BenQ G2450HM, GL2450HE, GL2450HM Service Manual

1

Applicable Country & Regions: Global

Service Manual for BenQ:

G2450HM: D-SUB + HDMI + DVI + AUDIO

P/N: 9H.L7NLA.TBW

GL2450HM: D-SUB + HDMI + DVI + AUDIO

P/N: 9H.L7CLA.TBE

GL2450HE: D-SUB + HDMI + DVI + AUDIO

P/N: 9H.L7CLA.FBE

Glossy Black Chassis Colors

Product Service Manual – Level 1~2

Version: 2nd

Date:10-31-2012

Notice:

For RO to input specific “Legal Requirement” in specific NS regarding to responsibility and

liability statements.

Please check BenQ’s eSupport web site, http://esupport.benq.com

, to ensure that you have the

most recent version of this manual.

First Edition (Sep. 2011)

©

Copyright BenQ Corporation 2011. All Right Reserved.

2

Content Index

Abbreviations & Acronyms ........................................................................................................................................ 3

1. About this Manual ................................................................................................................................................... 5

1.1 Important ............................................................................................................................................................ 5

1.2 Trademark .......................................................................................................................................................... 5

2. Introduction ............................................................................................................................................................. 6

2.1 RoHS (2002/95/EC) Requirements – Applied to all countries require RoHS. .................................................... 6

2.2 Safety Warning and Notice ................................................................................................................................. 6

2.3 Compliance Statement ....................................................................................................................................... 7

3. General Description ................................................................................................................................................ 8

4. Related service information ................................................................................................................................... 8

5. Product Overview ................................................................................................................................................... 9

5.1 Monitor Specifications ........................................................................................................................................ 9

5.2 Panel Inspection Specification .......................................................................................................................... 21

Level 1 Cosmetic / Appearance / Alignment Service ............................................................................................ 26

Visual Inspection & Cleaning .................................................................................................................................. 26

F/W Upgrade SOP .................................................................................................................................................. 26

Adjustment / Alignment Procedure ......................................................................................................................... 43

Level 2 Circuit Board and Standard Parts Replacement ...................................................................................... 58

Product Exploded View .......................................................................................................................................... 58

Six Angles’ View ..................................................................................................................................................... 60

Product Disassembly/Assembly ............................................................................................................................. 61

Block Diagram ........................................................................................................................................................ 71

Schematic Diagram ................................................................................................................................................ 74

Troubleshooting ...................................................................................................................................................... 85

PCB LAYOUT ............................................................................................................................................................. 91

Appendix 1 – Screw List / Torque ........................................................................................................................... 99

3

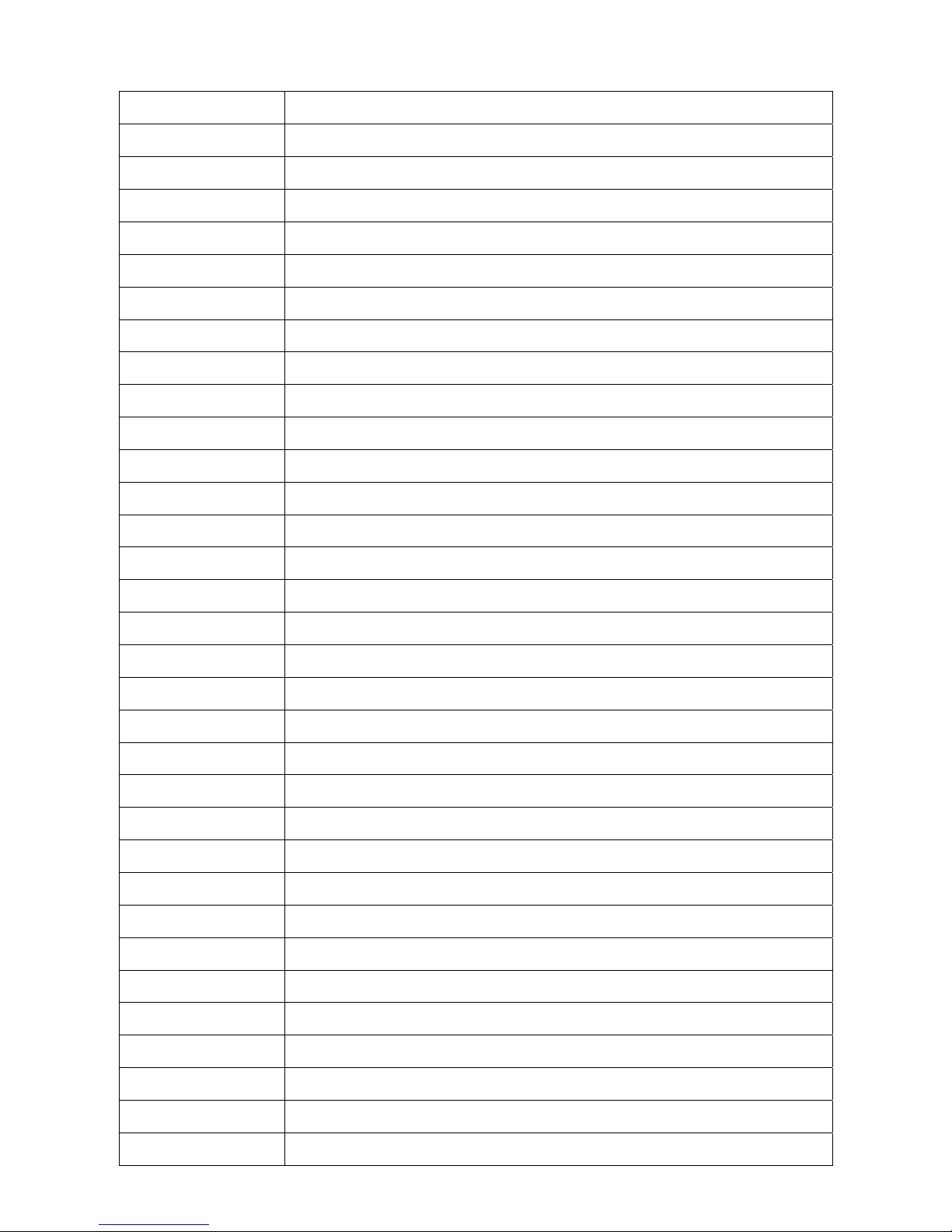

Abbreviations & Acronyms

A

ADC Analog to Digital Converter

AFC Automatic Frequency Control: control signal used to tune to the correct frequency

B

BenQ BenQ Corporation

BTSC Broadcast Television System Committee

C

CPU Central Process Unit

CVBS Composite Video Blanking and Synchronization

D

DLP Digital Light Processing / Texas Instruments®

DMD Digital Micro mirror Device

DRAM Dynamic RAM

DVI Digital Visual Interface

DVI-D Digital Visual Interface-digital

DVI-I Digital Visual Interface-Integrated

E

EEPROM Electrically Erasable and Programmable Read Only Memory

F

FLASH FLASH memory

G

G-TXT Green Teletext

H

HDMI High Definition Multimedia Interface, digital audio and video interface

HP Head Phone

I

I2C Integrated IC bus

L

LED Light Emitting Diode

LVDS Low Voltage Differential Signal, data transmission system for high

M

MOSFET Metal Oxide Semiconductor Field Effect Transistor

N

4

NC Not Connected

NVM Non Volatile Memory: IC containing TV related data (for example, options)

O

OSD On Screen Display

P

PC Personal Computer

PCB Printed Circuit Board (or PWB)

R

RC Remote Control transmitter

RGB

Red, Green and Blue. The primary color signals for TV. By mixing levels of R, G

and B, all colors (Y/C) are

ROM Read Only Memory

S

SDA Data signal on I2C bus

SDRAM Synchronous DRAM

SW Sub Woofer / Software

T

THD Total Harmonic Distortion

V

VGA Video Graphics Array

Y

YPbPr

Component video (Y= Luminance, Pb / Pr= Color difference signals B-Y and R-Y,

other amplitudes w.r.t. to YUV)

Y/C

Video related signals: Y consists of luminance signal, blanking level and sync; C

consists of color signal.

5

1. About this Manual

The purpose of Service Manual is to provide a guide line to engineers to repair different models. The appearance

and capability is introduced in this Service Manual. It is better for repair engineer to have a rough idea of this model

through reading the Service Manual. Please do pay attention to the item part of the disassembly when repair the

machine and also do the protection of panel any time. When repairing the circuit board, please follow the

requirement of RoHS and refer to the circuit diagram and repairing process that attached in the Service Manual.

The method of firmware updated, the way of using the menu and some information that may be used when

repairing are also attached in the Service Manual that provide repair engineer various choice.

1.1 Important

Only trained service personnel who are familiar with this BenQ Product shall perform service or maintenance to it.

Before performing any maintenance or service, the engineer MUST read the “Important Safety Information”.

1.2 Trademark

6

2. Introduction

This section contains general service information, please read through carefully. It should be stored for easy

access place.

2.1 RoHS (2002/95/EC) Requirements – Applied to all countries require RoHS.

The RoHS (Restriction of Hazardous Substance in Electrical and Electronic Equipment Directive) is a legal

requirement by EU (European Union) for the global electronics industry which sold in EU and some counties also

require this requirement. Any electrical and electronics products launched in the market after June 2006 should

meet this RoHS requirements. Products launched in the market before June 2006 are not required to compliant

with RoHS parts. If the original parts are not RoHS complaints, the replacement parts can be non ROHS

complaints, but if the original parts are RoHS compliant, the replacement parts MUST be RoHS complaints.

If the product service or maintenance require replacing any parts, please confirming the RoHS requirement before

replace them.

2.2 Safety Warning and Notice

Installation

1. Do not use your monitor under any of the following environmental conditions:

Extremely high or low temperature, or in direct sunlight

Dusty places

Highly humid, exposed to rain, or close to water

Exposed to vibrations or impacts in places such as cars, buses, trains, and other rail vehicles

Near heating appliances such as radiators, heaters, fuel stoves, and other heat-generating items (including

audio amplifiers)

An enclosed place (such as a closet or bookcase) without appropriate ventilation

An uneven or sloping surface

Exposed to chemical substances or smoke

2. Do not block vents and openings by clothes or curtains.

3. Carry the monitor carefully.

4. Do not place the monitor face down on the floor or a desk surface directly. Otherwise, scratches on the panel

surface may occur.

5. Do not place heavy loads on the monitor to avoid possible personal injury or damage to the monitor.

6. Ensure that children do not hang or climb onto the monitor.

7. Keep all packing bags out of reach of children.

7

Operation

1. To protect your eyesight, please refer to the user manual to set the optimal screen resolution and the viewing

distance.

2. To reduce eye fatigue, take a break on a regular basis while using the monitor.

Avoid taking either one of the following actions for a long time. Otherwise, burn marks may occur.

Use the monitor in the aspect ratio of 16:9.

Place a still image (such as an OSD menu, fixed text or image) on the screen.

3. To avoid possible damage to the monitor, do not touch the monitor panel by hand, pen, or any other sharp

objects.

4. Excessively frequent plug and unplug of video connectors (D-sub / DVI) may cause damage to the monitor.

5. This monitor is designed mainly for personal use. If you want to use the monitor in a public place or a harsh

environment, contact your nearest BenQ service center for assistance.

6. To avoid possible electric shock, do not dissemble or repair the monitor.

7. If a bad smell or an abnormal sound appears to come from the monitor, contact your nearest BenQ service

center for assistance immediately.

Cleaning

1. Ensure that the power is unplugged before cleaning your monitor

2. Use a monitor cleaner and a soft cloth to clean your monitor.

3. Do not use solvents such as alcohol to clean your monitor.

Power

1. To avoid possible damage to the monitor, do not use it in a region where power supply is unstable.

2. Ensure that the power cord is connected to a grounded power outlet before turning on the monitor.

3. Use only the power cord provided by BenQ.

4. Never use a power cord that appears to be damaged or frayed.

5. To avoid possible danger, observe the total electric load when using the monitor with a (multi-outlet) extension

cord.

6. Always turn off the monitor before unplugging the power cord.

2.3 Compliance Statement

Caution: This Optical Storage Product contains a Laser device. Refer to the product specifications and your local

Laser Safety Compliance Requirements.

8

3. General Description

This new LCD (Liquid Crystal Display) monitor BenQ G2450HM&GL2450HM/GL2450HE offers numerous features

and functions, for example:

Panel Type: TN + CCFL (For G2450HM)

Panel Type: TN + LED (For GL2450HM/GL2450HE)

Minimal space requirements thanks to slim casing

Optimum ergonomic characteristics (totally distortion-free, excellent picture definition and color purity right into

the corners)

Contrast ratio 50000:1 (DCR), brightness 300nits (For G2450HM)

Contrast ratio 12 million:1 (DCR), brightness 250nits (For GL2450HM/GL2450HE)

MAX. resolution (1920X1080)

Presentation of up to 16.7 M colors (in conjunction with an appropriate graphics card)

Automatic scanning of horizontal frequencies from 30 to 83 kHz and refresh rates (vertical frequencies) from 50

to 76 Hz (absolutely flicker-free)

Digital screen controller with microprocessor for storing 15 different display modes

Freely adjustable color alignment for matching the screen colors to the colors of various input and output devices

Convenient operation via integrated OSD (On-Screen-Display) menu

VESA-DDC compatibility

Plug & play capability

Power management for reducing power consumption when the computer is not in use

This operating manual contains important information you require to start up and run your LCD monitor.

This specification defines the requirements for the 24″ MICROPROCESSOR based Multi-mode supported high

resolution color LCD monitor. This monitor can be directly connected to general 15-pin VGA connector and 24-pin

DVI-D connector, also supports VESA DPMS power management and plug & play function.

Additional information

Due to the nature of liquid crystal display (LCD) technology, the picture resolution is always fixed. For the best

display performance, please set the display resolution to 1920X1080 pixels with an aspect ratio of 16:9. This is

called “Native Resolution” or maximal resolution - that is, the clearest picture. Lower resolutions are displayed on a

full screen through an interpolation circuit. Image blurring across pixel boundaries can occur with the interpolated

resolution depending upon the image type and its initial resolution.

4. Related service information

This Service Manual contains general information. There are 2 levels of service:

Level 1: Cosmetic / Appearance / Alignment Service

Level 2: Circuit Board or Standard Parts Replacement

Service Web Site

eSupport URL: http://esupport.benq.com

9

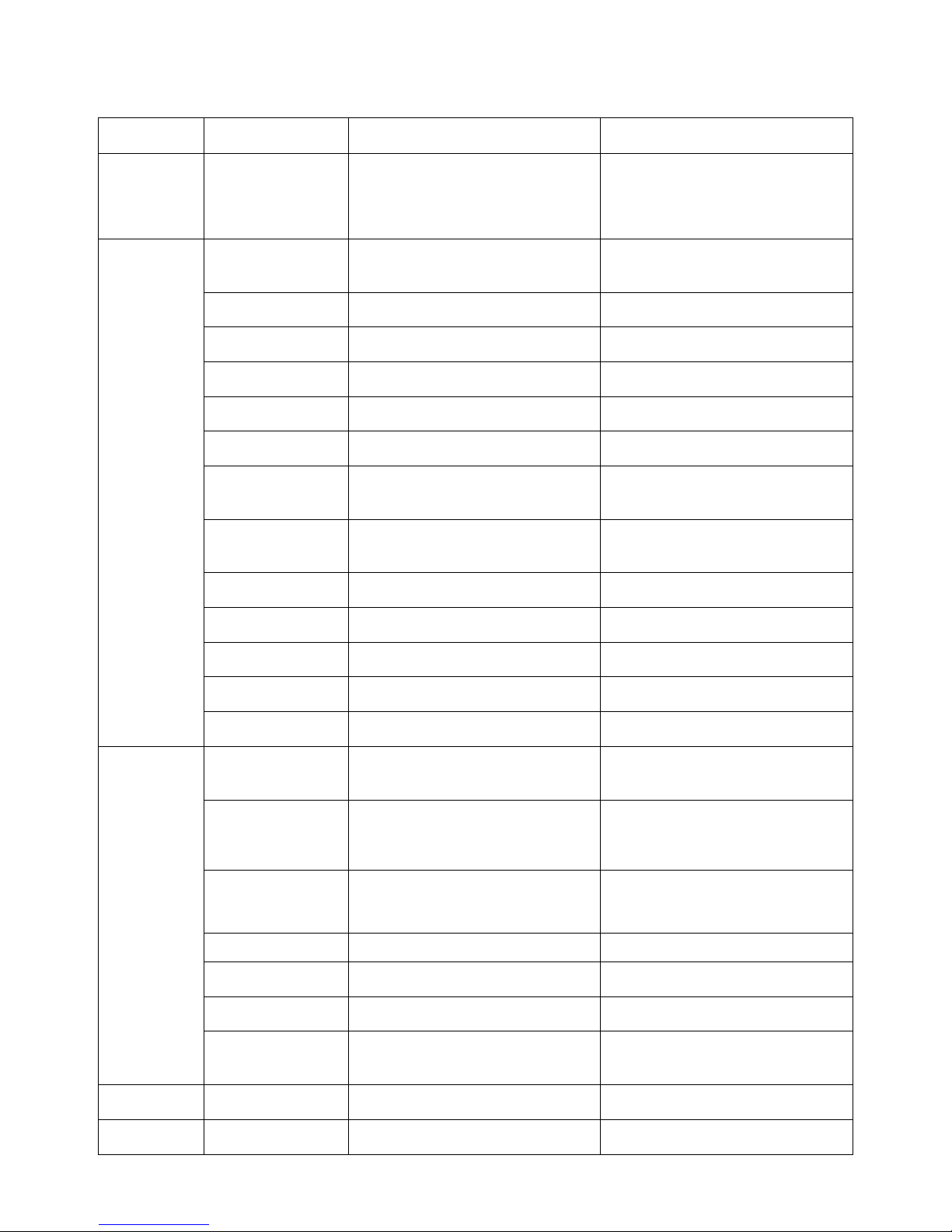

5. Product Overview

5.1 Monitor Specifications

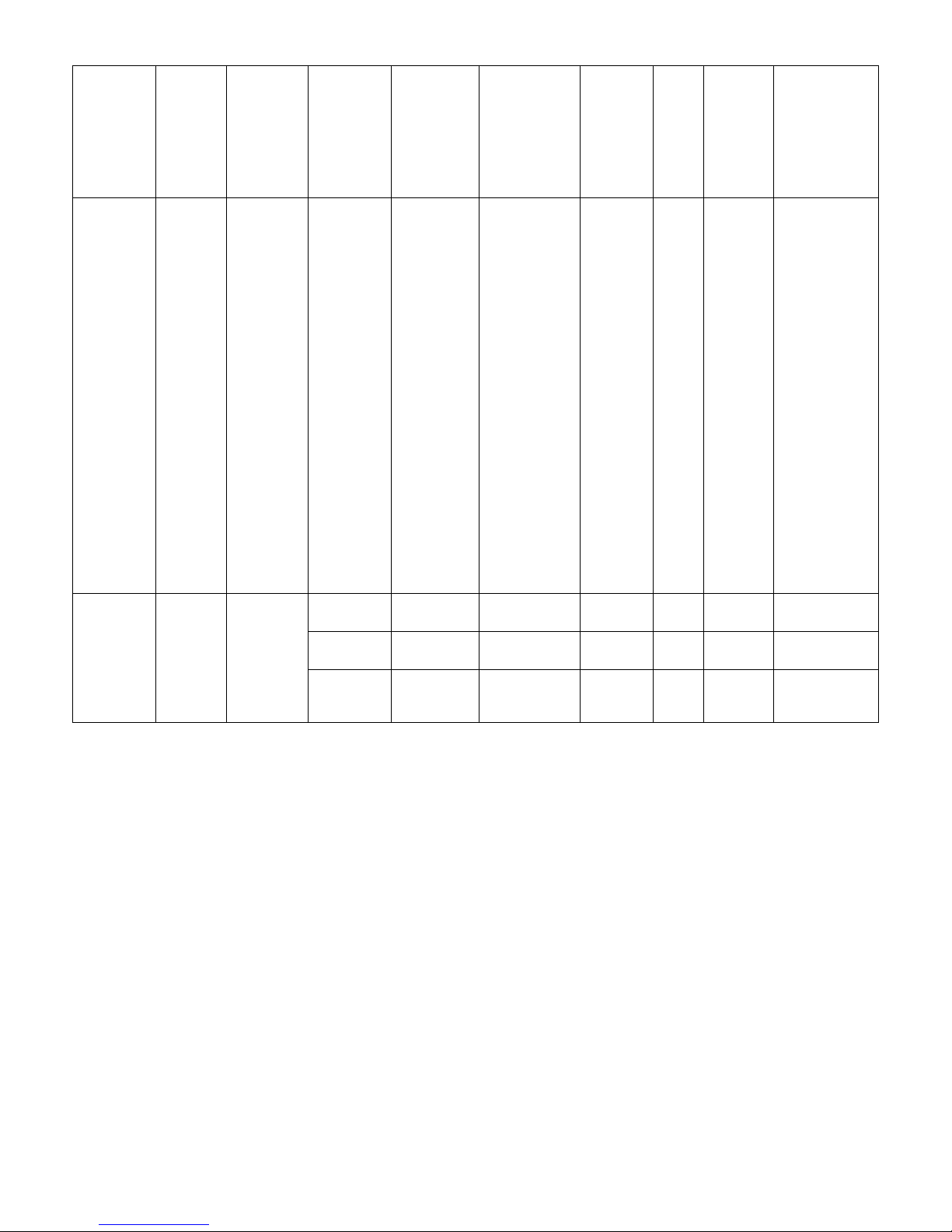

G2450HM GL2450HM/GL2450HE

Conf. 2

D-sub (include component source) +

DVI-D + HDMI + speaker

Conf. 3

D-sub (include component source) +

DVI-D + HDMI + speaker

Panel / Display

Panel Type (TN / VA /

IPS)

TN + CCFL TN + LED

Panel Size 24"W(16:9) 24"W(16:9)

Display Area 531.36x298.89 531.36x298.89

Max. Resolution 1920X1080 1920X1080

Pixel Pitch 0.276 0.276

Brightness (Typ.) 300 cd/m2 250 cd/m2

Contrast Ratio (Typ.)

/ DCR (Min.)

1000:1(Panel)/50000:1 (DCR) 1000:1(Panel)/12M:1 (DCR)

Viewing Angle (H/V),

CR≥10

170/160 170/160

Display Colors 16.7M 16.7M

Response Time 5ms (Tr+Tf) 5ms (Tr+Tf)

GtG response Time 2ms 2ms

MPRT N/A N/A

NTSC ratio 72% 70~72%

Video

BenQ Senseye

TM

Technology

Senseye 3 Senseye 3

BenQ Senseye

TM

Preset Modes

6 Modes (by hotkey) : Standard /

Movie / Game / Photo / s-RGB / ECO

6 Modes (by hotkey) : Standard /

Movie / Game / Photo / s-RGB / ECO

Color Temperature

Selection

Normal (6500°K) / Reddish (5800°K) /

Bluish (9300°K) / User Mode

Normal (6500°K) / Reddish (5800°K) /

Bluish (9300°K) / User Mode

AMA (Over Drive ) Yes Yes

Hor. Frequency (kHz) 30-83 30-83

Ver. Frequency (Hz) 50-76 50-76

Video Bandwidth

(MHz)

205 205

Audio Speakers (built-in) 2W x 2 2W x 2

Input/Output PC Video Input D-sub/DVI-D/HDMI D-sub/DVI-D/HDMI

10

Audio line in Yes Yes

Earphone Jack Yes Yes

Power Supply

Voltage Rating AC: 100~240V (Built-in) AC: 100~240V (Built-in)

Power-On Mode <35W (max) <35W (max)

Standby Mode <0.3W (max) <0.3W (max)

Power Off Mode <0.3W (max) <0.3W (max)

Mechanical

Design

Chassis Colors

(proposal A)

Glossy black, detail refer to artwork Glossy black, detail refer to artwork

Carton

Brown Carton with at least C flute (BE

flute CTN for BQjp shipments)

Brown Carton with at least C flute (BE

flute CTN for BQjp shipments)

Power LED Green (ON)/ Amber (Standby) Green (ON)/ Amber (Standby)

Tilt (Up / Down) 15° ~ -5° 15° ~ -5°

VESA Wall Mount 100 x 100 mm 100 x 100 mm

Kensington Lock Yes Yes

Container Loading

(foam cushion 40')

>1300 >1300

Container Loading

(foam cushion 20')

>650 >650

Multi-language

Support

OSD

17 Languages (English / Francais /

Deutsch / Italiano / Espanol / Polish /

Czech / Hungarian / Serbo-croatian /

Romanian / Netherlands / Russian /

Swedish / Portuguese / Japanese /

Chinese / S-Chinese)

17 Languages (English / Francais /

Deutsch / Italiano / Espanol / Polish /

Czech / Hungarian / Serbo-croatian /

Romanian / Netherlands / Russian /

Swedish / Portuguese / Japanese /

Chinese / S-Chinese)

Other feature

Vista Premium Premium

Win 7 Yes Yes

Dynamic Power

Saving (DPS)

Yes Yes

Accessories Refer to SKU list Refer to SKU list

Regulation

Approvals

Refer to the worksheet

"RFQ-Regulatory"

Refer to the worksheet

"RFQ-Regulatory"

11

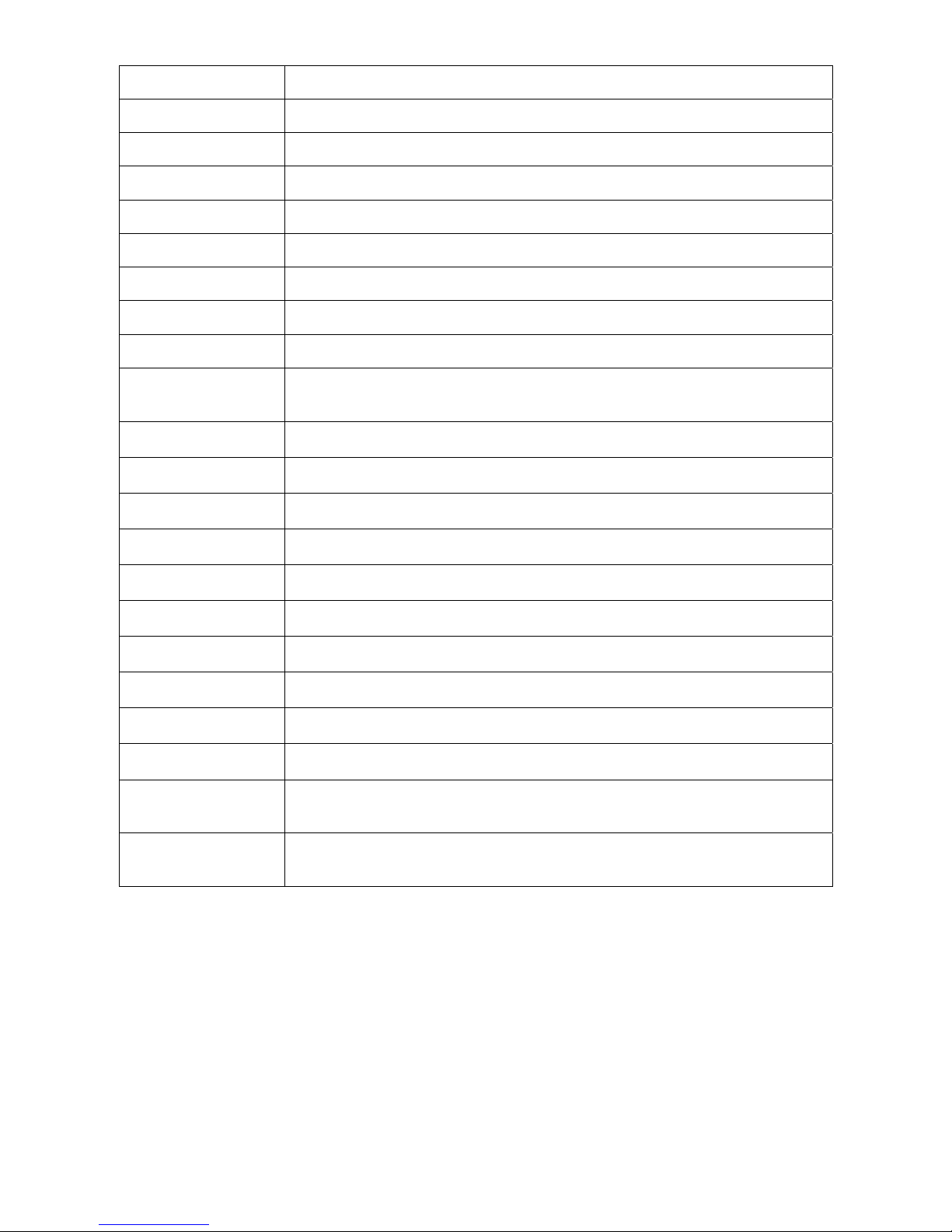

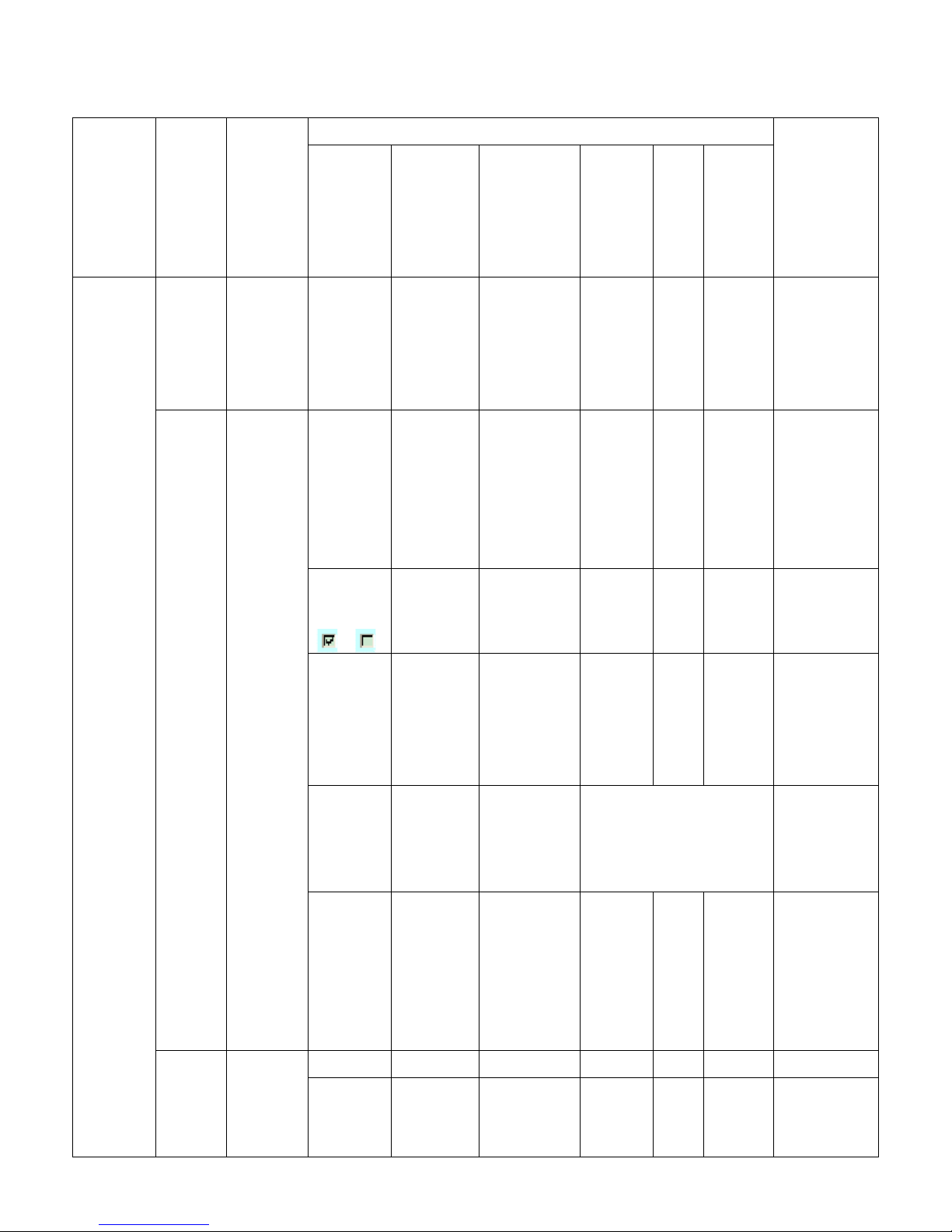

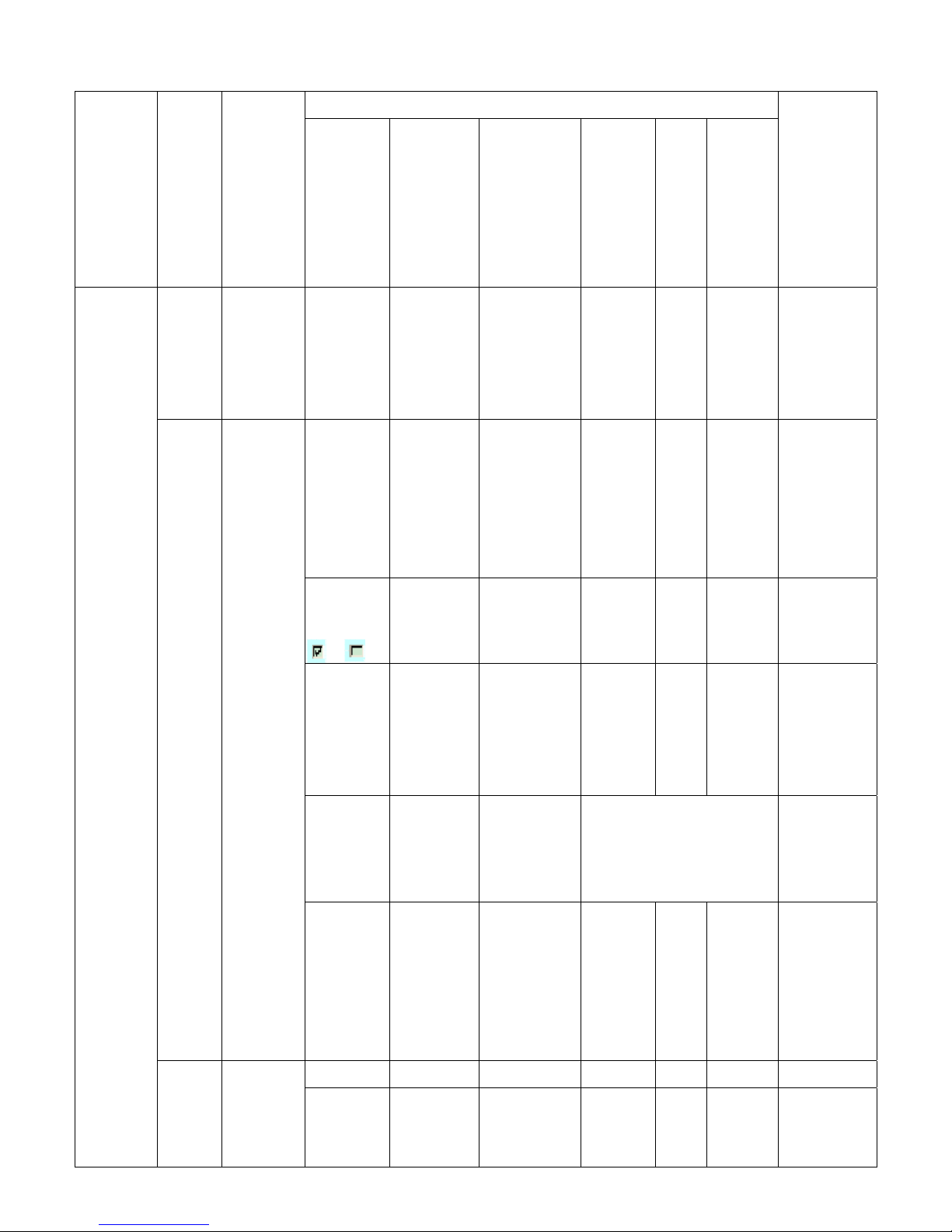

5.1.1 Certification

G2450HM

Region

Shipment

Country

(Pls

select)

Country

Certification / Requirement

Remark

Request for

Certification

(Pls select)

Certification

(Black is

mandatory

and blue is

voluntary)

Regulatory

Type

(safety/safety

&

EMC/EMC/GP)

A

pplied by

vendor

A

pplied

by

BenQ

BenQ

Sample

Reguest

Asia-Pacific

V

Australia,

New

Zealand

V C-Tick EMC V

Must include

radiation test

result for

frequency

above 1GHz

V China

V CCC Safety & EMC V

Including CCC

certificate,

CCC report

and CCC label

printing

permission

Eff(Minimun)

Level =

1 2

Energy Label GP V

V China RoHS GP

Vender

provide

relevant

information

and report

V China WEEE GP See Remark

Recycling

notice in User

Manual is

required.

V CECP GP V 1 set.

One sample of

DVT is

required for

the assigned

third-party

test.

V Japan

V VCCI EMI V

V PSE Safety V

PSE DOC for

HDMI sku

base on CB

12

and VCCI

V J-Moss GP

Vender

provide

relevant

information

and report

Class Level:

★ ★★

★★★

PC3R GP

Vender

provide

relevant

information

and report

V

If VOC

test is

requested,

please

provide 1

sample for

testing.

Meet the

PC3R

requirement of

2009 version.

V Korea

KCC EMC V

V KC Safety & EMC V

V e-Standby GP

Vender

provide

relevant

information

and

formal test

report

(Korean)

V 1 set.

One sample of

DVT

is required for

the assigned

third-party

test.

V Korea RoHS GP

Vender

provide

relevant

information

and report

V Singapore V PSB Safety V

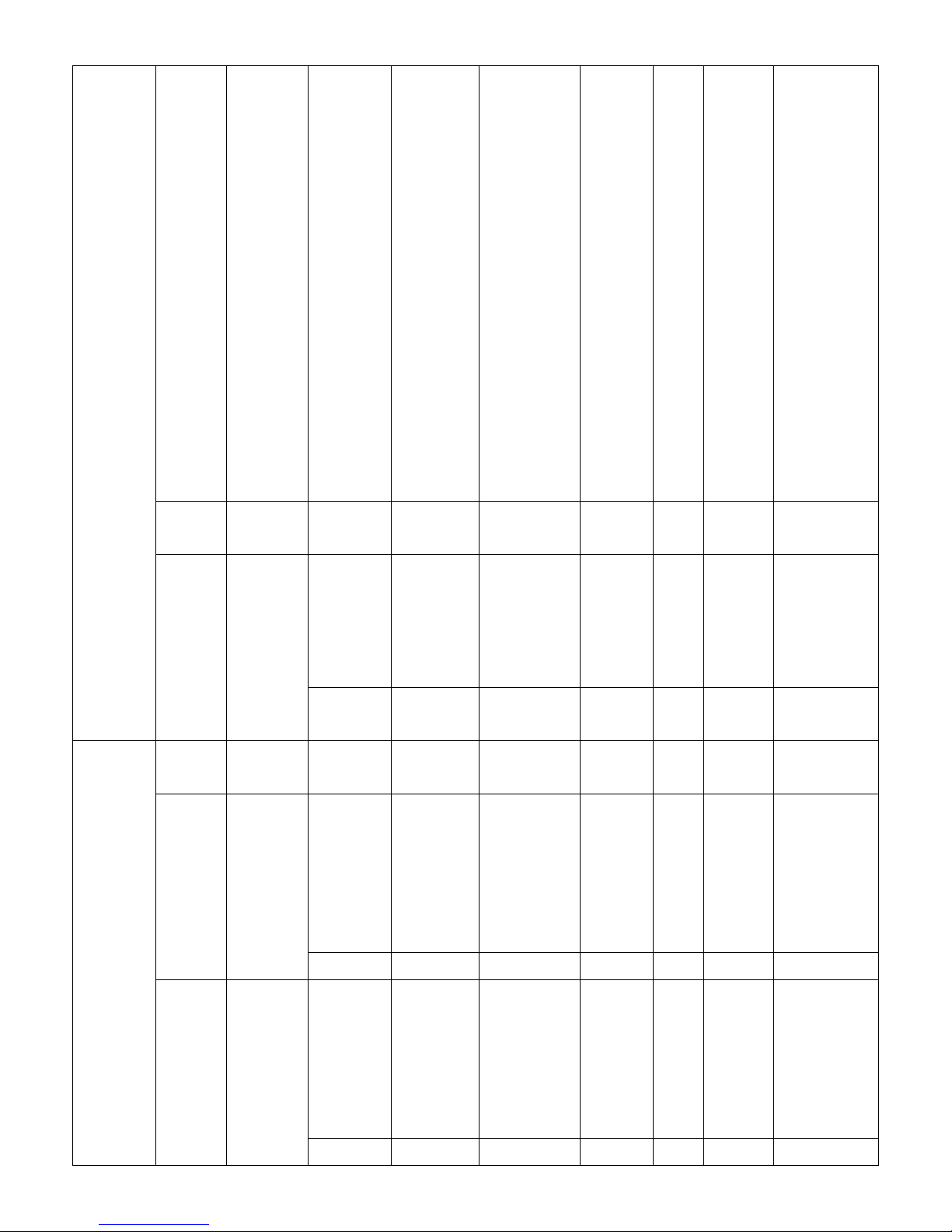

13

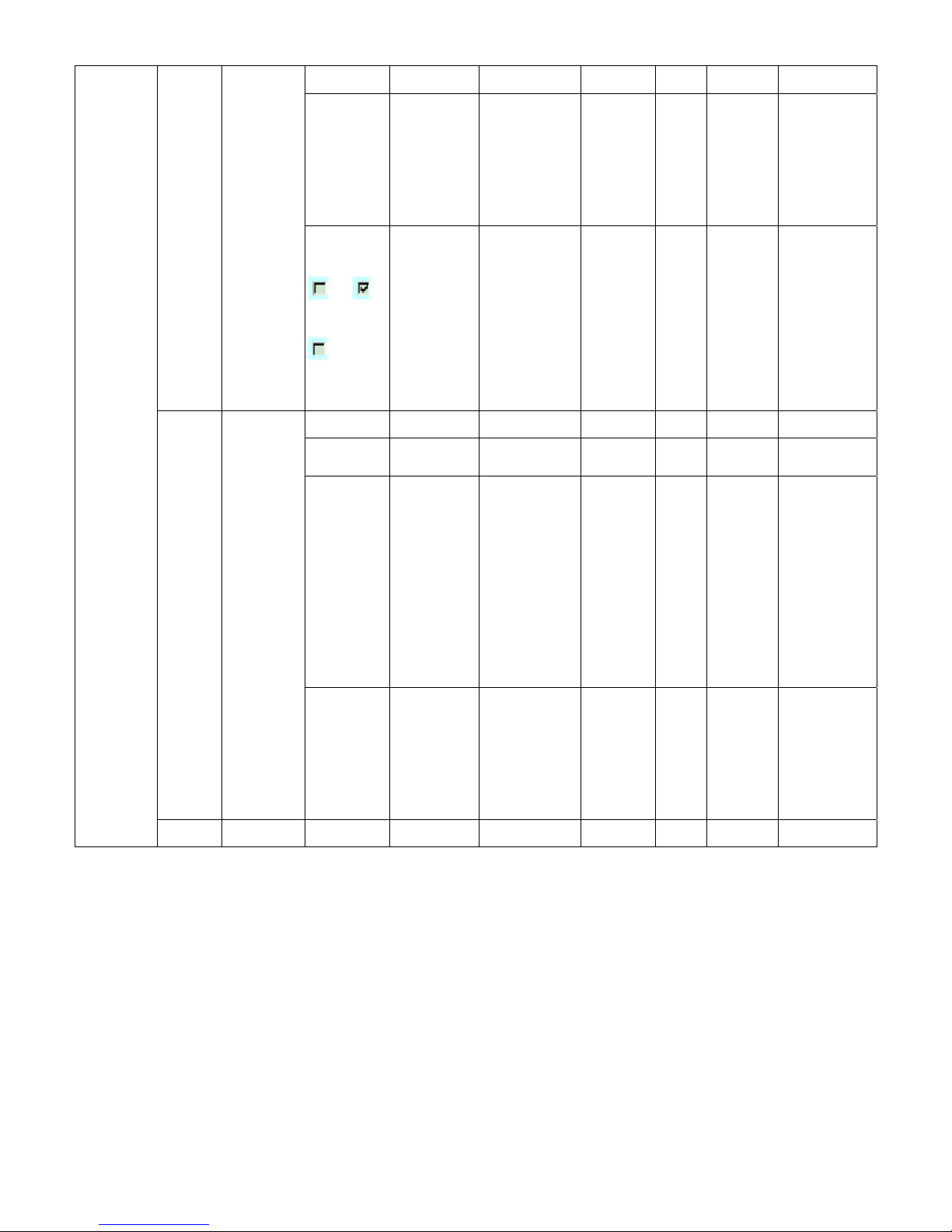

V Taiwan V BSMI Safety & EMC V

Including

BSMI

certificate,

BSMI report

and BSMI

authorization

letter for

BENQ if the

applicant of

BSMI

certificate is

vendor and

vendor will

perform the

clearance for

BenQ.

V

Saudi

Arabia

V SASO Safety V

V Turkey

V

EEE

Directive

GP

Vender

provide

relevant

information

and report

V TR RoHS

V CE Safety & EMC V

Same as the

CE of EU.

America

V Argentina V S Mark Safety V

TUV-S,

IRAM-S…etc

V Canada

V

USA-Canada

Certification

Safety V

Applicable

safety

certification

(such as

cULus,

cCSAus…etc.)

V IC EMC V

V

United

States

V

USA-Canada

Certification

Safety V

Applicable

safety

certification

(such as

cULus,

cCSAus…etc.)

V FCC EMC V

14

Class Level:

gold silver

cuprum

EPEAT GP

Vender

provide

relevant

information

and report

V

V Mexico V NOM Safety V

European

Union

V

Member

countries of

EU

V CE Safety & EMC V

V EuP GP

Vender

provide

relevant

information

and report

V WEEE GP

Vender

provide

relevant

information

and report

V REACH GP

Vender

provide

relevant

information

and report

V Germany

GS Safety V

V Bauart Safety V

V ISO9241-307 Safety V

V MPR II Safety V

Eastern

Europe

V Russia V GOST Safety & EMC V

V Ukraine

V UkrSEPRO Safety V

V EMC DoC EMC V

International V CB Scheme V CB Safety V

for CE DOC or

PSE DOC or

international

certification

International V International V RoHS GP

Vender

provide

relevant

information

and report

15

International V International V

BenQ

ecoFACTS

GP

Vender

provide

relevant

information

and report

Follow

ecoFACTS

Checklist in

RFQ

International V All V Energy Star GP V

Including Test

Report by EPA

recognition of

Accreditation

Laboratory

and Certificate

by EPA

recognition of

Certification

Body (CB).

Effective date:

2011-1-1.

BenQ phase

in date:

2010-12-06.

International V International

TCO'03 Safety & GP V

TCO'06 Safety & GP V

V

TCO

Displays 5.0

Safety & GP V

16

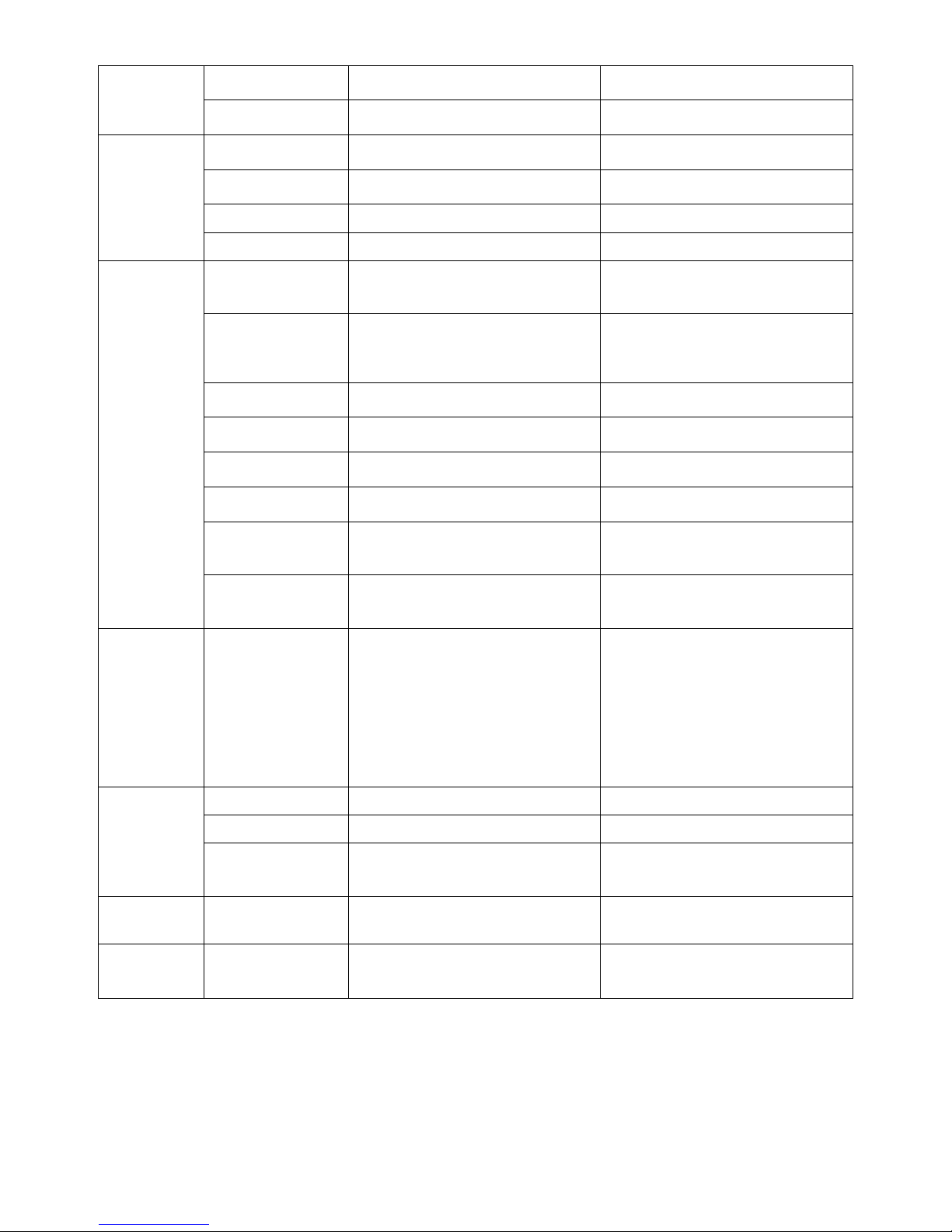

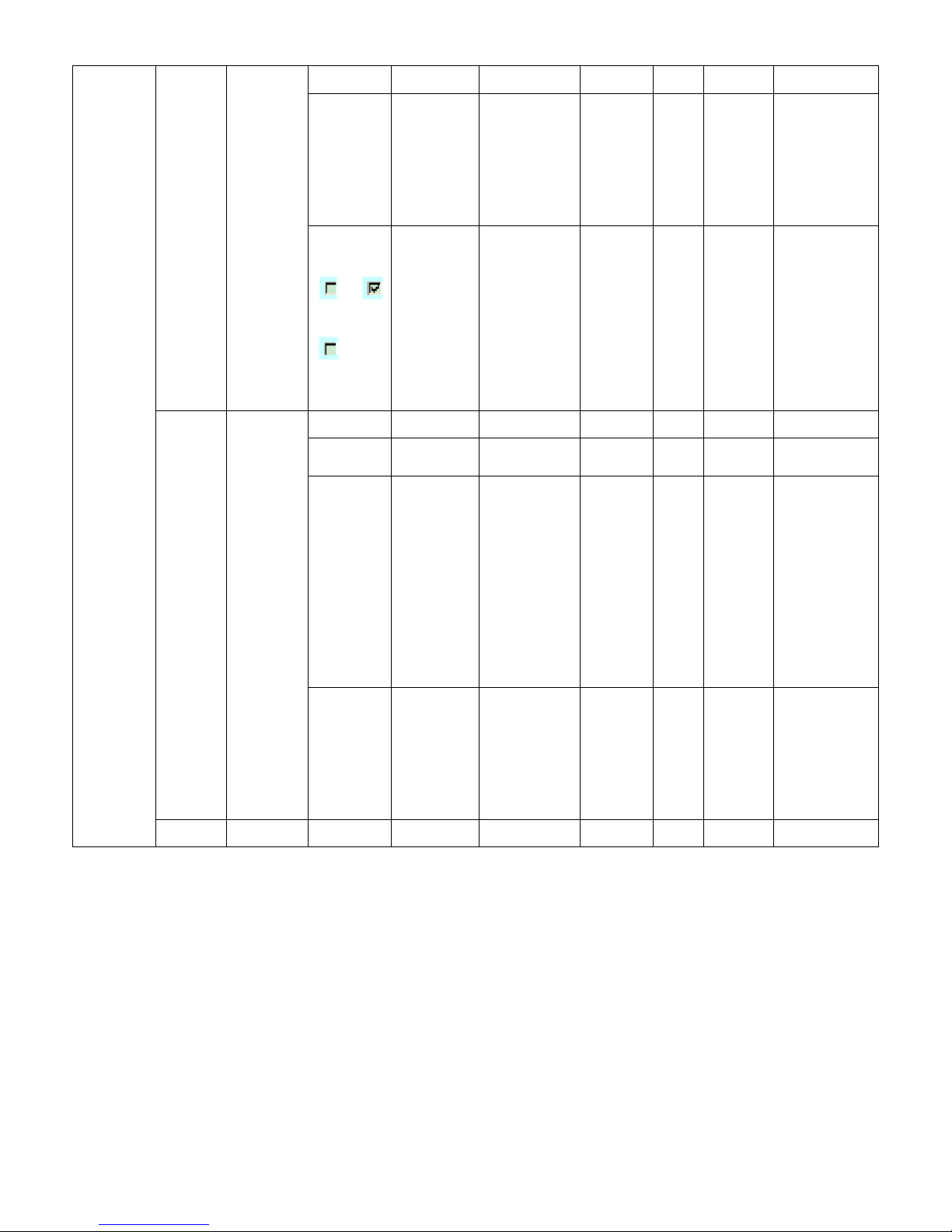

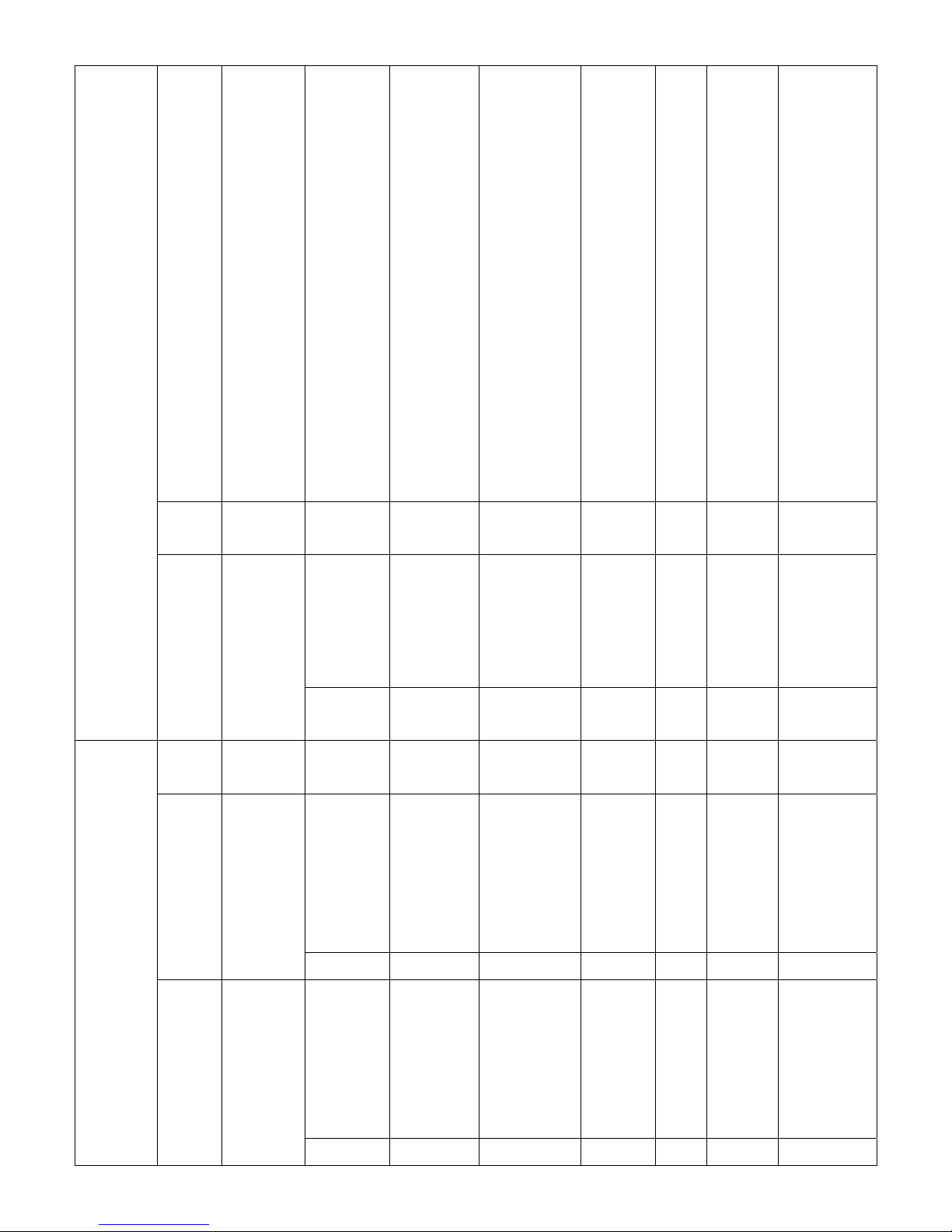

GL2450HM//GL2450HE

Region

Shipmen

t

Country

(Pls

select)

Country

Certification / Requirement

Remark

Request for

Certification

(Pls select)

Certification

(Black is

mandatory

and blue is

voluntary)

Regulatory

Type

(safety/safety

&

EMC/EMC/GP)

A

pplied by

vendor

Applied

by

BenQ

BenQ

Sample

Reguest

Asia-Pacific

V

Australia,

New

Zealand

V C-Tick EMC V

Must include

radiation test

result for

frequency

above 1GHz

V China

V CCC Safety & EMC V

Including CCC

certificate,

CCC report

and CCC label

printing

permission

Eff(Minimun)

Level =

1 2

Energy Label GP V

V China RoHS GP

Vender

provide

relevant

information

and report

V China WEEE GP See Remark

Recycling

notice in User

Manual is

required.

V CECP GP V 1 set.

One sample of

DVT is

required for

the assigned

third-party

test.

V Japan

V VCCI EMI V

V PSE Safety V

PSE DOC for

HDMI sku

base on CB

17

and VCCI

V J-Moss GP

Vender

provide

relevant

information

and report

Class Level:

★ ★★

★★★

PC3R GP

Vender

provide

relevant

information

and report

V

If VOC

test is

requested,

please

provide 1

sample for

testing.

Meet the

PC3R

requirement of

2009 version.

V Korea

KCC EMC V

V KC Safety & EMC V

V e-Standby GP

Vender

provide

relevant

information

and

formal test

report

(Korean)

V 1 set.

One sample of

DVT is

required for

the assigned

third-party

test.

V Korea RoHS GP

Vender

provide

relevant

information

and report

V Singapore V PSB Safety V

18

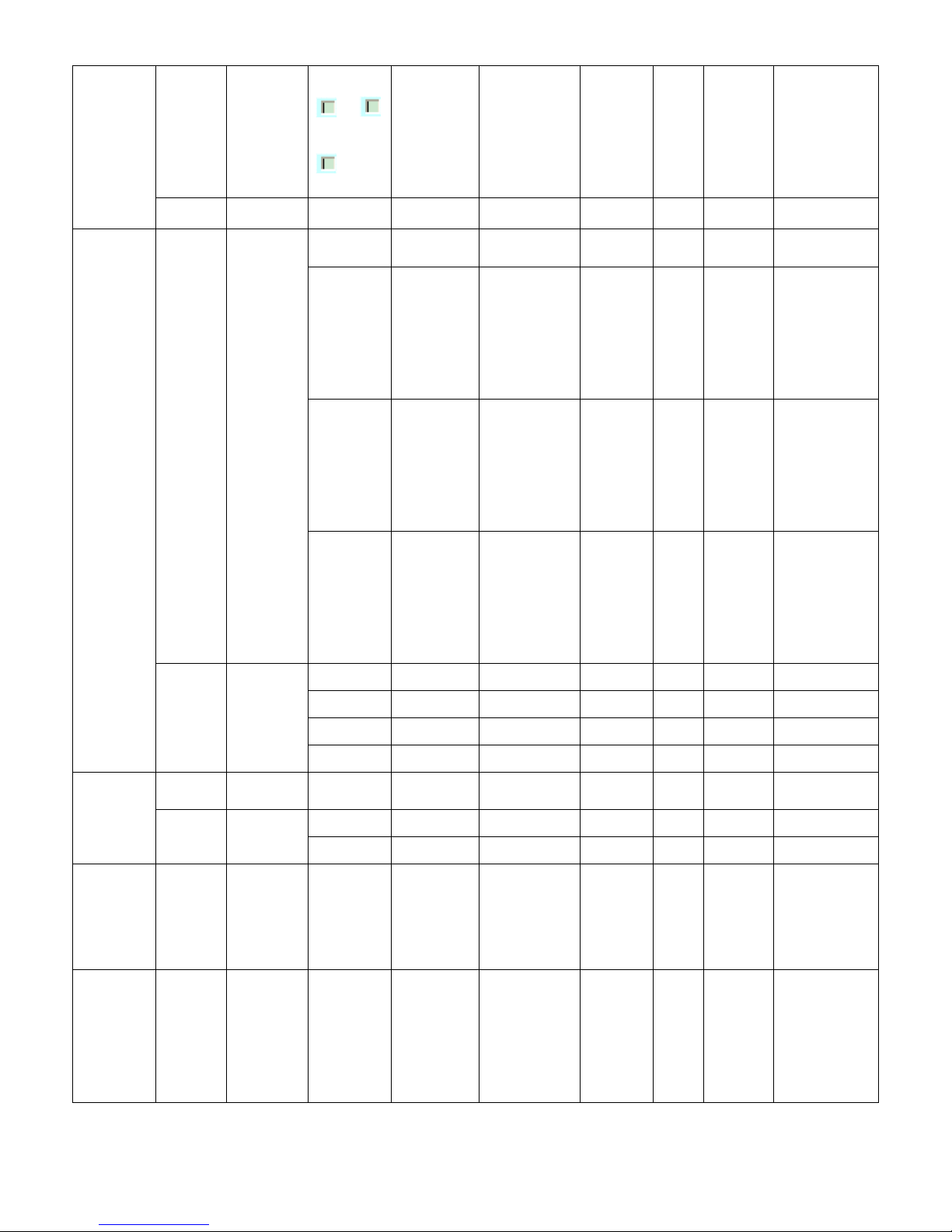

V Taiwan V BSMI Safety & EMC V

Including

BSMI

certificate,

BSMI report

and BSMI

authorization

letter for

BENQ if the

applicant of

BSMI

certificate is

vendor and

vendor will

perform the

clearance for

BenQ.

V

Saudi

Arabia

V SASO Safety V

V Turkey

V

EEE

Directive

GP

Vender

provide

relevant

information

and report

V TR RoHS

V CE Safety & EMC V

Same as the

CE of EU.

America

V Argentina V S Mark Safety V

TUV-S,

IRAM-S…etc

V Canada

V

USA-Canada

Certification

Safety V

Applicable

safety

certification

(such as

cULus,

cCSAus…etc.)

V IC EMC V

V

United

States

V

USA-Canada

Certification

Safety V

Applicable

safety

certification

(such as

cULus,

cCSAus…etc.)

V FCC EMC V

19

Class Level:

gold silver

cuprum

EPEAT GP

Vender

provide

relevant

information

and report

V

V Mexico V NOM Safety V

European

Union

V

Member

countries of

EU

V CE Safety & EMC V

V EuP GP

Vender

provide

relevant

information

and report

V WEEE GP

Vender

provide

relevant

information

and report

V REACH GP

Vender

provide

relevant

information

and report

V Germany

GS Safety V

V Bauart Safety V

V ISO9241-307 Safety V

V MPR II Safety V

Eastern

Europe

V Russia V GOST Safety & EMC V

V Ukraine

V UkrSEPRO Safety V

V EMC DoC EMC V

International V CB Scheme V CB Safety V

for CE DOC or

PSE DOC or

international

certification

International V International V RoHS GP

Vender

provide

relevant

information

and report

20

International V International V

BenQ

ecoFACTS

GP

Vender

provide

relevant

information

and report

Follow

ecoFACTS

Checklist in

RFQ

International V All V Energy Star GP V

Including Test

Report by EPA

recognition of

Accreditation

Laboratory

and Certificate

by EPA

recognition of

Certification

Body (CB).

Effective date:

2011-1-1.

BenQ phase

in date:

2010-12-06.

International V International V

TCO

Displays 5.0

Safety & GP V

21

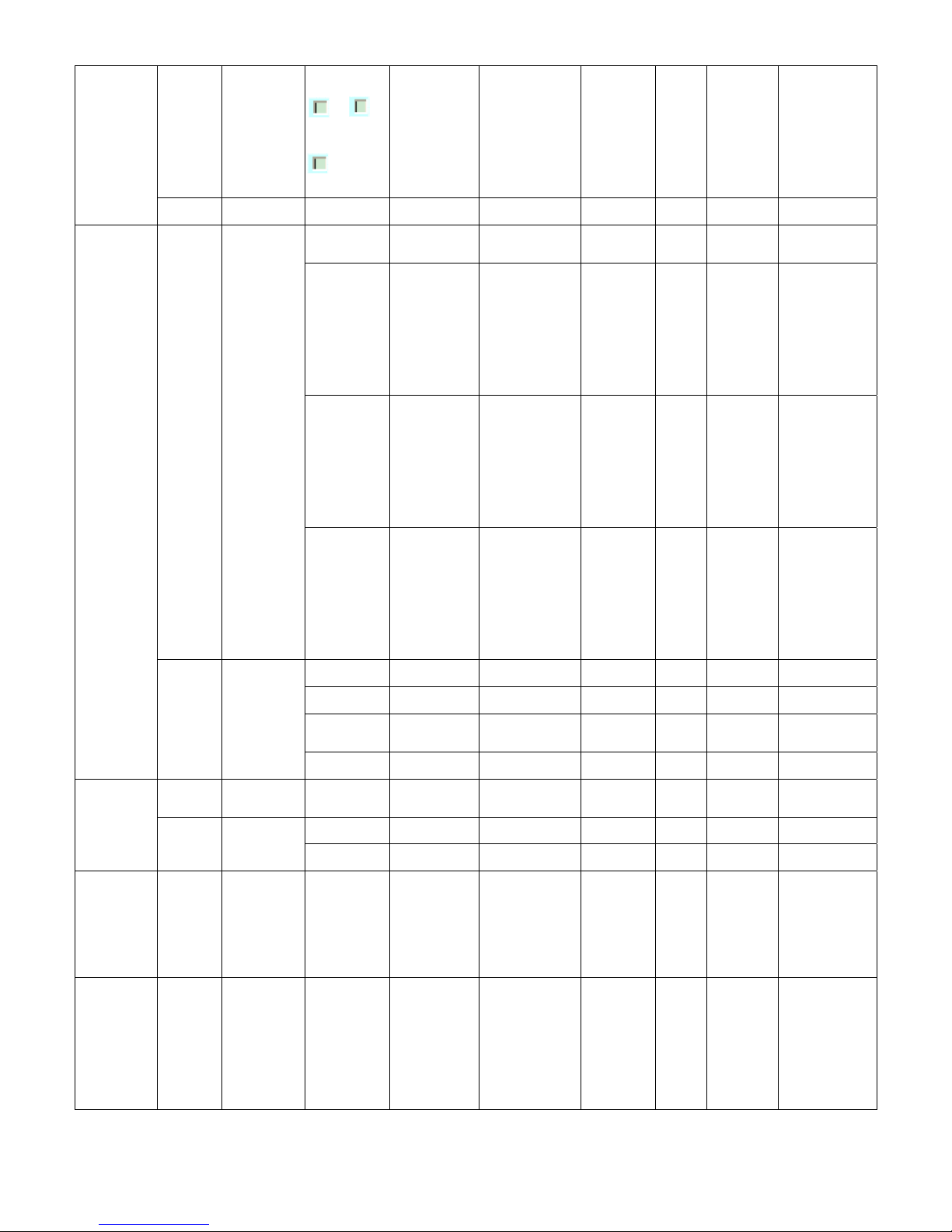

5.2 Panel Inspection Specification

1. Scope:

1.1 The incoming inspection standards shall be applied to TFT-LCD Modules (hereinafter called "Modules") that

supplied by AU Optronics Corporation (hereinafter called "seller").

1.2 Specifications contains

_ Electrical inspection specification

_ Appearance specification

_ Outside dimension specification

2. Incoming inspection:

The buyer (customer) shall inspect the modules within twenty calendar days of the delivery date (the "inspection

period”) at its own cost. The results of the inspection (acceptance or rejection) shall be recorded in writing, and a

copy of this writing will be promptly sent to the seller. The buyer may, under commercially reasonable reject

procedures, reject an entire lot in the delivery involved if, within the inspection period, such samples of modules

within such lot show an unacceptable number of defects in accordance with this incoming inspection standards,

provided however that the buyer must notify the seller in writing of any such rejection promptly, and not later than

within three business days of the end of the inspection period. Should the buyer fail to notify the seller within the

inspection period, the buyer's right to reject the modules shall be lapsed and the modules shall be deemed to have

been accepted by the buyer.

3. Inspection sampling method:

Unless otherwise agree in writing, the method of incoming inspection shall be based on MIL-STD-105E.

3.1 Lot size: Quantity per shipment lot per model.

3.2 Sampling type: Normal inspection, single sampling.

3.3 Sampling level: Level II.

3.4 Acceptable quality level (AQL):

Major defect: AQL= 1.0%.

Minor defect: AQL= 2.5%.

4. Inspection instruments:

4.1 Pattern generator: LD-2000 or equivalent model.

4.2 Video board: AU video board or equivalent. The output of the signal should comply with the specification

provided by AU.

4.3 Luminance colorimeter: Topcon BM-7 or equivalent model

5. Inspection environment conditions:

5.1 Room temperature: 20 ~ 25 C

5.2 Humidity: 65 ± 5% RH.

5.3 Illumination: Fluorescent light (day-Light Type) display surface illumination to be 300 ~ 700 Lux. (standard

500Lux.)

5.4 To be a distance about 35±5 cm in front of LCD unit, viewing line should be perpendicular to the surface of the

module judge the visual appearance with human’s eyes (±30° viewing edge will be allowed).

5.5 Take off the protection film of polarizer while judging the display area.

5.6 If there is any question while judging, check the panel again in operating mode.

6. Classification of defects:

Defects are classified as major defects and minor defects according to the degree of defectiveness defined herein.

22

Major defects: A major defect is a defect that is likely to result in failure, or to reduce materially the usability of the

product for its intended purpose. Minor defects: A minor defect either is a defect that is not likely to reduce materially

the usability of the product for its intended purpose, or is a departure from an established having little bearing on the

effective use or operation of the product.

6.1 Electrical inspection specification

Inspection Item Specification

1 Line defect Can’t be seen.

2 Bright dots ≤ 2 dots (Note1, 4)

3 Dark dots ≤ 5 dots

4 Total dots defect ≤ 5 dots

5

Adjacent dot defect

(Note 1, 2, 3)

Two continuous bright dots (vertical, horizontal, oblique): ≤ 1 pair

Three or more continuous bright dots (vertical, horizontal, oblique):

Not allowed

Two continuous dark dots (vertical, horizontal, oblique): ≤ 2 pair.

Three or more continuous dots – to be of any combination of dark dot

and bright dot (vertical, horizontal, oblique): Not allowed

Distance between 2 Bright dots: ≥ 15 mm

Distance between 2 Dark dots: ≥ 15 mm

Distance between Bright and Dark dots: ≥ 15 mm

6

Display non-uniformity

Or Mura (Note 5,6)

Use 8% ND filter or judged by equivalent limit sample

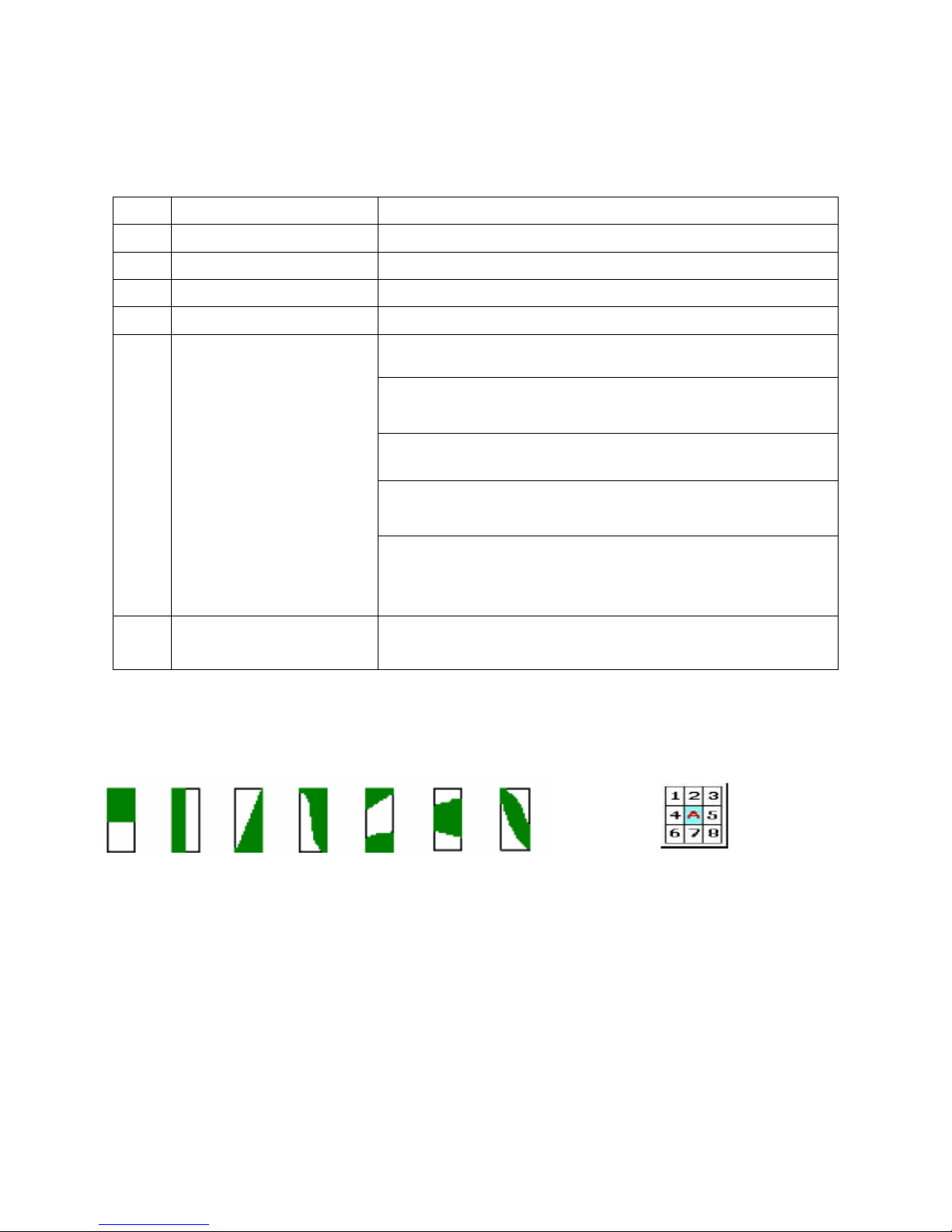

Note 1: For bright dot defect, bright area should be larger than 1/2 area of a sub-pixel to be count as 1 dot defect. A

dot defect that is smaller than the defined dot defect will be treated as small bright dot.

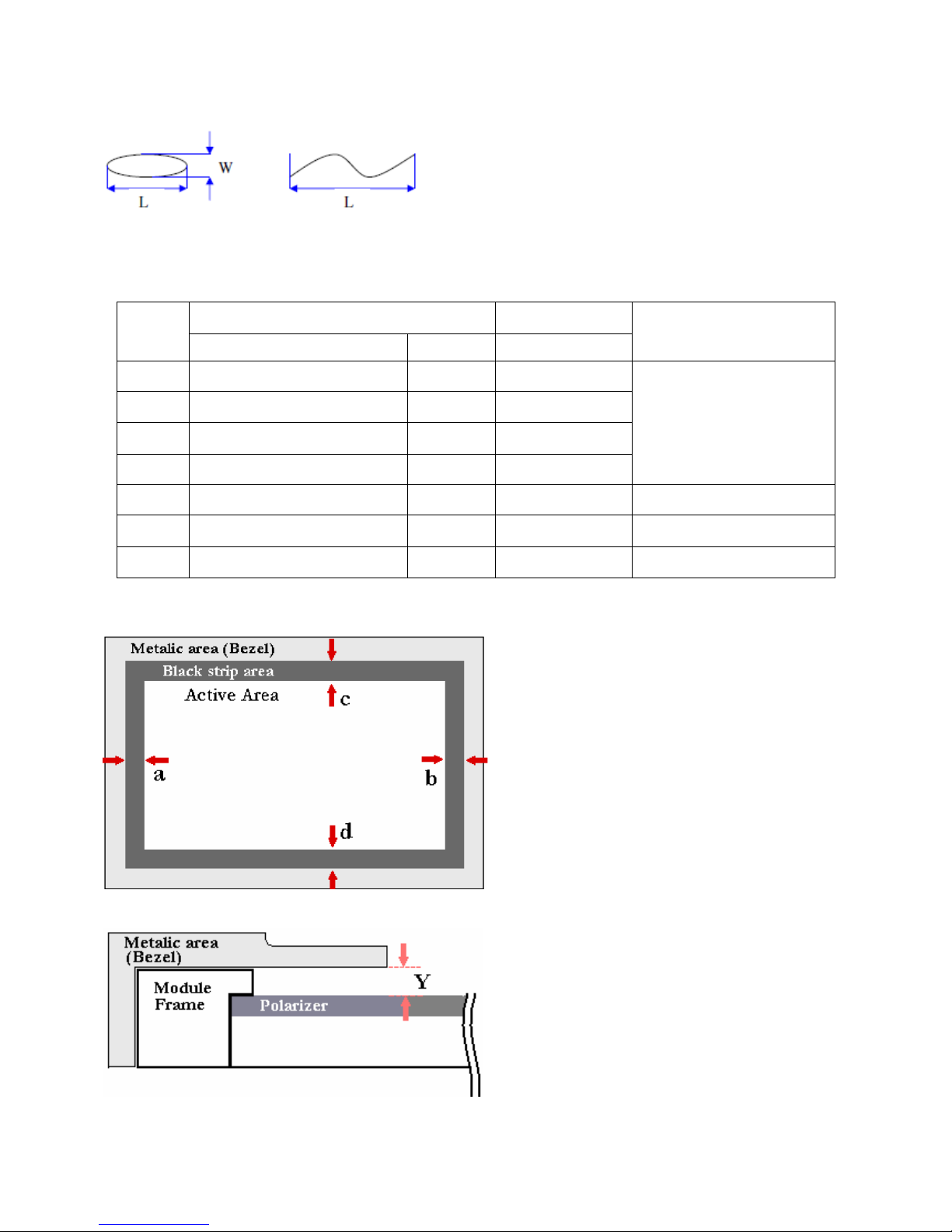

The drawing of 1/2 area sub-pixel definition: The 1/2 area sub-pixel can be defined as below one or more of specific

shapes (Fig.1).

Fig.1 Fig.2

All bright dot defects should not be noticeable by observer under specified inspection environment (Please refer to

item 5).

Note 2: (Fig.2) Adjacent-dot defect (refer to picture, dot 1,2,..,8 around A are all A’s adjacent dots) should be

inspected under the same display pattern in any one of White /Black /Red /Green /Blue /Monotone Gray pattern.

Note 3: Adjacent-dot defect should be observed under any one of White /Black /Red /Green /Blue pattern. 1 pair of

bright dots equals 2 dots. Inspection patterns: Standard inspection patterns of dot defect are listed below. AUO uses

these patterns as standard criteria for judging dot defect. Please inform AUO if any other pattern is to be used to

examine dot defect.

23

Test Pattern Defect

Full Black For bright dot(s)

Full White For dark dot(s)

Monotone Red /Green /Blue For bright and dark dot(s)

Note 4: The judgment criteria of particle occurred bright dot is the same as bright dot judgment criteria.

Note 5: The display uniformity (general mura) symptoms will use 8% ND Filter. That is, the definition of Not

Noticeable means the symptom can be covered by 8% ND Filter.

Note 6: The inspection method of ND Filter - holding ND filter in front of the panel around 1 cm and examine the

panel from 35±5 cm in the front view for 3 seconds.

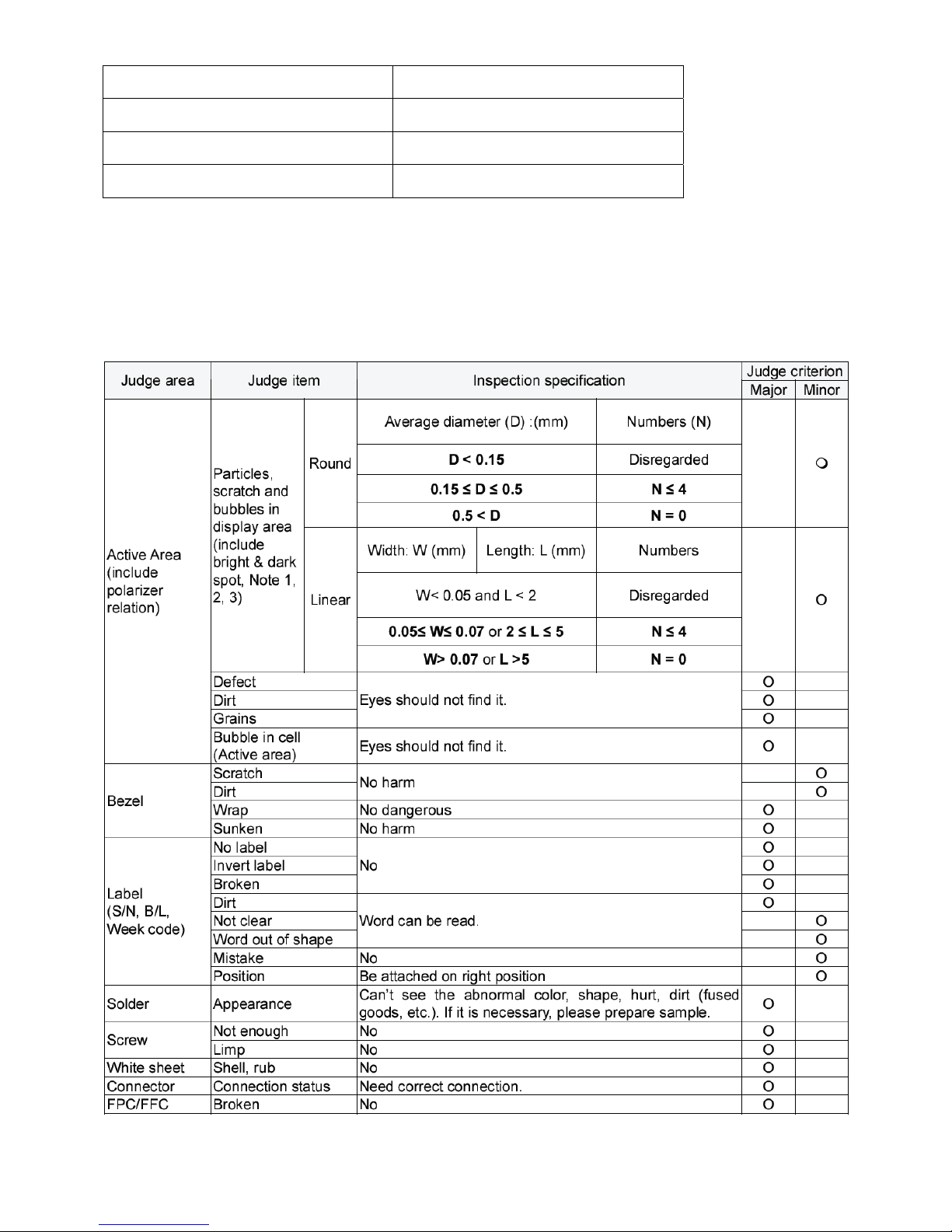

6.2 Appearance inspection specification

24

Note 1: When L>=2W, defect count as liner defect.

Note 2: D=1/2(W+L)

Note 3: To verify the responsibility of following defects was caused by supplier, the IQC checks as requested on

above items before mass production such as the Polarizer Scratch, Gap Mura, TFT Glass broken…etc.

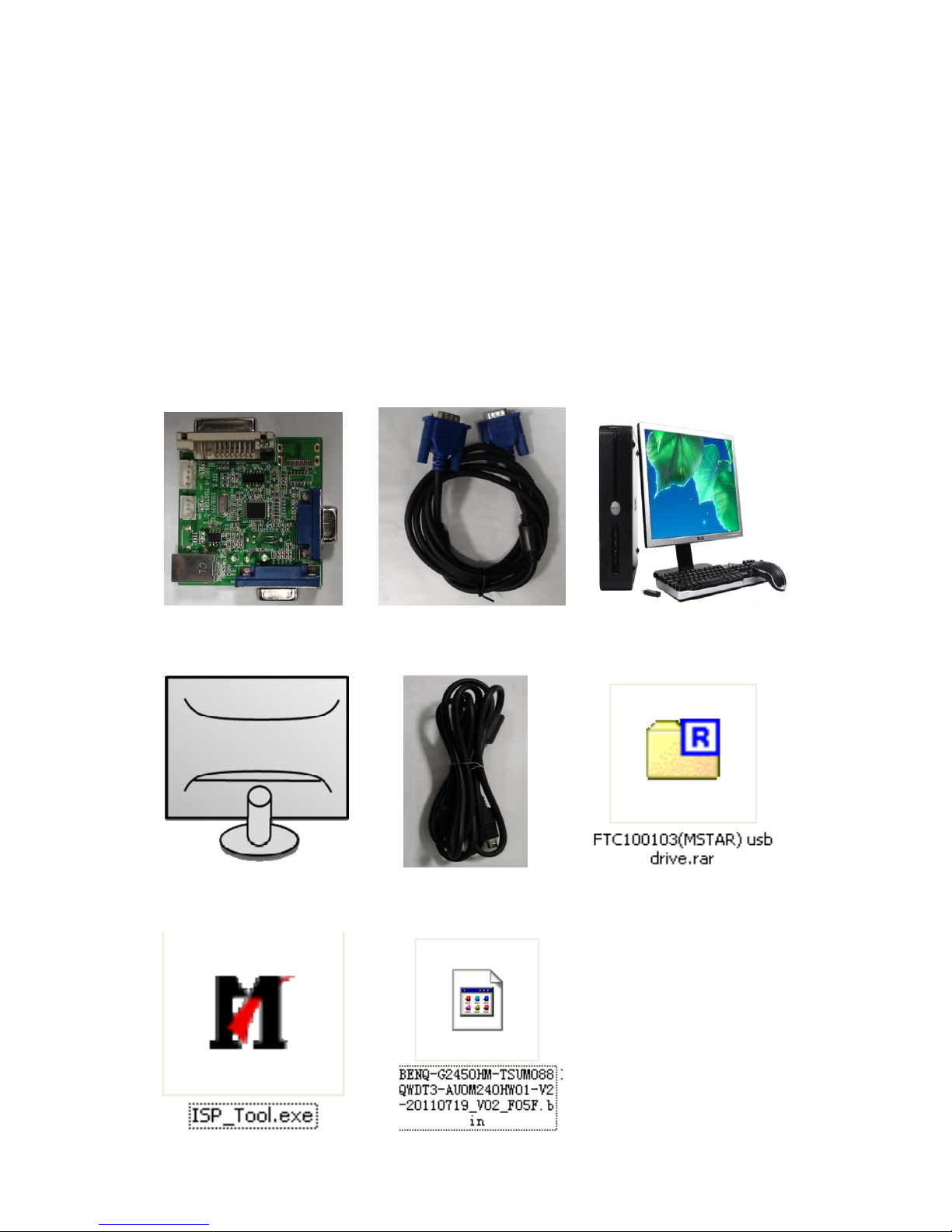

6.3 Outside dimension specification:

Testing

Order

Inspection Item Specification

Note

Name Unit Tolerance

1

Outside dimension (vertical)

mm ± 0.8 mm

Please refer to the product

spec for detailed dimension

definition

Note 1

2 Outside dimension (horizontal) mm ± 0.8 mm

3 Outside dimension (thickness) mm ± 0.8 mm

4 Weight g ± 100 g

5 Display tolerance ABS (a-b) mm 1.2 mm (Max.) Note 2

6 Display tolerance ABS (c-d) mm 1.2 mm (Max.) Note 2

7 Panel gap (Y) mm 1.0 mm (Max.) Note 3

Note 1: Thickness doesn’t include bending.

Note 2: Display tolerance definition

Note 3: Panel gap (Y) definition

25

7. Inspection judgment:

7-1 The judgment of the shipped lot (acceptance or rejection) should follow the sampling plan of MIL-STD-105E,

single sampling, normal inspection, level II.

7-2 If the number of defects is equal to or less than the applicable acceptance level, the lot shall be accepted.

7-3 If the number of defects is more than the applicable acceptance level, the lot shall be rejected and the buyer

should inform the seller of the result of incoming inspection in writing

8. Precaution:

Please pay attention to the following items when you use the LCD Module with back-light unit.

1. Do not twist or bend the module and prevent the unsuitable external force for display module during assembly.

2. Adopt measures for good heat radiation. Be sure to use the module within the specified temperature.

3. Avoid dust or oil mist during assembly.

4. Follow the correct power sequence while operating. Do not apply the invalid signal, otherwise, it will cause

improper shut down and damage the module.

5. Less EMI: it will be more safety and less noise.

6. Please operate module in suitable temperature. The response time & brightness will drift by different temperature.

7. Avoid displaying a fixed pattern (exclude the white pattern) for a long period, which may lead to image-sticking.

8. Be sure to turn off the power when connecting or disconnecting the circuit.

9. Polarizer scratches easily, please handle it carefully.

10. Display surface never likes dirt or stains.

11. A dewdrop may lead to destruction. Please wipe off any moisture before using module.

12. Sudden temperature changes cause condensation, and it will cause polarizer damaged.

13. High temperature and humidity may degrade performance. Please do not expose the module to the direct

sunlight and so on.

14. Acetic acid or chlorine compounds are not friends with TFT display module.

15. Static electricity will damage the modules; please do not touch the module without any grounded device.

16. No parts of the panel should be dismantled without the presence of AU engineer or the product will not be

warranted.

17. Be careful do not touch the rear side directly because of the backlight high voltage.

18. No strong vibration or shock. It will cause module broken.

19. Storage the modules in suitable environment with regular packing.

20. Be careful of injury from a broken display module. Please avoid the pressure adding to the surface (front or rear

side) of modules, because it will cause the display non-uniformity or other function issue.

26

Level 1 Cosmetic / Appearance / Alignment Service

Visual Inspection & Cleaning

Cleaning. Always unplug your monitor from the wall outlet before cleaning. Clean the LCD monitor surface with a

lint-free, non-abrasive cloth. Avoid using any liquid, aerosol or glass cleaners.

Slots and openings on the back or top of the cabinet are for ventilation. They must not be blocked or covered.

Your monitor should never be placed near or over a radiator or heat source, or in a built-in installation unless

proper ventilation is provided.

Never push objects or spill liquid of any kind into this product.

F/W Upgrade SOP

Upgrade by 715GT089-B/ C

1. Materials list

ISP JIG: 715GT089-B/C VGA cable PC

BenQ PN: 5D.Y3W37.031 TPV P/N: 089G728 GAA DB

Monitor USB cable USB port driver

TPV P/N: 089G1758 X

ISP tool: V4.5.0.8.0 New F/W

27

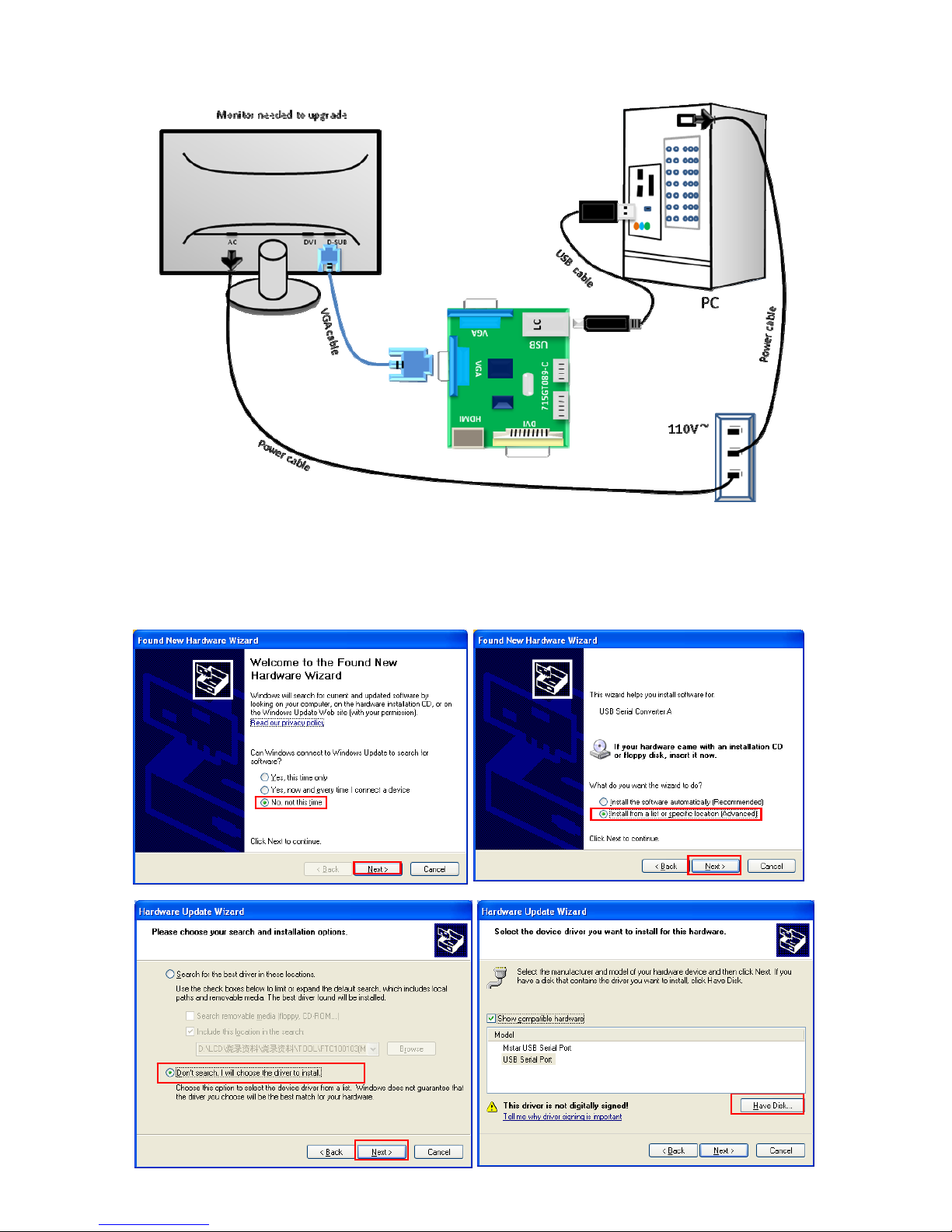

2.Connection

3.Install USB driver.

3.1. When insert the USB cable to PC USB port, will pop up a Hardware Wizard to help you install the USB driver if

you use this ISP board first time. You can install it successfully as the below instruction step by step.

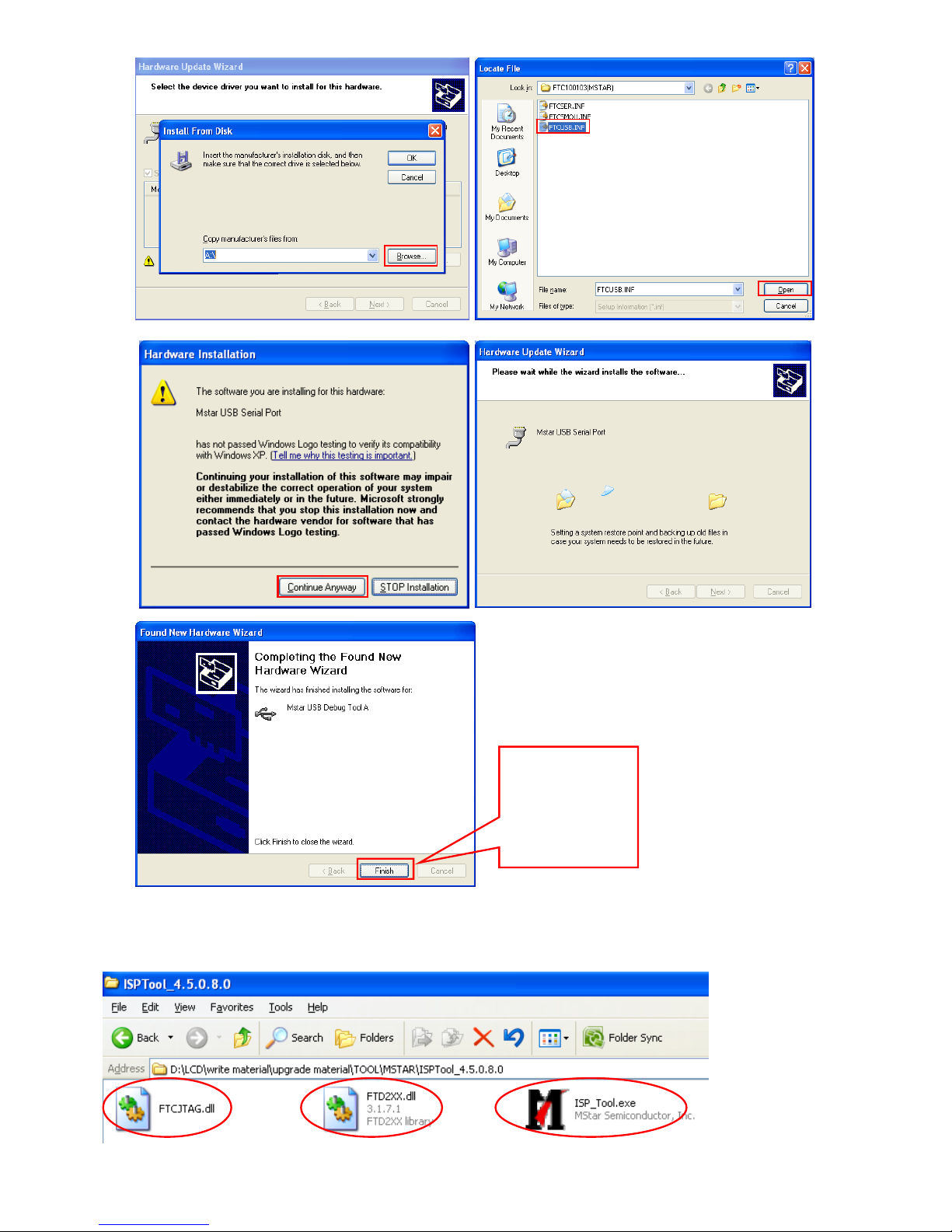

Remark: The USB driver files path: D:\FTC100103(Mstar)\FTCUSB.INF

28

4. Install the ISP tool.

4.1.Copy the three files in one folder.

Click “Finish” to

complete the

USB serial port

driver installation.

29

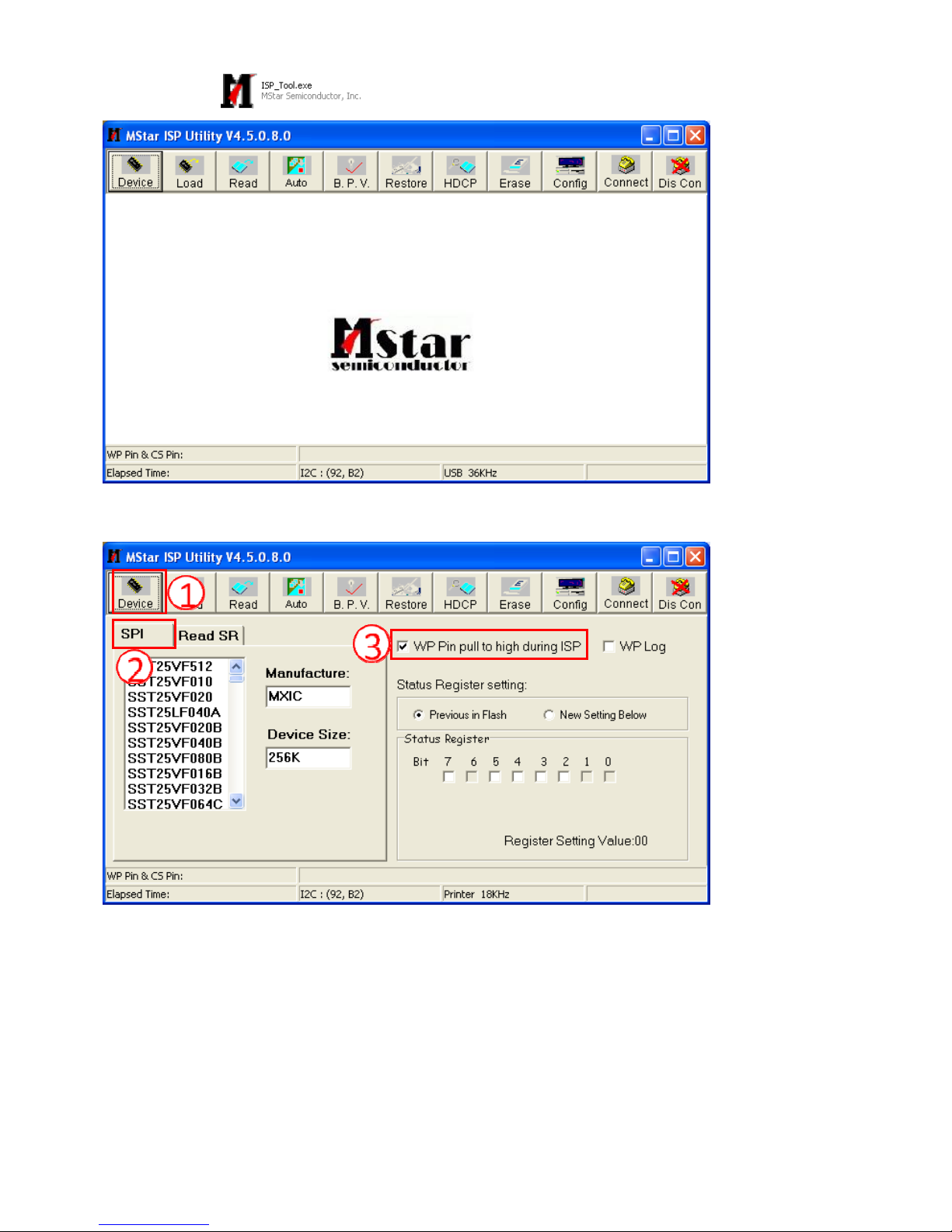

4.2. Double-click

to run the ISP tool.

4.3. Set the parameters in “Device” window. Tick “WP Pin pull to high during ISP”.

30

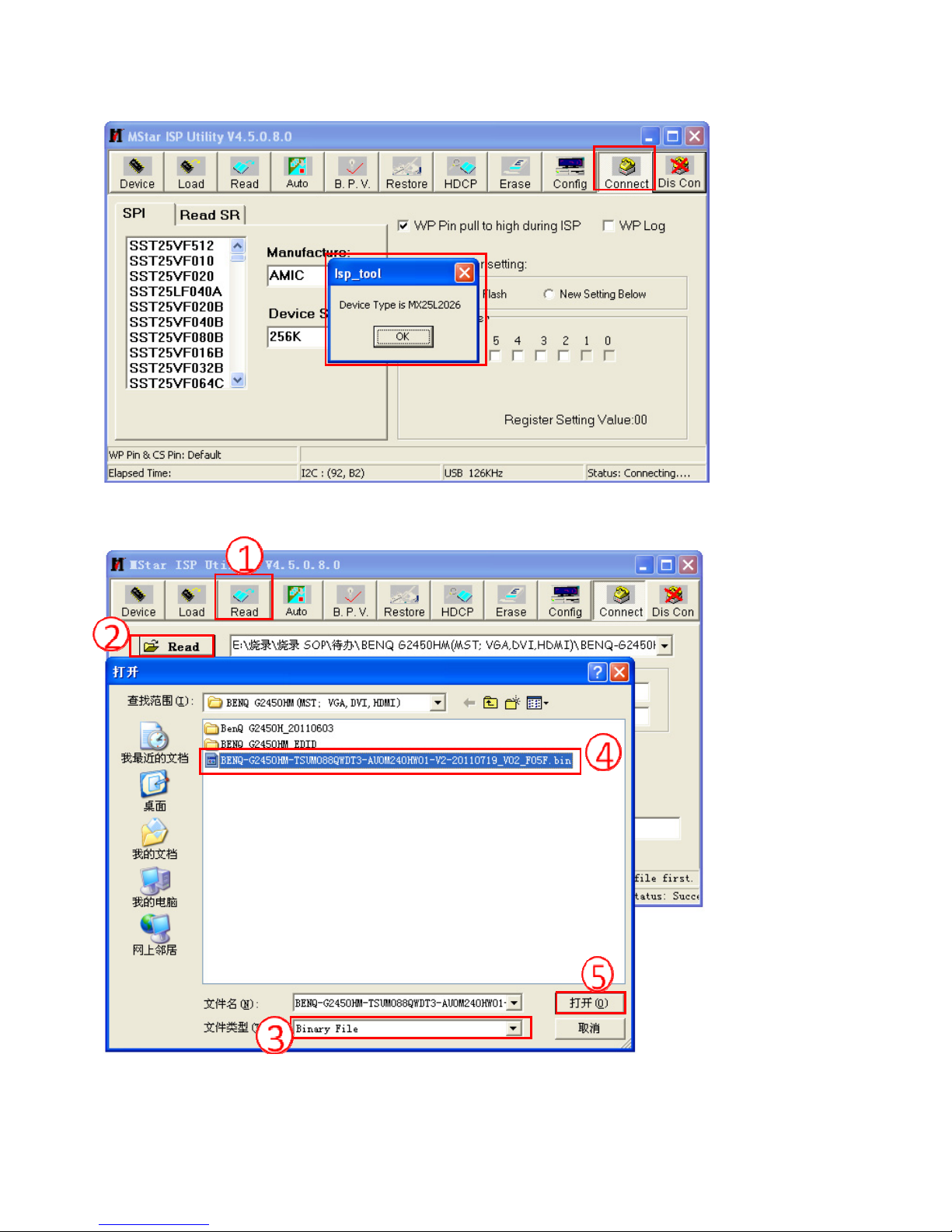

4.4. Connect to the monitor. Click “Connect”. If the tool communicate with monitor successfully, the tool will detect

the flash type of monitor.

4.5. Load the F/W you want to upgrade.

Loading...

Loading...