Page 1

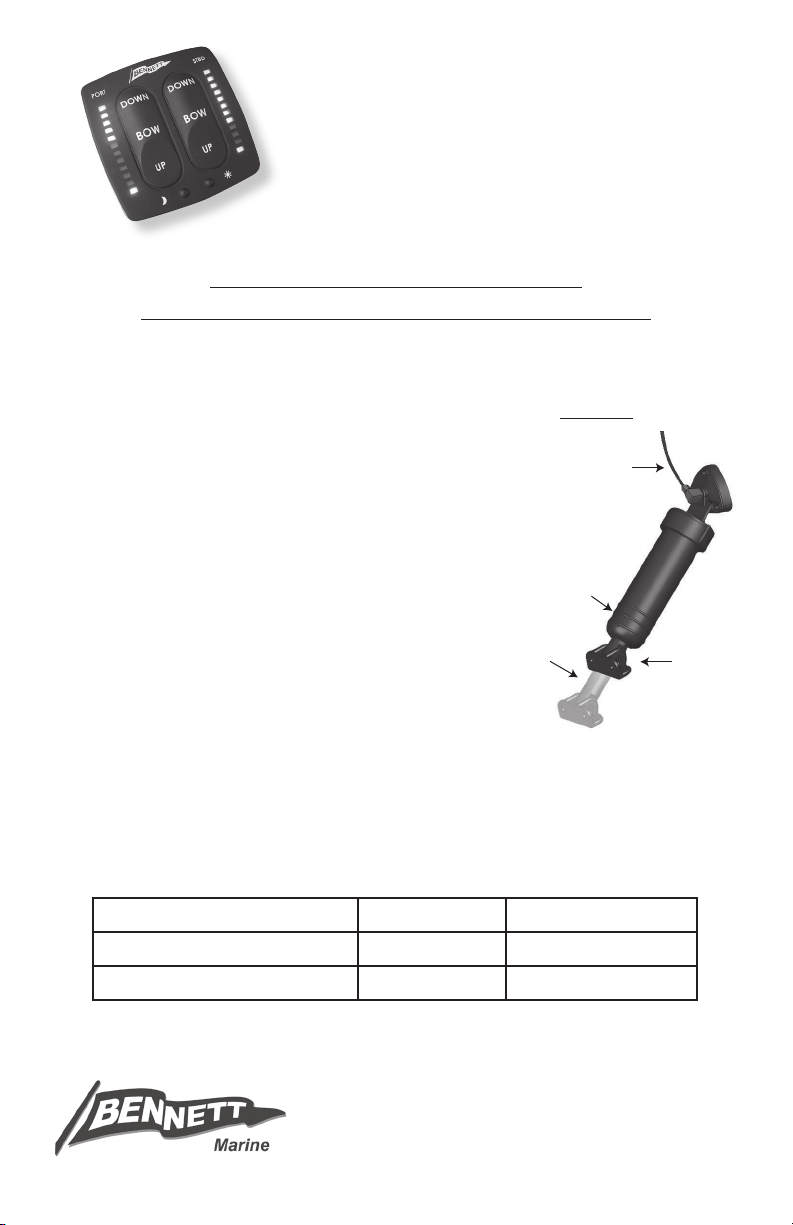

(EIC5000)

External Hydraulic

Tubing Connection

Three Rings

(cut rod only)

Less Than 1"

When Fully

Retracted

}

Less Than 1" or More

Than 2 ½" Total Stroke

}

ELECTRONIC INDICATOR CONTROL

INSTALLATION AND OPERATION

INSTRUCTIONS

BEFORE BEGINNING INSTALLATION:

READ INSTRUCTIONS COMPLETELY

MAKE SURE BATTERY POWER IS DISCONNECTED

TEST SYSTEM BEFORE PUTTING THE BOAT BACK IN THE WATER

IMPORTANT - SPECIAL REQUIREMENTS:

FIGURE 1

System is voltage specic. Please make sure •

you have a 12 or 24 volt EIC5000 depending

on your requirements.

(SEE FIGURE 1)•

Special sensor coils are required if:

- Actuator stroke is more than 2 ½" OR

- Less than 1" of piston shaft is exposed

when the actuator is fully retracted OR

- Actuator has external hydraulic connection

System will not work when actuator stroke is 1" or less•

If installing in an M80 or M120 Sport Tab kit, your actuator will have three molded rings as •

shown in Figure 1. Cut the metal rod to 6 ⁄" as indicated by score mark (see enclosed

instruction sheet for cutting the rod).

REQUIRED TOOLS

7/16", 1/2" & 9/16" Wrench Teon Tape Marine Grade Sealant

1/8", 3/16", 5/16" & 3/4" Drill Bit Wire Stripper Vise Grips

2" Hole Saw Electric Drill Wire Cutter

KEEP THIS MANUAL WITH BOAT OWNER’S INFORMATION

Bennett Marine, Inc.

550JimMoranBlvd•DeereldBeach,FL33442

Phone:954.427.1400•Fax:954.480.2897

Web: www.BennettTrimTabs.com

Page 2

IMPORTANT:

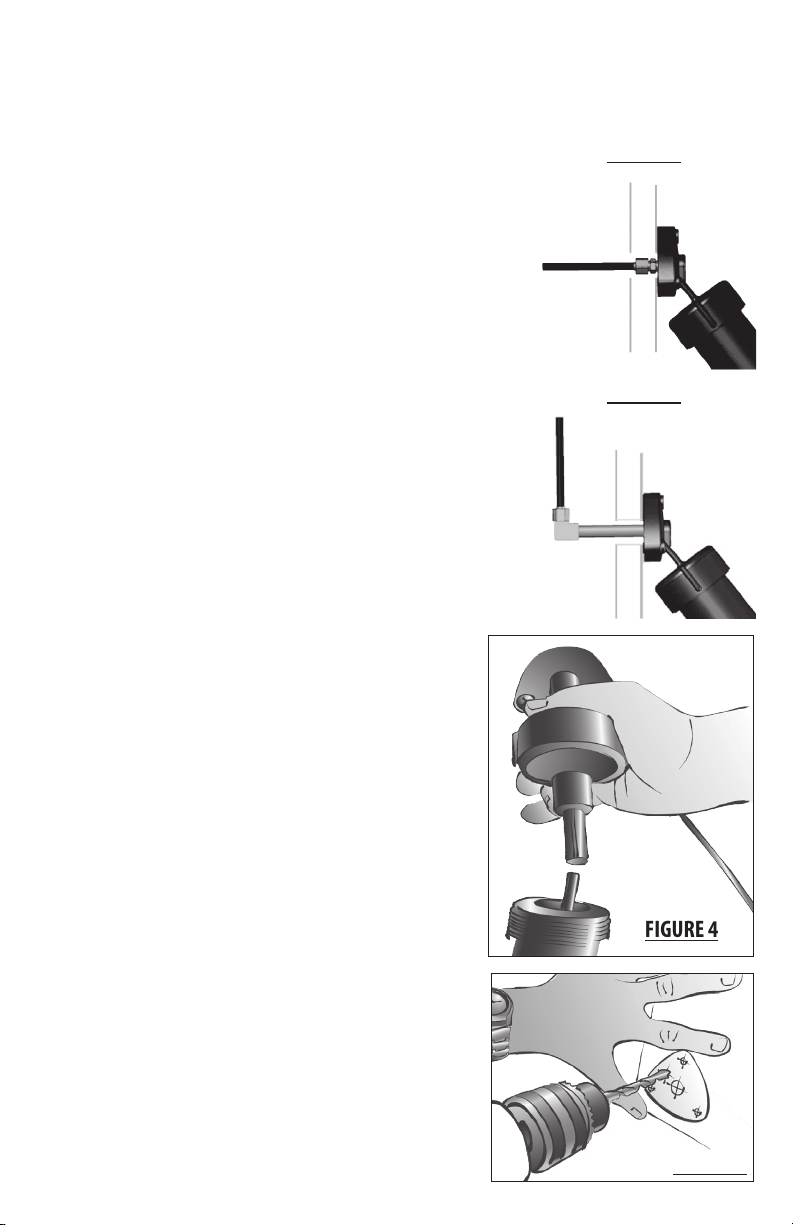

Hydraulic Tubing

Short

Hydraulic

Fitting

Transom

Transom

Hydraulic Tubing

Brass

Elbow

Nut

Pipe

Nipple

Check Special Requirements noted on the front cover of this manual before beginning installation.

If you are installing a preassembled actuator with the sensor wires already included, skip to step 6.

Installing New Upper Hinge with Sensor

Step 1 - Inside transom, with tabs in full up position, locate

trim tab hydraulic line. If there is no pipe nipple visible inside

the transom, you have a short through-transom tting connection,

(see Figure 2). Unscrew and remove actuator away from the

transom and use a 7/16" wrench to remove the tubing from

the upper hinge. Skip to step 3.

For standard installations, detach tubing from brass elbow (some

uid will drip out). While holding pipe nipples with vise grips,

unscrew brass elbow using 9/16" wrench. Do this procedure for

port and starboard cylinders (see Figure 3).

Step 2 - Outside transom, unscrew and remove actuator away

from the transom. Remove pipe nipple.

Step 3 - Start with the port side cylinder. Snap white

plastic clip on shaft protruding from bottom of cylinder.

IMPORTANT: This clip must be used to keep the spring

inside the cylinder compressed. Grasp cylinder upper hinge

with both hands and unscrew it counterclockwise from the

cylinder body (a small amount of uid may spill).

FIGURE 2

FIGURE 3

Step 4 - IMPORTANT: Use care when handling sensor

coils during assembly to avoid damaging wires. Insert

metal rod into piston, POINTED END DOWN. Make sure that

the O-ring is in place in new upper hinge with sensor coil.

Screw new upper hinge with Red Sensor Wire onto the

port side cylinder while keeping metal rod inserted into

center of sensor coil (see Figure 4). Tighten upper hinge

hand tight. You will nish tightening cylinder in Step 7.

Step 5 - Remove plastic clip from piston and repeat steps

2 - 4 for the starboard cylinder. Use upper hinge with

Green Sensor Wire for the starboard side.

Step 6 - Using template on the last page, drill 5/16" hole

in transom for the Sensor Wire (see Figure 5). Screw pipe

FIGURE 4

FIGURE 5

Page 3

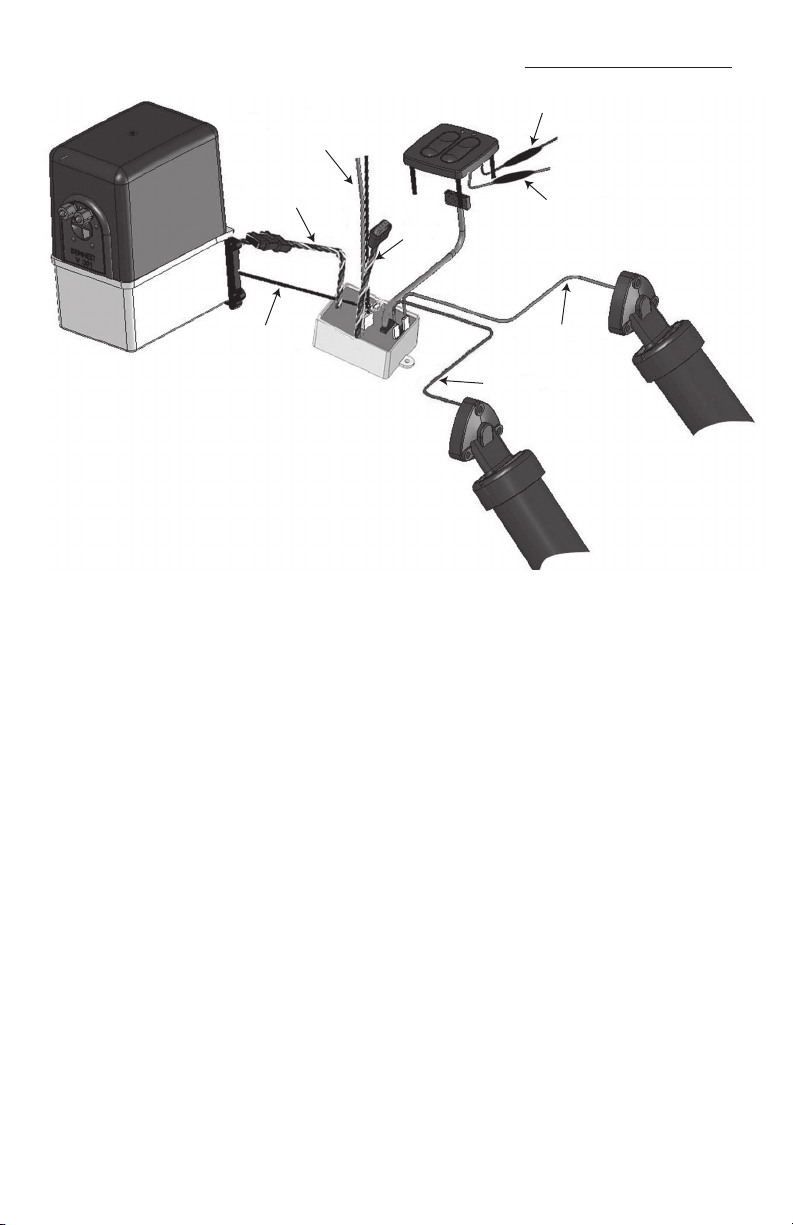

EIC Installation Overview

EIC Relay Module Power Lead

Orange (12 Volt +)

Black (12 Volt - )

Purple Power Lead

Orange Power Lead

Spare

ATC Lead

Starboard (Green)

Sensor Wire

Port (Red) Sensor Wire

Black Ground

Wire from HPU

Four-Color HPU

Wire Harness

EIC Relay Module

HPU

EIC Display

nipple into actuator upper hinge. Tighten nipple hand tight. Then, with vise grips, tighten two full

turns … NO MORE. Cover end of pipe nipple with masking tape. If you have the short throughtransom tting, using a 7/16" wrench, screw it in until the tting is snug; the shoulder of the

tting will just touch the plastic of the upper hinge.

Step 7 - Carefully feed Sensor Wire through 5/16" hole. Apply sealant to actuator upper hinge

surface around pipe nipple, screw holes, and cable. Secure actuator upper hinge to transom with

mounting screws. Grasp cylinder body with both hands and tighten (clockwise) securely.

Step 8 - Inside transom, remove masking tape from pipe nipples. Carefully wrap Teon tape

around male threads of pipe nipples. Holding pipe nipples with vise grips (to prevent them from

turning) re-secure 90 degree elbows. Re-attach hydraulic tubing, tightening nut nger tight.

Snug nut with 1/2" wrench. Do not over-tighten. Note: If you have the short through-transom

ttings, omit this step. Repeat for other side. Run Red and Green Sensor Wires to where you plan

to mount the EIC Module.

Step 9 - Mounting the EIC Display

Using the template on the last page, mark the location for your EIC Display and locate the centers

of the holes. Use a 2" hole-saw to cut the center hole and 3/16" drill for the four mounting stud

holes. Use a small bead of sealant around the perimeter of the display to seal. Plug the EIC Harness

(blue cable) into the back of the EIC Display. Use the 4 nylon thumb nuts to secure the display (use

care to avoid over-tightening).

Page 4

Step 10 - Mounting the EIC Relay Module

Connects to

HPU Harness

Spare: For

Optional Auto

Tab Control

Connects to EIC

Wire Harness

Starboard Sensor

Wire Connector

Port Sensor

Wire Connector

Attach Black Ground Wire from

Hydraulic Power Unit

Plug for

Power Connector

The Module is best located in a dry location close to the Hydraulic Power Unit. Use the mounting

hardware to secure it in place.

Step 11 - Running the EIC Wire Harness from the Display to the Module

Run the EIC Harness to the location you have selected for the EIC Relay Module. Plug the EIC Wire

Harness into the EIC Relay Module. The cable must be properly strain relieved and secured with

cable ties. For best results, create a drip loop.

Step 12 - Connecting the Wiring for the EIC

Purple wire with inline 1.5 amp fuse: Connect to ignition switch or any 12 volt circuit that

turns ON and OFF with ignition. This wire is used to initiate Auto Tab Retraction when the ignition

is switched to the OFF position. If Auto Tab Retraction is not desired this connection may be omitted.

Orange wire with inline 1.5 amp fuse: To source that supplies power to boat’s electronics and

or gauges. This wire switches the display system and must be installed.

Making Electrical Connections

(See Figure 6)

Ground wire from pump: Run the black ground

wire from the back of the hydraulic power unit to

the grounding stud on the Relay Module. Crimp

the supplied ring terminal on wire and secure with

10-32 hex nut.

FIGURE 6

HPU Connection: Plug the 4-color wire harness

from the Hydraulic Power Unit into the 4-color

output cable (longer of the two harnesses) on the

EIC Relay Module.

Sensor Wires: Plug Green Sensor wire into the

Green Wire Connector (starboard) on the

EIC Module. Plug Red Sensor Wire into the Red Wire

Connector (port) on the EIC Module.

Power Cable: Attach the black wire to 12 volt negative ground and the orange wire with inline

20 amp fuse to 12 volt positive source and plug into EIC Relay Module. Power source must be

capable of supporting 20 amps.

Auto Tab Control: (Shorter of two harnesses) This plug is used to interface a Bennett Auto Tab

Control into the EIC System. Please refer to Auto Tab Control Installation Instructions. If no Auto Tab

Control is installed this lead is not used.

Page 5

Calibration and Operation

Calibration – NOTE: If you have Upper and Lower Helm EIC Displays installed,

calibration must be done at the Lower Helm EIC Display.

Check trim tab system to ensure it is operational, then put both trim tabs in the FULL UP position

by holding down the “Bow Up” position.

The port and starboard 1. red LEDs will ash alternately, indicating that the system is not

calibrated.

Press and hold the sun and moon buttons on the EIC Display simultaneously for 2.

approximately 3 seconds. Both the port and starboard lower yellow LEDs will begin to

ash. Release the sun and moon buttons.

Using the EIC Display, run both trim tabs to the full down position (Bow Down on the control).3.

Make sure the tabs go all the way DOWN by holding the buttons down for at least

15 seconds or until the lower yellow LEDs stop ashing. (Holding the buttons after the tabs

are down will not harm the system).

A few seconds after the tabs are all the way down the port and starboard 4. upper yellow

LEDs will begin ashing. Again, using the EIC Display, run both tabs to the full up position

(Bow Up on the control). Make sure the tabs come all the way UP by holding the

buttons down for at least 15 seconds or until the upper yellow LEDs stop ashing.

The upper and lower yellow LEDs will then light up solidly, indicating that the EIC is 5.

calibrated and ready to operate. If you wish to recalibrate the EIC at any time, simply bring

the tabs to the full up position, press and hold the sun and moon buttons down and repeat

the calibration instructions.

Operation

The brightness of the display may be adjusted by pressing the sun button to brighten and the

moon button to dim the display.

Diagnostic Information

Port and starboard red LEDs alternately ash: EIC requires calibration. Follow steps above.

Upper yellow LED ashes on port or starboard side: Indicates the EIC Display is not receiving

a sensor signal. If the port upper yellow LED ashes, the fault is in the port (red) sensor or wires. A

ashing yellow LED on the starboard side would indicate a fault on the starboard (green) sensor or

wires. Switching the sensor connections on the EIC Relay Module will conrm the diagnostic code

if the ashing LED switches sides. If the problem switched sides, check the suspected faulty actuator

with an Ohm meter at the EIC sensor cable plug. The reading should be in the 220-260 Ohm range.

If the sensor readings are good, check for faulty connections (corrosion or broken wires).

Page 6

Electro-Hydraulic System Information

EIC Relay Module Fuse: 12 volt system uses 20 amp in-line fuse on positive, 24 volt uses 10 amp.

EIC Display Fuses: Both Purple and Orange wire fused at 1.5 amp for both 12 and 24 volts.

Hydraulic Power Unit and EIC Module Wiring

Red = Port Valve

Green = Starboard Valve

Yellow = Motor Reverse (pump retract)

Blue = Motor Forward (pump pressure)

Black on HPU = Connects to Ground Stud on EIC Module

Orange on EIC Module = Positive

Black on EIC Module = Ground (boat’s electrical system)

Troubleshooting

(This general information is not intended to be complete. Please feel free to contact Bennett Marine at

954.427.1400 or visit our website at www.BennettTrimTabs.com for additional information.)

If Trim Tabs do nothing, no movement, no sound from HPU:

Inspect 20 amp fuse on Orange wire at Relay Module and 1.5 amp fuse on Orange wire at display.

Inspect all wiring for disconnected or corroded connections.

HPU running but Trim Tabs do not move, or will go down but not retract:

Is the unit receiving a solid 12 volts to the EIC Module? Low voltage will sometimes cause the

solenoids to not open preventing the tabs from moving even though the pump motor is running.

Inspect all wiring for disconnected or corroded connections.

Conduct the following test using the “Spare for Auto Tab Control” connector at the EIC Module:

Operation = Reaction

Apply 12 volts (+)to blue, red = Port trim tab down

Apply 12 volts (+)to blue, green = Starboard trim tab down

Apply 12 volts (+)to blue, red, green = Both trim tabs down

Apply 12 volts (+)to yellow, red = Port trim tab up

Apply 12 volts (+)to yellow, green = Starboard trim tab up

Apply 12 volts (+)to yellow, red, green = Both trim tabs up

If the trim tabs function correctly for each wire grouping, then the Display or EIC Wire Harness is at

fault.

If the system does not function properly, then conduct the same test using the wire harness

connected to the HPU. If the trim tabs function correctly then the Module is faulty. If the trim tabs

do not function correctly, the HPU is at fault.

Page 7

2 1/8"

3/16"

2.83

2.83

2 1/8"

2

"

EIC Display Template

Ø 3/4

"

Ø 5/16

"

Ø 3/16

"

Ø 3/16

"

Ø 3/16

"

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

Ø 3/4

"

Ø 5/16

"

Ø 3/16

"

Ø 3/16

"

Ø 3/16

"

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

Upper Hinge Templates

Page 8

EIC5000 Electronic Indicator Control – Upper Helm

INSTALLATION AND OPERATION INSTRUCTIONS

READ INSTRUCTIONS COMPLETELY BEFORE

BEGINNING INSTALLATION

Step 1 Follow EIC5000 Installation Instructions to install system and Lower Helm EIC

Display.

Step 2 Mounting the Upper Helm EIC Display

Using the template, mark the location for your Upper Helm EIC Display and locate the

centers of the holes. Use a 2-1/8" holesaw to cut the center hole and 3/16" drill for

the four mounting stud holes. Use a small bead of sealant around the perimeter of the

display to seal. Using the 4 nylon thumb nuts secure the display (use care to avoid

overtightening).

Step 3 Mounting the Bridge Box

Mount the Bridge Box within 4 feet of the

Lower Helm EIC Display.

Step 4 Running the EIC Wire Harness from

Bridge Box to the EIC Relay Module

If you already have a Lower Helm EIC Display

installed, simply unplug the blue EIC Wire

Harness from the back of that Lower Helm

EIC Display and plug it into ANY of the three

connectors on the Bridge Box.

If this is a new installation, plug the blue EIC Wire Harness directly, connecting the EIC

Relay Module to any of the three connectors on the Bridge Box.

Step 5 Running the EIC Bridge Wire Harness to the Bridge Box

Plug the EIC Bridge Wire Harness into the back of the Upper Helm EIC Display, run it

down to the Bridge Box and plug it into ANY of the three connectors.

Step 6 Running the EIC 4-foot Wire Harness from the Lower Helm EIC Display to

the Bridge Box

Plug the 4-foot Wire Harness into the back of the Lower Helm EIC Display and plug into

the remaining connector on the Bridge Box.

Step 7 Connecting the EIC Display Wiring

The orange and purple wires at the Upper Helm EIC Display are NOT connected to any

power source. (They are connected at the Lower Helm EIC Display.)

Calibration

Refer to the EIC5000 Installation Instructions and calibrate system ONLY at the Lower

Helm EIC Display.

Page 9

EIC5000 Electronic Indicator Control – Upper Helm

INSTALLATION DIAGRAM

Loading...

Loading...