function until the selected temperature is reached,

afterwards it will be in “standby” again keeping the outlet temperature

displayed.

If faults arise in ignition or operations, the boiler performs a “SAFETY

STOP”: the triangle signalling faults will ash on the REC10. To identify the

fault codes and to reset the boiler, see the section

“5.15 Lights and faults”

.

E010

FLAME LOCKOUT

PRESS OK RESET

5.9 Reset function

In the event of a lockout, it is possible to try and restore the normal operation

of the appliance by pressing the key “ok” on the REC10 when the fault

message is displayed for resetting the alarm in progress.

b

If the release attempts do not restart the boiler, contact the local

Technical Assistance Centre.

Page 19

19

ENGLISH

5.10 Screed heating function

For a low temperature system the boiler has a “screed heating” function

that can be activated in the following way:

- set the status of the boiler to OFF

BOILER

OFF

SUMMER

WINTER

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- select SCREED HEATING with the “up” and “down” keys, confirming

the selection (note: SCREED HEATING is not available if the boiler is

not OFF)

EXHAUST PROBE RESET

SCREED HEATING

TECHNICAL

INSTALLER

CALIBRATION

RANGE RATED

SWEEPER

- select ACTIVATE FUNCTION with the “up” and “down” keys and

confirm the selection to activate the function

- select DEACTIVATE FUNCTION with the “up” and “down” keys and

confirm the selection to deactivate the function.

INSTALLER

SCREED HEATING

FUNZIONE GIORNALIERA

DEACTIVATE FUNCTION

ACTIVATE FUNCTION

The screed heating function, when active, is signalled on the main

screen by the scrolling message at the bottom of the SCREED HEATING

FUNCTION IN PROGRESS - OUTLET TEMPERATURE, while on the

electronic board the red and green LEDs flash alternately with a frequency

of 1 sec ON - 1 sec OFF.

The “screed heating” function lasts 168 hours (7 days) during which, in

the zones configured as low temperature, a heating request is simulated

with an initial zone outlet of 20°C, then increased in line with the table on

the side.

Accessing the INFO menu from the main page of the REC10 it is possible

to display the TIME FUNC SCREED HEATING value regarding the number

of hours since the start of the function.

Once activated, the function takes priority, if the appliance is shut down by

disconnecting the power supply, when it is restarted the function picks up

from where it was interrupted.

The function can be interrupted before its end by putting the appliance in

a condition other than OFF or else by selecting DEACTIVATE FUNCTION

from the relative menu.

Note: The temperature and increase values can be set to different values

only by qualified personnel, only if strictly necessary. The manufacturer

declines all responsibility if the parameters are incorrectly set.

DAY TIME TEMPERATURE

1 0 20°C

6 22°C

12 24°C

18 26°C

2 0 28°C

12 30°C

3 0 32°C

4 0 35°C

5 0 35°C

6 0 30°C

7 0 25°C

5.11 Checks during and after the rst commissioning

After starting up, check that the boiler carries out the start-up procedures

and subsequent shut-down properly.

Check the domestic hot water operation by opening a hot water tap in

SUMMER or WINTER mode.

Check the full stop of the boiler by turning off the system’s main switch.

After a couple of minutes of continuous operation to be obtained by turning

the system’s main switch to “ON”, setting the boiler mode selector to

SUMMER and by keeping open the domestic hot water device, the binders

and manufacturing waste evaporate and it will be possible to carry out:

- checking the combustion.

BOILER

OFF

SUMMER

WINTER

5.12 Gas conversion

It is easy to convert from one gas family to another even after the boiler

has been installed. This operation must be performed by professionally

qualied staff.

The boiler is designed to work with natural gas (G20). To convert the boiler

to LPG (G31) proceed as follows:

- access the technical parameters as explained in the section

“4.1 Access

to the technical parameters”

- set the password SERVICE

- select COMBUSTION CHECK with the “up” and “down” keys,

confirming the selection

-

VENT CYCLE

PARAMETERS

EXHAUST PROBE RESET

ALARM HISTORY

COMBUSTION CHECK

SERVICE

TECHNICAL

select GAS TYPE

COMBUSTION CHECK

COMBUSTION OFFSET

BOILER TYPE

GAS TYPE

SERVICE

Page 20

20

EXCLUSIVE

- select LPG

GAS TYPE

LPG

NG