Page 1

BenQ FP93GW Service Manual

FP93GS

9

9

Product Service Manual – Level 2

Service Manual for BenQ:

FP93GW

P/N: 9H.0A9LN.Ixx

Applicable for All Regions

Version: 002

Date:07/04/09

Notice:

- For RO to input specific “Legal Requirement” in specific NS regarding to responsibility

and liability statements.

- Please check BenQ’s eSupport web site, http://esupport.benq.com, to ensure that you

have the most recent version of this manual.

First Edition (June, 2006)

© Copyright BenQ Corporation 2006. All Right Reserved.

1

Page 2

BenQ FP93GW Service Manual

/ FP93GS

Content Index

1. Precautions & Safety Notices

1.Safety Precaution

2. Produce Safety Notice

3.Service Notes

2.Product Overview

2.1. Specification

2.2Signal interface

2.3 Video performance

2.4 Scan range

2.5 Plug & Play DDC2B DDC-CI Support

2.6 Support Timings

2.7 Operational &Function Specification

2.7.1 Video performance

2.7.2Brightness Adjustable Range

2.7.3 Acoustical Noise

2.7.4 Environment

2.7.5 Transportation

2.7.7 Electrostatic Discharge Requirements

2.7.8 EMC

2.7.9 Reliability

2.8 LCD Characteristics

2.8.1 The Physical definition & Technology summary of LCD panel

2.8.2 Optical characteristics of LCD panel

2.9 User Controls

2.9.1 User’s hardware control definition

2.9.2OSD control function definition

2.10 Mechanical Characteristics

2.10.1 Dimension

2.10.2 Weight

2.10.3 Plastic

2.10.4Carton

2.11 Pallet & Shipment

2.11.1 Container Specification

2.11.2 Carton Specification Product: Package:

3. Exploded View

3.1 Disassembly /Assembly

2

Page 3

BenQ FP93GW Service Manual

4. Level 1 Cosmetic / Appearance / Alignment Service

4.1 Software / Firmware Upgrade Process

4.2. Alignment procedure (for function adjustment)

4.2.1. Command definition

5. Level 2 Circuit Board and Standard Parts Replacement

5.1. Block diagram

5.1.1 Circuit operation theory

5.2. TROUBLE SHOOTING GUIDE

5.3. Spare Parts List

Appendix 1 – Screw List / Torque

3

Page 4

BenQ FP93GW Service Manual

PRECAUTIONS

This monitor is manufactured and tested on a ground principle that a user’s safety comes

first. However, improper used or installation may cause damage to the monitor as well as to

the user.

WARNINGS:

z This monitor should be operated only at the correct power sources indicated on the label

on the rear of the monitor. If you’re unsure of the power supply in you residence, consult

your local dealer or Power Company.

z Do not try to repair the monitor by yourself, as it contains no user-serviceable parts. This

monitor should only be repaired by a qualified technician.

z Do not remove the monitor cabinet. There is high-voltage parts inside that may cause

electric shock to human bodies.

z Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

z Put your monitor only in a lean, cool, dry environment. If it gets wet, unplug the power

cable immediately and consult your closed dealer.

z Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth.

Apply non-ammonia based cleaner onto the cloth, not directly onto the class screen.

z Do not place heavy objects on the monitor or power cord.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual

inspections and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Before replacing any of

these components read the parts list in this manual carefully. The use of substitute

replacement parts, which do not have the same safety characteristics as specified in the

parts list, may create shock, fire, or other hazards.

3. SERVICE NOTES

z When replacing parts or circuit boards, clamp the lead wires around terminals before

soldering.

z Keep wires away from high voltage, high temperature components and sharp edges.

z Keep wires in their original position so as to reduce interference.

z Adjustment of this product please refers to the user’ manual.

4

Page 5

BenQ FP93GW Service Manual

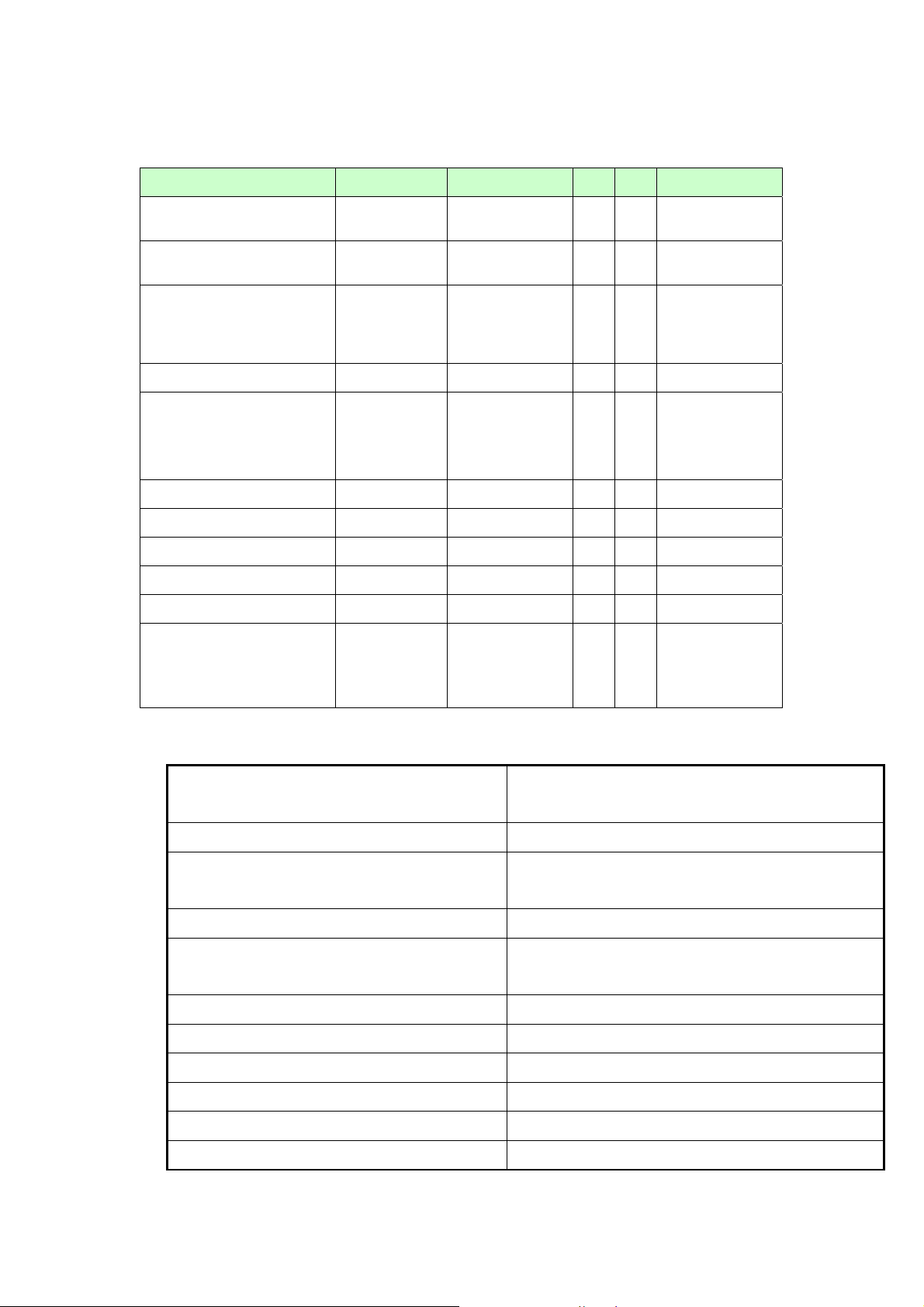

2.Product Overview

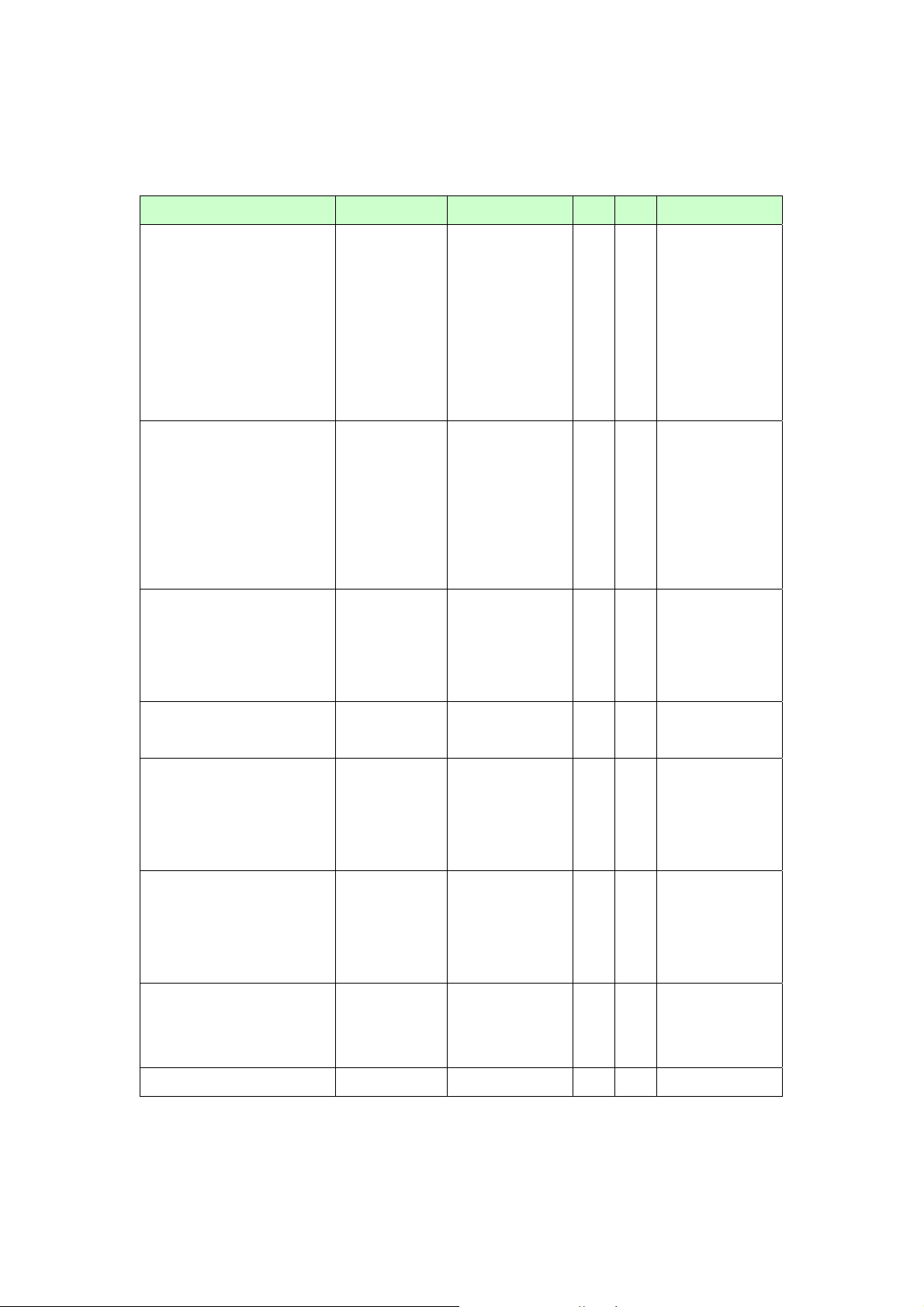

2.1 Power supply

Item condition Spec OK NA Remark

Input Voltage range

Input Current range

Power consumption

DMPS <2W

In rush Current

Earth Leakage Current

Hi-pot

Power Line Transient

CCFL Operation range

Power cord

Universal input

full range

100Vac

240Vac

with Audio,

normal “on”

operation

100Vac,cold

star,25°C;

240Vac,cold

star,25°C

100~240VAC

1.2A (max.)

0.6A (max.)

<45W

40A (max)

60A(max)

√

√

LED: Green

√

LED: Amber

√

√

√

To be determined

by the business

country.

2.2 Signal interface

Input Connector Analog : D-sub 15

Digital: DVI-D

Default Input Connector Defaults to the first detected input

Equal to twice the weight of the monitor for five

Video Cable Strain Relief

minutes

Video Cable Connector DB-15 Pin out Compliant DDC 2B / CI

1. Video RGB (Analog): Separate

Video Signals

2. DVI (Digital)

Video Impedance 75 Ohms (Analog), 100 Ohms (Digital)

Maximum PC Video Signal 950 mV with no damage to monitor

Maximum Mac Video Signal 1250 mV with no damage to monitor

Sync Signals TTL

DDC 1/2B Compliant with Revision 1.3

Sync Compatibility Separate Sync

5

Page 6

BenQ FP93GW Service Manual

Video Compatibility

Shall be compatible with all PC type computers,

Macintosh computers, and after market video cards

2.3 Video Performance

Item condition Spec OK NA Remark

Max. support Pixel rate 135MHz

Max. Resolution 1440x900

Rise time+Fall time <25% of

minimum pixel

clock period

Setting Time after

overshoot/undershoot

Overshot/undershoot

<5% final

full-scale value

<12% of step

function voltage

level over the full

√

√

Refer to VESA

√

Refer to VESA

√

Refer to VESA

√

VSIS Standard

V1R2

VSIS Standard

V1R2

VSIS Standard

V1R2

voltage range

2.4 Scan range

Item condition Spec OK NA Remark

Horizontal

Vertical

31 ~ 82 KHz.

56~76Hz

√

√

Without frame

buffer.

2.5 Plug & Play DDC2B DDC-CI Support

Item condition Spec OK NA Remark

DDC channel type DDC2B

EDID

Version #1,

Revision #3.

√

√

VESA’s EDID

Standard

Version #3,

Revision #0,

6

Page 7

BenQ FP93GW Service Manual

)

V-sy

)

V

2.6 Support Timings

Horizontal Scan Range: 31-82 KHz Vertical Refresh Rate: 56-76 Hz

Resolution Pixel clock (Mhz)H-sync (Khz

640x350 25.18 31.47 70.09 P N

30.24 35.00 66.67 N N

640x480

640x480 31.50 37.50 75.00 N N

720x400 28.32 31.47 70.08 N P

832x624 57.27 49.71 74.53 N N

800x600

848x480

720x576 32.71 35.83 60.00 N N

1024x768

1152x864

1152x870 100.00 68.68 75.06 N N

1152x900

1280x720

1280x768-R 68.25 47.40 60.00 P N

1280x768

1280x800 83.50 61.648 59.81 P N

1280x960 108.00 60.00 60.00 P P

1280x1024

1280x1024

1360x768 85.50 47.71 60.01 P P

1440x900-R 88.75 55.496 59.901 P N

1440x900 106.5 55.935 59.887 N P

1440x900 136.48 70.50 75.00 N P

25.17 31.47 59.94 N N

31.50 37.86 72.81 N N

36.00 35.16 56.25 P P

40.00 37.88 60.32 P P

50.00 48.08 72.19 P P

49.50 46.88 75.00 P P

33.75 31.02 60.00 P P

31.50 29.83 59.66 N P

37.52 35.00 70.00 N P

39.25 36.07 72.00 N P

41.00 37.68 74.77 N P

65.00 48.36 60.00 N N

75.00 56.48 70.07 N N

78.43 57.67 72.00 N P

80.00 60.24 74.93 N N

78.75 60.02 75.03 P P

94.50 63.85 70.01 P P

108.00 67.50 75.00 P P

92.94 61.80 65.95 N N

105.59 71.73 76.07 N N

74.25 45.00 59.94 N P

74.50 44.77 59.86 N P

95.75 56.46 74.78 N P

79.50 47.78 59.87 N P

102.25 60.29 74.89 N P

108.00 63.98 60.02 P P

126.99 74.88 69.85 P P

124.90 74.40 70.00 N N

134.60 77.90 72.00 P P

135.00 79.98 75.02 P P

135.09 81.18 76.16 N N

nc (Hz

H-Pol

-Pol

7

Page 8

BenQ FP93GW Service Manual

2.7 Operational &Function Specification

2.7.1 Video Performance

* All Spec. of monitor need to warm up at lease 1hr

Item condition Spec OK NA Remark

Resolution Any input

resolution

modes which

are list in the

timing table

(under

1440x900).

Contrast ratio

Max. resolution

1440x900

For INL

Min: 500:1

Typical: 700:1

For CMO

Min: 500:1

Typical: 850:1

Brightness Contrast and

brightness

max. value

230cd/m2

(Min.),

300cd/m2

(Typical)

√

√

√

Response time

Viewing angle

5 ms (Typical),

15ms (Max.)

Hor: 160°,

√

√

Ver: 160°

(Typical,

CIE coordinate of white

CR>10)

x--0.313 ±

√

0.030;

y--0.329 ±

0.030

Display colors

16.2M

√

(6-bits+FRC)

Response time with AMA

8

Page 9

BenQ FP93GW Service Manual

2.7.2 Brightness Adjustable Range

Item condition Spec OK NA Remark

Brightness adjustable range At default

contrast level

(saturate

point)&

Full-white color

pattern

2.7.3 Acoustical Noise

Item condition Spec OK NA Remark

Acoustical Noise At 1 meter

distance&

audio function

disable

2.7.4 Environment

Item condition Spec OK NA Remark

≧100 cd/m2

(Setting

brightness max.

value 100%; Min.

brightness value)

≦40dB/A

√

√

Temperature

Humidity

Altitude

2.7.5 Transportation

Item condition S pec OK NA Remark

Vibration

Unpackage vibration

Drop

Package, Non-operating Random Vibration:1. Sweep Frequency:

Unpackage , Non-operating

Package, Non-operating

Operating 0°C to 40°C

Non-operating -20°C to 60°C

Operating 20% to 80%

Non-operating 10% to 80%

Operating 0 to 3048 M (10000 ft)

Non-operating 0 to 12192M (40000 ft)

5~200Hz 2. Amplitude 1.47Grms 3.

Duration Time: 20 minute each axis( total

60 ) 4. Direction: 3 mutually perpendicular

axis (x, y, z)

91cm Height(1 corner,3 edges,6

√

√

√

√

√

√

√

√

√

faces)

shock

Wooden package ,

Non-operating

√

9

Page 10

BenQ FP93GW Service Manual

2.7.6 Electrostatic discharge Requirements

Item condition Spec OK NA Remark

Electrostatic discharge

InnoLux SPEC

Contact: 4KV

Air: 8KV

√

D-sub & DVI

cable pin only

need test 4KV

2.7.7 EMC

Item condition Spec OK NA Remark

TCO03

EMI

2.7.8 Reliability

Item condition Spec OK NA Remark

MTBF Prediction

CCFL life time

95% Confidence

Luminance

becomes 50%

≧ 60,000 Hours

≧ 40,000 Hours

at 6.8mA (min)

√

See note1.

√

Note1. Display an all white field at mid Brightness and Contrast settings.

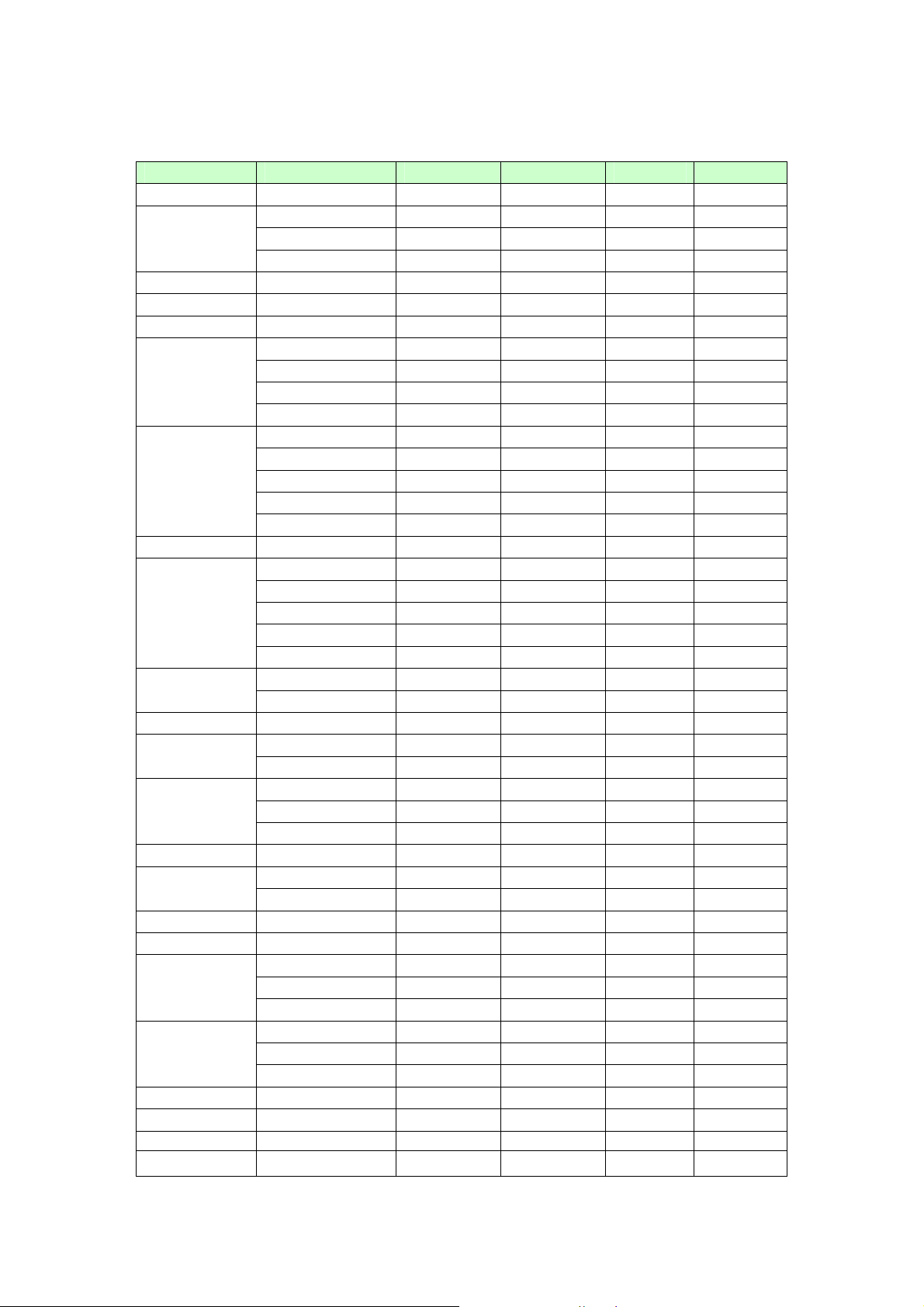

2.8. LCD Characteristics

2.8.1 The physical definition &technology summary of LCD panel

Item condition Spec OK NA Remark

LCD panel supplier INL&CMO

Panel type of supplier INL

MT190AW01 V.2;

CMO

M190A1- L02

Screen diagonal 19 inch diagonal

Display area 410.4mm (H)

x256.5mm (V)

Physical size

427.2mm

√

√

√

√

√

(W)x277.4mm

(H)x17mm(D)

(Typ.)

Weight 2500g (max.)

Technology TN type √

Pixel pitch

0.285mm x

10

√

v Per one triad.

Page 11

BenQ FP93GW Service Manual

0.285 mm

Pixel arrangement R/G/B vertical

strip

Display mode Normal white

Support color 16.2M colors (6

bits with FRC)

√

√

√

2.8.2 Optical characteristics of LCD panel

Item unit Conditions min Typ. max remark

Viewing angle

Contrast ratio Normal Direction 500 700

[degree]

[degree]

Horizontal

(Right/Left) CR ≥

10

Vertical

(Up/Down) CR ≥

10

70/

70

70/

70

80/

80 - -

80/

80 - -

Response time

Color/chromaticity

[msec] Rising Time - 1.5 6.5

[msec] Falling Time - 3.5 8.5

[msec] Rising + Falling - 5 15

Red x 0.610 0.640 0.67

0

Red y 0.304 0.334 0.36

4

Green x 0.256 0.286 0.31

6

Green y 0.569 0.599 0.62

9

Blue x 0.124 0.154 0.18

4

Blue y 0.047 0.077 0.10

7

White x 0.283 0.313 0.34

White y 0.299 0.329 0.35

Luminance uniformity

[%] 9 points 75 80 -

3

9

11

Page 12

BenQ FP93GW Service Manual

measurement % %

White Luminance @CCFL

[cd/m2] 220 300 -

7.0mA (center)

Crosstalk

2.9User Controls

2.9.1 User’s hardware control definition

Item condition Spec OK NA Remark

Monitor power button

Enter button

Right/Inc.button

Left/Dec. button

I-key button

Mode selection button

Input Select key

Mute button

Input source select button

√

√

√

√

√

√

√

√

√

2.9.2 OSD control function definition

Item condition Spec OK NA Remark

Monitor power button

Enter button

a. Turn on the

monitor.

b. Activate the OSD

control menu.

c. Select the

specific function.

d. Turn off the

monitor by pressing

the button for

3seconds.

√

√

12

Page 13

BenQ FP93GW Service Manual

Right/Inc.button

Left/Dec. button

a. Activate the

Volume control

menu, and increase

the value (optional)

b. View the

previous function in

the main OSD

menu

c. Increase the

value of specific

function which has

been selected

a. Activate the

Volume control

menu, and

decrease the value

(optional)

√

√

I-key button

Mode selection button

Input Select key

b. View the next

function in the main

OSD menu

c. Decrease the

value of the specific

function which has

been selected

Up + Down

Activate the Auto

Adjustment function

to optimize the

picture

performance

automatically

√

Auto adjustment

√

√

Mute button

Input source select button

2.10 Mechanical characteristics

2.10.1Dimension

13

√

√

Page 14

BenQ FP93GW Service Manual

Item condition Spec OK NA Remark

Bezel opening

Monitor without stand

Monitor with stand

Carton Box(outside)

Tilt and Swivel range

2.10.2 Weight

Item condition Spec OKNA Remark

Monitor (Net)

Monitor with packing(Gorss)

2.10.3 Plastic

Item condition Spec OK NA Remark

Flammability

Heat defelection to

UV stability

411.6x 257.7mm

L×W×Hmm

L×W×Hmm

L×W×Hmm

435.6*285.7*63.0mm

435.6*366.3*174.4mm

514*156*422mm

Tilt:-4~20degree

Swivel:

0 degree

4.25±0.3 Kg

5.50±0.3 Kg

√

√

94-HB

ABS 80°C

ABS

Delta E<12

√

√

√

√

√

√

√

√

resin

Texture

Color

2.10.4 Carton

Item condition Spec OK NA Remark

Color

Material

Compression strength

Burst strrngth

Stacked quantity

2.11. Pallet &Shipment

2.11.1 Container Specification

ABS

MT11000&MT11010&

MT11020

BCS-7015A(BLACK)/

BCS-8110C

Kraft

C Flute

180 KGF

16 KGF/cm2

5 Layers

√

√

√

√

√

√

√

√

LENS: MT11000

BACK COVER&Logo

cover: MT11020

Others:MT11010

Bezel painting

Stowing

Type

Containter Quatity of

Produces

(sets)

(Every

14

Quatity of

Produces

(sets)

(Every Pallet)

Quatity of

Pallet (sets)

(Every

container)

Page 15

BenQ FP93GW Service Manual

container)

With Pallet

20’ 800 Pallet A:80 Pallet A:10

40’ 1600 Pallet A:80 Pallet A:20

Without

Pallet

20’

40’

N/A N/A N/A

N/A N/A N/A

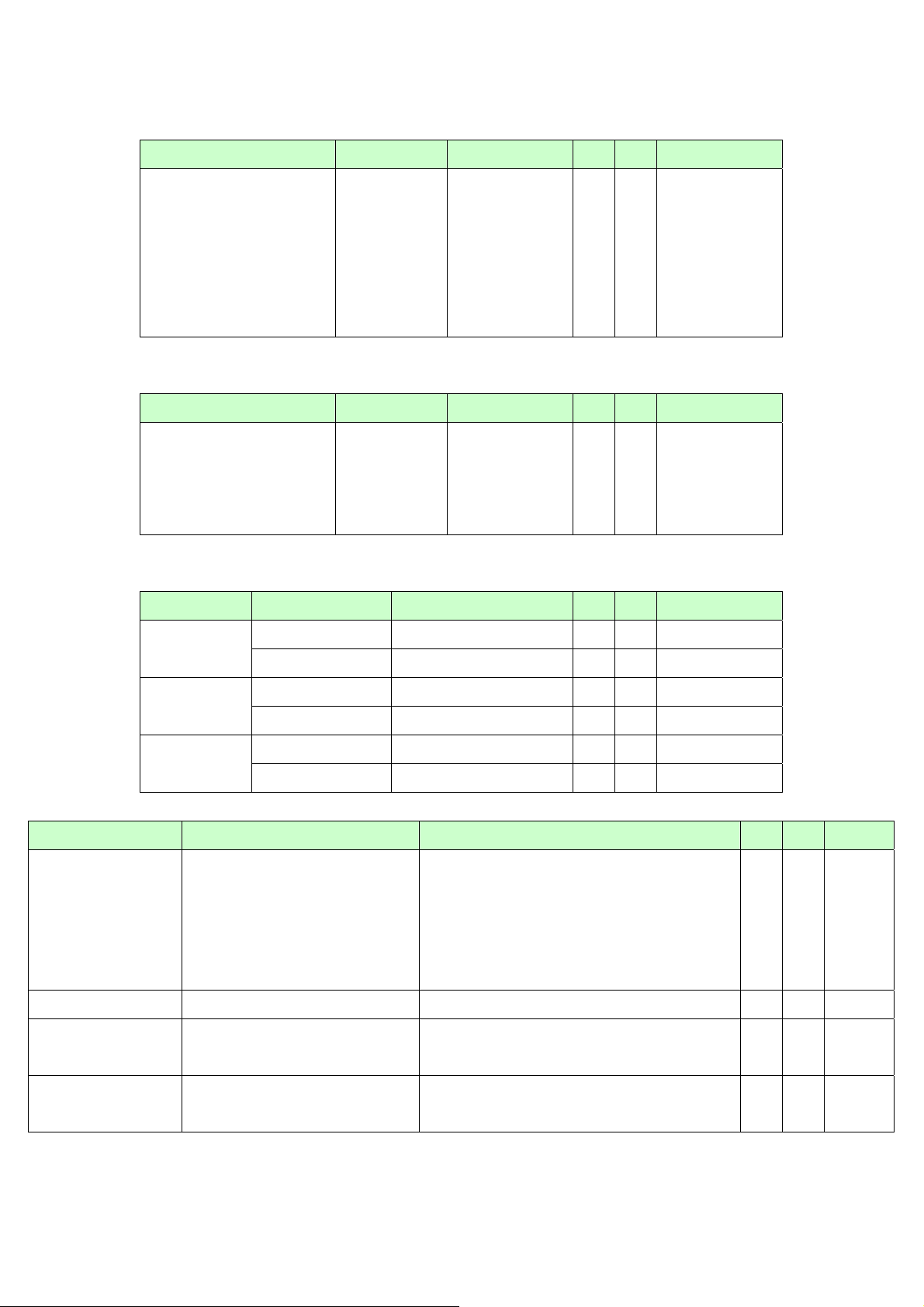

2.11.2 Carton Specifition

Product:

Net Weight (Kg) Gross Weight(Kg) Dimension w/o Base

LxWxH (mm)

4.25±0.3 Kg

Package:

Carton Interior Dimension (mm)

LxWxH

5.5±0.3 Kg

435.6*285.7*63.0mm 435.6*366.3*174.4mm

Carton External Dimension (mm)

LxWxH

Dimension w/ Base

LxWxH (mm)

506*148*405mm

514*156*422mm

15

Page 16

BenQ FP93GW Service Manual

3. Disassembly & Assembly

3.1 Exploded Diagram

714080250000R A SSY,PANEL(B),W/O SPK,LE1965-512

16

Page 17

BenQ FP93GW Service Manual

ASSEMBLY BLOCK

NOTES: The screw marked by purple color is the fix screw for two adjacent block

17

Page 18

BenQ FP93GW Service Manual

18

Page 19

BenQ FP93GW Service Manual

19

Page 20

BenQ FP93GW Service Manual

20

Page 21

BenQ FP93GW Service Manual

DISASSEMBLY BLOCK

NOTES: The screw marked by purple color is the fix screw for two adjacent

block

21

Page 22

BenQ FP93GW Service Manual

22

Page 23

BenQ FP93GW Service Manual

23

Page 24

BenQ FP93GW Service Manual

24

Page 25

BenQ FP93GW Service Manual

4Level 1 Cosmetic / Appearance / Alignment Service

4.1 Software / Firmware Upgrade Process

Upload firmware to MCU via VGA Cable

1. Connect ISP board between monitor and PC as below configuration

.

Insert to Parallel

Port on PC

ISP Board

Parallel

D-SUB

2. Press the “connect” button in ISP.exe, and select the device type, which is used in this

monitor. Choose the corresponding firmware version, and load to MCU.

3. After finish, please plug out power cable and re-start monitor again.

LCD Monitor

D-Sub

4.2 Alignment procedure (for function adjustment)

4.2.1.1 Preparation:

1. Setup input timing VESA to 1440*900@75Hz,32-Grays pattern.

2. Setup units and keep it warm up for at least 30 minutes.

4.2.1.2 timing adjustment

1. Enter to factory mode setting area (by pressing "minus"+ "power" at the same time during

power off).

2. Check the settings to following values:

contrast =50;

brightness=100;

color enhancement=general;

3. Then turn off the monitor power.

4.2.3 Function key Definitions

4.2.3.1 Control buttons on the Back bezel

• 3 buttons at the rear side of monitor

•

“UP”

Activate the Volume control menu, and increase the value

25

Page 26

BenQ FP93GW Service Manual

(optional)

View the previous function in the main OSD menu

Increase the value of specific function which has been

selected

•

“MENU/POWER”

Turn on the monitor

Activate the OSD control menu

Select the specific function

Turn off the monitor by pressing the button for 3 seconds

“DOWN”

•

Activate the Volume control menu, and decrease the value

(optional)

View the next function in the main OSD menu

Decrease the value of the specific function which has been

selected

•

“UP” and “DOWN”

Activate the Auto Adjustment function to optimize the picture

performance automatically

4.2.3.2 Hot Key Operation

CONTROL KEY KEYS FUNCTION

A. When OSD displays, press [MENU] to return to previous level menu

[MENU]

[Enter]

[►], [◄]

[POWER] Power on or power off the monitor

B. When OSD isn’t shown on screen, press [MENU] to enter OSD interface

C. press [Enter] to enter Service Page When OSD isn’t shown on screen in Service

Page Mode

A. When OSD isn’t shown on screen, press [Enter] to Select Input Source

B. When OSD displays, press [Enter] to perform function of menu icon that is highlight

or enter next level menu

A. When “MENU OSD” displays, press these keys to change the contents of an

adjustment item, or change an adjustment value

B. When “MENU OSD” un-displays, press [◄],to show Brightness/Contrast Menu

press [►] to Show Picture Mode Menu.

[iKey] press [iKey] to perform auto-adjustment

4.2.3.3OSD Control

The On-Screen Display (OSD) shall be an easy to use icon based

menu through keypad OSD buttons or remote control unit. The unit

shall leave the factory with all OSD controls set to their default values.

26

Page 27

BenQ FP93GW Service Manual

Main Menu, Analog Input

Level 1 Level 2 Level 3 Default

EXIT

AUTO

ADJUSTMENT

CONTRAST 50

BRIGHTNESS 100

INPUT SIGNAL

SELECT

OSD MENU

LANGUAGE

EXIT

ANALOG (D-SUB)

DIGITAL (DVI)

EXIT

ENGLISH

GERMAN

FRENCH

ITALIAN

SPANISH

ANALOG (D-SUB)

ENGLISH

ASPECT RATIO

COLOR

SIMPLIFIED CHINESE

TRADITIONAL CHINESE

JAPANESE

RUSSIAN

SWEDISH

POLISH

DUTCH

Serbo-Croatian

Czech

Hungarian

Portuguese

Romanian

EXIT

NATIVE

FULL SCREEN

EXIT

NATIVE

GENERAL

ENHANCEMENT

POWER SAVING EXIT STANDARD

GENERAL

TEXT

PICTURE

27

Page 28

BenQ FP93GW Service Manual

MODE

OTHERS

STANDARD

ADVANCED

EXIT

AUTO COLOR

DDC/CI

COLOR TEMPERATURE

OSD MENU POSITION

EXIT

ON

OFF

EXIT USER

USER/RED 80

USER/GREEN 80

USER/BLUE 80

COOL

WARM

EXIT

RIGHT

CENTER

ON

RIGHT

LEFT

CLOCK 50

PHASE By Timing

HORIZONTAL POSITION 50

VERTICAL POSITION 50

INFORMATION BY TIMING

RECALL

Main Menu, Digital Input

Level 1 Level 2 Level 3 Default

EXIT

CONTRAST 50

BRIGHTNESS 100

INPUT SIGNAL

SELECT

EXIT

ANALOG (D-SUB)

DIGITAL (DVI)

ANALOG (D-SUB)

OSD MENU

LANGUAGE

EXIT

ENGLISH

GERMAN

FRENCH

ITALIAN

28

ENGLISH

Page 29

BenQ FP93GW Service Manual

ASPECT RATIO

SPANISH

SIMPLIFIED CHINESE

TRADITIONAL CHINESE

JAPANESE

RUSSIAN

SWEDISH

POLISH

DUTCH

Serbo-Croatian

Czech

Hungarian

Portuguese

Romanian

EXIT

NATIVE

FULL SCREEN

NATIVE

COLOR

ENHANCEMENT

POWER SAVING

MODE

OTHERS

EXIT

GENERAL

TEXT

PICTURE

EXIT

STANDARD

ADVANCED

EXIT

DDC/CI

COLOR TEMPERATURE

EXIT

ON

OFF

EXIT USER

USER/RED 80

USER/GREEN 80

USER/BLUE 80

COOL

GENERAL

STANDARD

ON

OSD MENU POSITION

29

WARM

EXIT

RIGHT

CENTER

LEFT

RIGHT

Page 30

BenQ FP93GW Service Manual

INFORMATION BY TIMING

RECALL

• Volume Menu

Level 1 Default

VOLUME 50%

4.2.3.4. Factory Mode Introduction

When signal is input, press “power key” to turn off the monitor. Press “-” and “Power” together

to turn on the monitor. After power on, press “Power” to call out Main Menu, then press “-“for

select the “F” item, then press “power/menu”, you can go into Factory mode.

EXIT: Escape from Factory menu.

PANEL: Display panel information.

AUTO COLOR: Automatically calibrate chip ADC parameter by using chip internal DAC.

GAIN: ADC gain value

OFFSET: ADC offset value

SPAN and STEP: Spread spectrum value.

BRI: Brightness value

CON: Contrast value

9300K: Set color temperature 9300K

6500K: Set color temperature 6500K

USER: Set user preferred color temperature

RS232: F/W RS232 debug on or off

BANK, ADDR, VALUE, H-TOTAL:F/W adjust the scaler register and h-total to panel for better

performance.

TIME: The time of backlight used.

4.2.3.5 After repair, to ensure the quality you should do the following test and

adjustment

Item Content Equipment

Tes t O SD

function

1.Signal is set as 1440×900@60Hz under General-1

2.Checking whether each single function key and

compound function key can be worked.

Chroma

Signal Generator

30

Page 31

BenQ FP93GW Service Manual

g

g

Contrast

Check

Color

Temperatur

e

Modes

switching

check

1. Set input mode to 1440×900@60Hz

2. Set Pattern to 32 gray shades

3. Set contrast to the max. The brightest 5~8 shades

brightness

cannot be distinguished.

1. Do “Auto color Balance” at 1440×900@60Hz, 32gray

shades

2. Measure color temperature, check it complies with the

following temperature :

6500K x = 0.313 +/- 0.03, y = 0.329+/-0.03

1. Use Chroma Pattern Generator to make sequence.

VESA (640x480 800x600 1024x768 1280x1024),

and power saving signal,etc.

2. Confirm the above timing modes must be full screen

Chroma

Signal Generator

Chroma Signal

Generator and color

analyzer

Chroma

Signal Generator

VGA cable

detector

Panel

Flicker

Power

saving

and

When VGA cable is not plugged, the monitor will work in

power saving mode.

1. Mode:1440×900@60Hz

2. Set Brightness& contrast to default value

3. Do “Auto Adjustment”

4. Shut down PC to check whether there’s glitter on the

1.

Mode:1440×900@60Hz

Visual check

Chroma Si

nal

Chroma signal

generator

& PC

Chroma signal

at each modes

2. Pattern: full white

generator

State Power LED color

Normal

reen

Stand By amber

Power Key Off

no

31

Page 32

BenQ FP93GW Service Manual

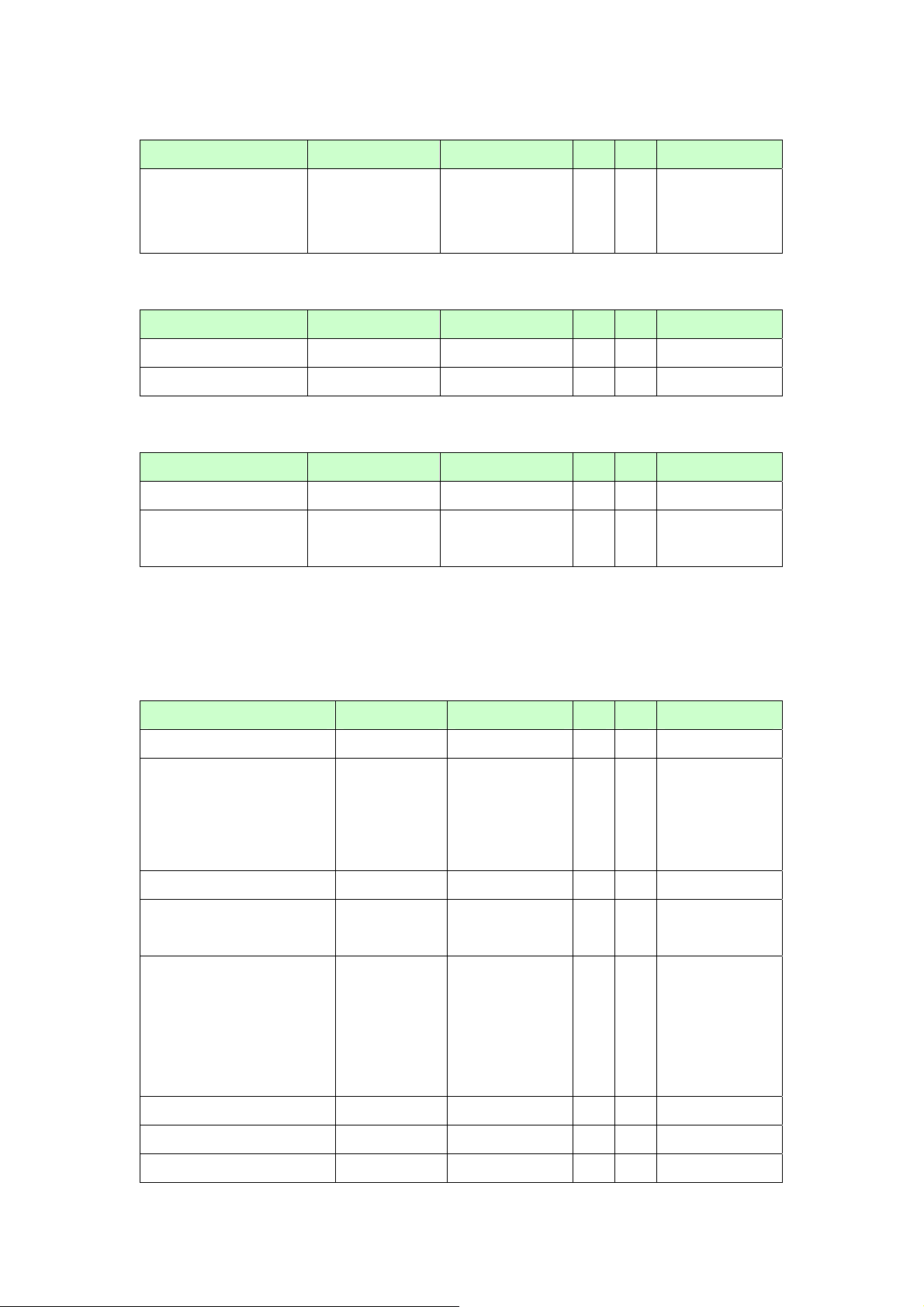

5. Level 2 Circuit Board and Standard Parts Replacement

5.1. Block diagram

Power Board

D801

1

BL4-06

100u/450V

3

-+

4

AC 264V RMS

2

L801

12mH

4 1

3 2

R801

R802

1M

1M

C803

0.47/275V

NTC 5R

C802

2200p/250V

RT801

AC 264V RMS

2200p/250V

F801

2A/250V

C801

1 2 3

L

P801

N

AC_SKT

IF Board

R502

10K 1%

C503

3300p/50V

C504

FT

10u/16V

R504

REF

1M

BRIGHTNESS

ON/OFF

+14V

R509

10K

R510

10K

OV

R514

68K

R515

22K 1%

C502

NC

10R

1000p/500V

R827

T801

D802

100p/1KV

R517

220K

C808

R513

22

C825

0.1/50V

C806

4700p/400V

C807

47u/25V

R813

1K

C527

1000p/50V

R512

22

C528

1000p/50V

R518

D510

10K

SN4148

R520

10K

D511

SN4148

C805

2200p/400V

DC 700V Max.

+

1

2 3

1

2 3

D804

SRF103

VCC5V

ON/OFF 2

BRIGHTNESS2

Volume 4

Audio_MUTE 4

U501

AP9962GH

U502

AP9962GH

REF

R521

75K

R522

75K

1

2

3

4

5

C513

0.1/25V

3

D503

BAW56

D504

3

BAW56

SPW-055

C823

4700p/400V

3

IC801

LTV817M

VIN

OL3

1

OL2

2

OL4

1

OL1

2

11

10

D803

UFF80-015C T

9

8

7

6

PMBT3904 NC

C509

C515

R523

2.2u/25V

2.2u/25V

NC

C516

R524

2.2u/25V

NC

DC 380V Max.

R804

68K 2W

R808

10R

12p/1KV

R806

R810

510K

R811

510K

45

GNDDRV

3

CS

2

FB

1

BO

R815

12K 1%

CN801

1

2

3

4

5

6

7

8

60mm 8P

TO SCALER BD C N101

C508

1u/16V

16

AGND

15

GND

14

BG

13

VCC

12

SW

11

TG

10

BT

VIN

+

C501

680u/25V

L501

5uH

R516

165K 1%

R506

150K 1%

1

Q501

Q503

2N7002

PMBT3904

510K

R809

510K

D512

SN4148

32

32

MUR1100ERL

DC

700V

Max.

23

AP2761I

C826

Q804

1

R812

10K

R814

1K

R807

1K

R805

0R24 2W

C811

0.1/50V

C812

220p/50V

C510

NC

REF

C511

0.047/50V

+

Q502

2N7002

1

R519

C517

1M

0.1/50V

1

R525

1M

C518

0.1/50V

+

C804

R803

18K

AC 264V RMS

IC802

6

Vcc

7

NC

8

HV

R505

100K 1%

R511

100K 1%

1

2

1

2

100p/1KV

LV1

LV2

LV3

LV4

C809

C810

0.1/50V

1

OV

OV

LI

2

LI

3

COMP

4

FT

LCS

5

FSET

6

BOSC

7

DBRT

8 9

EN VIN

IC501

MP1008

C507

0.01/50V

FT

NCP1337

C512

470u/25V

D513

SN4148

LCS

32

AC 264V RMS

C506

220p/50V

3

D501

BAV70

3

D502

BAV70

C813

470u/25V

+

D806

1N4148

+

C827

47u/25V

+

C819

C815

680u/25V

C816

680u/25V

R830

10K

5uH

L802

+

5uH

L803

+

C821

0.1/100V

C

R

A IC803

TLV431ALP

1

3

10R

R828

1

3

D805

SRF5-04CT

14

2

Q802

C824

0.1/50V N C

2

C814

1000p/500V

2

470u/25V

C818

R819

1K

R820

1K

32

1

InnoLux

Docum ent Num b er : SIZE :

TITLE :

DATE :

SHEET OF

C514

2.2u/25V

2

3

5

6

SPW-078 14:2600 300mh

2

3

5

6

T501

T502

SPW-078

PI BOARD_POWER

2006-12-13

C519

10p/3KV

C520

4700p/50V

8

7

C521

10p/3KV

C522

4700p/50V

C523

10p/3KV

C524

7

4700p/50V

8

C525

10p/3KV

4700p/50V

Docume nt Numb e r : SIZE :

TITLE :

DATE :

SHEET OF

470u/25V

1K

R821

LV4

C817

LV1

R527

20K 1%

LV2

R528

20K 1%

LV3

R529

20K 1%

R530

20K 1%

InnoLux

+

ZD803

9V1

R817

200R

C820

47u/25V

+

C822

0.1/50V

R822

5K1 1%

R824

3K3 1%

benq 19

A4

Rev :

R545

470

OL1

R535

D508

820 1%

SN4148

OL2

R536

820 1%

D507

SN4148

R546

OL3

470

R537

820 1%

D505

SN4148

R547

470

OL4

R538

820 1%

D506

SN4148C526

LI

PI BORA D_INVERTER

2006-12-13

R823

51K 1%

V0176

R544

470

R543

2K2 1%

Rev :

2

3

1

10K

R829

APPRO BY :

CHECK BY :

DRAWN BY :

CN504

1

H

4100-D02

2

L

R539

20K 1%

CN501

4100-D02

1

H

2

L

R540

20K 1%

CN503

4100-D02

1

H

2

L

R541

20K 1%

CN502

4100-D02

1

H

2

L

R542

20K 1%

A3doc

0177

R816

100R 1W

Q801

2PC1815GR

F802

4A/125V

ZD801

5V6 NC

R825

1K NC

APPRO BY :

CHECK BY :

DRAWN BY :

ZD802

16V NC

R826

200R NC

+14V

VCC5V

32

Page 33

BenQ FP93GW Service Manual

5.2 Circuit operation theory

The operation for the interface board is to convert the analog signals of Red,

Green and Blue to the digital signals of Red, Green and Blue. The scaling

IC has the internal A/D converter, MCU,OSD and auto detecting input timing

functions. A/D converter converts analog signals to digital data. OSD offers

adjustable functions to the end-users. Auto detecting timing function can

detect change modes. LVDS transmitting circuit is also embedded in the

TSUM56AL. It outputs the digital R-G-B data, pixel clock and control signal

to TCON of the LCD module. The flash ROM (PM25LV010A-100SCE) to

store the firmware code. The MCU (TSUM56AL) is also responsible for the

system processing. EEPROM 24C02 stores the DDC data. EEPROM

24C04 store the data of OSD parameter and user preset timings.

IC introduction:

1) TSUM56AWHK SCALER IC: There are A/D converter, DVI-Rx,scaling,

OSD, MCU, LVDS transmitting system in the TSUM56AL IC. The scaling

engine is revolutionary, capable of expanding any input resolution to a

highly uniform and sharp image. It consists of quality integrated 8 bits

triple-ADC and patented Rapid-lock digital clock recovery system. It also

supports detecting modes and DPMS control. The MCU does all the control

management. Any interrupt signals from the control board would be picked

up by the MCU and actions will be processed accordingly.

2) Flash:The flash ROM will be used to store the firmware.

3) EEPROM: We use two 24C04 EEPROMs .One is used to store the

data of OSD parameter and user preset timings.The other(optional) is used

to store HDCP data..And we used two 24c02 EEPROMS. One is used to

store the VGA DDC data,the other is used to store the DVI DDC data. PC

can access the EEPROM data indirectly through the Dsub(DVI)-SDA and

Dsub(DVI)-SCL channels. (IIC communication)

Power board diagram:

AC Current Input Circuit

P801 is a connector for connecting AC Power. F801 is a fuse to

protect all the circuit. AC input voltage is from 90V to 264V. R801 and

R802 joined between two inputting main circuit to prevent man from

shock. L801 is used to clear up low frequency wave. C801 and C802

are used to discharge the waves that L801 produced. High frequency

33

Page 34

BenQ FP93GW Service Manual

waves are damped by C801 and C802. D801 is a rectifier which

composed of 4 build-in diodes, it inverts AC to DC.

High Voltage to Low Voltage Control Circuit

C804 is used to smooth the waveform from rectifier. IC802 is a highly

integrated PWM controller, which control the power MOSFET Q804.

When rectified DC high voltage is applied to the DRAIN pin during

start-up, the MOSFET is off initially, and the capacitor C808 be

charged through D802,R803 and the HV pin of IC802,when the

voltage VCC reaches the threshold level 12.8V,IC 802 start up and

create a PWM signal to control the power MOSFET, then energy is

transferred to secondary terminal through the transformer T801,the

auxiliary voltage 12V and the output voltage 5V/14V be created ,the

auxiliary voltage supply a continue current to IC802,the level of output

voltage is feedback to FB pin of IC802 through

R823,R824,R822,IC803 and IC803 witch control the duty of the PWM

signal, then all the convert circuit go to a stable operating station.

R805 R806 R833 ZD801 ZD806 and Q801 formed a under input

voltage protection circuit , only the input AC voltage over the

threshold level approximately 63V AC, the switch Q801 can be on

and then the auxiliary voltage can supply a continue current to

IC802;R808,R807,R812,R815,R836,D806 and Q805 formed a over

line current protection circuit witch limited the input power under

approximately 63W. ZD805 will be on when the output voltage is too

high or the feedback circuit open, the current will drive transistor

Q805 open through R830,D814 and made IC802 off the PWM

waveform; the high voltage spike created by transformer’s primary

winding during the transistor turn off will be consumed through D804

R813 R814 and C806, This will prevent MOSFET which built-in IC802

from being damaged under large current impulse and voltage spike.

DC_5V and DC_14V Output Circuit

For DC 5V, D808 is used to rectify the inducted current. R817 and

C815 are used to store energy when current is reversed. The parts

including C824,C818,C822 and L803 are used to smooth the current

waves.

For DC 14V, D807 is used to rectify the inducted current. R816 and

C814 are used to store energy when current is reversed. The parts

including C816,C817,C819 and L802 are used to smooth the current

34

Page 35

BenQ FP93GW Service Manual

waves.

Feedback and OVP Protect Circuit

Pin R of IC803 is supplied 2.5V stable voltage. It is connected to 5V

and 14V output through R823, R824 and R822. R823 R824 and R822

are output sampling resistor. When the sampling voltage more than

2.5V or less than 2.5V, feedback current of IC802 will change, this

can change the voltage from transformer T801.

For output OVP, ,ZD802 and ZD803 are zener diode, when the

voltage add to the zener up to their’s rating voltage 5.6V, or 16V, the

zener’s leakage current cause R828 voltage become up to 0.7V,

Q803 is triggered and OVP starts. The collector current of Q803 is

used to make build-in diode light. FB Current of IC802 will be

changed; it can change the output voltage from T801.

5.2.2Inverter Circuit

Inverter circuit

1. Low voltage to high voltage circuit

14VDC provides the power for IC501; the control signals Brightness and

ON/OFF come from I/F board. ON/OFF signal connect to pin9 of IC501 and

makes IC501 enable. Brightness signal connect to pin7 of IC501 and regulates

the panel brightness, R504, C504 make up a network of delaying time circuit

and R509, make up a divided voltage network, C506 is used to dump noise.

The operation frequency is determined by the external Resistor R505

connected to pin5 of IC501.

The output drives, include BG, TG (pins11,14 respectively) output square

pulses to drive MOSFET U501, U502, and each of U501, U502 , is consist of a

N channel MOSFET. U501,OR U502 work as Half bridge topology, it is high

efficient, PWM switching.

During start up, VSEN (pin6) senses the voltage at the transformer

secondary. When OV reaches 1.2V, the output voltage is regulated. If no

current is sensed approximately 1.5seconds IC501 shut off.

The current flowing through CCFL is sensed and regulated through sense

resistor R502, R543 The feedback voltage connected to Pin2 (ISEN), then

compared with a reference voltage (1.2V) via a current amplifier, resulting in

PWM drive outputs to Half bridge switches.

2. Protection circuit

Over Voltage Protection and over-current protection are monitored by the

35

Page 36

BenQ FP93GW Service Manual

voltage on OV(Pin 1) During normal operation , if a CCFL is damaged or

removed ,the voltage at VSEN (Pin1) increases .Once the voltage at OV

exceeds 1.2V (OV Setting) the driver the shutdown delay timer is set the

overall protection threshold voltage that is lower than 1.2V (FT threshold).

Once the voltage at FT pin reached about 1.2v ,the IC will shut down and

latch .C519,C521,C523,C525, are connected in high voltage output connector,

the divided AC voltage is inverted DC voltage through D501,D502 ,R515,

C502are used to rectify wave & dump noise. Then the voltage signal reaches

Pin1 OV of IC501, when the voltage changes, build-in PWM of IC501 will

adjust output voltage.

Open Lamp Protection: In normal operation, R502 are sensed a high level

DC voltage, If a CCFL is removed or damaged during normal , Q502 or Q501

Gate voltage will change to low voltage ,the D513 Cathode will is a high

voltage ,a current charge the c504,when FT reaches a threshold of

approximately 1.2V, ,The drive outputs shut down and latch .

36

Page 37

BenQ FP93GW Service Manual

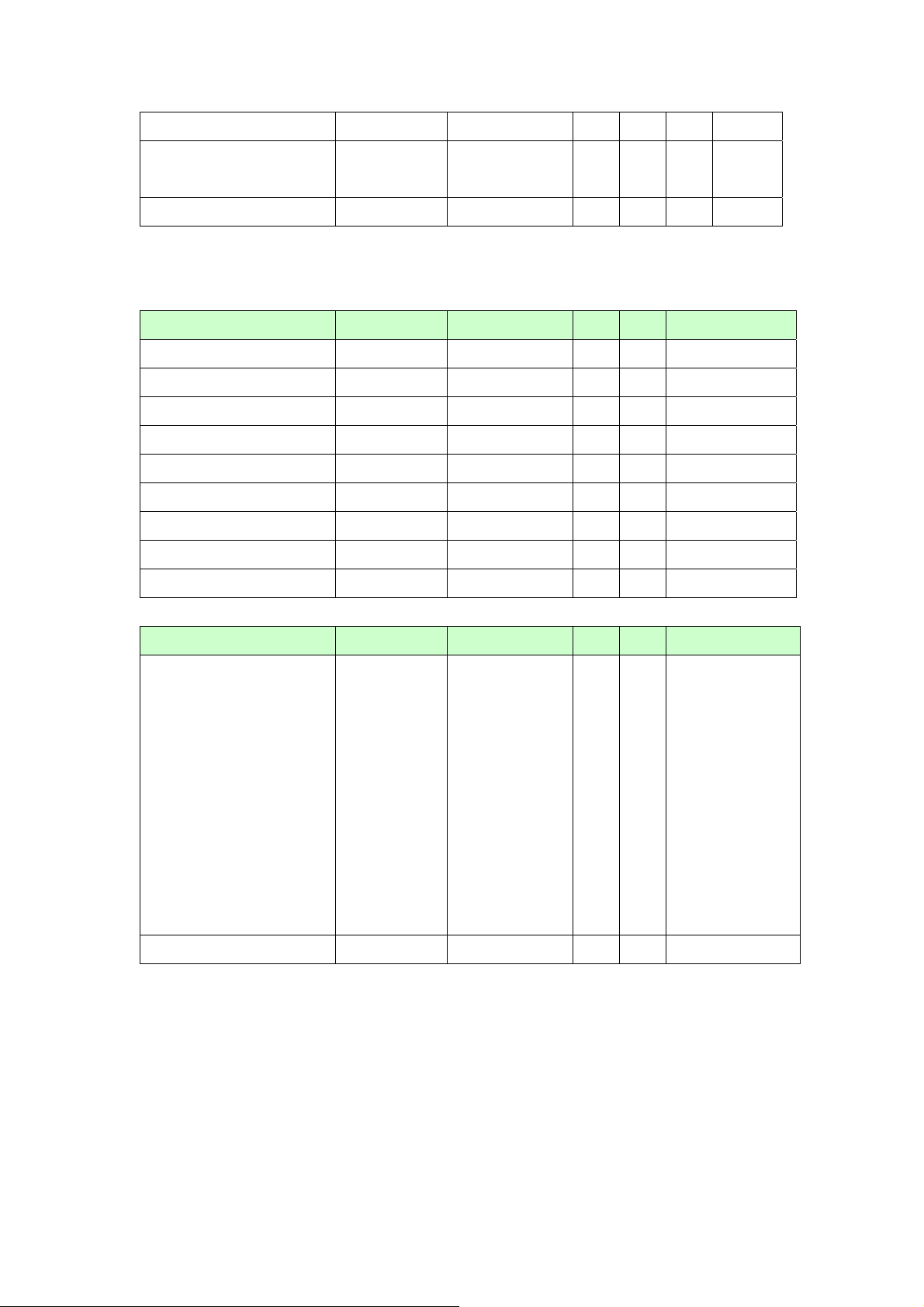

5.3 TROUBLE SHOOTING GUIDE

37

Page 38

BenQ FP93GW Service Manual

38

Page 39

BenQ FP93GW Service Manual

No raster

39

Page 40

BenQ FP93GW Service Manual

5.3 Spare Parts List

Category

Panel

PCBA

Cover

Innolux Part

Innolux Description MOQ

Number

631102090650R LCD PANEL 19" M190A1-L02(A)(CMO)RoHS 20

631102090821R LCP 19" MT190AW01-V2- G1,AM1900004201(IN 20

790981300520R PCBA,I/F BOARD(L02),LE1965-512 ROHS 20

790981300610R PCBA,I/F BOARD(V2),LE1965-612 ROHS 20

790981400600R PCBA,P/I BOARD,LE1965-612 ROHS 20

790981500000R PCBA,KEYPAD BOARD,LE1965 ROHS 20

501010210800R BEZEL,FRONT(S),LE1965 20

501010210801R BEZEL,FRONT(B),LE1965 20

501030206600R BUTTON,FUNCTION KEY(S),LE1965 20

501030206601R BUTTON,FUNCTION KEY(B),LE1965 20

501030206610R BUTTON,FUNCTION KEY 1(S),LE1965 20

501030206611R BUTTON,FUNCTION KEY 1(B),LE1965 20

501120105700R LENS,LE1965 20

714010010200R ASSY,STAND(B),LE1965 20

Cable

714020009100R ASSY,BASE(B),LE1965 20

714030010500R ASSY,FRONT BEZEL(S),LE1965 20

714030010501R ASSY,FRONT BEZEL(B),LE1965 20

714050009800R ASSY,BACK COVER(B),LE1965 20

430300801010R HRN ASS'Y 8P to 6P 100mm UL1571#28,RoHS 20

430303000940R HRN LVDS FFC 30P 168mm,ROHS 20

453010100310R CABLE D-SUB 15P MALE 6FT BLACK/BLUE ROH 20

453070800150R PWR CORD 10A/125V BLK 6FT UL/CSA SVT 3Cx(USA) 20

453070800170R PWRCORD 10A/250V BLK 6FT CHINA.RVV 3Gx0. 20

453070800420R

453070800500R

453070800640R

453070800790R

PWRCORD 10A/250V BLACK 6FT SAA

H05W-F/3G(AUS)

PWRCORD 16A/250V BLK 6FT KTL H05VV-F

3Gx(KOREA)

PWRCORD 7A/125V BLK 6FT PSE VCTF

3Gx0.75(JAPAN)

PWRCORD 16A/250V BLK 1830mm STQC

H05VV-F(india)

20

20

20

20

KIT

703000000210R KIT ACCESSORY BenQ-Jap,LE1965 20

40

Page 41

BenQ FP93GW Service Manual

9

703000000230R KIT ACCESSORY BenQ-Ind,LE1965 20

703000000240R KIT ACCESSORY BenQ-Kor,LE1965 20

703000000250R KIT ACCESSORY BenQ-Aus,LE1965 20

506020001400R CARTON,BENQ,LE1965 30

Carton

506020001410R CARTON BENQ-CHINA,LE1965 30

506040012100R CUSHION,EPS-TOP,LE1965 30

506040012110R CUSHION,EPS-BOTTOM,LE1965 30

Appendix 1 – Screw List / Torque

BenQ FP93GW Screw List

P/N DESCRIPTION Q'TY

509212610300R SCREW,F,CROSS,T-T4*10,BLK,ROHS 3

509216610500R SCREW,F,CROSS,M4*10,BLACK,NYLOK

509916306200R SCREW,C,CROSS,M3*6,Zn-Cc,ROHS

509000000700R BOLT,#4-40x11.8,Ni FOR D-SUB/DVI

CONN.ROHS

2

6

4

Torque

(kg.f) Remark

For hinge to stand-cover

10.5±0.5

10.5±0.5

6.5±0.5

4.0±0.5

For back-cover to hinge

For PCB

For D-SUB/DVI Connection

509412306100R SCREW,B,CROSS W/W(T)M3*6,ZnROHS 1 3.5-4.0 For PCB

41

Loading...

Loading...