Page 1

NMEA1 INSTALLATION INSTRUCTIONS

READ INSTRUCTIONS COMPLETELY BEFORE BEGINNING INSTALLATION

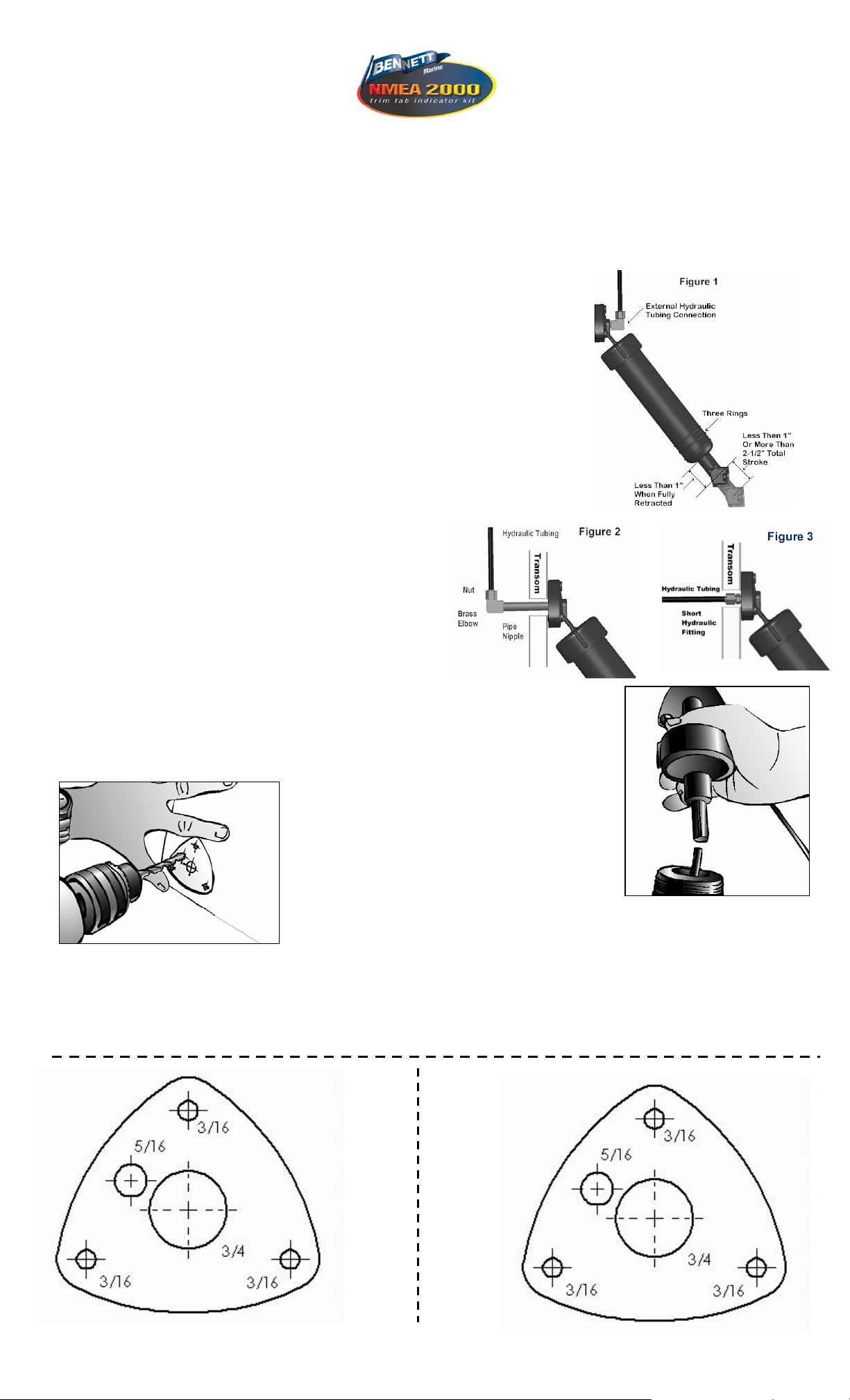

IF ACTUATOR STROKE IS LESS THAN 1" OR MORE THAN 2-1/2", OR IF LESS THAN 1" OF PISTON SHAFT IS EXPOSED

WHEN THE ACTUATOR IS FULLY RETRACTED, HAS EXTERNAL HYDRAULIC CONNECTION, OR THREE RINGS MOLDED

ON CYLINDER BODY (SEE FIGURE 1), SPECIAL SENSOR COILS ARE REQUIRED. (CONTACT BENNETT MARINE)

MAKE ALL ELECTRICAL CONNECTIONS WITH POWER OFF

TEST SYSTEM BEFORE PUTTING THE BOAT BACK IN THE WATER

Tools required:

1/2" & 7/16” Wrench

5/16" Drill Bit

Teflon Tape

Wire Stripper

Electric Drill

Installing New Upper Hinge with Sensor

Step 1 Inside transom, with tabs in full up position, locate trim tab hydraulic line and

detach tubing from brass elbow (some fluid will drip out). While holding pipe nipples

with vise grips, unscrew brass elbow. Do this procedure for port and starboard

cylinders (see figure 2). If there is no pipe nipple visible inside the transom, you have a

short fitting connection (see figure 3), skip to step 2.

Step 2 Outside transom, snap white plastic clip on shaft protruding from bottom of

cylinder. Grasp cylinder body with both hands and unscrew counterclockwise from

cylinder upper hinge (a small amount of fluid will spill).

Step 3 Insert metal rod into piston, POINTED END DOWN.

Make sure that the O-ring is in place in new upper hinge with

sensor coil. Screw new upper hinge onto cylinder while keeping

metal rod inserted into center of sensor coil. Red cable for port

side and green cable for starboard side. Tighten upper hinge

hand tight. IMPORTANT: Use care when handling sensor

coils during assembly to avoid damaging wires.

Step 4 Remove upper hinge from transom and remove pipe nipple. If you have a short

fitting use a 7/16” wrench to remove it from the upper hinge.

Step 5 Remove plastic clip from piston and repeat steps 2 - 4 for the starboard cylinder.

Step 6 Using template, drill 5/16" hole in transom for the sensor cable. Screw pipe nipple

(clockwise) securely. Repeat for other side. Run cables to helm.

Step 8 Inside transom, remove masking tape from pipe nipples. Carefully wrap Teflon tape around male threads of pipe

nipples. Holding pipe nipples with vise grips (to prevent them from turning) re-secure 90 degree elbows. Re-attach

hydraulic tubing, tightening nut finger tight. Snug nut with 1/2" wrench. Do not over-tighten. Note: If you have the short

fittings omit this step.

Marine Grade Sealant

Vise Grips

Wire Cutter

into new actuator upper hinge. Tighten nipple hand

tight. Then, with vise grips, tighten two full turns . . .

NO MORE. If you have the short fitting, using a ½”

wrench screw it in until the fitting is snug, the

shoulder of the fitting will just touch the plastic of the

upper hinge.

Step 7 Cover end of pipe nipple with masking tape.

Apply sealant to actuator upper hinge surface around pipe nipple, screw holes, and

cable. Feed actuator cable through 5/16" hole and secure actuator upper hinge to

transom with mounting screws. Grasp cylinder body with both hands and tighten

Page 2

Wiring NMEA1 to NMEA2000 Backbone

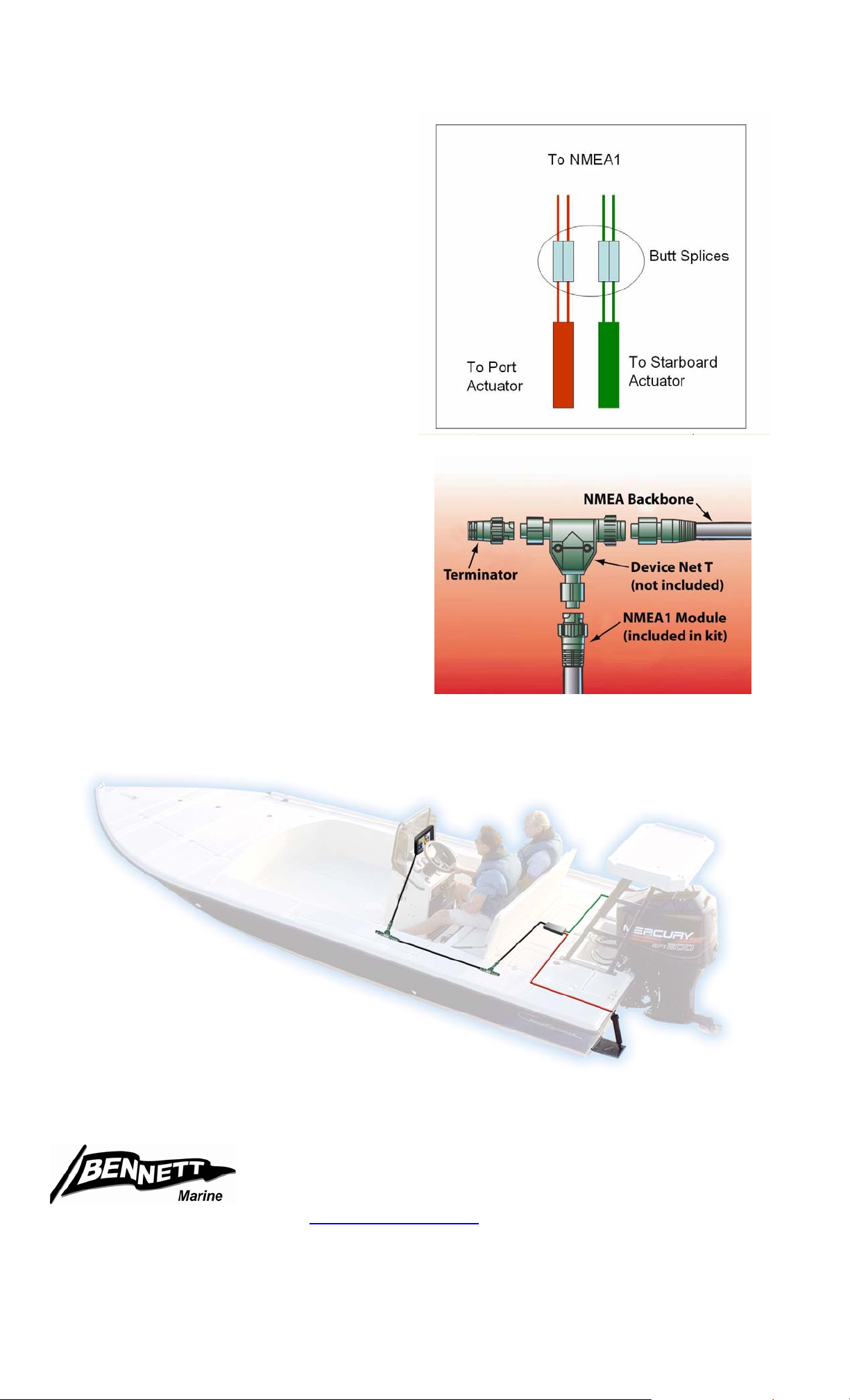

1. Using red butt connectors,

splice the red and green wires

from sensors to the red and

green wires from the NMEA1

module. Note either red and

green wires from the sensor

may be spliced to either red or

green wire from the NMEA1

module.

2. Run the connection cable from

the NMEA1 Module to the

Backbone cable of your NMEA2000 system.

3. Connect the cable into the Backbone

using a red Device Net “T” (not included).

You will need to purchase this “T” or

buy an adapter to fit your current

NMEA2000 system. Please contact

your electronics manufacturer.

4. Make sure the Backbone system

has the correct terminator in place.

5. Your NMEA1 Trim Tab position

sensor is now installed. Refer

to the Lowrance, or other

electronics manufacturer’s

instructions for calibration of

the system.

Bennett Marine

550 Jim Moran Blvd. Deerfield Beach, FL 33442 USA

Phone 954-427-1400 Fax 954-480-2897

Web Site

E-mail info@BennettTrimTabs.com

www.BennettTrimTabs.com

Loading...

Loading...