KYO

Unit

MADE

IN

ITALY

MAIN UNIT

MANUAL

®

®®

KYO 4 M – KYO 8 M – KYO 8W M – KYO 32 M – KYO 4 P – KYO 8 P – KYO 8W P – KYO 32 P

KYO 8GWP-SW1 – KYO 8GWP-SW2 – KYO 8GWL-SW1 – KYO 8GWL-SW2

KYO 8G P-SW1 – KYO 8G P-SW2 – KYO 32G P-SW1 – KYO 32G P-SW2

KYO 8G L-SW1 – KYO 8G L-SW2 – KYO 32G L-SW1 – KYO 32G L-SW2

Hereby, Bentel Security, declares the above mentioned Control Panels to be in compliance with the

The manufacturer recommends that the installed system should be completely tested at least once a month.

essential requirements and other relevant provisions of 1999/5/EC Directive.

The complete R&TTE Declaration of Conformity for each Panel can be found at

These Control Panels comply with

Installation of these systems must be carried out strictly in accordance with the instructions

described in this manual, and in compliance with the local laws and bylaws in force.

The above mentioned Control panels have been designed and made

BENTEL SECURITY Srl shall not assume the responsibility

The above mentioned Control panels have no user-friendly components, therefore,

www.bentelsecurity.com/dc.html.

CEI 79-2 2 ed. 1993

to the highest standards of quality and performance.

for damage arising from improper applicati on or use.

should be serviced by authorized personnel only.

a

.

IMPORTANT: The following information is for disassembled Control Panels ONLY.

Ensure that the Manual you are using corresponds to, or is higher than the one requested

on the “RELEASE ISSUES” label (see below).

RELEASE ISSUES

OK32 1.01

Installation Manual

User Manual

Keypad Prog. Man.

Main Unit Manual

Kyo Unit Software

1.1

1.1

1.1

1.1

5.10

Firmware Release

Manual Release

Software Release

If the Manual/KYO Unit Software release does not correspond, DO NOT attempt to assemble or install the Control Panel.

The Manual Release Number can be found at the bottom of the last page, between the

Code and Date, as shown in the Fig. below.

Manual

Release

Number

ISTUCBLEUNKYO 190503 P70

BENTEL SECURITY srl reserves the right to modify the technical specifications of this product without prior notice.

1.2

DateCode

®®

TABLE OF CONTENTS

Section 1 - Introduction .............................................................5

Certification Formalities ......................................................................................... 5

General Features..................................................................................................... 5

About the System .................................................................................................... 7

Control panel Versions ........................................................................................... 7

Components and Accessories .............................................................................. 8

Technical Specifications ........................................................................................ 9

Section 2 - Identification of Components .............................. 10

KYO 4 M — KYO 8 M — KYO 8W M — KYO 32 M ................................................. 10

KYO 4 P — KYO 8 P — KYO 8W P — KYO 32 P .................................................... 11

KYO 8G P-SW1 — KYO 8GWP-SW1 — KYO 32G P-SW1..................................... 12

KYO 8G P-SW2 — KYO 8GWP-SW2 — KYO 32G P-SW2..................................... 13

KYO 8G L-SW1 — KYO 8GWL-SW1 — KYO 32G L-SW1 ..................................... 14

KYO 8G L-SW2 — KYO 8GWL-SW2 — KYO 32G L-SW2 ..................................... 15

Section 3 - Mounting the Components .................................. 19

Introduction ........................................................................................................... 19

Boxes and Accessories ....................................................................................... 19

Installing the Transformer and Mains Screw Terminal - Fused ......................... 20

Metal box (BOX-M) ............................................................................................ 20

Plastic box (BOX-P) .......................................................................................... 21

Mounting K4-K8-K8W-K32 PCBs .......................................................................... 22

Metal box (BOX-M) ............................................................................................ 22

Plastic box (BOX-P) .......................................................................................... 22

Installing ‘G’ series PCBs (K8G-K8GW-K32G) ..................................................... 23

Plastic box (BOX-P) .......................................................................................... 23

Metal box BOX-L ............................................................................................... 23

Installing the Switching Power Supply ................................................................ 24

Installing BAQ15T12 Switching Power Supplies ............................................. 24

Installing BAQ35T12 Switching Power Supplies ............................................. 25

Replacing BAQ35T12 Fuse ............................................................................. 25

Earthing the PCB ................................................................................................... 26

Marking Ticket ....................................................................................................... 26

Connecting the KST Thermal Probe .................................................................... 26

Connecting the NC2/VOX Voice Board ................................................................. 27

Metal box ........................................................................................................... 27

Plastic box ........................................................................................................ 27

PCB Identification Label ....................................................................................... 28

3

4

Multifunction Control Panel

Section 4 - Installing the Control Panel ................................. 29

Mounting the Control Panel .................................................................................. 29

Opening and Closing the Control Panel ............................................................... 30

Section 5 - Installing the NC2/VOX......................................... 32

General Features................................................................................................... 32

Additional VOX-REM Modules............................................................................... 32

Installing Additional VOX-REM Modules .......................................................... 32

Record / Play Messages ....................................................................................... 33

Selecting Messages ........................................................................................ 34

Recording Alarm Messages ............................................................................ 34

Playing Messages ............................................................................................ 34

Programming ........................................................................................................ 35

Activation ............................................................................................................... 35

®®

®®

SECTION 1 - INTRODUCTION

Certification Formalities

The KYO-Unit series can be purchased as out-of-the-box Control panels, or as separate package components. Bentel Security S.r.l declares

that KYO-Unit separate package components comply with the essential requirements and other relevant provisions of Directive R&TTE

1999/5/CE — only when they are assembled by a security professional,

and are used as part of one of the Control panels provided for in

Section 3, and indicated in Table 1.1. in this Manual. Bentel Security S.r.l. declares that CE Certification is not applicable when KYO

separate package components are improperly assembled or used.

General Features

This Manual is designed for anyone using a Control panel from the KYO range.

Most of the features described in this Manual are included on all KYO Control

panels (refer to Table 1.1). However, some features are included on certain

models only, in such cases, the Control panel will be specified.

Section 1 - Introduction

5

Control Panel

8 Programmable Input Zones (4 for KYO 4 M and KYO 4 P)

Expandable to 32 Input Zones via optional M-IN/6 Input Expanders (for

KYO 32 series Control panels)

1 Balanced 24h Tamper Zone

1 Programmable Alarm Output: 1A relay (3A on ‘G’ models)

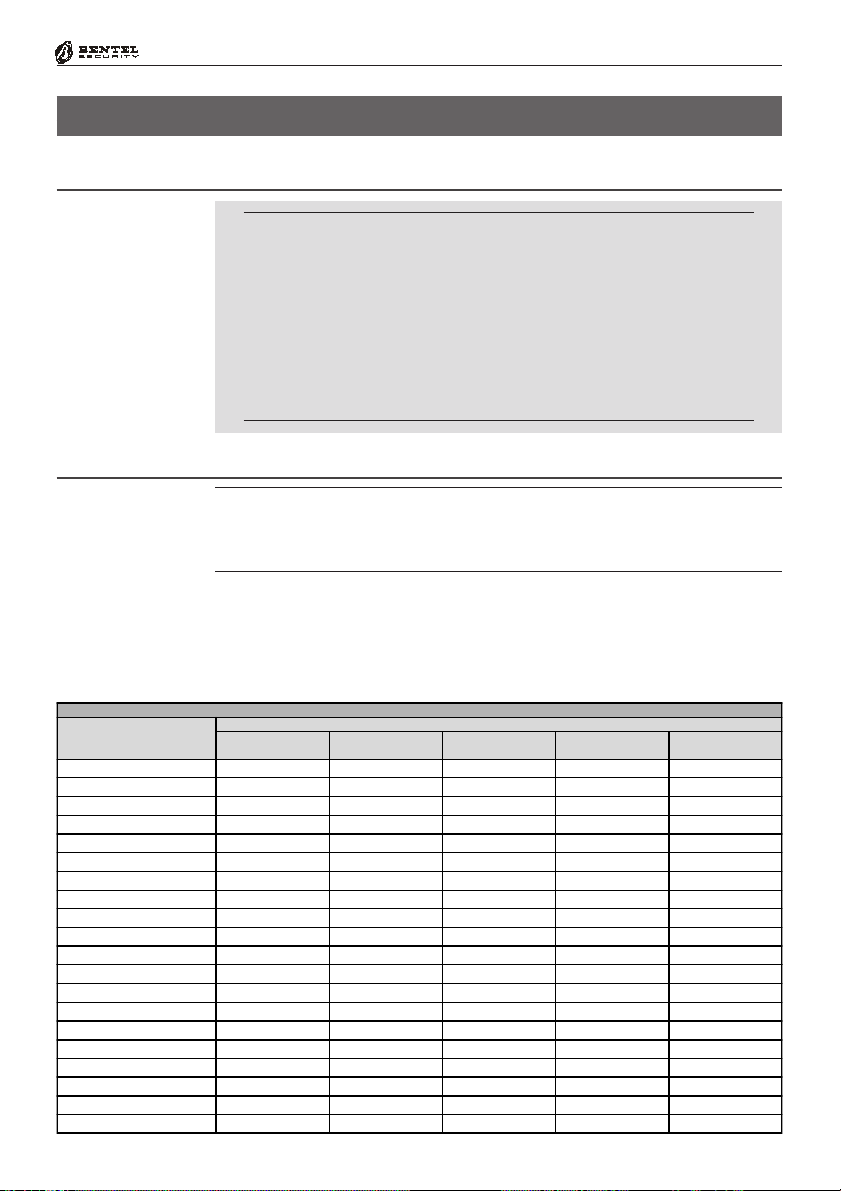

Table 1.1 - Version

Version

KYO 4 M K4 BO X-M

KYO 8 M K8 BO X-M

KYO 8W M K8W BO X-M

KYO 32 M K32 BO X-M

KYO 4 P K4 BO X-P

KYO 8 P K8 BO X-P

KYO 8W P K8 W BO X-P

KYO 32 P K3 2 BO X-P

KYO 8G P-SW1 K8G BO X-P

KYO 8GWP-SW1 K8G W BO X-P

KYO 32G P-SW 1 K32G BOX-P

KYO 8G P-SW2 K8G BO X-P

KYO 8GW P-SW2 K8G W BO X-P

KYO 32G P-SW 2 K3 2G BO X-P

KYO 8G L-SW1 K8G BO X-L

KYO 8GW L-SW1 K8 G W BO X-L

KYO 32G L-SW1 K32G BO X-L

KYO 8G L-SW2 K8 G BO X -L

KYO 8GW L-SW2 K8G W BO X-L

KYO 32G L-SW2 K32 G BO X-L

PCB Box Transf. TRF

Component

Power Supply

BAQ15T12

Power Supply

BAQ 35T12

6

Digital Dialler

Multifunction Control Panel

Auxiliary Open-Collector Outputs (OC):

3 x 150 mA for KYO 4, KYO 8, KYO 8W and KYO 32 series

5 x 500 mA for KYO 8 G, KYO 8 GW and KYO 32 G series

Expandable to 14 x 150 mA Outputs for KYO 32 series

Expandable to 16 x 150 mA Outputs for KYO 32 G series

Metal box (Model M or L) or Plastic Box (Model P)

Accepts Conventional Fire Detectors, and provides restoral facility

Supports up to 8 Keypads

Supports up to 16 Readers (ECLIPSE and/or PROXI)

Accepts up to 128 SAT Keys and/or PROXI-CARDs

Manages 4 independent Partitions (8 for KYO 32 and KYO 32 G)

3 Arming Modes (Global, A Mode and B Mode): A and B Mode can be

programmed as: Away, Stay or Stay with no Entry delay

Auto-Arming for each Partition on Daily or Weekly basis

24 Programmable Codes (4 to 6 digits)

Partition Bypass for Patrol purposes with automatic or manual Rearming

Can be programmed from an LCD or LED Keypad

Can be programmed from a computer via RS232 link cable or via telephone

Power Supplies:

Integrated 1A linear Power Supply in KYO 4, KYO 8, KYO 8W and KYO 32

1.5A Switching Power Supply in SW1 Models

3A Switching Power Supply in SW2 Models

Touch-tone (MF) or Pulse dialling

Manages 8 Telephone numbers for Alarm and Central Station calls

Supports the following Reporting Formats:

ADEMCO / SILENT KNIGHT - Slow 10 baud - 3/1, 4/1, 4/2

ADEMCO / SILENT KNIGHT - Fast 14 baud - 3/1, 4/1, 4/2

FRANKLIN / SECOA / DCI-VERTEX - Fast 20 baud - 3/1, 4/1, 4/2

RADIONICS - 40 baud - 3/1, 4/1, 4/2

SCANTRONIC - 10 baud - 3/1, 4/1, 4/2

CONTACT ID

CESA

Accepts commands from touch-tone phones (Arm, Disarm, Turn ON/OFF

Main board Outputs; Remote Talk/Listen-in — requires optional NC2/VOX

Voice Board

Manages Voice Calls (requires optional NC2/VOX Voice Board)

Remote Telephone Access via Dialler or Answer Mode

Remote Talk/Listen-in (requires optional NC2/VOX Voice Board)

256 Event Logger (can be viewed on computer or LCD Keypad) on Series

32 Models. 128 Events on Series 4-8 Models.

3 function keys for immediate Alarm calls from Keypad

Programmable Test Call

Teleservice Management

Double Call

Line-sharing Management

®®

®®

About the System

Section 1 - Introduction

7

The Control panel

The Digital

Communicator

Voice Messages

using NC2/VOX

Teleservice

Telemonitoring

Accessing the system

using a remote

Touch-tone Telephone

Programming the

system

The Control panel is made up of a Control Unit, Digital Communicator and

Modem. It can be controlled from remote Keypads and/or Digital Key/Card

Readers.

The Digital Communicator can call up to 8 Telephone numbers for Teleservice

and communication to Central Stations. You can program the system to report

events using any one of the supported formats.

The NC2/VOX Voice board (accessory item) will allow the Communicator to

send 8 Voice messages to up to 8 Telephone numbers. The NC2/VOX Voice

board also provides the Talk/Listen-in feature.

The B-MOD Modem and Management software will allow you to program,

control and Teleservice (provide remote maintenance) from a remote computer.

The B-MOD/Rx Modem and the WinBCS software will allow you to program,

control, Teleservice and Monitor the system from a remote computer.

All Events, Alarms and Troubles, complete with Customer and Event details will

be logged on the Event Logger.

The User can access the system over the phone, in order to:

Arm/Disarm the system

Turn ON/OFF Reserved Outputs

Activate Talk/Listen-in sessions (NC2/VOX required)

This Control panel can be programmed:

a) on-site, using an LCD or LED Keypad (accessory item);

b) on-site, using an RS232 Computer link;

c) from remote computer, using a modem and downloading software.

Control panel Versions

Table 1.2 - Functional diffe rences between Mode ls

Model

KYO 4 M

KYO 8 M

KYO 8W M

KYO 32 M

KYO 8GW Series Yes 4 8 5 x 500 mA

**

The

**

The M-OUT/6 Expander Module manages 6 OC Outputs — 150 mA (6 x 150 mA)

KYO 4 P No 4 4 3 x 150 mA

KYO 8 P No 4 8 3 x 150 mA

KYO 8W P Yes 4 8 3 x 150 mA

KYO 32 P Yes 8

KYO 8G Series No 4 8 5 x 500 mA

KYO 32G Series Yes 8

M-IN/6 Expander Module manages 6 Inputs

Wireless

Management

Partition Input (Zone ) O.C. Output

Features

8

Expandable to 32*

8

Expandable to 32*

3 x 150 mA

Expandable to 14 **

5 x 500 mA

Expandable to 16 **

8

Multifunction Control Panel

Components and Accessories

Table 1.3 - Components and Accessory Items

Code Description

K4 - K8 - K8W - K32 PCB for KY O 4, KY O 8, KYO 8 W and KY O 32

K8G - K8GW - K32G PCB for KYO8 G, KYO8 GW and KYO32 G

BOX-M Metal box for M Models

BOX-P Plastic box for P Models

BOX-L Metal box for L Models

TRF 17 Vac - 1.5 A Power Transformer

BAQ15T12 1.5 A Switching P ower Supply for SW1 Models

BAQ35T12 3 A Switching Pow er Supp ly for SW2 Models

MIA/S or MIA/D LCD Keypad

Alison/S or A lison/DV LCD Keypad (DV Model with built-in Voice Module)

OMNIA/TA ST -R LCD Keypad

NC2/TAST LED keypad

ICON /K P LED keypad

Alison/8L or Alison/32LP LED Keypad (32LP Model with built-in PROXI Reader)

ECLIPSE Flush Mount Contactless Key Reader

PROXI Proximity Reader

SAT Digital key for ECLIPSE and PRO XI Readers

PROXI-CARD PROXI Card

NC2/VOX Voice Board

VOX-REM Talk/Listen-In Zone Expander Module (Microphone + Loudspeaker)

M-IN/6 6 Input Expander Module

M-OUT/6 6 Output Expander Module (150 mA )

OMNIA/4R 4 relay Module for Output Expanders

KISUNIT Manual Kit

VECTOR/RX and /RX 8 Wireless Receiver

ARC20 Wireless Key for Vector/RX and Vector/RX8

AMD10 Wireless Pet Immune PIR for Vector/RX and Vector/RX8

AMC10 Wireless Magnetic Contact for Vector/RX and Vector/RX8

ASD10 Wireless Sm ok e Detector fo r Vecto r/R X and Vector/RX8

AGD10 Wireless Glassbreak Detector for Vector/R X and Vector/R X8

B-MOD Te les erv i ce M o d em

B-MOD/RX Teleservice and Telemonitoring Modem

SECURITY SUITE Management Software

CVSER/9F9F Computer Serial Link

ADSER/9M25F Adapter for CVSER/9F9F link cable for 25 Pole Serial Ports (DB-25)

KST Therm al P ro be (fo r G Models only)

OVC-Link Output Voltage Control wire (for G Models only)

ASNC

MINI-ASNC Sn atch Micro switch fo r PRO XI-REA DERs

MAXI-ASNC Tamper Microswitch for Metal boxes (BOX-M and BOX-L)

Microswitch provides Snatch protection for MIA and ALISON Keypads, and

Snatch /Tamp er pr otection fo r BO X-P

®®

®®

Section 1 - Introduction

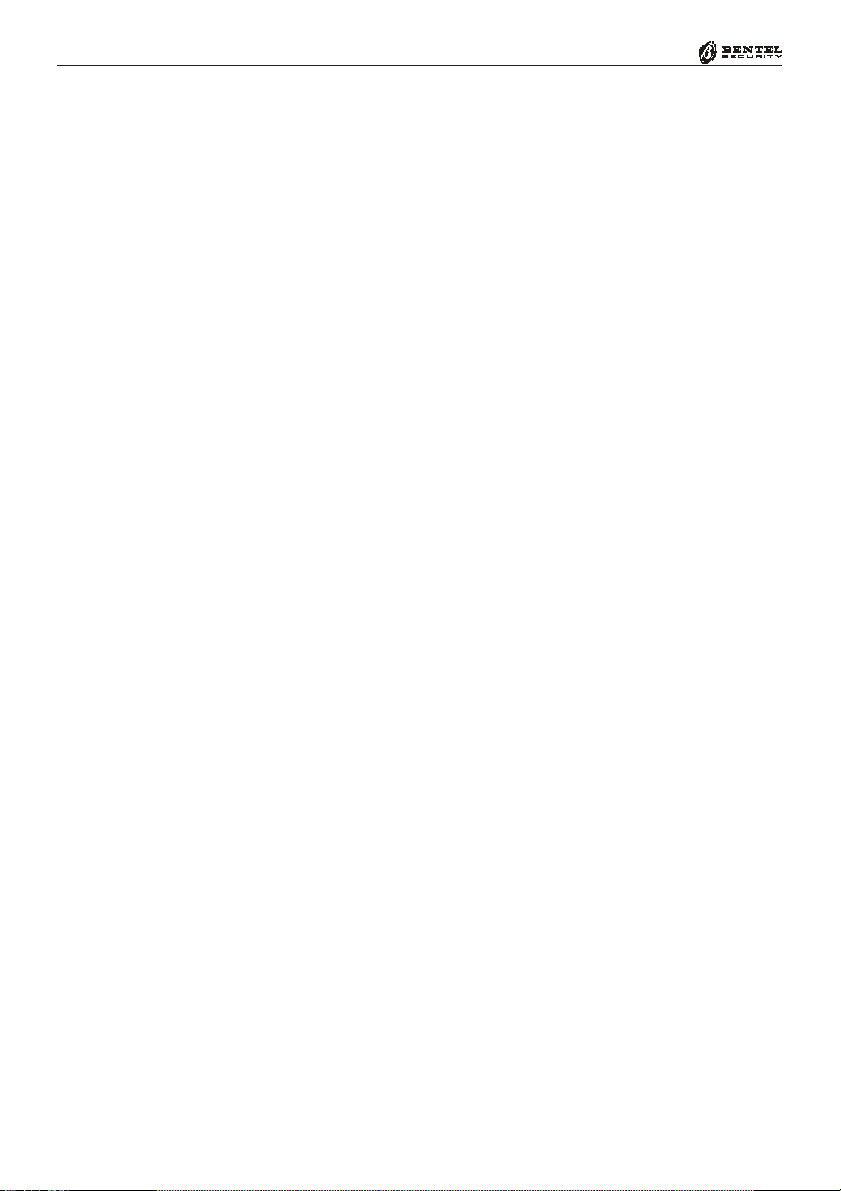

Technical Specifications

Table 1.4 - T echni cal Specificati ons

Control Panels

Values

KYO 4 M

KYO 4 M

Specifications

Volt age

KYO 4 MKYO 4 M

KYO 8 M

KYO 8 M

KYO 8 MKYO 8 M

KYO 8W M

KYO 8W M

KYO 8W MKYO 8W M

KYO 32 M

KYO 32 M

KYO 32 MKYO 32 M

230V

Maximum Current draw

Maximum Power

Power Supply Battery-charger

13.8 V

Insulation Class

Maximum Current

available for peripherals

Max. Battery Charge Current

Battery Housing

(Brand and Type)

YUASA NP7-12 FR or Equivalent with UL94-V2 (or superior) Case Flame Class

IP Protecti on Level

Recognized MF Tones

Operating Temperature

Dimensi ons mm (W x H x D) 235 x 269 x 77 309 x 227 x 89 339 x 488 x 108 309 x 227 x 89 339 x 488 x 108

Weight (without Battery)

Compli es with

CEI Normat ive Laws

2.7 Kg 1.8 Kg 1.2 Kg 5.3 Kg 1.3 Kg 5.4 Kg

EN 60950:2000 - EN50081-1:1992 - EN50130-4:1995+A1:1998 - CEI 79-2 2

KYO 4 P

KYO 4 P

KYO 4 PKYO 4 P

KYO 8 P

KYO 8 P

KYO 8 PKYO 8 P

KYO 8W P

KYO 8W P

KYO 8W PKYO 8W P

KYO 32 P

KYO 32 P

KYO 32 PKYO 32 P

~ 50Hz ±10% 100÷240 V~ 47÷63Hz 230V~ 50Hz ±10%

KYO 8 G P-SW1

KYO 8 G P-SW1

KYO 8 G P-SW1KYO 8 G P-SW1

KYO 8 GWP-SW1

KYO 8 GWP-SW1

KYO 8 GWP-SW1KYO 8 GWP-SW1

KYO 32 G P-SW1

KYO 32 G P-SW1

KYO 32 G P-SW1KYO 32 G P-SW1

KYO 8 G L-SW1

KYO 8 G L-SW1

KYO 8 G L-SW1KYO 8 G L-SW1

KYO 8 GWL-SW1

KYO 8 GWL-SW1

KYO 8 GWL-SW1KYO 8 GWL-SW1

KYO 32 G L-SW1

KYO 32 G L-SW1

KYO 32 G L-SW1KYO 32 G L-SW1

KYO 8 G P-SW2

KYO 8 G P-SW2

KYO 8 G P-SW2KYO 8 G P-SW2

KYO 8 GWP-SW2

KYO 8 GWP-SW2

KYO 8 GWP-SW2KYO 8 GWP-SW2

KYO 32 G P-SW2

KYO 32 G P-SW2

KYO 32 G P-SW2KYO 32 G P-SW2

KYO 8 G L-SW2

KYO 8 G L-SW2

KYO 8 G L-SW2KYO 8 G L-SW2

KYO 8 GWL-SW2

KYO 8 GWL-SW2

KYO 8 GWL-SW2KYO 8 GWL-SW2

KYO 32 G L-SW2

KYO 32 G L-SW2

KYO 32 G L-SW2KYO 32 G L-SW2

0,2 A 0,42 A 0,5 A

45 W 50 W 115 W

_ ±1% / 1 A 13.8 V_ ±2% / 1.5 A 13.8 V_ ±1% / 3 A

I

0.6 A 1 A 2.3 A

0.3 A 0.5 A

12V - 7Ah (17Ah in "L" model s)

IP30

Minimum Level 200 mVpp (-23 dBV)

+5 ÷ +40º C

a

ed. 1993

9

Descripti on

K4-K8-K8W-K32

Main

Main

MainMain

Board

Board

BoardBoard

K8G-K8G-K32G

MIA/S and MIA/D

ALISON/S

ALISON/DV

Keypad

Keypad

KeypadKeypad

ALISON/8L

ALISON/32LP

OMNIA/TAST-R

NC2/ TAST

ICON/KP

der

der

derder

M-OUT/6 (Output)

ECLIPSE

PROXI

M-IN/6 (Input)

Reader

Reader

ReaderReader

Expan-

Expan-

Expan-Expan-

NC2/VOX Voice Board

VectorRX Receiver

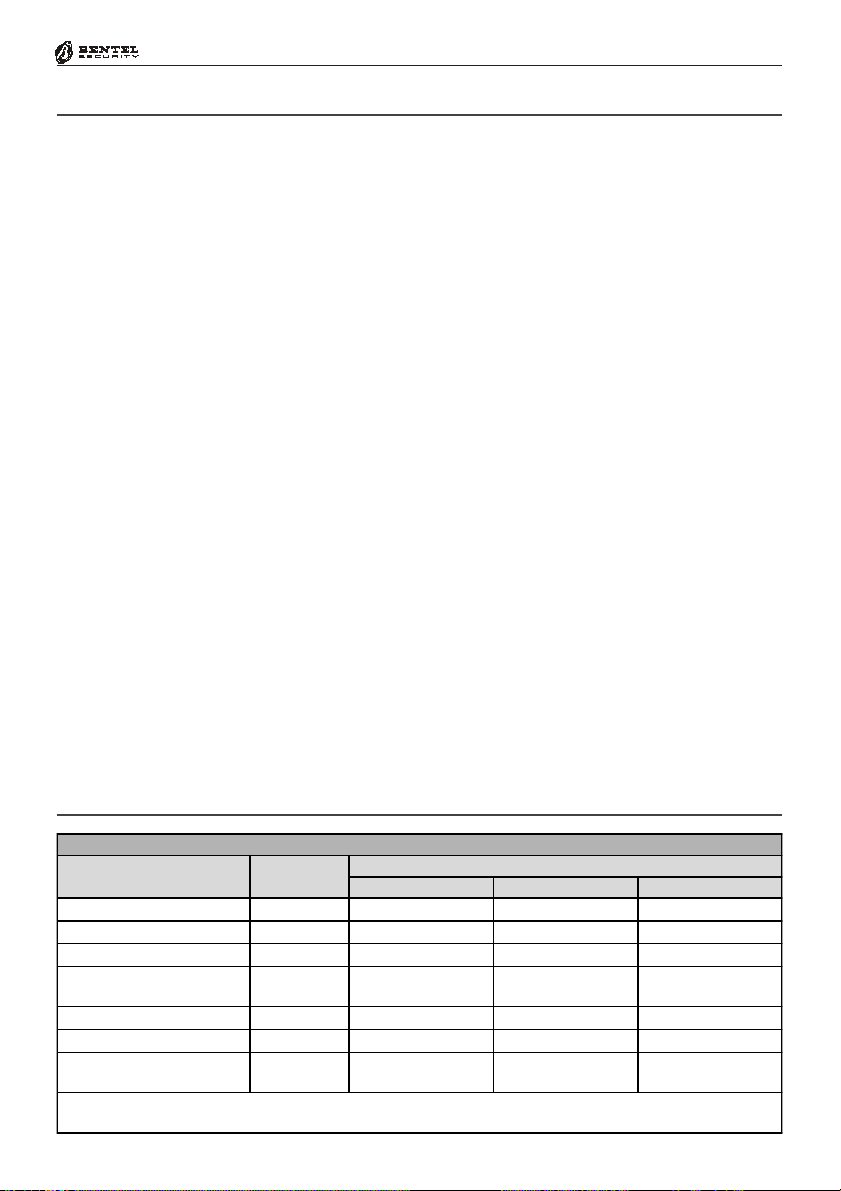

COMPONENTS and ACCESSORY ITEMS

Max. Current Draw

(mA)

Dimensions (W x H x D) mm

100 122 x 118

150 166 x 109

50 164 x 133 x 44

90 143 x 115 x 38

90 160 143 x 115 x 38

50 160 x 73 x 30

80 117 x 96 x 25

80 160 x 73 x 30

30 20 x 44 x 48

30 78 x 108 x 22

27 108 x 101 x 34

11 108 x 101 x 34

30 58 x 71

50 146 x 290 x 28

10

Multifunction Control Panel

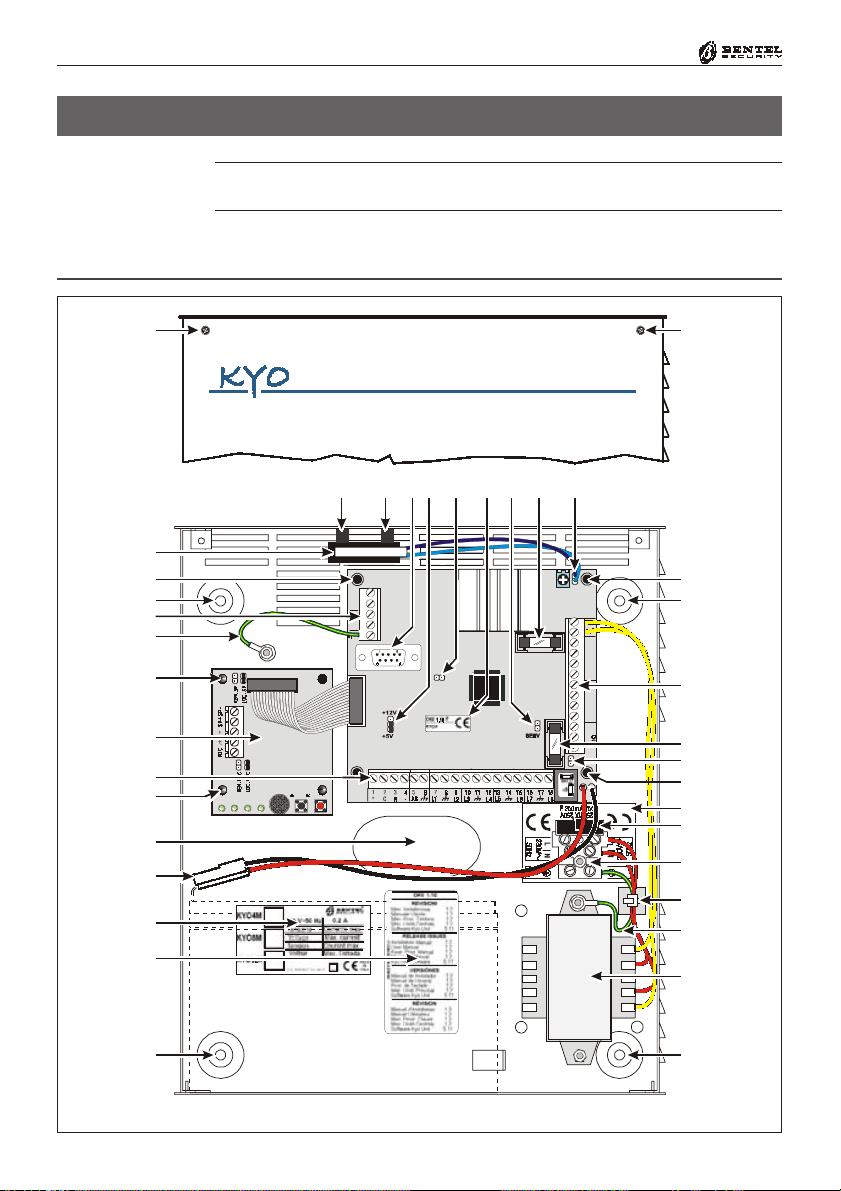

SECTION 2 - IDENTIFICATION OF COMPONENTS

The numbers in boldface in square brackets “[ ]”, in this and other Manuals

relevant to this product, refer to the components described in this section.

KYO 4 M — KYO 8 M — KYO 8W M — KYO 32 M

®®

1

11d

56

11d 9d

7

8 9a

10

11b

3a

2 2

4

13c

3a

12a

LE LI

3332 3 4 35 36

31

AC

30

REDBLKYEL

27 2928

GRN

03

25 26

KYO8

COMNC 0201+B

19 20 2221 2423

4

3a

17

15

18a

18b

1

3a

4

9c

10

3a

19c

19b

19a

18c

13a

14

2

Fig. 2.1 - KYO 32 M Control panel complete with NC2/VOX Voice Board (accessory item)

2

®®

Section 2 - Identification of Components

KYO 4 P — KYO 8 P — KYO 8W P — KYO 32 P

11

11

12b

11a

12a

13b

12b

3c

17

11e

11f

15

18a

18b

9d

51

96

9a

10 22546 783b 3b

11a

4

KYO8

9c

10

4

3c

19c

L

N

L

N

19b

19a

18c

14

2

2

Fig. 2.2 - KYO 32 Control panel complete with NC2/VOX Voice Board (accessory item)

12

Multifunction Control Panel

KYO 8G P-SW1 — KYO 8GWP-SW1 — KYO 32G P-SW1

®®

12b

11a

13b

12a

12b

10

9e

17

11e

11f

15

18b

18a

1

54683b 3b

11c

11g

29a

9d

7

29b

22

1

11a

9b

9c

BPI

+F

4

10

3c

4

LN

13b

24

28

22b

19a

26

2

Fig. 2.3 - KYO 32G P-SW1 Control panel complete with NC2/VOX Voice Board (accessory item)

20b

2

24

®®

Section 2 - Identification of Components

KYO 8G P-SW2 — KYO 8GWP-SW2 — KYO 32G P-SW2

13

11

12b

11a

12a

12b

10

3c

9e

24

11e

11f

15

17

18b

18a

26

54683b 3b

11c

11g

7

9d

29a

29b

22

11a

9b

9c

BPI

+F

4

10

3c

13b

25a

19a

27

28

23

22a

21

20a

2

2

25b

Fig. 2.4 - KYO 32G P-SW2 Control panel complete with NC2/VOX (accessory item)

3d

14

Multifunction Control Panel

KYO 8G L-SW1 — KYO 8GWL-SW1 — KYO 32G L-SW1

®®

13c

12a

11f

18b

11e

18a

3a

3a

9e

10

3e

17

15

11d

79d8

29a

11d

11b

4

1

2

4

9b

5

6

BPI

+F

9c

11c

11g

10

3a

16

29b

13c

LN

24

28

22b

19a

20b

26

Fig. 2.5 - KYO 32G L-SW1 Control panel complete with NC2/VOX Voice Board (accessory item)

24

2

®®

Section 2 - Identification of Components

KYO 8G L-SW2 — KYO 8GWL-SW2 — KYO 32G L-SW2

15

13c

12a

11f

18b

11e

18a

3a

3a

9e

10

3e

17

15

11d

79d8

29a

11d

11b

4

1

2

29b

4

9b

5

6

BPI

+F

9c

11c

11g

10

3a

16

24

19a

25a

23

27

28

22a

21

20a

26

24

25b

3d

2

Fig. 2.6 - KYO 32G L-SW2 Control panel complete with NC2/VOX Voice Board (accessory item)

16

Multifunction Control Panel

Table 2.1 - Identification the Main Unit Parts

Part Description

1 Frontplate Screws (2)

2 Locations (4) for backplate screws (Ø = 5 mm)

3a Reverse locking PCB supports (see Figure 3. 3)

3b PCB location Tabs

3c Locations (2) for PCB screws

3d Arrester for BAQ35T12 Switching Power-Supply/Battery Charger

3e 13 mm plastic support

4 Terminal Board

5 DB-9 male connector for computer link

6 BPI Level Jumper:

12Vk5V

5 V (at default);

12Vj5V

12 V

7 Firmware Release label

Stop Alarm Jumper: Open ( ) A larms Uninhibited (default);

8

Stop Alarm Jumper: Closed (K) Alarms Inhibited

9a BAT T Fuse: F8A - 250V

9b BPI Fuse (Fuse — protects BPI Bus [+] terminal): F2A - 250V

+B Fuse: F5A - 250V (K4, K8, K8W and K32 boards)

9c

+F Fuse: F5A - 250 V (Only for 'G' boards)

9d Reserved Jumper

9e Auxiliary Connector for BPI Devices (K8G, K8GW, K32 and K32G boards ONLY)

10 Connector for Tamper and Snatch Microswitches (N.O. at default)

11a Tamper Microswitch for BOX-P (A ccessory Item , code A SN C)

11b Tamper Microswitch for BOX-M and BOX-L (Accessory Item, co de MA XI-A SNC)

11c On-Board Tamper Microswitch (Only for 'G' PCBs)

11d Plastic spacers (2): inside the MAXI-A SNC Tamper Microswitch package

11e Snatch Microswitch (Accessory Item)

11f Snatch Micr oswitch bracket

Jumper for on-board Tamper-Microswitch [11c]:

11g

Open (J) Microswi tch disabled,

Closed (K) Microswitch enabled (at default)

12a Optional Voice Board (Order Code: NC2/VOX — refer to Section 5)

12b Voice Board Holder

13a Earth Wire

13b Earth Wire on PCB - terminal (L=400 mm)

13c Earth Wire on PCB - terminal (L=120 mm)

14 Power Transformer — 220-17Vac-1.5A (Order Code: TRF)

15 Battery wires

16 Cable supports

17 Cable entry

18a Marking ticket

18b Release Label

®®

®®

Section 2 - Identification of Components

Table 2.2 - Identification of the Switching Power Supply Components

Part Description

18c Cable Tie Bases

19a Mains Screw Terminal — for Mains and Earth

19b General protection Fuse: F500MA - 250

19c Adhesive Label

20a BAQ35T12 Switching Power Supply

20b BAQ15T12 Switching Power Supply

21 Mains LED (ON = Mains OK)

22a Fine Adjustment Trimmer

22b

KST Jumper — If you are connecting a KST Thermal Probe to the battery, this

jumper must be inserted.

23 Auxiliary Terminals for system peripheral (Output = 13.8 Vcc)

Screw to secure the Switching Power Supply to the backplate:

24

1 x BAQ35T12 - 2 x BAQ15T12

25a Screw for the Switching Power Supply

25b Snap Rivet

26 Thermal prob e — to be fitted to the battery (Order Code: KST)

27 Fuse — protects Switching Power Supply (F2A-250V)

28 Fuse — protects against Battery pol arity inversion (F6.3A -250V)

29a Connector for the Switching Power Supply

29b OVC-Link wire (Output Voltage Control)

17

18

Table 2.3 - Identification of the NC2/VOX Components

Part Description

LOC-MIC Jumper: K (at Default) - NC2/VOX Microphone Enabled

35

LOC-MIC Jumper: J - NC2/VOX Microphone Disabled

REM-MIC Jumper: J (at Default) - VOX-REM Remote Microphone Disabled

36

REM-MIC Jumper: K - VOX-REM Remote Microphone Enabled

37 Terminal bo ard for VOX- REM Module

REM-SP Jumper: J (at Default) - VOX-REM Remote Speaker Disabl ed

38

REM-SP Jumper: K - VOX-REM Remote Speak Enabled

LOC-SP Jumper: K (at Default) - NC2/VOX Speaker Enabled

39

LOC-SP Jumper: J - NC2/VO X Loudspeaker Disabled

40 Flat Cable

41 Microphone

42 PLAY button

43 RECORD button

44 Status LEDs

Multifunction Control Panel

®®

35 36

44

41

42

43

Fig. 2.7 - NC2/VOX Voice Board Components

37

38

39

40

®®

Section 3 - Mounting the Components

SECTION 3 - MOUNTING THE COMPONENTS

Introduction

Please read this section to get an overall view of the steps involved in installing

Control panels from the KYO Unit range.

The end of the stranded conductor must not be soft soldered in places where it is

subject to contact pressure. The Mains wiring must comply with the rules for

double or reinforced insulation. Use an adhesive cable grip to secure the wires

to the terminal boards.

Boxes and Accessories

Metal and Plastic boxes are available.

Metal box BOX-M

Plastic box BOX-P

Large Metal Box

The Metal Box (BOX-M) kit includes the following parts:

18 Balance Resistors — 10 Kohm

4 plastic PCB supports

1 x 12cm Earth wire (Yellow-Green) with eyelet [13c]

4 hexagonal nuts — M3

2 Parker screws — 2.9 x 7.5 to secure the Frontplate

The Plastic Box (BOX-P) kit includes the following parts:

18 Balance Resistors — 10 Kohm

1 x 40 cm Earth wire (Yellow-Green) without eyelet [13b]

2 Parker screws — 2.9 x 7.5 to secure the PCB

1 Parker screw — 2.9 x 9.5 to secure the BAQ35T12 Switching Power Supply

2 Parker screws — 3.9 x 9.5 to secure the Frontplate

1 Parker screw — 3 x 14.2 to secure the Mains Screw Terminal

2 Parker screws — 3 x 8 to secure the Transformer or BAQ15T12.

The Large Metal Box (BOX-L) kit includes the following parts:

BOX-L

18 Balance Resistors — 10 Kohm

1 x 13 mm plastic support for the PCB

4 plastic supports for the PCB

2 x 12 cm Earth wire (Yellow-Green) with eyelet [13c]

1 hexagonal nut — M3

1 plastic Snatch microswitch bracket [11e]

2 x 3mm cogged metal washers

2 screws 3x6

2 screws 3x8

2 Parker screws — 2.9 x 7.5 to secure the frontplate

1 “Protected Enviroment” label

19

20

Multifunction Control Panel

Installing the Transformer and Mains Screw Terminal - Fused

The Transformer (see Fig. 3.1) package includes the following parts:

1 Mains Screw Terminal - Fused [19a] — 500 mA

1 Adhesive Label [19c] for the Mains Screw Terminal

1 x 12 cm Earth wire (Yellow-Green) with eyelet [13a] for earthing the

Metal box or Transformer

To install the Transformer (Order Code TRF), work carefully through the following steps (refer to Fig. 3.1).

Metal box (BOX-M)

1. Stick the label [19c] onto the backplate (one aperture must be positioned

over the fixed screw, and the other over the Mains Terminal [19a] screw

location.

2

. Fit the Mains Screw Terminal [19a] onto the fixed screw (as indicated on

the label) then, using the hexagonal nut, secure it to the backplate.

3

. Mount the Transformer onto the 2 fixed screws (M3x10) on the backplate

of the Metal box.

. Fit the eyelet terminal [13a] to the fixed screw (as shown in Fig. 3.2a) then,

4

using two hexagonal nuts, secure the transformer to the backplate.

5

. Connect the Transformer primary (RED wires) to terminals [N] and [L].

6

. Connect the free end of the Earth wire [13a] to the [

Mains Screw Terminal [19a] (as shown in Fig. 3.2a).

Use the cable tie bases (refer to [18c] in Fig. 2.1) to bunch the Red wires of the

Transformer and the Earth wire [13a].

QQ

Q ] terminal on the

QQ

®®

[19c]

[19a]

M3 Nut to secure

Mains Terminal

71.75 mm

Metal Box — BOX-M Plastic Box — BOX-P

Fixed screws

M3x10

Screw Location Ø 2.5mm

Fig. 3.1 - Installing the Transformer and Mains Terminal board

71.75 mm

[19c]

[19a]

Screw to secure

Terminal board

®®

Section 3 - Mounting the Components

21

Plastic box (BOX-P)

1. Stick the label [19c] onto the backplate (as shown in Fig. 3.1). Ensure that

the 2 label holes correspond to the 2 holes on the backplate.

2

. Place the Mains Screw Terminal onto the screw location (Ø 2.5) then, using

the Parker screw (3 x 14.2) secure it to the backplate.

. Using the 2 holes on the backplate as reference, mount the Transformer

3

[14] (as shown in Fig. 3.2b).

4

. Using the two 3 x 8 parker screws, secure the Transformer to the backplate.

5

. Connect the Transformer primary (RED wires) to terminals [N] and [L].

[13a]

Hexagonal

nuts M3

Metal Box — BOX -M

Fig. 3.2 - Connecting the Earth wire [13a]

51

96

Fig. 3.3 - Fitting the Reverse Locking PCB Supports

22

Multifunction Control Panel

Mounting K4-K8-K8W-K32 PCBs

Please read this section to get an overall view of the steps involved in installing

K4, K8, K8W and K32 PCBs in Metal and Plastic boxes.

Metal box (BOX-M)

For the following procedure, see Fig. 2.1.

1

. Insert the 4 reverse locking PCB supports [3a] into their locations on the

backplate, then attach the PCB. If you are installing an NC2/VOX Voice

Board, insert the supports (LEDs to the bottom), then attach the NC2/

VOX Voice board (see Fig. 3.3).

. Using a hexagonal nut (M3), secure the Earth wire (Yellow-Green) eyelet

2

[13c] to the screw (M3x10) on the backplate.

3

. Connect the other end of the Earth wire (Yellow-Green) to terminal 36

--

(

- ) on the PCB.

--

4

. Connect the Transformer secondary (YELLOW wires) to terminals 30-31

(AC) on the PCB.

. If you are fitting a Tamper microswitch [11b], insert the two spacers [11d]

5

then, using the two hexagonal nuts( M3), secure it to its location (see Fig.

3.3). Connect the wire to the connector [10].

Plastic box (BOX-P)

For the following procedure, see Fig. 2.2.

1

. Slide the PCB under the 2 tabs [3b].

. Using the 2 (2.9 x 7.5) Parker screws (in screw locations [3c]), secure the

2

PCB to the backplate.

3

. Connect one end of the Earth wire (Yellow-Green) [13b] to the [

terminal (36) on the PCB, and the other to the [

Screw Terminal [19a].

Use the cable tie bases (refer to [18c] in Fig. 2.2) to bunch the Red wires of the

Transformer and the Earth wire [13b].

. Connect the Transformer secondary (YELLOW wires) to terminals 30-31

4

(AC) on the PCB.

5

. If you are fitting a Tamper microswitch [11a], insert it into its location, then

connect the wire to one of the two connectors [10] on the PCB. The second

connector [10] can be used for an external Tamper microswitch (on the

outside of the cabinet).

6

. If you are fitting a Snatch microswitch [11e], insert it into its location, then

connect the wire to terminals no. 5 and no. 6 (AS) and connect, in series, a

10 Kohm EOL resistor.

--

- ]

--

QQ

Q ] terminal on the Mains

QQ

®®

NOTE: Cut off the Snatch microswitch connector before connecting the wire.

®®

Section 3 - Mounting the Components

Installing ‘G’ series PCBs (K8G-K8GW-K32G)

Please read the following instructions, to get an overall view of the steps

involved in installing K8G, K8GW and K32G PCBs. “G” series PCBs can be

installed in plastic boxes (BOX-P) and large metal boxes (BOX-L).

Plastic box (BOX-P)

For the following procedure, refer to Fig. 2.3 and Fig. 2.4.

1

. Slide the PCB under the 2 tabs [3b].

. Using the 2 (2.9 x 7.5) Parker screws (in screw locations [3c]), secure the

2

PCB to the backplate.

3

. If you are fitting a Tamper microswitch [11a ], insert it into its location, then

connect the wire to one of the two connectors [10] on the PCB (see Fig. 2.3

or 2.4). The second connector [10] can be used for an exterrnal Tamper

microswitch (on the outside of the cabinet).

4

. If you are fitting a Snatch microswitch [11e], insert it into its location, then

connect the wire to connector [10].

Metal box BOX-L

For the following procedure, refer to Fig. 2.5 and Fig. 2.6.

1

. Insert the plastic support [3e] into its location.

2

. Insert the 4 reverse locking PCB supports [3a] into their locations on the

backplate, then attach the PCB (see Fig. 3.3). If you are installing an NC2/

VOX Voice Board, insert the supports [3a], then attach the NC2/VOX

Voice board (LEDs to the left).

. Using a hexagonal nut (M3), secure the Earth wire (Yellow-Green) eyelet

3

[13c] to the soldered screw on the backplate.

4

. Connect the other end of the Earth wire (Yellow-Green) [13c] to terminal 51

--

(

- ) on the PCB.

--

5

. If necessary, remove the Jumper [11g] in order to disable the Tamper micro-

switch [11c ].

. If you are fitting a Tamper microswitch [11b], insert the two spacers [11d]

6

then, using the two hexagonal nuts (M3), secure it to its location (see Fig.

3.3). Connect the wire to the connector [10].

7

. If you are fitting a Snatch microswitch [11e ], position the bracket [11 f]

then, using the two hexagonal nuts (M3), secure the Snatch microswitch to

its location. Connect the wire to the connector [10].

23

24

Multifunction Control Panel

Installing the Switching Power Supply

Please read the following instructions to get an overall view of the steps involved in installing Switching Power Supplies in ‘G’ series Control panels (i.e.

Control panels with K8G, K8GW and K32G PCBs). Two Switching Power

Supplies are available:

SW1) BAQ 15T12 (1,5 A)

SW2) BAQ 35T12 (3 A)

Installing BAQ15T12 Switching Power Supplies

BOX-P Plastic Box

To install a BAQ15T12 in a plastic box, work carefully through the following

steps (see Fig. 2.3 and 3.5).

1

. Using the 2 holes on the backplate as reference, mount the BAQ15T12 to

the backplate.

. Using the 2 Parker screws [24] (3 x 8), secure the BAQ15T12.

2

3

. Connect one end of the Earth wire (Yellow-Green) [13b] to the Earth

terminal 51 (

--

- ) on the PCB, and the other to terminal [

--

BAQ15T12 Switching Power Supply.

4. Plug the Switching Power Supply into the connector [29a] on the PCB.

. Connect one end of the OVC-Link wire [29b] to the OVC connector on

5

the PCB, and the other to the NTC connector on the BAQ15T12. This

connection will allow the system to monitor the battery status constantly.

QQ

Q ] on the

QQ

®®

BOX-L

Large Metal Box

To install a BAQ15T12 in a metal box, work carefully through the following

steps (see Fig. 2.5 and 3.5).

1

. Using the 2 holes on the backplate as reference, mount the BAQ15T12 to

the backplate.

2

. Using the 2 screws [24] (3 x 8), secure the BAQ15T12.

3. Connect one end of the Earth wire (Yellow-Green) [13c] to the Earth

terminal [

QQ

Q ] on the BAQ15T12 then, using the screw (3x6) and washer,

QQ

secure the other end to its location on the backplate (see Fig. 2.5).

4

. Plug the Switching Power Supply into the connector [29a] on the PCB.

5. Connect one end of the OVC-Link wire [29b] to the OVC connector on

the PCB, and the other to the NTC connector on the BAQ15T12. This

connection will allow the system to monitor the battery status constantly.

®®

Plastic Box BOX-P

BOX-L

Large Metal Box

Section 3 - Mounting the Components

25

Installing BAQ35T12 Switching Power Supplies

To install a BAQ35T12 in a plastic box, work carefully through the following

steps (see Fig. 2.4 and 3.5).

1. Locate the BAQ35T12 onto its supports on the backplate. Ensure that the

Switching Power Supply is secured firmly in place by the arrester [3d].

. Using the Parker screw [24] (2.9 x 9.5), secure the BAQ35T12 in place.

2

3

. Connect one end of the Earth wire (Yellow-Green) [13b] to terminal 51

--

(

- ) on the PCB, and the other to terminal [

--

Switching Power Supply.

4

. Insert the Switching Power Supply plug into the connector [29a] on the

PCB.

. Connect one end of the OVC-Link wire [29b] to the OVC connector on

5

the PCB, and the other to the NTC connector on the BAQ15T12. This

connection will allow the system to monitor the battery status constantly.

To install a BAQ35T12 in a metal box, work carefully through the following

steps (see Fig. 2.6 and 3.5).

1

. Locate the BAQ35T12 onto its supports on the backplate. Ensure that the

Switching Power Supply is secured firmly in place by its arrester [3d].

. Using the washer and screw [24] (3 x 6), secure the BAQ35T12 in position.

2

3. Insert the Switching Power Supply plug into the connector [29a] on the

PCB.

4. Connect one end of the OVC-Link wire [29b] to the OVC connector on

the PCB, and the other to the NTC connector on the BAQ35T12. This

connection will allow the system to monitor the battery status constantly.

QQ

Q ] on the BAQ35T12

QQ

Replacing BAQ35T12 Fuse

Please read the following instructions, to get an overall view of the steps

involved in replacing the Fuse [28] of the BAQ35T12 Switching Power Sup-

ply (see Fig. 2.4).

1

. Disconnect the Mains Power.

. Remove the snap rivet [25b].

2

3

. Remove the screws [25a].

4

. Remove the cover, then replace the Fuse.

. Replace the cover, snap rivet [25b] and screw [25a].

5

6

. Restore the Mains Power.

IMPORTANT - If the Mains Fuse [27] blows, DO NOT replace it. This

condition indicates general malfunction and requires specialist intervention,

Therefore, return the Switching Power Supply to your nearest Service Centre

for repair.

26

Multifunction Control Panel

Earthing the PCB

The PCB must be earthed by means of the Earth wire ([13a], [13b] or [13c]), in

order to protect it from electrical surges from the Telephone Line, and comply

with Safety Regulations.

Marking Ticket

Once you have assembled the components, specify the type of Control panel

that you have constructed.

Using an indelible pen, tick the relevant box on the Marking Ticket [18] (as

shown in Fig. 3.4).

NOTE: SW1 indicates the presence of a BAQ15T12 Switching Power Supply (1.5

A), and SW2 indicates the presence of a BAQ35T12 Switching Power Supply (3 A).

Connecting the KST Thermal Probe

‘G’ series PCBs have on-board connectors (PTC in Fig. 3.5.) for KST Thermal

Probes [26]. Addition of a KST Thermal Probe will optimize the Battery Charge

process, by regulating the Battery Charge Voltage in accordance with the Battery

temperature. The probe must be attached to the Battery by means of adhesive tape.

The KST connection cannot be considered complete until the OVC-Link Wire

[29b] (supplied with the Switching Power Supply) has been connected.

®®

Using an in delib le pen ,

corresponds to the assembled

Fig. 3.4 - Marking Ticket

Marking Ticket for BOX-M and BOX-L Metal Box

tick the box that

Control panel

Marking Ticket for BOX-P Plastic Box

If the Con trol panel is equipped

with a Transformer

(Order Code TRF), tick the box that

corresponds to the assembled

Control panel

If the Control panel

is equipped with a

Switching Power Supply,

tick the box that corresponds

to the assembled Control panel

(SW1= BAQ15T12, S W2=BAQ35T 12)

®®

Section 3 - Mounting the Components

If you are connecting a KST thermal probe to a Control panel with a BAQ15T12

Power Supply, ensure that the BAQ15T12 on-board Jumper [22b] is inserted.

For further information, refer to the Insert in the KST package.

Connecting the NC2/VOX Voice Board

To install the NC2/VOX Voice Board, work carefully through the relevant steps

(Metal box or Plastic box), and refer to Fig. 3.6.

NOTE: If you are connecting an NC2/VOX Voice Board to a Control panel

that is already in service, ensure that the Mains and Battery have been DISCONNECTED before starting the connection procedure.

Metal box

1. Remove the paper from the self-adhesive rubber gasket, and position it in

the centre of the 4 board support locations on the backplate.

2. Insert the reverse-locking board supports [3a], then attach the NC2/VOX

(refer to Fig. 3.3). If you are using a BOX-L, locate the boar as shown in Fig.

2.5 or 2.6.

3. Connect the Flat cable to connector A on the NC2/VOX Voice board, and to

Connector B on the PCB.

Plastic box

1. Slot the NC2/VOX board in the holder [12b] — LEDs to the top.

2. Connect the Flat cable to connector A on the NC2/VOX Voice board, and to

Connector B on the PCB.

27

PTC Connector OVC Connector

Control Circuit (PCB)

Fig. 3.5 - Connecting the KST Thermal Probe to ‘G’ series PCBs

KYO UNIT

Battery

KST Thermal

Probe

OVC-Link

NTC Connector

Switching

Power Supply

(BAQ35T12 or BAQ15T12)

28

Multifunction Control Panel

®®

BACKPLATE

CONTROL

A B

[12]

CIRCUIT

(PCB)

GASKET

[12]

CONTROL

CIRCUIT

(PCB)

A B

Fig. 3.6 - Installing the NC2/VOX Voice board in Metal box (Left) or Plastic box (Right)

PCB Identification Label

The self-adhesive PCB Identification Label (supplied with the PCB) should be

located on the frontplate, as shown in Fig. 3.7.

BACKPLATE

Locate the PCB

Identification Label here

KYO 32

Fig. 3.7 - Locating the PCB Label

Locate the PCB

Identification Label here

KYO 32G

®®

Section 4 - Installing the Control Panel

SECTION 4 - INSTALLING THE CONTROL PANEL

Mounting the Control Panel

The Control panel must be mounted in a safe, dry place, close to the placement

of command devices (Keypads, Readers, etc.). Once you have selected a

mounting location and created a layout, ensure that you will be able to connect

the Mains and Telephone line.

The Main Unit must be at least 2 metres from GSM and radio relay systems.

To mount the backplate:

. Remove the screws [1] and frontplate.

1

2

. Pull the cables through the wire entry [17], then using 4 anchor screws for

all the screw locations [2], secure the backplate to the wall.

3

. Complete the connections on the Terminal board [4] (refer to Table 4.1).

GG

G - In order to comply with safety regulations, the Mains power

GG

supply must be fitted with a bipolar insulating device (e.g. Automatic

isolating switch) for protection against overvoltage and short-circuit

(see Fig. 4.1a).

29

4. Connect the Mains power supply to the Mains terminal [19a]: Neu-

tral to terminal [N], Phase to terminal [L] and Earth to terminal [

Phase

230 V

Neutral

50 Hz

Earth

Control Panel

a b

Fig. 4.1 - Connecting the Insulating device

18c

QQ

Q ].

QQ

30

Multifunction Control Panel

NOTE: In order to comply with the Safety Regulations in force,

this device must be protected against electrical surges (e.g. from the

Telephone Line), therefore, it must be properly connected to the

Mains Earth line. The warranty does not cover damage to the PCB

caused by non-connection, or improper connection to a faulty Mains

Earth line.

Use the cable tie bases (refer to [18c] in Fig. 4.1b) to bunch the 220 V Mains

wires and the Earth wire.

. Disable the Alarm Output, as described in the following paragraph ‘Open-

5

ing and Closing the Control panel’.

. Connect the battery wires [15].

6

7

. Program the Control panel, as described in the INSTALLATION

MANUAL.

8

. Close the Control panel then, using the 2 screws [1], secure the Frontplate.

Opening and Closing the Control Panel

If the Tamper microswitches ([11a ], [11b] or [11c]) are enabled, do not open the

Control panel until you have disabled the Alarm output.

To open the Control panel:

Opening the Control

Closing the Control

1. Enter the Installer Code at any Keypad, then press ENTER (press

panel

MIA Keypads or

EE

E on ALISON Keypad).

EE

2. Remove the screws [1] and Frontplate.

3. Insert the Stop Alarm Jumper [8].

To close the Control panel:

1. Remove the Stop Alarm Jumper [8].

panel

2. Replace the Frontplate and screws [1]

3. Exit the Menu (as described in the PROGRAMMING FROM KEYPAD

Manual). The system will become operative when you exit the Menu.

EE

E on

EE

®®

NOTE: If you are using a LED Keypad, press the e key to exit Menu.

®®

Section 4 - Installing the Control Panel

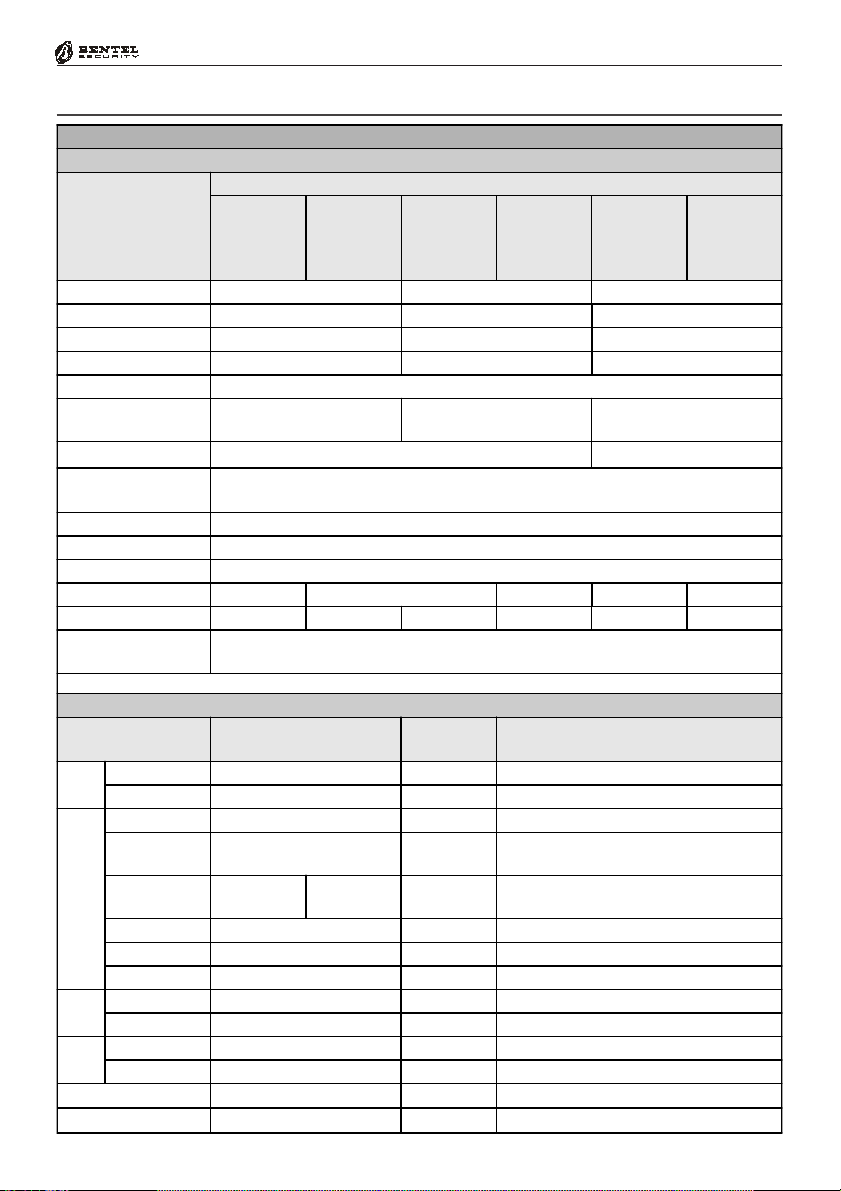

Table 4.1 - Description of the Terminals

PCB Terminals

K8G - K8GW - K32G K4 - K8 - K8W - K32

1-2-3-4

[+][C][R][-]

5 [AS] 17 [A S]

6-9-12-15-18-21-24-

27-30-37

[MMMM]

7-10-13-16-19-22-25-28

[+F]

8-11-14-17-20-23-26-29

[L1] ... [L8]

4-6-8-11-14-17

[MMMM]

22 [+B]

7-9-10-12-13-15-16-18

[L1] ... [L8]

Terminals for the BPI Device connections

(Keypads, Readers, Expander, etc.)

Balanced 10K Tamper Line ––

Negative Terminal 0 –

Positive Terminal — power supply to the

Detectors

Programmable Alarm Lines

(KYO4 manages Lines L1 ... L4)

Description

Free Voltage Changeover A larm Relay:

31-32-33

[NC][COM][NO]

19-20-21

[NC][NO][COM]

during Standby COM Terminal

connected to NC (NO floating)

during Alarm COM Terminal

connected to NO (NC floating)

Positive is present on this termi nal

34 [+N] –

during Standby

this Terminal is Open during Alarm

Positive is present on this termi nal

35 [+A] –

during Alarm

this Terminal is Open during Standby

36

[+B]

–

38-39-40-41-42

[O1][O2][O3]

[O4][O5]

43-44-45-46

[GRN][YEL]

[BLK][RED]

47-48

[LE]

49-50

[LI]

51

[----]

– 30-31 [AC]

22

[+B]

23-24-25

[O1][O2][O3]

–

26-27-28-29

[GRN][YEL]

[BLK][RED]

32-33

[LE]

34-35

[LI]

36

[----]

Auxiliary Power Supply for peripherals 13.8 (*)

150 mA Auxiliary Open-Collector

Outputs — Programmable

500 mA Auxiliary Open-Collector

Outputs — Programmable

Key Bus Terminals (if present):

RED Positive BLK Negative

External Telephone Line Terminals ––

Terminal for line-sharing devices (Fax,

Modem, Telepho ne, etc.) — connected to

the same Telephone line as the P anel

Terminal for the Earth connection ––

Terminals for the Transformer

secondary connection

(*) - the total c urre nt d raw o f the se te rminal s m ust not ex cee d :

(*) -

- for K4, K8, K8W and K32 with Transforme rs

0.6 A

(*) - 1 A - for K8G-SW1, K8GW-SW1 and K32G-SW1 with the BAQ15T12 Switching Power Supply

(*) - 2.3 A - for K8G-SW2, K8GW-SW2 and K32G-SW2 with the BAQ35T12 witching Powe r Sup ply

(*) - (the Battery Charge value must be subtracted from these values)

Volta ge

(V)

Current

Max. (A)

13.8 (*)

13.8 (*)

––

––

13.8 (*)

13.8 (*)

–

0.15

(*)

0.5

(*)

13.8 (*)

––

––

31

32

Multifunction Control Panel

SECTION 5 - INSTALLING THE NC2/VOX

The NC2/VOX Voice Board (Accessory Item) will allow you to record and

send Voice messages to the programmed Telephone numbers. For the installation instructions refer to Section 3 under ‘NC2/VOX’.

General Features

Voice synthesizer — Records/Plays Messages

Records 8 Messages: 4 x 15 seconds and 4 x 7 seconds

Repeats the Alarm Message up to 4 times

Loudspeaker

Talk Listen-in function (Telemergency)

Additional VOX-REM Modules

If the NC2/VOX Voice Board is unable to cover the entire premises (e.g. due to

the size of the building), you can extend cover by using additional VOX-REM

Modules (Microphone and Loudspeaker). The additional VOX-REM Modules can be located as required (see Fig. 5.1).

®®

VOX-REM Jumpers

GG

G - For proper operation, the wire length between the additional VOX-REM

GG

Module and the NC2/VOX Voice Board should not exceed 50 metres.

The ALISON/DV Keypad has a built-in Microphone [60a] and Loudspeaker

[60b] which perform the same operations as the VOX-REM Module. Fig. 5.1

illustrates connections of a VOX-REM Module and an ALISON/DV Keypad.

Additional VOX-REM Modules must be connected in parallel to the NC2/VOX

Voice Board (see Fig. 5.1).

Installing Additional VOX-REM Modules

The VOX-REM must be mounted in 2 separate boxes (Minibox), as shown in

Fig. 5.1: one for the board and the other for the loudspeaker.

If you intend using the VOX-REM Microphone, you must insert the Jumper

marked EN LOC MIC.

If you intend using a remote Microphone, you must insert the Jumper marked

EN REM MIC. The Microphone must be connected to the connector marked

MIC on the VOX-REM Module.

NOTE: Use shielded cable for all connections. For proper operation, the wire

length must not exceed 2 metres.

The Loudspeaker must be connected to the bipolar connector (see Fig. 5.1).

®®

Section 5 - Installing the NC2/VOX

33

NC2/VOX Jumper

Settings

NOTE: If you connect a VOX-REM Module, you must set the jumpers on the

NC2/VOX as follows:

LOC-MIC Open (oo)

REM-MIC Closed (//)

LOC-SP Open (oo )

REM-SP Closed (//)

GG

G - The NC2/VOX supports up to 4 additional VOX-REM Modules.

GG

Record / Play Messages

Put the system in SERVICE Mode (as per maintenance) by inserting the

Jumper [8] (as described in Section 4 under ‘Opening and Closing the Control

panel’), or by using a valid SAT key (with the Service attribute) at an

ECLIPSE Reader.

VV

The

V LED on the Keypad will blink, and the 4 Green LEDs on the NC2/VOX

VV

will go through the 8 message configurations (refer to the ‘Select Message’).

LED

MIC

EN LOC MIC

EN REM MIC

BL229

+

SP+

SP-

MIC

Loudspeaker Connector

Fig. 5.1 - Installing Additional VOX-REM Modules

VOX-REM

Additional Module

MIC MIC

SP– SP–

SP+ SP+

NC2/VOX

Voice Board

ALISON-DV

MIC

SP–

SP+

34

Message No. 1 2 3 4 5 6 7 8

Length 15 sec 15 sec 15 se c 15 sec 7 sec 7 sec 7 sec 7 sec

LED 1

LED 2

LED 3

LED 4

ON

OFF

OFF OFF

OFF OFF OFF

Multifunction Control Panel

Table 5.1 - Selecting the Message

OFF OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON ON ON

ON

ON ON

ON ON ON

OFF

ON ON

OFF

Selecting Messages

The Voice Board can record up to 8 Alarm messages. Four messages of 15

seconds (messages 1, 2, 3 and 4), and four of 7 seconds (messages 5, 6, 7 and

8). The 8 message configurations (refer to Table 5.1) can be viewed on the Green

LEDs at 1 second intervals.

To select a message: press and hold keys [42] and [43] until the required configuration is shown on the LEDs.

Recording Alarm Messages

Press and hold key [43] until the 4 LEDs start to blink to signal the elapsing

message time (7 or 15 seconds).

You can start recording the Alarm message, as soon as you release the key.

Speak at a distance of approximately 20 cm from the Microphone.

Recording will stop automatically when the message time elapses. You can stop

recording at any moment by pressing key [43].

®®

ON

OFF

Playing Messages

Press and hold key [42] until the 4 LEDs start to blink to signal the elapsing

message time (7 or 15 seconds).

The Alarm Message will play.

You can stop playback at any moment by pressing key [42].

®®

Programming

Activation

Section 5 - Installing the NC2/VOX

35

Proper operation of the NC2/VOX Voice Board depends on Telephone and

the Events pages (refer to ‘Programming from PC’ in the ‘INSTALLATION

MANUAL’).

Fig. 5.2 shows the various phases of the Alarm call procedure. If a messagerelated event occurs, the Control panel will perform the following actions:

1. Engage the Telephone line.

2. Wait 10 seconds for the Dial Tone.

- If the Dial Tone is recognized, it will go to step 3.

- If the Dial Tone is not recognized, it will hang up and go back to step 1.

NOTE: In some cases, the Dial Tone check must be disabled (for example,

if the system is connected to a Switchboard which operates with non-standard tones). If the Dial Tone check is disabled, step 2 will be ignored.

3. Dial the programmed Telephone number.

4. Wait 30 seconds for the Line Free Tone.

- If the Line Free Tone is recognized, it will go to step 5.

- If the Line Free Tone is not recognized, it will hang up and go back to

step 1.

5. Wait 20 seconds for a Valid Handshake.

- If a Valid Handshake is recognized, it will go to step 5.

- If a Valid Handshake is not recognized, it will hang up and go back to

step 1.

6. Play the respective Alarm message 4 times.

- If a call is unsuccessful (for example, unanswered or invalid handshake), it

will make 8 tries before quitting.

NOTE: If several events occur simultaneously, the relative Alarm messages will

be played in chronological order during the same Telephone call.

Maximum 8 times

Phase 1

Enage

Line

Fig. 5.2 - Voice Message Flow Chart

Phase2

Dial

Ton e?

Phase3

Dial

Number

Hang up!Hang up!Hang up!

Phase 5Phase 4

Answer?Free?

Phase 6

Play Message

4 times

®®

BENTEL SECURITY S.r.l. - C.da Ravigliano, Z.I. S. Scolastica - 64013 CORROPOLI - TE - ITALY

Tel.: +39 0861 839060 - Fax: +39 0861 839065

E-mail: info@bentelsecurity.com - http://www.bentelsecurity.com

ISTUCBLEUNKYO 2.0 231104 P70

Loading...

Loading...