BE Pressure supply AC1030K5000W User Manual

operation manual

Model #

AC1030K5000

AC1030K5000W

AC1330HB3000W

AC1330HB5500

AC1330HEB

CAUTION READ THIS MANUAL CAREFULLY before operating or servicing this

air compressor, to familiarize yourself with the proper safety, operation, and standard

operating procedures of this unit. FAILURE TO COMPLY WITH INSTRUCTIONS

IN THIS MANUAL COULD RESULT IN THE VOIDING OF YOUR WARRANTY,

AND PERSONAL INJURY, AND/OR PROPERTY DAMAGE. THE MANUFACTURER OF THIS AIR COMPRESSOR WILL NOT BE LIABLE FOR ANY DAMAGE BECAUSE OF FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS

MANUAL. By following the instructions and recommendations in this manual you

will ensure a longer and safer service life of your air compressor.

introduction

Attention: Read through the complete

manual prior to the initial use of your

Compressor

Using the Operator’s manual

The operating manual is an important part of your Compressor and

should be read thoroughly before initial use, and referred to often to make

sure adequate safety and service concerns are being addressed.

Reading the owner’s manual thoroughly will help avoid any personal injury

or damage to your pump. By knowing how best to operate this machine

you will be better positioned to show others who may also operate the

unit.

You can refer back to the manual at any time to help troubleshoot any

specific operating functions, so store it with the machine at all times.

2

product identification

Record Identification Numbers

Compressor

If you need to contact an Authorized Dealer or Customer Service line

(1-866-850-6662) for information on servicing, always provide the

product model and identification numbers.

You will need to locate the model and serial number for the pump and

record the information in the places provided below.

Date of Purchase:

Dealer Name:

Dealer Phone:

Product Identification Numbers

Model Number:

Serial Number:

3

safety

Safety Precautions and Warnings

Listed are some, but not all safety precautions that must be observed

with compressors. Failure to follow any of these warnings may result

in severe personal injury, death, property damage and/or compressor

damage.

• Air from this compressor will cause severe injury or death if used for

breathing or food processing.

• Air used for these processes must meet OSHA 29 CFR 1910 or FDA

21 178.3570 regulations.

• This compressor is designed for use in the compression of normal

atmospheric air only. No other gases, vapors or fumes should be

exposed to the compressor intake, nor processed through the

compressor.

• Disconnect all power supplies to the compressor plus any remote

controllers prior to servicing the unit.

• Relieve all pressure internal to the compressor prior to servicing.

• Do not depend on check valves to hold system pressure.

• A properly sized safety valve must be installed in the discharge piping

ahead (upstream) of any shutoff valve (block valve), heat exchanger,

orifice or any potential blockage point. Failure to install a safety relief

valve could result in rupturing or explosion of some compressor or

safety component.

• Do not change the pressure setting of the safety relief valve, restrict the

function of the safety relief valve, or replace the safety valve with a plug.

• Over pressurization of some system or compressor component can

occur, resulting in severe personal injury, death and property damage.

• Never use plastic pipe, rubber hose, or soldered joints in any part of the

compressors. Failure to ensure system compatibility with compressor

piping is dangerously unsound.

• Never use a flammable or toxic solvent for cleaning the air filter or any

parts.

• Do not attempt to service any part while the compressor is operating.

• Do not operate the compressor at pressures in excess of its rating.

• Do not remove any guards while the compressor is operating.

• Observe gauges daily to ensure compressor is operating properly.

• Follow all maintenance procedures and check all safety devices on

schedule.

• Compressed air is dangerous, do not play with it.

• Use the correct lubricant at all times.

4

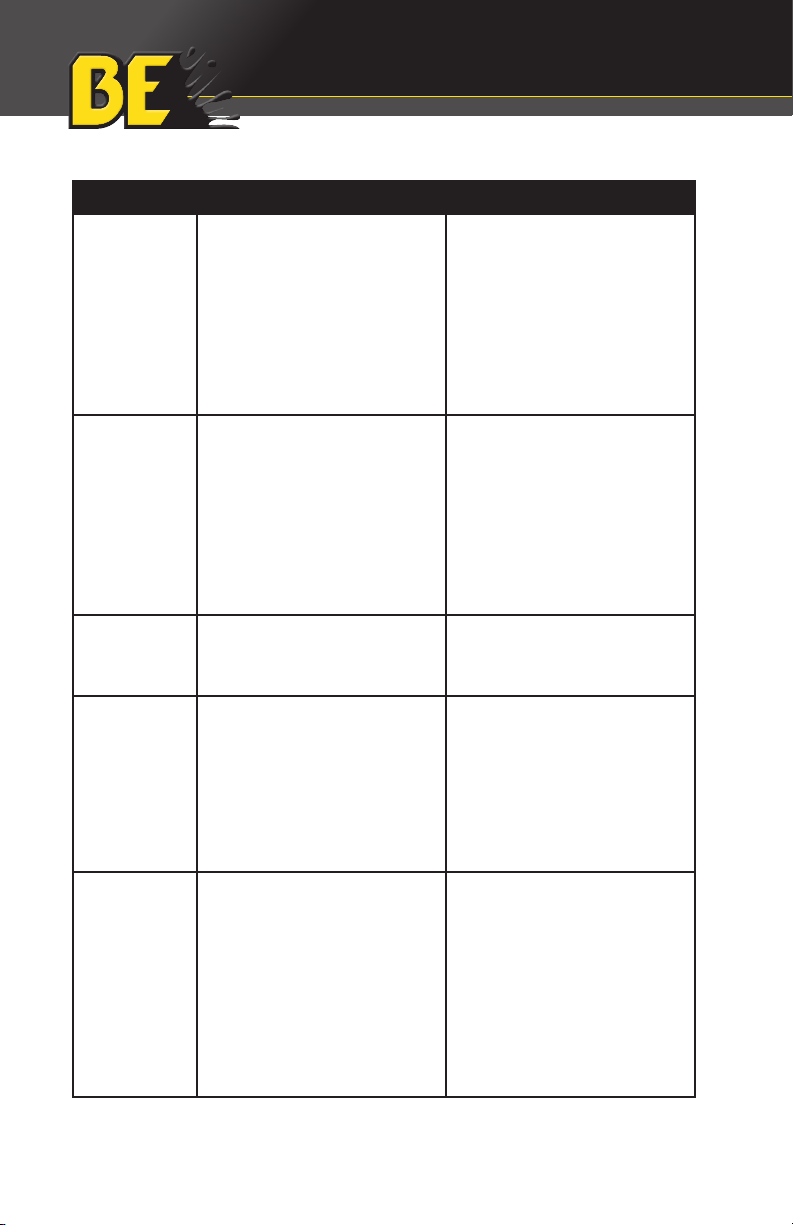

troubleshooting

Troubleshooting Chart

NOTE: Troubleshooting problems may have similar causes and solutions.

Make sure drive engine battery is disconnected before any maintenance or repair.

ALWAYS MAKE SURE COMPRESSOR DRIVE ENGINE KEY

SWITCH IF OFF AND REMOVED FROM THE COMPRESSOR

You should always contact an authorized service center before attempting to fix or repair your air compressor.

Problem Possible Cause Solutions

Compressor

stalls and dies

Compressor

is running but

is not

compressing air

Compressor

does not idle

up for

compression

Compressor

pump knocking

1. Drive engine low on fuel.

2. Compressor check valve not

functioning.

3. Compressor Pilot valve not

functioning.

4. Spark Plug in engine is bad.

5. Drive engine low on oil.

1. Compressor pilot valve is

actuated.

2. Compressor pilot valve is

malfunctioning.

3. Compressors pump head

unloaders stuck engaged.

1. Throttle control valve (bullwhip)

not engaging.

2. Throttle control valve cable

broken.

3. Drive engine throttle linkage

damaged.

1. Loose motor pulley or

compressor flywheel.

2. Low oil level in compressor

pump.

3. Carbon build up on valve and

piston.

1. Check fuel level in drive engine.

2. Inspect compressor check valve.

3. Check drive engine spark plug.

4. Check oil level on compressor

drive engine.

5. Check oil on compressor pump.

1. Check pilot valve to make sure

it is in the proper position.

2. Replace compressor pilot valve.

3. Check and clean compressor

pump head unloaders.

1. Check throttle control valve

(bullwhip) for proper function.

2. Replace throttle control valve.

3. Check drive engine throttle

linkage.

1. Tighten pulley or flywheel.

2. Keep oil level at recommended

level for proper operation.

3. Only use factory recommended

oil.

5

troubleshooting

Problem Possible Cause Solutions

Excessive oil

discharge in

air (All

Compressors

have a small

amount of oil

carry over in

compression)

Compressor

Overheating

Excessive belt

wear

Compressor

won’t start in

cold

weather

Compressor

has excessive

vibration

1. Worn piston rings or cylinder.

2. Restricted air intake.

3. Oil level to high.

4. Compressor has exceeded it

duty cycle.

1. Poor ventilation.

2. Dirty cooling surfaces.

3. Compressor is out of its

operating duty cycle.

1. Pulley out of alignment.

2. Improper belt tension.

3. Pulley damaged of loose.

1. Bad check valve.

2. Compressor has wrong grade

oil.

3. Control lines frozen.

1. Compressor is not properly

mounted on vibration isolation

pads.

2. Compressor pulley is out of

alignment.

3. Engine is low on fuel of throttle

is out of adjustment.

1. Clean or replace air filters.

2. Reduce oil level to

recommended amount.

3. Reduce compressor duty cycle

(repair leaks or add another unit

to handle the excess demand).

1. Relocate compressor to any

area with better ventilation (at

least 18 inches from the nearest

wall).

2. Clean all cooling surfaces.

3. Reduce compressor duty cycle

(repair leaks or add another unit

to handle the excess demand).

1. Realign pulley with flywheel.

2. Readjust belt tension.

1. Use IS 100 (30W) compressor

oil for cold weather conditions.

2. Move compressor to a warmer

location.

3. Put a heat lamp on compressor

to maintain above freezing

temperatures.

1. Properly mount compressor on

vibration isolation pads.

2. Re-align pulleys.

3. Check drive engine oil and fuel

level.

4. Re-adjust engine throttle control

(bull whip).

6

compressor maintenance

Compressor Maintenance

WARNING

To avoid personal injury, always turn drive engine key off and remove

from compressor, relive all air pressure from the system, also

disconnect the battery power connections before starting any service

or maintenance on the compressor.

Daily:

Drain the receiver. Condensation will accumulate in the tank daily, and

should be drained at least once a day. This is done to reduce corrosions

of the tank from the inside. Always wear protective eye wear when

draining the tank.

Check pump oil level. All units have a sight glass the oil level non running

units should be no lower than ½ way on the sight glass if it is lower then

you need to add oil until it is at least ½ way up the sight glass.

Check unit for any unusual noise or vibrations.

Weekly:

Clean air filter to ensure that no dirt or heavy particulate makes its way

into the compressors valve assemblies.

Clean external parts of compressor and electric motor, this helps to

ensure proper cooling and prevents rust and corrosion on critical parts.

Check safety valves to ensure they are not stuck in place and are

operating properly.

Elite units check auto tank drain for proper function.

Monthly:

Inspect complete air system for leaks to make sure the compressor does

not get out of its duty cycle due to air leak in the system.

Inspect oil for contamination to ensure that harmful deposits do not build

up in the oil.

Check belt tension, to ensure the belts do not fail pre-maturely. Tighten

them as needed to ensure they do not slip. If belts are loose, tighten

per instructions on next page. Failure to tighten can cause pre-mature

belt failure.

7

storage

Every 3 months:

Change oil to ensure that the compressor has proper oil level and that

the oil in the machine does not deteriorate past factory specifications.

Inspect valve assemblies to prevent premature failure and clean out and

carbon that can form in older valves.

*Elite units clean auto tank drain strainer and check for proper function.

Inspect pressure switch for proper function.

Inspect check valve for proper function and remove any carbon

accumulation to prevent premature failure.

*Clean belt guard coolers (if equipped).

Storage of Compressor:

Before storing the compressor for a prolonged period of time, use a blow

gun to clean all debris from compressor. Shut OFF main power and turn

OFF disconnect. Drain tank pressure, clean air filter, drain old oil and

replace with new oil. Cover the unit to prevent dust and moisture from

collecting on the unit.

8

Loading...

Loading...