Page 1

BBeennQ

Q SSoollaarr PPhhoottoovvoollttaaiicc

M

Moodduulleess

IInnssttaallllaattiioonn GGuuiiddee

((IIEECC,, EETTLL))

Poly 60 cells

Poly 60 cellsPoly 60 cells

Poly 60 cells series

seriesseries

series

PM

PMPM

PM060PW

060PW060PW

060PWXXXX

Mono 60 cells series

Mono 60 cells seriesMono 60 cells series

Mono 60 cells series

PM

PMPM

PM060

060060

060MMMMWWWWXXXX////PM060M

PM060MPM060M

PM060MBBBBXXXX

Mono 60 cells with light weight series

Mono 60 cells with light weight seriesMono 60 cells with light weight series

Mono 60 cells with light weight series PM060M0

PM060M0PM060M0

PM060M0XXXX

Poly

Poly Poly

Poly 72 cells series

72 cells series72 cells series

72 cells series

PPPPM072PW

M072PWM072PW

M072PWXXXX/PM072MW

/PM072MW/PM072MW

/PM072MWXXXX

Back contact 96 cells series

Back contact 96 cells seriesBack contact 96 cells series

Back contact 96 cells series PM096B0

PM096B0PM096B0

PM096B0XXXX

Version 2.

Version 2.Version 2.

Version 2.2222

Note: The content of this manual is subject to change without notice.

© 2014 AU Optronics All Rights Reserved

Page 2

1

BenQ Solar

BenQ SolarBenQ Solar

BenQ Solar Photovoltaic Modules

Photovoltaic ModulesPhotovoltaic Modules

Photovoltaic Modules (IEC

(IEC (IEC

(IEC, ET

, ET, ET

, ETLLLL))))

Installation Guide for U

Installation Guide for UInstallation Guide for U

Installation Guide for Users

serssers

sers

Table of Contents

Table of ContentsTable of Contents

Table of Contents

Chapter 1 General Information

Chapter 1 General InformationChapter 1 General Information

Chapter 1 General Information................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................

....................

.......... 2222

1.1 Introduction...........................................................................................................................................2

1.2 Limited Warranty and Product Certifications...............................................................................2

1.3 Disclaimer of Liability ..........................................................................................................................2

1.4 Guidelines for Safe Handling and Installation.................................................................................3

Chapter 2 BenQ Solar Module Specifications

Chapter 2 BenQ Solar Module SpecificationsChapter 2 BenQ Solar Module Specifications

Chapter 2 BenQ Solar Module Specifications ................................

................................................................

................................................................

................................................................

..................................................

....................................

.................. 6666

2.1 Performance of PV Modules ..............................................................................................................6

2.2 PM060PW0 Series................................................................................................................................6

2.3 PM060MW0 / PM060MB0 Series .....................................................................................................7

2.4 PM060M01 Series.................................................................................................................................7

2.5 PM072PW0 / PM072MW0 Series.....................................................................................................7

2.6 PM096B00 Series..................................................................................................................................8

Chapter 3 Mounting Guidelines

Chapter 3 Mounting GuidelinesChapter 3 Mounting Guidelines

Chapter 3 Mounting Guidelines ................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................

..................

......... 9999

3.1 Mounting with Screws.........................................................................................................................9

3.2 Mounting with Clamps ..................................................................................................................... 10

Chapter 4 Wirin

Chapter 4 WirinChapter 4 Wirin

Chapter 4 Wiring, Connecting and Grounding BenQ Modules

g, Connecting and Grounding BenQ Modulesg, Connecting and Grounding BenQ Modules

g, Connecting and Grounding BenQ Modules................................

................................................................

..................................................

....................................

.................. 16

1616

16

4.1 Wiring & Connecting........................................................................................................................ 16

4.2 Module Grounding............................................................................................................................ 18

4.3 System Grounding (Negative) ........................................................................................................ 19

4.4 System Grounding (Transformerless or Positive) ..................................................................... 20

4.5 Limitation in Connection................................................................................................................. 20

Chapter 5 Maintenance

Chapter 5 MaintenanceChapter 5 Maintenance

Chapter 5 Maintenance................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................................

............................................

...................... 21

2121

21

5.1 Module Cleaning Guidelines ........................................................................................................... 21

5.2 Module Cleaning Instructions......................................................................................................... 22

5.3 Cleaning the Frame........................................................................................................................... 22

5.4 Visual inspection of the module..................................................................................................... 22

5.5 Inspecting connections and cabling................................................................................................ 22

Chapter 6 Certifications

Chapter 6 CertificationsChapter 6 Certifications

Chapter 6 Certifications ................................

................................................................

................................................................

................................................................

................................................................

................................................................

....................................................

........................................

.................... 23

2323

23

6.1 IEC Certification................................................................................................................................ 23

6.2 ETL Certification ............................................................................................................................... 23

Page 3

2

Chapter 1 General Information

Chapter 1 General InformationChapter 1 General Information

Chapter 1 General Information

1.1 Introduction

The following is the product installation guide for the BenQ Solar photovoltaic modules.

BenQ Solar modules should be installed by qualified professionals only. This guide is designed

to be used in combination with industry recognized best practices and all applicable rules and

regulations.

Please read these instructions in entirety before handling or using this product in any way.

IMPORTANT

IMPORTANTIMPORTANT

IMPORTANT

BENQ SOLAR MODULES AND THIS GUIDE ARE DESIGNED FOR USE BY QUALIFIED

PROFESSIONALS ONLY. FAILURE TO FOLLOW INSTRUCTIONS IN THIS GUIDE AND

OBSERVE INDUSTRY BEST PRACTICES MAY RESULT IN DANGEROUS CONDITIONS

AND COULD VOID THE PRODUCT WARRANTY.

1.2 Limited Warranty and Product Certifications

See BenQ Solar Limited Warranty document for full product warranty details and limitations.

Product Warranty version is based on warranty note in effect at the time of product

manufacturing date. Please download and save a copy of the Warranty Note for reference.

Some product certifications are detailed in chapter 6 of this document. See individual Module

Specifications sheet for more information about product certifications of the desired BenQ

Solar module model.

The most up to date version of both of these documents can be found in the BenQsolar.com

Document Center.

http://www.benqsolar.com/

1.3 Disclaimer of Liability

It is each installer’s responsibility to abide by all relevant rules and regulations when using this

product. Always observe Industry Best Practices when handling, installing, and using this

product. This guide is designed for use by trained and certified solar professionals only. BenQ

Solar does not assume responsibility for loss, damage or expense resulting from installation,

handling or use of this product. BenQ Solar further disclaims any responsibilities to those

installers who did not follow the installation manual to install otherwise.

Page 4

3

1.4 Guidelines for Safe Handling and Installation

IMPORTANT

IMPORTANTIMPORTANT

IMPORTANT

THIS PRODUCT IS DESI

THIS PRODUCT IS DESITHIS PRODUCT IS DESI

THIS PRODUCT IS DESIGNED FOR INSTALLATIO

GNED FOR INSTALLATIOGNED FOR INSTALLATIO

GNED FOR INSTALLATION BY QUALIFIED PERSO

N BY QUALIFIED PERSON BY QUALIFIED PERSO

N BY QUALIFIED PERSONNEL ONLY.

NNEL ONLY.NNEL ONLY.

NNEL ONLY.

ALL HANDLING AND INS

ALL HANDLING AND INSALL HANDLING AND INS

ALL HANDLING AND INSTALLATIONS MUST BE P

TALLATIONS MUST BE PTALLATIONS MUST BE P

TALLATIONS MUST BE PERFORMED IN COMPLIAN

ERFORMED IN COMPLIANERFORMED IN COMPLIAN

ERFORMED IN COMPLIANCE WITH

CE WITH CE WITH

CE WITH

ALL APPLICABLE CODES

ALL APPLICABLE CODESALL APPLICABLE CODES

ALL APPLICABLE CODES,,,, RUL

RUL RUL

RULES AND REGULATIONS.

ES AND REGULATIONS.ES AND REGULATIONS.

ES AND REGULATIONS.

In addition to the applicable rules and regulations, please follow all guidelines for safe handling

and/or installation of BenQ Solar modules. In addition to the guidelines below, always observe

industry best practices when handling and/or installing any BenQ Solar module. Save this

Installation Guide for future reference.

LIFTING AND HANDLING

LIFTING AND HANDLINGLIFTING AND HANDLING

LIFTING AND HANDLING

Do not lift the module or carry module by junction box or PV cables.

Do not drill holes in the frame. This will void warranty and may affect frame strength.

Avoid scratching the frame. Scratches to the frame will compromise protective coating

and can result in corrosion or weakened structure.

Do not scratch or damage the module backsheet. Scrathes to the backsheet could affect

module performance.

Do not stand on, drop, scratch or allow objects to hit modules (especially module glass).

Do not install or handle the modules when wet or during periods of high wind.

Do not install the modules where there may be flammable gases or vapors, since sparks

may be produced.

When storing the modules, take steps to cover the DC connectors and prevent dust

from collecting on or in the connectors.

Save these instructions for future reference.

ELECTRICAL HANDLING AND INSTALLATION

ELECTRICAL HANDLING AND INSTALLATIONELECTRICAL HANDLING AND INSTALLATION

ELECTRICAL HANDLING AND INSTALLATION

Modules interconnect points conduct direct current (DC) and are sources of voltage

when the module is under load and when it is exposed to light.

Direct current can arc across gaps and may cause injury or death if improper connection

or disconnection is made, or if contact is made with module leads that are frayed, torn

or otherwise damaged.

Page 5

4

Please use caution when handling or connecting any module.

Remove all metallic jewelry prior to installing this product to reduce the chance of

accidental exposure to live circuits.

Use properly insulated tools to reduce your risk of electric shock.

Do not touch the terminals while the module is exposed to light.

During installation use suitable protection prevent a discharge of at least 30 direct

current volts to each person on crew.

Do not connect or disconnect modules when current from the modules or an external

source is present.

Do not remove or misuse module connectors, this could void module warranty.

Cover all modules in the PV array with an opaque material before making or breaking

any connections.

Use only the supplied locking connectors and safety clips in order to prevent untrained

persons from disconnecting the modules once installed.

There are no serviceable parts within the module. Do not attempt to change or repair

any part of the module.

Damaged modules (broken glass, torn back sheet, broken j-boxes, broken connectors,

etc) can present electrical hazards as well as laceration hazards. Contact with damaged

module surfaces or module frame can cause electric shock. The dealer or installers

should remove the module from array and contact the distributor for disposal

instructions.

FIRE RATING:

BenQ Solar

BenQ Solar BenQ Solar

BenQ Solar Modules have been listed as Class C according to IEC 61730

Modules have been listed as Class C according to IEC 61730Modules have been listed as Class C according to IEC 61730

Modules have been listed as Class C according to IEC 61730----2

2 2

2

standard. In case of roof installation, the PV module assemble is to be mounted o

standard. In case of roof installation, the PV module assemble is to be mounted ostandard. In case of roof installation, the PV module assemble is to be mounted o

standard. In case of roof installation, the PV module assemble is to be mounted on a fire

n a fire n a fire

n a fire

resistant roof covering rated for the application. The PV module is comprised of a glass

resistant roof covering rated for the application. The PV module is comprised of a glass resistant roof covering rated for the application. The PV module is comprised of a glass

resistant roof covering rated for the application. The PV module is comprised of a glass

front surface and

front surface and front surface and

front surface and PET backsheet and has a Class C fire rating.

PET backsheet and has a Class C fire rating.PET backsheet and has a Class C fire rating.

PET backsheet and has a Class C fire rating. For a non

For a nonFor a non

For a non----integral module

integral module integral module

integral module

or panel, the assembly is to be mounted over a fire resistant roof

or panel, the assembly is to be mounted over a fire resistant roofor panel, the assembly is to be mounted over a fire resistant roof

or panel, the assembly is to be mounted over a fire resistant roof----co

coco

covering rated for the

vering rated for the vering rated for the

vering rated for the

application. Modules may be mounted at any angle, from horizontal to vertical.

application. Modules may be mounted at any angle, from horizontal to vertical.application. Modules may be mounted at any angle, from horizontal to vertical.

application. Modules may be mounted at any angle, from horizontal to vertical.

Page 6

5

NOTE: Shading a small/narrow portion of the module (e.g. narrow bands of shade

caused by leafless branches or tall grass) can cause local cell temperature to rise,

temporarily decreasing overall module output.

Removing the source of any narrow bands of shade will prevent these “hot spots” from

occurring, and ensure maximum module productivity. The module will resume normal

performance once the source of shade is removed, with no impact to lifetime.

STORAGE

STORAGESTORAGE

STORAGE

When storing modules for any period of time, cover modules to ensure protection from

the elements. Take special steps to cover/protect the module connectors.

When storing the modules, turn so that the glass is face down. Do not allow water or

dust to collect inside module, this can damage module connectors.

When storing the modules, do not allow the anodized profiles (frames) to come into

contact with contaminants such as cement or mortar, which will cause damage to the

anodic oxide coatings.

*A

*A*A

*Always contact your module supplier for additional instructions if maintenance is necessary.

lways contact your module supplier for additional instructions if maintenance is necessary.lways contact your module supplier for additional instructions if maintenance is necessary.

lways contact your module supplier for additional instructions if maintenance is necessary.****

Page 7

6

Chapter 2

Chapter 2Chapter 2

Chapter 2 BenQ Solar Module Specifications

BenQ Solar Module SpecificationsBenQ Solar Module Specifications

BenQ Solar Module Specifications

The module electrical ratings are measured under Standard Test Conditions (STC) of

1000W/m2 irradiance with AM 1.5G spectrum and a cell temperature of 25ºC. BenQ Solar

modules electrical characteristics depend on module Series and Wattage. Please refer to the

tables below to learn more about the characteristics of your module(s).

2.1 Performance of PV Modules

A PV module may produce more current and/or voltage than reported at STC. Sunny, cool

weather and reflection from snow or water can increase current and power output.

Therefore, the values of Isc and Voc shown below should be multiplied by a factor of 1.25

when determining component voltage ratings, conductor capacities, fuse sizes, and size of

controls connected to PV output. An additional 1.25 multiplier may be required by the NEC

for sizing fuses and conductors as described in the NEC section 690.8.

While module current depends on solar irradiance, module voltage will vary depending on

device temperature. This means overall production will vary depending on solar radiation, the

temperature of the cells/module and the equipment to which they are connected.

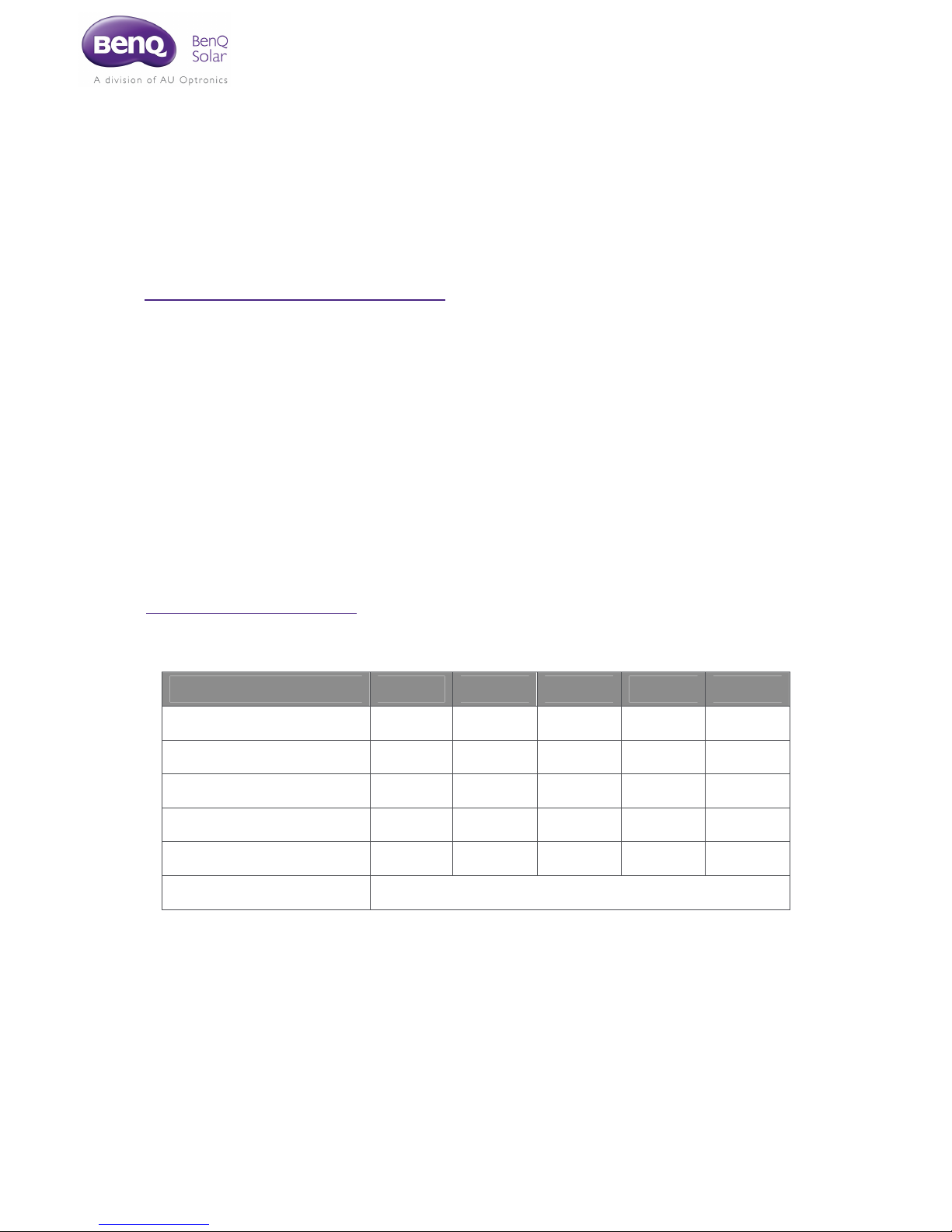

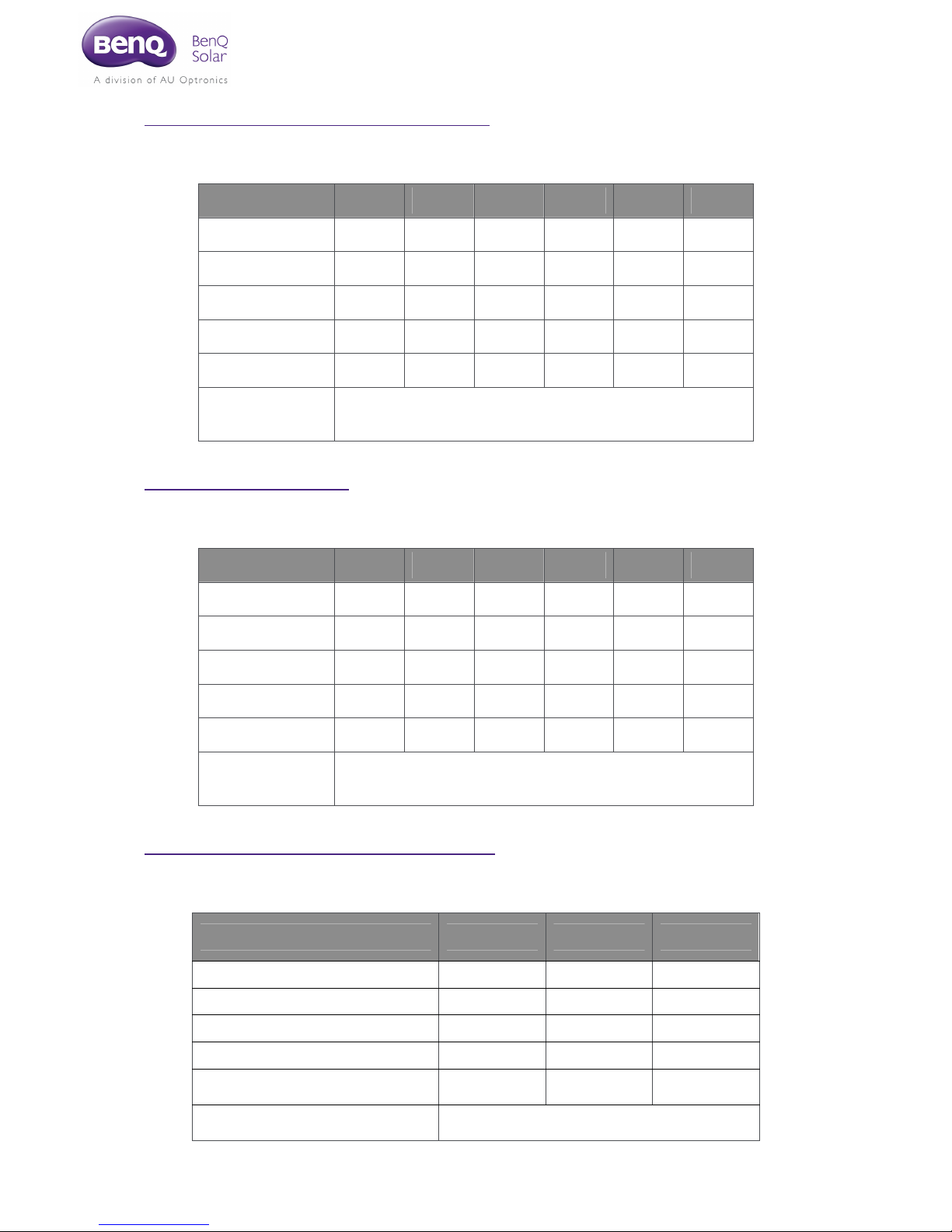

2.2 PM060PW0 Series

Module Dimensions (L x W x H):

Module Dimensions (L x W x H):Module Dimensions (L x W x H):

Module Dimensions (L x W x H): 1639 x 983 x 40 mm (64.52 x 38.7 x 1.57 in)

Module Weight:

Module Weight: Module Weight:

Module Weight: 18.5 kg (41.1 lbs)

Power

250W

255W

260W

265W

270W

Efficiency

15.5% 15.8% 16.1% 16.4% 16.7%

Vmp (V)

30.6 30.8 31.2

31.6

32.0

Imp (A)

8.17 8.28 8.34 8.39 8.44

Voc (V)

37.4 37.7 37.7 37.9 38.1

Isc (A)

8.69 8.76 8.83 8.87 8.93

Maximum Tolerance of Power

0 / +3%

Page 8

7

2.3 PM060MW0 / PM060MB0 Series

Module Dimensions (L x W x H):

Module Dimensions (L x W x H):Module Dimensions (L x W x H):

Module Dimensions (L x W x H): 1639 x 983 x 40 mm (64.52 x 38.7 x 1.57 in)

Module Weight:

Module Weight:Module Weight:

Module Weight: 18.5 kg (41.1 lbs)

Power 265W 270W 275W 280W 285W 290W

Efficiency

16.4% 16.8% 17.1% 17.4% 17.7% 18.0%

Vmp (V)

31.30 31.80 32.30 32.70 31.00 31.30

Imp (A)

8.47 8.50 8.52 8.57 9.20 9.27

Voc (V)

38.2 38.5 38.7 38.9 40.0 40.4

Isc (A)

8.98 9.01 9.03 9.06 9.80 9.82

Maximum Tolerance

of Power

0 / +3%

2.4 PM060M01 Series

Module Dimension

Module DimensionModule Dimension

Module Dimensions (L x W x H):

s (L x W x H):s (L x W x H):

s (L x W x H): 1639 x 983 x 35 mm (64.52 x 38.7 x 1.38 in)

Module Weight:

Module Weight: Module Weight:

Module Weight: 10.5 kg (23.3 lbs)

Power 265W 270W 275W 280W 285W 290W

Efficiency

16.4% 16.8% 17.1% 17.4% 17.7% 18.0%

Vmp (V)

31.30 31.80 32.30 32.70 31.00 31.30

Imp (A)

8.47 8.50 8.52 8.57 9.20 9.27

Voc (V)

38.2 38.5 38.7 38.9 40.0 40.4

Isc (A)

8.98 9.01 9.03 9.06 9.80 9.82

Maximum Tolerance

of Power

0 / +3%

2.5 PM072PW0 / PM072MW0 Series

Module Dimensions (L x W x H):

Module Dimensions (L x W x H):Module Dimensions (L x W x H):

Module Dimensions (L x W x H): 1956 x 992 x 40 mm (77.00 x 39.05 x 1.57 in)

Module Weight:

Module Weight: Module Weight:

Module Weight: 26 kg (57.33 lbs)

Power

300W

305W

310W

Efficiency

15.4% 15.7% 16.0%

Vmp (V)

36.7 36.9 37.1

Imp (A)

8.17 8.25 8.33

Voc (V)

45.5 45.6 45.7

Isc (A)

8.62 8.68 8.77

Maximum Tolerance of Power

0 / +3%

Page 9

8

2.6 PM096B00 Series

Module Dimensions (L x W x H):

Module Dimensions (L x W x H):Module Dimensions (L x W x H):

Module Dimensions (L x W x H): 1559 x 1046 x 46 mm (61.38 x 41.18 x 1.81 in)

Module Weight:

Module Weight:Module Weight:

Module Weight: 18.6 kg (41.3 lbs)

Power

315W

320W

325W

327W

330W

Efficiency

19.3% 19.6% 19.9% 20.1% 20.3%

Vmp (V)

54.7 54.7 54.7 54.7 54.7

Imp (A)

5.76 5.86 5.94 5.98 6.04

Voc (V)

64.6 64.8 64.9 64.9 64.9

Isc (A)

6.14 6.27 6.39 6.46 6.52

Maximum Tolerance of Power

0 / +3%

Page 10

9

Chapter 3

Chapter 3 Chapter 3

Chapter 3 Mounting

MountingMounting

Mounting Guidelines

Guidelines Guidelines

Guidelines

Modules may be mounted at any angle from horizontal to vertical. Select the appropriate

orientation to maximize sunlight exposure.

A gap between the module and system structure or ground is required to prevent wire

damage and to allow air to circulate behind the module.

Take care to follow all applicable regulations, especially municipal and fire codes, when

planning and executing your installation. Do not remove or alter the module frame.

Additional mounting holes may damage the module and reduce the strength of the frame.

IMPORTANT

IMPORTANTIMPORTANT

IMPORTANT

MODULES

MODULESMODULES

MODULES SHOULD ONLY BE MOUN

SHOULD ONLY BE MOUN SHOULD ONLY BE MOUN

SHOULD ONLY BE MOUNTED USING ONE OF THE

TED USING ONE OF THETED USING ONE OF THE

TED USING ONE OF THE FOLLOWING

FOLLOWING FOLLOWING

FOLLOWING

METHODS

METHODSMETHODS

METHODS.... DEVIATING FROM THE

DEVIATING FROM THE DEVIATING FROM THE

DEVIATING FROM THE MOUNTING INSTRUCTION

MOUNTING INSTRUCTIONMOUNTING INSTRUCTION

MOUNTING INSTRUCTIONS BELOW COULD

S BELOW COULD S BELOW COULD

S BELOW COULD

AFFECT MAX WIND LOAD

AFFECT MAX WIND LOADAFFECT MAX WIND LOAD

AFFECT MAX WIND LOAD AND/OR PRODUCT WARR

AND/OR PRODUCT WARR AND/OR PRODUCT WARR

AND/OR PRODUCT WARRANTY.

ANTY.ANTY.

ANTY.

3.1 Mounting with Screws

• Secure the module to the structure using only the factory drilled mounting holes.

• Do not drill any additional holes in module frame (doing so would void the warranty).

• Use corrosion-proof fastening materials.

• A torque wrench must be used for assembly. In the examples shown, the tightening

torque of M6 size screw should be 8N.m and the tightening torque of M8 size screw

should be 21N.m.

• Refer to product datasheet for the module dimensions and mounting hole locations.

PM060PW0 / PM060PW1 / PM060MW0 / PM060MW1 / PM060MW2 / PM060MW3 /

PM060PW0 / PM060PW1 / PM060MW0 / PM060MW1 / PM060MW2 / PM060MW3 / PM060PW0 / PM060PW1 / PM060MW0 / PM060MW1 / PM060MW2 / PM060MW3 /

PM060PW0 / PM060PW1 / PM060MW0 / PM060MW1 / PM060MW2 / PM060MW3 /

PM060MB0 / PM060MB1 / PM060MB2 / PM060MB3

PM060MB0 / PM060MB1 / PM060MB2 / PM060MB3PM060MB0 / PM060MB1 / PM060MB2 / PM060MB3

PM060MB0 / PM060MB1 / PM060MB2 / PM060MB3

Secure each module to the structure using four stainless steel bolts, with nuts, washers, and

lock washers. When using this mounting option, only the existing mounting holes (with the

current diameter of 9mm

9mm9mm

9mm) can be used for module to meet 5400Pa design strength under IEC

61215/ IEC 61730 and UL 1703.

Page 11

10

PM060

PM060PM060

PM060MMMMWWWWRRRR / PM060

/ PM060 / PM060

/ PM060MBR

MBRMBR

MBR

Secure each module to the structure using four stainless steel bolts, with nuts, washers, and

lock washers. When using this mounting option, only the existing mounting holes (with the

current diameter of 9mm

9mm9mm

9mm) can be used for module to meet 5400Pa design strength under UL

1703.

PM

PMPM

PM060M01

060M01060M01

060M01

Secure each module to the structure using four stainless steel bolts, with nuts, washers, and

lock washers. Only the existing mounting holes (Diameter: 6.

6.6.

6.6666mm

mmmm

mm) that can be used for

module to meet 3600Pa design strength under IEC 61215/ IEC 61730 and to meet 2400Pa

design strength under UL 1703.

PM

PMPM

PM072

072072

072PPPPWWWW0000 / PM072MW0

/ PM072MW0 / PM072MW0

/ PM072MW0

Secure each module to the structure using four stainless steel bolts, with nuts, washers, and

lock washers. When using this mounting option, only the existing mounting holes (with the

current diameter of 8888mm

mmmm

mm) can be used for module to meet 5400Pa design strength under UL

1703.

PM

PMPM

PM072

072072

072PPPPWWWWAAAA

Secure each module to the structure using four stainless steel bolts, with nuts, washers, and

lock washers. When using this mounting option, only the existing mounting holes (with the

current diameter of 8mm

8mm8mm

8mm) can be used for module to meet 5400Pa design strength under IEC

61215/ IEC 61730.

PM096B00

PM096B00PM096B00

PM096B00

Secure each module to the structure using four M6 (¼”)

M6 (¼”)M6 (¼”)

M6 (¼”) stainless steel bolts, with nuts,

washers, and lock washers per module. Only the mounting holes that are 322mm (12.6772

inches) from the short end of the module can be used for the module to meet 5400 Pa design

strength.

3.2 Mounting with Clamps

• Clips and clamps are not provided by BenQ Solar.

• The clamping clips on the side frame must be in parallel – equidistant from the closest

module frame corner (see Figure 1).

• Ensure the clamps are of sufficient design strength to allow for the maximum design

pressure of the module.

Page 12

11

• Measurements of D1, D2, D3, and D4 below describe the centerline of the mounting

clamp to the closest corner of the module frame.

• Clips and clamps are not provided by BenQ Solar.

BenQ Solar suggests following conditions below for installation.

a. Width of clip or clamp : 100mm

b. Material : Aluminum

c. Height of clip of clamp : equal to module frame height

d. Recommended bolt torque : refer to item 3.1

• Installation guide

a. Please check the center of the clamps alignment with mounting points.

b. The ranges of mounting places are illustrated in Figure 2 and Figure 3.

c. Clamp and frame should attached well without gap as picture ○c shown below.

d. Please fix clamps on system rails as the picture○d shown below.

e. Please tighten the screws in bolt torque of 20 N.m, then finish the installation as

the picture○e shown below.

Page 13

12

X : equal to module frame height

X : equal to module frame heightX : equal to module frame height

X : equal to module frame height

• There are two clamping methods available (see Clamp Location Details below for

specific measurements):

o Clamp on the long side of the frame (see Figure 2, measurements below)

o Clamp on the short side of the frame (see Figure 3, measurements below)

Figure

Figure Figure

Figure 1111 Top view and back view of module installed on a parallel mounting structure

Page 14

13

Figure

Figure Figure

Figure 2222 Long rail mounting clamp range (D1 and D2)

Figure

Figure Figure

Figure 3333 Short rail mounting clamp range (D3 and D4)

Page 15

14

Long Rail (5400 Pa)

Long Rail (5400 Pa)Long Rail (5400 Pa)

Long Rail (5400 Pa) Short Rail (2400 Pa)

Short Rail (2400 Pa)Short Rail (2400 Pa)

Short Rail (2400 Pa)

Model Name D1 D2 D3 D4

PM060PW0

165 mm ( 6.49 in) 245mm (9.64 in) 158 mm (6.22 in) 238 mm (9.36 in)

PM060PW1

165 mm ( 6.49 in) 245mm (9.64 in) 158 mm (6.22 in) 238 mm (9.36 in)

PM060PWA

165 mm ( 6.49 in) 245mm (9.64 in)

PM060PWB

165 mm ( 6.49 in) 245mm (9.64 in)

PM060M01*

281 mm (11.06 in) * 375 mm (14.76 in) *

PM060MW0

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MW1

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MW2

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MW3

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MWR

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MB0

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MB1

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MB2

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MB3

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM060MBR

205mm (8.07in)

271mm (10.67in)

124 mm (4.88 in) 198 mm (7.80 in)

PM072PW0

130mm (5.11 in) 490 mm (19.29 in)

PM072PWA

130mm (5.11 in) 490 mm (19.29 in)

PM072MW0

130mm (5.11 in) 490 mm (19.29 in)

PM096B00

250 mm (9.84 in) 400 mm (15.75 in) 215 mm (8.46 in) 315 mm (12.4 in)

* PM060M01 has a max design strength of 3600 Pa.

PM060PW0

PM060PW0PM060PW0

PM060PW0 / PM060PW1

/ PM060PW1 / PM060PW1

/ PM060PW1 Module Clamp Location Details

Module Clamp Location DetailsModule Clamp Location Details

Module Clamp Location Details

• Long rail

Long railLong rail

Long rail clamping for 5400 Pa design strength: clamp between D1

D1 D1

D1 –––– 165

165 165

165 mm (

mm (mm (

mm ( 6.49

6.49 6.49

6.49 in)

in) in)

in)

and D2

and D2 and D2

and D2 –––– 245

245 245

245 mm (

mm (mm (

mm (9.64

9.649.64

9.64 in)

in) in)

in) from the closest short side of the module.

• Short rail

Short railShort rail

Short rail clamping for 2400 Pa design strength: clamp between D3

D3 D3

D3 ––––111158

5858

58 mm (

mm ( mm (

mm (6666....22

2222

22 in)

in) in)

in)

and D4

and D4 and D4

and D4 –––– 23

2323

238 mm

8 mm8 mm

8 mm ((((9999....36

3636

36 in)

in) in)

in) from the closest long side of the module.

Page 16

15

PM060PWA / PM060PWB

PM060PWA / PM060PWB PM060PWA / PM060PWB

PM060PWA / PM060PWB Module Clamp Location Details

Module Clamp Location DetailsModule Clamp Location Details

Module Clamp Location Details

• Long rail

Long railLong rail

Long rail clamping for 5400 Pa design strength: clamp between D1

D1 D1

D1 –––– 165

165 165

165 mm (

mm (mm (

mm ( 6.49

6.49 6.49

6.49 in)

in) in)

in)

and D2

and D2 and D2

and D2 –––– 245

245 245

245 mm (

mm (mm (

mm (9.64

9.649.64

9.64 in)

in) in)

in) from the closest short side of the module.

PM060MW0 /

PM060MW0 / PM060MW0 /

PM060MW0 / PM060MW

PM060MWPM060MW

PM060MW1 /

1 / 1 /

1 / PM060MW2

PM060MW2PM060MW2

PM060MW2 //// PM060MW3

PM060MW3PM060MW3

PM060MW3 //// PM060MWR /

PM060MWR / PM060MWR /

PM060MWR / PM060MB0

PM060MB0PM060MB0

PM060MB0 ////

PM060MB1

PM060MB1PM060MB1

PM060MB1 //// PM060MB2

PM060MB2PM060MB2

PM060MB2 //// PM060MB3

PM060MB3PM060MB3

PM060MB3 / PM060MBR

/ PM060MBR / PM060MBR

/ PM060MBR Module Clamp Location Details

Module Clamp Location DetailsModule Clamp Location Details

Module Clamp Location Details

• Lon

LonLon

Long rail

g railg rail

g rail clamping for 5400 Pa design strength: clamp between D1

D1 D1

D1 –––– 205

205 205

205 mm (

mm (mm (

mm ( 8.07

8.07 8.07

8.07 in)

in) in)

in)

and D2

and D2 and D2

and D2 –––– 271

271 271

271 mm (

mm (mm (

mm (10.67

10.6710.67

10.67 in)

in) in)

in) from the closest short side of the module.

• Short rail

Short railShort rail

Short rail clamping for 2400 Pa design strength: clamp between D3

D3 D3

D3 –––– 1

1 1

124

2424

24 mm (

mm ( mm (

mm (4444.8

.8.8

.88888 in)

in) in)

in)

and D4

and D4 and D4

and D4 –––– 111198 mm

98 mm98 mm

98 mm ((((7777....80

8080

80 in)

in) in)

in) from the closest long side of the module.

PM

PMPM

PM060

060060

060M01 Module Clamp Location Details

M01 Module Clamp Location DetailsM01 Module Clamp Location Details

M01 Module Clamp Location Details

• Long rail

Long railLong rail

Long rail clamping for 3600

36003600

3600 Pa design strength: clamp between D1

D1 D1

D1 –––– 281

281281

281 mm (

mm ( mm (

mm (11.06

11.0611.06

11.06 in)

in) in)

in)

and D2

and D2 and D2

and D2 –––– 375

375 375

375 mm (

mm (mm (

mm (14.76

14.7614.76

14.76 in)

in) in)

in) from the closest short side of the module.

PM

PMPM

PM072PW0 /

072PW0 /072PW0 /

072PW0 / PM

PMPM

PM072PWA /

072PWA /072PWA /

072PWA / PM

PM PM

PM072MW0

072MW0072MW0

072MW0 Module Clamp Location Details

Module Clamp Location Details Module Clamp Location Details

Module Clamp Location Details

• Long rail

Long railLong rail

Long rail clamping for 5400 Pa design strength: clamp between D1

D1 D1

D1 –––– 130

130130

130 mm (

mm ( mm (

mm (5.11

5.115.11

5.11 in)

in) in)

in)

and D2

and D2 and D2

and D2 –––– 490

490490

490 mm (

mm ( mm (

mm (19

1919

19....29

2929

29 in)

in) in)

in) from the closest short side of the module.

PM096B

PM096BPM096B

PM096B00000 Module Clamp Location Details

0 Module Clamp Location Details0 Module Clamp Location Details

0 Module Clamp Location Details

• Long rail

Long railLong rail

Long rail clamping for 5400 Pa design strength: clamp between D1

D1 D1

D1 –––– 2

2 2

250

5050

50 mm (9.84 in)

mm (9.84 in) mm (9.84 in)

mm (9.84 in)

and D2

and D2 and D2

and D2 –––– 400

400400

400 mm (15.75 in)

mm (15.75 in) mm (15.75 in)

mm (15.75 in) from the closest short side of the module.

• Short rail

Short railShort rail

Short rail clamping for 2400 Pa design strength: clamp between D3

D3 D3

D3 –––– 215

215215

215 mm (

mm ( mm (

mm (8888....46

4646

46 in)

in) in)

in)

and D4

and D4 and D4

and D4 –––– 315

315315

315 mm (1

mm (1 mm (1

mm (12.4

2.42.4

2.4 in)

in) in)

in) from the closest long side of the module.

Page 17

16

Chapter

Chapter Chapter

Chapter 4444 Wiring

WiringWiring

Wiring, Connecting

, Connecting , Connecting

, Connecting and Grounding

and Groundingand Grounding

and Grounding BenQ Modules

BenQ Modules BenQ Modules

BenQ Modules

4.1 Wiring & Connecting

DO NOT do any change or adjustment on the cable of Junction Box.

DO NOT disconnect DC Cables alone, someone should always be nearby!

DO NOT disconnect/connect modules while they are under load!

DO NOT assemble the connector with wet or dirty hands.

Always make sure that all locking connectors are fully engaged and locked. Otherwise faulty

connetions can result in arcs, electrical shock, and equipment damage.

IMPORTANT

IMPORTANTIMPORTANT

IMPORTANT

Do not bend the cable directly behind the contact point. A minimum bending radius of r≥4x

(static steady), r≥5x (dynamic) cable diameter must be maintained. The cable must be routed

in a way that tensile stress on the conductor or connection(s) is avoided.

Table1 PV Cable Feature

Table1 PV Cable FeatureTable1 PV Cable Feature

Table1 PV Cable Feature

Figure

Figure Figure

Figure 4444 The minimum bending radius of cable

Pay attention to the following when wiring:

Pay attention to the following when wiring:Pay attention to the following when wiring:

Pay attention to the following when wiring:

1.

1.1.

1. Correct wiring scheme

Correct wiring schemeCorrect wiring scheme

Correct wiring scheme

Check that the wiring is correct before commissioning the system. If the measured open

circuit voltage differs from the specifications, then there is a wiring fault. Ensure that the

polarity is correct.

Page 18

17

2.

2.2.

2. Correct DC plug connection method

Correct DC plug connection methodCorrect DC plug connection method

Correct DC plug connection method

Make connections only in dry conditions. Ensure that connections are secure and tight.

3.

3.3.

3. Use

Use Use

Use correctly rated materials

correctly rated materialscorrectly rated materials

correctly rated materials

Use PV rated solar cable for wiring and suitable connectors only. Ensure that they are in

perfect electrical and mechanical condition. Use only single wire cables. Select a suitable

conductor diameter to minimize voltage drop.

4.

4.4.

4. CCCCaaaable protection

ble protectionble protection

ble protection

Secure the cables to the mounting system using UV-resistant cable ties. Protect exposed

cables from damage using suitable precautions. Avoid leaving DC cables in direct and

extended exposure to sunlight.

WWWWIRING AND INSTALLATION GUIDELINES

IRING AND INSTALLATION GUIDELINESIRING AND INSTALLATION GUIDELINES

IRING AND INSTALLATION GUIDELINES

Please note the following instructions:

• To ensure the correct orientation of the module, the module should face southwards

in the northern hemisphere and northwards in the southern hemisphere.

• The module must be installed so that air can freely circulate around it. Keeping the

cells’ operating temperature low will allow for the best possible performance. The

module’s performance will be enhanced.

• Do not install modules in systemic and ongoing shade; this can cause the temperature

of exposed cells to rise, reducing output, and may stress conductive bonds in module.

• The DC conductors must be properly gauged so that the voltage drop does not

exceed 2% of the nominal voltage.

• BenQ Solar PV modules are supplied with or without cables, according to where they

are ordered. If supplied without cables, it is recommended that cables with cross

sections between 4 and 10 mm2 be used.

• The cables, which allow easy handling while providing high protection against

overloads and short-circuits. They are made of flexible Cu conductors, cross linked

insulated polyethylene and coated with polyvinyl chloride or similar insulation. The

insulation is flame, acid and alkali resistant and should be stored in an area free of any

corrosive gases.

DC CONNECTION WIRING/ INSTALLATION WARN

DC CONNECTION WIRING/ INSTALLATION WARNDC CONNECTION WIRING/ INSTALLATION WARN

DC CONNECTION WIRING/ INSTALLATION WARNINGS

INGSINGS

INGS

• The modules should be handled and installed by qualified persons only.

• Keep all panel connectors dry and clean at all times. Do not attempt to establish an

electrical connection with wet, soiled, dusty/dirty, or otherwise faulty connectors.

• Unconnected connectors must be covered/protected at all times to prevent dust,

foreign particles, etc. from accumulating within prior to connection.

• Do not allow unprotected connectors to rest on the ground or roof surface.

Page 19

18

• Do not climb up or walk on the module.

• Do not drop the module or throw objects on the module.

• Use the module only for the purpose to which it is designed.

• Do not dismantle the module or remove any part, label, or piece assembled by the

manufacturer without the manufacturer’s authorization.

• Do not concentrate sunlight or other artificial light sources onto the module.

• Use tools duly coated with insulating material while working with the modules.

• Always work under dry conditions.

• Do not install the modules where there may be flammable gases or vapors, since

sparks may be produced.

• Take care to avoid electric discharges when installing, wiring, starting up or carrying

out maintenance work on the modules.

• Do not touch the terminals while the module is exposed to light.

• Install with suitable protection to redirect a discharge of 30 or more direct current

volts to if delivered any person on the installation team.

• Please prevent adherent of oil such as paraffin liquid, animal oil and vegetable oil form

molding parts. It may be cracked or broken and loose the performance of Junction

Box and connectors.

4.2 Module Grounding

BenQ Solar PV modules have a clearly marked grounding hole on each side of the frame for

inserting the ground contact. The grounding screw and bolt are usually sold separately from

the mounting equipment.

Please make sure the grounding screw breaks the anodized surface of the module frame

around the holes. Another option is to scratch off the anodizing before the grounding

connection is made. The frame is fully insulated by the anodizaiton process, so this step is

essential for proper ground contact..

An anti-oxidation compound should be applied to the bare aluminum surface for protection.

Use a layer of insulation if the support structure material is different than the frame material

(aluminum) to prevent galvanic corrosion.

If the support structure is a non conductor, a dedicated ground cable must be connected to

each module frame by means of a suitable fastening system. The fastening system must be

spliced with a cable that has a minimum diameter of 2.5mm2.. Please make sure that each

module is grounded properly per local municipal requirements. The recommended assembly

of grounding screw is shown below in Figure 5.

Note: When using a Tapping Screw for grounding, the cap washer is used for buffer only and can be substituted

by any M4-M4.5 washer.

Page 20

19

Figure

Figure Figure

Figure 5555 Recommended grounding connection

Per NEC 250.136, electrical equipment secured to and in electrical contact with a metal rack

or structure provided for its support and grounded by one of the means indicated in 250.134

shall be considered effectively grounded.

Failure to

Failure to Failure to

Failure to properly ground each module

properly ground each moduleproperly ground each module

properly ground each module will reduce the performance of the system and

will reduce the performance of the system and will reduce the performance of the system and

will reduce the performance of the system and

invalidate BenQ

invalidate BenQ invalidate BenQ

invalidate BenQ SSSSolar

olarolar

olar’s

’s’s

’s Limited Power Warranty for PV Mo

Limited Power Warranty for PV Mo Limited Power Warranty for PV Mo

Limited Power Warranty for PV Modules.

dules. dules.

dules.

Grounding of the module frame can be achieved through use of clamps that penetrate the

anodization in conjunction with grounding of the mounting system or through direct

grounding of the frames by attaching a copper wire to a grounding hole of each module (bolt

size, M6 × 1.0 × 50).

4.3 System Grounding (Negative)

PM060PW0 /

PM060PW0 / PM060PW0 /

PM060PW0 / PM060PW

PM060PWPM060PW

PM060PW1111 /

/ /

/ PM060P

PM060PPM060P

PM060PWA

WA WA

WA / PM060PW

/ PM060PW/ PM060PW

/ PM060PWB

B B

B //// PPPPM060M01 /

M060M01 / M060M01 /

M060M01 / PM060MW0

PM060MW0 PM060MW0

PM060MW0 ////

PM060MW1

PM060MW1PM060MW1

PM060MW1 //// PM060MW2

PM060MW2PM060MW2

PM060MW2 //// PM060MW3

PM060MW3PM060MW3

PM060MW3 //// PM060MWR /

PM060MWR / PM060MWR /

PM060MWR / PM060MB0

PM060MB0PM060MB0

PM060MB0 //// PM060MB1

PM060MB1PM060MB1

PM060MB1 ////

PM060MB2

PM060MB2PM060MB2

PM060MB2 //// PM060MB3

PM060MB3PM060MB3

PM060MB3 / PM060MBR / PM072PW0

/ PM060MBR / PM072PW0 / PM060MBR / PM072PW0

/ PM060MBR / PM072PW0 / PM

/ PM/ PM

/ PM072

072072

072PWA

PWAPWA

PWA / PM072MW0

/ PM072MW0/ PM072MW0

/ PM072MW0

For optimal performance, AUO photovoltaic modules should only be used in conjunction

with galvanically insulated inverters where the negative (-) polarity of the PV array is

connected to ground protected by a fuse.

Page 21

20

4.4 System Grounding (Transformerless or Positive)

PM

PMPM

PM096B00

096B00096B00

096B00

Comply with the local regulations for earthing the modules and the PV array.

Grounding of the module frame can be achieved through use of clamps that penetrate the

anodization in conjunction with grounding of the mounting system or through direct

grounding of the frames by attaching a copper wire to a grounding hole of each module.

4.5 Limitation in Connection

IEC

IECIEC

IEC

The IEC 61730 certificate of these modules guarantees their insulation up to a DC voltage of

The IEC 61730 certificate of these modules guarantees their insulation up to a DC voltage of The IEC 61730 certificate of these modules guarantees their insulation up to a DC voltage of

The IEC 61730 certificate of these modules guarantees their insulation up to a DC voltage of

1000 V. (IEC

1000 V. (IEC1000 V. (IEC

1000 V. (IEC 61730

61730 61730

61730 Standard).

Standard). Standard).

Standard).

ET

ETET

ETLLLL

The UL 1703 certificate of these modules guarantees their insulation up to a DC voltage of

The UL 1703 certificate of these modules guarantees their insulation up to a DC voltage of The UL 1703 certificate of these modules guarantees their insulation up to a DC voltage of

The UL 1703 certificate of these modules guarantees their insulation up to a DC voltage of

1000

10001000

1000 V. (UL

V. (UL V. (UL

V. (UL 1703

1703 1703

1703 Standard).

Standard).Standard).

Standard).

Both standards apply to all module series described in this manual, however, a cable with a

suitable cross section must be used for conducting the sum of the currents as generated by

the modules. A series protection fuse of 15A is recommended for each string when module

strings are wired in parallel.

BenQ Solar recommends the PV conductor, which cross section is 4 mm2. External

connection boxes can be used to enable greater cable cross section area for long distance

transmission.

The modules are qualified for the application class A: Hazardous voltage (IEC 61730: higher

than 50V; EN 61730: higher than 120V), hazardous power applications (higher than 240W)

where general contact access is anticipated.

Recommended maximum series/parallel module configurations for 1000V inverter.

Maximum series = 1000V / Product Voc / 1.25 (safety factor)

Example : The Voc of PM200M00_200 is 30.4V,then the maximum series/parallel module

configurations for 1000V inverter is 26.

Formula

1000V / 30.4V / 1.25 = 26

Page 22

21

Chapter

Chapter Chapter

Chapter 5555 Mainten

MaintenMainten

Maintenance

anceance

ance

Inspect all modules annually for safe electrical connections, sound mechanical connection,

and corrosion.

BenQ Solar PV module may use Anti-Reflective Coating (ARC) glass technology to

enhance power output.

Do not to touch glass surface unless wearing clean gloves in order to prevent

fingerprints or smudges on the ARC. Fingerprints may be removed with standard glass

cleaner.

Periodically clean glass and the module surface only with a soft cloth or sponge using

mild detergent and water.

Do not use harsh cleaning materials such as scouring powder, steel wool, scrapers,

blades, or other sharp instruments to clean the glass surface of the module. Use of such

materials will void the product warranty.

5.1 Module Cleaning Guidelines

Dirt piled up on the module’s transparent surface reduces its performance and may cause the

module hot spot effect. This problem may become serious in the case of industrial waste and

bird droppings collecting on the module surface.

Thin layers of dust (normal soiling) that reduce the sun’s intensity evenly are not dangerous

and the power reduction is not as significant as other debris.

Clean the module array regularly to address reduced production due to soiling. The

frequency of cleaning depends on how quickly material accumulates. Mounting the module at

or above a 15 degree angle will help prevent dust and debris from collecting on the module.

In many cases, rainfall may reduce or remove the need to clean the modules. It is best to

clean the module during early morning, late afternoon or cloudy day. Do not clean module

during high temperature, temperature lower than zero degrees Celsius, or any time when

there is a large temperature difference between module and cleanser.

If it is necessary to clean back side of module, do not damage any components. Avoid allowing

any oily liquids such as paraffin liquid, animal oil, or vegetable oil contacting with junction box,

cable and connector. BenQ Solar PV modules can withstand snow pressure of 2400 Pa.(UL

1703) Please use soft brush lightly removing snow pileup. Do not try to remove frozen snow

and solid ice on the module (it will eventually melt off).

Page 23

22

5.2 Module Cleaning Instructions

Solution Mixture:

Solution Mixture:Solution Mixture:

Solution Mixture: clean water with low mineral amount, non-abrasive/ non-caustic detergent,

weak acid/weak alkalescent solution, or solution of PH < 10.

Cleaning

Cleaning Cleaning

Cleaning Tool:

Tool:Tool:

Tool: soft brush, non-conductive brush, non-abrasive sponge, non-abrasive cloth,

seamless cloth. Do not use high pressure spray.

1. Clean module and glass surface with solution and tools fitting the above descriptions.

2. If dirty area on glass surface which is hard to be cleaned such as oily substances or sap,

try to use commercial glass detergent, alcohol, isopropanol (IPA), or sodium

bicarbonate solution.

3. Use clean water to rinse glass clean of all cleaning solution. Dry wet modules using a

clean and dry cloth. Do not leave stagnant water on glass surface.

5.3 Cleaning the Frame

BenQ Solar module frames include an anodic oxide coating to increase produce life. The

cleaning cycle for regular anodic oxide coatings is generally every six months. When

cleaning, be sure not to damage or scratch this coating. Dirt on the frame can generally be

cleaned off using warm, mildly soapy water and a fiber brush. Do not use abrasive cleaning

tools like steel wool or acidic/ alkaline chemicals to clean.

(Reference:GB 5237.2, Wrought aluminum alloy extruded profiles for architecture)

5.4 Visual inspection of the module

During regular cleaning cycles, be sure to visually inspect each module. The purpose of visual

inspection is to detect possible faults or damage. Specifically:

Possible broken glass.

Rust on the circuits and soldering of the PV cells. Normally this is due to moisture

entering the module through a breakage in the encapsulating layer during installation or

transport.

5.5 Inspecting connections and cabling

While performing semi annual maintenance, carry out the following operations:

Check the tightness and condition of the connection cable junctions.

Check the junction box sealing. Should sealing faults be observed, the items which have

been affected should be replaced and cleaned. Contact BenQ Solar for additional

information about resolving faults in module seal.

Page 24

23

Chapter 6 Certification

Chapter 6 CertificationChapter 6 Certification

Chapter 6 Certificationssss

6.1 IEC Certification

The PV modules provided by BenQ Solar all pass the design qualification and type

approval standard IEC 61215 edition 2.

The PV modules provided by BenQ Solar all pass the safety qualification standard IEC

61730 certified for application class A.

Modules qualified for safety through EN IEC61730.1 and EN IEC61730.2 within this

application class are considered to meet the requirements for Safety Class II.

6.2 ETL Certification

This product meets or exceeds the requirements set forth by UL1703 for PV Modules.

This UL1703 Standard covers flat-plate PV modules intended for installation on buildings

and those intended to be freestanding.

To satisfy the listing for this product the modules must be mounted with a rack or

standoff structure.

It does not include integration into a building surface because additional requirements

may apply.

This product is not intended for use where artificially concentrated sunlight is applied to

the module.

If the module is intended to be used on the roof in America, it must be used in

combination with a rack that meets the below conditions:

1. This rack has been tested in accordance with UL1703 system fire test and has a

system fire class rating.

2. During system fire test, the rack must use same “Type1/2” of module.

BenQ Solar is a division of AU Optronics.

© Copyright AU Optronics Corp. All rights reserved. AUO reserves the right to update, delete or modify the

information at any time without prior notification. All modifications and amendments shall be effective

immediately.

Page 25

24

版本

Rev.

修訂日期

Rev. Date

修訂內容

Update contents

1.0 2013/7/23 New issue

1.1 2013/7/25 Add section 4.4 transformer less of PM096

1.2 2014/04/23 1. Add new model : PM096B01, PM245P03

2. Modify the typo of PM096 clamping area

1.3 2014/06/30 Add new model : PM060P00

1.4 2014/07/01 Add new model : PM048M00/PM060M01/PM060M02

2.0 2014/12/11 Add new model : PM072P00, Modify electrical characteristic of modules.

2.1 2015/05/06 Add warning of legal

2.2 2015/12/01 Update model name and clamp position

Loading...

Loading...