Page 1

Release 1.2

Service Manual

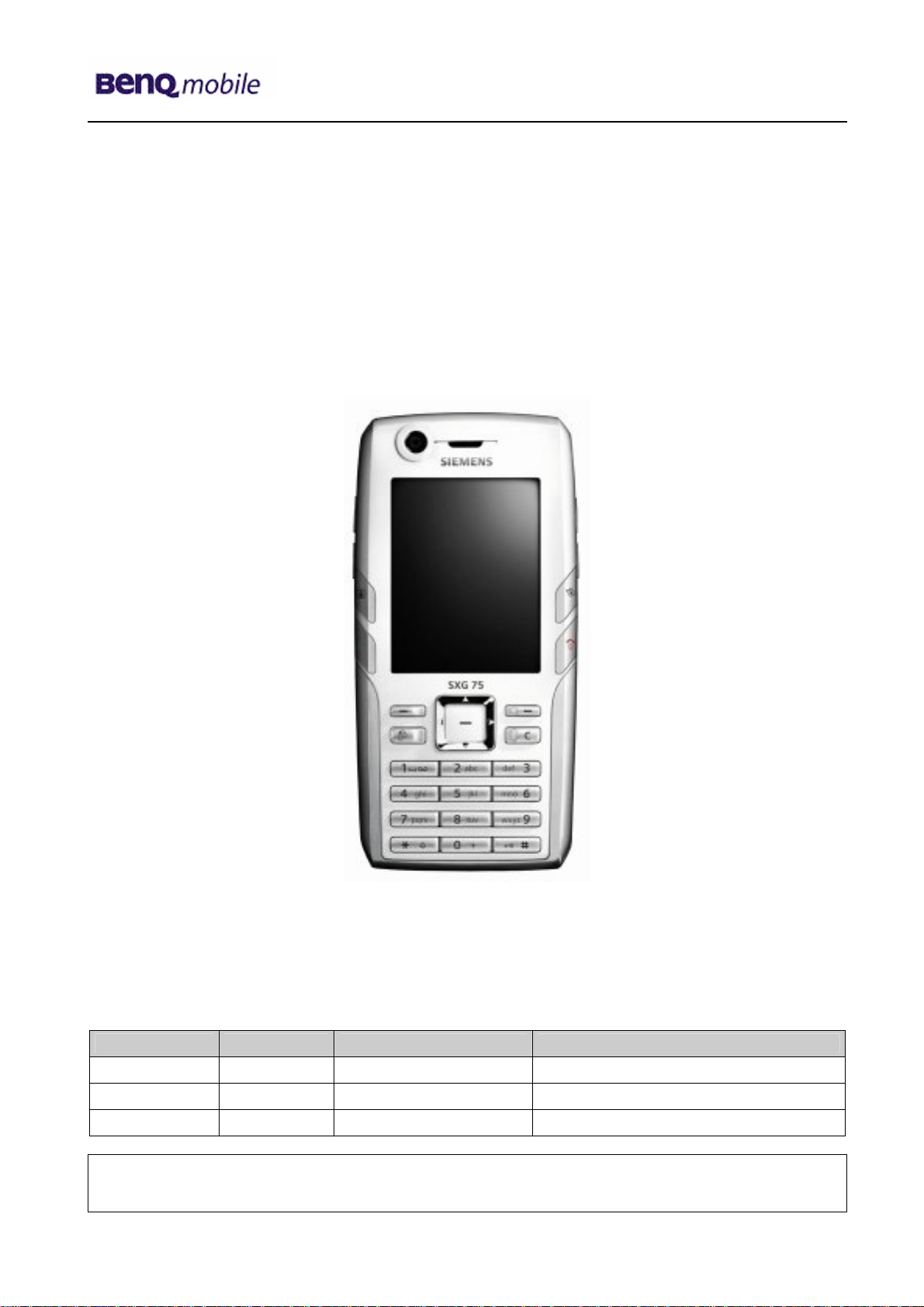

SXG 75

Level 1 - 3

Release Date Department Notes to change

R 1.0 29.11.2005 BenQ Mobile CC S CES New document

R 1.1 22.02.2006 BenQ Mobile CC S CES SWU Process modified

R 1.2 24.05.2006 BenQ Mobile CC S CES Chapter 5 Step 4-5 modified

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 1 of 60

Company Confidential

2006©BenQ

05/2006

Page 2

Release 1.2

Table of Content

1 Key Features..............................................................................................................................3

2 SXG75 Interface to Accessories ..............................................................................................5

3 Unit Description of SXG75........................................................................................................6

4 Exploded View of SXG75..........................................................................................................7

5 Disassembly of SXG75 .............................................................................................................8

6 Assembly of SXG75 ................................................................................................................18

7 BenQ Service Equipment User Manual.................................................................................27

8 GRT Software: Functionality Configuration........................................................................28

9 GRT Software: Regular Usage ...............................................................................................30

10 JPICS (Java based Product Information Controlling System)............................................35

11 International Mobile Equipment Identity, IMEI......................................................................41

12 General Testing Information...................................................................................................42

13 Introduction of Service Repair Documentation Level 3 – SXG75....................................49

14 List of available level 3 (basic) parts.....................................................................................50

15 Hardware requirements ..........................................................................................................50

16 SXG75 Board layout................................................................................................................51

17 SIM Card Problems .................................................................................................................52

18 IO Connector Problems ..........................................................................................................53

19 B to B connector Problems....................................................................................................55

20 Battery Connector Problems.................................................................................................. 56

21 Camera Connector Problems.................................................................................................57

22 IRDA Problems ........................................................................................................................58

23 Display Problems ....................................................................................................................59

24 MMC Connector Problems......................................................................................................60

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 2 of 60

Company Confidential

2006©BenQ

05/2006

Page 3

Release 1.2

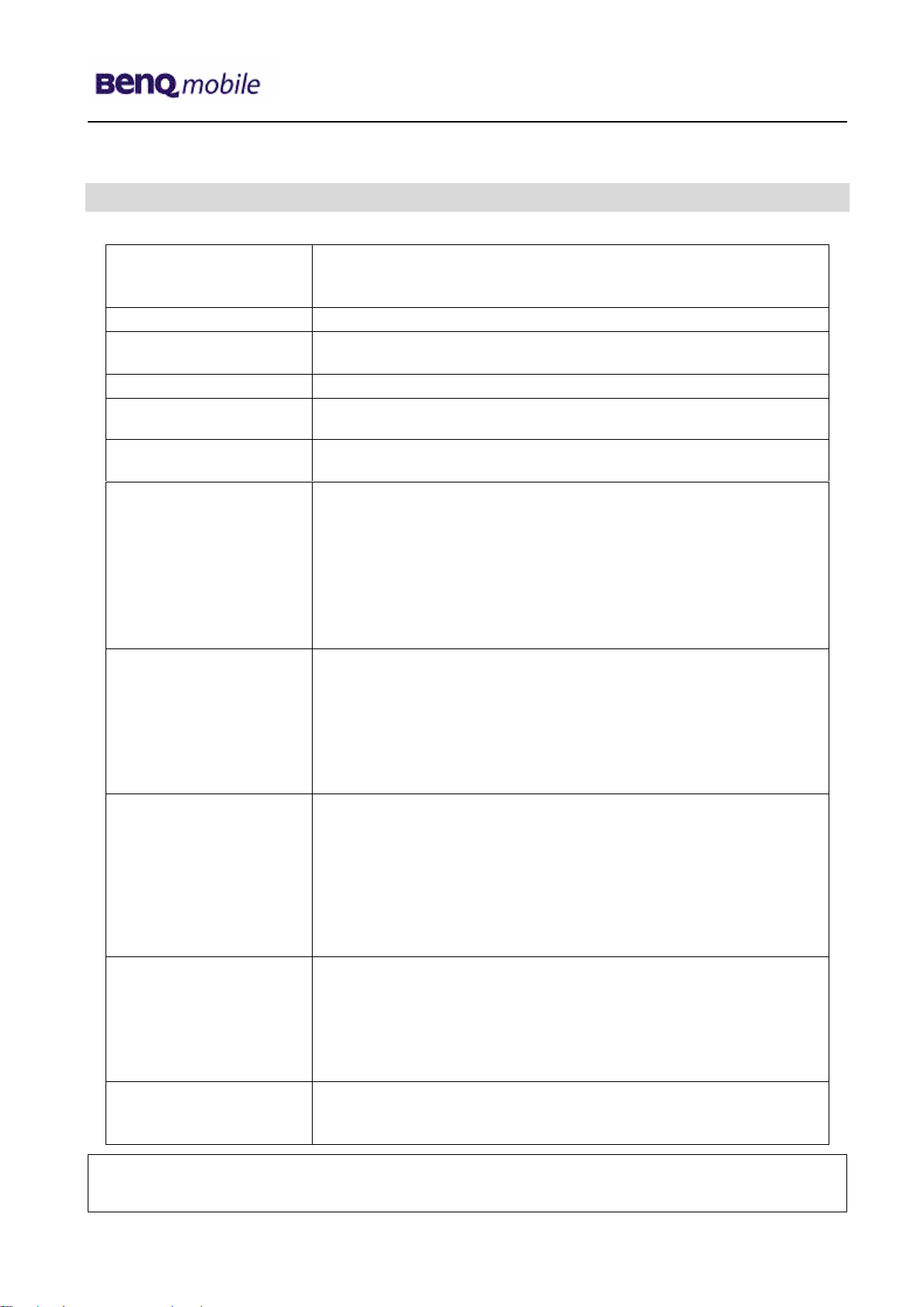

1 Key Features

Battery

Stand – by Time

Talk Time

SIM Card

Speech Coder

Temperature Range

Display

3x4 Block Keypad

Function block with

Operator key

Edge Keys

Side keys

• Li – Ion Battery Pack

• Nominal Capacity: 1000 mAh

• GSM Capacity: 980 mAh

• Up to 420h

• GSM: Up to 3,6hr

• WCDMA: Up to 3,1hr

• Small (“Plug In”) 1,8 V or 3 V -SIM card (Phase II)

• Half Rate, Full Rate, Enhanced Full Rate and Adaptive

Multi Rate speech coders are available as standard

• -10°C to + 55°C (Normal operation)

• -30°C to + 85°C (Storage capability)

• Type: Full graphic

• Resolution: 240 x 320 Pixel

• Technology: TFT (Epson)

• No of colours: 256k

• Frame Rate: 15 frames/sec

• Pixel size / mm: 0.141 mm x 0.141 mm

• Active area / mm: 33,84 mm x 45.12 mm

• Illumination: White (4LEDs in series integrated)

• Front side decorated

• Partly bridgeless keypad (i.e. horizontally bridgeless)

• 12 – key – block (o-9,#,*)

• tactile finder on key “5”

• colour adapted to u-shaped aluminium brushed sheet

metal piece

• Four blue LED’s for keypad

• Five – way Navikey

• Chrome plated navi key ring with center push button,

operator logo can be printed on the button which is clipped

on the navi key.

• Four keys, functions: Back, Web access, Left & right soft

key

• All keys except navi have front side decoration

• Four blue LED’s for Navikey

• ON/OFF key combined with the END key; the symbol ¢ (I

inside O) is used as a symbol for ON/OFF.

• Viedeo telephony key

• Task key

• Two LED’s for edge keys, one red, one green

• Front side decorated

• No illumination

• Three side keys, functions: PoC, Volume, Camera

• Side keys galvanized

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 3 of 60

Company Confidential

2006©BenQ

05/2006

Page 4

Release 1.2

Acoustics

Antenna

Receiver

Sensitivity

Transmitter Power

• Combined handsfree/ringer speaker at rear side of phone,

next to camera

• Dedicated ear piece speaker, allowing small dimensions

as not needed as handfree speaker

• Uni - directional microphone

• Poliphonic ringer tones (parallel to GPRS data transfer: 16

voices; all other Use Cases: 40 voices)

• Hands free mode

• Different selectable volume levels for handsfree, handset

and ringer mode (for the amount see SW product

description)

• Integrated Quad band antenna

• Compliant with 3GPP specification TS34.121, Rel.99

• Compliant with 3GPP specification TS34.121, Rel.99

The transmitter output power is compliant to following

Power classes:

UMTS: nominal 0,25W -> power class 4

GSM 900: nominal 2W -> power class 4

GSM 1800/GSM 1900: nominal 1W -> power class 1

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 4 of 60

Company Confidential

2006©BenQ

05/2006

Page 5

Release 1.2

2 SXG75 Interface to Accessories

The phone has the following compatible interfaces to accessories:

- electrically by the Lumberg I/O connector (Lumberg slim)

- antenna connection by courtesy of RF connector

- IR and Bluetooth interface is implemented

- Slot wit reader for additional reduced size MultiMediaCard (exchangeable) is

available

- car holder interface is implemented

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 5 of 60

Company Confidential

2006©BenQ

05/2006

Page 6

Release 1.2

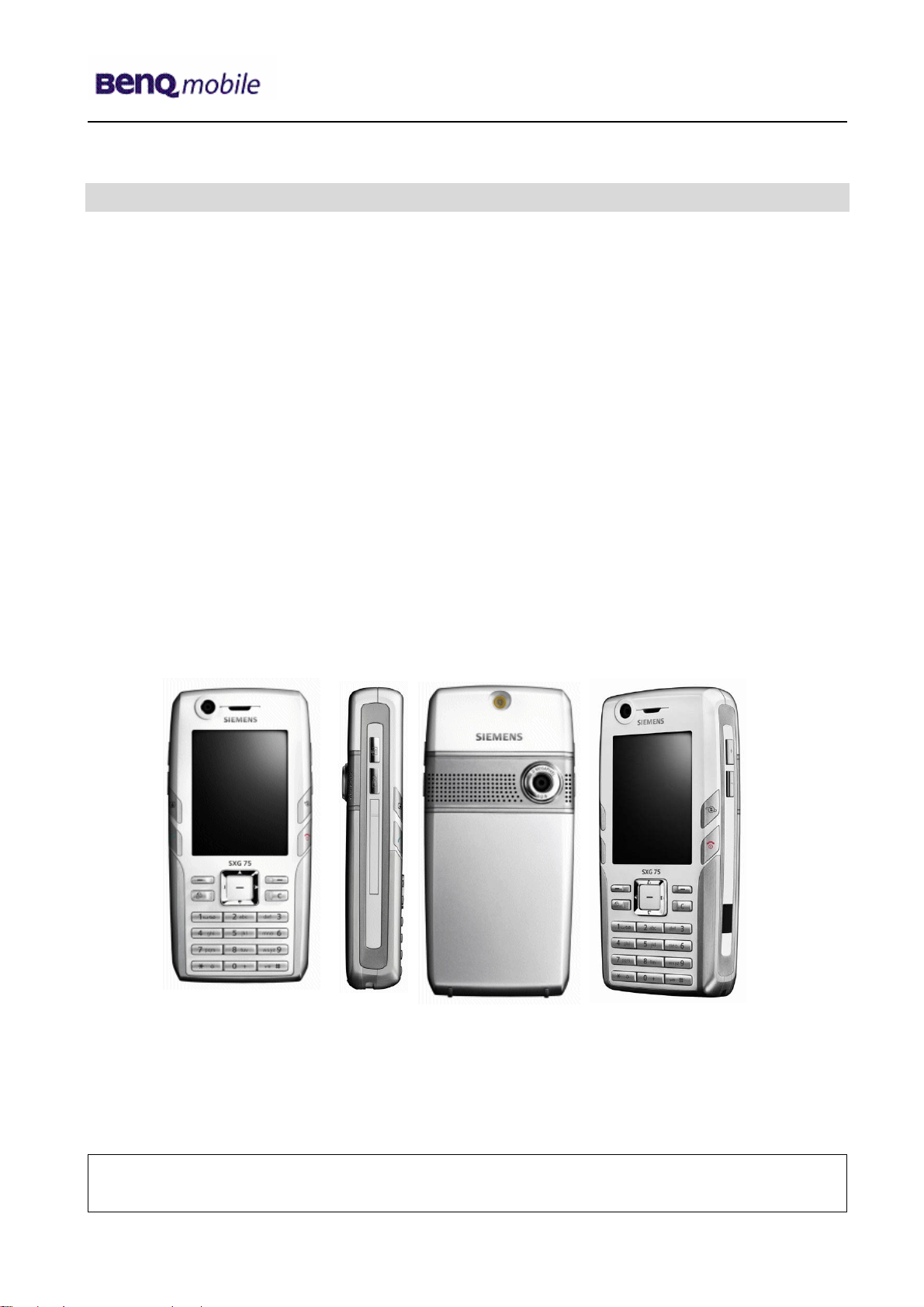

3 Unit Description of SXG75

The SXG75 is a brick phone with 2 integrated cameras for video telephony and photo

applications. The phone has two different acoustic modules one for receiver mode on the

topside and one for sound ringer and hands free mode with separate hole on the bottom

side. Additional speciality is a slot for exchangeable RS MultiMediaCard at the side of the

phone.

The keypad is new for a Siemens brick phone and has beside the usual navigation and

number key block beneath the display and the 2 side keys on both side surfaces further 4

edge keys (2 on each side) beside the LCD module for extended UMTS related

functionality. Special design element on the rear side is a prominent area with a grid of

holes for the loudspeaker.

There will be one colour variant, white/silver.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 6 of 60

Company Confidential

2006©BenQ

05/2006

Page 7

Release 1.2

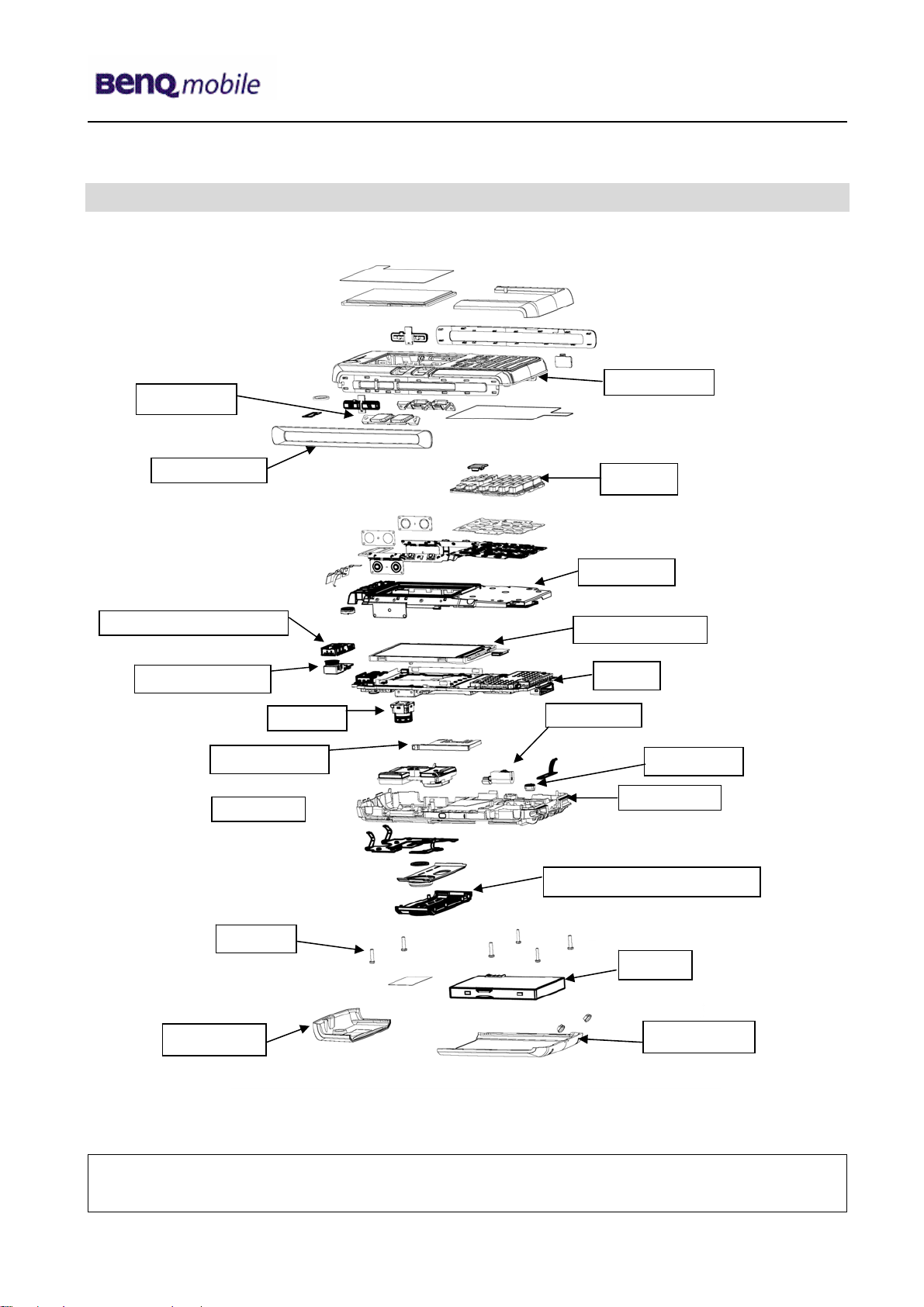

4 Exploded View of SXG75

Side - Keys

-

UMTS - Camera

MMC - Holder

Disassembled Camera Cover

Screws

Rear Cover

Upper Case

Keypad

Flexible PCB

Display - Module

PCB

Microphone

Battery

Battery Cover

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 7 of 60

Company Confidential

2006©BenQ

Page 8

Release 1.2

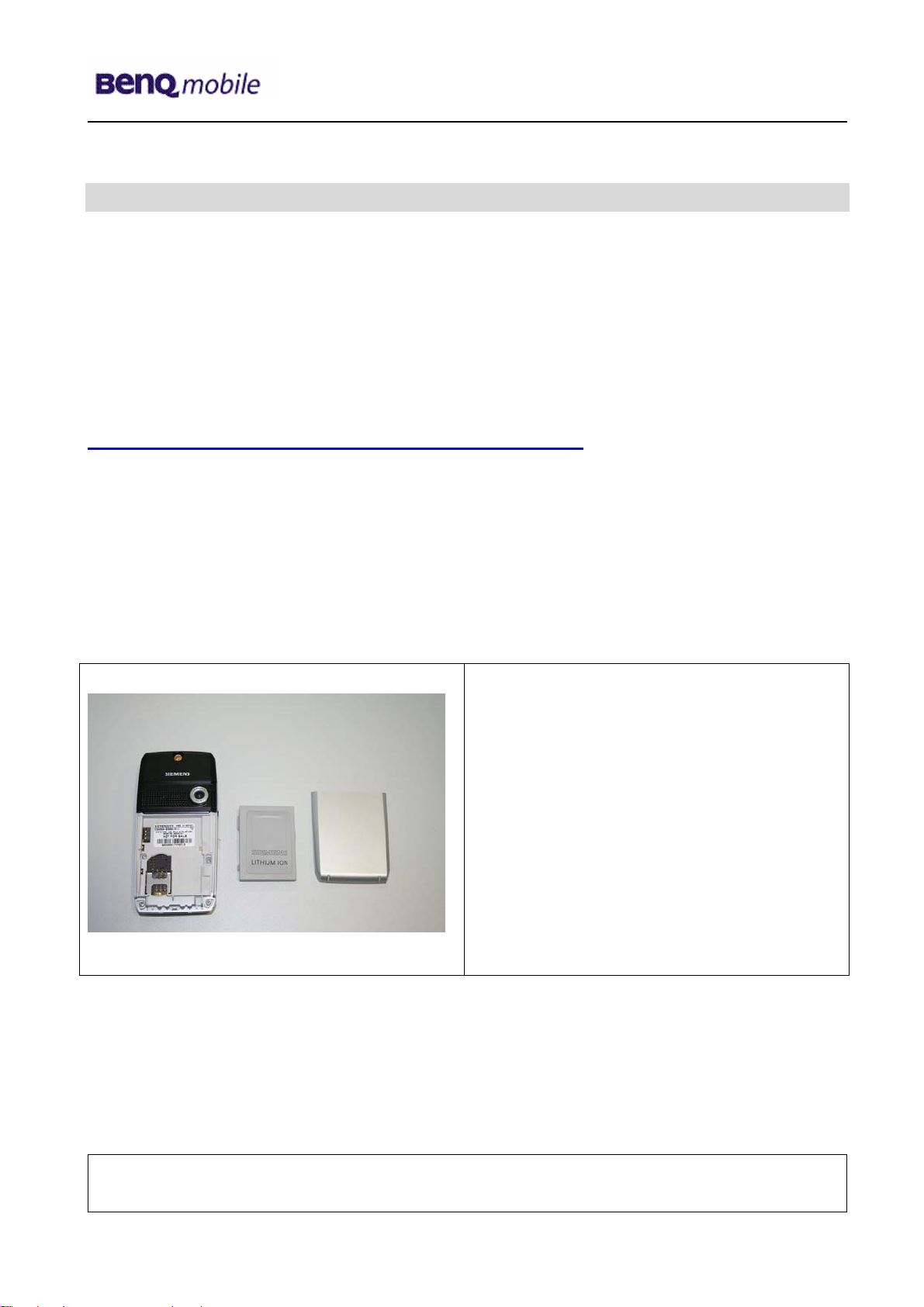

5 Disassembly of SXG75

All repairs as well as disassembling and assembling have to be carried out in an ESD

protected environment and with ESD protected equipment/tools. For all activities the

international ESD regulations have to be considered.

For more details please check information in c – market

https://market.benqmobile.com/SO/welcome.lookup.asp

There you can find the document “ESD Guideline”.

Step 1

Remove Battery Cover and Battery.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 8 of 60

Company Confidential

2006©BenQ

05/2006

Page 9

Release 1.2

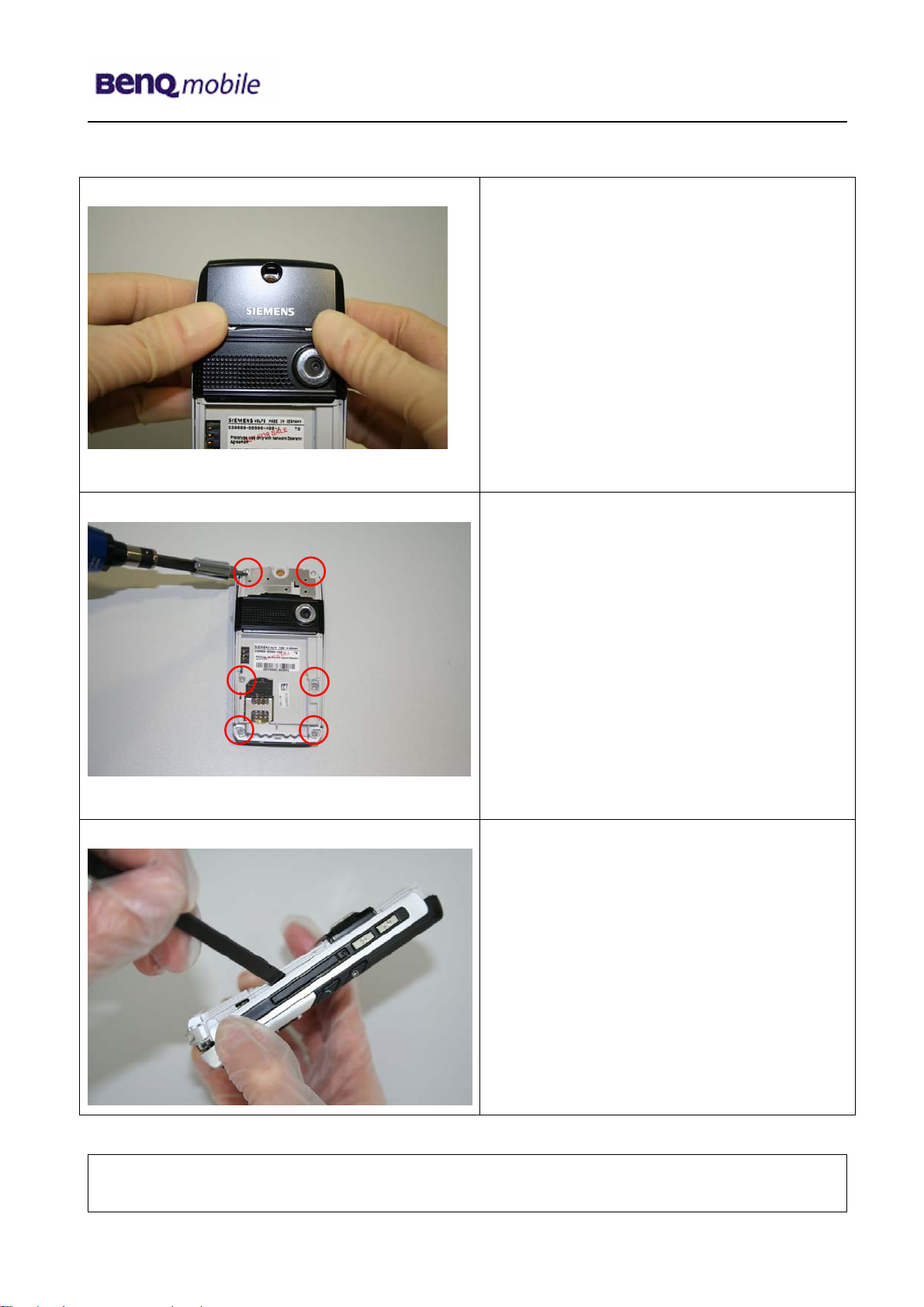

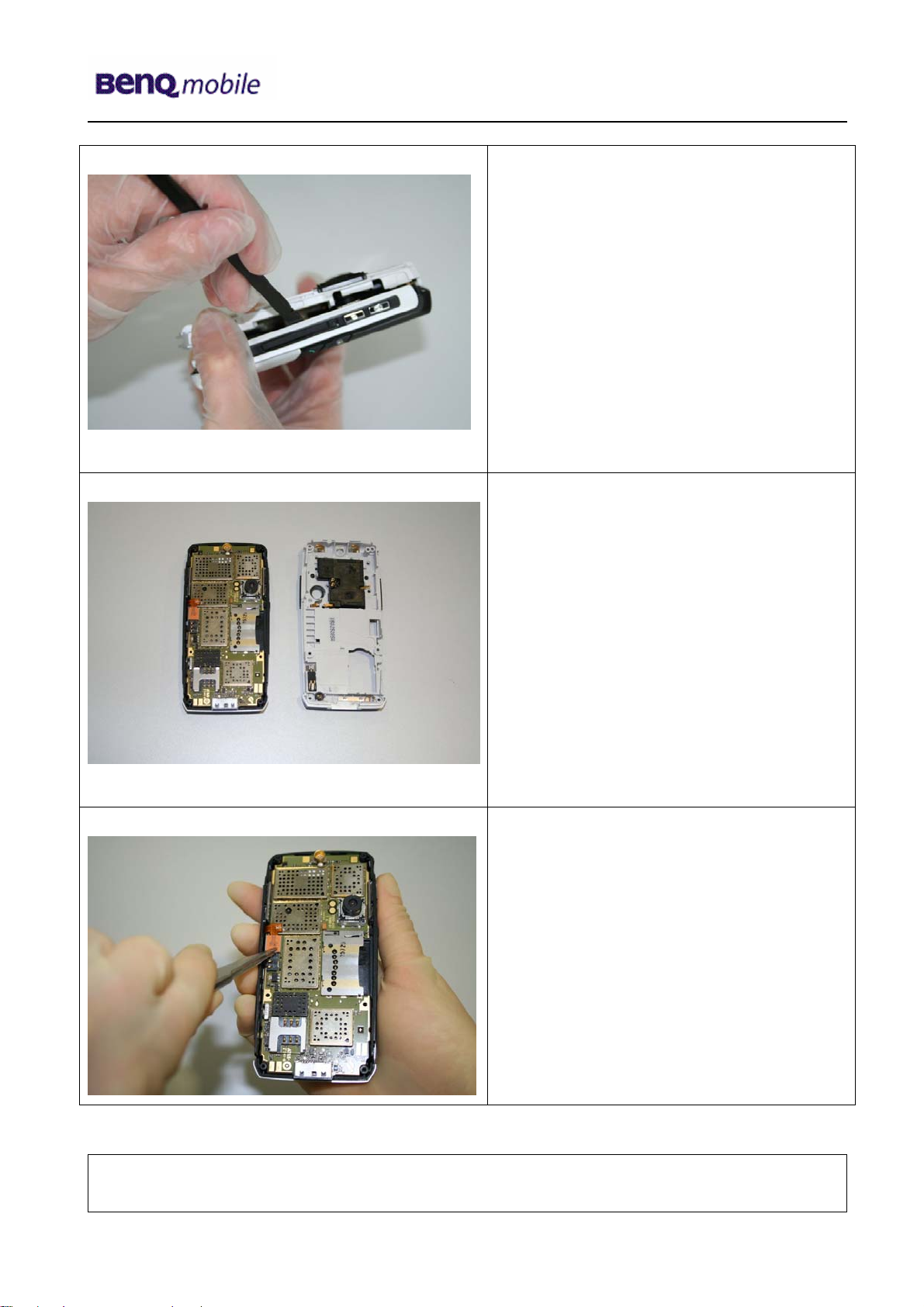

Step 2

Step 3

Remove Rear Cover by pushing it with

both thumbs forwards.

Remove screws with Torque - Screwdriver.

Screws size: T5+

Step 4

Remove Upper Case by using Alternative

Opening Tool carefully.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 9 of 60

Company Confidential

2006©BenQ

05/2006

Page 10

Release 1.2

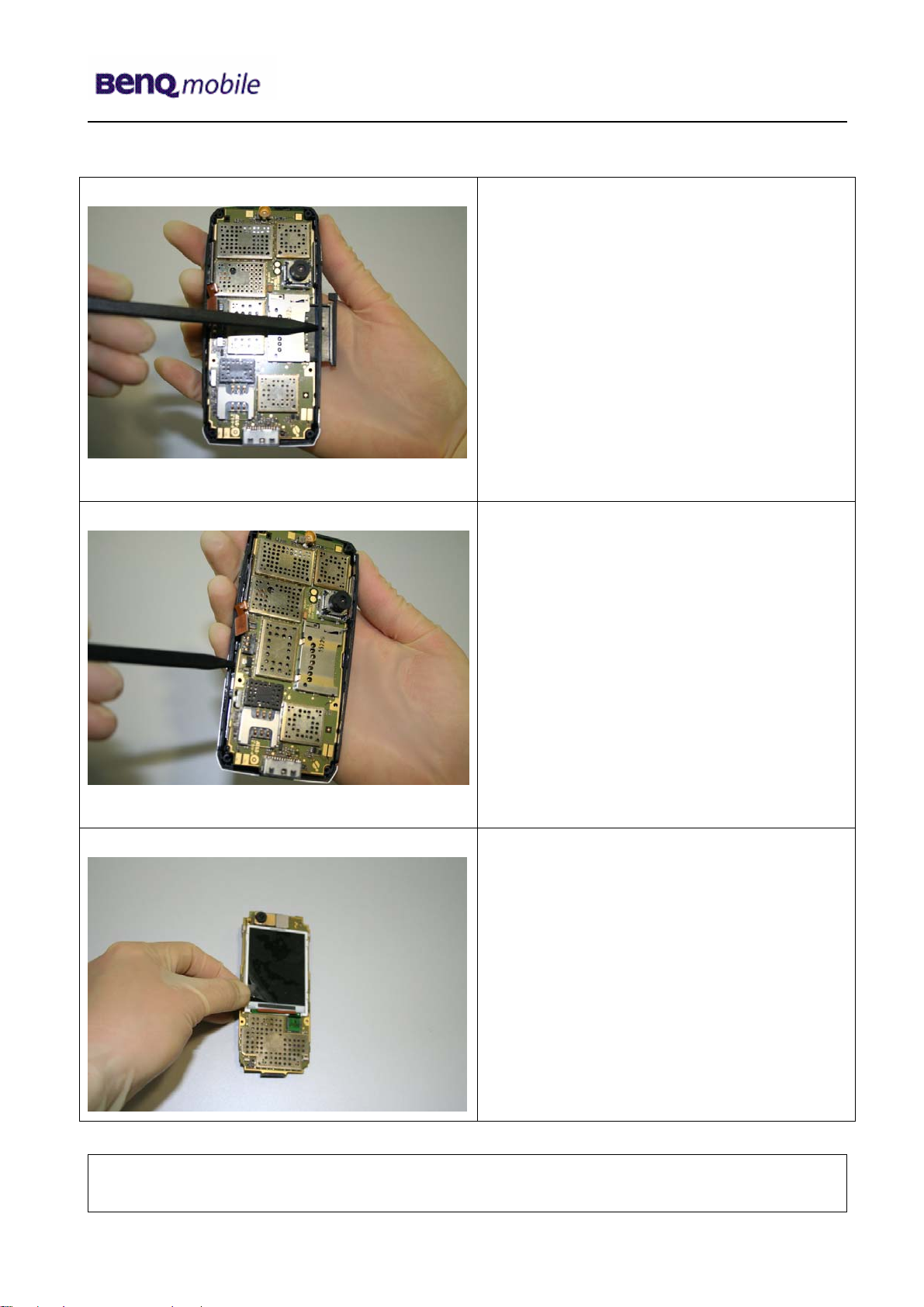

Step 5

Step 6

Step 7

Disconnect Flex Cable from PCB by using

Tweezers carefully.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 10 of 60

Company Confidential

2006©BenQ

05/2006

Page 11

Release 1.2

Step 8

Step 9

Remove MMC Holder by pushing it with

Alternative Opening Tool outside the frame.

Use Alternative Opening Tool to remove

PCB from Lower Case carefully.

Step 10

To avoid scratches it is mandatory to place

a Protection Foil onto the Display.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 11 of 60

Company Confidential

2006©BenQ

05/2006

Page 12

Release 1.2

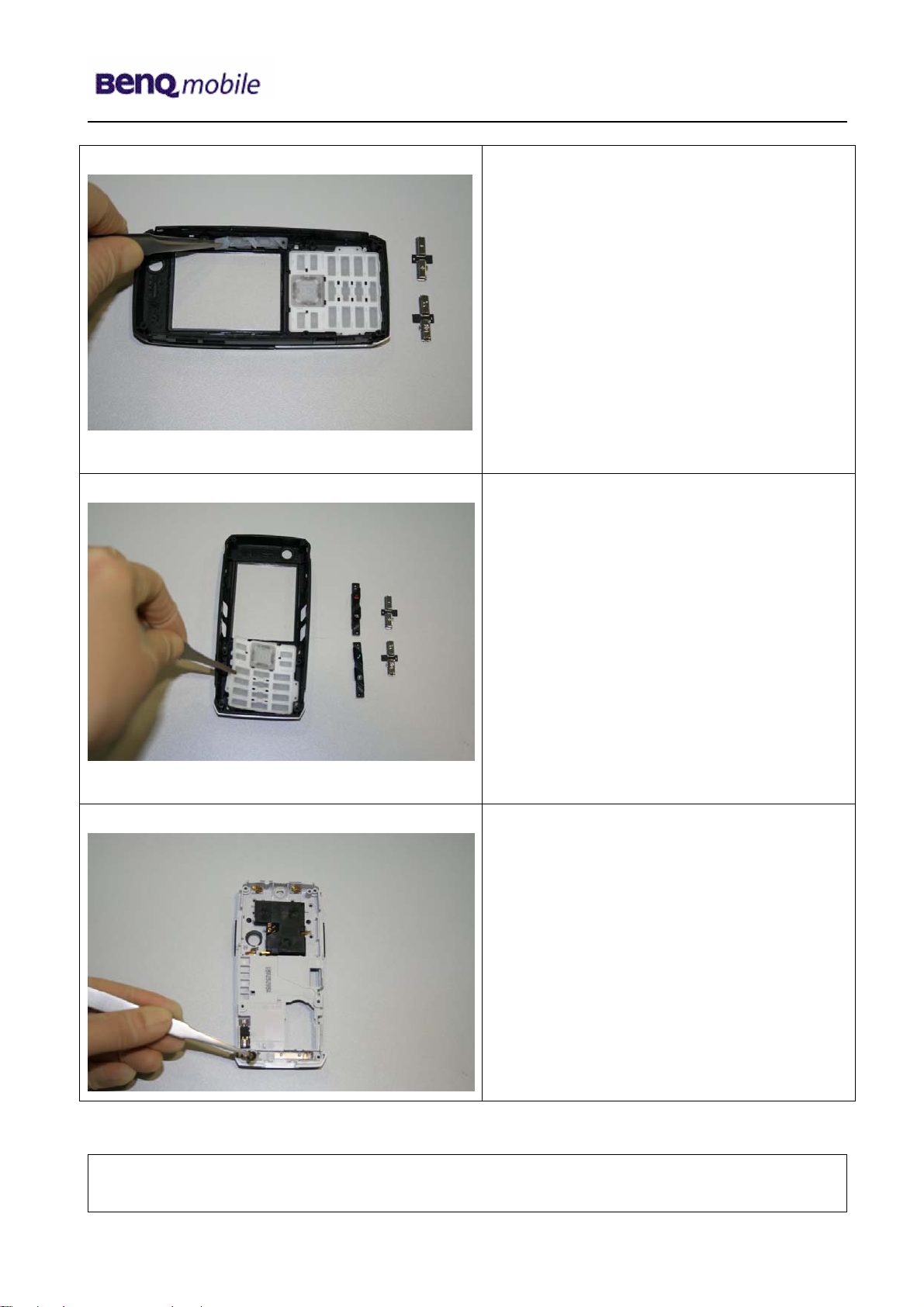

Step 11

Step 12

Remove Flexible PCB with Alternative

Opening Tool carefully.

The Loudspeaker is not removable.

Step 13

Remove Side keys by using Tweezers.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 12 of 60

Company Confidential

2006©BenQ

05/2006

Page 13

Release 1.2

Step 14

Step 15

Step 16

Use Tweezers to remove Keypad.

Remove Microphone by using Tweezers

carefully.

Be careful with the spring contacts of the

Microphone!

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 13 of 60

Company Confidential

2006©BenQ

05/2006

Page 14

Release 1.2

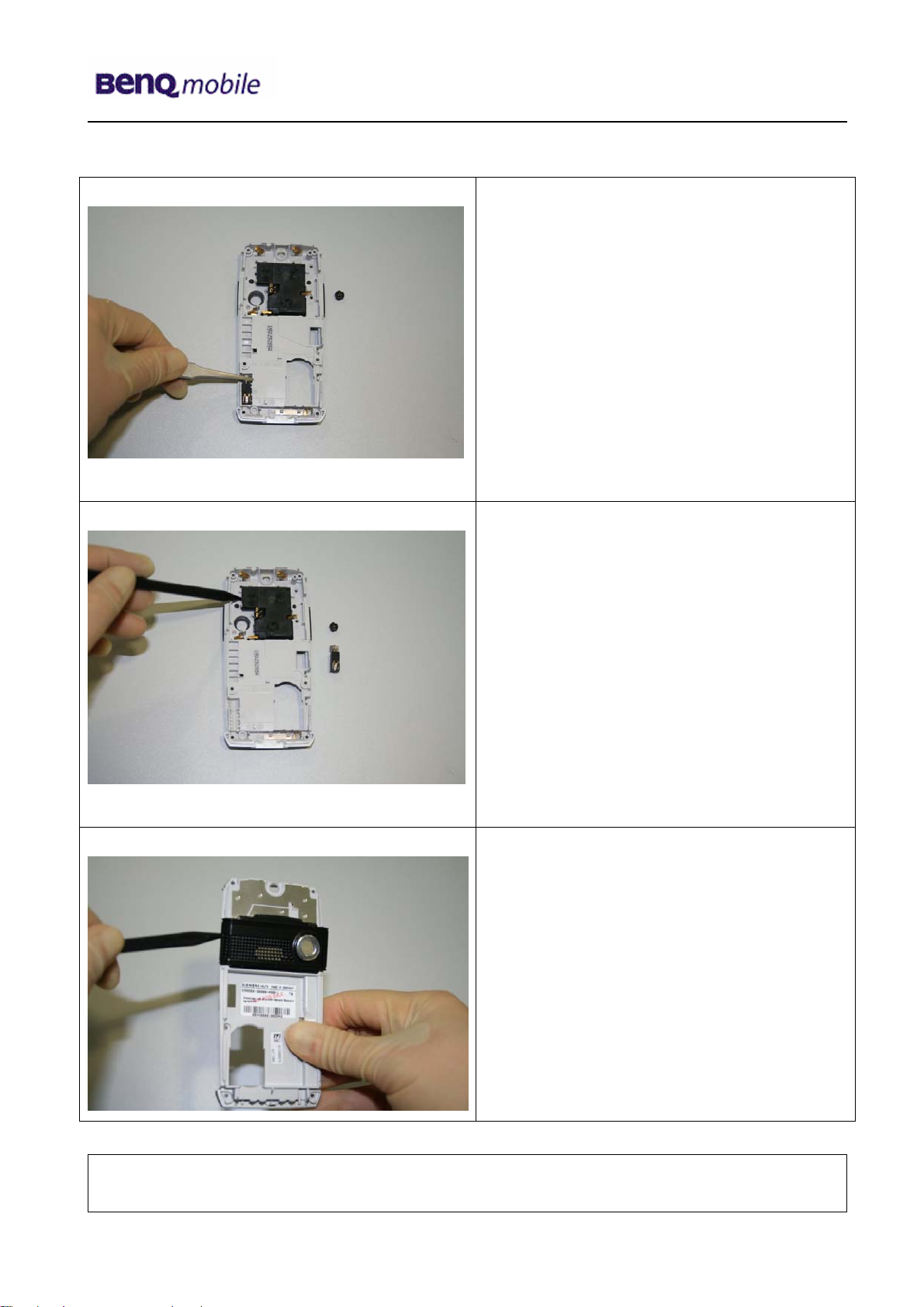

Step 17

Step 18

Remove Vibramotor by using Tweezers

carefully.

Remove Earphone by using Tweezers

carefully.

Step 19

Use Alternative Opening Tool to remove

Camera Cover carefully.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 14 of 60

Company Confidential

2006©BenQ

05/2006

Page 15

Release 1.2

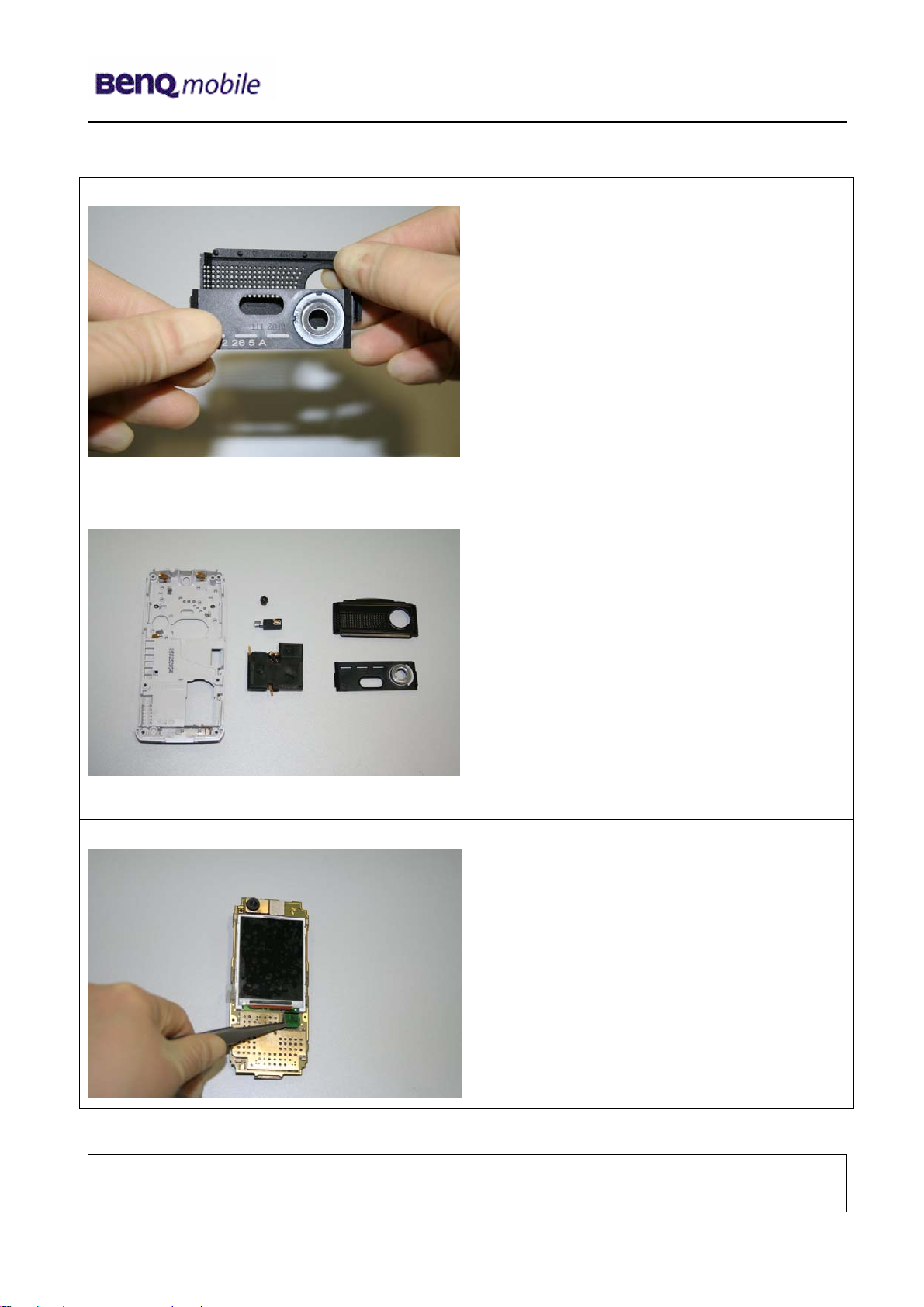

Step 20

Step 21

Step 22

Disconnect Flex Cable from PCB with

Tweezers.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 15 of 60

Company Confidential

2006©BenQ

05/2006

Page 16

Release 1.2

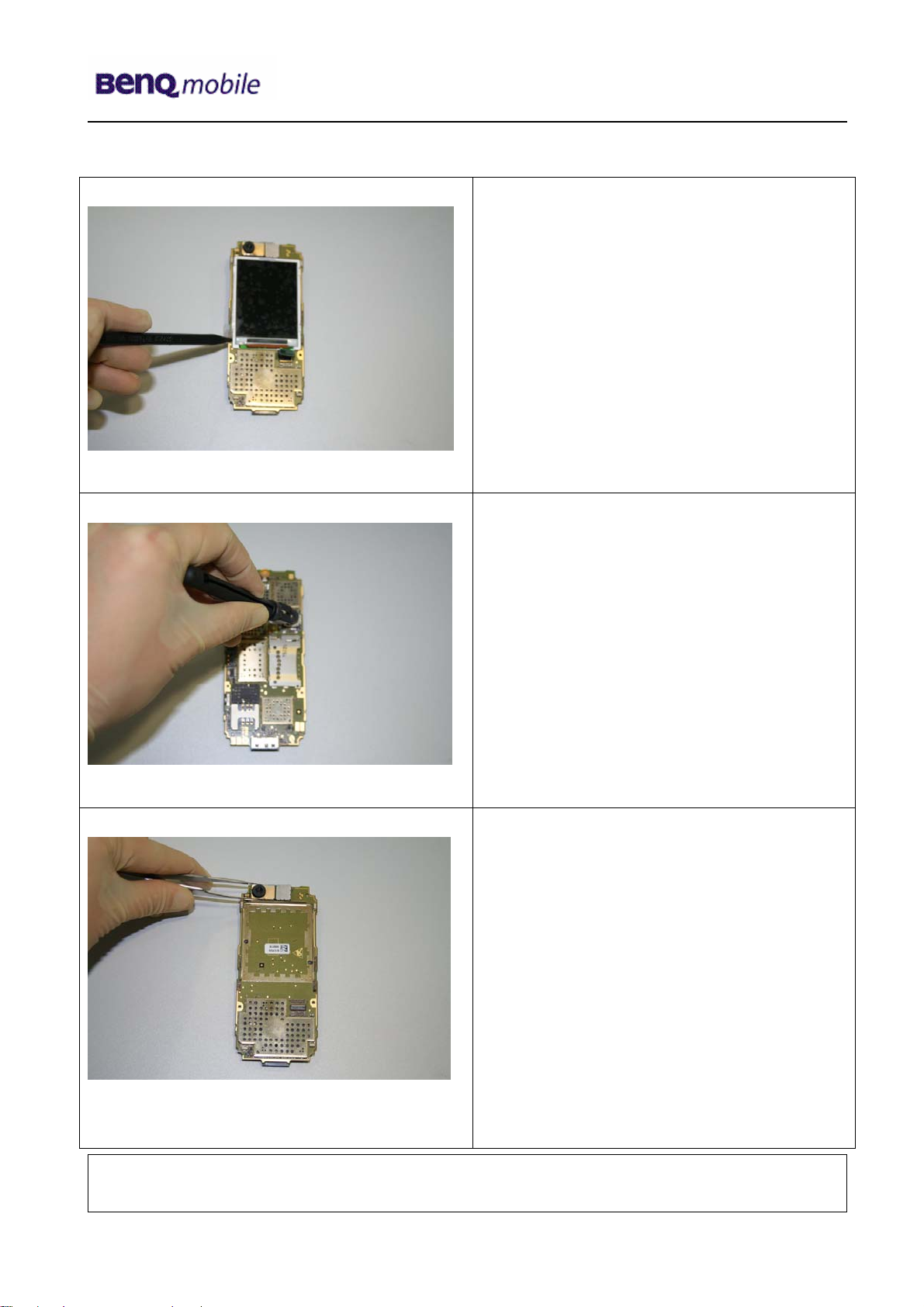

Step 23

Step 24

Remove Display from PCB by using

Alternative Opening Tool very carefully.

Put the Camera Ejector Jig professional

through the four edges between the Camera

and the Camera Connector. Now push the

Ejector Jig and pull out the Camera

Step 25

carefully.

Remove UMTS Camera Cover by using

Tweezers carefully.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 16 of 60

Company Confidential

2006©BenQ

05/2006

Page 17

Release 1.2

play

yp

y

p

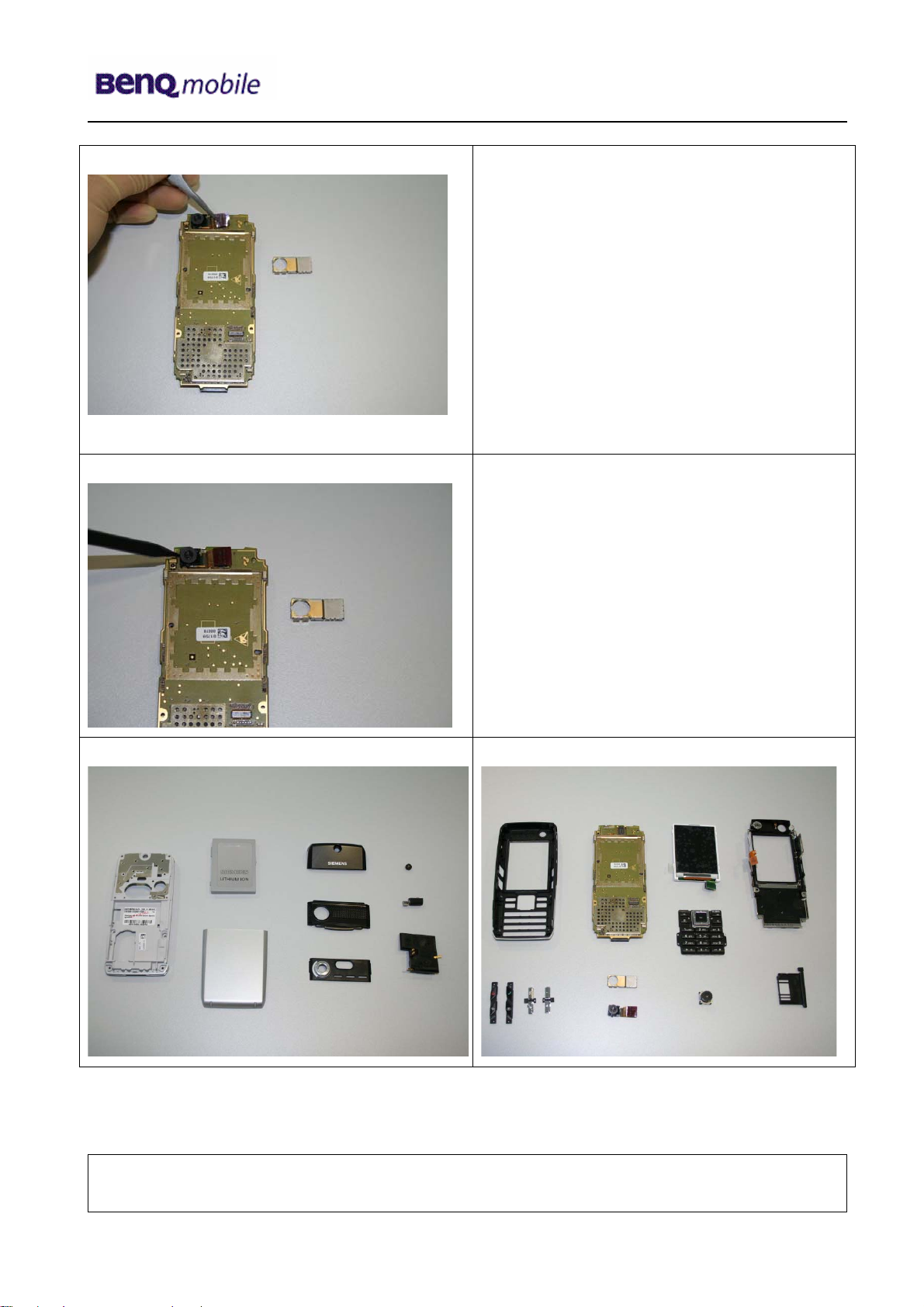

Step 26

Step 27

Remove UMTS Camera with Alternative

Opening Tool very carefully.

Overview Lower Parts Overview Upper Parts

Lower Case

Battery

Rear Cover

Upper Case

Microphone

Vibramotor

PCB

Flexible PCB

Dis

Ke

ad

s

Battery cover

Disassembled

Camera Cove

Sideke

Ear

hone

Camera Cover

UMTS - Camera

Camera

MMC - Holder

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 17 of 60

Company Confidential

2006©BenQ

05/2006

Page 18

Release 1.2

6 Assembly of SXG75

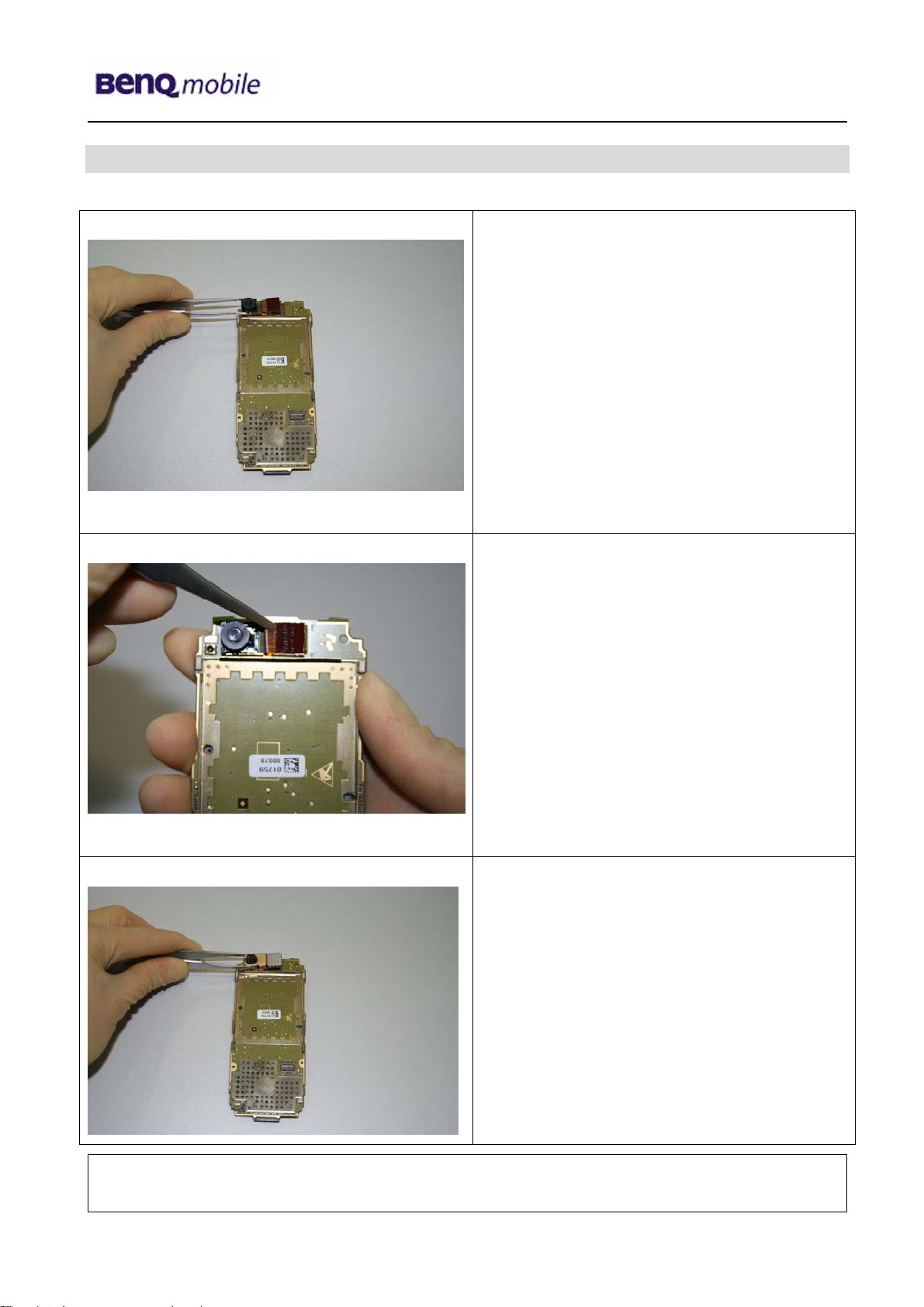

Step 1

Step 2

Assemble UMTS - Camera by using

Tweezers.

Connect the UMTS – Camera with PCB by

using Tweezers.

Step 3

Use Tweezers to assemble Camera Cover.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 18 of 60

Company Confidential

2006©BenQ

05/2006

Page 19

Release 1.2

Step 4

Step 5

Assemble Camera by using Camera Ejector

Jig.

Assemble Display by fixing it in the given

frame.

Take care of the Display!

Step 6

Assemble Camera Cover.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 19 of 60

Company Confidential

2006©BenQ

05/2006

Page 20

Release 1.2

Step 7

Step 8

Assemble Earphone by using Tweezers

carefully.

Step 9

Assemble Vibramotor by using Tweezers

carefully.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 20 of 60

Company Confidential

2006©BenQ

05/2006

Page 21

Release 1.2

Step 10

Step 11

Assemble Microphone by using Tweezers.

Be careful with the spring contacts of the

Microphone!

Assemble Side keys with Tweezers.

Step 12

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 21 of 60

Company Confidential

2006©BenQ

05/2006

Page 22

Release 1.2

Step 13

Use Tweezers to assemble Keypad.

Step 14

Step 15

Assemble Flexible PCB by using

Tweezers.

Push it carefully with both thumbs in the

Upper Case.

Before assembling PCB in the Upper Case,

remove Display Foil!!!

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 22 of 60

Company Confidential

2006©BenQ

05/2006

Page 23

Release 1.2

Step 16

Step 17

Step 18

Assemble PCB by fixing it in the Upper

Case.

To assemble PCB connect it with Flex

Cable.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 23 of 60

Company Confidential

2006©BenQ

05/2006

Page 24

Release 1.2

Step 19

Assemble MMC holder by pushing it in the

given frame.

Step 20

Step 21

Fix the Upper Case on the before

assembled Lower Case and PCB.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 24 of 60

Company Confidential

2006©BenQ

05/2006

Page 25

Release 1.2

Step 22

Step 23

Place screws by using Torque –

Screwdriver.

Top screw (Antenna):

Screw size: T5+

Torque: 17 cNm

Centre/ Bottom screws:

Screw size: T5+

Torque: 20 cNm

Assemble Rear Cover.

Step 24

Assemble Battery.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 25 of 60

Company Confidential

2006©BenQ

05/2006

Page 26

Release 1.2

Step 25

Assemble Battery Cover.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 26 of 60

Company Confidential

2006©BenQ

05/2006

Page 27

Release 1.2

7 BenQ Service Equipment User Manual

Introduction

Every LSO repairing BenQ handset must ensure that the quality standards are observed.

BenQ has developed an automatic testing system that will perform all necessary

measurements. This testing system is known as:

BenQ Mobile Service Equipment

• For disassembling / assembling

Torque – Screwdriver

Part Number: F 30032 – P 228 –

A1

Opening tool

(Case opening without

destroying)

Part Number: F 30032 – P 38 –

A1

Alternative Opening tool

Part Number: F30032 – P583 –

A1

Tweezers

Camera Ejector Tool

Professional

Part Number: F30032 – P514 –

A1

• For testing

All mobile phones have to be tested with the GRT – Software. The service partner is

responsible to ensure that all required hardware is available.

For additional Software and Hardware options as well as the supported GRT equipment,

please check the GRT User manual.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 27 of 60

Company Confidential

2006©BenQ

05/2006

Page 28

Release 1.2

8 GRT Software: Functionality Configuration

Note: Not implemented in GRT Version 3.x. For Software Update please use the tool

3GSWUP_FU. Manual and Software are available in the Technical Support section of

the C-market.

Sep 1:

Step 2:

Technical Documentation

Select „Settings >> SWUP / JPICS”

Proceed as follows:

¾ Select all required Variants you need to repair (click onto the “+” in

front of the product name.

¾ Check Com-Port setting. If necessary change it

¾ Check speed setting. Select always the lowest speed if your PC

does not have a fast serial card

¾ Enter the value for “JPICS Server Timeout”. Be careful, this value

defines how long GRT tries to reach the server until you get an

error message. Do not select a very long time

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 28 of 60

Company Confidential

2006©BenQ

Page 29

Release 1.2

Step 3: Connect to GRM Server

• Choose in the section „GRM” the „Connect to GRM Database“ functionality

Enter your GRT-Username and

Password into this fields

Activate always both boxes if you

connect to the database. Start

with “Connect”

It you IT infrastructure parameter

have changed, use this button to

move to the configuration mask

• End the connection with a click onto the „Exit button“ (appearing after successful data

exchange)

GRT Software has now finished all required settings and configuration tasks. All

files have been down- and uploaded.

In dependency of the selected number of mobile phones and variants the volume

of transferred date could be (~100MB)

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 29 of 60

Company Confidential

2006©BenQ

Page 30

Release 1.2

9 GRT Software: Regular Usage

Step 1:

Step 2: Choose the area you want to work with

In any case customer data can be erased on request. (xfs and mapping have to be

activated) Of course JPICS hardware and authorisation have to be available.

Select the section SWUpdate

• Personal Repair

Personal Repair is always accessible. Basis for the decision if a SW-Update is

authorised by Siemens is the so called

Example: Mobile Phone has already SW50.

In this case SW-Update is not necessary and therefore not authorised

• Operator SWAP

This area is only accessible if you are released by the service management to

perform SW-Updates for Net-Operators. Basis for the decision if a SW-Update is

authorised by Siemens is the so called

Customer data will be erased without any exception and any chance to influence by

the user. JPICS hardware and authorisation have to be available.

• Operator SWUpdate

This area is only accessible if you are released by the service management to

perform SW-Updates for Net-Operators. Basis for the decision if a SW-Update is

authorised by Siemens is the so called

Like in “Personal Repair” customer data can be erased on request. (xfs and mapping

have to be activated) Of course JPICS hardware and authorisation have to be

available.

Service Release-Table .

Service -Release-Table shows SW50

Master-Table .

Master-Table .

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 30 of 60

Company Confidential

2006©BenQ

Page 31

Release 1.2

)

A

9.1 Window explanation

This general explanation is valid for all SW-Update channels

(Personal Repair, Operator SWAP, Operator SWUpdate)

1.1.1.1.1.1.3 Automatic read

out function of phone

type/Variant. Appearing in the

Remarks:

In case of malfunction please check

o Is the correct phone type selected

o Is the correct COM-Port selected

o If a variant is missing, move back to Settings select the missing variant and

conncet the GRM Server. Then continue with SW-Update.

After using „Check Variant“ Phone IMEINumber will be shown here

Select boxes for:

Content = xfs

Settings = mapping

Attention:

ctivation of the boxes

will cause erase of

customer date while SWUpdate

Window to select the mobile

phone CPU

Shows the different SW –Versions

a) SW inside the mobile phone

b) Version of Service Release Table

SW

Version of Master Table SW

c

Start button for SWUpdate

Stop / leave SW-Update

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 31 of 60

Company Confidential

2006©BenQ

Page 32

Release 1.2

9.2 Case 1: Personal Repair (green)

Step 1: Carry out step 1 – 4 to start SW-Update.

Remarks:

Select the mobile phone CPU type

Start SW-Update

Choose if customer data shall be erased.

If “Yes” activate the boxes in front of xfs

and mapping

1.1.1.1.1.1.2 Read out phone

type/Variant. >>Appears in the

window ab ove.

- The decision about a Siemens authorised SW-Update depends only on the

Service Release-Table .

- The SW which is booted by GRT can be below the SW mentioned in the

Service Release Table, if this SW is not released for the Net-Operator

- If xfs and mapping are activated, GRT will erase in any case the customer

data even if the action is cancelled.

- If the user wants to download an other variant then the automatically identified

one, he has simply to select an other variant from the list. Afterwards he has to

start the SW-Update

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 32 of 60

Company Confidential

2006©BenQ

05/2006

Page 33

Release 1.2

9.3 Case 2: Operator SWAP (red)

Step 1: Carry out step 1 – 4 to start SW-Update.

Remarks:

1.1.1.1.1.1.1 Read out phone

type/Variant. >>Appears in the

window above.

- The decision about a Siemens authorised SW-Update depends only on the

Master-Table .

- The user has no chance to influence the decision

- Xfs and mapping are always activated there is no chance to deactivate them.

GRT will erase in any case the customer data even if the action is cancelled.

- If the user wants to download an other variant then the automatically identified

one, he has simply to select an other variant from the list. Afterwards he has to

start the SW-Update

Select the mobile phone CPU type

Start SW-Update

Choose if customer data shall be erased.

If “Yes” activate the boxes in front of xfs

and mapping

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 33 of 60

Company Confidential

2006©BenQ

05/2006

Page 34

Release 1.2

9.4 Case 3 Operator SWUpdate (blue)

Step 1: Carry out step 1 – 4 to start SW-Update.

Remarks:

1.1.1.1.1.1.4 Read out phone

type/Variant. >>Appears in the

window above.

- The decision about a Siemens authorised SW-Update depends only on the

Master-Table .

- The user has no chance to influence the decision

- Xfs and mapping can be activated on demand. GRT will erase in any case

the customer data even if the action is cancelled.

- If the user wants to download an other variant then the automatically identified

one, he has simply to select an other variant from the list. Afterwards he has to

start the SW-Update

Select the mobile phone CPU type

Start SW-Update

Choose if customer data shall be erased.

If “Yes” activate the boxes in front of xfs

and mapping

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 34 of 60

Company Confidential

2006©BenQ

05/2006

Page 35

Release 1.2

10 JPICS (Java based Product Information Controlling System)

Overview

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 35 of 60

The following functions are available for the LSO:

• General mobile information

• Generate PINCODE

• Generate SIMLOCK – UNLOCK – Code

• Print IMEI labels

• Lock, Unlock and Test the BF - Bus

05/2006

Company Confidential

2006©BenQ

Page 36

Release 1.2

The access to the JPICS server which is located in Kamp – Lintfort is protected by chip card

and in addition using secure socket layer (SSL) connection.

The JPICS server is only available for authorized users with a specially coded smart card.

These smart cards and the administration of the JPICS web server and the PICS database

– server can only be provided by the JPICS – TRUST – Center of the

responsible

department in Kamp – Lintfort.

In case of any questions or requests concerning smart cards or administration of the

databases please ask your responsible BenQ Customer Care Manager.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 36 of 60

Company Confidential

2006©BenQ

05/2006

Page 37

Release 1.2

Installation overview

The following installation description assumes that a web browser is already installed.

JPICS is tested with the following browsers:

Internet Explorer Version 5.5 and higher

1.

Netscape Version 6 and higher

2.

For further information regarding supported browsers, browser version and supported

operating systems, see the

Sun FAQ’s.

Here is a step by step instruction to install all the required components:

It is necessary to follow this order!

Smart Card Reader (Omnikey: Cardman 2020 USB or Cardman 3121 USB)

1.

CardOS interface (Siemens Version 3.0 B)

2.

Java Runtime Environment (Sun)

3.

Java additional components

4.

Every user is responsible for a proper installation matching the license

agreements.

For installation and further access you need the following:

1. The JPICS Installation – CD

2. The Smart Card JPICS. These cards can be ordered via your responsible Customer

Care Manager within Siemens or on

http://jpics.siemens.com/jpics/admin/request-

new_jpics.jsp

3. A supported Smart Card Reader (Omnikey Cardman) in order to access your Smart

Card.

Remark: We recommend using Cardman 2020 USB or Cardman 3121 USB. Serial card

readers are not supported!!!

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 37 of 60

Company Confidential

2006©BenQ

05/2006

Page 38

Release 1.2

Generate Codes

In the JPICS application you can choose to generate:

• Masterphone codes

• Simlock – Unlock – Codes

Masterphone codes

The Masterphone code is used to unlock blocked mobiles.

Masterphone codes can only be supplied for mobiles which have been delivered in a

regular manner.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 38 of 60

Company Confidential

2006©BenQ

05/2006

Page 39

Release 1.2

Simlock – Unlock – Code

The Simlock – Unlock – Codes can only be generated if the following conditions are given:

• Mobile must have an active Simlock inside.

• The user must be given the authorization to obtain Simlock – Unlock – Codes for

the variant of the operator to which the mobile was delivered last time.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 39 of 60

Company Confidential

2006©BenQ

05/2006

Page 40

Release 1.2

Printing IMEI label

The module “printing IMEI label” offers the possibility to re-print IMEI labels for mobiles

again.

You are able to print 1 label in just one step.

To prevent that misaligned labels are being printed, the setting “Print test labels =

9” is

activated by default. After having printed a well aligned test label you can uncheck the

setting and print the correct label.

Hint:

For correct printing of IMEI labels you must have a Zebra – label printer with special

material that fits for label printing. This printer has to be connected to local LPT1 printer port

(also see Installation of IMPRINT) and MUST feature a printing resolution of 300dpi.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 40 of 60

Company Confidential

2006©BenQ

05/2006

Page 41

Release 1.2

11 International Mobile Equipment Identity, IMEI

The mobile equipment is uniquely identified by the International Mobile Equipment Identity,

IMEI, which consists of 15 digits. Type approval granted to a type of mobile is allocated 6

digits. The final assembly code is used to identify the final assembly plant and is assigned

with 2 digits. 6 digits have been allocated for the equipment serial number for manufacturer

and the last digit is spare.

The part number for the SXG75 is

housing and software variant.

S30880-8900-#xxx where the last for letters specify the

SXG75 series IMEI label is accessible by removing the battery.

Re – use of IMEI label is possible by using a hair – dryer to remove the IMEI label.

On this IMEI label, BenQ has also includes the data code for production or service, which

conforms to the industrial standard DIN EN 60062. The data code comprises of 2

characters: first character denotes the year and the second character denotes the month.

For example: S5

CODE Year Month CODE

P 2 0 0 2 M A R C H 3

R 2 0 0 3 A P R I L 4

S

T 2 0 0 5 J U N E 6

2 0 0 4 M A Y

5

U 2 0 0 6 J U L Y 7

To display the IMEI number, exit code and SW/HW version, key: * # 0 6 #

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 41 of 60

Company Confidential

2006©BenQ

05/2006

Page 42

Release 1.2

12 General Testing Information

General Information

The technical instruction for testing GSM mobile phones is to ensure the best repair quality.

Validity

This procedure is to apply for all from Siemens AG authorized level 2 up to 2.5e workshops.

Procedure

All following checks and measurements have to be carried out in an ESD protected

environment and with ESD protected equipment/tools. For all activities the international

ESD regulations have to be considered.

Get delivery:

¾ Ensure that every required information like fault description, customer data a.s.o. is

available.

¾ Ensure that the packing of the defective items is according to packing requirements.

¾ Ensure that there is a description available, how to unpack the defective items and

what to do with them.

Enter data into your database:

(Depends on your application system)

¾ Ensure that every data, which is required for the IRIS-Reporting is available in your

database.

¾ Ensure that there is a description available for the employees how to enter the data.

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 42 of 60

Company Confidential

2006©BenQ

05/2006

Page 43

Release 1.2

Incoming check and check after assembling:

!! Verify the customers fault description!!

¾ After a successful verification pass the defective item to the responsible

troubleshooting group.

¾ If the fault description can not be verified, perform additional tests to save time and to

improve repair quality.

- Switch on the device and enter PIN code if necessary unblock phone.

- Check the

- Check the display for error in

function of all keys including side keys.

line and row, and for illumination.

- Check the ringer/loudspeaker acoustics by individual validation.

- Perform a GSM Test as described on page 36.

Check the storage capability:

¾ Check internal resistance and capacity of the battery.

¾ Check battery charging capability of the mobile phone.

¾ Check charging capability of the power supply.

¾ Check current consumption of the mobile phone in different mode.

Visual inspection:

¾ Check the entire board for liquid damages.

¾ Check the entire board for electrical damages.

¾ Check the housing of the mobile phone for damages.

SW update:

¾ Carry out a software update and data reset according to the master tables and

operator/customer requirements.

Repairs:

The disassembling as well as the assembling of a mobile phone has to be

carried out by considering the rules mentioned in the dedicated manuals. If

special equipment is required the service partner has to use it and to ensure the

correct function of the tools.

If components and especially soldered components have to be replaced all rules

mentioned in dedicated manuals or additional information e.g. service

information have to be considered

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 43 of 60

Company Confidential

2006©BenQ

05/2006

Page 44

Release 1.2

GSM Test:

With the availability of the GRT Test /Alignment software, this tool has to be used to perform

the outgoing test!

>Connect the mobile/board via internal antenna (antenna coupler) and external antenna

(car cradle/universal antenna clip) to a GSM tester

>Use a Test SIM

For Triple Band phones use a separate test case, if the test software allows only one handover.

Skip the GSM Band test cases if not performed by the mobile phone

example: 1. Test file Band 1 = GSM900 / Band 2 = GSM1800

2. Test file Band 1 = GSM1900

Internal Antenna

Test case Parameter Measurements Limits

1 Location Update • GSM Band 1

• BS Power = -55 dBm

• middle BCCH

2 Call from BS • low TCH

• highest PCL

• BS Power = -75 dBm

• middle BCCH

3 TX GSM Band 1 • low TCH

• highest PCL

• BS Power = -75 dBm

• middle BCCH

4 Handover to GSM Band 2

Including Handover

Check

5 TX GSM Band 2 • low TCH

6 Call relaese from BS

• highest PCL0

• BS Power = -75 dBm

• middle BCCH

• Display check • individual

check

• Ringer/Loudspeaker

check

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• individual

check

• GSM Spec.

• GSM Spec.

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 44 of 60

Company Confidential

2006©BenQ

Page 45

Release 1.2

External Antenna

7 Call from MS • GSM900

• high TCH

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

8 TX GSM Band 1 • high TCH

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

9 RX GSM Band 1 • high TCH

• BS Power = -102 dBm

• 50 Frames

• middle BCCH

10 Handover to GSM Band 2

Including Handover

Check

11 TX GSM Band 2 • high TCH

12 RX GSM Band2 • high TCH

13 Call relaese from MS

• second highest PCL

• BS Power = -75 dBm

• middle BCCH

• BS Power = -102 dBm

• 50 Frames

• middle BCCH

• Keyboard check • individual

check

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• RX Level

• RX Qual

• BER Class Ib

• BER Class II

• BER Erased Frames

• Frequency Error

• Phase Error RMS

• Phase Error Peak

• Average Power

• Power Time Template

• RX Level

• RX Qual

• BER Class Ib

• BER Class II

• BER Erased Frames

• GSM Spec.

• GSM Spec.

• GSM Spec.

• GSM Spec.

Final Inspection:

The final inspection contains:

1) A 100% network test (location update, and set up call).

2) Refer to point 3.3.

3) A random sample checks of:

- Data reset (if required)

- Optical appearance

- complete function

4) Check if PIN-Code is activated (delete the PIN-Code if necessary).

Basis is the international standard of DIN ISO 2859.

Use Normal Sample Plan Level II and the Quality Border 0,4 for LSO.

Remark: All sample checks must be documented.

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 45 of 60

Company Confidential

2006©BenQ

Page 46

Release 1.2

WCDMA Test:

With the availability of the GRT Test /Alignment software, this tool has to be used to perform

the outgoing test!

>Connect the mobile/board via internal antenna (antenna coupler) and external antenna

(car cradle/universal antenna clip) to a WCDMA tester

>Use a Test USIM

Internal Antenna

Test case Parameter Measurements Limits

1 Location Update • Band 1

2 Call from NodeB

3 WCDMA TX Test • UARFCN 10750

• ULTA -30

4 Call relaese from NodeB

• Peak Power (dBm)

• Magnitude Error RMS

• EVM RMS

• Phase Error RMS

• Frequence Error Average

• WCDMA Spec.

External Antenna

5 Call from UE

6 Audio Test • Audio Loop • Individual check

7 WCDMA TX Min Power • Peak Power (dBm)

• Magnitude Error RMS

• EVM RMS

• Phase Error RMS

• Frequence Error Average

8 WCDMA TX Max Power • Peak Power (dBm)

• Magnitude Error RMS

• EVM RMS

• Phase Error RMS

• Frequence Error Average

9 Call relaese from NodeB

• WCDMA Spec

• WCDMA Spec

10 Test RX BER • UARFCN 10750

• ULTA -30

• Bit Error Rate

• Block Error Rate

• WCDMA Spec

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 46 of 60

Company Confidential

2006©BenQ

05/2006

Page 47

Release 1.2

Annex 1

Test SIM Card

There are two different “Test SIM Cards” in use:

1) Test SIM Card from the company “ORGA”

Pin 1 number: 0000

PUK 1 : 12345678

Pin 2 number: 0000

PUK 2 : 23456789

2) Test SIM Card from the company “T-D1”

Pin 1 number: 1234

PUK : 76543210

Pin 2 number: 5678

PUK 2 : 98765432

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 47 of 60

Company Confidential

2006©BenQ

05/2006

Page 48

Release 1.2

Annex 2

Battery Date Code overview

Varta

Date code example N 9 A VA

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Hitachi / Maxwell

Date code example N 9 A MX

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Sanyo

Date code example N 9 A SY

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

NEC

Date code example N 8 A NT

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Panasonic

Date code example O N A PAN

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Sony

Date code example P N A SO

Year (O:2002, P:2003...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 48 of 60

Company Confidential

2006©BenQ

Page 49

Release 1.2

13 Introduction of Service Repair Documentation

Level 3 – SXG75

13.1 Purpose

This Service Repair Documentation is intended to support Service partners to carry out repairs on

BenQ repair level 3. The described failures shall only be repaired in BenQ authorized local

workshops.

The level 3 (former Level 2.5light) partners are obliged to repair level 3 classified boards, up to their

repair level, under consideration of this repair instruction.

All repairs have to be carried out in an ESD protected environment and with ESD protected

equipment/tools. For all activities the international ESD regulations have to be considered.

Assembling/disassembling has to be done according to the latest CF110 Level 1-2 repair

documentation. It has to be ensured that every repaired mobile Phone is checked according to the

latest released General Test Instruction document (both documents are available in the Technical

Support section of the C-market).

Check at least weekly C-market for updates and consider all CF110 related Customer Care

Information

SXG75 Partnumber on IMEI label: S30880-S8900-#xxx

, while # may be any letter (A-Z) and xxx may be any number from 100, 101, 102....

Scrap Handling: All Scrap information given in this manual are related to the

SCRAP-Rules and instructions.

Attention: Consider the new "LEAD-FREE" soldering rules (available in the communication

market), avoid excessive heat.

13.2 Scope

This document is the reference document for all BenQ mobile authorised Service Partners which are

released to repair BenQ mobile phones up to level 2.5 light.

13.3 Terms and Abbreviations

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 49 of 60

Company Confidential

2006©BenQ

05/2006

Page 50

Release 1.2

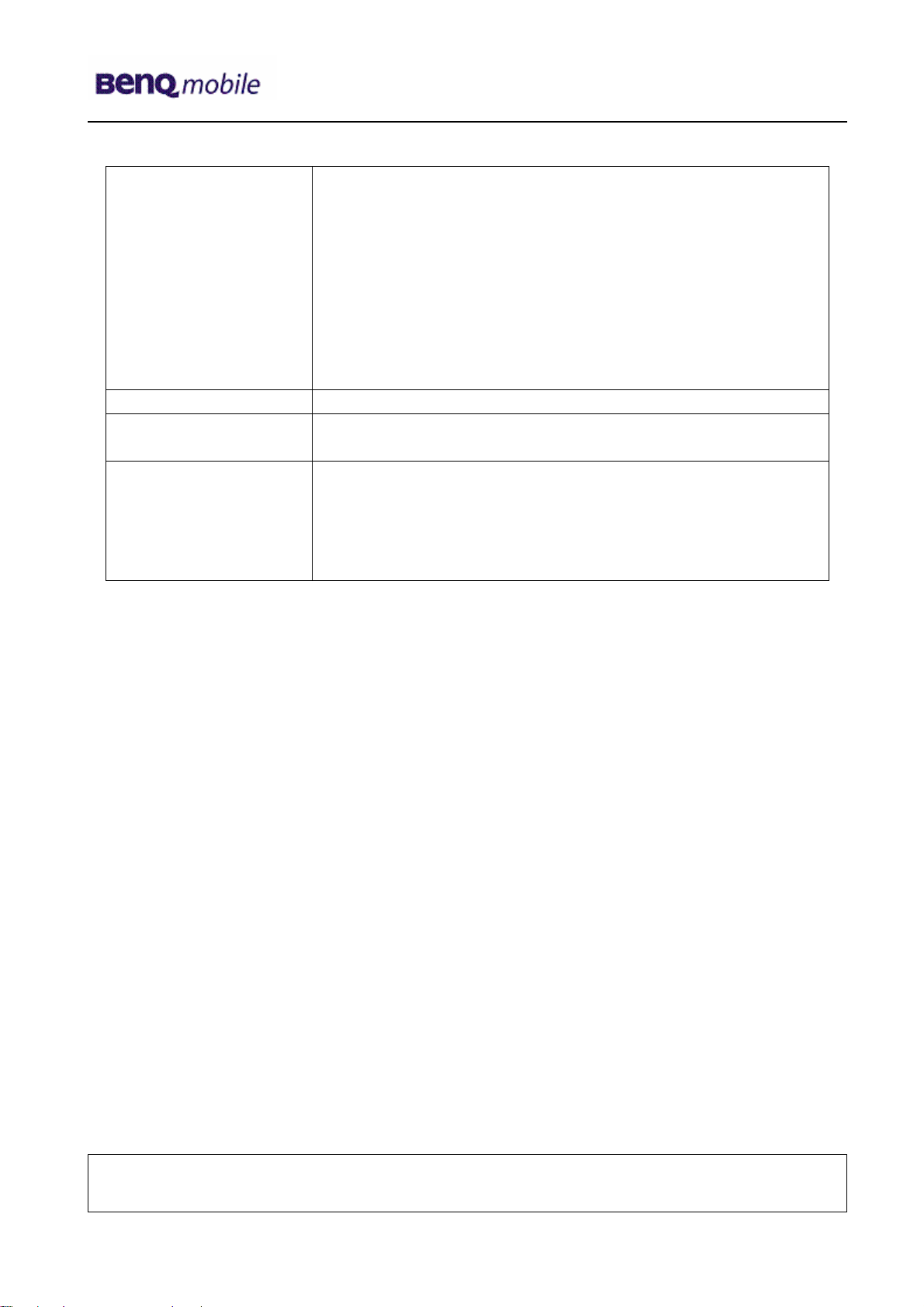

14 List of available level 3 (basic) parts

(according to Component Matrix V1.19 - check C-market for updates)

Product ID Order Number Description CM

SXG75 V2100 L36197-F5008-F492 IRDA 115.2 KBIT

SXG75 X100 L36334-Z93-C303 IO-JACK SLIM 12-POL

SXG75 X1100 L36334-Z97-C213 CONNECTOR BATTERY 3-POL

SXG75 X1400 L50634-Z97-C348 CONNECTOR RS-MMC-READER X75

SXG75 X1500 L36334-Z97-C337 CONNECTOR SIM CARD READER K1

SXG75 X1900 L36197-F5008-F341 CONNECTOR BOARD TO BOARD 20-POL

SXG75 X1901 L50634-Z97-C379 CONNECTOR CAMERA-SOCKET

SXG75 X200 L36334-Z93-C297 CONNECTOR ANTENNA 6mm

SXG75 X2000 L50697-F5008-F288 BOARD TO BOARD 16-POL 0,5MM

SXG75 X2201 L50634-Z97-C340 BOARD TO BOARD 30-POL

15 Hardware requirements

(according to General soldering information V1.3 - check C-market for updates)

Jigs, Tools and working materials for all described repairs:

hot air blower

soldering gun

tweezers

flux

solder

SXG75 dome sheet jig

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 50 of 60

Company Confidential

2006©BenQ

Page 51

Release 1.2

r

16 SXG75 Board layout

Upper board side

Lower board side

IO Jack

Slim

Connector

SIM Card

Reade

Connector

Front Camera

IRDA

Connector

Battery

Connector

RS – MMC

Connector

Display

Connector

Board to

Board 20

Connector

Camera socket

Connector

Antenna

Technical Documentation

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 51 of 60

Company Confidential

2006©BenQ

05/2006

Page 52

Release 1.2

y

y

r

y

y

17 SIM Card Problems

Fault Symptoms

Customer: GRT:

Handset does not accept SIM card SIM Card Problems

SIM Card Problems

Watch for oxidation and

damaged pads of the

SIM Card reader

okay

Check the status of the

EMI Filter visually

not

oka

Check the status of the

SIM Card reader visually

Exchange

SIM Card reade

Connector SIM Card Reader

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding components!

Resolder new component afterwards.

E-commerce order number: L50634-Z97-C406

E-commerce order name: CONNECTOR SIM CARD READER R65 (B)

Soldering temperature: ~ 360°C TIP Temp.

not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

okay

okay

not

oka

okay

Back to customer

without repair

not

oka

caused by customer

SCRAP - has to be send

separately to WSC

Exchange the

damaged Filter

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 52 of 60

Company Confidential

2006©BenQ

Page 53

Release 1.2

y

y

r

y

18 IO Connector Problems

Fault Symptoms

Customer: GRT:

Charging Problems No connection to GRT

Problems with external loudspeaker or microphone when using a

car kit

Problems with accessories connected at the IO connector

IO connector Problems

Watch for oxidation and

damaged pads of the

IO connector

not

oka

okay

not

oka

not

oka

Check the dust inside

the IO connector

okay

Check the status of the

IO connector visually

okay

Exchange

IO connecto

Connector IO Jack

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L36334-Z93-C303

E-commerce order name: IO-JACK SLIM 12-POL

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 46100 Interface/Charging Connector/Mechanical Damage

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

okay

47300 Interface/Data Interface/Mechanical Damage

4B100 Interface/Headset Connector/Mechanical Damage

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

Clean IO connector

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 53 of 60

Company Confidential

2006©BenQ

Page 54

Release 1.2

Important additional soldering hints

The MMC Reader is located on the opposite of the SLIM-Lumberg connector.

Therefore the risk to damage the plastic material of this MMC-Reader is potentially high if excessive

heat is used while removal or soldering of the SLIM-Lumberg connector.

Please follow these instructions:

a) Remove the SLIM-Lumberg connector with a soldering iron and Desolder Wick

b) Clean the Pads afterwards

c) Solder the new connecter by using soldering iron under consideration of the max. allowed

temperature range.

Samples of critical area:

Lock mechanism damaged Lock mechanism OK

Lock mechanism damaged Lock mechanism OK

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 54 of 60

Company Confidential

2006©BenQ

Page 55

Release 1.2

y

y

19 B to B connector Problems

not

oka

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Fault Symptoms

Customer: GRT:

Upper slider keyboard malfunction Keyboard malfunction

Upper slider keypad illumination does not work Current measured failed

Display problems

B to B connector problems

Watch for oxidation and

damaged pads of the

B to B connector

okay

not

oka

Check the status of the

B to B connector visually

okay

Exchange

B to B

connector

Continue with

higher repair level

Connector Board to Board

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C340

E-commerce order name: BOARD TO BOARD 30-POL

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 32100 Keys / Main / No Function

32200 Keys / Main / Reduced Functionality

36000 Keys / Illumination

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 55 of 60

Company Confidential

2006©BenQ

Page 56

Release 1.2

y

y

y

y

20 Battery Connector Problems

Fault Symptoms

Customer: GRT:

Mobile does not switch on No connection to GRT

Battery connector problems

Watch for oxidation and

damaged pads of the

battery connector

not

oka

okay

not

oka

Check the status of the

battery connector

visuall

okay

Exchange

battery

connector

not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts. The value

must be ~ 0.

okay

Connector BATTERY

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L36334-Z97-C213

E-commerce order name: CONNECTOR BATTERY 3-POL

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 13000 Battery/Mechanical Damage

Technical Documentation

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 56 of 60

Company Confidential

2006©BenQ

Page 57

Release 1.2

y

y

y

y

21 Camera Connector Problems

not

oka

okay

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Fault Symptoms

Customer: GRT:

Camera malfunction Tbd.

Camera connector Problems

Watch for oxidation and

damaged pads of the

camera connector

okay

not

oka

Check the status of the

camera connector

visuall

Exchange

camera

connector

not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

Connector CAMERA

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C379

E-commerce order name: CONNECTOR CAMERA-SOCKET

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: BA000 Accessories / Camera

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 57 of 60

Company Confidential

2006©BenQ

Page 58

Release 1.2

y

y

22 IRDA Problems

not

oka

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Fault Symptoms

Customer: GRT:

No infrared connection possible Tbd.

IRDA Problems

Watch for oxidation and

damaged pads of the

IRDA

okay

not

oka

Check the status of the

IRDA visually

okay

Exchange

IRDA

Continue with

higher repair level

IRDA

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L36197-F5008-F492

E-commerce order name: IRDA 115.2 KBIT

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 41100 Interfaces / IRDA / No Function

41300 Interfaces / IRDA / Mechanical Damage

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 58 of 60

Company Confidential

2006©BenQ

Page 59

Release 1.2

y

y

y

y

23 Display Problems

not

oka

okay

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Fault Symptoms

Customer: GRT:

Display problems Current measured failed

Display Problems

Watch for oxidation and

damaged pads of the

Display connector

okay

not

oka

Check the status of the

Display connector

visuall

Exchange

display

connector

not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

Connector DISPLAY

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C380

E-commerce order name: CONNECTOR DISPLAY 20POL

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 21000 Display / Performance

22000 Display / Background Illumination

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 59 of 60

Company Confidential

2006©BenQ

Page 60

Release 1.2

y

24 MMC Connector Problems

not

okay

okay

Back to customer

without repair

caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Fault Symptoms

Customer: GRT:

MMC malfunction Tbd.

MMC connector problems

Watch for oxidation and

damaged pads of the

MMC connector

okay

not

oka

Check the status of the

MMC connector visually

Exchange MMC

connector

not

okay

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

The value must be ~0

okay

contacts.

Connector MMC

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C415

E-commerce order name: CONNECTOR RS MMC X75; CONNECTOR RS MMC X75

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 4E000 Interfaces/ Memory Card Rerader

Attention: Avoid excessive heat in order not to damage the plastic material of the

connector (see problem SLIM-Lumberg connector)

Technical Documentation

05/2006

TD_Repair_L1-L3_SXG75_R1.2.pdf Page 60 of 60

Company Confidential

2006©BenQ

Loading...

Loading...