Page 1

178 034 82-3 2018-04-11

Providing sustainable energy solutions worldwide

Installation- and maintenance instruction

BG 550/650/700/800/950

BMS LMV Biogas

J/K

Page 2

Page 3

General

Table of contents

General

GENERAL

1. General Information

_______________________________________________________5

Safety instructions ______________________________________________________5

Actions to take if you smell gas ____________________________________6

Burner servicing schedule ___________________________________________7

Component replacement intervals ________________________________7

Delivery check ____________________________________________________________7

2. Technical data

_______________________________________________________________8

2.1 Burners are intended for use at: _________________________________8

2.2 Dimensions _____________________________________________________________8

2.3 Description BG 550/650 _________________________________________16

2.4 Description BG 700/800/950___________________________________18

3. General instruktions

____________________________________________________20

3.1 General instructions ________________________________________________20

3.2 Operating instructions _____________________________________________20

3.3 Instructions ____________________________________________________________20

3.4 Inspection and maintenance ____________________________________20

3.5 Start up _________________________________________________________________20

3.6 Commissioning of installation___________________________________20

4. Installation

__________________________________________________________________21

4.1 Delivery check _______________________________________________________21

4.2 Preparations for installation _____________________________________21

4.3 Gas supply ____________________________________________________________21

4.4 Electric connection _________________________________________________21

4.5 Skeleton diagrams _________________________________________________22

4.6 Fitting the burner to the boiler __________________________________ 23

4.7 Handling and lifting instruction _________________________________24

4.8 Inspection of gas nozzle before commissioning _________25

5. Setting the burner

_______________________________________________________26

5.1 Setting the combustion assembly ____________________________26

5.2 Setting the air damper ____________________________________________27

5.3 Setting the gas damper __________________________________________27

5.4 Recommended excess air when using default setting 27

5.5 Determining the gas quantity for the system ______________27

5.6 Calculating the quantity of gas supplied ____________________29

6. Service

________________________________________________________________________30

6.1 Servicing the combustion assembly _________________________30

6.2 Servicing air dampers _____________________________________________31

6.3 Replacement of damper motor, air ___________________________ 32

BG700-950 _____________________________________________________________33

BG550/650 _____________________________________________________________33

BG550-950 _____________________________________________________________33

6.4 Replacement of damper motor, gas _________________________ 34

6.5 Flame monitoring and ionisation current check __________35

6.6 Gas nozzle BG 550/650 __________________________________________37

6.7 Gas nozzle BG 550LN ____________________________________________37

6.8 Gas nozzle BG 700/800 __________________________________________38

6.9 Gas nozzle BG 950 ________________________________________________39

6.10 UV detector

___________________________________________________________40

6.11 Setting the air pressure switch _________________________________41

6.12 Setting the min. gas pressure switch ________________________42

6.13 Setting the max. gas pressure switch _______________________43

6.14 Vibration ________________________________________________________________44

7. Handing over of the installation

8. Fault location, functional troubles

9. Regulators

10. Damper motors

__________________________________________________________________46

_______________________________________________________47

___________________________________45

________________________________45

10.1 SQN damper motor ________________________________________________ 47

10.2 SQM damper motor _______________________________________________ 49

11. Gas train

__________________________________________________________________51

11.1 DMK gas butterfly damper ______________________________________ 51

11.2 MULTI-BLOCK VGD40… SKP15/25 ________________________53

11.3 MULTI-BLOCK, MB-DLE 412-420 ___________________________57

12. Electric equipment

___________________________________________________62

12.1 Safety system _______________________________________________________ 62

12.2 Wiring diagram ______________________________________________________63

12.3 Wiring diagram RWF 50:3 _______________________________________ 64

12.4 Wiring diagram RWF 50:2 _______________________________________ 65

12.5 Wiring diagram Jumo 316 _______________________________________ 66

12.7 List of components_________________________________________________ 67

12.6 Components, electrical cabinet ________________________________ 67

13. LMV37 automatic control unit

__________________________________68

13.1 System structure/function description _______________________68

13.2 General information ________________________________________________69

13.3 Technical Data Basic unit LMV37.4... ________________________69

13.4 Connection and internal diagram _____________________________ 74

14. Operation

_______________________________________________________________76

14.1 LMV37 automatic control unit __________________________________ 76

14.2 List of phase displays _____________________________________________ 78

14.3 Automatic control unit levels ____________________________________79

14.4 Setting the automatic control unit _____________________________84

14.5 Backup and restore ______________________________________________ 103

14.6 Fault status message, display of errors and info _______ 107

14.7 Dispaly message of info ________________________________________ 113

14.8 Resetting the automatic control unit _______________________ 114

14.9 Manual output _____________________________________________________115

15. Parameter list

16. Error code list

17. Declaration of conformity

18. General instruction for gasburner

________________________________________________________ 117

________________________________________________________ 126

______________________________________ 140

___________________________ 141

3 Bentone BFG1

Page 4

General

4

Bentone BFG1

Page 5

1. General Information

This Installation and Maintenance manual:

• is to be regarded as part of the burner and must always be kept near

the installation site

• is intended for use by authorised personnel

• must be read prior to installation

• must be observed by all who work with the burner and associated

system components

• work with the burner may only be carried out by certifi ed installers/

personnel

Enertech AB is not liable for any typographical errors and reserves the right

to make design changes without prior notice.

Safety instructions

• The burner may only be used for its intended purpose in accordance

with the product’s technical data.

• The burner may only be installed and operated by authorised

personnel.

• The product is packaged to prevent damage from occurring during

handling. Handle the product with care. Lifting equipment must be

used to lift larger packages.

• The products must be transported/stored on a level surface in a dry

environment, max. 80% relative humidity, no condensation.

Temperature -20 to +60 °C.

• Check that the burner is compatible with the boiler’s output range.

• All components must be installed without being bent, twisted or

subjected to mechanical or thermal forces which can affect the

components.

• The burner must be installed so that it complies with local regulations

for fi re safety, electrical safety, and fuel distribution.

• The gas outlet from the pressure regulator shall be confi gured in

accordance with applicable regulations and lead to a safe area.

• Make sure when installing the equipment that there is enough space to

service the burner.

• Permitted temperature during operation -10 to +60 °C. Max 80%

relative humidity, no condensation.

• The installer must ensure that the room has adequate air supply.

• The room must comply with local regulations pertaining to its intended

use.

• The installation site must be free of chemicals.

• Burner pipes, fan wheels and air dampers may contain sharp edges.

• The surface temperature of the burner’s components can exceed 60

°C.

• Caution: The burner has moving parts, and there is risk of crushing

injuries.

General

172 515 01 2018-01-02

5 Bentone

Page 6

General

• The electrical installation must be professionally carried out in

accordance with applicable high voltage regulations, as per Enertech’s

recommendations.

• Before servicing, shut off the fuel supply and turn off the power to the

burner.

• Seal inspections must be performed during installation and servicing to

prevent gas leakage.

• Care should be taken by the installer to ensure that no electrical cables

or fuel lines are crushed or otherwise damaged during installation or

servicing.

• If the boiler is equipped with an access hatch, this must be equipped

with a hatch opening switch connected to the burner's safety system.

• When in operation, the burner’s noise level can exceed 85 dBA.

Use hearing protection.

• The burner must not be put into operation without proper safety and

protection devices.

• A Class BE fi re extinguisher is recommended.

• It is forbidden to alter thedesign or use accessories which have not

been approved by Enertech in writing.

• Prior to operation, the following points must be checked:

- fi tting and installation work has been completed and approved

- electrical installation has been correctly performed

- fl ue gas ducts and combustion air ducts are not blocked

- all actuators and control and safety devices are in working order and

correctly set

Actions to take if you smell gas

Turn off the equipment and the boiler. Open windows and doors. Prevent

open fl ames or sparking, e.g. do not turn lights on or off, do not use any

electrical appliances, do not use mobile phones. Open windows and doors.

Close the gas ball valve. Warn residents; do not use doorbells. Evacuate

the building. Notify the installer or gas supplier once the building has been

evacuated.

172 515 01 2018-01-02

Bentone

6

Page 7

General

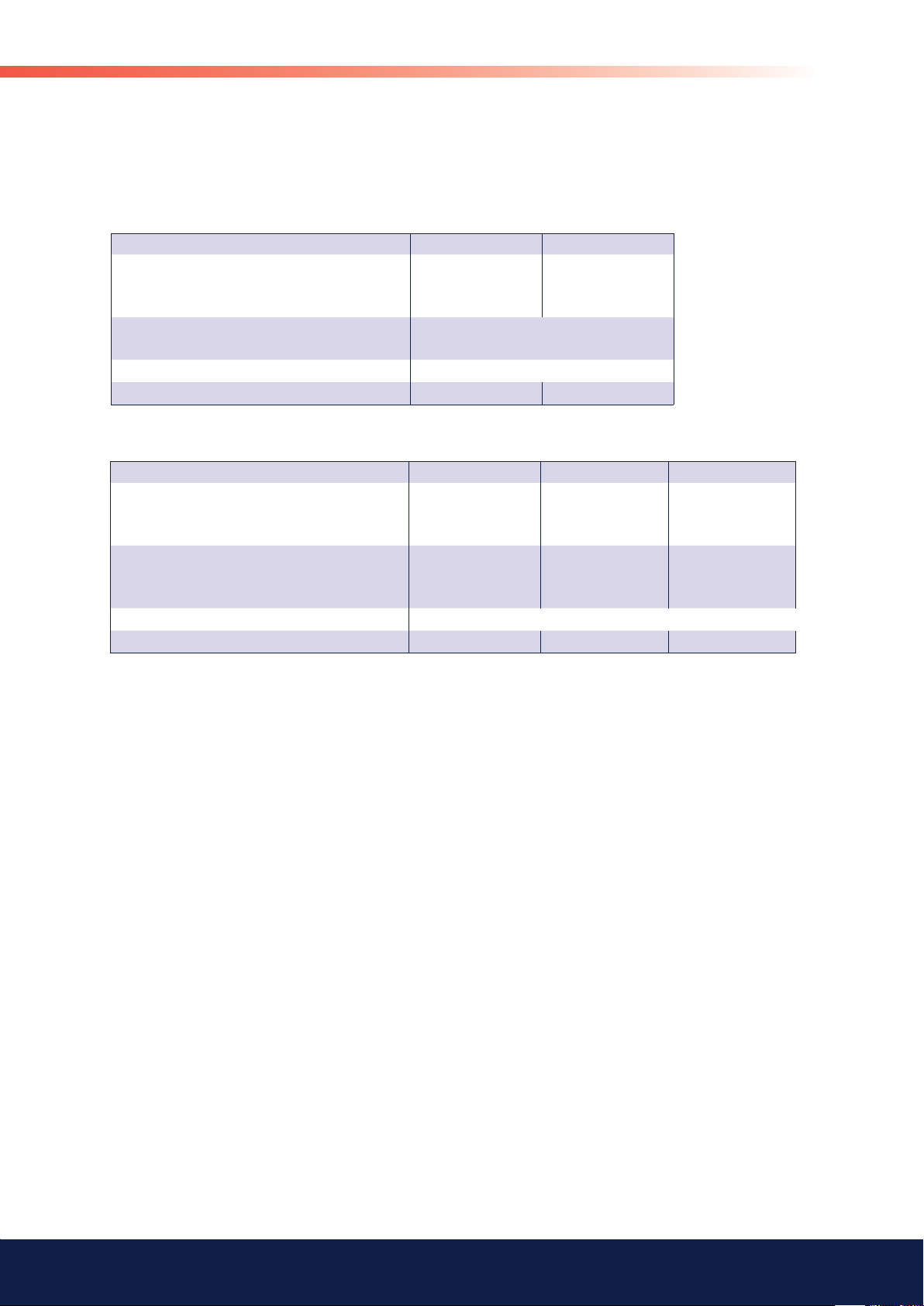

Burner servicing schedule

Servicing must be carried out once a year or after 3000 hours of operation

Burner 1 year 3000 hrs

Inspection of electrical installation 1 year 3000 hrs

Leakage check 1 year 3000 hrs

Filter 1 year replacement at ∆p>10 mbar 3000 hrs replacement at ∆p>10

mbar

Electrodes Replacement/Cleaning 1 year Replacement/Cleaning 3000 hrs

Brake disc Replacement/Cleaning 1 year Replacement/Cleaning 3000 hrs

Motor 1 year 3000 hrs

Fan wheel 1 Year

Replacement when cleaning

needed/ imbalance

3000 h

Replacement when cleaning

needed/ imbalance

Component replacement intervals

Control system 10 years 250,000 starts

Valve control system 10 years 250,000 starts

Pressure switch 10 years 250,000 starts

Ignition system with flame guard 10 years 250,000 starts

UV flame sensor 10000 hrs N/A

Gas pressure regulators 15 years N/A

Gas valve without seal testing 10 years 250,000 starts

Gas valve with seal testing Replacement upon fault detection N/A

Gas pressure switch 10 years 250,000 starts

Safety blow-off system 10 years N/A

Damper motor N/A 500,000 starts

Contactor 10 years 500,000 starts

The burner and its components must be recycled according to applicable regulations.

Delivery check

• Make sure everything is delivered and the goods have not been

damaged during transit.

• If something is wrong with a delivery, report it to the supplier.

• Transport damage must be reported to the shipping company.

7 Bentone

Page 8

General

2. Technical data

2.1 Burners are intended for use at:

• Water heating generators

• Steam generators

• Industrial applications

• Hot air generators

2.2 Dimensions

C

B

E

G

F

E

I

H

Dimensions stated in mm

Type

Standard 1 256 226

BG 550

Standard 3 456 426

BG 650

BG 700

BG 800

Standard 1 316 286

Standard 2 416 386

Standard 363 328

Långt utförande 663 628

Standard 396 361

Långt utförande 696 661

Length of

burner tube

A

Flange

measure A

D

**J

Burner tube

measure B

162 162Standard 2 356 326

184 162

220 205

261 205

Burner tube

measure C

8

BG 950

Bentone BFG1

Standard 1 350 310 280 254

Page 9

D E F G H I **J

BG 550

BG 650

BG 700

BG 800

BG 950

660 320 400 *590 *743 343 200

660 320 400 *590 *743 343 200

820 410 510 *730 *970 420 200

820 410 510 *730 *1022 472 200

890 410 510 *730 *1027 472 200

* The above dimensions are max. measurements. Depending on the

components used, the measurements may vary.

** Min. recommended distance to floor.

2.2.1 Heat generator connection dimensions

General

BG 550

BG 650

BG 700

BG 800

BG 950

K L M

M12 (Ø 210) Ø 255-290 Ø 170

M12 (Ø 210) Ø 254-280 Ø 190

M14 (Ø 280) Ø320-380 (Ø 210) Ø 230

M14 (Ø 280) Ø320-380 (Ø 210) Ø 270

M14 (Ø 340) Ø420-490 (Ø 260) Ø 290

M

K

L

9 Bentone

Page 10

General

2.2.2 Capacity range

Type Grade

of gas

BG 550 G20

BG 550 G25

BG 550 G30

BG 550 G31

BG 650 G20

BG 650 G25

BG 650 G30

BG 650 G31

BG 700 G20

BG 700 G25

BG 700 G31

BG 800 G20

BG 800 G25

BG 800 G30

BG 950 G20

BG 950 G25

BG 950 G30

BG 950 G31

Capacity kWGas quantity

at min. power

Nm3/h 1)

140–628 15 67

140–628 17 73 see data plate

140–628 4 19 see data plate

Gas quantity

at max.

power Nm3/h

1

)

Max.

connection

pressure

mbar

360

Min

connection

pressure mbar

see data plate

140–628 6 25 see data plate

200–1125 21 118

200–1125 24 137 see data plate

200–1125 6 35 see data plate

360

see data plate

200–1125 6 35 see data plate

300–1500 31 157

360–1500 37 183 see data plate

360

see data plate

380–1650 15 67 see data plate

380–2400 40 252

380–2400 46 293 see data plate

360

see data plate

380–2400 40 252 see data plate

500–3200 52 336

500–2800 61 342 see data plate

500–3200 15 98 see data plate

360

see data plate

500–3200 20 130 see data plate

Lower heat value Hu at normal state 15°C and 1013.25 mbar EN676

Grade of gas

Natural gas

Natural gas

Propane

Butane

kWh/Nm

3

G20 9.5 34.02 8126

G25 8.2 29.25 6986

G31 24.6 88.00 21019

G30 32.5 116.09 27728

MJ/Nm

3

kcal/Nm

3

Gas quantity and capacity vary according to grade of gas and connection

pressure.

10

Bentone

Page 11

, RO, SE,

3R

2.2.3 Appliance categories

Only dry gas is permitted for use

BG 550

General

Gerätekategorien

Appliance categories

II

2R/3R

II

2H3B/P

II

2H3P

II

2L3B/P

II

2E3B/P

I

2E(R)B

I

3P

BG 650

Gerätekategorien

Appliance categories

II

2R/3R

II

2H3B/P

II

2H3P

II

2L3B/P

II

2E3B/P

I

2E(R)B

I

3P

BG 800

Gerätekategorien

Appliance categories

II

2R/3R

II

2H3B/P

II

2H3P

II

2L3B/P

II

2E3B/P

I

2E(R)B

I

2H

I

3B/P

I

Versorgungsdrücke

Supply pressures

Bestimmungsländer

Countries of destination

30-360mBar "BG, CZ, DE, EE, ES, FR, GR,

HU, IS, IT, LU, LV, NO, PT, SI,

All countries"

30-360mBar AT, CH, CY, DK, FI, LT, RO, SE,

SK

30-360mBar GB, IE,

30-360mBar NL, RO

30-360mBar PL

30-360mBar BE

30-360mBar BE

Versorgungsdrücke

Supply pressures

Bestimmungsländer

Countries of destination

40-360mBar "BG, CZ, DE, EE, ES, FR, GR,

HU, IS, IT, LU, LV, NO, PT, SI,

All countries"

40-360mBar AT, CH, CY, DK, FI, LT

SK

40-360mBar GB, IE,

40-360mBar NL, RO

40-360mBar PL

40-360mBar BE

40-360mBar BE

Versorgungsdrücke

Supply pressures

40-360mBar ”CZ, DE, EE, ES, FR, GR, IT,

40-360mBar ”AT, CH, CY, DK, FI, LT, RO,

40-360mBar GB, IE,

40-360mBar NL, RO

40-360mBar PL, RO

40-360mBar BE

40-360mBar HU, LT, LV

30-360mBar BE, HU,LT

30-360mBar GB,LT

Bestimmungsländer

Countries of destination

LT, LU, LV, IT, NO, PT, SI,

All countries”

SE,

SK”

11 Bentone

Page 12

General

Bestimmungsländer

Countries of destination

NO,

,

3R

BG 700

Gerätekategorien

Appliance categories

Versorgungsdrücke

Supply pressures

II

2R/3R

II

2H3P

II

2H3P

II

2L3P

II

2E3P

I

2E®

I

3P

BG 950

Gerätekategorien

Appliance categories

II

2R/3R

II

2H3B/P

II

2H3P

II

2L3B/P

II

2E3B/P

I

2E(R)B

I

2H

I

3B/P

I

40-360mBar ”BG, CZ, DE, EE, ES,

HU, IS, IT, LU, LV,

All countries”

40-360mBar ”AT, CH, CY, DK, FI, LT

SK”

40-360mBar GB, IE,

40-360mBar NL, RO

40-360mBar PL

40-360mBar BE

40-360mBar BE

Versorgungsdrücke

Supply pressures

40-360mBar ”CZ, DE, EE, ES, FR, GR, IT,

40-360mBar ”AT, CH, CY, DK, FI, LT, RO,

40-360mBar GB, IE,

40-360mBar NL, RO

40-360mBar PL, RO

40-360mBar BE

40-360mBar HU, LT, LV

30-360mBar BE, HU,LT

30-360mBar GB,LT

Bestimmungsländer

Countries of destination

LT, LU, LV, IT, NO, PT, SI,

All countries”

SE,

SK”

Bentone

12

Page 13

General

2.2.4 Electric Specification

Burner correspond to IP40

Type BG 550 BG 650

Motor

230/400V, 50Hz,

3,5/2,5A, 0,75kW

2860 Rpm

The recommended main fuse

motor

Control power

Sound

Type BG 700 BG 800 BG 950

Motor

89 dBA ± 0,5 dBA 91 dBA ± 0,5 dBA

230/400V, 50Hz,

230V1F~2,5A

10,4/5,5A, 3,0kW,

2940 Rpm

The recommended main fuse

motor

C16A D20A D20A

230/400V, 50Hz,

6,5/4,0A, 1,5kW,

2890 Rpm

C10A

230/400V, 50Hz,

20,5/12,0A,

5,5kW, 2950 Rpm

230/400V, 50Hz,

21,5/13,5A,

5,5kW, 2950 Rpm

Control power

Sound

93 dBA ± 0,5 dBA 96 dBA ± 0,5 dBA 97 dBA ± 0,5 dBA

Measurements according to EN 3746: 2010

Alt.1 The sound level of the burner can be reduced by equipping the burner

with silencer. Installation must be done so it does not prevent air supply

to the burner.

Alt.2 The burner’s noise level can be reduced by connecting the burner’s air

intake to the air duct that opens into an appropriate location. Installation

must be done so it does not prevent air supply to the burner.

230V1F~2,5A

13 Bentone

Page 14

General

2.2.5 Working field

BG 550

140-628 kW

Do not exceed working

field

!

BG 650

200-1125 kW

Do not exceed working

field

!

14

12

10

8

6

4

2

0

Pressure in fire place mbar

-2

100 200 300 400 500 600 700

14

12

10

8

6

4

2

0

-2

200 300 400 500 600 700 800

Pressure in fire place mbar

900 1000 1100 1200

kW

kW

14

Bentone

Page 15

General

mbar

BG 700

G20, G21 300-1500 kW

G31 380-1650

Do not exceed working

field

!

BG 800

380-2400 kW

Do not exceed working

field

!

14

12

10

8

6

4

2

0

-2

200 400 600 800 1000 1200 1400 1600

32

28

24

20

16

12

8

4

0

-4

200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

kW

kW

BG 950

500-3200 kW

Do not exceed working

field

!

32

28

24

20

16

12

8

4

0

-4

400 900 1400 1900 2400 2900 3400

kW

15 Bentone

Page 16

General

2.3 Description BG 550/650

11

10

12

13

14

122

2

3

4

5

6

7

15

89

12

16

11

17

18

16

Bentone

Page 17

General

17

16

19

22 21

2

4

9

2.3.1 Components BG 550/650

1. Burner tube

2. Damper motor, gas

3. Min. gas pressure switch/tightness check

4. MultiBloc

5. Air damper

6. Damper motor, air

7. Connection gas fi ttings

8. Air pressure switch

9. Fan house

10. Sight glass

11. AZL display for LMV automatic control unit

12. Switch 0-l

13. Brake plate adjustment

20

14. Guide bar

15. Ignition electrode

16. Shrouded disc

17. Ionisation electrode

18. Electrical connection

19. Gas nozzle

20. Motor

21. Measuring nipple, fan pressure

22. Connection fl ange

18

17 Bentone

Page 18

General

2.4 Description BG 700/800/950

14

5

1

2

3

4

7

10

15

6

8

9

12

16

17

11

18

18

Bentone

Page 19

17

General

22

21

19

2.4.1 Components BG 700/800/950

1. Burner tube

2. Damper motor, gas

3. Min. gas pressure switch/tightness check

4. MultiBloc

5. Air damper

6. Damper motor, air

7. Connection gas fittings

8. Air pressure switch

9. Fan house

10. Sight glass

11. AZL display for LMV automatic control unit

12. Switch 0-l

13.

18

20

14. Guide bar

15. Ignition electrode

16. Shrouded disc

17. Ionisation electrode

18. Electrical connection

19. Gas nozzle

20. Motor

21. Measuring nipple, fan pressure

22. Connection flange

19 Bentone

Page 20

General

3. General instruktions

3.1 General instructions

The installation of the gas burner must be carried out in accordance with

current regulations and standards. The installers of gas burners should

therefore be acquainted with all regulations and ensure that the installation

complies with the requirements. The installation, mounting and adjustment

should be made with the greatest care and only the correct gas should be

used.

3.2 Operating instructions

The operating instructions accompanying the burner should be left in a

prominent position in the boiler room.

3.3 Instructions

The user should be thoroughly in-structed in the function of the gas burner

and the whole installation. The supplier must instruct the user.

3.4 Inspection and maintenance

Daily inspection is advisable..

3.5 Start up

After the burner has been fitted to the boiler and the electric connection, the

leakage control, the venting and the electric function test have been carried

out, the burner will be ready for start-up.

Howerer, study the sections dealing with adjustments of multi-bloc,

combustion air and combustion head. Open the ball valve and switch on the

main switch. If the burner starts the actual adjustment can be made.

3.6 Commissioning of installation

Control of the combustion. The combustion quality is checked by means of a

flue gas analysis device. Adjust the burner to appr. 20%

excess air in accordance with the table. Check the flue gas temperature.

Calculate the efficiency. Check also the actual gas volume on the gas meter

so that the correct input is achieved.

20

Bentone

Page 21

4. Installation

4.1 Delivery check

Check that all has been delivered and that the goods have not been

damaged during transport. If that is not the case, please notify the delivery

company. Transport damages should be reported to the forwarding agency.

4.2 Preparations for installation

Check that the measurements and capacity range of the burner are

compatible with the boiler. The power ratings on the type plate refer to the

min. and max. power of the burner.

4.3 Gas supply

For good operating safety, it is important that the gas supply system is

installed correctly.

Consider the following:

1. Check that the burner is approved for the gas quality of the installation.

If not, please contact the supplier.

2. Check that the gas components of the burner are approved for

indicated gas pressure.

3. The gas supply system should be installed in accordance with current

standards.

4. Pipe lines should be run so that service on boiler and burner is

facilitated.

5. Pipe lines should be run so that eventual contaminants cannot come

into contact with the gas components.

General

4.4 Electric connection

Before starting the electric installation, the main switch must be turned off.

If the boiler has a 7-pole and a 4-pole Eurostecker connector, these usually

fit directly to the burner. If not, use the connectors included.

(Refer to connection under Electric equipment)

If an electric connection other than the one recommended by Enertech is used, a risk of damage and

injury can arise.

!

21 Bentone

Page 22

General

4.5 Skeleton diagrams

4

5a

2

1

3

5b

6a

8910

6b

Multibloc

1. Ball valve

2. Filter

3. Governor

4. Pressure gauge with shut-off cock

5a. Gas pressure switch, mini

5b. Gas pressure switch, maxi

6a. Main valve, 2 -stage

6b. Safety valve

7. 1) Valve proving system

8. Air damper motor

9. Air pressure switch

7

10. Gas burner control LMV

Pos. 5b, 7: Components not required according to EN 676.

1)

Required over 1200 kW according to EN 676

When Bio gas is used, Enertech shall always be contacted.

!

Bentone

22

Page 23

4.6 Fitting the burner to the boiler

Use 4 x M12 bolts to fit the burner to the boiler. See technical data for the

hole pattern.

To make the fitting process easier, it is possible

to separate the burner body from the gas flange

with the combustion head and valve assembly

in place.

Proceed as follows:

1. Ensure that no power is going to the

burner. Switch off the main power supply

and disconnect the Euro plugs from the

burner. NOTE! If the burner is directly

connected, ensure that all components

on the burner are without power.

2. Remove the cover plate from the fan

housing.

3. Undo the nut (D) to the nozzle assembly.

(applies to BG 550 & 650; does not feature on BG 700, 800 & 950)

4. Disconnect the electrical cables to the valve assembly and gas damper

motor.

5. Undo the screws (B) on both sides.

6. Undo the end stops (C) on the guides.

7. Disconnect the ignition cable, ionisation cable and control arm

(550/650 only) from the gas nozzle.

8. Pull out the burner body from the guides and put it in a suitable place.

After separating the burner body and gas flange it is easier to fit the gas

flange with the combustion head and valve assembly to the boiler. Once the

gas flange is fitted to the boiler, it is easy to lift the burner body up onto the

guides. Assemble the burner in reverse order to its disassembly.

General

Service position

Check the gas tightness.

!

23 Bentone

Page 24

General

4.7 Handling and lifting instruction

4.7.1 BG 550, BG 650

Option

The lifting aid we used

here are available as

!

spare parts, Figure 1

4.7.2 BG 700, BG 800, BG 950

Figure 1

3

24

1

2

Bentone

Page 25

4.8 Inspection of gas nozzle before

commissioning

The gas nozzle can easily be inspected by using the guides on the burner.

Proceed as follows:

1. Ensure that no power is going to the burner. Switch off the main power

supply and disconnect the Euro plugs from the burner.

If the burner is directly connected, ensure that all components on

the burner are without power.

!

2. Remove the cover plate from the fan housing.

3. Undo the nut (D) to the nozzle assembly. (applies to BG 550 & 650;

does not feature on BG 700, 800 & 950)

4. Disconnect the ignition cable and ionisation cable for the gas nozzle.

5. Ensure there is enough slack in the electrical cables to the valve

assembly and gas damper motor to pull out the burner body in the rear

position on the guides. If there is not enough slack the cables can be

disconnected.

6. Undo the screw (B) on both sides.

7. Pull out the burner on the guides.

8. Undo the screw(s) (A) on the gas flange.

9. Take out the gas nozzle.

10. See section 11.7-11-10

Re-assemble the burner in reverse order to that described above. When reassembling, make sure that the O-ring located between the gas nozzle and

the gas flange is in the correct position when the nozzle is re-fitted.

General

If the burner tube is the long variant, the gas nozzle must be removed from the connection tube and then

inserted backwards into the fan housing (from the boiler) to enable maintenance of the brake plate, nozzle,

!

electrodes, etc.

25 Bentone

Page 26

General

5. Setting the burner

5.1 Setting the combustion assembly

It may sometimes be necessary to adjust the combustion assembly, i.e. the

position of the brake plate in the burner tube.

5.1.1 Setting the combustion assembly, BG

550 & 650

The burner is equipped with a lever that changes the position

of the brake plate in the combustion head. This is used to set

the correct pressure drop across the combustion assembly and

thereby obtain good combustion without ripples.

The best position is, among other things, dependent on the input

power and overpressure in the boiler.

A general rule of thumb is that the smaller the capacity, the smaller the gap

should be between the brake plate and the combustion assembly.

The position of the brake plate also has an impact on the quantity of air

supplied for combustion. This means that once the brake plate has been

adjusted, the combustion should be checked and, if necessary, the setting of

the air damper adjusted to obtain good combustion.

Make the adjustment by turning screw X.

A left turn opens the brake plate, providing a lower pressure drop and more

air to the combustion process.

A right turn closes the brake plate, providing a higher pressure drop and less

air to the combustion process.

5.1.2 Setting the combustion assembly, BG 700,

800 & 950

The burner is not equipped with a lever that changes the position of the

brake plate in the combustion head.

On these burners the combustion assembly is designed so that good

combustion can be obtained without adjusting the brake plate.

X

5.2 Setting the air damper

The position of the air damper must be adjusted to achieve a suitable fuel-air

mixture in the operational events that are programmed.

See section 13.4 (LMV) for the setting procedure.

Bentone

26

Page 27

5.4 Calculate prepurge time

Parameter 225 is used to set the blowing time

General

V = Fire box size m

3

Q = Burner output at prepurge [kW]

X = Prepurge time seconds Water boilers

100% air rate

50 % air rate

33% air rate

at least 20s prepurge time

at least 40s prepurge time

at least 60s prepurge time

X = Prepurge time seconds Steam generators

at last prepurge 5 times fi rebox volume

X = Prepurge time seconds Industrial heating process

at least prepurge at least 5 times fi rebox and

adapted compartments volumes together

Local regulations must be followed

Calculation example:

Example A: V=2m

Example B: V=9,5m

Example C: V=25m

3

3

3

Q=200

Q=500

Q=2200

Example A

Example B

Example C

X = V

((Q · 1,2) / 3600) ((200 · 1,2)/3600)

X = V

((Q · 1,2) / 3600) ((500 · 1,2)/3600)

X =

((Q · 1,2) / 3600) ((2200 · 1,2)/3600)

.

5

.

5

.

5

V

=

=

=

2 · 5

9,5 · 5

25 · 5

= 150 seconds

= 285 seconds

= 170 seconds

5.3 Setting the gas damper

The position of the gas damper must be adjusted to achieve the desired

minimum and maximum input power.

See section 13.4 (LMV) for the setting procedure.

27 Bentone

Page 28

General

5.4.1 Example of how to calculate the gas quantity

(natural gas G20):

V0 = Desired quantity of gas [Nm3/h]

Q = Boiler output [kW]

= Gas heat value [kWh/Nm3] or [MJ/Nm3] or [kcal/

H

U

Nm3]

η=

Calculation example:

Q = 2200 kW

Boiler efficiency [%]

H

= Example A: 34,020 MJ/Nm

U

3

Example B: 9.5 kWh/Nm3

Example C: 8126 kcal/Nm

3

η = 90%

Example A

V

0A

Example B

V

0B

Example C

V

0C

If the barometer reading (altitude), pressure and temperature of the gas

deviate significantly from normal values, this must be taken into account as

follows:

T = Temperature of gas at the gas meter [°C]

B = Barometer reading [mbar]

P = Pressure of gas at the gas meter [mbar]

f = Factor calculated for multiplication with flow in Nm

V = Actual flow [m

f =

= Q . 3600

· η

H

u

= Q

· η

H

u

=

Q

· 0,00116 · η

H

u

arrive at actual flow in Nm

273

273+T 1013.25

B+P

·

=

≈

=

3

/h.

2200 · 3600

34,200 · 0.90

2200

9.5 · 0.90

2200

8126 · 0.00116 · 0.90

3

/h to

≈ 258 Nm

≈ 257 Nm

≈ 259 Nm3/h

3

/h]

3

/h

3

/h

28

Bentone

Page 29

Calculation example:

T = 15°C

B = 945 mbar

P = 15 mbar

General

f = 273

273+15 1013.25

.

945+15

≈ 0.90 Nm

3

/h

This means that the quantity of gas read from the gas meter should actually

be read off as 1.11 . the calculated flow in a normal state.

V = V

= V

V

A

V

=

B

V

=

C

. f

0

. f = 258 . 0.90 ≈ 232 m3/h

0A

V

. f = 257 . 0.90 ≈ 231 m3/h

0B

V

. f = 259 . 0.90 ≈ 233 m3/h

0C

5.5 Calculating the quantity of gas

supplied

The quantity of gas supplied can be calculated if the system is equipped with

a gas flow meter of some type. The procedure here is usually to measure

how long it takes for the burner to consume a certain quantity of gas.

To measure:

t = Time for a certain quantity of gas consumed by the burner. [h]

M = Quantity of gas consumed. [m

3

]

V = Actual gas flow [m

V = M

t

[m

3

/h]

Calculation example:

t = 1 min 10 s

M = 4500 dm

M = 4500 = 4.5 m

3

(litre)

3

1000

t = 1 + 10 = 0.0194 h

60 3600

3

V = M = 4.5 ≈ 232 m

/h

t 0.0194

3

/h]

29 Bentone

Page 30

General

6. Service

Whoever carries out service and maintenance on the burner must be

authorised to do so. If components need to be replaced, the replacements

must be of the same make and type and be approved by the authorities. If

the burner is to be used for a different grade of gas, a new adjustment must

be carried out. If town gas is to be used, it is also necessary to convert the

combustion assembly; in some cases the multi-block or valves and gas train

may also need to be changed to a larger type.

6.1 Servicing the combustion assembly

Removal and installation

1. Switch off the main power supply and disconnect the Euro plugs from

the burner.

If the burner is directly connected, ensure that all components on

the burner are without power.

!

2. Remove the cover and disconnect the ignition cable, ionisation cable

and control arm (550/650 only) from the gas nozzle.

3. Loosen the nuts (B) and pull the burner body out of the guides.

4. Loosen the screw (A); this releases the combustion assembly and

allows it to be lifted out.

5. Check and clean the brake plate and gas inlet. If necessary, replace

the worn parts.

6. Check the ignition electrode (see chapter 11.7–11.10). Replace if

necessary.

7. Check the ionisation electrode (see chapter 11.7–11.10). Replace if

necessary.

8. Fit the combustion assembly in reverse order.

9. Press the burner together and lock using the nuts (B).

10. Fit the Euro plugs and turn on the main power supply.

11. Check/adjust the combustion.

30

Bentone

Page 31

6.2 Servicing air dampers

Removal and installation

1. Switch off the main power supply and disconnect the Euro plugs from

the burner.

If the burner is directly connected, ensure that all components on

the burner are without power.

!

2. Loosen the nuts (B) and pull the burner body out of the guides.

3. Remove the intake grille at the air intake.

4. Remove the screws (G) securing the damper motor mounting plate.

5. Lift up the damper motor.

6. Clean the air damper (F) and the intake. Lubricate any damper shaft.

7. Re-install the damper motor and mounting plate on the air intake.

Ensure that the damper shaft and control arm are connected correctly.

8. Adjust the home position of the damper before tightening the screws

(I).

9. Push the damper motor forwards and backwards in the adjustment

slot.

10. Lock the damper motor in position where the damper is almost

engaged but still has a small air gap by the fan housing.

11. Install the intake grille for the air intake.

12. Press the burner together and lock using the nuts (B).

13. Check/adjust the combustion.

General

31 Bentone

Page 32

General

6.3 Replacement of damper motor, air

Removal and installation

1. Switch off the main power supply and disconnect the Euro plugs from

the burner.

If the burner is directly connected, ensure that all components on

the burner are without power.

!

2. Disconnect the damper motor cable from the automatic control unit.

3. Remove the screws (I) securing the damper motor.

4. Loosen the screws (G) to the damper motor mounting plate.

5. Lift up the damper motor.

6. Remove (H) the control arm from the motor shaft.

7. Remove the damper motor from the mounting plate (I).

SQM must be connected and supplied with power before

installation to ensure that the motor shaft and direction of rotation

!

are set correctly.

8. Install the new damper motor on the mounting plate.

For BG 550/650, SQN 14 is used for air control.

For BG700/800/950, SQM 33 is used.

!

Parameter 601.00:0

Parameter 601.01:1

Parameter 602.00:0

Parameter 602.01:1

9. Fit the control arm on the damper motor shaft. It is important that the

screw is perpendicular to the plane of the shaft.

10. Re-install the damper motor and mounting plate on the air intake.

Ensure that the damper shaft and control arm are connected correctly.

11. Connect the damper motor cable to the automatic control unit.

12. Fit the Euro plugs and turn on the main power supply.

13. Adjust the home position of the damper before tightening the screws.

14. Push the damper motor forwards and backwards in the adjustment

slot.

15. Lock the damper motor in position where the damper is almost

engaged but still has a small air gap by the fan housing.

16. Connect the damper motor cable to the automatic control unit.

17. Fit the Euro plugs and turn on the main power supply.

18. Check/adjust the combustion.

32

!

Bentone

NOTE! When resetting dampers, ensure that they do not

engage in the close damper position. If dampers do engage, the

automatic control unit will report an error message.

Page 33

General

BG700-950

BG550/650

G

I

G

G

I

I

G

BG550-950

I

H

33 Bentone

Page 34

General

6.4 Replacement of damper motor, gas

Removal and installation

1. Switch off the main power supply and disconnect the Euro plugs from

the burner.

If the burner is directly connected, ensure that all components on

the burner are without power.

!

2. Disconnect the damper motor cable from the automatic control unit.

3. Undo the screw (Y) on the connection between the motor and damper.

4. Undo the screws (X) and remove the damper motor from its damper

plate.

5. Install the new damper motor, tighten the screws (X).

An SQN 13 damper motor must be used to adjust the gas valve.

!

6. When tightening screw (Y), ensure that the damper is in the closed

position.

7. Connect the damper motor cable to the automatic control unit.

8. Fit the Euro plugs and turn on the mains power.

9. Check / adjust combustion.

34

Bentone

Page 35

6.5 Flame monitoring and ionisation

current check

The standard version of the burner is monitored according to the ionisation

principle. The ionisation current should be checked on initial start-up and at

each service visit.

The reason for low ionisation current can be leakage current, poor

connection to earth, fouling or incorrectly positioned ionisation electrode in

the combustion head. Sometimes the wrong gas-air mixture can also cause

a very poor ionisation current.

The ionisation current is measured with a microampere meter (µA) that is

connected in series with the ionisation electrode and the gas burner control.

Connect the µA meter according to the figure. The minimum required

ionisation current is shown in the table. In practice, this current must be

significantly higher, preferably more than 10µA. The connection of the µA

instrument is made easier by the fact that all gas burners are equipped with

a divisible ionisation cable.

General

Technical data

For continuous operation!

No-load voltage at ION terminal

(X10–05 terminal 2)

Protect the ionization probe against electric shock hazard!

Approx. UMains

!

Short-circuit current Max. AC 1 mA

Required detector current Min. DC 4 µA, flame display approx.

30%

Possible detector current Max. DC 16…40 µA, flame display

approx. 100%

Threshold values when flame is supervised by an ionization probe:

- Start prevention (extraneous

light)

- Operation Intensity of flame (parameter 954) >24%

Intensity of flame (parameter 954) ≥18%

35 Bentone

Page 36

General

ION input

Ionization current in

A

Flame intensity in %

7541d46e/0208

ION input

100

90

80

70

60

50

40

30

20

10

Flame intensity in %

0

0 2 4 6 8 10 12 14 16 18 20

Ionization current in µ A

µ

Figure 1: Ionization input at AC 120 V / AC 230 V

LMV

X10-05,2

Bentone

36

Page 37

6.6 Gas nozzle BG 550/650

General

Towngas

Biogas (UV detector)

Natural gas, Propane

6.7 Gas nozzle BG 550LN

A = 10 mm Front edge of brake plate

B = 3 mm

A

B

A = Position of ionisation detector

B = Position of ignition electrode

A B

37 Bentone

Page 38

General

6.8 Gas nozzle BG 700/800

Natural gas, Propane

3-4

≈

1

Propane

45°

Natural gas

15-20

Biogas (UV detector)

10-12

3-3,5

38

Bentone

Page 39

6.9 Gas nozzle BG 950

Natural gas, LPG

Distance electrode - brake plate.

3-4

45°

General

Biogas (UV-sond)

39 Bentone

Page 40

General

6.10 UV detector

This should not be exposed to temperatures higher than 60°C. The current

passing though the UV detector, when it is lit up, should be at least 70 µA for

LFL1. This current can be measured using a multimeter, although this is only

necessary if a malfunction is suspected.

If flame detectors QRA2… / QRA4.U / QRA10... are used for

flame supervision with the LMV37.4..., it must be ensured that the

!

basic unit is permanently connected to power (conforming to EN

230 / EN 298), thus enabling the system to detect flame detector

failures during startup and shutdown.

Operating voltage Max. 350 V peak

Required detector current in

operation

Possible detector current in

operation

Permissible length of flame

detector cable

- normal cable (laid separately)

Min. 70 µA

Max. 600 µA

Max. 20 m

UV flame detector QRA...Measuring circuit for detector

current measurement

Legend

A Incidence of light

C Electrolytic capacitor 100...470 µF;

DC 10...25 V

M Microammeter Ri max. 5000

• Input QRA... is not short-circuit-proof! Short-circuits of X1006 Pin 2 against earth can destroy the QRA... input

!

Threshold values when flame is supervised by QRA...:

• Simultaneous operation of QRA... and ionization probe is

not permitted!

- Start prevention (extraneous light) Intensity of flame (parameter 954) ≥18%

- Operation Intensity of flame (parameter 954) >24%

A

QRA

+

-

M

C

+

X10-06.2

X10-06.1

LMV

-

!

Warning!

40

Bentone

Page 41

6.11 Setting the air pressure switch

The air pressure switch should block the burner if the air quantity supplied

for combustion is insufficient. The air pressure switch must be set so that,

if there is a defective air supply at the burner’s max. or min. capacity, it

reacts before the monitored pressure falls so much that it results in poor

combustion.

Inställningsområde ca:

LGW 10 1-10 mbar

LGW 50 2,5-50 mbar

Setting for air pressure switch

1. Remove the protective cover, screw (Y).

Be careful when adjusting the air pressure switch; it contains a

live component.

!

General

2. Start the burner.

3. Carefully turn the scale on the air pressure switch clockwise until the air

pressure switch stops the burner. Is the tolerance on the scale for

the min. air pressure switch approx. ±15%?

4. Try to find the pressure at which the burner stops for both the

minimum and maximum input power by turning the scale. Make a note

of the values and then set the air pressure switch on the basis of the

highest pressure noted at which the burner stopped.

5. The air pressure switch should be set to a pressure approx. 10–15%

lower than the highest noted pressure at which the burner stopped.

6. After setting the air pressure switch, perform repeated starts and run

through the burner’s set output range several times. This is to ensure

the reliable function of the burner. If breakdowns or interruptions occur,

the air pressure switch is probably set to a too narrow position.

7. Fit the protective cover, screw (Y).

Y

Y

41 Bentone

Page 42

General

6.12 Setting the min. gas pressure

switch

The min. gas pressure switch should react to a burner connection pressure

that is too low and in such cases prevent the burner from starting. If the

connection pressure to the burner is too low during operation, the min. gas

pressure switch should stop the burner. The burner can start again once

the connection pressure has risen above the pressure set for the min. gas

pressure switch.

Setting for min. gas pressure switch

1. Remove the protective cover, screw (Y).

2. Open the pressure outlet (X) and connect a manometer to measure the

connection pressure.

3. Start the burner.

4. Measure and make a note of the connection pressure to the burner

during normal operation at the highest input power.

5. Based on the desired connection pressure set, determine the

connection pressure at which the gas pressure switch should stop the

burner. Set the connection pressure at which the burner is stopped at

a level where the burner is stopped before poor combustion occurs.

6. Set the min. gas pressure switch to this value by turning the scale.

7. Check the setting by carefully closing the ball valve while measuring the

connection pressure.

8. When the min. gas pressure switch stops the burner, the value

measured should then approximately correspond to the setting on the

min. gas pressure switch. The tolerance on the scale for the min. gas

pressure switch is approx. ±15%.

9. Open the ball valve.

10. Remove the pressure gauge and close the pressure outlet (X).

Check the gas tightness.

!

11. Fit the protective cover, screw (Y).

Bentone

42

X

Y

Page 43

6.13 Setting the max. gas pressure

switch

The burner is only equipped with a max. gas pressure switch if the customer

makes such a request. It should block the burner if the gas pressure

exceeds the set value. Starting can then only take place through a manual

reset (gas burner control or overpressure switch).

Setting for min. gas pressure switch

1. Remove the protective cover, screw (Y).

2. Open the pressure outlet (X) and connect a manometer to measure the

pressure downstream of the gas valve.

3. Start the burner.

4. Measure and make a note of the highest pressure downstream of the

gas valve within the range of the set input power when the burner is

operating under normal conditions.

5. Based on the highest pressure measured downstream of the gas

valve, the desired pressure at which the burner must be stopped is set

downstream of the gas valve.

6. Set the max. gas pressure switch to this value by turning the scale.

The tolerance on the scale for the max. gas pressure switch is approx.

±15%.

7. Remove the pressure gauge and close the pressure outlet (X).

General

Check the gas tightness.

!

8. Fit the protective cover, screw (Y).

X

Y

Setting range:

2.5–50 mbar GW 50

5-150 mbar GW 150

Gas pressure switch, air pressure switch

43 Bentone

Page 44

General

6.14 Vibration

Maximum vibration level are 5,0 mm/s

• Check all bolts and nuts for correct torque

• Check fan wheel for damage and contamination. Change when dirty/

unbalanced

• Check motor bearings. If worn change motor/bearings

Use lid screw

hole for sensor

mounting

44

Bentone

Page 45

7. Handing over of the

installation

• Make repeated start attempts to ensure that the adjustments function.

• Close the ball valve during operation to check that the gas switch

switches off at the set value.

• Remove the hose for the air pressure switch to check that the burner

locks out.

• Check that all protective covers and measurement nipples are

mounted and fastened.

• Fill out necessary test reports.

• Instruct the persons in charge of the operation on the service and

maintenance of the installation and what to do should any troubles

occur.

• Inspection and service must be carried out by authorized personnel.

General

Review and service should be performed by authorised personnel

only

!

8. Fault location,

functional troubles

Trouble free operation is dependent on three factors: electricity, gas and air

supply. Should there be any changes in the ratio between these three factors

there is a risk of break downs. It has been proved that most break downs

are caused by simple faults. Before calling the service engineer, the following

should therefore be checked:

• Is the gas cock open?

• Are all fuses in order and the current switched on?

• Are the thermostats correctly set?

• Are pressostats, overheating protection etc. in operating position and

not locked-out?

• Is the gas pressure sufficient?

• Is the gas burner control in start position?

• Has the gas control or the motor protector locked out? - Reset.

• Is the circulation pump in operation?

• Is there a supply of fresh air to the installation?

• If integral components are of a different make from what is stated in

this manual, see the enclosed loose-leaf.

45 Bentone

Page 46

General

9. Regulators

The burner can be either fi tted with a regulator on the burner or connected

to an external regulator if this is preferred. The interface with the regulator

is a Stecker connector in the electrical cabinet, irrespective of whether the

regulator is internal or external. Connection of the preferred type of regulator

can be made here easily.

Three variants of regulator for installation directly on the burner are available.

• JUMO dTRON 316 With three position signal: up signal, no signal and

down signal.

• RWF50.2 With three position signal: up signal, no signal and down

signal.

• RWF50.3 With analogue signal 4–20 mA or 0–10 V. LMV37 uses 4–20

mA.

For information and operation of the different regulators which can be

installed directly on the burner, see the enclosed manual.

When connecting an external regulator of a type other than those which

are installed on burners, see the manufacturer’s recommendations and the

wiring diagram for burners.

46

Bentone

Page 47

10. Damper motors

The burner is fi tted with two damper motors, one for the gas damper and

one for the air damper. They can be SQN13, SQN14 or SQM33.4 type

motors.

10.1 SQN damper motor

10.1.1 Technical specifi cation

General

Torque Up to 1 Nm (rated output torque)

SQN13… Gas

SQN14… Air

Running time Adjustable on the LMV3...

Supply voltage AC / DC 24 V ±20 % (load on interface)

Power consumption Max. 7.5 W

Perm. on time Max. 50 %

Perm. running time Max. 60 s

Angular adjustment Usable range max. 90°

Degree of protection IP40

Rated resolution encoder monitoring 0.7°

0-position of actuator drive shaft As supplied 0 +2° / -2°

Environmental conditions:

Temperature range -10...+60 °C

Humidity <95 % r.h.

47 Bentone

Page 48

General

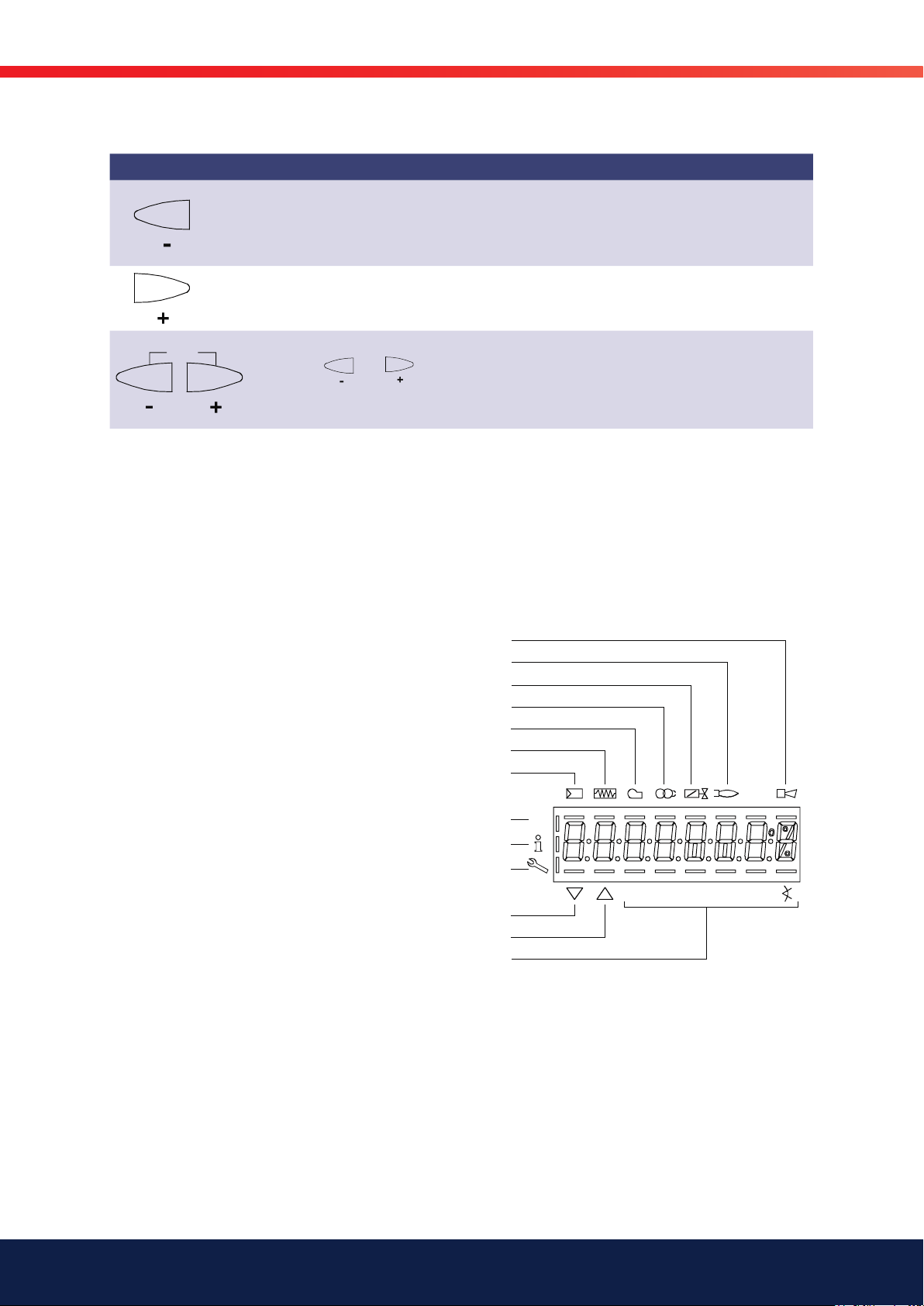

10.1.2 Mounting position

Optional

10.1.3 Choice of damper motor variant

An SQN14 damper motor is used on BG 550 and BG 650 burners to control

the amount of air. An SQN13 damper motor is used on BG 550, BG 650, BG

700, BG 800 and BG 950 burners to control the amount of gas.

10.1.4 Important to remember

• When servicing/replacing a damper motor, select the correct motor for

the desired control as the direction of rotation varies.

• When servicing/replacing a damper motor, clean it and check that the

damper is not sluggish to avoid problems with the damper motor not

managing to make adjustments.

• The tightening torque of 1.5 Nm for the fixing screws must not be

exceeded to prevent damage to the actuator and to ensure that the

actuator does not twist on its mounting surface

• When mounting the actuator, ensure that the permissible axial and

radial loads on the bearing are no not be exceeded

• When fitting the actuator to the controlling element, the correct

mounting order must be observed. It is usually as follows:

1. Screw on the actuator

2. Connect the actuator’s drive shaft to the controlling element using the

coupling pin screw.

• The actuators are supplied with attached connecting cable and plug

• Single bend when laying the cable: 2 x cable diameter

• Always run the high-voltage ignition cables separate from the unit and

other cables while observing the greatest possible distance.

• The holding torque is reduced when the actuator is disconnected from

power.

48

Bentone

Page 49

10.2 SQM damper motor

10.2.1 Technical specifi cation

General

Torque up to 3 Nm nominal output torque

self-holding torque

SQM33.5… Parameter 601.00:0

Parameter 601.01:1

Parameter 602.00:0

Parameter 602.01:1

Cable length:

SQM33.510… 1,5 m

SQM33.511… 3,0 m

Running time Adjustable on the LMV3...

Supply voltage AC / DC 24 V ±20 % (load on

interface)

Power consumption Max. 10 W

Perm. on time 50%, max. 3 min. continuously

Angular adjustment Usable range max. 90°

Degree of protection IP40

Rated resolution encoder monitoring 0.7°

0-position of actuator drive shaft Supply state 0 ±0.6°

Environmental conditions:

Temperature range -20...+60 °C

Humidity <95% r.h.

49 Bentone

Page 50

General

10.2.2 Mounting position

Optional

10.2.3 Choice of damper motor variant

An SQN13 damper motor with anticlockwise rotation is used on BG 550 and

BG 650 burners to control the amount of air. An SQN14 damper motor with

clockwise rotation is used on BG 550 BG 650, BG 700, BG 800 and BG 950

burners to control the amount of gas.

10.2.4 Important to remember

• When servicing/replacing a damper motor, select the correct motor for

the desired control as the direction of rotation varies.

• When servicing/replacing a damper motor, clean it and check that the

damper is not sluggish to avoid problems with the damper motor not

managing to make adjustments.

• The tightening torque of 1.5 Nm for the fixing screws must not be

exceeded to prevent damage to the actuator and to ensure that the

actuator does not twist on its mounting surface

• When mounting the actuator, ensure that the permissible axial and

radial loads on the bearing are no not be exceeded

• When fitting the actuator to the controlling element, the correct

mounting order must be observed. It is usually as follows:

1. Screw on the actuator

2. Connect the actuator’s drive shaft to the controlling element using the

coupling pin screw.

• The actuators are supplied with attached connecting cable and plug

• One-time bend when laying the cable: 2 x cable diameter

• Always run the high-voltage ignition cables separate from the unit and

other cables while observing the greatest possible distance.

• The holding torque is reduced when the actuator is disconnected from

power.

50

Bentone

Page 51

11. Gas train

11.1 DMK gas butterfly damper

11.1.1 Technical specification

Max. operating pressure 500 mbar

Max. differential pressure over

damper

Max. damper setting angle 90°

Required torque:

DMK 512, 515 and 520 min. 50 Ncm

DMK 5065 and 5080 min. 150 Ncm

Throat diameter:

DMK 512 21 mm

DMK 515 32 mm

DMK 520 40 mm

DMK 5065 65 mm

DMK 5080 80 mm

Threaded versions: DMK 512, 515 and 520

Flanged versions: DMK 5065 and 5080

DMK 5065 and 5080 Environmental conditions:

Temperature range -15...70 °C

Humidity <95% r.h.

Gas qualities No nonferrous materials. Suited for

250 mbar

use with gases up to max. max. 0,1

vol. % H2S, dry

General

51 Bentone

Page 52

General

11.1.2 Installation position

Use with actuator drive any installation position posiable.

11.1.3 Important to remember

• Before replacing a butterfly damper, make sure you order the correct

damper size with the correct inlet diameter.

• When performing installation and service, check whether the gas

damper is in the closed position when the burner is turned off. See

image

• When installing a gas damper, observe the direction of flow shown on

the gas damper.

• After working on a gas damper, check the gas tightness

52

Bentone

Page 53

11.2 MULTI-BLOCK VGD40… SKP15/25

11.2.1 Technical specification

All components must be installed without being

bent, twisted or subjected to mechanical or thermal

forces which can affect the components.

!

Max. connection pressure:

VGD40.65/SKP15/25 1500 mbar (static pressure when valves are closed)

VGD40.65/SKP15/25 700 mbar (dynamic pressure when valves are open)

VGD40.80/SKP15/25 1500 mbar (static pressure when valves are closed)

VGD40.80/SKP15/25 700 mbar (dynamic pressure when valves are open)

Adjustable regulator pressure:

VGD40.65/SKP15/25 with spring AGA 29 ≤ 22 mbar

VGD40.65/SKP15/25 with spring AGA 22 15 - 120 mbar

VGD40.80/SKP15/25 with spring AGA 29 ≤ 22 mbar

VGD40.80/SKP15/25 with spring AGA 22 15 - 120 mbar

General

Dirt trap Built in (mesh size 0.9 mm)

Solenoid valve V1 SKP15 opening time varies with valve size, 14 s for

max stroke closing time <0,8 s

Solenoid valve V2 SKP25 opening time varies with valve size, 14 s for

max stroke closing time <0,8 s

Voltage / Frequency 50 - 60 Hz 220 - 240 V AC -15 % +10 %

Switch-on duration 100%

Degree of protection IP54

Multi-block connection flange

VGD40.65/SKP15/25 DN65

VGD40.80/SKP15/25 DN80

Environmental conditions:

Temperature range -10...60 °C

Humidity <95% r.h.

Gas qualities No nonferrous materials.

Suited for use with gases up to max. max

0,1 vol. % H2S, dry

53 Bentone

Page 54

General

11.2.2 Overview

9

19

11

6

18

17

1. V1 SKP15

2. V2 SKP25

3. Motor gas valve

4. V2 Stroke indication

5. Adjustment pressure regulator

6. Measuring nipple/ pressure switch/min/VPS/Pm

7. Connection ¼” pG

8. Impuls tube pG

9. Test nippel pG (measurement of pressure after V2)

10. Connection Pm

11. Connection Pi

19

11

16

7

19

2

7

5

8

14

3 4

20

12

12. Butterfl y damper

13. Electrical connection gas valve V1

14. Electrical connection gas valve V2

15. Indication of V1 and V2 in operation

16. Electrical connection gas pressure switch min/VPS

17. Pressure switch min/VPS

18. Flange connection inlet

19. Data plate

20. Flange connection, outlet

15

19

1

13

15

11

18

10

1085 mm

A gas pressure switch for monitoring that the connection pressure does not get too low is mounted on the multiblock so that it can be used both as a gas pressure switch and to check for tightness. The burner can also be fi tted

with an additional gas pressure switch to monitor that the nozzle pressure does not get too high.

Bentone

54

Page 55

11.2.3 Installation position

General

11.2.4 Adjusting the multi-block

When the multi-block is used together with the LMV37 control unit with

butterfl y valve on the gas pipe, the multi-block acts as a clean valve, which

is not used to set the correct gas fl ow. However, some adjustment of the

multi-block may help to achieve robust burner function. The regulator on the

multi-block should be set in such a way that the input pressure is reduced

using the regulator; this ensures that any variation in the input pressure will

not affect the pressure leaving the block.

11.2.5 Actuator SKP15

SKP15 is mounted on the fi rst valve of the multi-block in the direction of gas

fl ow. The only function of this actuator is open/close.

11.2.6 Actuator SKP25

SKP25 is mounted on the second valve of the multi-block in the direction of

gas fl ow. This actuator has two functions: open/close and controlling the gas

pressure leaving the multi-block.

11.2.6.1 Adjusting the pressure regulator on

actuator SKP25

1. Remove protective plug X.

2. Adjust the pressure regulator by turning the

adjuster screw with the slotted screwdriver to

the desired output pressure in Pa, see image.

Turning to right = higher regulator pressure

Turning to left = lower regulator pressure

3. Fit protective plug X.

Possible output pressure range 15–120 mbar.

Pressure is measured at the pressure outlet on

SKP25. See section 10.2.2.

X

55 Bentone

Page 56

General

11.2.6.2 Replacing the spring on the pressure regulator

for an SKP25 actuator

The SKP25 actuator is fi tted with an AGA29 type spring for the regulator at

the factory.

1. Remove protective plug X.

2. Remove pressure regulator screw Y.

3. Take out the spring and replace it.

4. Fit pressure regulator screw Y and set to

the desired regulator pressure.

5. Fit protective plug X.

11.2.6.3 Impulse pipe for pressure

regulator SKP25

On multi-block VGD40…/SKP15/25 there is

an impulse pipe for the nozzle pressure which

is necessary for regulator SKP25 to function

properly. The impulse pipe has an inside

diameter of 4 mm and an outside diameter of 6 mm. The impulse pipe for

the nozzle pressure to the regulator is fi tted at the factory. When replacing

the impulse pipe, a steel pipe must be used with an inside diameter > 4 mm.

The impulse pipe must be protected again breakage and damage. If damage

should occur, the impulse pipe must be replaced before the burner is put

into operation again.

X

Y

56

Bentone

Page 57

11.3 Double solenoid valve Type DMV-D.../11

Type DMV-DLE.../11

Nominal widths

DN65-80

Electrical connection IEC 730-1

(VDE 0631 T1)

Volt U n ~(AC) 230 V

Valve 2 x Class A

Ambient temperature -15 °C … +60 °C

IP 54

Family 1 + 2 + 3

Max. operating pressure 500 mbar

General

DMV 5065-5080/11

Pressure taps

1, 2, 3, 5 Sealing plug

6, 7 G 1/4

8, 9 G 1/2 Option

Screw plugs 1,2,3 ,5may also be

replaced by a measuring socket

G 1/8 DIN ISO 228.

Concealed connecting bore for

system accessories.

172 515 83 2018-04-05

57 Bentone

Page 58

General

B

C

C

A

A

4. Mounting

1. Insert setscrews A, refer to Fig. 1

2. Insert seals B.

3. Insert setscrews C.

4. Tighten setscrews A+C. Ensure

correct seating of the seal!

5. Perform leak and functional tests

after mounting.

B

C

C

A

A

5. Lead seal Lead seal eye 2 in 1.5

mm dia. sealing valve. Lead seal

eye 3 in 1.5mm cap stand headed

screw. After setting the requested

pressure setpoint:

1. Close protective valve 1.

2. Route wire through 2 and 3,

Fig. 2.

3. Press lead around wire ends,

keep wire loop short.

Bentone

58

5.

°

Vmin. / mini.> 0.1 x Vmax. / maxi.

°

Page 59

General

6.

6. DMV Main flow setting only

possible at V1! Set main volume

on open valve. Set valve V1 during

operation.Check setting values

continuously. Smallest setting

volume flow:

9. Replacing the solenoid Versions

with adjusting plate DMV-D 5.../11or

hydraulic brake DMV-DLE 5../11

1. Remove hydraulic brake or

adjusting plate as described

on page 6: ”Replacing the

hydraulic brake or adjusting

disk”, steps 1 - 5.

2. Replace solenoid

Important: Make sure that the

solenoid no. and voltage are

correct!

3. Remount hydraulic brake or

adjust-ing plate as described

on. ”Replacing the hydraulic

brake or adjusting plate”, steps

7 -11.

7. 8.

7. DMV-DLE Rapid stroke

adjustment V start Factory setting

DMV-DLE: Rapid stroke not adjusted

1. Unscrew the adjustment cap E

from the hydraulic brake.

2. Turn the adjustment cap and

use as a tool.

3. Turn a-clockwise = increase

rapid stroke (+).

8. Replacing hydraulic brake unit or

adjustment plate

1. Switch off firing system.

2. Remove locking varnish from

countersunk screw A.

3. Unscrew countersunkscrew A.

4. Unscrew socket headscrew B.

5. Raise adjustment plate C or

hy-draulic brake D.

6. Remove sealing plug E

7. Exchange adjustment plate C

or hydraulic brake D

8. Screw in countersunk and

socket head screw. Only

tighten socket head screw so

that hydraulic brake can just

be turned.

9. Coat countersunk screw A

with locking varnish.

10. Leakage test: Pressure tap at

sealing plug 3

11. Perform functional test.

12. Switch on firing system.

59 Bentone

Page 60

General

12. Gas pressure regulator Type FRS

Nominal diameters

Rp 3/8 - Rp 2 1/2

DN 40 - DN 150

Never close vent nozzle!

!

Vent plug

Pressure taps

1. Vent plug

2. Connection for external pulse

G 1/4 screw plug ISO 228, on

both sides, optional.

3. G 1/4 screw plug ISO 228, in

inlet pressure range, on both

sides

Vent nozzle

Max. operating pressure 500 mbar

Pressure regulator Class A

Ambient temperature -15 °C … +70 °C

Inlet pressure range 5 - 500 mbar

Family 1 + 2 + 3

Outlet pressure range 2,5 - 200 mbar

60

Bentone

Page 61

Dimensions [ mm]

General

b

b

e

f

a

Type

Weight Order

h

p

max.

Number

d

Rp/DN

mbar

e

h

d

DN

c

f

a

DN

c

Dimensions mm

a b c d e f g h kg

FRS 507 070 391 500 Rp ¾ 100 130 28 165 G¼ G¼ G1/8 245 1,00

FRS 510 070 409 500 Rp 1 110 145 33 190 G¼ G¼ G1/8 310 1,20

FRS 515 058 446 500 Rp 1½ 150 195 40 250 G½ G¼ G¼ 365 2,50

FRS 520 058 628 500 Rp 2 170 250 47 310 G½ G¼ G¼ 450 3,50

FRS 525 083 303 500 Rp 2½ 230 285 60 365 G½ G¼ G¼ 550 6,00

FRS 5065 058 792 500 DN65 290 285 95 405 G½ G¼ G¼ 590 7,50

FRS 5080 079 681 500 DN80 310 285 95 405 G½ G¼ G¼ 590 10,00

Do not use unit as lever.

DN 40 50 65 80 100 125 150

Rp 3/8 1/2 3/4 11 1/2 2 21/2 -- -- -- -M

max

70 105 225 340 610 1100 1600 2400 5000 6000 7600

(Nm) < 10s

T

max

35 50 85 125 200 250 325 400 -- -- -(Nm) < 10s

61 Bentone

Page 62

General

Adjustment of outlet pressure

(setpoint adjustment)

Factory setting: Standard spring p 2

10-30 mbar

1.

1. Unscrew protective cap A.

2. Adjustment (+) Setting spindle

B ”Turn counter-clockwise”

= Increasing outlet pressure

(setpoint)

or

2.

Adjustment (-) Setting spindle B

”Turn clockwise” = Reducing outlet

pressure (setpoint)

4. Check setpoint

5. Screw on protective cap A.

6. Attach lead seal (Page 5).

2.1.

B

A

B

Replace setting spring 3-4

1. Remove protective cap. A.

Release spring by turning

adjustment spindle B counter

clockwise. Turn spindle to

stop.

2. Unscrew complete adjustment

device B and remove spring C.

3. Insert new spring D.

4. Assemble complete

adjustment device and adjust

desired off-set.

5. Screw on protective cap A.

Stick adhesive label E onto

typeplate.

6. Attach lead seal.

3.

4.

B

E

A

B

C/D

62

Bentone

Page 63

13. Electric equipment

13.1 Safety system

Safety systems must be installed in accordance with regulations that are

applicable for the appliance. This may differ according to the process burner

are installed in to. Se local regulations for information.

Safety system cables must be run in separate cables outgoing signal must

not come in same cable as incoming signal. Signals must be in different

harnesses for safety reasons.

Safety system as door switches, water level, pressure, temperature and

other safety limiters must be installed in safety loop according to process.

The switch for high gas pressure can be installed for different uses.

Installation must be carried out pursuant to applicable regulations.

• The switch can be installed so that it reacts either to inlet pressure or

pressure according to the multi-block pressure regulator.

• The high gas pressure switch can be installed to the connection pipe

between the multi-block and the burner head, and will then function as

a power monitor.

• Installation will block burner operation and a manual restart will be

required.

Installation must be carried out pursuant to applicable regulations.

General

63 Bentone

Page 64

General

13.2 Wiring diagram

64

Bentone

Page 65

13.3 Wiring diagram RWF 50:3

General

65 Bentone

Page 66

General

13.4 Wiring diagram RWF 50:2

66

Bentone

Page 67

13.5 Wiring diagram Jumo 316