®

INSTALLATION MANUAL

Via Gabbiano, 22 - Z.I. S.Scolastica - 64013 CORROPOLI (TE) - ITALY

Installation manual: Analogue Fire Control Panel FireClass200

Istruzioni Inst. Inglese Antin. FC200/UK ISTINSFC200/UK

The following versions of the Fireclass200 series are available:

FC200 - Master panel with 4 A Linear power supply;

FC200/S - Master panel with 2.5 A Switching power supply;

FC200/SL - Slave panel without power supply unit;

f a technical feature is common to all versions, the name Fireclass200 is used in the description.

If a technical feature applies to a specific version, the name of the version concerned is specified.

Proper functioning of the FireClass200 components can be guaranteed ONLY when ambient

conditions, external to the cabinet, comply with the 3k5 category of IEC 721-3-3:1978.

The Loops of the FireClass200 control panel support 396 Analogue Devices.

The Conventional Zone of the FireClass200 control panel supports30 Conventional Devices.

The Fireclass200 supports a maximum of 512 devices in all.

In order to meet standards and qualify for IMQ Certification, the FC200/SL Slave panel must

be equipped with a BENTEL BA424 (27.6 V - 4 A) Linear power supply or

BENTEL BAQ60/24 (27.6 V - 2.5 A) Switching power supply.

Only the Manufacturer (Access Level no. 4 — refer to “Accss Levels” section) can install the

FC200/SL Slave panel power supply.

The FC200/SL Slave panel can operate ONLY when connected to a FireClass200 Master panel.

BENTEL SECURITY srl reserves the right to change the technical features of this product

without prior notice.

Fc100 - Master panel with 2.5 A Switching power supply;

I

FC200 - FC200/S - FC200/SL - FC100:

.

Hereby, Bentel Security,

declares the above mentioned Control Panels to be in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC

These Control Panels comply with

Installation of these systems must be carried out strictly in accordance with the instructions

described in this manual, and in compliance with the local laws and bylaws in force

The above mentioned Control panels have been designed and made to the highest

standards of quality and performance.

The manufacturer recommends that the installed system should be completely tested

at least once a month.

The complete R&TTE Declaration of Conformity for each Panel can be found

at www.bentelsecurity.com/dc.html.

.

.

BENTEL SECURITY Srl shall not assume the responsibility for damage arising from

improper application or use. The above mentioned Control panels have no user-friendly

components, therefore, should be serviced by authorized personnel only.

EN54-2EN54-4 1999;

TABLE OF CONTENTS

FC200 and FC100 . . . . . . . . . . . . . . . . . . . . 6

OVERVIEW 7

Access Levels . . . . . . . . . . . . . . . . . . . . . . 7

Main Features . . . . . . . . . . . . . . . . . . . . . . 7

Options with requirements . . . . . . . . . . . . . . . . 8

Telecom Module FC200/COM (Accessory item) . . . . . 8

Alarm cycle . . . . . . . . . . . . . . . . . . . . . . . . 8

Upgraded/New technical features (Firmware

version 4.00) . . . . . . . . . . . . . . . . . . . . . . 10

PARTS IDENTIFICATION 11

Main unit (FireClass200) . . . . . . . . . . . . . . . . . 11

Output Expander (FC200/6OUT) . . . . . . . . . . . . 18

Loop Interface . . . . . . . . . . . . . . . . . . . . . . 18

Telecom Module FC200/COM . . . . . . . . . . . . . . 19

Repeater . . . . . . . . . . . . . . . . . . . . . . . . . 20

INSTALLATION 21

Mounting the Control panel . . . . . . . . . . . . . . . 21

Installing Output expanders (FC200/6OUT) . . . . . . 22

Installing the Telecom Module (FC200/COM) . . . . . 22

Installing Repeater Panels (FC200/REP) . . . . . . . 22

Completing the Connections . . . . . . . . . . . . . . 23

Main board terminals . . . . . . . . . . . . . . . . . . 23

Connectiing Addressable Analogue Devices . . . . . 26

Connecting Conventional Devices . . . . . . . . . . . 28

Connecting Repeaters and Slave Panels . . . . . . . 29

Connecting Output Devices . . . . . . . . . . . . . . . 30

Bell Outputs . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting the Telecom Module (FC200/COM) . . . . 31

Connecting the Power Supply . . . . . . . . . . . . . 32

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 33

3

USING THE SYSTEM 35

Operating the system . . . . . . . . . . . . . . . . . . 35

Accessing the system . . . . . . . . . . . . . . . . . . 37

PROGRAMMING 39

Auto (Autolearning - Automatic enrolling) . . . . . . . 40

Connections: Loop 1 and Loop 2 . . . . . . . . . . . . 41

Connections: Network . . . . . . . . . . . . . . . . . 43

Programming: Fire detectors . . . . . . . . . . . . . . 44

Programming: Input modules . . . . . . . . . . . . . . 46

Programming: Output modules . . . . . . . . . . . . . 47

Programming: Conventional Zone module . . . . . . . 49

Programming: Repeaters and Slave panels . . . . . . 49

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Loop 1 and Loop 2 . . . . . . . . . . . . . . . . . . . 50

Conventional Line . . . . . . . . . . . . . . . . . . . . 51

Bell Outputs . . . . . . . . . . . . . . . . . . . . . . . 52

Network . . . . . . . . . . . . . . . . . . . . . . . . . 53

Password (PassWD) . . . . . . . . . . . . . . . . . . . 54

Welcome Message (MesINI) . . . . . . . . . . . . . . . 55

Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Prealarm time (P) . . . . . . . . . . . . . . . . . . . . 58

Warning Threshold (W) . . . . . . . . . . . . . . . . . 58

Alarm Verify (V) . . . . . . . . . . . . . . . . . . . . . 59

Drift Compensation . . . . . . . . . . . . . . . . . . . 60

Timer and Special Timer (T and S) . . . . . . . . . . . 61

Delay . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Extinction Mode . . . . . . . . . . . . . . . . . . . . . 64

System . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Date and Time . . . . . . . . . . . . . . . . . . . . . 66

Blink . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Wires . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Silence mode . . . . . . . . . . . . . . . . . . . . . . 68

Walk Test . . . . . . . . . . . . . . . . . . . . . . . . 69

Network . . . . . . . . . . . . . . . . . . . . . . . . . 70

4 Analogue Fire Control Panel FireClass200

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Factory . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Restore default . . . . . . . . . . . . . . . . . . . . . 72

Maintenance . . . . . . . . . . . . . . . . . . . . . . 72

Telephone . . . . . . . . . . . . . . . . . . . . . . . . 73

Dial. (Telephone Dialler) . . . . . . . . . . . . . . . . 74

Digital Telephone Communicator (Digital Commun.) . . 76

Telephone Numbers (T.Num) . . . . . . . . . . . . . 78

Options . . . . . . . . . . . . . . . . . . . . . . . . . 78

Remote management . . . . . . . . . . . . . . . . . . 80

MODIFYING 81

Disable . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Delete Verify . . . . . . . . . . . . . . . . . . . . . . . 84

Delete Log (Del. Log) . . . . . . . . . . . . . . . . . . 85

Telecom Module . . . . . . . . . . . . . . . . . . . . . 85

READING PARAMETER 87

Devices/Zones/Outputs . . . . . . . . . . . . . . . . . 87

Options . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Version . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Log data . . . . . . . . . . . . . . . . . . . . . . . . 90

Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Telecom Module . . . . . . . . . . . . . . . . . . . . . 92

QUICK GUIDE 95

General features . . . . . . . . . . . . . . . . . . . . . 95

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 96

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5

FC200 and FC100 Features

FC200 FC100

EN54 Approved EN54 Approved

2 analogue loop: supports 99 sensors and 99

modules

1 analogue loop: supports 99 sensors and 99

modules

Automatic device-drift compensation Automatic device-drift compensation

Modular loop management

1 conventional input line: supports 30 fire detectors and an unlimited number of Callpoints

1 conventional input line: supports 30 fire

detectors and an unlimited number of

Callpoints

16 programmable software zones 16 programmable software zones

16 alarm repeat outputs (open-collectors): 1

per zone

16 alarm repeat outputs (open-collectors): 1

per zone

1 "C" alarm output 1 "C" alarm output

4 programmable, supervised, silenceable

alarm output (relays) ---- expandable to 16 using FC-200/6OUT expander modules

1 programmable, supervised, silenceable

alarm output (relay)

1 NON-supervised, NON-silenceable ancillary

alarm output (relay)

1 NON-supervised, NON-silenceable Fault output (relay)

RS485 Interface ---- supports 8 repeaters RS485 Interface ---- supports 8 repeaters

RS232 Interface for serial printer ---- linked to

the Control panel or a PC for upload/download

operations

RS232 Interface for serial printer ---- linked to

the Control panel or a PC for upload/download

operations

200 event log 200 event log

Supports 2 FC200/6OUT output expanders to

provide 16 outputs

Supports 2 FC200/6OUT output expanders to

provide 13 outputs

Local/Remote Upload/Down load from PC Local/Remote Upload/Down load from PC

TELECOM Module (Accessory item) TELECOM Module (Accessory item)

Power supply: 230 Vca +/- 10% Power supply: 230 Vca +/- 10%

Available with 2.5 A power supply/battery charger

and with 27.6V-4A linear power supply

Available with 2.5 A power supply/battery

charger

Housing for 2 x 17 Ah batteries Housing for 2 x 17 Ah batteries

Dimensions (w x h x d): 432 x 577 x 131 mm Dimensions (w x h x d): 432 x 577 x 131 mm

Weight (without batteries): max. 9.0 Kg Weight (without batteries): max. 9.0 Kg

FC200 and FC100

The Installer and Operator manuals can be used with FC200 and FC100

Fire Control panels, however, where features and capacity differ, refer to

the above table.

6 Analogue Fire Control Panel FireClass200

OVERVIEW

Access Levels

The FireClass200 Access Levels filter system control as follows.

Level 1 All persons can view the system status through the Plexiglas window.

Level 2A Only authorized key holders can open the cabinet door access the manual

commands (RESET, SILENCE and LOGGER).

Level 2B Only authorized User PINs (1 to 5 digit codes) can Enable/Disable the

Loop devices, Bell Outputs, Software Zones and Network devices.

Level 3A Only the Installer PIN (1 to 5 digit code) can access the parameter pro-

gramming phase.

Level 3B 0nly authorized personnel are allowed to open the cabinet (remove the screws

and open the control panel door) for maintenance work (change the battery,

replace fuses, etc).

Level 4 Only the manufacturer is allowed to open the cabinet (remove the screws

and open the control panel door) for PCB repair work (replace components, etc.).

Main Features

Day/Night The FireClass200 can operate in Day or Night Mode.

If the system is silenced during Day Mode, SILENCE status will be held

until the system is unsilenced (i.e. unless new alarms or faults occur).

If the system is silenced during DAY Mode, SILENCE status will be held

until the system is unsilenced (i.e. unless new alarms or faults occur).Silence will be enabled until the SILENCE button is pressed again.

If the system is silenced during NIGHT Mode, SILENCE status will be for

the preset time (accepted values: 30 seconds to 30 minutes).

This system provides Automatic Alarm Threshold variation.

The preset Alarm Threshold of analogue detectors will be increased during

Day Mode, in order to avoid false alarms caused by persons (cigarette

smoke, etc.) in the protected ambient.

OVERVIEW 7

Options with requirements

The FireClass200 control panel provides the following options with requirements (complies with European norm EN54 part 2):

Ø outputs to fire alarm routing equipment

Ø co-incidence detection

Ø fault signals from points

Ø disablement of addressable points

Ø Test condition

Telecom Module FC200/COM (Accessory item)

The Telecom Module sends recorded messages to programmed telephone

numbers and, using reporting protocols, transmits data to central stations.

This module allows operators to manage the system over-the-phone by

means of the FC200/SW software package.

Description

r 8 independent channels

r Records one 11 second alarm message per channel

r 32 programmable telephone numbers

r Accepts 15 digit telephone numbers and 1 or 5 second pauses

r Repeats alarm messages for up to 20, 40, 60 or 80 seconds

r Repeats call cycle up to 5 times

r Voice answer detection

r Bypassable "dial tone" test

r Telephone-line Interface

r Protected against over-voltage

r DTMF and Pulse dialling

r Digital recording/Message playback

r Non-volatile memory

r Manages the following reporting protocols:

ADEMCO SLOW 10 BAUD, ADEMCO FAST 14 BAUD, FRANKLIN 20

BAUD, RADIONICS 40 BAUD, SCANTRONIC 10 BAUD, CONTACT ID

(DTMF), SIA 300 BAUD.

Alarm cycle

If an alarm channel triggers an alarm, the telephone dialler will generate

the respective alarm cycle (as per figure 1).

8 Analogue Fire Control Panel FireClass200

Phase 1 The dialler will switch to the telephone line.

Phase 2 The dialler will wait 3 seconds then will engage the telephone line.

Phase 3 If the Dial-tone check option is enabled (refer to the "Programming" sec-

tion), the dialler will wait for the dial tone.

NOTE: If the dialler does not detect the dialling tone within the preset

time, it will repeat the process 4 times before hooking-up and stepping

back to phase 1.

If this option is disabled the dialler will go directly to the next phase.

Phase 4 The dialler will dial the telephone number associated the with the alarm

channel concerned.

Phase 5 If the Voice answer detection option is enabled (refer to the "Programming"

section), the dialler will wait 25 seconds for a voice answer and, if detected,

will step to the next phase. If the Voice answer detection option 6 is disabled,

the dialler will pause for several seconds before going to the next phase.

Phase 6 The dialler will send the respective alarm channel message. The message

will be played for the preset Message playback time (20, 40, 60 or 80

seconds).

Call cycle The Call cycle (set up during the programming phase) determines the

number of times each telephone number ---- assigned to the alarm channel

concerned ---- will be dialled (1 to 5 times).

Figure 1 Telecom Module alarm cycle

OVERVIEW 9

Upgraded/New technical features (Firmware version 4.00)

r Extended template provides full alarm details (refer to the Operator’s Man-

ual ---- pages 9, 10)

r RS485 protocol upgrade for fast data transmission

r Centralized Master panel Log ---- retrieves, saves and broadcasts all the

network events (refer to the Operator’s Manual pages 9, 10)- Logger on

Slave: (refer to the Software Manual "System")

r View Alarm event details from Repeaters (refer to the Operator’s Manual

---- pages 9, 10)

r New "Ignore output supervision" option for dry-contact management of

Output Modules (refer to Installation Manual page 48)

r New Single Zone/ALL Zone Double knock option (refer to the Installer’s

Manual ---- pages 48, 49)

r New Zone Prealarm event (refer to the Installer’s Manual ---- pages 47, 48,

49)

r Resets slave panel from master (refer to the Software Manual "System")

r Resets master panel from slave (refer to the Software Manual "System")

r Sets to Day Mode on power up (at default)

r Verify Alarm option (refer to the Installer’s Manual ---- page 44, 45 and Op-

erator’s Manual ---- pages 18, 25).

r Manages Prealarms (refer to the Installer’s Manual ---- page 58 and Opera-

tor’s Manual ---- pages 9, 13).

r Manages Warning signals (refer to the Installer’s Manual ---- pages 47, 48,

53, 59, 75)

+

FireClass control panel firmware verions 4.00 and Repeater firmware versions 1.2 CANNOT operate on applications using FireClass control panels

and Repeaters with lower firmware versions.

10 Analogue Fire Control Panel FireClass200

PARTS IDENTIFICATION

This chapter holds the full description of the main components and LEDs

of the FireClass200. In most cases, the numbers in boldface refer to the

parts shown in the tables and figures.

Main unit (FireClass200)

The Flashing status of certain LEDs is not dealt with in the following table, as it signals that the assigned event occurred and ended before the

last rearming operation.

LED MEANING

ALARM ON: the control panel is in ALARM status.

MORE ALARMS ON: presence of more than one alarm condition.

PRE-ALARM

FLASHING: PRE-ALARM status - the sensors have detected an alarm

condition. The Outputs will be activated when the PRE-ALARM delay

ends.

TELECOM ON: the control panel is physically connected to the telephone line.

MAIN POWER

OFF: mains failure. Mains power must be restored before the batteries

empty.

WALK TEST

FLASHING: Walk Test mode on a Software Zone; an alarm condition on

the Zone in question will generate an alarm status on the assigned

Outputs for approximately one second.

DISABLED ON: at least one device is disabled.

NIGHT ON: the control panel is operating in NIGHT mode.

DAY ON: the control panel is operating in DAY mode.

FAULT

ON: presence of at least one fault condition; the type of fault will be

signalled by the associated LED and/or on the display.

MAINS

ON: mains failure; the standby batteries will takeover the power supply to

the control panel. This LED is complementary to the green MAINSPOWER LED, and will continue to signal the fault event after mains

power has been restored (memory).

LOW BATTERY

ON: low batteries; proper functioning of the control panel cannot be

guaranteed in the event of black-out. Wait several hours, if the LED stays

ON the batteries are not rechargeable and must be replaced

BATTERY FAULT ON: batteries are completely empty or not connected - check fuse 41

GROUND ON: voltage leak to ground - check connection insulation.

FUSES

ON: burnt fuse (fuse 41 or 42) - the fuse concerned will be indicated on

the display.

LOGIC UNIT ON: "blocked" microprocessor - call Installer for service.

PARTS IDENTIFICATION 11

ADDRESS ON: loss of a loop device.

SAME ADDRESS ON: two devices on the same loop have the same address.

SILENCE

ON: the SILENCE button has been used to places the SILENCEABLE

Outputs in standby status. DAY mode SILENCE status will be held until

the SILENCE button is pressed again. NIGHT mode SILENCE will be

held for the programmed SILENCE time.

Z01 ÷ Z16

ON: the corresponding zone is in ALARM Status.

Flashing (3 secs. ON - 1 sec. OFF): the corresponding Zone is in PREALARM status .

Flashing (1 sec. ON - 0.5 sec. OFF): the FIXED delay is active.

Flashing (2 secs ON - 2 secs OFF): the PAS delay is active.

BUTTON FUNCTION

SILENCE

Places the SILENCEABLE Outputs in standby status: DAY mode

SILENCE status will be held until the SILENCE button is pressed again.

NIGHT mode SILENCE is held for the programmed SILENCE time.

ACK Activates the PAS delay (if pressed when the FIXED delay is active).

RESET REARMS the control panel.

TEST

Tests the control panel buzzer and LEDs. When this button is pressed,

all warning LEDs should light and the buzzer should emit a intermittent

acoustic signal (1 sec. beep - 1 sec. pause).

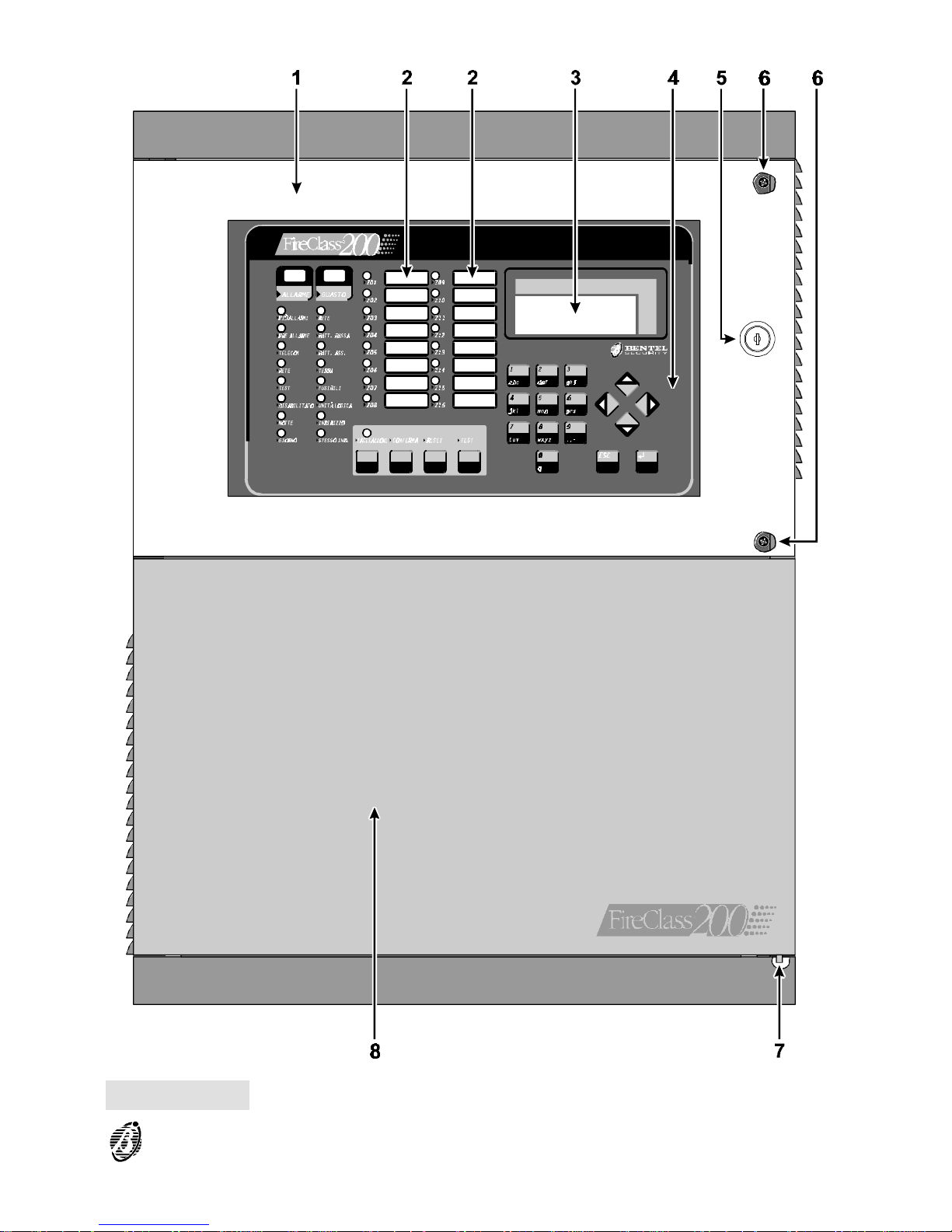

PART DESCRIPTION

1 Control panel door with Plexiglas window

2 Pocket for zone description

3 LCD 4 rows ---- 20 columns

4 Command panel

5 Control panel door lock

6 Two screws for securing command panel and battery compartment door

7 Battery compartment door stop

8 Battery compartment door

12 Analogue Fire Control Panel FireClass200

Figure 2 Main unit parts (external)

PARTS IDENTIFICATION 13

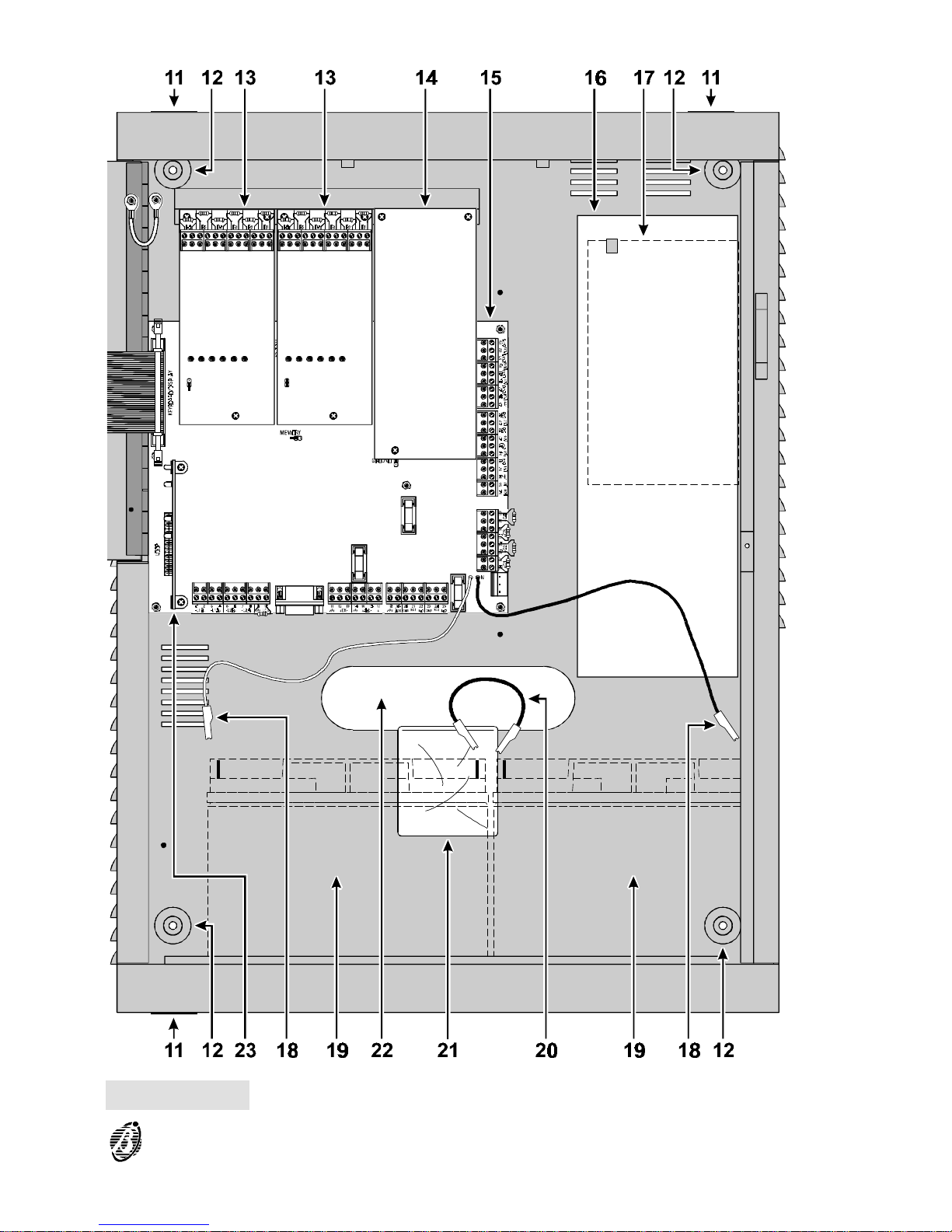

PART DESCRIPTION

9

Jumper to enable programming:

> programming enabled (default)

> programming disabled

10 Keypad/Display board

11

Cable passage (3 x ∅ 30 mm)

12

Wall mounting holes (4 x ∅ 5 mm)

13 6 Output expander FC200/6OUT (optional - 2 maximum)

14 Telecom module FC200/COM (optional)

15 Main board

16 27.6 V - 4 A linear power supply/battery charger

17 27.6 V - 2.5 A switching power supply/battery charger

18 Battery connectors

19 Compartment for two (optional)12 V, 17 Ah batteries

20 Jumper for series connection of batteries

21

Bag holding: two F 250V 3.15A fuses; one F 250V 6.3A fuse; two keys;

four 1N4007 diodes; jumper for series connection of batteries

22 Chased cable passage (40 x 170 mm)

23 Loop interface

14 Analogue Fire Control Panel FireClass200

Figure 3 Main unit parts (internal)

PARTS IDENTIFICATION 15

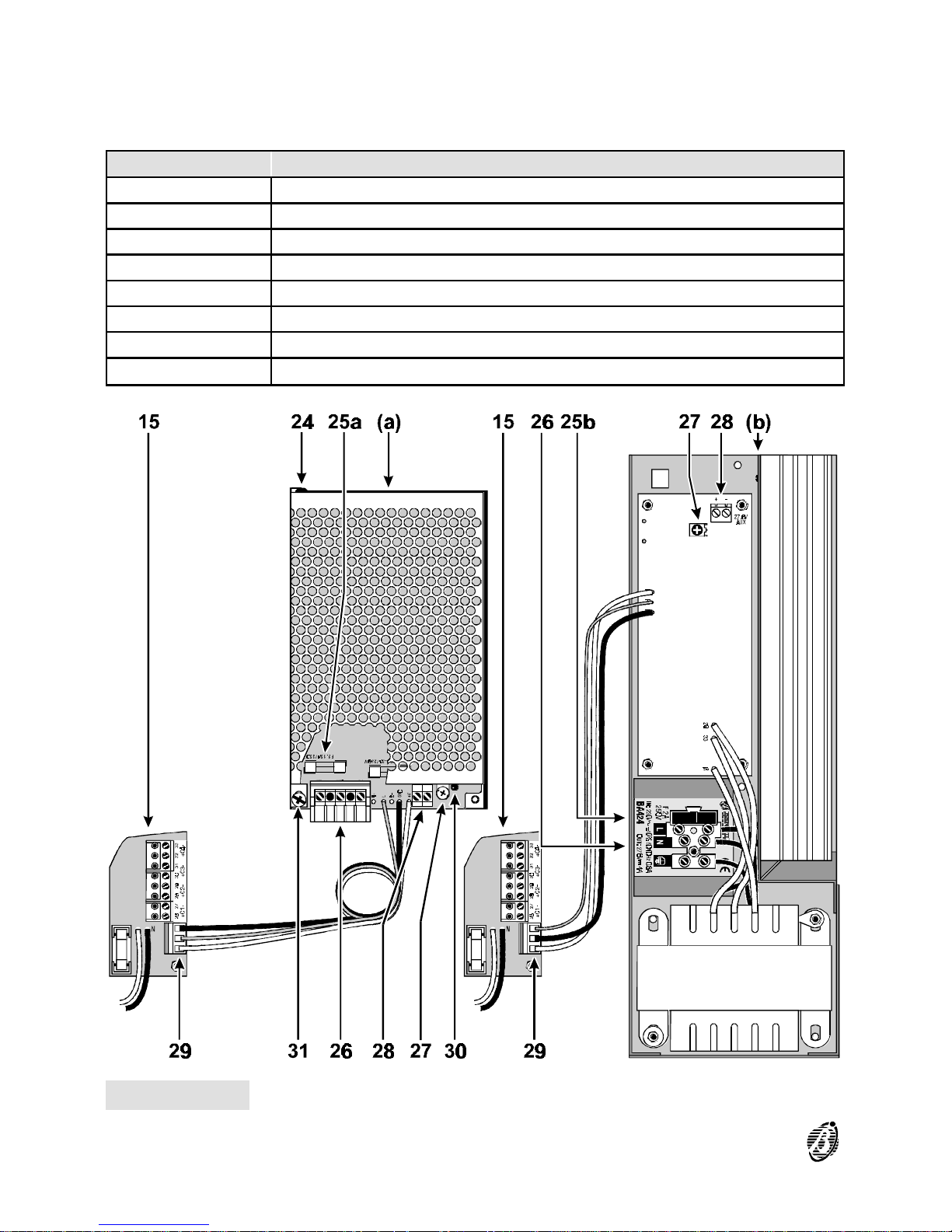

Power unit The FireClass200 is available in two models: FC200/S - with 27.6 V - 2.5 A

Switching power supply (see fig. 3a); FC200 - with 27.6 V - 4 A Linear

power supply (see fig. 3b).

PART DESCRIPTION

24 Rivet to secure switching power supply

25 Power supply protection fuse: a) F3.15A 250V; b) F 2A 250V

26 Terminal board for Mains power connection

27 Fine adjustment trimmer for output voltage

28 Power supply output for devices operating at 24 V (27.6 V)

29 Connector for power supply to the main board

30 Switching-power-supply output voltage signal

31 Screws to secure Switching power supply

Figure 4 Parts of the Power Supply Unit

16 Analogue Fire Control Panel FireClass200

PART DESCRIPTION

32 Connector for Keypad/Display

33 Connectors (2) FC200/6OUT Output expanders

34

Jumper to enable data storage:

> memory disabled (default)

> memory enabled

35 Microprocessor

36 Connector for FC200/COM Telecom module

37 Reserved jumper

38 Extractable terminal boards

39 EOL Resistor (2.700 ohm / red-purple-red-gold)

40 Power-supply connector

41 F 6.3A 250V protection fuse against battery polarity inversion

42 F 3.15A 250V protection fuse for +AUX output

43 F 3.15A 250V protection fuse for the power supply line of the RS458 bus

44 RS232 Serial Port

45 Loop interface connector

Figure 5 Main board parts

PARTS IDENTIFICATION 17

Output Expander (FC200/6OUT)

PART DESCRIPTION

46

Output status:

LED OFF > corresponding Output in standby status

LED ON > corresponding Output active

47

Address assignment jumper:

> Expander of Output no. 1 (Outputs no. 5 through no. 10)

> Expander of Output no. 2 (Outputs no. 11 through no. 16)

Loop Interface

PART DESCRIPTION

48 Loop 2 Status: polling (Red LED)

49 Loop 2 Status: response (Green LED)

50 Loop 1 Status: polling (Red LED)

51 Loop 1 Status: response (Green LED)

Figure 6 Parts of the FC200/6OUT Output Expander (a) and Loop Interface (b) and

Telecom module (c)

18 Analogue Fire Control Panel FireClass200

Telecom Module FC200/COM

PARTS DESCRIPTION

52 Main board connector

53 Microphone

54 Loudspeaker connector

55 Terminal board for telephone line connections

56 Screws for backplate

57

Earth cable with eyelet terminal ---- to be fixed to the screw on the

backplate, and connected to the earth terminal of the Telecom Module

58

Cable and connector for connecting the loudspeaker to the Telecom

Module

59

Plastic (ABS) gaskets to be used when mounting the loudspeaker to the

backplate

60 Loudspeaker

Figure 7 Parts of Telecom Module.

PARTS IDENTIFICATION 19

Repeater

PART DESCRIPTION

61

Wall mounting holes (3) for (∅ 5 mm)

62

Cable duct holes (2) for (∅ 30 mm)

63 Microprocessor

64 Address assignment switches

Figure 8 Repeater parts

20 Analogue Fire Control Panel FireClass200

INSTALLATION

ATTENTION Installation of the FireClass200 must be carried out in

strict accordance with the instructions herein and in compliance with

the local laws and bylaws in force.

Work carefully through the following steps (refer to the figures on pages 11

and 13).

Ø Plan the system layout.

Ø Lay the cables.

Ø Mount the control panel.

Ø Install add-on boards (if necessary).

Ø Complete the connections.

WARNING: DO NOT connect the Mains until all other wiring has been

completed.

Ø Program the control panel parameters.

Ø Test the system (detectors, signalling and ancillary devices).

Mounting the Control panel

When selecting the mounting location, ensure that:

Ø the Mains power, peripherals and the telephone line can be connected to

the control panel without difficulty;

Ø there is at least 20 cm space on all sides of the control panel to allow for

air flow.

Work carefully through the following steps.

1. Open the control panel door 1: pull the plastic bag 21 through the wire en-

try 22 (the control panel key is inside the plastic bag).

2. Remove the screws 6 and the control panel frontplate.

3. Lift the battery-housing door off its hinge 7 and open the door.

4. Drill the anchor screw holes 12 (use the backplate for the screw locations).

CAUTION Check for water pipes and cable conduits before drilling.

5. Pull the chased wires through the wire entry 22 and attach the control

panel to the wall.

INSTALLATION 21

6. Using a hammer, remove the knockout and pull the external wires through

the wire entry 11.

+

Use HB flame class (or higher) lock nuts to secure the cable conduit union to the box.

Installing Output expanders (FC200/6OUT)

Work carefully through the following steps (refer to the figures on pages 11

and 12).

1. Insert the Output Expander into the respective connector (33 or 34).

2. Using the screws and gaskets (supplied), secure the Output Expander in

place (use the longer screw for the lower part, and the two shorter screws

for the upper part).

3. Using the jumper 47, assign an address to the Output Expander (refer to

the following chart).

JUMPER

47

OUTPUT

EXPANDER No.

CORRESPONDING OUTPUT

C5/11 C6/12 C7/13 C8/14 C9/15 C10/16

1 05 06 07 08 09 10

2 11 12 13 14 15 16

+

You must assign a different address to each output expander.

Installing the Telecom Module (FC200/COM)

Work carefully through the following steps (refer to the figures on pages 17

and 18).

1. Insert the Telecom module into the respective connector 36.

2. Using the screws and gaskets (supplied), secure the Telecom module in

place (use the longer screw and gasket for the lower part, and the two

shorter screws for the upper part).

Installing Repeater Panels (FC200/REP)

Work carefully through the following steps (refer to the figure on page 13).

1. Drill the anchor screw holes 52 (use the backplate for the screw locations).

2. Pull the wires through the wire entry 53 then attach the repeater panel to

the wall.

3. Complete the connections on the terminal board 38.

22 Analogue Fire Control Panel FireClass200

4. Using the microswitches 55, assign an address to the repeater panel (refer

to the following chart).

MICROSWITCH No.

ADDRESS No. 1 2 3 4

1 OFF OFF OFF OFF

2 ON OFF OFF OFF

3 OFF ON OFF OFF

4 ON ON OFF OFF

5 OFF OFF ON OFF

6 ON OFF ON OFF

7 OFF ON ON OFF

8 ON ON ON OFF

+

You must assign a different address to each repeater panel.

Completing the Connections

+

Use a shielded cable ---- connect one end to the control panel ground and

leave the other floating.

CAUTION Separate the low voltage wires (24V) from the high voltage

wires and make two wire bunches. This will prevent stray wires from

coming into contact with other wires and/or components.

Main board terminals

[L1B] Loop 1 communication IN.

[L1A] Loop 1 communication OUT.

[L2B] Loop 2 communication IN.

[L2A] Loop 2 communication OUT.

+

Each loop supports 99 analogue detectors and 99 analogue devices (Input

modules, Conventional Zone modules, Manual callpoints, Output modules

and Sounders).

[LC] Conventional Input Line - Supervised and Silenceable ---- This line sup-

ports 30 conventional fire devices (RF501t Optic Smoke detectors, RT

101/102 Heat detectors, Manual callpoints, Gas detectors----maximum 3).

Connect terminal 10[+] to ground (terminal 9[ ]) using a 2,700 ohm resistor

(red-purple-red-gold). A 680 ohm resistance (normal value for Fire detectors)

parallel to the 2,700 ohm resistor will activate the programmed actions and

preset times of the Conventional Line outputs and the Non-supervised output

(terminals CM1, NC1 and NO1).

INSTALLATION 23

+

The Conventional Line supports 30 Conventional detectors.

WARNING Do not connect more than 512 devices to the control panel.

[EX] Reserved Output.

[485] Serial Bus ---- Terminals for FC200/REP repeater panels (maximum 8)

and FireClass200 Slave panels (maximum 7).

Serial bus terminals ---- 15[+] and 16[-];

27.6 V power voltage terminals ---- 14[ ] and 17[+].

[AUX] Aancilliary power 24 V ---- Power supply to devices that operate at 24 V

(protected by fuse 42 and powered by the standby batteries):

Ø Positive (27.6 V) on terminal 19[+];

Ø Ground on terminal [ ].

[CM1]

[NC1]

[NO1]

Non-supervised fault output ---- Dry contact relay for non-supervised devices:

Ø During standby status ---- terminal 20[CM1] closes to terminal 21[NC1];

Ø In the event of fault ---- terminal 20[CM1] closes to terminal 22[NO1].

+

Blackout events (mains and battery supply failure) will activate the Non-supervised fault output.

[CM2]

[NC2]

[NO2]

Non-supervised fire output ---- Dry contact relay for non-supervised devices:

Ø During standby status ---- terminal 23[CM2] closes to terminal 24[NC2];

Ø In the event of fire ---- terminal 23[CM2] closes to terminal 25[NO2].

[C] Type C output - Supervised ---- Terminals for supervised devices acti-

vated by positive (24 V):

Ø During ALARM status ---- positive (27.6 V) on terminal [+]; ground on terminal [-].

Ø This output can be bypassed via the DISABLE menu.

+

ALARM status will activate this non-programmable output.

[C2] [C3] [C4] Positive outputs - Programmable - Supervised ---- Terminals for super-

vised devices activated by positive (24 V):

Ø Output active ---- positive (27.6 V) on terminal [+]; ground on terminal [--].

Ø These outputs can be bypassed via the DISABLE menu.

Connect an EOL 2,700 ohm resistor (red-purple-red-gold) to terminals [+]

and [--] of these outputs. This will allow the control panel to detect and signal when the outputs are shorted and/or open.

NOTE: The EOL resistor must be connected to the last device on the Su-

pervised output.

Connect a diode (1N4002 or 1N4007) in series to the devices connected to

these outputs.

24 Analogue Fire Control Panel FireClass200

+

All the [+] terminals of the Supervised outputs must be closed to the [--] terminal of the same output. For for example, the connection on terminal

26[+] must close only to terminal 27[--].

[REM] Logic Unit Blocked ---- Output for remote signalling of the Logic Unit

Blocked fault:

Ø During Blocked fault ---- positive (27.6 V) on terminal 34[REM].

+

An external power supply must be used to supply the devices connected to

the REM output.

[DEF] Default programming ---- This output will indicate when the control panel

is operating with default programming values:

Ø Default programming values ---- Negative on terminal 35[DEF] (if the

control panel is operating with default programming).

[OC1] ... [O16] Bypassable Zone Alarm outputs ---- These are normally-open terminals

(open-collector) which close to ground when the corresponding zones go into

alarm status. These terminals will remain closed to ground even after the generating event has ended. These are non-supervised/non-silenceable outputs

which can be forced to standby by bypassing the zone concerned or rearming

the control panel.

These terminals can be used for selective fire-prevention operations (closure of fire-barrier doors; activation of localized extinguishment systems).

+

The Zone Alarm outputs will not activate if their associated zones are

disabled, however, they will activate as soon as their associated

zones are enabled.

INSTALLATION 25

Connectiing Addressable Analogue Devices

The control panel has 2 loops for addressable analogue devices.

WARNING Do not break off the Output module tab.

Each loop supports 99 addressable analogue fire detectors and 99 analogue devices (Input modules, Conventional Zone modules, Output modules, Manual callpoints and Sounders).

Devices of the same type cannot have the same address, therefore, you

must assign a DIFFERENT address to each detector on the loop, and likewise for the modules.

+

Different device types (e.g. Fire detector and module) can have the same

address.

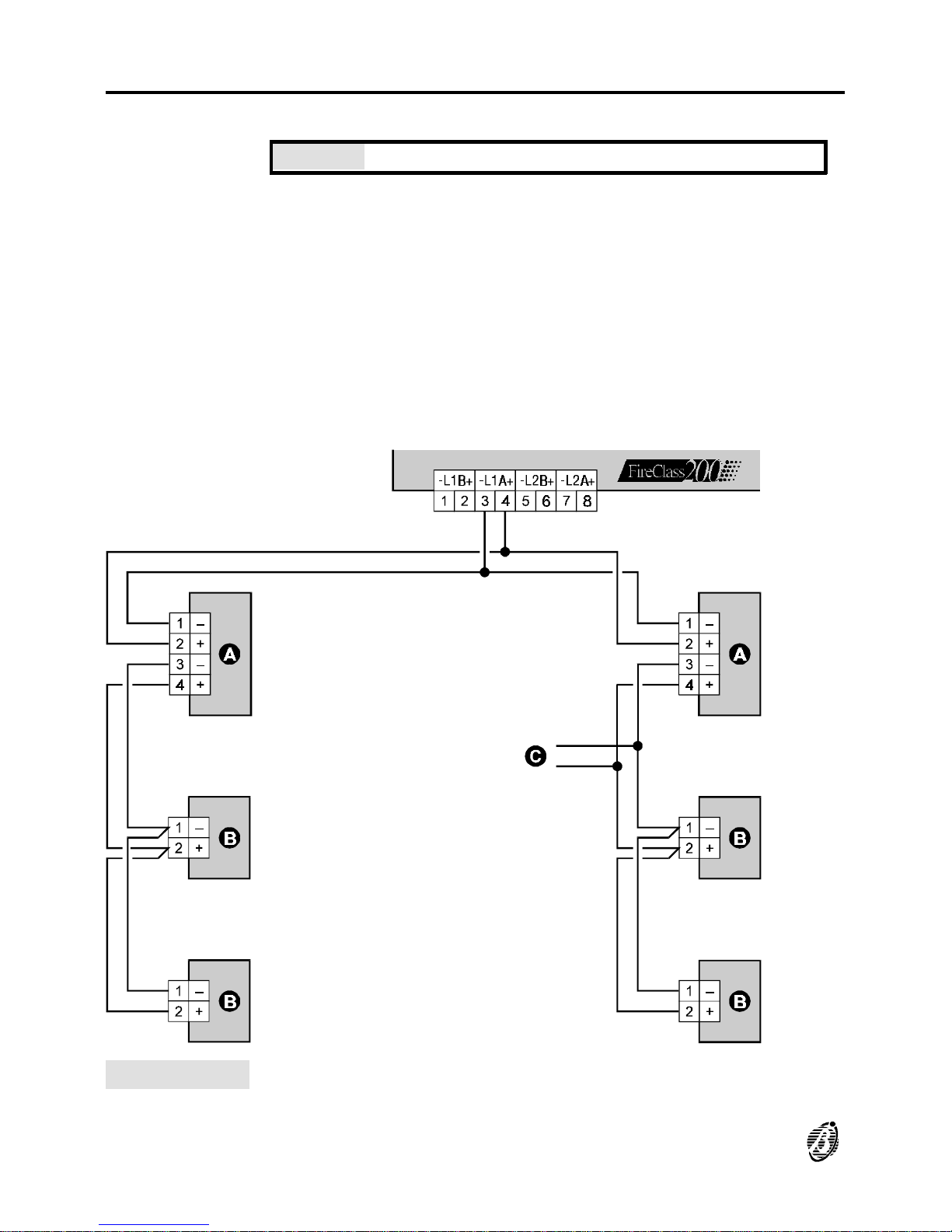

Figure 9 Wiring diagram of a 2 wire connection: a) Insulators; b) Compatible ana-

logue devices (Fire detector, Input modules, Output modules, Conventional

Zone modules, Manual callpoints); c) T connection.

26 Analogue Fire Control Panel FireClass200

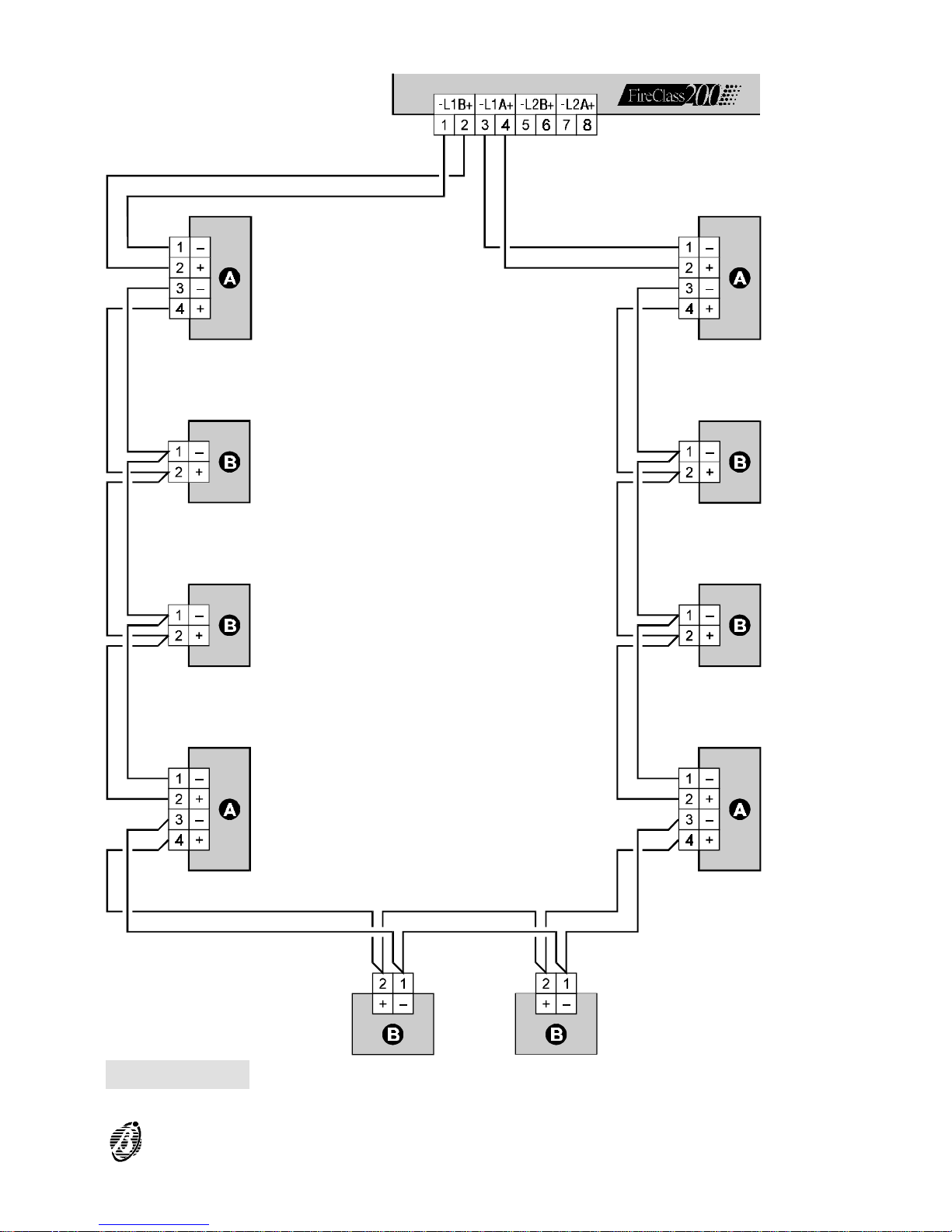

Figure 10 Wiring diagram of a 4 wire connection: a) Insulators; b) Compatible ana-

logue devices (Fire detectors, Input modules, Output modules, Conventional

Zone modules, Manual callpoints).

INSTALLATION 27

You can use 2 or 4 wires for the loop connections.

NOTE: The loop connection type must be specified during the programming phase.

Figure 9 illustrates the 2 wire connection to Loop 1.

Figure 10 illustrates the 4 wire connection to Loop 1.

+

The 2 wire connection does not permit more than 32 detectors per loop.

+

The 4 wire connection does not permit T connections.

Connecting Conventional Devices

Connect Conventional devices to terminals 9[ ] and 10[LC+].

Fire detectors Connect the Conventional Fire detectors in parallel to terminals [LC+] and

[ ]. The resistor (2,700 ohm) connected to these terminals must be

moved to the terminals indicated in the instructions of the last device on

the Conventional Line (see fig. 10a).

Manual

callpoints

Connect the Common (C) and the Normally Open (NO) terminals of the

Manual callpoint in parallel to terminals [LC+] and [ ]. When pressed, the

callpoint must not be shorted but must have a 680 ohm resistance. If

the callpoint does not have a 680 ohm resistor, connect one externally. If

the manual callpoint is the last device on the Conventional Line, the EOL

resistor must be connected as per figure 10a.

NOTE: Conventional devices can be connected to the loops by means of

Conventional Zone modules.

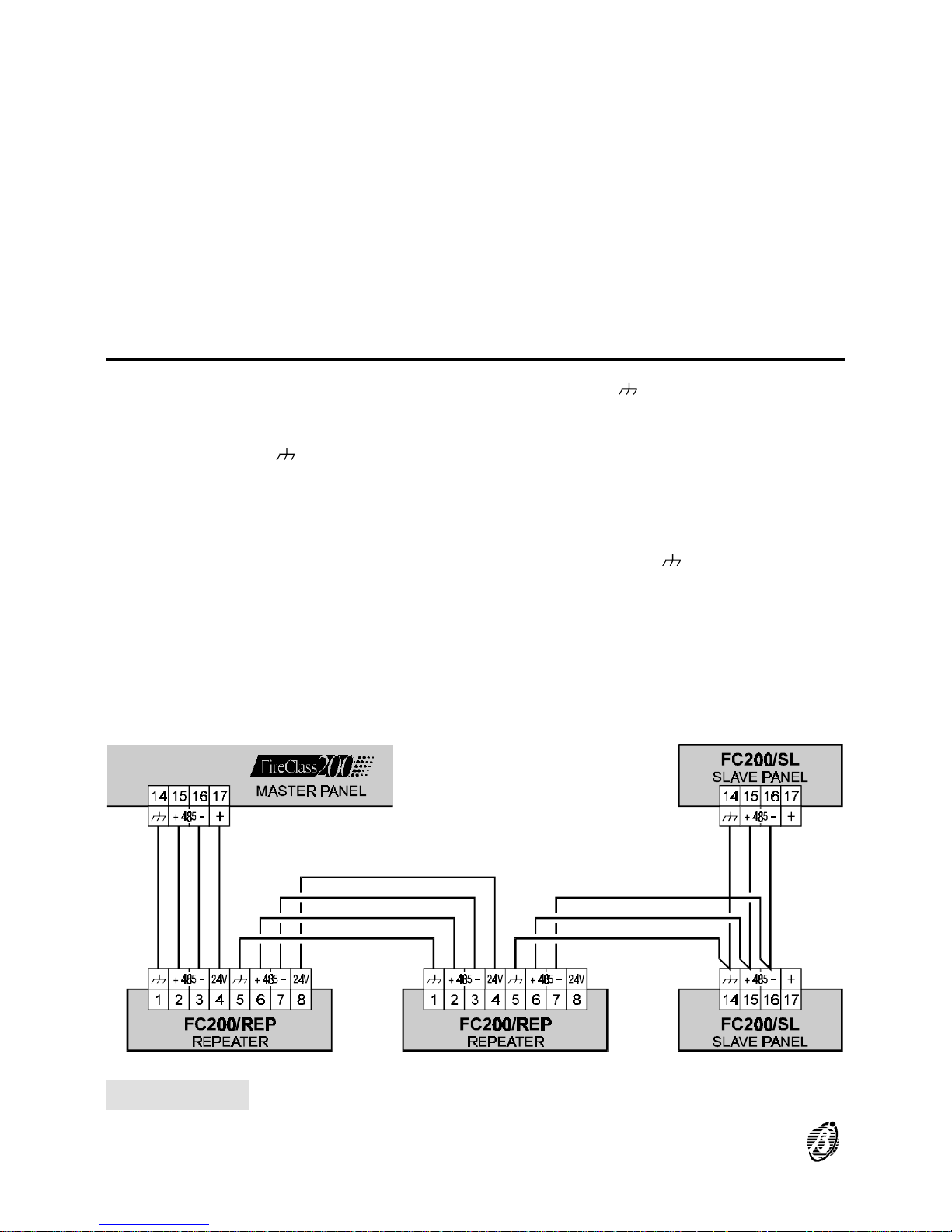

Figure 11 Wiring diagram of Repeater and Slave Panels connected to the RS485 network

28 Analogue Fire Control Panel FireClass200

Connecting Repeaters and Slave Panels

The RS485 port of the FireClass200 (terminals 15[+485] and 16[--485]) accepts up to 8 FC200/REP repeater panels and 7 FC200/SL slave panels.

Terminals 17[+] and 14[ ] supply the power (27.6 V) to the repeater panels.

The FireClass200 must be programmed as Master, otherwise, it will be unable to communicate with the system repeater panels and/or slave panels.

Assigning addresses

Using the Network option from the System Menu, assign a different address to each slave panel

Figure 12 Wiring diagram of Conventional device connections

INSTALLATION 29

Connecting Output Devices

The control panel has 2 Non-supervised outputs, 4 Bell outputs (supervised) and 8 Alarm Repeat outputs (one for each Software zone).

The control panel can manage two FC200/6OUT Output Expanders (accessory items) which provide 6 Bell outputs each.

NOTE: Output devices can be connected to the loops by means of Output

modules.

Bell Outputs

The Bell outputs are indicated by the letter "C" and their address number.

You can fully customize the activation modes and times of the Bell outputs.

+

The address of the Output-Expander Bell outputs depends on the OutputExpander address.

+

The terminal marked "C" is a Type C Output and not a Bell output.

The Type C Output is a Non-programmable, Supervised output.

The Bell outputs can be forced to standby status by means of the SILENCE button. Once an alarm has been acknowledged, you can silence

the audible signalling devices and leave the visual signalling devices active

until the alarm conditions cease.

For example, a connection similar to the wiring diagram in figure 14 will activate the Flasher, the Bell and the visual and audible signalling device of

the Self-powered Siren in the event of an alarm.

Using the SILENCE button will stop the horn but not the flasher, which will

continue to signal Alarm status until the RESET button is pressed.

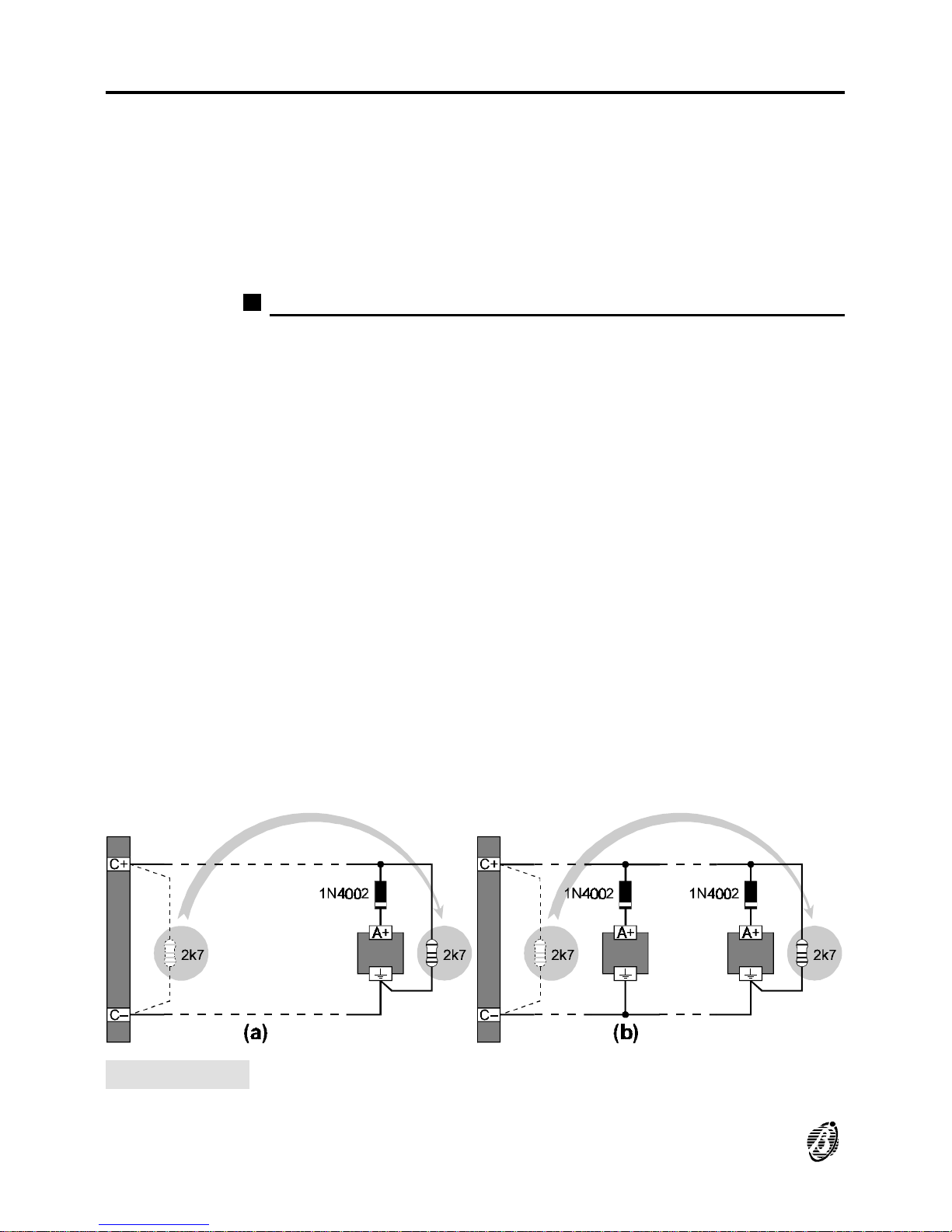

Figure 13 Wiring diagram of the connection of a single device (a) and several devices

(b) to Bell outputs (device activated by positive (27.6 V) on terminal [A+]).

30 Analogue Fire Control Panel FireClass200

Loading...

Loading...