Page 1

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

1. Alignment procedure (for function adjustment)

A. Preparation:

1. Setup input timing ICL-605( 1280x1024@75Hz ), 32-Grays pattern.

2. Setup unit and keep it warm up at least 30 minutes.

B. Timing adjustment:

1. Enter factory setting area (press “ENTER”, “EXIT” and then press “SOFTPOWER”).

2. Check the settings to following values:

Then, turn off the monitor power.

3. Turn on power enter user area.

C. Color balance adjustment:

Contrast = 50

Brightness = 90

OSD time = 20

Color = Normal

Language = English

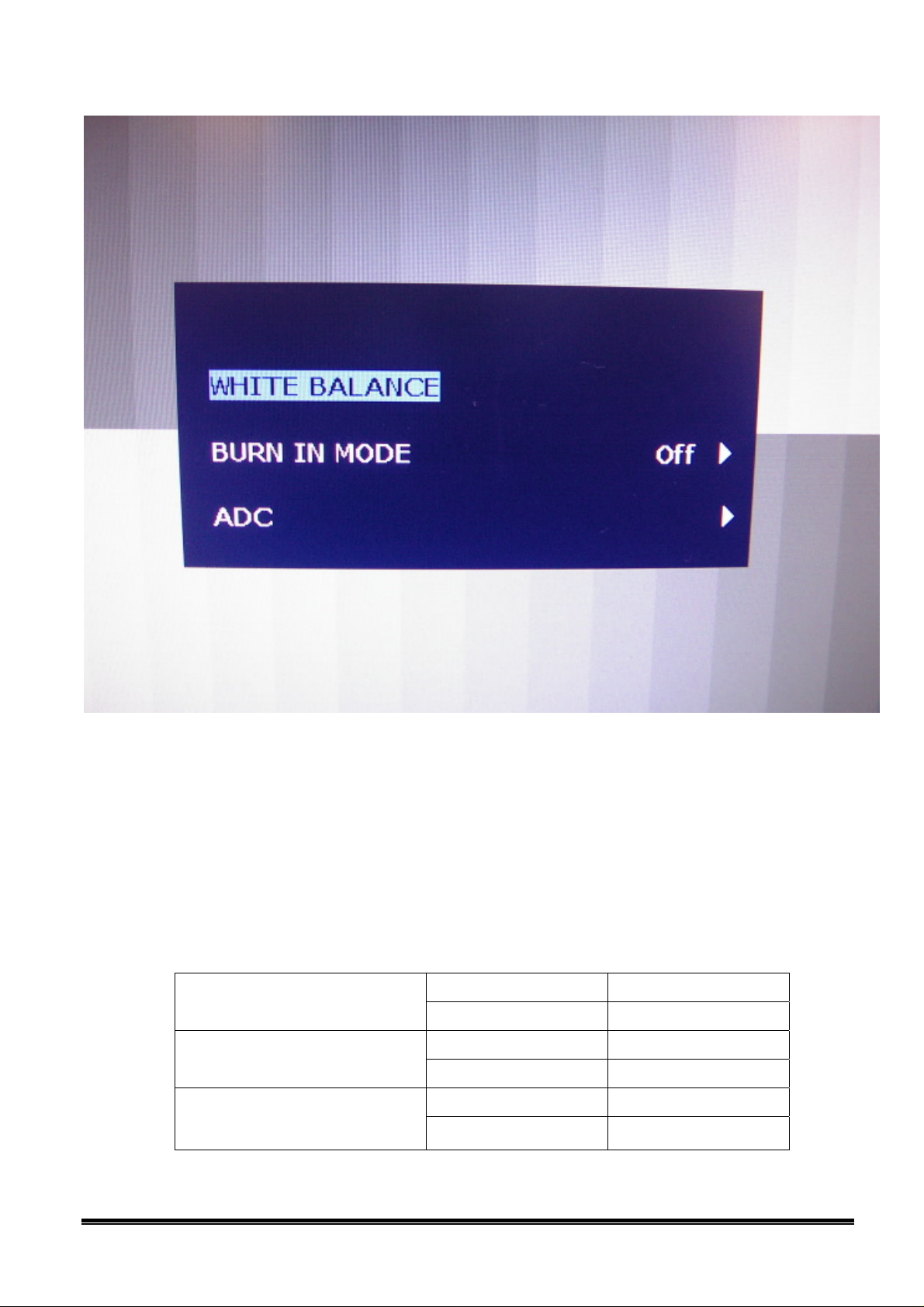

1. Enter factory setting area (press “ENTER”, “I-Key” and then press “SOFTPOWER”).

2. Setup input timing ICL-605(1280x1024@75Hz), 32-Gray pattern (pattern 48) .

3. Press “I-KEY”, and than OSD will show “White Balance” item and than press “ENTER” button

to do auto color.

1

Confidential

Page 2

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

D. Color adjustment:

1. Setup input timing ICL-605, white pattern .

2. Confirm auto color adjustment had already done.

3. Measure color temperature by Minolta CA-110 (or equivalent equipment).

4. Check the color temperature Bluish, Reddish & Normal. The color temperature specification

as follows:

X+- 0.283+(-) 0.03 White Balance

(Bluish, 9300K set on OSD)

Y+- 0.297+(-) 0.03

X+- 0. 326+(-) 0.03 White Balance

(Reddish, 5800K set on OSD)

Y+- 0. 342+(-) 0.03

X+- 0.313+(-) 0.03 White Balance

(sRGB, 6500K set on OSD)

Y+- 0. 329 +(-) 0.03

2

Confidential

Page 3

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

5. Setup input timing , 32 -Gray pattern.

To check if there are any abnormal display problems of preset timing modes .

Check the following preset timings with General pattern:

No. Mode H V

1 720×400 @ 70Hz 31.468 70.8

2 640×480 @ 60Hz 31.469 59.940

3 640×480 @ 75Hz 37.500 75.000

4 800×600 @ 60Hz 37.879 60.317

5 800×600 @ 75Hz 46.875 75.000

6 1024×768 @ 60Hz 48.363 60.004

7 1024×768 @ 75Hz 60.023 75.029

8 1152x864 @ 75Hz 67.500 75.000

9 1280×1024 @ 60Hz 63.981 60.020

10 1280×1024 @ 75Hz 79.976 75.025

6. Checking if the picture is no good, reject this monitor.

7. To check the power consumption by disabling “burn-in mode” setting

8. To clear user data and program complete DDC data to monitor by IIC bus communication.

E. Writing EDID file:

1. Setup a PC with DDC card.

2. Connect PC to monitor with a D-sub signal cable.

3. Please refer to the C212 for the correct EDID file.

4. Runs the writing program to write the EDID file into EEPROM .

5. Read EEPROM data and confirm it to match with the C212 document definition.

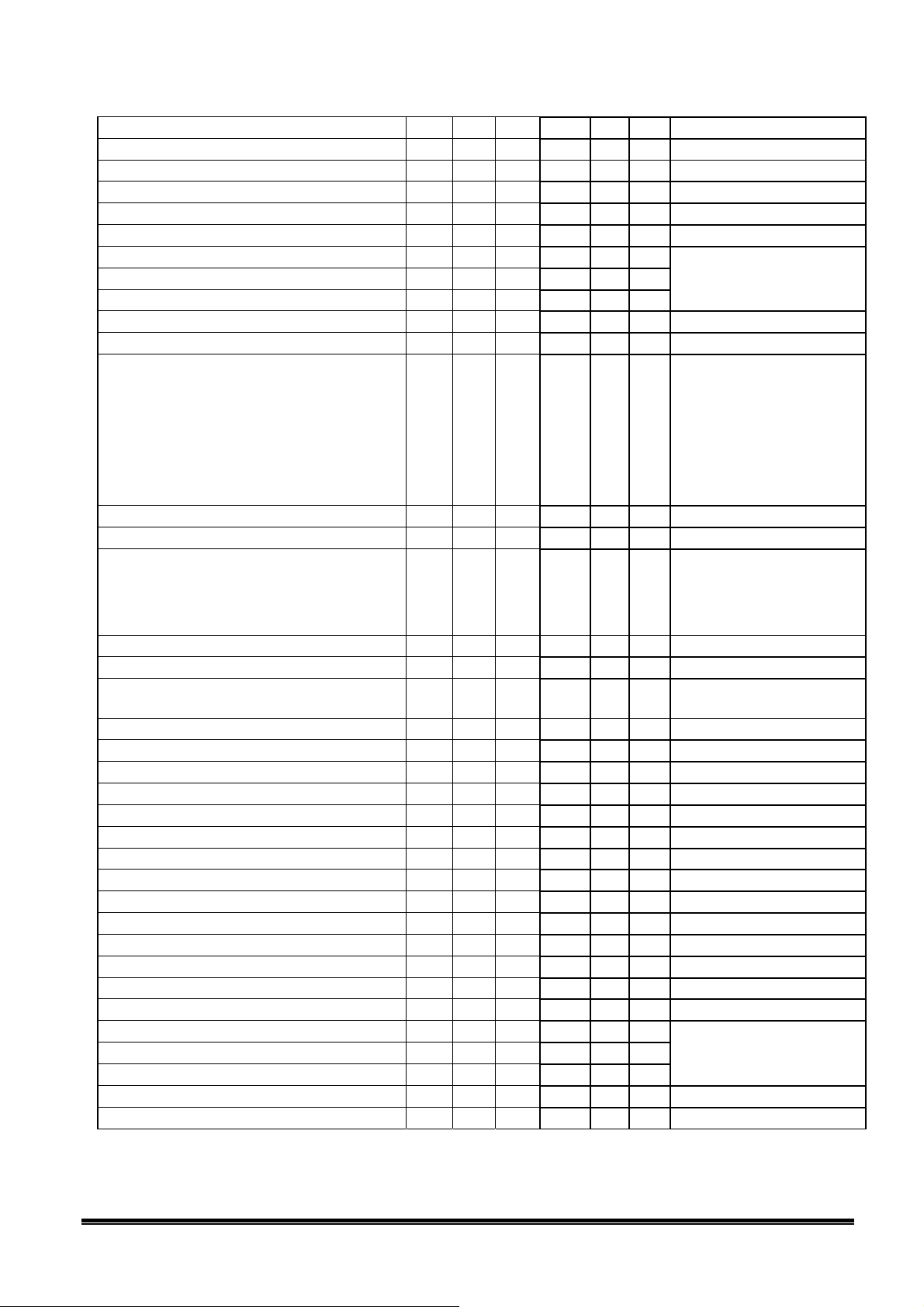

F. Command definition :

PC Host will send 0x7C IIC slave address and then following 4 bytes command

I2C Send Command

Write Contrast to MCU RAM CA 55 Data cksum

Write Brightness to MCU RAM CA 56 Data cksum

Write Red Gain to MCU RAM CA 57 Data

Write Green Gain to MCU RAM CA 58 Data cksum

Write Blue Gain to MCU RAM CA 59 Data cksum

Read Contrast from MCU RAM C3 55 XX cksum

Read Brightness from MCU RAM C3 56 XX cksum

Read Red Gain from MCU RAM by color index C3 57 XX cksum

Read Green Gain from MCU RAM by color

index C3 58 XX cksum

Read Blue Gain from MCU RAM by color index C3 59 XX cksum

Write C1 (Bluish) R-Gain Data to EEPROM AA 3C Data cksum

Write C1 (Bluish) G-Gain Data to EEPROM AA 3D Data cksum

Write C1 (Bluish) B-Gain Data to EEPROM AA 3E Data cksum

Write C2 (sRGB) R-Gain Data to EEPROM AA 4C Data cksum

Write C2 (sRGB) G-Gain Data to EEPROM AA 4D Data cksum

Write C2 (sRGB) B-Gain Data to EEPROM AA 4E Data cksum

Byte1 Byte2 Byte3

Byte4

cksum

OK N.A. Remark

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

Write data to MCU RAM and

update the related register to

refresh the screen immediately.

Don’t store data to EEPROM.

Base on current color index to

read back the right gain value.

3

Confidential

Page 4

Q7T4-FP71G LCD Monitor Service Guide

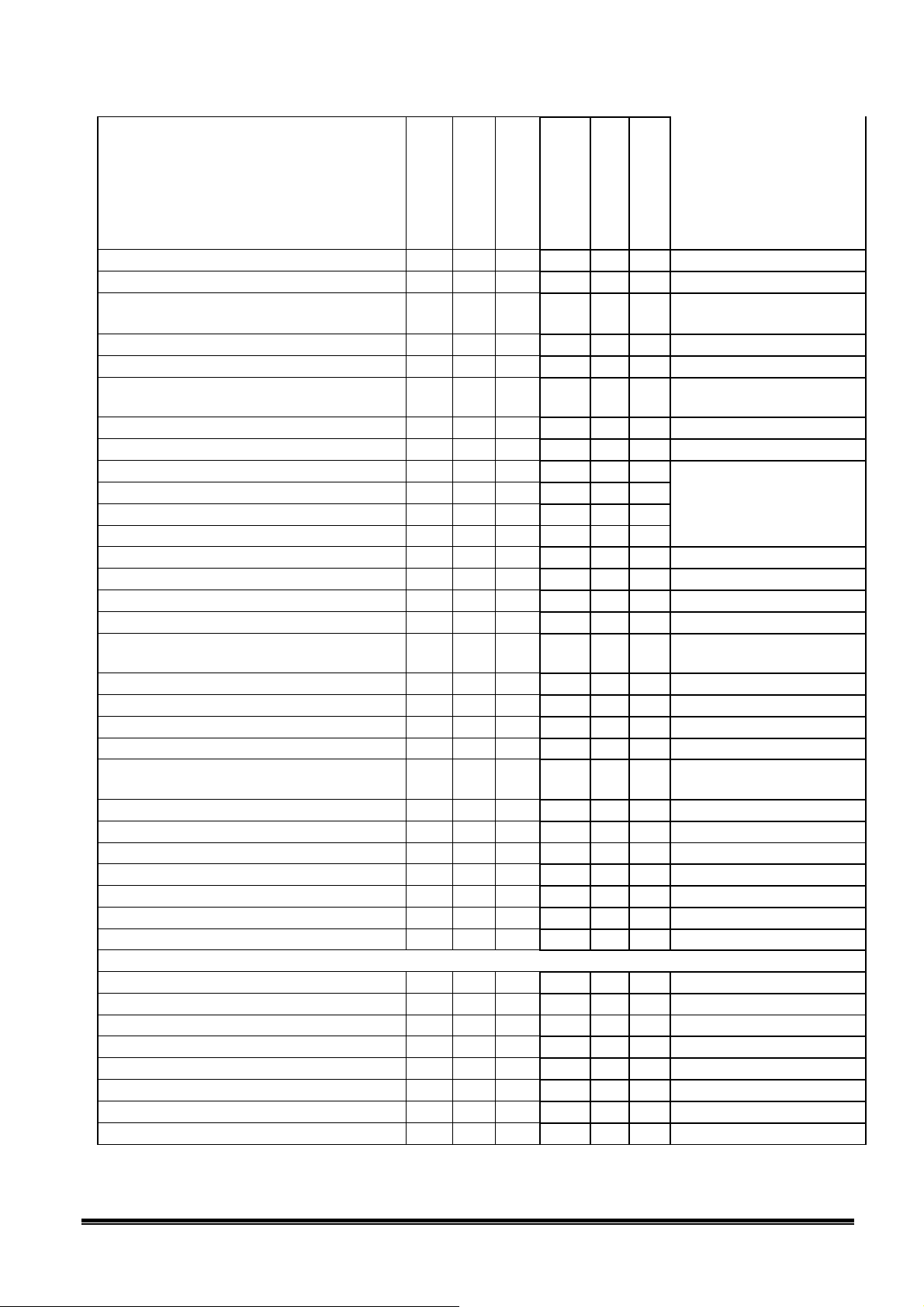

Write C3 (Reddish) R-Gain Data to EEPROM AA 5C Data cksum

Write C3 (Reddish) G-Gain Data to EEPROM AA 5D Data cksum

Write C3 (Reddish) B-Gain Data to EEPROM AA 5E Data cksum

Write User R-Gain Data to EEPROM AA 6C Data cksum

Write User G-Gain Data to EEPROM AA 6D Data cksum

Write User B-Gain Data to EEPROM AA 6E Data cksum

Write Cx R-Gain Data to EEPROM AA 7C Data cksum

Write Cx G-Gain Data to EEPROM AA 7D Data cksum

Write Cx B-Gain Data to EEPROM AA 7E Data cksum

Write Contrast to EEPROM AA 92 Data

Write Brightness to EEPROM

Write C/T index to EEPROM

Write OSD-Hpos to EEPROM

Write OSD-Vpos to EEPROM AA 96 Data

AA

AA

AA

93 Data

94 0~4

95 Data

cksum

cksum

cksum

cksum

cksum

√

√

√

√

√

√

√

√

√

√

√

Alignment Procedure

√

Reserved for some model have

√

extra color temperature

√

1=C1/9300/Bluish,

2=C2/6500/sRGB/,

3=C3/5800/Reddish,

4=User, 5=Cx

Write Language to EEPROM

Write EEPROM OSD Timer

Write EEPROM Volume

Write EEPROM Gamma index AA 9A Data

Write OSD Transparency to EEPROM

Write OSD Rotation to EEPROM AA 9F Data cksum

Read C1 (Bluish) R-Gain data from EEPROM A3 3C XX cksum

Read C1 (Bluish) G-Gain data from EEPROM A3 3D XX cksum

Read C1 (Bluish) B-Gain data from EEPROM A3 3E XX cksum

Read C2 (sRGB) R-Gain data from EEPROM A3 4C XX cksum

Read C2 (sRGB) G-Gain data from EEPROM A3 4D XX cksum

Read C2 (sRGB) B-Gain data from EEPROM A3 4E XX cksum

Read C3 (Reddish) R-Gain data from EEPROM A3 5C XX cksum

Read C3 (Reddish) G-Gain data from EEPROM A3 5D XX cksum

Read C3 (Reddish) B-Gain data from EEPROM A3 5E XX cksum

Read User R-Gain data from EEPROM A3 6C XX cksum

Read User G-Gain data from EEPROM A3 6D XX cksum

Read User B-Gain data from EEPROM A3 6E XX cksum

Read Cx R-Gain data from EEPROM A3 7C XX cksum

Read Cx G-Gain data from EEPROM A3 7D XX cksum

Read Cx B-Gain data from EEPROM A3 7E XX cksum

Read Contrast from EEPROM A3 92 XX

Read Brightness from EEPROM A3 93 XX

AA

AA

AA

AA

97 0~7

98 Data

99 Data

9E Data cksum

cksum

cksum

cksum

cksum

cksum

cksum

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

0=DE, 1=EN, 2=ES, 3=FR,

4=IT, 5=JA, 6=繁中, 7=簡中

(Also Update MCU RAM)

For model with Gamma curve

selection function

√

√

√

√

Reserved for some model have

√

extra color temperature

√

4

Confidential

Page 5

Q7T4-FP71G LCD Monitor Service Guide

And

Alignment Procedure

1=C1/9300/Bluish,

2=C2/6500/sRGB/,

3=C3/5800/Reddish,

4=User, 5=Cx

Read C/T index from EEPROM A3 94 XX

Read OSD-Hpos EEPROM A3 95 XX

Read OSD-Vpos from EEPROM A3 96 XX

Read Language from EEPROM A3 97 XX

Read OSD Timer from EEPROM A3 98 XX

Read Volume from EEPROM A3 99 XX

Read Gamma index from EEPROM A3 9A XX

Read OSD Transparency from EEPROM A3 9E XX cksum

Read OSD Rotation from EEPROM A3 9F XX cksum

Change Color Temp. to C1/9300K/Bluish CC 01 XX cksum

Change Color Temp. to C2/6500K/sRGB CC 02 XX cksum

Change Color Temp. to C3/5800K/Reddish CC 03 XX cksum

Change Color Temp. to User CC 04 XX cksum

Change Color Temp. to Cx CC 05 XX cksum

Change Input Source to D-Sub CD 01 XX cksum

Change Input Source to DVI CD 02 XX cksum

On burn in mode CE 01 XX cksum

Off burn in mode CE XX* XX cksum

Monitor is forced power saving CF 01 XX cksum

Monitor wake up from power saving CF XX* XX cksum

User mode to factory mode 1A 5A XX cksum

Auto Color (Offset1, Offset2, Gain) 1B 5A XX cksum

Copy EDID Serial number to EEPROM

Factory mode to User mode 1E 5A XX cksum

Clear user mode and factory recall 1F 5A XX cksum

Write EDID data to MCU DDC RAM

Copy DDC RAM data to EEPROM

Drive WP pin to low to enable write DDC IC

Drive WP pin to high to disenable write function

1C 5A XX cksum

55 NA NA NA

BB NA NA NA

55 NA NA NA

BB NA NA NA

cksum

cksum

cksum

cksum

cksum

cksum

cksum

EEPROM Bank R/W (For Debug using only, not for Production Line Write EEPROM directly)

Read EEPROM Bank 0 B0

Read EEPROM Bank 1 B1

Read EEPROM Bank 2 B2

Read EEPROM Bank 3 B3

Write EEPROM Bank 0 B8

Write EEPROM Bank 1 B9

Write EEPROM Bank 2 BA

Write EEPROM Bank 3 BB

Address

Address

Address

Address

Address

Address

Address

Address

XX cksum

XX cksum

XX cksum

XX cksum

Data cksum

Data cksum

Data cksum

Data cksum

√

√

√

0=DE, 1=EN, 2=ES, 3=FR,

4=IT, 5=JA, 6=繁中, 7=簡中

√

√

√

For model with Gamma curve

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

selection function

√

√

√

Change C/T immediately.

store C/T index to EEPROM.

Reserved

√

√

√

Store data to EEPROM

XX* = Non “1” value

Store data to EEPROM

√

XX* = Non “1” value

√

√

For specified “Industry

Customer” model.

√

Store data to EEPROM

For MTV312 MCU type

For MTV312 MCU type

For stand alone DDC IC

√

For stand alone DDC IC

√

(For 24C08 type)

√

(For 24C08 type)

√

(For 24C08 type)

√

(For 24C08 type)

√

5

Confidential

Page 6

Q7T4-FP71G LCD Monitor Service Guide

N

Alignment Procedure

Note A: Byte4 (cksum) = Byte1 + Byte2 + Byte3

Note B: Data = The value write to MCU or EEPROM

Note C: XX = don't care, any value (<=0xFF).

When PC Host sends 0x7D command to MCU, MCU must return as following (2 bytes)

Return Code R-Byte1 R-Byte2

Checksum error code FC AA

ormal return code the above Byte3 (/data) FC

If normal return code is exact FCh FC CF

6

Confidential

Page 7

Q7T4-FP71G LCD Monitor Service Guide

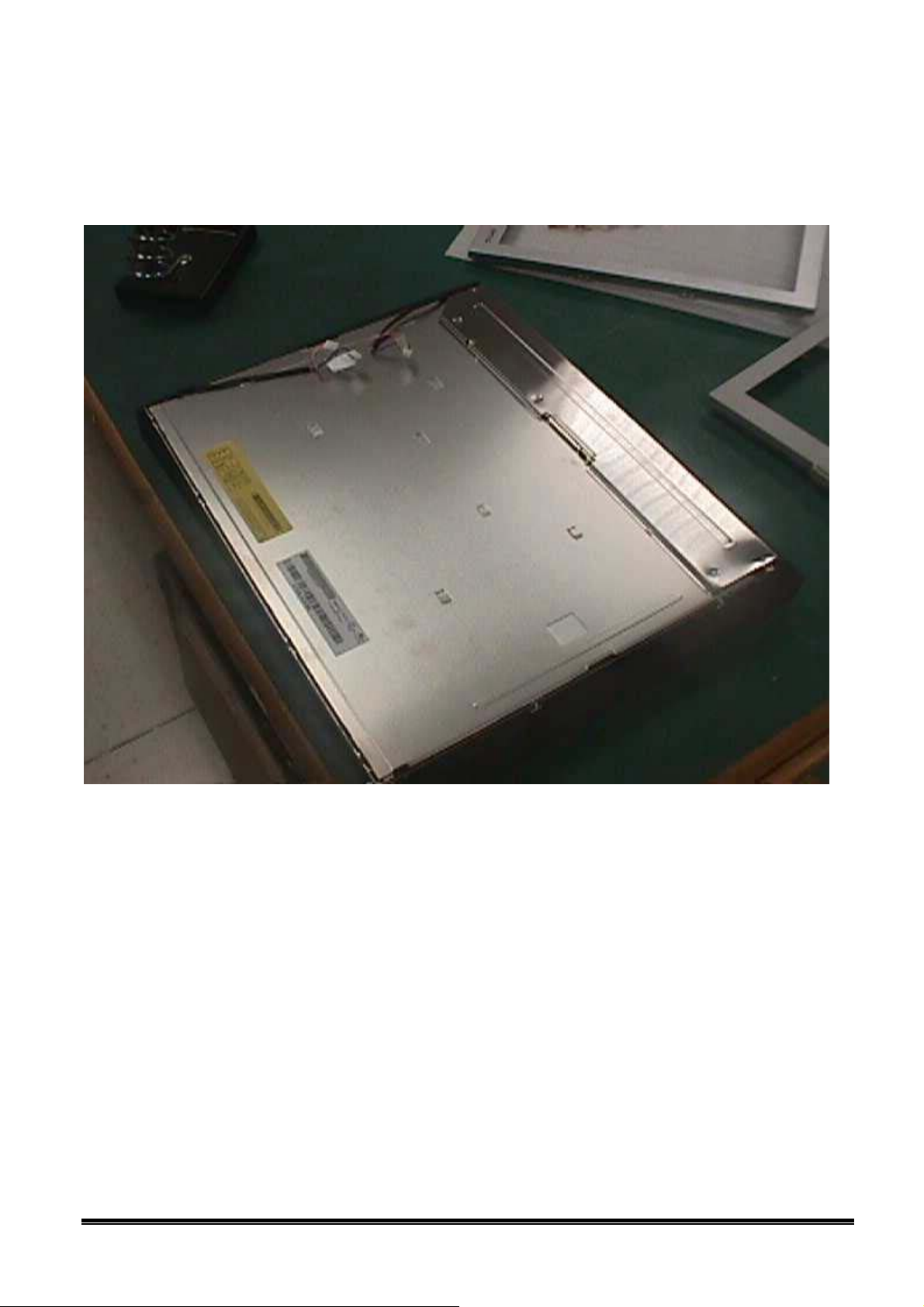

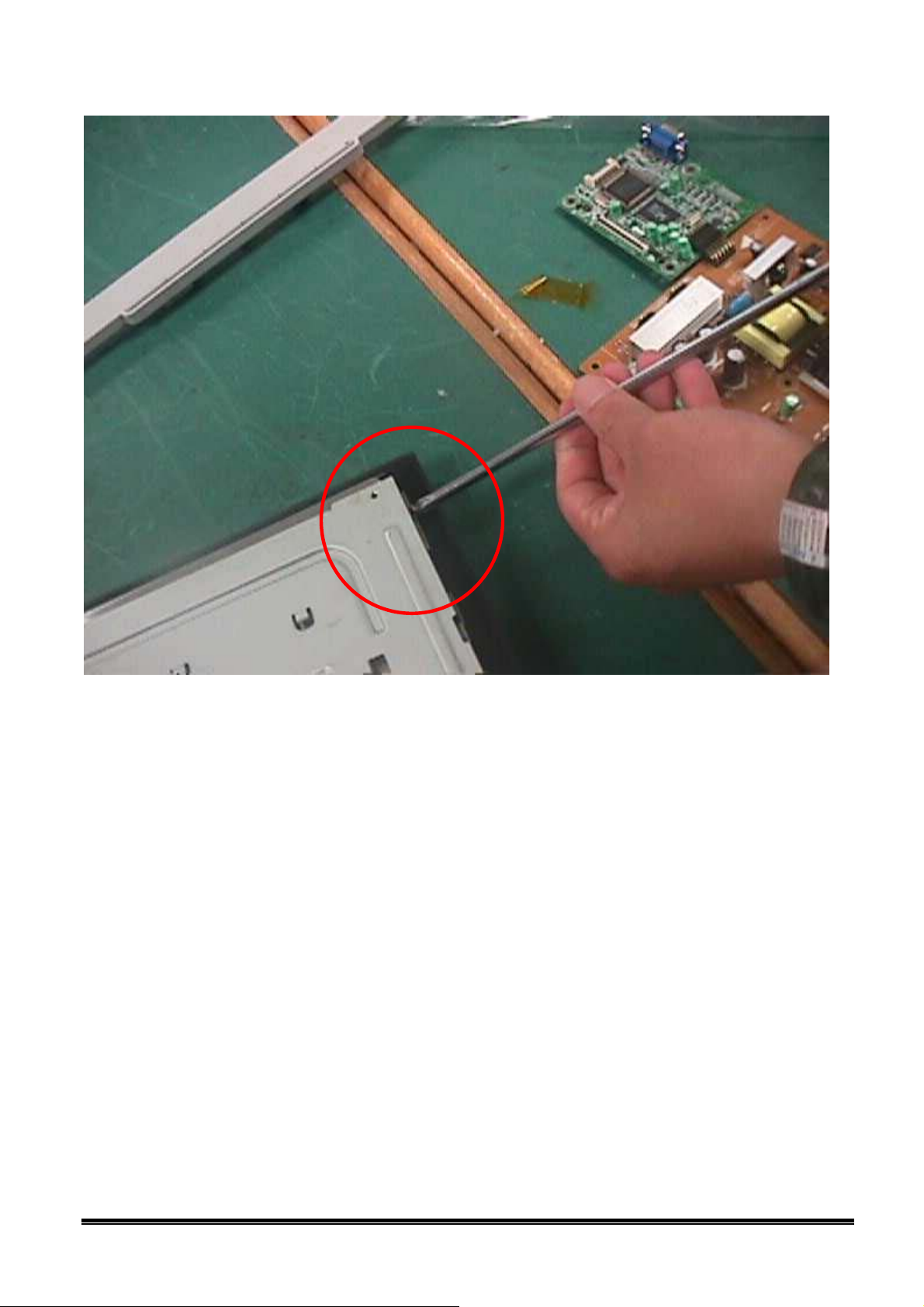

4. Wire Dressing and assembling concern

Prepare 1 panel

Alignment Procedure

Assembly panel and main BKT

7

Confidential

Page 8

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add 4 screw between panel and main BKT

8

Confidential

Page 9

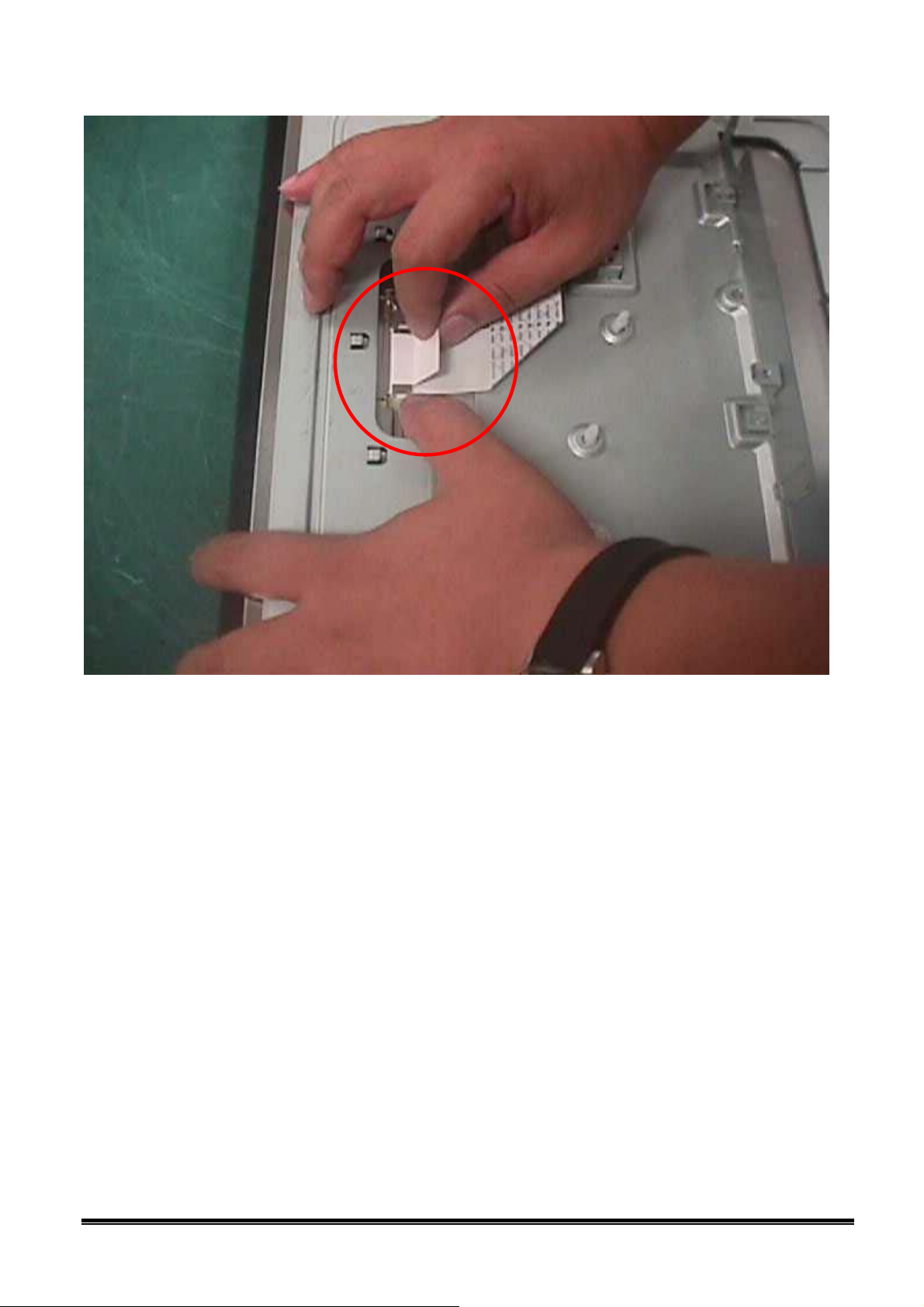

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add FFC

9

Confidential

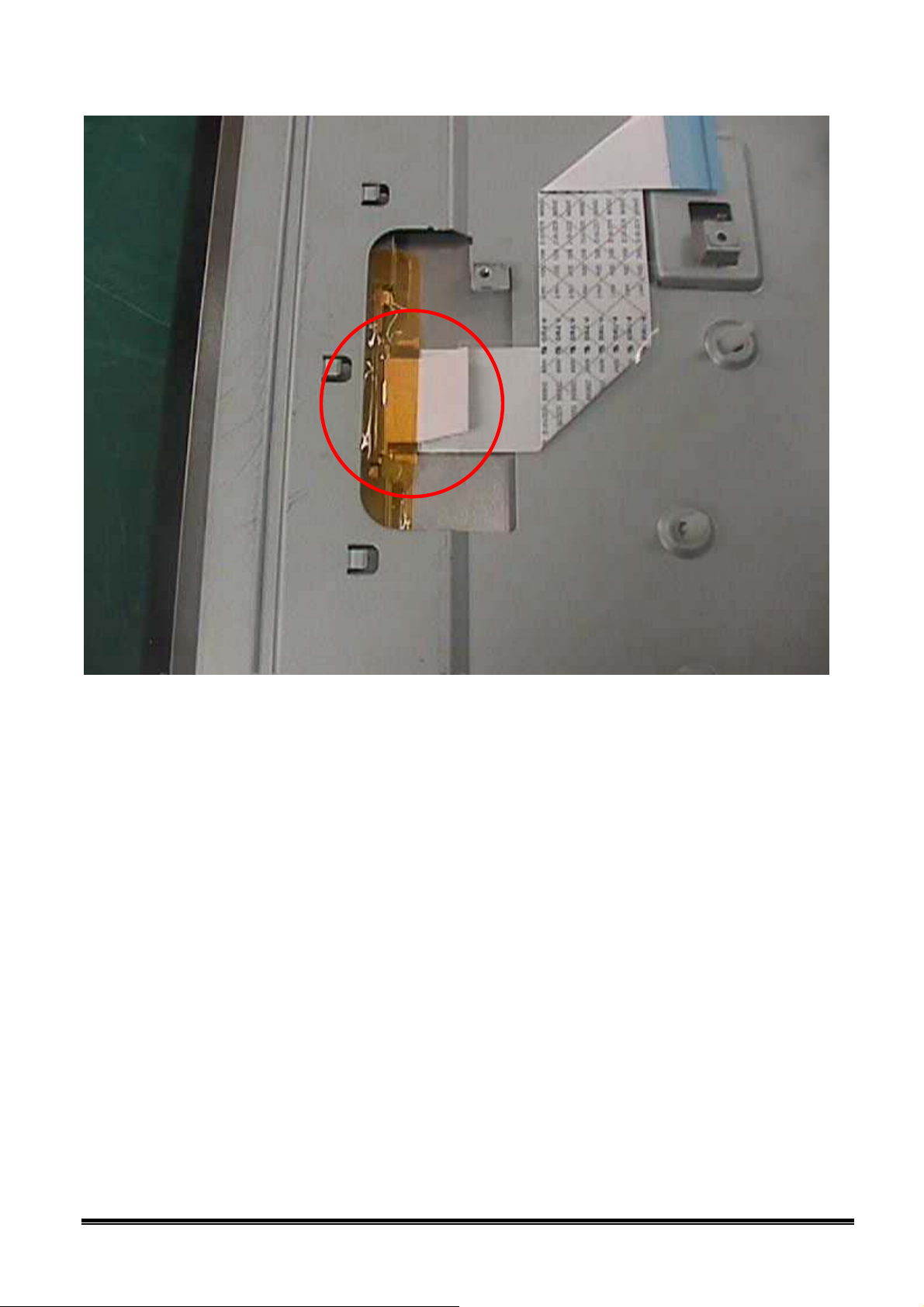

Page 10

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add Tape

10

Confidential

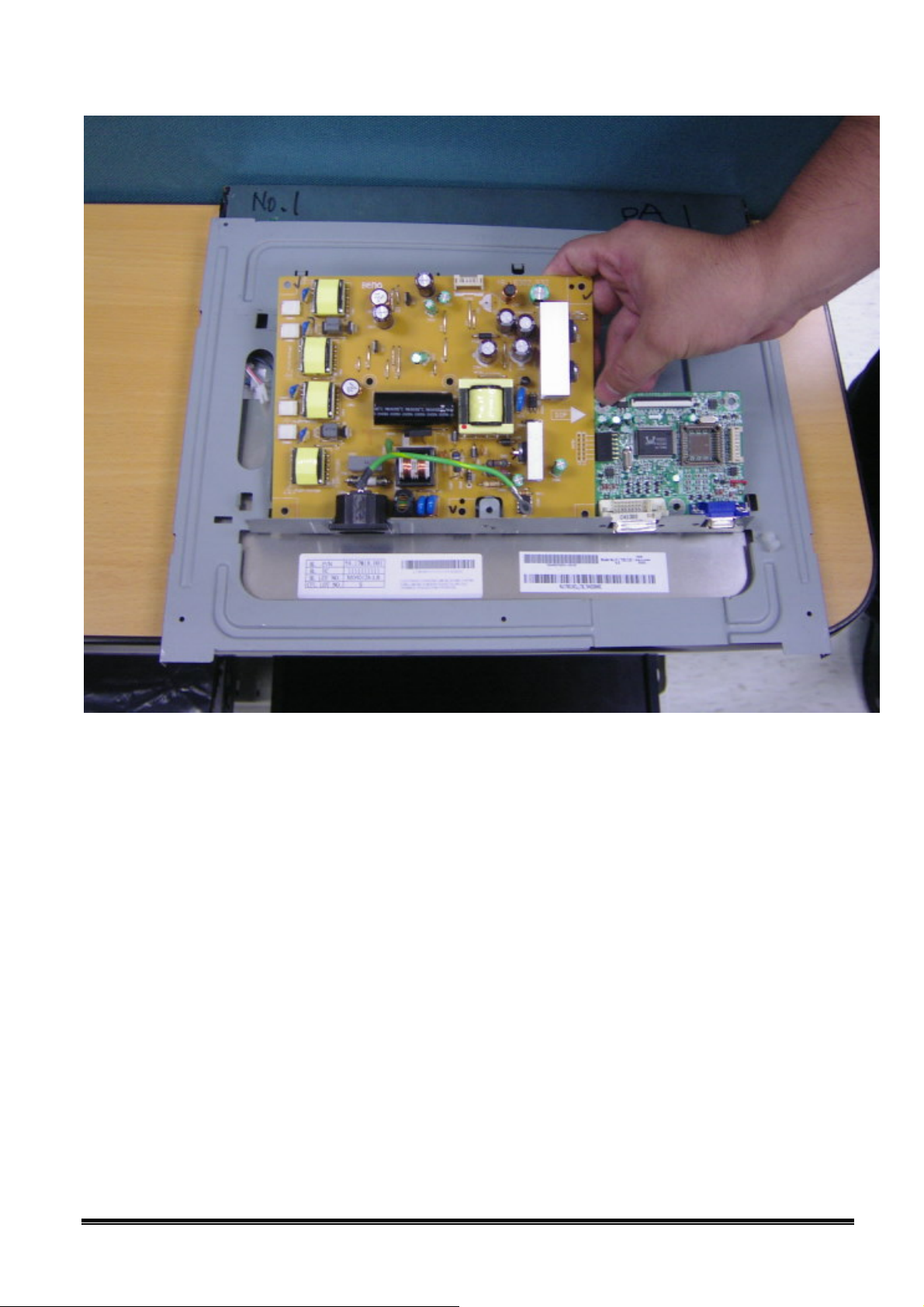

Page 11

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly IF board and Power Board

11

Confidential

Page 12

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly PCB module and main BKT

12

Confidential

Page 13

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

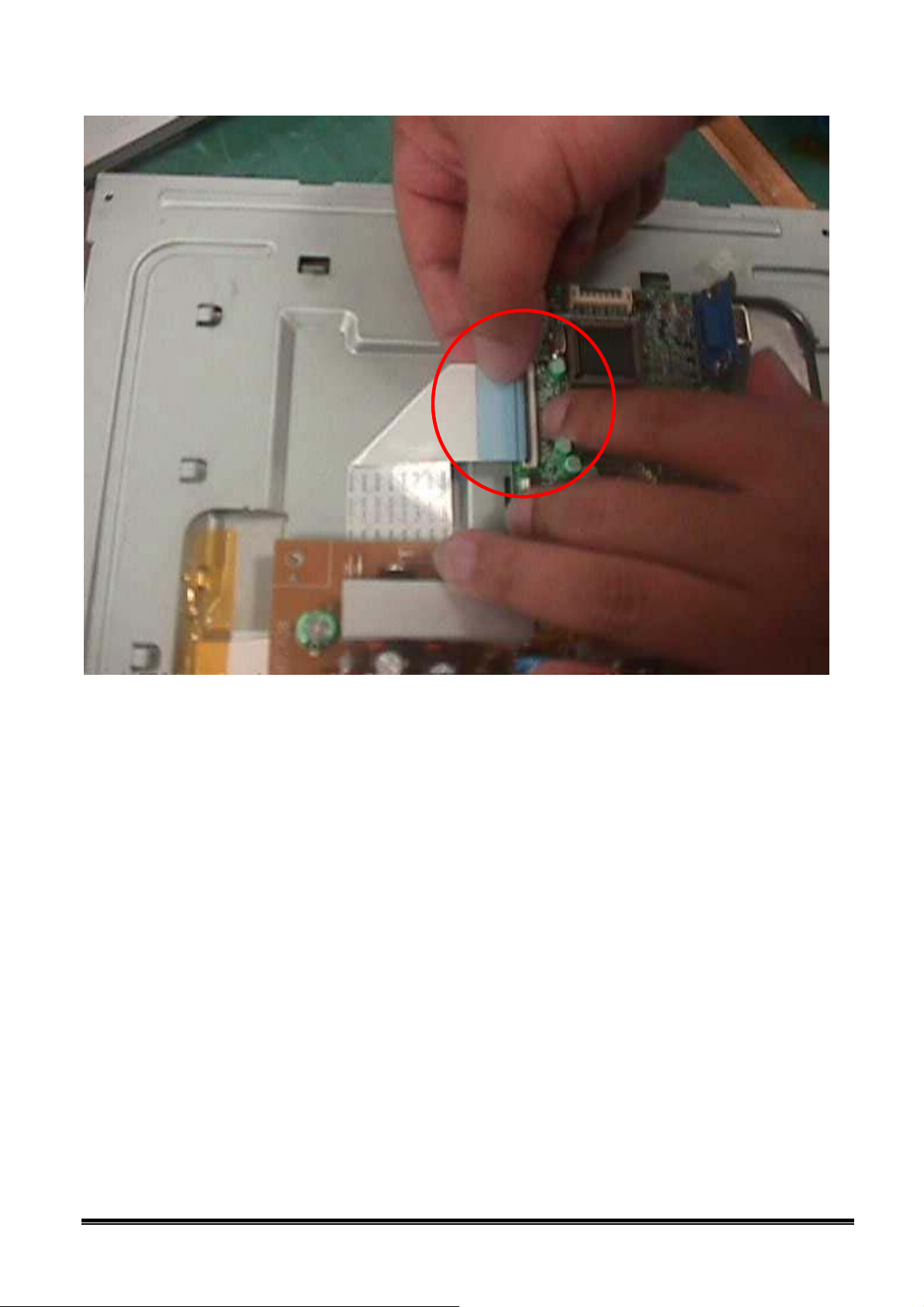

Assembly IF board and FFC

13

Confidential

Page 14

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add one tape

14

Confidential

Page 15

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

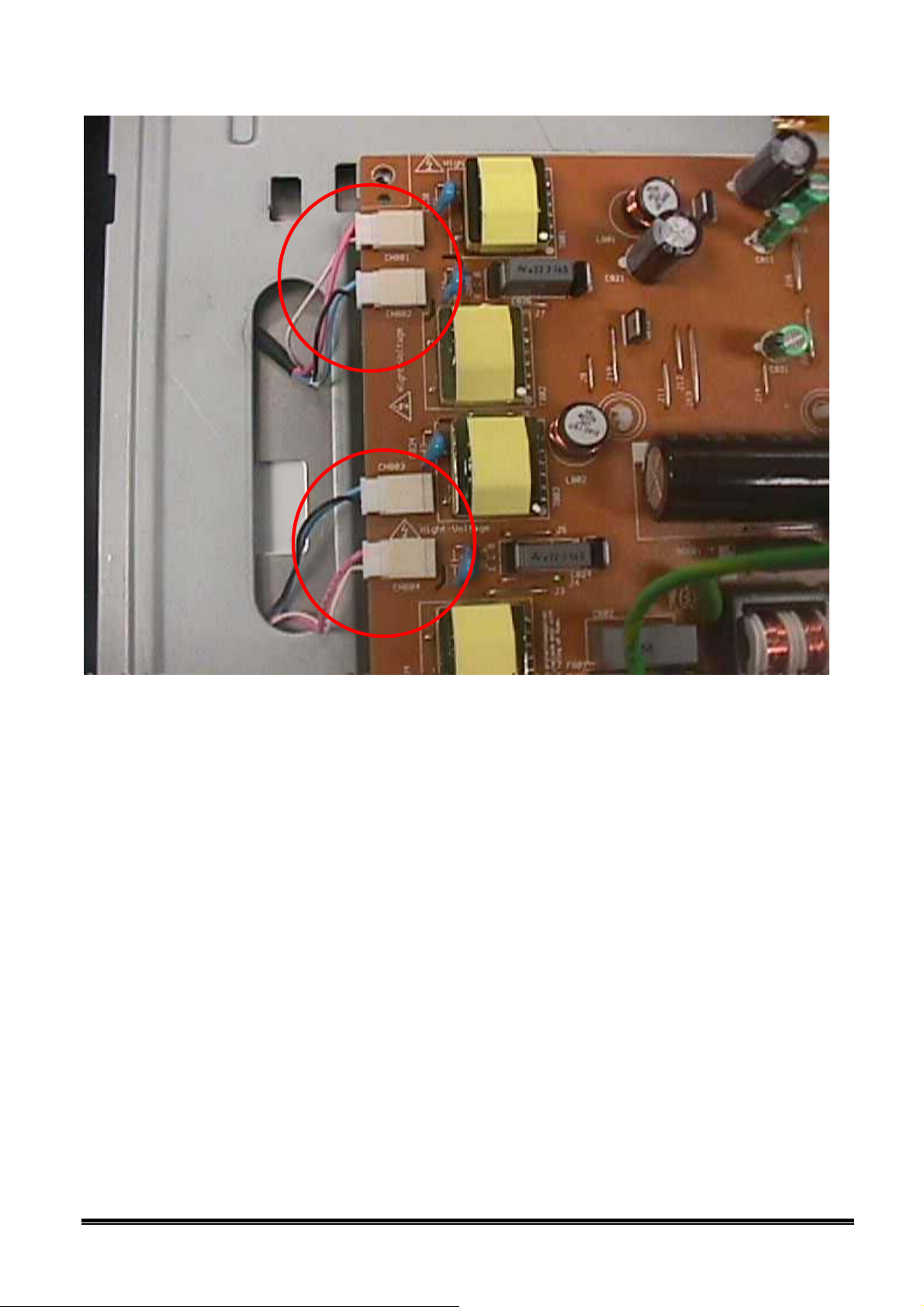

Assembly lamp wire and Power Board

15

Confidential

Page 16

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

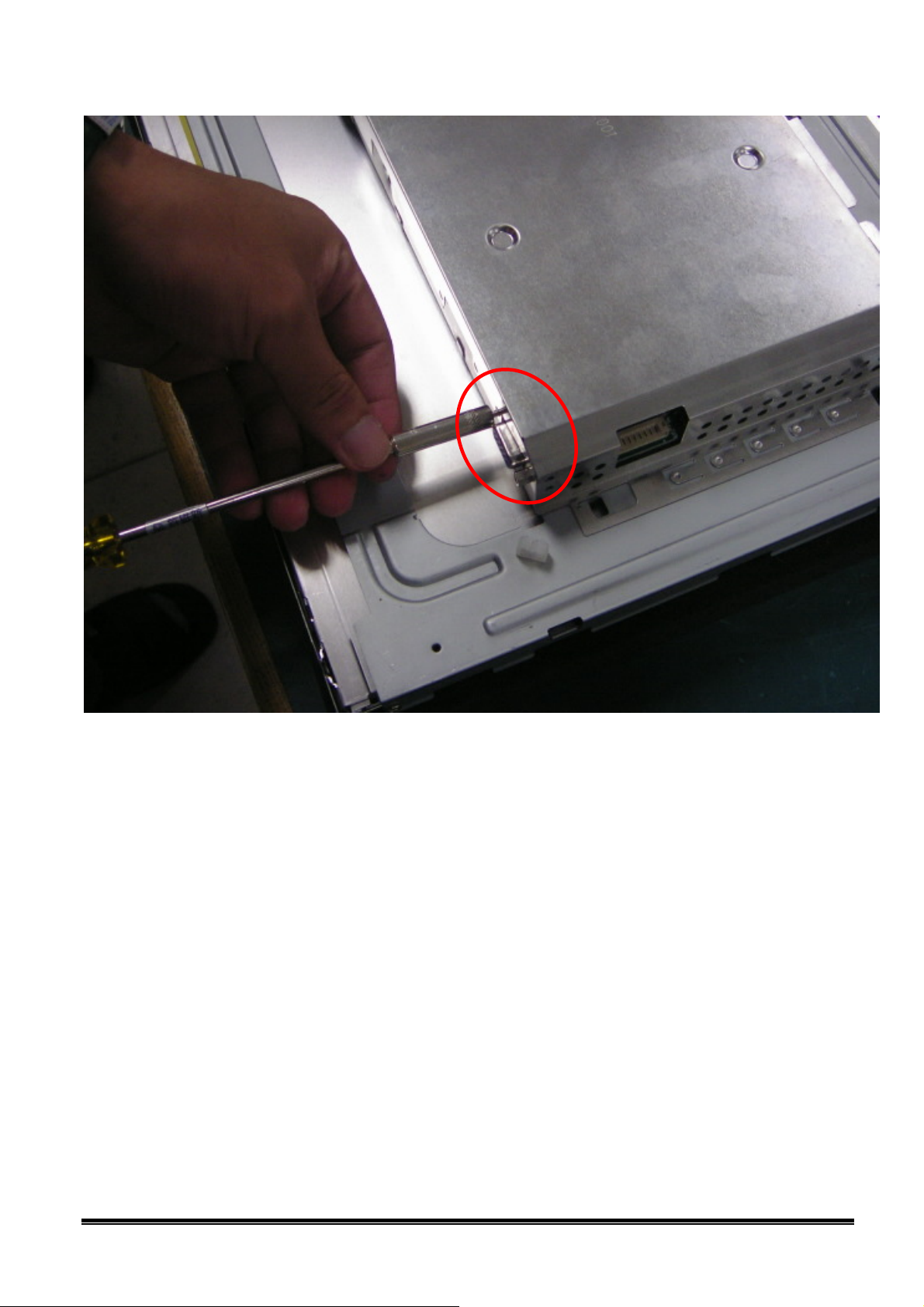

Add one screw

16

Confidential

Page 17

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add 5 screw

17

Confidential

Page 18

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly main shielding and main BKT

18

Confidential

Page 19

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add 2 screw

19

Confidential

Page 20

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly control board wire and IF board

20

Confidential

Page 21

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

21

Confidential

Page 22

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add one tape

22

Confidential

Page 23

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly Bezel and Rear Cover

23

Confidential

Page 24

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add 4 screw

24

Confidential

Page 25

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Add 1 screw

25

Confidential

Page 26

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Assembly Base and Rear cover

26

Confidential

Page 27

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

Finished

27

Confidential

Page 28

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

28

Confidential

Page 29

Q7T4-FP71G LCD Monitor Service Guide

Alignment Procedure

29

Confidential

Page 30

Q7T4-FP71G LCD Monitor Service Guide

Circuit Operation Theory

I. Introduction:

The Q7T4 is a 17” SXGA (1280x1024) , 16.2M colors(R, G, B 6-bit data+FRC data) TFT

LCD monitor. It’s an analog only interface LCD monitor with a 15 pins D-sub signal cable. it’s

compliant with VESA specification to offer a smart power management and power saving function. It

also offers OSD menu for users to control the adjustable items and get some information about this

monitor, and the best function is to offer users an easy method to set all adjustable items well just by

pressing one key, we called it “Auto key” which can auto adjusting all controlled items. Q7T4 also

offer DDC2 function to meet VESA standard.

II. Block diagram

The Q7T4 consists of a LCD module with 4 lamps, an power board, a control board ,and a

interface BD. The block diagram is shown as below.

LCD module with 4 lamps (backlight)

Inverter

Power

Interface board

Control board

D-Sub

AC power in

III. Circuit operation theory:

A-1.) Interface board diagram:

1

Confidential

Page 31

Q7T4-FP71G LCD Monitor Service Guide

MTV312M

64(AJ)

Circuit Operation Theory

Clock

Generator

D-SUB

140MHz

ADC

(a) Circuit operation theory:

A basic operation theory for the interface board is to convert input signal into digital RGB .

RTD 2023

XGA

1280×1024

LCM

Keypad IIC

Analog RGB signal is converted to digital signal through ADC. The microprocessor RTD2023

receives video data and optimizes the image automatically. It also supports 16 color from a 64k

palette bitmap OSD, and keypad controlling. The output data are sent to LCD module.

(b) IC introduction:

1.) DDC (Display Data Channel) function: We use DDC IC to support DDC/2B function. DDC

data is stored in 24C04(EEPROM). Those data related to LCD monitor specification. PC

can read them by “SDA” and “SCL” serial communication for I²C communication for

DDC2B.

2.) RTD2023 IC: There are triple ADC, LVDS transmitter ,Scaling, and OSD functions in the

RTD2023 IC. Scaling IC is revolutionary scaling engine, capable of expanding any source

resolution to a highly uniform and sharp image, combined with the critically proven

integrated 8 bit triple-ADC and patented Rapid-lock digital clock recovery system. It also

2

Confidential

Page 32

Q7T4-FP71G LCD Monitor Service Guide

support detect mode and DPMS control.

3.) MTV312M64: To stored the source code which is accessed by MCU to run program.

4.) EEPROM: We use 24C04 to store all the adjustable data and user settings.And use 24C02 to

store DVI EDID data.

A-2.) Control board introduction:

There are 6 keys for user's control which includes “Power”, “Enter”, “Up/Plus”,

“Down/Minus” , “Exit”, and “iKey” . The following descriptions are the introduction of these keys.

(1) Power key: to turn/off power of monitor

(2) “Enter” key: to enter sub-menus or select items.

(3) “Up/Plus key: to select previous and to increase adjustment

(4) “Down/Minus” key: to select next and to decrease adjustment

(5) “Exit” key: to back to previous menu, or leave OSD (auto save)

(6) “iKey”: to perform auto adjustment

(7) LED:

It indicates the DPMS status of this LCD monitor; green light means DPMS on (Normal

operating condition). Amber light means DPMS off (Powersaving).

Circuit Operation Theory

A-3.) Power board diagram:

EMI Filter Rectifier and

PWM controller

filter

Isolation power

transformer

Switching element

Rectifier and filter

Rectifier and filter

Inverter circuit

LDO regulator

Feedback Isolation

Fig.1

3

Confidential

Page 33

Q7T4-FP71G LCD Monitor Service Guide

Circuit Operation Theory

#1 EMI Filter

This circuit (fig. 2) is designed to inhibit electrical and magnetic interference for meeting FCC, VDE,

VCCI standard requirements.

Fig. 2

#2 Rectifier and filter

AC Voltage (90-264V) is rectified and filtered by BD601, C605 (See Fig 3) and the DC Output

voltage is 1.4*(AC input). (See Fig.3)

Fig. 3

4

Confidential

Page 34

Q7T4-FP71G LCD Monitor Service Guide

#3 Switching element and Isolation power transformer

When the Q601 turns on, energy is stored in the transformer.

During Q601 turn-off period, the stored energy is delivered to the

secondary of transformer. R607, C607 and D601 is a snubber circuit.

R615 is current sense resistor to control output power. (See Fig.4)

Circuit Operation Theory

Fig. 4

#4 Rectifier and filter

D701 and C703 are to produce DC output. L701 is used to suppress high Frequency switching spikes.

(See Fig.5)

Fig. 5

5

Confidential

Page 35

Q7T4-FP71G LCD Monitor Service Guide

#5 PWM Controller

The PWM controller NCP1200A implements a standard current mode architecture. With an

internal structure operating at a fixed 40KHz. Where the switch time is

dictated by the peak current set-point. When the current set-point falls

below a given value. The output power demand diminishes, the IC

automatically enters the so-called skip cycle mode and provides

excellent efficiency.

Circuit Operation Theory

Fig. 6

#6 Feedback circuit

PC123 is a photo-coupler and TL431 is a shunt regulation. They are

used to detect the output voltage change and be the primary and

secondary isolation. When output voltage changes, the feedback voltage

will be compared and duty cycle will be decided to control the correct

output voltage. (See Fig.7)

6

Confidential

Page 36

Q7T4-FP71G LCD Monitor Service Guide

A-3.) Control board introduction:

The main parts of the control board are a push button, and a LED.

(a) Push button:

It’s a simple switch function, pressing it for “ON” to do the auto

adjustment function, releasing it for “OFF” to do nothing.

(c) LED:

It indicates the DPMS status of this LCD monitor; green light means DPMS on

(Normal operating condition). Amber light means DPMS off (Power off condition).

Circuit Operation Theory

Fig. 7

7

Confidential

Page 37

Q7T4-FP71G LCD Monitor Service Guide

A-4.) Inverter diagram:

1.Block Diagram:

Circuit Operation Theory

15Vin

ON/OFF

BRT_ADJ

ON/OFF

switching

PWM CONTROLLER

TL1451 CIRCUIT

2. General Specification

Input Voltage: 15V

Input Current: 2A max.

ON/OFF Voltage: 5V

PWM Duty: 5V/50KHz

Output Requirement:

Max. Output Current: 7.5mA

Min. Output Current: 3.3mA

OSCILATOR

CIRCUIT

TRANSFORMER CCFL

PROTECTION

AND DETECT

Lamp Working Voltage: 660Vrms

Open Lamp Voltage: 1500Vrms

Frequency: 50KHz

8

Confidential

Page 38

Q7T4-FP71G LCD Monitor Service Guide

Circuit Operation Theory

3.Circuit Operation Theorem

3.1 ON/OFF SWITCH

The turn-on voltage was controlled by R815 and R816.The inverter was turned on or off by the

switching transistors Q801 and Q802.

9

Confidential

Page 39

Q7T4-FP71G LCD Monitor Service Guide

3.2 PWM Control circuit

Circuit Operation Theory

TL1451 is a dual PWM controller.C807 and R811 decide the working frequency.BLT_ADJ signal is

from control board, control pulse width then decide how much energy delivery to CCFL also decide

CCFL brightness. Q810 and Q811 be the buffer to rise the drive capability and the totem poles

circuit can improve a capable of driving for Q812.C813 decide the striking time delay.

10

Confidential

Page 40

Q7T4-FP71G LCD Monitor Service Guide

Circuit Operation Theory

3.3 Oscillator Circuit

Royer circuit uses the characteristic of transformer saturation to oscillate. When the DC power inject,

Q808 or Q809 will turns on, and the current Ic increases. After a period, the transistor will leave the

saturation status and Vce increase. The result causes the voltage of primary coil get lower. Finally the

transistor turn off, and another transistor turn on. These statuses are repeated and the pin7 and pin8 of

T801 will get a sine wave to turn on CCFL.

11

Confidential

Page 41

5

4

3

2

1

D D

C C

B B

CON 301

1

2

3

4

5

6

7

8

9

10

20600 89110

KEY_EXIT

KEY_ LEFT

BL U

OR G

KEY_ RI GHT

KEY_ MENU

PW_S W

LED3 01 BL U/ORG

BL U

A2

A1

KEY_ MENUI _K EY

J

KEY_ RI GHTOR G

KEY_ LEFT

PW_S W

KEY_EXIT

I _K EY

SW3 01 22 40069431

1 2

G2G1

SW3 02 22 40069431

1 2

G2G1

SW3 03 22 40069431

1 2

G2G1

SW3 06 22 40069431

1 2

G2G1

SW3 04 22 40069431

1 2

G2G1

SW3 05 22 40069431

1 2

G2G1

LED use 06.3N5YG.14X;

Key use 22.40069.431

Pro jec t Co de

99. L1C72.001

A A

5

4

3

Title

Size Doc ument Nu mb er R e v .

PCB P/ N

<Size>

Da te : Sheet

2

48. L1C03.S02

Thu rsd ay , A ugu st 26, 2004

Pre par ed By

ANGE L HU

Mod el Na me

Q7T4

CTRL BOA RD

PC B R ev.

S02

Re vi ew e d B y Ap pr ov ed By

ALL EN PC LEE DA VE N WU

OEM /ODM Mode l Nam e

99.L 1C72. 000- C3-30 4-00 2

1 1

1

NA

0

o f

Page 42

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

Table of Contents

1. Introduction 3

2. Operational Specification 3

2.1 Power supply.................................................................................................................................3

2.2 Signal interface .............................................................................................................................4

2.3 Video performance........................................................................................................................5

2.4 Scan range.....................................................................................................................................6

2.5 Plug & Play DDC2B Support .......................................................................................................6

2.6 Support Timings............................................................................................................................6

3. Operational & Functional Specification 7

3.1 Video performance........................................................................................................................7

3.2 Brightness Adjustable Range........................................................................................................7

3.3 Acoustical Noise ...........................................................................................................................7

3.4 Environment..................................................................................................................................7

3.5 Transportation...............................................................................................................................7

3.6 Electrostatic Discharge Requirements...........................................................................................8

3.7 EMC..............................................................................................................................................8

3.8 Reliability......................................................................................................................................8

3.9 Audio performance........................................................................................................................9

4. LCD Characteristics 9

4.1 The Physical definition & Technology summary of LCD panel...................................................9

4.2 Optical characteristics of LCD panel............................................................................................9

5. User Controls 10

5.1 User’s hardware control definition................................................................................................10

5.2 OSD control function definition....................................................................................................10

6. Mechanical Characteristics 11

6.1 Dimension.....................................................................................................................................11

6.2 W eight...........................................................................................................................................11

6.3 Plastic............................................................................................................................................11

6.4 Carton............................................................................................................................................12

1

Confidential

Page 43

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

Table of Contents

7. Pallet & Shipment 12

7.1 Container Specification.................................................................................................................12

7.2 Carton Specification......................................................................................................................12

Product:.................................................................................................................................12

Package:................................................................................................................................ 12

8. Certification 12

Appendix: Physical Dimension Front View and Side view 14

2

Confidential

Page 44

Q7T4-FP71G LCD Monitor Service Guide

N

Engineering Specification

1. Introduction

This specification describes Q7T4, which is a 17.0” analog interface color TFT LCD monitor without audio. The

monitor supports up to 1280x1024 pixel resolution and refresh rate of 75 Hz. The independent 6 bits R, G, B

colors are capable of displaying 16.2M colors (RGB-6bit + FRC data). In addition, dithering function is

supported. The features summary is shown below,

*All panel spec. in C201 definition depends on the variance of panel source.

Feature items Specifications Remark

Panel supplier & module name

Screen diagonal 17.0” (432mm) 337.920(H) x 270.336(V)

Display Format SXGA / 1280 (H) x 1024 (V)

Pixel Pitch 0.264 mm x 0.264 mm

Viewing Angle (@ Contrast Ratio = 10)

Analog interface with Scaling supported

DVI interface with Scaling supported

Video interface with Scaling supported No

Max resolution mode supported 1280 x 1024 @ 75Hz

umber of Display Colors supported 16.2M colors (RGB 6-bits + FRC data)

Contrast Ratio

Luminance

AC power input

DC power input (with AC power adapter) No

DPMS supported

LED indicator for power status showed

OSD for control & information supported

Multi-language supported for OSD

Buttons control supported

Flywheel control supported No

Scaling function supported

Auto adjustment function supported

DDC function supported (EDID ver. 1.3)

Audio speakers supported

Audio Jack (input connector) supported

Earphone Jack (input connector) supported

Microphone function supported No

Mechanical Tilt base design

VESA wall mounting design

Mechanical Rotate design No

Mechanical Lift base design No

Kensington compatible lock design

AUO M170EG01

R/L: 70/70 degrees (typ.)

and U/D: 70/60 degrees (typ.)

Yes

No

450:1 (typ.)

2

260 cd/m

(typ.)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

Yes

Yes

Yes

Further divided into v.0 and v.1

versions (spec v.1)

Panel spec.

With 15-pin D-sub connector

White Luminance@CCFL

7.5mA (center)

90-264 Volts, 47-63 Hz.

≤ 1W at 115±5 VAC

≤2W at 230 VAC in Power off

Preferred Mode

Green/Amber/Non

8 languages

6 buttons including 1 monitor

power on/off control button.

“i-key” function

DDC2B only

From -5 to +20 degree

2. Operational Specification

2.1 Power supply

3

Confidential

Page 45

Q7T4-FP71G LCD Monitor Service Guide

Item Condition Spec OK N.A Remark

Input Voltage range

Input Current range

Power Consumption

DPMS

Inrush Current

Earth Leakage Current

Hi-Pot

Power Line Transient

CCFL operation range

CCFL Frequency

Power cord

Universal input full range 90~264VAC /47~63Hz

90 ~ 264VAC < 2.0 Arms

Normal “On” operation < 40 W

DPMS “Off” state

110 VAC

220 VAC

264 VAC/50Hz < 3.5 mA

1. 1500VAC, 1 sec

2. Ground test: 30A, 1sec

IEC1000-4-4 1KV √

IEC1000-4-5 (Surge)

90 ~ 264VAC 3 mA ~8mA

90 ~ 264VAC 40KHz ~ 80KHz

Engineering Specification

<

1 W in power preferred

mode, 115V

2 W, 230V

<

< 30 A (peak)

< 60 A (peak)

Without damage

< 0.1 ohm

Common: 2KV,

Differential: 1KV

Color: Black

Length: 1500

+/- 50 mm

√

√

LED: Green

√

LED: Amber

√

Cold-start

√

√

(on-line test)

√

√

√

√

√

(in-lab test)

Panel Spec.

3.0 ~ 8.0mA rms

Panel Spec.

40KHz ~ 80KHz

2.2 Signal interface

Item Condition Spec OK N.A Remark

Signal Cable

Pin assignment

Sync input

15-pin D-Sub

24-pin DVI-D

15-pin D-sub connector

24-pin DVI-D connector

Signal type

Level

Impedance

Signal type

Level

Impedance

Sync Pulse Width (SPW)

Color: Black

Length: 1500

Color: Black

Length: 2000

Separate analog R/G/B

700 mV (peak to peak)

75 Ohms +/- 1.5 Ohms

Separate H/V-sync

Composite H/V-sync

(Positive/Negative)

Logic High: 2.4V ~ 5.5V

Logic Low: 0V ~ 0.5V

(TTL level)

Minimum 2.2K

0.7μs < H-SPW

1H < V-SPW

+/-

+/-

See Note-1

See Note-2

Ω(pull down)

30 mm

50 mm

√

√

√

√

√

√

For 15-pin D-sub

For 24-pin DVI-D

√

For 15-pin D-sub

Video input

√

√

√

√

For 15-pin D-sub

Refer to VESA VSIS

Standard V1R1

10KΩ for application

Note-1: The pin assignment of 15-pin D-sub connector is as below,

1 5

6

11 15

10

4

Confidential

Page 46

Q7T4-FP71G LCD Monitor Service Guide

Pin Signal Assignment Pin Signal Assignment

1 Red video 9 PC5V (+5 volt power)

2 Green video 10 Sync Ground

3 Blue video 11 Ground

4 Ground 12 SDA

5 Cable Detected 13 H-Sync (or H+V)

6 Red Ground 14 V-sync

7 Green Ground 15 SCL

8 Blue Ground

Engineering Specification

Note-2: The pin assignment of 24-pin DVI-D connector is as below,

Pin Signal Assignment Pin Signal Assignment

1 TMDS RX2- 13 Floating

2 TMDS RX2+ 14 +5V Power

3 TMDS Ground 15 Ground

4 Floating 16 Hot Plug Detect

5 Floating 17 TMDS RX06 DDC Clock 18 TMDS RX0+

7 DDC Data 19 TMDS Ground

8 Floating 20 Floating

9 TMDS RX1- 21 Floating

10 TMDS RX1+ 22 TMDS Ground

11 TMDS Ground 23 TMDS Clock+

12 Floating 24 TMDS Clock-

2.3 Video performance

Item Condition Spec OK N.A Remark

Max. support Pixel rate

Max. Resolution

< 6.25 ns

Rise time + Fall time

Settling Time after

overshoot /undershoot

Overshoot/Undershoot

< 12% of step function

< 5% final full-scale value

voltage level over the full

5

Confidential

135 MHz

1280 x 1024

(50% of minimum pixel

clock period)

voltage range

√

√

√

√

√

1280 x 1024 @ 75Hz

(max. support timing)

Refer to VESA VSIS

Standard V1R1

Refer to VESA VSIS

Standard V1R1

Page 47

Q7T4-FP71G LCD Monitor Service Guide

OS

OS

OS

VES

VES

VES

VES

VES

VES

VES

VES

VES

SU

SU

VES

VES

S

2.4 Scan range

Item Condition Spec OK N.A Remark

Horizontal

Vertical

2.5 Plug & Play DDC2B Support

Item Condition Spec OK N.A Remark

DDC channel type

EDID

2.6 Support Timings

30 ~ 83 KHz

56 ~ 76 Hz

DDC2B

Version 1.3

Engineering Specification

√

Without Frame buffer

√

√

Refer to Q7C4 S/W

√

spec. document to see

the detailed EDID data

definition.

Input Timing

Resolution

640x350 31.47(P) 70.08(N) 25.17 1280x943

720x400 31.47(N) 70.08(P) 28.32 1280x1024

640x480 31.47(N) 60.00(N) 25.18 1280x1024

640x480 35.00(N) 67.00(N) 30.24 1280x1024

640x480 37.86(N) 72.80(N) 31.5 1280x1024

640x480 37.50(N) 75.00(N) 31.5 1280x1024

800x600 37.88(P) 60.32(P) 40.00 1280x1024

800x600 48.08(P) 72.19(P) 50.00 1280x1024

800x600 46.86(P) 75.00(P) 49.50 1280x1024

832X624 49.72(N) 74.55(N) 57.29 1280x1024

1024x768 48.36(N) 60.00(N) 65.00 1280x1024

1024x768 56.48(N) 70.10(N) 75.00 1280x1024

1024x768 60.02(P) 75.00(P) 78.75 1280x1024

1024X768 60.24(N) 74.93(N) 80.00 1280x1024

1152x864 67.50(P) 75.00(P) 108.00 1280x1024

1152x870 68.68(N) 75.06(N) 100.00 1280x1024

1152x900 61.80(N) 66.00(N) 94.50 1280x1024

1152x900 71.81(N) 76.14(N) 108.00 1280x1024

1280x1024 64.00(P) 60.00(P) 108.00 1280x1024

1280x1024 75.83(N) 71.53(N) 128.00 1280x1024

1280x1024 80.00(P) 75.00(P) 135.00 1280x1024

1280x1024 81.18(N) 76.16(N) 135.09 1280x1024

Horizontal Vertical Dot Clock Actual display

Actual Output

OK N.A

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

Remark

D

D

D

Macintosh

A

A

A

A

A

Macintosh

A

A

A

Macintosh

A

Macintosh

N 66

N

A

IBM1

A

PARC2

Note-3: “P”, “N” stands for “Positive”, “Negative” polarity of incoming H-sync/V-sync (input timing).

6

Confidential

Page 48

Q7T4-FP71G LCD Monitor Service Guide

p

3. Operational & Functional Specification

3.1 Video performance

Item Condition Spec OK N.A Remark

Resolution

Contrast ratio

Brightness

Response time

Viewing angle

CIE coordinate of White

Display colors

Any input resolution modes

which are under 1280 x 1024

450:1 (typ.)

At R/G/B saturated condition 260 cd/m2 (typ.) @ 7.5mA

Rising + Falling time 16 ms (typ.)

At Contrast ratio = 10 R/L: 70/70 degrees (typ.)

At Contrast ratio = 10 U/D: 70/60 degrees (typ.)

(0.31, 0.33) +/- (0.03, 0.03)

3.2 Brightness Adjustable Range

Item Condition Spec OK N.A Remark

At default contrast level

Brightness adjustable range

(saturate point) & Full-white

color pattern

Engineering Specification

1280 x 1024

16.2M colors

(RGB 6-bits + FRC data)

(Max. brightness value –

Min. brightness value)

≧ 100 cd/㎡

√

√

√

√

√

√

√

Support dithering

√

√

3.3 Acoustical Noise

Item Condition Spec OK N.A Remark

Acoustical Noise

3.4 Environment

Item Condition Spec OK N.A Remark

Temperature

Humidity

Altitude

3.5 Transportation

Item Condition Spec OK N.A Remark

(1) Vibration

At 1 meter distance

& “Audio” function disabled

Operating

Non-operating

Operating 10 ~ 90%

Non-operating 5 ~ 95%

Operating 0~3048m (10,000ft)

Non-operating 0~12,192m (40,000ft)

(1) Sine wave

5~200Hz 1.5G, 1 octave/min,

15 min dwell on each resonant

Package, Non-Operating

frequency, all primary axis,

one sweep (30 min minimum)

er orientation, total of 90+

min.

≦ 40 dB/A

0 ~ +40 ℃

-20 ~ +60 ℃

√

√

√

Non-condensing

√

Non-condensing

√

Without packing

√

With packing

√

√

7

Confidential

Page 49

Q7T4-FP71G LCD Monitor Service Guide

(2) Unpackaged Vibration

(3) Drop

(4) Shock

Unpackaged, Non-Operating

Package, Non-Operating

Wooden package,

Non-Operating

Engineering Specification

(2) Random

5 ~100 Hz, 0 dB/Oct. 0.015

2

/Hz

g

100 ~200 Hz, -6 dB/Oct.

200 Hz, 0.0038 g

Equivalent to 1.47 Grms, All

primary axis, 20 min perorientation, total is 60 min.

(3) Procedure:

Confirmed sample with

appearance and function ready

before testing then compare

with after test record as

brightness, uniformity and

contrast ratio. Perform

random vibration after

sine-wave vibration test.

Test Spectrum:

20 Hz 0.0185(g2/Hz)

200Hz 0.0185(g2/Hz)

Duration : 5 Minutes

Axis : 3 axis ( Horizontal

and Vertical axis ,Z axis)

91 cm Height (MP stage)

(1 corner, 3 edges, 6 faces)

Waveform: half sine

Faces: 6 sides/ per orientation

3 shocks.

Duration: <3ms

Velocity accelerate: 75g

2

/Hz

√

√

√

3.6 Electrostatic Discharge Requirements

Item Condition Spec OK N.A Remark

Electrostatic Discharge

3.7 EMC

Item Condition Spec OK N.A Remark

TCO03

EMI

3.8 Reliability

Item Condition Spec OK N.A Remark

MTBF Prediction

CCFL Life time

IEC801-2 standard

Electric

Magnetic

FCC part 15J class B

EN55022 class B

Refer to MIL-217F > 60,000 Hours

At 25±2℃, under 7.0mA

After Mass production under

1dBuv for constant measure.

Besides DNSF and VCCI

class-2 are optional.

Contact: 8KV

Air: 15KV

Band 1 < 10 V/m

Band 2 < 1 V/m

Band 1 < 200nT

Band 2 < 25nT

50,000 Hours (typ.)

√

√

√

√

Excluding CCFL

√

See Note-4

√

Note-4: CCFL lifetime is determined as the time at which brightness of lamp is 50%. The typical lifetime of

CCFL is on the condition at 7.5mA lamp current.

8

Confidential

Page 50

Q7T4-FP71G LCD Monitor Service Guide

3.9 Audio performance

Item Condition Spec OK N.A Remark

Preamp + Power amp

(1)Output power

(2)THD (@ 1W)

(3)S/N ratio

Speaker Driver

(1)Nominal impedance

(2)Rated input power

(3)Frequency response

(4)Output sound pressure level

(5)Dimension of box

Audio Control

(1)Volume range

(2)Mute

Engineering Specification

1 Wrms/CH @ 1KHz

<1%

>40dB

8 ohm

2 W/CH

180~20KHz SPL-10dB

84 ± 3 dB (1W 0.5M)

62x33cx20 mm

0 ~100 levels

On/Off

2

√

√

√

√

√

√

√

√

√

√

4. LCD Characteristics

4.1 The Physical definition & Technology summary of LCD panel

Item Condition Spec OK N.A Remark

LCD Panel Supplier

Panel type of Supplier

Screen Diagonal

Display area

Physical Size

Weight

Unit=mm 337.920(H) x 270.336(V)

Unit=mm 358.5(H) x 296.5(V) x 17.0 (D) (typ.)

Unit=gram 1900 (typ.)

Technology

Pixel pitch

Unit=mm 0.264 x 0.264

Pixel arrangement

Display mode

Support color

TN type

R/G/B vertical stripe

16.2M colors (RGB 6-bits + FRC data)

AUO

M170EG01 V1

432mm(17.0”)

Normally white

√

√

√

√

√

√

√

Per one triad

√

√

√

√

4.2 Optical characteristics of LCD panel

Item Unit Conditions Min. Typ. Max. Remark

Viewing Angle

Contrast ratio

Response Time

Color / Chromaticity

[degree]

[degree]

[degree]

[degree]

[msec] Rising Time - 12 20

[msec] Falling Time - 4 5

[msec] Rising + Falling - 16 25

Horizontal (Right)

CR = 10 (Left)

Vertical (Up)

CR = 10 (Down)

Normal Direction

Red x 0.61 0.64 0.67

Red y 0.31 0.34 0.37

60

60

60

50

250 450

70

70

70

60

-

-

-

-

9

Confidential

Page 51

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

Green x 0.26 0.29 0.32

Coordinates (CIE)

Color Coordinates (CIE) White

Luminance Uniformity

White Luminance @ CCFL

7.5mA (center)

Crosstalk (in 75Hz)

* The test methods for the above items’ definition, please refer to the relative panel specification.

Green y 0.58 0.61 0.64

Blue x 0.11 0.14 0.17

Blue y 0.04 0.07 0.10

White x 0.28 0.31 0.34

White y 0.30 0.33 0.36

[%] 9 points measurement

[cd/m2]

[%]

75 80 -

210 260 -

1.5

5. User Controls

5.1 User’s hardware control definition

Item Condition Spec OK N.A Remark

Monitor Power button

Enter button

Right/Inc. button

Left/Dec. button

Exit /Volume button

I-key button

Mode Selection button

Mute button

Input source select button

√

√

√

√

√

√

√

√

√

5.2 OSD control function definition

Item Condition Spec OK N.A Remark

Auto Adjust

Brightness

Contrast

Horizontal Position

Vertical Position

Pixel Clock

Phase

Color

OSD Position

OSD Time

Language

Recall

Mode Selection

Auto-Geometry

Bluish

Reddish

sRGB

: Separate R/G/B adjustment

User

OSD Horizontal position

OSD Vertical position

From 5 sec to 60 sec

8 languages

Color recall

Recall All

√

√

√

√

√

√

√

√

√

√

√

√

√

10

Confidential

Page 52

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

Input Select

Sharpness

Display Information

Volume

Mute

Hot key for Brightness

Hot key for Contrast

Hot key for Volume

Hot key for Mode

* The detailed firmware functions’ specification, please refer to C212 S/W spec. document.

D-sub

DVI

For input timing

√

√

√

√

6. Mechanical Characteristics

6.1 Dimension

Item Condition Spec OK N.A Remark

Bezel opening

Monitor without Stand

Monitor with Stand

Carton Box (outside)

Tilt and Swivel range

L x W x H mm

L x W x H mm

L x W x H mm

339.84 x 272.24 mm

323.75*378*60.5mm

362*378*135.31 mm

456(L)*423(W)*114(H)

Tilt: -5 ~ +20 degree

Swivel: 0 degrees

√

√

√

√

√

√

√

√

√

√

6.2 Weight

Item Condition Spec OK N.A Remark

Monitor (Net)

Monitor with packing

6.3 Plastic

Item Condition Spec OK N.A Remark

Flammability

Heat deflection To

UV stability

Resin

Texture

Color

(Gross)

ABS

ABS

(VW55/VE0856/D350)

3.8 Kg

5.7 Kg

94-HB

65 ℃

Delta E < 8.0

MPRII:

BCS-Y5003A

ABS

MT-11020

√

√

√

√

√

√

√

√

Bezel texture

MT-11000

Bezel painting

T8020C

11

Confidential

Page 53

Q7T4-FP71G LCD Monitor Service Guide

6.4 Carton

Item Condition Spec OK N.A Remark

Color

Material

Compression strength

Burst Strength

Stacked quantity

7. Pallet & Shipment

7.1 Container Specification

Quantity of products

Stowing Type Container

(sets)

(Every container)

Engineering Specification

Kraft

B Flute

288 KGF

(sets)

2

16 KGF/cm

18 Layers

Quantity of Products

(Every Pallet)

√

√

√

√

√

Quantity of pallet

(sets)

(Every Container)

With pallet

Without pallet

7.2 Carton Specification

Product:

Net Weight (Kg) Gross Weight (Kg)

Package:

20'

40'

20'

40'

3.8Kg 5.7Kg 323.75*378*60.5mm 362*378*135.31 mm

Carton Interior Dimension (mm)

L*W*H

1080 Pallet A: 90 Pallet A: 12

Pallet B: 72 Pallet B: 12

2520 Pallet A: 90 Pallet A: 14

Pallet B: 72 Pallet B: 14

X X

X X

X X

X X

Dimension w/o Base

L*W*H (mm)

Carton External Dimension (mm)

L*W*H

Dimension w/ Base

L*W*H (mm)

448(L)*415(W)*100(H) 456(L)*423(W)*114(H)

8. Certification

Item Condition Spec OK N.A Remark

Environment

12

Confidential

Green design

Blue Angel German Standard

E-2000 Switzerland

API Doc. 715-C49

√

√

√

ISO14000

Requirement

Page 54

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

PC-Monitor

Safety

EPA USA Standard

TCO’99

TCO’03

Green Mark

Microsoft Windows PC98/99

DPMS VESA

DDC 2B Version 1.3

USB External

UL (USA) UL60950 3rd edition

CSA (Canada) CAN/CSA-C22.2 No. 60950

Nordic / D.N.S.F EN60950

FIMKO EN60950

CE Mark 73/23/EEC

IEC60950

EN60950

CB

EN60950

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

EMC

X- Ray Requirement

TUV/GS

EN60950 /

EK1-ITB 2000:2003

CCC (China)

GOST EN60950

SASO

CE Mark 89/336/EEC

FCC (USA) FCC Part 15 B

√

√

√

√

√

√

EN55022 Class B

√

CISPR 22 Class B

VCCI (Japan) VCCI Class B

BSMI (Taiwan) CNS 13438

C-Tick (Australia) AS/ NZS CISPR22

DHHS (21 CFR) USA X- Ray Standard

DNHW

PTB German X- Ray standard

√

√

√

√

√

√

√

√

√

√

Ergonomics

TUV / Ergo

ISO 13406-2

prEN50279

13

Confidential

Page 55

Q7T4-FP71G LCD Monitor Service Guide

Engineering Specification

Appendix: Physical Dimension Front View and Side view

Fig. 1 Physical Dimension Front View and Side view

14

Confidential

Page 56

5

3.3 V_MCU

D N1

BAV70 LT1

2

1

R1 3

4.7K

R1

4.7K

DD C_ WP_A

R2

4.7K

PC 5V

DS UB_S CL

DS UB_S DA

DS UB_S DA

DSU B_SC L

R1 4

47

R1 5

47

3

C2

0. 1U

U1

1

D D

2

3

4

A0

A1

A2

VSS

R1 0

AT24 C02A

8

VCC

7

WP

6

SCL

5

SDA

0

3.3 V_MCU

C C

J2

TP18

TP19

TP20

TP21

TP22

TP23

TP24

TP12

TP13

TP14

TP15

TP16

TP17

RX2RX1RX0RX2+

RX1+

RX0+

Hot -Plug

DVI _SC L

DVI PC5 V

DVI _SD A

R3 0

RXC+

10K

RXC-

D-d etec t

D6

6.2 V

1 2

D8

D7

6.2 V

6.2 V

ESD solution

1 2

1 2

C1 6

0.0 1U

3

1

1

9

9

17

17

2

2

10

10

18

18

3

3

11

11

19

19

4

4

12

12

20

20

5

5

13

13

21

21

6

6

14

14

22

22

7

7

B B

15

15

23

23

8

8

16

16

24

24

G1

G1

G2

G2

202 2009024

4

3

2

1

3.3 V_MCU

D N2

BAV 99

PC5 V

D1

6.2 V

1 2

11

TP5

12

TP7

13

TP9

14

TP10

15

TP1

TP2

J1

G1G2

6

1

7

2

8

3

9

4

10

5

TP3

TP4

TP6

TP8

202 4012A15

D2

D3

6.2 V

6.2 V

1 2

1 2

R1 6

R1 7

R1 8

D4

6.2 V

1 2

D5

2K

R1 9

2K

6.2 V

1 2

3.3 V_MCU

C1 5

2

D N7

BAV 99

3

RX0- RX0M

RX0+

RX1-

RX1+

RX2-

2

DN 13

BAV9 9

1

RX2+

RXC-

RXC+

2

D N8

1

BAV 99

3

2

D N9

1

BAV 99

3

2

DN 10

1

BAV9 9

3

2

DN 11

1

BAV 99

3

1

3

0.0 1U

2

DN 12

BAV 99

2

DN 14

1

BAV 99

3

2

DN 15

1

BAV 99

3

2

3

1

D N3

BAV 99

TP11

200

200

ESD solution

R2 2

R2 4

R2 6

R2 8

R3 1

R3 2

R3 3

R3 4

D N4

D N5

2

2

1

C7 7

0. 1U

BAV 99

3

2

BAV 99

C1

ESD solution

0.0 1U

3

3

1

1

R3

R4

75

R5

75

75

R+

L1

A-d etect

Z60

L2

Z60

L3

Z60

C1 0

C9

4.7 P C

4.7 P C

G+

B+

R3 5

100

C1 1

4.7 P C

C2 0

0.0 1U J

R6

R7

R8

R9

R1 1

R1 2

C2 5

0.0 1U J

100

C3 0.0 47U

100

C4 0.0 47U

100

C5 0.0 47U

100

C6 0.0 47U

C7 0.0 47U

100

C8 0.0 47U

100

RE D-

RE D+

GR EEN-

GRE EN+

BLU E-

BLU E+

C4 9

0.0 1U J

HS YN C

VS YN C

C1 3

C1 2

20P J

22P J

3.3 V_MCU

D N6

BAV7 0LT1

2

1

3

C1 4

0.1 U

U2

0

0

RX0P

0

RX1M

0

RX1P

0

RX2M

0

RX2P

0

RXCM

0

RXC P

1

2

3

4

R2 7

A0

A1

A2

VSS

AT2 4C02A

8

VCC

7

WP

6

SCL

5

SDA

0

R2 0

4.7K

DD C_ WP_D

R2 9

4.7K

3.3 V_MCU3.3 V_MCU

R2 1

4.7K

DV IPC 5V

R2 3

47

R2 5

DV I_SC L

47

DV I_SD A

1

A A

Pro ject Code

99. L1C7 2.001

Title

Size Docu ment Nu mber Re v .

PC B P/ N

<Size>

Thu rsda y, July 29, 2004

Dat e: Sheet

Pre pare d By

5

4

3

2

AN GEL HU

Mod el Nam e

INT ERF ACE BO ARD

48. L1C0 1.S02 S02

PC B Rev.

Re view ed By Ap pro ved By

ALL EN P C LEE DAV EN WU

1

Q7T4

OEM /ODM Model Name

NA

99. L1C7 2.00 0-C3-304 -001

o f

1 6

1

Page 57

5

Delete FB1, C20; FB2, C25 ;

6/16 change FB3,FB4,FB5 from

0805 to 0603

3.3 V_MCU

D D

C C

B B

FB 4

220 OHM

12

+

+2. 5V

FB 5

220 OHM

3.3 V_MCU AD C_V CC

FB 3

220 OHM

C3 4

22U 25V

<Spec >

R3 .3D VCC

12

+

C4 2

22U 25V

12

+

C3 0

22U 25V

C3 5

0. 1U

C2 6

0. 1U

<Spe c>

<Spe c>

C3 6

0. 1U

C2 7

0. 1U

C4 3

0. 1U

C3 1

0. 1U

C3 7

C3 8

0.1 U

0. 1U

TMD S_VCC

C2 8

C2 9

0.1 U

0. 1U

C4 4

C4 5

0.1 U

0. 1U

C3 2

C3 3

0.1 U

0. 1U

C3 9

0. 1U

R2 .5D VCC

C4 6

0. 1U

4

R3 .3D VCC

C4 0

C4 1

0. 1U

0. 1U

C1 7

18P J

C1 8

18P J

R3 .3D VCC

TMD S_VCC

AD C_V CC

RTD _RESE T

3

Y1

24. 576MH Z

C2 1

0. 1U

3.3 V_MCU

RESE T

R3 8

4.7K

2

R3 .3D VCC R 2.5 DVCC

109

XO

XI

DPLL_VDD

APLL_VDD

DPLL_GND

APLL_GND

PLL_TEST1

PLL_TEST2

TMDS_TST/PWM1

EXT_RES

RX2P

RX2N

RX1P

RX1N

RX0P

RX0N

RXCP

RXCN

TMDS_VDD

TMDS_VDD

TMDS_VDD

TMDS_VDD

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

B+

BSOG/ADC_TEST

G+

GR+

R-

ADC_VDD

ADC_VDD

ADC_VDD

ADC_REFIO

ADC_GND

ADC_GND

ADC_GND

ADC_GND

AHS

AVS

120

XO

1

XI

R6 7

RX2P

RX2M

RX1P

RX1M

RX0P

RX0M

RXC P

RXCM

RTD _SD O/SD I

DS UB_S DA

DS UB_S CL

12

14

15

17

18

20

21

23

24

11

13

19

26

10

16

22

25

30

31

33

34

35

37

38

29

36

41

28

27

32

39

40

42

43

RTD _SCL K

SD IO1

SD IO2

SD IO3

RTD _SCS B

2

4

5

3

8

6

7

9

C2 2

0.1 U

R3 9

1K

BLU E+

BLU E-

GRE EN+

GRE EN-

RE D+

RE D-

C2 4 0.1 U

HS YN C

VS YN C

R4 0

0

R4 1

0

4.7K

3.3V Ground

84

3.3V Ground

3.3V Ground963.3V Ground

SDIO[0]54SCLK50SCSB

53

121

57

48

3.3V Ground723.3V Ground

49

58

95

110

3.3V Power713.3V Power

3.3V Power

3.3V Power833.3V Power

3.3V Power

3.3V Ground

RTD2523

RESET#

DDCSDA47DDCSCL2

TCON[2]/SDIO[3]/PWM251TCON[3]/SDIO2]52TCON[4]/SDIO[1]

DDCSDA2

DDCSCL

56

46

111

126

125

128

69

97

98

127

3.3V Power

44

45

70

TCON[12]/COUT/PWM2

TCON[13]/COUT/PWM2

2.5V Power

2.5V Power

2.5V Power

2.5V Power

2.5V Ground

2.5V Ground

2.5V Ground

2.5V Ground

AG2N/TCON[10]

AG2P/TCON[11]

TCON[0]/VCLK

TCON[1]/V[7]

TCON[7]/V[4]

TCON[11]/V[0]

TCON[10]/V[1]

TCON[9]/V[2]

TCON[8]/V[3]

TCON[6]/V[5]

TCON[5]/V[6]

124

123

118

114

115

116

117

119

122

delete RN1, add R65

R66;Delete RN2 Add R67;

R35: Delete R65,R66 0615

PWM0/REFCLK

AR1N

AR1P/TCON[0]

AR2N/TCON[1]

AR2P/TCON[5]

AR3N/TCON[6]

AR3P/TCON[7]

AG1N/TCON[8]

AG1P/TCON[9]

BG3N

BG3P

BCLKN

BCLKP

BB1N

BB1P

BB2N

BB2P

BB3N

BB3P

AG3N/TEAN

AG3P/TEAP

ACLKN/TEBN

ACLKP/TEBP

AB1N/TECN

AB1P/TECP

AB2N/TECLKN

AB2P/TECLKP

AB3N/TEDN

AB3P/TEDP

BR1N/TOAN

BR1P/TOAP

BR2N/TOBN

BR2P/TOBP

BR3N/TOCN

BR3P/TOCP

BG1N/TOCLKN

BG1P/TOCLKP

BG2N/TODN

BG2P/TODP

R3 6

113

112

55

108

R3 7

107

106

105

104

103

102

101

100

99

68

67

66

65

64

63

62

61

60

59

94

93

92

91

90

89

88

87

86

85

82

81

80

79

78

77

76

75

74

73

RXOI N0RXOI N0+

RXOI N1RXOI N1+

RXOI N2RXOI N2+

RXO CKINRXO CKIN+

RXOI N3RXOI N3+

RXEI N0RXEI N0+

RXEI N1RXEI N1+

RXEI N2RXEI N2+

RXEC LKRXE CKIN+

RXEI N3RXEI N3+

1

100

12

+

100

12

+

C1 9

4.7 U 25 V

C2 3

4.7 U 25 V

VOL _ADJ

BRT _ADJ

3.3 V_MCU

A A

Pro ject Code

99. L1C7 2.001

Title

Size Docu ment Nu mber Re v .

PC B P/ N

<Size>

Thu rsda y, July 29, 2004

Dat e: Sheet

Pre pare d By

5

4

3

2

AN GEL HU

Mod el Nam e

INT ERF ACE BO ARD

48. L1C0 1.S02 S02

PC B Rev.

Re view ed By Ap pro ved By

ALL EN P C LEE DAV EN WU

1

Q7T4

OEM /ODM Model Name

NA

99. L1C7 2.00 0-C3-304 -001

o f

2 6

1

Page 58

5

4

3

2

1

delete RN4,RN5,RN6,RN8;

Q1,R44,C49,R46,R47

D D

RTD _SC SB

PAN EL_O N

**C50 cl ose to scaler, R43 clo se to MCU.

RESE T

3.3 V_MCU

3.3 V_MCU

R4 5

C5 0 6.8 P J

Y2

C5 1 6.8 P J

C C

RTD _SD O/SD I

SDI O1

SDI O2

SDI O3

RTD _SC LK

B B

R5 3

KEY_ EXIT

KEY _LEFT

KE Y_RI GHT

KE Y_ME NU

PW _SW

I- KEY

A A

1K

R5 4

5

12M HZ

SD A

SC L

DD C_ WP_A

DD C_ WP_D

1K

R5 5

1K

R5 6

1K

D-d etec t

3.3 V_MCU

C4 8

0.2 2U K

7

8

4.7K

9

10

11

12

13

14

15

16

17

LE D_OR G

LE D_G RN

R5 7

1K

R5 8

1K

3.3 V_MCU

3

4NC5NC6

RST

VDD

P6.3/AD3

VSS

X2

X1

ISDA/P3.4/T0

ISCL/P3.5/T1

STOUT/P4.2

P6.2/AD2/HLFHI

P1.0

RTD _RESE T

LE D_O RG

LE D_G RN

VDD3

U5

SOCKET P/N: 22.10079.044

MTV31 2MV64

P1.118P3.2/INT019P1.220P1.321P1.422P1.523P1.624P1.725P6.1/AD126P6.0/AD027HSDA/P3.1/Txd

R4 8

10K

R5 0

10K

L6

C6 7

100P

50V J

C6 8

100P

50V J

4

1

DA2/P5.21DA1/P5.12DA0/P5.0

L7

44

VSYNC

3.3 V_MCU

3 2

C6 9

100P

50V J

43

HSYNC

2N3 906

Q2

1

42

HSCL/P3.0/Rxd

28

2N3 906

Q3

3 2

L8

DA5/P5.540DA4/P5.441DA3/P5.3

DA8/HLFHO

DA9/HALFV

HBLANK/P4.1

VBLANK/P4.0

DA7/HCLAMP

DA6/P5.6

P6.7/DA13

P6.6/DA12

P6.5/DA11

P6.4/DA10

R N7

220 P J

R4 9

R5 1

C7 0

100P

50V J

123

876

3.3 V_MCU

C6 4

220

220

I- KEY

4

5

L9

3.3 V_MCU

876

5

4.7K

R N3

123

4

PW _SW

39

38

37

DD C_ WP_D

36

DD C_W P_A

35

34

33

32

31

30

29

KEY _LEFT

KEY_ EXIT

A-d etect

C5 4

100P

50V J

C5 5

100P

50V J

4.7K

C6 5

C6 6

0. 1U

0. 1U

L10

C7 1

100P

50V J

C7 2

100P

50V J

3

R6 8

4.7K

L11

KE Y_M ENU

3.3 V_MCU

TP32

TP33

TP34

TP35

TP36

TP37

TP38

TP39

TP40

KE Y_RI GHT

LE D_OR G

LE D_G RN

BL_ ON

VOL _ON

DSU B_SC L

DS UB_S DA

BRT _ADJ

VOL _ADJ

J4

1

2

3

4

5

6

7

8

9

206 0091109

C5 8

0. 1U

TP26

TP30

C5 9

0. 1U

TP25

1

3

5

7

9

11

J3

1

3

5

7

9

11

207 2060206

3.3 V_MCU

C4 7

U4

0. 1U

1

2

3

4

3.3 V_MCU

2

2

4

4

6

6

8

8

10

10

12

12

12

+

C5 6

22U 25V

R5 2

2

A0

VCC

A1

A2

SCL

GND

SDA

AT2 4C04 N-10SI- 2.7

U6

1

VIN

C5 2

0.1 U

C6 0

0. 1U

0

8

7

WP

6

5

GMT

3

VOUT

GND

GND

G950 T65U

2

G1

12

C6 1

+

C5 7

22U 25V

0. 1U

Pro ject Code

Title

Size Docu ment Nu mber Re v .

<Size>

Dat e: Sheet

R4 3

R4 2

4.7K

4.7K

+2. 5V

C5 3

0.1 U

L4

Z30

C6 3

C6 2

0. 1U

0.1 U

99. L1C7 2.001

PC B P/ N

48. L1C0 1.S02 S02

Thu rsda y, July 29, 2004

Pre pare d By

AN GEL HU

SC L

SD A

TP27

BL_ ON

TP28

L5

220 OHM

Mod el Nam e

Q7T4

INT ERF ACE BO ARD

PC B Rev.

Re view ed By Ap pro ved By

ALL EN P C LEE DAV EN WU

1

+5V

TP29

3.3 V_MCU

TP31

VOL _ON

OEM /ODM Model Name

99. L1C7 2.00 0-C3-304 -001

3 6

NA

1

o f

Page 59

5

4

3

2

1

D D

R6 0

PANEL_ ON

C C

B B

A A

5

20K

12

C7 5

+

OP EN

25V

4

R6 1

10K

5V_ PANEL

+5V

1

R6 2

R6 3

R6 4

RXEIN3+

RXEIN3RXECKIN+

RXECLK-

RXEIN2+

RXEIN2-

RXEIN1+

RXEIN1-

RXEIN0+

RXEIN0-

RXOI N3+

RXOI N3-

RXO CKIN +

RXO CKIN -

RXOI N2+

RXOI N2-

RXOI N1+

RXOI N1-

RXOI N0+

RXOI N0-

R5 9

100K

32

Q5

2N3904

0

0

0

TP45

TP46

TP47

TP48

TP49

TP50

TP51

TP52

TP53

TP54

TP55

TP56

TP57

TP58

TP59

TP60

TP61

TP62

TP63

TP64

TP41

TP42

TP43

TP44

+5V

1

C7 6

0. 1U

G1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

G2

20K2085030

3

G1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

G2

5V_ PANEL

3

Q4

ELM13 401CA

2

J5

12

+

C7 3

22U 25V

C7 4

0. 1U

G(1)

S(2)

D(3)

Pro jec t Co de

99. L1C72.001

Title

Size Doc ument Nu mb er R e v .

PCB P/ N

<Size>

Da te : Sheet

2

48. L1C01.S02 S02

Th ursda y, Ju ly 29, 2 004

Pre par ed By

ANGE L HU

Mod el Na me

Q7T4

IN TERFACE BO ARD

PC B R ev.

Re vi ew e d B y Ap pr ov ed By

ALL EN PC LEE D A VE N WU

OEM /ODM Mode l Nam e

99.L 1C72. 000- C3-30 4-00 1

4 6

1

NA

1

o f

Page 60

5

D D

C C

4

3

2

1

1

5

B B

Opti cal Po ints

OP1OPOP2

OP

A A

5

OP3

OP

4

3

2

H1

HOL E-V8

4

9

8

7

6

5

4

3

2

H2

HOL E-V8

1

9

8

7

6

5

4

3

2

H3

HOL E-V8

3

1

9

8

7

6

Proj ect Cod e

99.L 1C72.001

Title

Size D ocum ent Nu mber R ev .

PC B P/N

<Size>

48.L 1C01.S02 S02

Th ursda y, Ju ly 29, 2004

Da te: S heet

Pre pared By

2

AN GEL HU

Mod el Name

Q7T4

INT ERFA CE BO ARD

PC B R ev.

Re view ed B y Ap prove d By

ALL EN PC L EE D AVEN WU

OEM/ ODM Mo del Name

99.L 1C72.0 00-C3-304-00 1

5 6

1

NA

1

o f

Page 61

1. Add C20, C25, C49, C77 , R35

D D

C C

5

4

3

2

1

B B

A A

Proj ec t Code

Mode l Nam e

OEM/O DM Mod el Nam e

Q7T4

INT ER FA CE B OAR D

PC B R ev.

99.L 1C 72 .000 -C3-30 4-001

6 6

Revi ew ed By Ap pr ove d By

ALLE N P C LEE DA VE N W U

NA

1

99.L 1C 72.001

Title

Size D oc um e nt Numb er Re v.

PCB P/N

<Size>

48.L 1C 01.S0 2 S02

Thur sd ay , J ul y 29 , 20 04

Date : Sheet of

Prep ar ed B y

5

4

3

2

ANGE L HU

1

Page 62

Q7T4-FP71G LCD Monitor Service Guide

Trouble Shooting

Q7T4 TROUBLE SHOOTING GUIDE

No Display or display is unstable:

1.1 Interface Board:

No picture or picture unstable

Power off Yes Turn on power

No

Does cable plugs in No Check all of wire then turn on power

connector? switch again.

Yes

Does power stable? No Check Power BD

Yes

Is LED light green/orange? No Check control BD

Yes

Is LED status normal? No Check Flash Rom or replace it

Yes

Does crystal work correctly? No Check crystal CKT or replace it

Yes

Is interface BD normally? No Replace interface BD

Yes

Replace panel

1

Confidential

Page 63

Q7T4-FP71G LCD Monitor Service Guide

Trouble Shooting

2. BUTTON function:

2.1 Control Board

OSD is not working

Yes

Is control BD connecting? No Plug control BD then retry

Yes

Is bottom switch normally? Yes Replace control BD then retry

No

Replace Control BD

Is OSD working??

No

Check Interface BD

3. OSD function:

OSD doesn’t work

Is control BD working? No Replace control BD

Check interface BD

4. Power Board

2

Confidential

Page 64

Q7T4-FP71G LCD Monitor Service Guide

Backlight didn't shine

Trouble Shooting

Plug CN701 again or

checking I/F BD

Plug CN601 again or

checking PW BD

Insert them again

Y

IC801 PIN 9 IS 15V?Replace Q761

N

PWM existed?

(BLT_ADJ)

N

Turn on leve l existed?

N

Check CN801, CN802

was pluged properly?

Replace IC801,Q805

N

Y

(BLT_ON)

Y

Y

Y

LED shined?

N

Y

3.3V existed? IS I/F board connected ?

Y

Replace new fuse

N

Y

Check IC701 OK?

N

Checking F601

Broke?

N

Check IC601 Vcc

existed?

Y

Y

Replace IC701

Replace new fuse

Replace

IC601,Q602,Q603

R602

N

Replace new fuse

N

Replace IC602,

IC702,D701 or check

I/F BD

3

Confidential

Page 65

Page 66

BENQ LCD Q7T4(FP71G) Spare Parts List

P/N: 99.L1C72.ASE

ITEM DESCRIPTION PART NO. LOCATION

1 PCBA I/F BD MI AUO M170EG01 55.L1C01.001

2 IC CONTROLER RTD2023 QFP 128P 71.02023.00E U3

IC EEPROM AT24C02N-10SI-1.8SON 72.02402.C01 U1

3

IC EEPROM AT24C04N-10SI-2.7SON 72.02404.N01 U4

4

IC VR G950T65U SOT-223 74.95065.03C U6

5

IC FLASH MTV312MV64 (AJ) PLCC44 71.31264.A03 U5

6

PCBA SPS BD MI QT74 EG01 55.L1C02.001

7

8 PCBA CTRL BD MI Q7T4 55.L1C03.001

9 LCDM 17 M170EG01 V.1 AUO 56.91L83.011

10 ASSY FC ABS 8020C Q7T4 60.L1C01.001

11 ASSY RC ABS 5003A Q7T4 60.L1C02.001

12 ASSY BASE-CLUM ABS 5003A Q7T4 60.L1C03.001

13 CTN B 456*423*114 Q7T4/BENQ 44.L1C01.001

14 CSN BTM EPS Q7T4 47.L1C01.001

15 CSN TOP EPS Q7T4 47.L1C02.001

16 CABLE SIGNAL 15/15P CORE*1 1.5M 50.L9005.501

17 CD MANUAL Q7T4 53.L1C01.001

18 ASSY BASE ABS 5003A Q7T4 60.L1C04.001

* THIS PARTS LIST MAY BE SUBJECT TO CHANGE

WITH PRIOR NOTICE BY CSD OF BENQ.

Page : 1 / 1

Loading...

Loading...