Page 1

178 116 35-5 2017-12–05

Providing sustainable energy solutions worldwide

Installation- and maintenance instruction

BF1 RME

Page 2

Page 3

Table of contents

General

GENERAL

1. GENERAL INSTRUCTIONS

__________________________________________4

1.2 Manual ____________________________________________________________________4

1.3 Safety directions ______________________________________________________4

1.1 General rules ___________________________________________________________4

1.1 Model BF1 FUV 63-16 ______________________________________________6

1.1.1 Burner output/ Basic settings _________________________6

1.2 Model BF1 KV 76-26 ________________________________________________7

1.2.1 Burner output/ Basic settings _________________________7

2. TECHNICAL DATA

_______________________________________________________8

2.1 Dimensions BF1 _______________________________________________________8

2.1.1 Dimensions, flanges _______________________________________ 8

2.2 Recommended nozzles and pressures _______________________9

2.3 Nozzle table, 8-15 bar ______________________________________________9

2.3.1 Burner with preheater ____________________________________9

2.4 Description ____________________________________________________________10

2.4.1 Components _______________________________________________11

3. INSTALLATION

__________________________________________________________12

3.1 Delivery checks ______________________________________________________12

3.2 Preparations for installation _____________________________________12

3.3 Oil supply ______________________________________________________________12

3.4 Electrical connection _______________________________________________12

3.5 Choice of nozzle ____________________________________________________12

3.6 Brake plate and airflow setting _________________________________12

3.7 Burner installation ___________________________________________________ 13

3.7.1 Hole pattern ________________________________________________13

3.7.2 Burner installation ________________________________________13

3.7.3 Oil pipes _____________________________________________________ 13

3.7.4 Electrical connection ____________________________________ 13

4. BASIC SETTINGS

______________________________________________________14

4.1 Example of basic setting _________________________________________14

4.1.1 Choice of nozzle __________________________________________ 14

4.1.2 Basic setting _______________________________________________ 14

4.1.3 Nozzle assembly adjustment ________________________ 15

4.1.4 Air intake adjustment ___________________________________ 15

4.1.5 Method of adjusting air quantity ____________________ 15

4.1.6 Inlet cone, air adjustment _____________________________ 15

4.1.7 Air intake rotation ________________________________________ 16

4.1.8 Air duct ______________________________________________________ 16

5. BURNER SERVICING

________________________________________________17

5.1 Warning ________________________________________________________________17

5.1.1 Service position ___________________________________________ 17

5.1.1.1 Service position 1 ______________________________________17

5.1.1.2 Service position 2

5.1.1.3 Service position 3

______________________________________17

______________________________________18

5.1.2 Combustion assembly service ______________________ 18

5.1.3 Preheater replacement _________________________________ 19

5.1.4 Oil pump replacement __________________________________ 20

5.1.5 Fan motor replacement ________________________________ 21

5.1.6 Air intake and intake cone service _________________ 22

5.1.7 Fan wheel checks ________________________________________ 22

5.1.7.1 Inspection ______________________________________________22

5.1.7.2 Cleaning, alternative 1

5.1.7.3 Cleaning, alternative 2

__________________________________23

__________________________________24

5.1.8 Electrical module _________________________________________ 24

5.1.8.1 Replacement of complete electrical package __________25

5.1.8.2 Replacement of individual electrical components

______25

6. PUMP INSTRUCTIONS ______________________________________________ 26

6.1 Suntec ANV47C _____________________________________________________26

6.1.1 Technical data ____________________________________________26

6.1.2 Components _______________________________________________26

6.1.3 Filter replacement ________________________________________ 27

6.1.4 One-pipe system ________________________________________ 27

6.1.5 Two-pipe system _________________________________________27

6.1.6 Solenoid valve _____________________________________________ 27

6.1.7 Function ANV47C ________________________________________ 28

6.1.8 Suction pipe tables ANV47C ________________________ 29

6.1.8.1 Overhead Tank _________________________________________29

6.1.8.2 Underlying Tank

________________________________________29

7. PREHEATER ______________________________________________________________ 30

7.1.1 Function FPHE 5 _________________________________________ 30

8. ELECTRICAL EQUIPMENT

LMO1..2..4..

____________________________________________________________31

8.1 Wiring diagram ______________________________________________________ 31

8.1.1 Component list____________________________________________ 32

8.1.2 Function LMO1..2..4.. __________________________________ 32

8.1.3 Technical data _____________________________________________33

8.1.4 Colour codes LMO14/24______________________________ 34

8.1.5 Fault codes LMO14/24 ________________________________ 34

9. FAULT LOCATION

______________________________________________________35

9.1 Burner will not start ________________________________________________ 35

9.2 Burner will not start after normal use ________________________ 35

9.3 Delayed ignition, burner starts; pulsation ___________________ 35

10. DECLARATION OF CONFORMITY

11. OIL BURNERS MAINTENANCE INSTRUCTIONS

_____________________________36

________37

3 Bentone BF1

Page 4

General

1. GENERAL INSTRUCTIONS

1.2 Manual

• The contents of this manual are to be observed by all who work for any

reason on the unit and its appertaining system parts.

• This manual is intended especially for authorised personnel.

• This manual is to be regarded as part of the burner and shall always be

available near the place of installation.

1.3 Safety directions

The electrical installation shall be made according to valid regulations for

heavy current and in a professional way, so that the risk of leaking oil, fire or

personal injury is avoided.

Care should be taken by the installer to ensure that no electrical cables or

fuel/gas pipes are trapped or damaged during installation or service/

maintenance.

1.1 General rules

This is a burner designed for FAME (RME) fuel. The fuel must meet the

requirements of standard EN 14214 for FAME. The equipment on the burner

is, however, of such a quality that it is possible to use EO1 type oil without

modification, although with appropriate adjustments to the combustion

values after each change of fuel type.

The installation of an oil burner should be carried out in accordance with

local regulations. The installer of the burner must therefore be aware of all

regulations relating to oil and combustion.

Only oil suitable for the burner must be used and then in combination with a

suitable oil filter designed for FAME (RME) and installed before the burner’s oil

pump.

If the burner is replacing an existing burner, ensure that the oil filter is

changed to a filter designed for FAME (RME). Installation may only be

performed by qualified personnel.

Care should be taken by the installer to ensure that no electrical cables

or fuel/gas pipes are trapped or damaged during installation or service/

maintenance.

Burners which are fuelled by FAME (RME) are and must be equipped with

parts designed for this fuel. This applies in particular to oil-related parts such

as the pump, solenoid valve, oil filter and hoses. It is very important when

carrying out a service to replace old parts with new parts of the same quality.

4

Bentone BF1

Page 5

General

Adjustment of burner

The burner is from the factory preset to an average value

that must then be adjusted to the boiler in question.

All burner adjustments must be made in accordance with

boiler manufacturers instructions.These must include

the checking of flue gas temperatures, average water

temperature and CO2 or O2 concentration.

To adjust the combustion device, start by increasing the

air volume and the nozzle assembly somewhat. When

the burner starts it is burning with excess air and smoke

number 0. Reduce the nozzle assembly adjustment

until soot occurs, and then increase the adjustment to

make the soot disappear again. Then the volume of air is

reduced until soot occurs and increased again to reach a

combustion free of soot.

By this procedure an optimum adjustment is obtained. If

larger nozzles are used the preadjustment of both the air

volume and the nozzle assembly must be increased.

A whistling sound may be heard which can be

eliminated or reduced as follows: Increase the nozzle

assembly adjustment somewhat. The CO2-content and

consequently the air volume will then be reduced.

Condensation in chimney

A modern burner works with less excess air and often

also with smaller nozzles than older models. This

increases the efficiency but also the risk of condensation

in the chimney. The risk increases if the area of the

chimney flue is too large. The temperature of the flue

gases should exceed 60°C measured 0,5 metres from

the chimney top.

Pump adjustment

See separate description.

Maintenance

The boiler/burner should be examined regularly for any

signs of malfunction or oil leakage. Any boiler/burner that

uses FAME (RME) as fuel must be serviced at least twice

a year.

Installation instructions

General installation instructions ac company the burner

and should be left in a prominent place adjacent to the

burner.

Oil supply

The oil line should be dimensioned in accordance with

the pump manufacturer´s instruction. A filter designed for

FAME (RME) that prevents any particles in the oil from

reaching the burner is mounted in the burner’s suction

pipe. If the installation consists of several burners each

one should have its own suction line from the tank or a

circulation system should be used.

The temperature in the oil line should be kept as

constant as possible. Avoid exposing the line to

excessive cold which may cause blockages.

The oil pipe and electric cable should be fitted so that

the burner can be placed on the floor for inspection of

the combustion device.

Oil hoses must be of a quality designed for FAME (RME).

• Measures to raise the temperature:

• Insulate the chimney in cold attics

• Install a tube in the chimney

• Install a draught regulator (dilutes the flue gases

during operation and dries them up during

standstill)

• Increase the oil quantity

• Raise the flue gas temperature by removing

turbulators, if any, in the boiler.

Detailed ecodesign information can be downloaded at:

www.bentone.com/ecodesign

5 Bentone BF1

Page 6

General

1.1 Model BF1 FUV 63-16

ø16

ø67

ø63

Protrusion from flange, measurement B

Length of blast tube

Flange

1 2 3 4

103 68 81 89 88

133 98 111 119 118

183 148 161 169 168

1.1.1 Burner output/ Basic settings

1,3 - 4,6 kg/h

15 - 55 kW

4,0

3,5

3,0

2,5

2,0

1,5

1,0

0,5

Boiler overpressure, mbar

0,0

-0,5

10 15 20 25 30 35 40 45 50 55 60

Burner output, kW

22,0

20,0

Scale

18,0

16,0

14,0

12,0

10,0

8,0

6,0

4,0

2,0

0,0

15 20 25 30 35 40 45 50 55

1,6–2,0

7,0–8,0

Air settings

Nozzle assembly

(-0,1)+0,5

Burner output, kW

6

Scale value applies to 0 mbar furnace pressure.

!

Bentone BF1

Page 7

4,0

1.2 Model BF1 KV 76-26

General

ø26

ø70

ø76

Protrusion from flange, measurement B

Length of blast tube

1 2 3 4

117 82 95 103 102

147 112 125 133 132

197 162 175 183 182

Flange

1.2.1 Burner output/ Basic settings

3,8 - 8,0 kg/h

25 - 75 kW

8,0-9,0

2,7-3,3

0,5-1,5

3,5

3,0

2,5

2,0

1,5

Boiler overpressure, mbar

1,0

0,5

0,0

-0 ,5

40 4 5 50 5 5 60 6 5 7 0 75 80 8 5 90 9 5 10 0

Burner output, kW

Scale value applies to 0 mbar furnace pressure.

!

7 Bentone BF1

Page 8

General

2. TECHNICAL DATA

2.1 Dimensions BF1

B

ø89

145

305

226

172

190

2.1.1 Dimensions, fl anges

Flange 1 Flange 2

10,3

Flange 3 Flange 4

10

ø89,7

130–150

ø90

125

25

12

4

10,3

ø89,5

136–150

ø90

125–150

12

5

8

Scale value applies to 0 mbar furnace pressure.

!

Bentone BF1

Page 9

General

2.2 Recommended nozzles and pressures

Because of the different types of boiler in existence, with varying furnace

geometries and furnace loads, it is not possible to commit to any given spray

angle or spay pattern. Note that spray angles and spray patterns change

with pump pressures.

Nozzle 60° Solid/Hollow cone

80° Solid/Hollow conel

Pump pressure 10 bar (8–14 bar) Fuel oil 1, RME

Kerosene

2.3 Nozzle table, 8-15 bar

Pump pressure, bar

Gph 8 9 10 11 12 13 14 15

kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW kg/h kW

0,40 1,33 16 1,41 17 1,49 18 1,56 18 1,63 19 1,70 20 1,76 21 1,82 21

0,50 1,66 20 1,76 21 1,86 22 1,95 23 2,04 24 2,12 25 2,20 26 2,28 27

0,60 2,00 24 2,12 25 2,23 26 2,34 28 2,45 29 2,55 30 2,64 31 2,73 32

0,65 2,16 26 2,29 27 2,42 29 2,54 30 2,65 31 2,75 33 2,86 34 2,96 35

0,75 2,49 29 2,65 31 2,79 33 2,93 35 3,08 36 3,18 38 3,30 39 3,42 40

0,85 2,83 33 3,00 36 3,16 37 3,32 39 3,47 41 3,61 43 3,74 44 3,87 46

1,00 3,33 39 3,53 42 3,72 44 3,90 46 4,08 48 4,24 50 4,40 52 4,56 54

1,10 3,66 43 3,88 46 4,09 48 4,29 51 4,48 53 4,67 55 4,84 57 5,01 59

1,20 3,99 47 4,24 50 4,47 53 4,68 55 4,89 58 5,09 60 5,29 63 5,47 65

1,25 4,16 49 4,40 52 4,65 55 4,88 58 5,10 60 5,30 63 5,51 65 5,70 68

1,35 4,49 53 4,76 56 5,02 59 5,27 62 5,50 65 5,73 68 5,95 70 6,15 73

1,50 4,98 59 5,29 63 5,58 66 5,85 69 6,11 72 6,36 75 6,60 78 6,83 81

1,65 5,49 65 5,82 69 6,14 73 6,44 76 6,73 80 7,00 83 7,27 86 7,52 89

1,75 5,82 69 6,18 73 6,51 77 6,83 81 7,14 85 7,42 88 7,71 91 7,97 94

2,00 6,65 79 7,06 84 7,45 88 7,81 93 8,18 97 8,49 101 8,81 104 9,12 108

2,25 7,49 89 7,94 94 8,38 99 8,78 104 9,18 109 9,55 113 9,91 117 10,26 122

The table applies to oils with a viscosity of 4.4 mm

2

/s (cSt) at a density of 830 kg/m3.

2.3.1 Burner with preheater

Allow for a reduction in oil quantity of 5–20% with preheating owing to:

• Temperature increases at the nozzle.

• Nozzle design.

• Capacity (the higher the capacity the lower the difference).

9 Bentone BF1

Page 10

General

2.4 Description

1

2

10

3 4

5

6

7

9

2.4.1 Components

1. Brake plate

2. Nozzle

3. Fan housing, front

4. Ignition transformer

5. Separating screw

6. Oil burner control

7. Electrical contact X3 (refer to wiring diagram)

8. Motor

9. Capacitor

10. Preheater, where fitted

11. Ignition electrode

12. Ignition cable

8

13. Photoresistor

14. Inspection glass

15. Nozzle assembly adjustment

16.

17. Blast tube

18. Grid

19. Solenoid valve

20. Oil pump

21. Air regulator

22. Air intake

23. Air flow indicator

24. Fan housing, rear

10

Bentone BF1

Page 11

General

3

15

13

5

17

14

19

20

24

22

21

1

23

2

11 12

10

11 Bentone BF1

Page 12

General

3. INSTALLATION

3.1 Delivery checks

Check that everything has been delivered and that the goods are not

transport damaged. Any delivery faults must be reported to the supplier.

Transport damage must be reported to the forwarder.

3.2 Preparations for installation

Check that the burner’s measurements and capacity range is suitable for

the boiler in question. The power information on the data plate refers to the

burner’s max. and min. power.

3.3 Oil supply

In order to achieve good operational reliability it is important that the oil

supply system is laid out correctly.

Observe the following:

• Choice of pipe diameters, pipe lengths and height differences (refer to

pump instructions).

• Piping should be run with a minimum of joints/compression fittings.

• Pipework must be laid out so that oil hoses are not subjected to

tension or overbending when the burner is swung out or removed for

service.

• The oil filter should be installed so that the filter cartridge can easily be

replaced

3.4 Electrical connection

Before electrical installation is begun, electricity must be switched off at

the main switch. If the boiler has a 7-pole or a 4-pole Eurostecker (only on

2-stage burners), these often fit directly to the burner. Otherwise use the

connectors supplied. The operating thermostat, the max. thermostat and the

inspection hatch (where fitted) interlock can then be wired in series on the

incoming phase connected to L1 or connected between T1 and T2. In the

first mentioned case a jumper is installed between T1 and T2.

(Refer to connection in the section Electrical equipment).

If any electrical connection is used other than that recommended

by Enertech, there may be a risk of equipment damage and personal injury.

!

3.5 Choice of nozzle

(Technical data): Recommended nozzle and nozzle table.

3.6 Brake plate and airflow setting

Before operations basic burner setting may be made according to the

diagram. (Refer to basic settings). Note that this only refers to the basic

setting; the setting must be adjusted after the burner has been started.

At this time flue gas analysis and soot measurement must be carried out.

12

Bentone BF1

Page 13

3.7 Burner installation

3.7.1 Hole pattern

Check that the hole pattern matches the flange supplied.

(Refer to Technical data.)

3.7.2 Burner installation

1. Install the flange and the gasket on the boiler.

2. Attach the front piece to the flange.

3. Insulate between the burner register and the boiler cover for reduced

heat radiation.

4. Install the selected nozzle. (Refer to Technical data.)

5. Install the brake plate and check the ignition electrodes (refer to Burner

service.).

6. Install the burner body to the front piece and lock with screw (E).

General

E

3.7.3 Oil pipes

1. Check the oil pipe dimensions. (Refer to Pump Instructions.)

2. The oil filter should be installed in the oil supply line. If an air separator is

fitted, the oil filter should be installed before the air filter to increase the

life span of the filter.

3. For one-pipe systems the return plug must be removed. (Refer to

Pump Instructions.)

4. When installing oil hoses, check that the supply and return hoses are

connected to the correct connections on the oil pump. The hoses

must be run so that they are not bent or tensioned.

5. Purge the oil system. The oil pump will be damaged if it is run dry.

6. The vacuum should not be lower than 0.3 bar depression in the suction

line at start up.

3.7.4 Electrical connection

If the boiler lacks ready-connected plugs, connect using the supplied plug,

X4 in accordance with the wiring diagram.

1. Disconnect the power at the main switch.

2. Wire the Eurostecker X4 as in alt. 1–3 (refer to Electrical equipment).

3. Connect the Eurostecker X4 to the burner.

4. Switch on the power at the main switch.

E

Return Inlet

X3

X4

13 Bentone BF1

Page 14

General

4. BASIC SETTINGS

4.1 Example of basic setting

4.1.1 Choice of nozzle

BF1 FU 63-16/BF1 K 76-26

Burner output 30 kW

Estimated nozzle output: 30 / 11,86* = 2,53 kg/h

Choice of nozzle according to table. (Refer to Technical data.)

According to the nozzle table, the following nozzle is indicated:

Nozzle: 0,65 Gph

Pump pressure: 11,0 bar

BF1 FUV 63-16/BF1 KV 76-26

Burner output 30 kW

Because of preheater, output is adjusted upward for choice of nozzle

according to table. (Refer to Technical data 2.6).)

Estimated nozzle output: 30 x 1,06 = 31,8 kW

31,8 / 11,86* = 2,68 kg/h

Choice of nozzle according to table. (Refer to Technical data).

According to the nozzle table, the following nozzle is indicate

Nozzle: 0,75 Gph

Pump pressure: 9,5 bar

* Calorfic value Light oil

= 11,86 kWh/kg

4.1.2 Basic setting

Setting values for 30 kW according to basic settings tables.

(Refer to Technical data FUV 63-16).

Air setting = 11,0

Insert setting = 4,0

14

Bentone BF1

Page 15

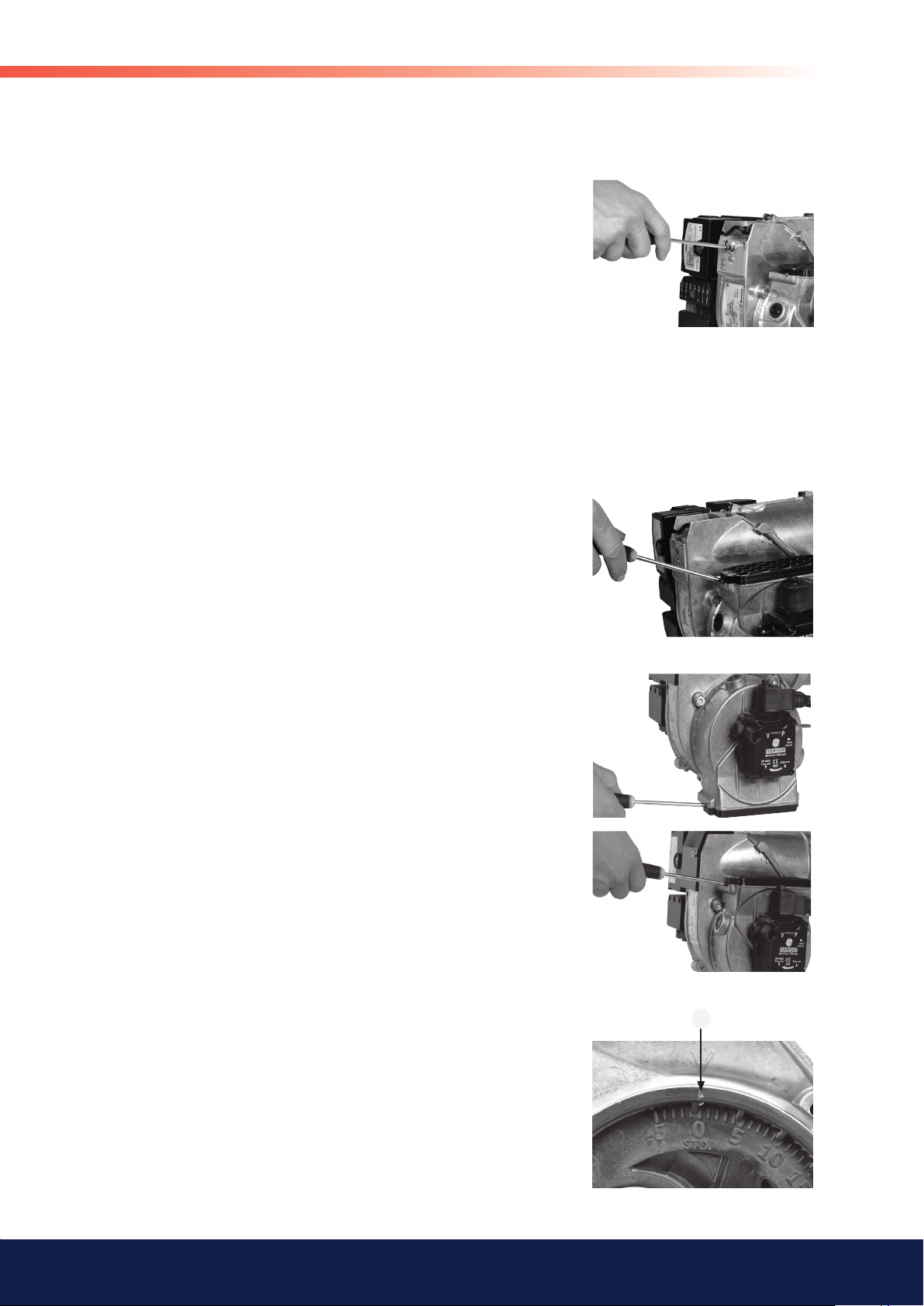

4.1.3 Nozzle assembly adjustment

The burner is fitted with a regulator which changes the brake plate position

in the blast tube. This is used to set the correct pressure drop across the

combustion assembly and thereby achieve good combustion without

pulsation.

The setting to be chosen is dependent among other things on set output

and furnace pressure.

Brake plate setting

• Less diffusion: turn screw to left.

• More diffusion: turn to right.

Setting brake plate position affects air flow. It is therefore always

necessary to adjust the air with the burner air regulator afterwards.

General

4.1.4 Air intake adjustment

Air settings are very important for achieving good combustion with neither

too much, nor too little, air. Adjustment of combustion airflow is carried out

by turning the air regulator with an Allen key. How far open the air regulator

must be is determined by output, furnace pressure and other burner settings

such as blast tube position.

4.1.5 Method of adjusting air quantity

Setting the air regulator is dependent on how the screw (with which air

regulation is adjusted) is installed. If the air intake is installed underneath

as shown in illustration Ι, turning the screw clockwise will reduce airflow,

and anticlockwise increase it. If the air intake is installed on top as shown

in illustration Π, clockwise adjustment increases airflow, and anticlockwise

reduces it.

Ι

Π

4.1.6 Inlet cone, air adjustment

Airflow is also affected by the position of the inlet cone. However, it is

extremely rare that this needs to be adjusted; it should be left in the

standard STD position to achieve good starts and operations. (A cast-in

arrow on the fan housing indicates the position of the inlet cone. In addition

to the scale on the inlet cone casting, there is also a mark (M) indicating the

factory setting.)

M

15 Bentone BF1

Page 16

General

4.1.7 Air intake rotation

It is possible to rotate the air intake to adapt the burner to different

surroundings. It is possible to rotate the air intake to a number of positions,

not just the positions shown to the right.

To rotate the air intake, undo the three screws that fasten the air intake and

the two screws which retain the pump. Then rotate the air intake to the

desired position and tighten the screws.The position of the air intake affects

the airflow through the burner somewhat.

The position which provides best airflow is with the air intake pointing

downwards.

4.1.8 Air duct

A hose connection air duct is available in three different dimensions: 48, 68,

and 78 mm outer diameter (D). The air duct is installed on the air intake at

the place where the grille is attached in the standard model

D

16

Bentone BF1

Page 17

5. BURNER SERVICING

5.1 Warning

Service must be carried out after 3,000 operating hours, or at least once per

year.

Only authorized personnel may perform service.

Before any type of service work is begun, switch of the power at the main

switch and shut off the oil.

Exercise caution as parts which are exposed when the burner is taken apart

can be hotter than 60°C. The installation engineer must be especially careful

to ensure that no electrical wiring or oil lines are pinched or damaged during

installation or service.

5.1.1 Service position

5.1.1.1 Service position 1

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan housing,

but only so much as to allow the fan housing to be removed from the

burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Suspend the fan housing by the fan housing attachment point (for

joining the front piece to the fan housing) on the screw (for joining the

front piece to the fan housing) as illustrated. If necessary, tighten the

screw somewhat to ensure that the burner is suspended safely.

General

!

Warning

5.1.1.2 Service position 2

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan housing,

but only so much as to allow the fan housing to be removed from the

burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Turn the screw into the front piece until there is a gap of approx. 5 mm

between the metal and the screw head.

5. Suspend the fan housing by the fan housing service attachment on

the screw used for joining the front piece to the fan housing, with the

motor upwards, as shown in the illustration.

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

17 Bentone BF1

Page 18

General

5.1.1.3 Service position 3

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. Undo the screw which fastens the burner front piece to the fan

housing, but only so much as to allow the fan housing to be removed

from the burner front piece.

3. Remove the fan housing from the burner front piece and pull it

backwards until the combustion assembly is free of the burner front

piece.

4. Turn the screw into the front piece until there is a gap of approx. 5 mm

between the metal and the screw head.

5. Suspend the fan housing by the fan housing service attachment on the

screw used for joining the front piece to the fan housing, with the air

intake upwards, as shown in the illustration.

5.1.2 Combustion assembly service

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 1 may be used.

3. Carry out a visual inspection of the combustion assembly and check

the various parts for defects.

4. Undo and remove the brake plate and the electrode package from the

oil pipe. Clean the brake plate as necessary.

5. Screw off the nozzle.

6. Install the nozzle. The nozzle may not be cleaned; it must be replaced

with a new nozzle if the existing one is considered defective.

7. Check the ignition electrodes. Replace as necessary (refer to Technical

data for electrode settings).

8. Install the brake plate and electrode package. Check that the distance

between the nozzle and brake plate is correct

(refer to Technical data).

9. Undo the screw that the fan housing is suspended from. Reassemble

the front piece and the fan housing and fasten them together.

10. Connect the Eurostecker and switch on the power at the main switch.

11. Start the burner and check the combustion.

18

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

Bentone BF1

Page 19

5.1.3 Preheater replacement

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 1 may be used.

3. Remove the brake plate and electrode package.

4. Disconnect the preheater cable from the preheater.

5. Screw off the nozzle.

6. Undo the nut that connects the oil pipe to the preheater.

7. Install the new preheater. Check the condition of the O-ring; replace

as necessary.

8. Connect the preheater cable.

9. Install the nozzle.

10. Install the brake plate and electrode package. Check that the distance

between the nozzle and brake plate is correct

(refer to Technical data).

11. Re-assemble the burner.

12. Connect the Eurostecker and switch on the power at the main switch.

13. Start the burner and check the combustion.

General

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

19 Bentone BF1

Page 20

General

5.1.4 Replacing the oil pump

1. Break the main current and disconnect the Euro plug from the burner.

2. Disconnect the electrical plug from the oil valve (1).

3. Detach the oil hoses from the pump.

4. Detach the solenoid valve housing from the valve (2). Remove the

entire solenoid valve housing.

5. Disconnect the oil connection pipes from the solenoid valve (3).

6. Loosen the screws (4) and pull out the oil pump and solenoid valve as

one assembly.

7. Turn the valve forward and detach it from the pump.

8. Reassemble in reverse order.

Do not forget thread

sealer between the

pump and the elbow.

!

(t.ex Loctite 5188,

5400)

1

2

4

3

fi g 1

20

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

Bentone BF1

Page 21

5.1.5 Fan motor replacement

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 2 may be used.

3. Remove the electrical connection from the motor.

4. Remove the electrical box retaining screw.

5. Remove the cable conduit entry to the ignition electrodes and the

preheater (where fitted) and remove the photocell cable from the motor

flange.

6. Undo the screws (H) to the motor flange, 5 pcs.

7. Lift away the motor.

8. Remove the drive coupling end from the motor shaft, loosen and

remove the fan wheel.

9. Install the fan wheel on the new motor, tighten the locking screw. The

fan wheel must be installed in the bottom position toward the motor

shaft. Install the drive coupling end.

10. Align and fit the motor flange to the fan housing. Pay attention to the

drive coupling so that it does not fall out, and also that it aligns

correctly in the drive coupling end of the motor and pump.

11. Bolt the motor flange and fan housing together. Tighten the screws

diagonally, and do not tighten hard one at a time. This is in order to

ensure the fan housing and the motor flange assume the correct

relative positions.

12. Place the cable conduit entry and the photocell cable in position.

13. Screw the electrical console in place.

14. Connect the motor wiring.

15. Join together the fan housing and the burner front piece.

16. Connect the Eurostecker and switch on the power at the main switch.

17. Start the burner and check the combustion.

General

H

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

21 Bentone BF1

Page 22

General

5.1.6 Air intake and intake cone service

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 3 may be used.

3. Remove the solenoid cable from the pump.

4. Remove the connecting pipe from the pump.

5. Undo the air intake retaining screws (I).

6. Remove the air intake.

7. Undo the inlet cone retaining screw; make note of the inlet cone

position.

8. Remove the inlet cone from the fan housing.

9. Check the function and visual condition of the various air regulator

components. Clean and replace components as necessary.

10. Re-assemble the burner. Be especially careful when installing the inlet

cone; install it in the same position it had at removal.

11. Fit the O-ring in the groove between the fan housing and inlet cone.

Ensure that it is properly located in the groove and is not damaged

when the air intake is fitted.

12. Connect the Eurostecker and switch on the power at the main switch.

13. Start the burner and check the combustion.

I

5.1.7 Fan wheel checks

5.1.7.1 Inspection

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 1 may be used.

3. Perform a visual inspection of the fan wheel. Spin the fan wheel with

your finger, or carefully using a tool.

4. If the fan wheel is not very dirty, clean it carefully where possible.

5. If thorough cleaning is required, refer to point 5.1.7.2 or alternatively

5.1.7.3.

6. If cleaning is not necessary, re-assemble the burner.

7. Connect the Eurostecker and switch on the power at the main switch.

8. Start the burner and check the combustion.

22

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

Bentone BF1

Page 23

5.1.7.2 Cleaning, alternative 1

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 3 may be used.

3. Remove the solenoid cable from the pump.

4. Remove the connector pipe from the pump.

5. Undo the air intake retaining screws (I).

6. Remove the air intake.

7. Undo the inlet cone retaining screw; make note of the inlet cone position.

8. Remove the inlet cone from the fan housing.

9. Clean the fan wheel. Undo and if necessary remove the fan wheel for

more thorough cleaning of the fan and fan housing.

10. Install the fan wheel; tighten the retaining screw. The fan wheel must

be installed in the bottom position toward the motor shaft. Install the

drive coupling end.

11. Re-assemble the burner. Pay attention to the drive coupling so that it

does not fall out, and also that it aligns correctly in the drive coupling

end of the motor and pump.

12. Fit the inlet cone in the same position as before disassembly

13. Fit the O-ring in the groove between the fan housing and inlet cone.

Ensure that it is properly located in the groove and is not damaged

when the air intake is fitted.

14. Connect the Eurostecker and switch on the power at the main switch.

15. Start the burner and check the combustion.

General

I

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

23 Bentone BF1

Page 24

General

5.1.7.3 Cleaning, alternative 2

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 2 may be used.

3. Remove the electrical connection from the motor.

4. Remove the electrical box retaining screw.

5. Remove the cable conduit entry to the ignition electrodes and the

preheater (where fitted) and remove the photocell cable from the

motor flange.

6. Undo the motor flange retaining screws (H), 5 pcs.

7. Lift away the motor.

8. Clean the fan wheel and the fan housing. For more thorough cleaning

remove the drive coupling from the motor shaft and loosen and remove

the fan wheel.

9. Install the fan wheel on the motor and tighten the locking screw. The

fan wheel must be installed in the bottom position toward the motor

shaft. Install the drive coupling end.

10. Align and fit the motor flange to the fan housing. Pay attention to the

drive coupling so that it does not fall out, and also that it aligns correctly

in the drive coupling end of the motor and pump.

11. Screw the motor flange and the fan housing together. Tighten the

screws diagonally, and do not tighten hard one at a time. This is in

order to ensure the fan housing and the motor flange assume the

correct relative positions.

12. Place the cable conduit entry and the photocell cable in position.

13. Screw the electrical box in place.

14. Connect the motor wiring.

15. Join together the fan housing and the burner front piece.

16. Connect the Eurostecker and switch on the power at the main switch.

17. Start the burner and check the combustion.

H

5.1.8 Electrical module

Check that the electrical console retaining screw is tight so that good

contact to earth is established between the console and the burner body.

Only use electrical components recommended by Enertech.

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

Bentone BF1

24

!

Warning

Page 25

5.1.8.1 Replacement of complete electrical package

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 2 may be used.

3. Remove the electrical connection from the motor.

4. Remove the electrical box retaining screw.

5. Remove the cable conduit entry to the ignition electrodes and the

preheater (where fitted) and remove the photocell cable from the

motor flange.

6. Install the new electrical package.

7. Place the cable conduit entry and the photocell cable in position.

8. Screw the electrical box in place.

9. Connect the motor wiring.

10. Assemble the fan housing and burner front piece.

11. Connect the Eurostecker and switch on the power at the main switch.

12. Start the burner and check the combustion.

General

5.1.8.2 Replacement of individual electrical components

1. Switch off the power at the main switch and disconnect the Eurostecker

from the burner.

2. If so desired, service position 2 may be used.

3. Remove the oil burner control.

4. Disconnect the wires to the components that are to be replaced.

5. Insert the new wires.

6. Install the oil burner control.

7. Assemble the fan housing and burner front piece.

8. Connect the Eurostecker and switch on the power at the main switch.

9. Start the burner and check the combustion.

When replacing the electrical components transformer and control box

included in the electrical package, the junction box lid need not be removed.

When servicing or replacing components that affect combustion, analyses and soot tests must be carried

out on the installation.

!

25 Bentone BF1

Page 26

General

6. PUMP INSTRUCTIONS

6.1 Suntec ANV47C

6.1.1 Technical data

Viscosity range: 2,0–75,0 mm2/s (cSt)

Pressure range: 7–14 bar

Oil temperature: max. 60°C

6.1.2 Components

1. Nozzle connection G 1/8”

2. Vacuum manometer connection G 1/8”

3. Manometer connection G 1/8”

4. Filter

5. Suction line G 1/4”

6. Metal plug G 1/4”

7. Return plug

8. Return line G 1/4”

9. Pressure regulation

26

Bentone BF1

Page 27

6.1.3 Filter replacement

Cut off the power and shut off the oil.

Remove the pump cover with the aid of a 4 mm Allen key. If necessary a

screwdriver may be used between the cover and the housing to carefully

pry the cover loose. Replace the old fi lter by a new one. Replace the cover,

tighten lightly.

Do not forget to replace the gasket.

Open the oil supply and switch on the power.

General

6.1.4 One-pipe system

Conversion to one-pipe system

Remove the return plug (8), plug the return

line (9) with the metal plug (7) G 1/4”.

6.1.5 Two-pipe system

Conversion to two-pipe system

Remove the metal plug (7) G ¼”, fi t the

return plug (8) in the return line (9).

Return plug are not included in products

with one-pipe system, separately sold.

6.1.6 Solenoid valve

9

8

7

5

6

1

32

4

27 Bentone BF1

Page 28

General

6.1.7 Function ANV47C

Pressure

adjustment

By-passed oil

returned to tank,

Back to

suction

Return

plugged

or to suction

By-pass plug

removed

One pipe

installation

Shaft seal

By-pass plug

inserted

Two pipe

installation

Gear set

Return Inlet

Pump working method

The oil pump is combined with an external solenoid valve that regulates oil

flow and providing a precise pressure within a large speed range.

The pump’s gear wheels draw oil from the tank through the integral filter

and conveys the oil to the regulator valve which pressurizes the nozzle

connection.

The quantity of oil that does not go to the nozzle connection is led through the

valve back to the return line, or in the case of a one-pipe installation, back to

the suction connection in the gear wheel pump.

To the nozzle

via external

solenoid valve

Pressure

gauge port

Oil under pressure

Vacuum

gauge port

Oil under suction

- Two-pipe system

When the solenoid valve is not activated, the return plug channel between the

pressure side and the return side of the pressure valve is open. No pressure

will be built up to open the pressure valve, regardless of gear wheel pump

rpm. When the solenoid valve is activated, the return plug channel is shut.

The gear wheel pump’s rotation at full rpm quickly builds up the pressure

necessary for opening the valve and provides a sharp opening action.

- One-pipe system

Purging of the oil line system is not automatic in the one-pipe system; open

the manometer connection for purging.

Shut-down

When the burner stops, the solenoid valve opens the return plug channel

and drains oil to the return line. At that same moment the nozzle line is

closed. This provides a sharp cut-off. The on and off functions can be

controlled independent of motor rpm, and react very quickly. When the

solenoid valve is not activated torque is low up to full motor rpm.

28

Bentone BF1

Page 29

6.1.8 Suction pipe tables ANV47C

6.1.8.1 Overhead Tank

One-pipe system

General

Height m

4,0 3,0 2,0 1,0 0,5 0,0

Line diameters

ø 4 mm 100 100 100 91 82 74

The table applies to Fuel oil 1Two-pipe system

Height m

4,0 3,0 2,0 1,0 0,5 0,0

Line diameters

ø 6 mm 29 25 22 18 16 14

The table applies to Fuel oil 1

6.1.8.2 Underlying Tank

One-pipe system

For reliable operations, use of a Tigerloop is recommended in underlying

tanks.

Two-pipe system

Height m

0,0 -0,5 -1,0 -2,0 -3,0 -4,0

Line diameters

ø 6 mm 14 12 10 7 3 0

H

H

The table applies to Fuel oil 1

The suction line tables comprise theoretically calculated values where

pipe dimensions and oil flow are adapted to prevent turbulent flows from

occurring.

Turbulent flows can result in pressure losses and noise in the pipework. A

typical pipe system usually comprises pipe runs with 4 bends, a non return

valve, a shut-off valve and a pre-filter.

The total resistance of these items is such that it can be disregarded. In the

tables no run longer than 100 m is listed, as experience shows this not to be

required.

The tables apply to standard heating oil of normal grade merchantable

according to existing norms. When starting operations with an empty pipe

system, the pump should not be run without oil for more than 5 min.

The tables give the total suction line length in meters with a nozzle

capacity of 2.1 kg/h. Max. permissible pressure on the suction and return

lines is 2.0 bar. For a two-pipe system the Q

46 l/h pump capacity at 0 bar

max

applies.

29 Bentone BF1

Page 30

General

7. PREHEATER

7.1.1 Function FPHE 5

When the boiler thermostat connects, the PTC element is energized and oil

begins to preheat. When the oil has reached the correct temperature, the

preheater thermostat closes and the burner receives the start signal.

During operations the PTC element compensates its output so that the

temperature does not become too high.

If the oil temperature is low and the oil flow high, the preheater thermostat

may open owing to the PTC element’s inability to maintain oil temperature. In

this case it is important to use oil burner controls with a preheater holding

circuit.

30

Bentone BF1

Page 31

8. ELECTRICAL EQUIPMENT

LMO1..2..4..

8.1 Wiring diagram

General

Alt. 1

According to DIN 4791

Alt 2 Alt 3 Alt 4

31 Bentone BF1

Page 32

General

8.1.1 Component list

A1 Oil burner control S3 Operations thermostat

E1 Preheater S4 Temperature limiter

F1 Fuse, max 10 A S7 Main switch

H1 Alarm lamp T1 Ignition transformer

M1 Burner motor Y1 Solenoid valve

P1 Timer (Accessory) X3 Plug-in contact, burner

R1 Photocell QRB X4 Plug-in contact, boiler

U2 UV-cell QRC

Preheater wiring colours: A Blue B Brown C Black

The installation must be connected to the mains and fused according to local

regulations.

8.1.2 Function LMO1..2..4..

1a. Operations switch ON, thermostat ON

The burner motor starts, ignition sparks initiated and pre-ventilation

continues until the set pre-ventilation period is over and the

solenoid valve (2) opens..

1b. Operations switch ON, thermostat ON

The preheater is energized and the pre-heating period begins.

This continues until the operating temperature is reached and the

preheater thermostat closes. The burner motor starts, ignition

sparks initiated and pre-ventilation continues until the set preventilation period is over and the solenoid valve (2) opens.

2. Solenoid valve opens

The oil mist is formed and ignited. The photocell indicates flame.

The ignition spark ceases 15 sec. after flame indication.

3.

Safety period runs out

a

If the flame is not present before the end of this period, the oil burner

control blocks further operation.

b

If the flame for any reason disappears after this time period, the

burner will make a new start attempt.

4-5 During operation

If burner operations are interrupted via the main switch or

thermostat, a new start will be initiated when conditions according

to point 1 are fulfilled.

Oil burner control blocks

Red light on the oil burner control illuminates. The burner is restarted by pressing the reset button.

32

Bentone BF1

Page 33

8.1.3 Technical data

LMO14 LMO24

Pre-ignition period:

Pre-ventilation period:

Post-ignition period:

Safety period:

Re-connection after release:

Reaction time flame extinction:

Ambient temperature:

Min. current with flame:

Max current when dark, start:

Ingress Protection:

LOA not to be used within EU

Photocell current checks

Photocell current is measured with a direct current ammeter

(mulitimeter A) connected in series with the photocell.

15 s 25 s

16 s 26 s

10 s 5 s

< 10 s < 5 s

< 1 s < 1 s

< 1 s < 1 s

-5 - +60°C -5 - +60°C

45 µA 45 µA

5,5 µA 5,5 µ A

IP 40 IP 40

General

33 Bentone BF1

Page 34

General

8.1.4 Colour codes LMO14/24

When the burner starts, three signal lights in the reset switch indicate the

normal sequence, as well as provide indication if something abnormal is

happening in accordance with the following table:

Preheater in operation Solid yellow

Ignition switched on Flashing yellow

Normal operation Solid green

Operation, poor flame signal Flashing green

Undervoltage Flashing yellow-red

Fault, alarm Solid red

False light Flashing red-green

Communication mode Fluttering red

8.1.5 Fault codes LMO14/24

When the red light for a blocked relay box comes on, you can get

information about what has caused the problem by pressing and holding the

reset button for 3 seconds.

The number of flashes below is repeated with a pause in between.

2 flashes No flame signal when safety time

expires

4 flashes False light during start

7 flashes 3 x Losses of flame during operation

8 flashes Time-out for preheater *

10 flashes Incorrect wiring, internal fault or

simultaneous occurrence of two faults

* In order for this fault code to occur, the preheater shall not reach its

cut-off temperature within 10 mins. from switch on.

To return to normal operation: Press the reset button for 1 second.

If the reset button is instead kept pressed a second time for at least 3

seconds, you can, via an interface, obtain the corresponding information on

a computer or flue gas analyser.

To return to normal operation: Press the reset button for 1 second

34

Bentone BF1

Page 35

9. FAULT LOCATION

9.1 Burner will not start

Symptom

Motor starts

Burner pre-ventilates

Flame formed

Burner trips

Motor starts

Burner pre-ventilates

No flame formed

Burner trips

Incorrect combustion apparatus settings

Flame monitor doe s not register light

Causes

Unstable flame

Excess air

Low oil pressure

Defective flame monitor

Defective oil burner control

No oil

False light

No spark

General

Remedies

Adjust the damper

Check the oil pressure

Check the nozzle in relation to the

combustion apparatus dimensions and the

ignition electrode position

Check the flame monitor is clean and can

register light

Check with using new photocell

Check using new oil burner control (Note:

replacement of photocell recommended if oil

burner control replaced)

Check the oil supply to the burner and that

there are no air bubbles in the pump

Check function of solenoid

Check flame monitor does not register

ambient light

Check high voltage wiring and ignition

electrodes

9.2 Burner will not start after normal use

Burner does not start

Burner pre-ventilates

Burner stops

Overheating protection has deployed

Too great a pressure drop at brake plate

Too strong draught prevents flame forming

Fuse blown

Boiler thermostat has not reset

Defective preheater

Defective oil burner control or

flame monitor

No oil supply

No spark

Check that tank, oil lines, solenoid valves,

9.3 Delayed ignition, burner starts; pulsation

Burner pulsates at start with

hot flue gases

Burner pulsates at start

Too strong a draught

Too great a pressure drop at brake plate

Nozzle partially blocked

Oil pressure too low

Flue blocked or damaged

Fan wheel slipping on shaft

Pump coupling loose or worn

Preheater clogged

Delayed ignition

Too strong a draught

Too great a pressure drop at brake plate

Check and replace fuse as necessary.

Investigate cause of fault

Adjust thermostat

Reset the overheating protection.

Investigate the cause of its deploying.

Remedy fault

Check by replacing with new

pump and nozzle are in good condition

Adjust the burner

Correct the boiler draught

Check the ignition transformer. Check the

ignition electrode settings and ceramics

Correct the boiler draught

Adjust the burner

Replace nozzle

Check and adjust

Check and correct

Check and tighten

Replace

Check ignition electrode adjustment

(refer to technical data)

Check ignition electrodes

not damaged

Check high voltage wiring

Check position of nozzle

assembly adjustment

Correct the boiler draught

Adjust the burner

35 Bentone BF1

Page 36

10. DECLARATION OF

CONFORMITY

Page 37

11. OIL BURNERS MAINTENANCE

OIL BURNERS MAINTENANCE

INSTRUCTIONS

General information

Keep the boiler room clean. Ensure that the boiler

room has permanent fresh air intake. Switch off before

dismantling the oil burner.

At hinged mounting, make sure that an automatic safety

switch is fi tted, so that the burner cannot start when

theswing door is open.

Don´t use the oil fi red boiler to burn paper or

rubbish,unless the boiler is especially fi tted with a hinged

door tomake this possible.

Don´t fi ll tank while burner is working.

Starting precautions

Make sure that the oil tank is not empty

Make sure that the valves on oil and water supply pipes

areopen.

Make sure that the boiler fl ue damper is open.

Make sure that the boiler thermostat is set at the correct

temperature.

Switch on the current. Most relay systems have a

delayed action so that the burner will not start for

perhaps 20 seconds.

With heavy oil the delay will be longer as the burner

will notstart until the oil in the preheater reaches the

requiredtemperature.

If the burner will not start

INSTRUCTIONS

If the burner starts but does not ignite

Make an attempt to start the burner.

Never make close repeated start attempts.

Don´t restart the burner until the boiler is free from oil

gases.

If the burner still does not ignite send for the service

engineer.

When switching off during summer

Always use the main switch to cut out the burner even

when adjusting the burner or cutting off the heating for

ashort time. For longer periods of shut down, close all

valves and the oil supply stop-cock.

Clean the fi lter and nozzle by washing in petrol or

paraffi n.

Make sure the fi lter medium is not damaged or defective.

Protect electrical gear from damp.

Warning

Never stand too near or put your face to the inspection

or fi re door, when the burner is about to start.

Never use a naked fl ame to ignite oil if the electrical

ignition fails.

Always wait for about 10 minutes for the unburnt gases

to disperse before restarting the oil burner if it has failed

to ignite previously.

Press the reset button on the relay. Check that the

thermostats are correctly adjusted.

Don´t forget the room thermostat, check that any

fusesare intact and main switch is on.

Installed by:

Tel:

170 025 01 2012-04-16

Page 38

Page 39

Page 40

Enertech AB. P.O Box 309, SE-341 26 Ljungby.

www.bentone.se, www.bentone.com

Loading...

Loading...