BOILER OPERATING AND INSTALLATION

INSTRUCTION MANUAL

BENEKOV S16

BENEKOV S26

BENEKOV S51

2

Dear client,

Thank you for purchasing a BENEKOV S series automatic wood pellet boiler and

placing your confidence in our company, BENEKOVterm s.r.o. of Horní Benešov.

To use your new product correctly, from the outset, please first read this operating

manual, especially Chapters 7 and 8. Please follow the information below and

observe the manufacturer’s instructions or those of the service company that

installed your boiler.

These boilers were approved for operation in EU member states by Strojírenský

zkušební ústav, s.p. (Engineering Testing Institute, state-owned-enterprise), Notified

Body 1015, Authorized Body 202, Brno based on certificate no. B-30-00612-16 of

31.5.2016.

In accordance with Government Regulation No. 176/2008 Coll., Annex 1, section

1.7.4. it is an

ORIGINAL INSTRUCTION MANUAL

Copyright 2011 Leopold Benda jr. et al., license BENEKOVterm spol. s.r.o.

All rights reserved.

All texts, images are subject to copyright and other intellectual property protection.

3

Table of Contents

1. Boiler use and advantages ..................................................................................................................4

2. Technical specifications......................................................................................................................4

3. Specified fuel for boilers .....................................................................................................................6

4. Boiler description ................................................................................................................................6

4.1. Boiler design....................................................................................................................................6

4.2. Control and safety elements of the boiler......................................................................................18

4.3. Boiler accessories..........................................................................................................................18

5. Boiler placement and installation......................................................................................................22

5.1. Regulations and directives ............................................................................................................22

5.2. Boiler placement options ...............................................................................................................23

6. Commissioning of the boiler - instructions for contracted service organizations .............................25

6.1. Electric connection using via connectors.......................................................................................25

6.2. Verification activities before start-up..............................................................................................29

6.3. Putting into operation.....................................................................................................................29

7. Boiler operation by user....................................................................................................................31

7.1. Making fire in the boiler .................................................................................................................31

7.2. Boiler operation..............................................................................................................................32

7.3. Boiler shutdown .............................................................................................................................32

7.4. Residual risks and their prevention...............................................................................................33

8. Boiler maintenance...........................................................................................................................34

9. Troubleshooting................................................................................................................................35

10. Guidelines for sustained compliance with the environmental parameters of the product............... 36

11. Instructions for product disposal after the end of its service life......................................................37

12. Guarantee and liability for defects...................................................................................................37

4

1. Boiler use and advantages

Boiler use:

The BENEKOV S16 hot water boiler is designed for heating small, low-energy family houses, cottages and

other building facilities whose heat output demand does not exceed 20 kW.

The BENEKOV S26 hot water boiler is designed for heating family houses, cottages, office buildings, small

establishments and building facilities whose heat output demand does not exceed 26 kW.

The BENEKOV S51 hot water boiler is designed for heating medium-sized buildings - shops, schools,

recreational facilities, large family houses, office buildings, establishments and other building facilities, whose

heat output demand does not exceed 49 kW.

Boiler advantages:

• Automatic boiler operation

• Possibility of combustion of a renewable energy source in the form of wood pellets

• Mechanical fuel supply from standardized container (or general bunker) into the combustion chamber

• Possibility of increasing the capacity of the basic standardized fuel container with additional modules

• Automatic cleaning of heat transfer surfaces of the heat exchanger

• Simple, quick operation and maintenance

• Low operating costs

• 3-draught design of the exchanger guaranteeing high efficiency

• Low emissions for the neighbourhood

• Controlled combustion assisted by lambda probe

• Modulation of thermal output over the entire power output range

• Possibility of connecting boiler auto ignition (optional)

• Possibility to connect ash removing device (optional)

• Modern design

2. Technical specifications

Tab. no. 1 Dimensions and technical parameters of boilers

Boiler type

BENEKOV

S16

BENEKOV

S26

BENEKOV

S51

Weight (boiler body + feeder

to the boiler + turnstile)

Kg 340 410 765

Water compartment volume dm3 62 89 175

Flue gas duct diameter Mm 145 195

Boiler heat transfer surface m2 1,90 2,84 5,64

Boiler dimensions: Mm Fig. no. 5, 6, 7 Fig. no. 8, 9,

10

Boiler class according to ČSN

EN 303-5

5

Maximum permissible

operating pressure

Bar 2,0

Testing pressure Bar 4,0

Recommended operating

temperature of heating water

°C 65 - 80

Lowest temperature of the

inlet water

°C 60

5

Hydraulic loss

∆ T = 10 K

mbar

4

16

8

∆ T = 20 K mbar 1,6 4 2

Sound pressure level LpA dB < 65dB (A)

Required chimney draft mbar 0,12 – 0,15 0,15 – 0,20 0,20 – 0,25

Boiler connections - heating

water

Js G 1” G 6/4”

- return water Js G 1” G 6/4”

Supply voltage 400V / 16A / ~ 50 Hz

Electrical power input at rated

power output

W 33 38 51

Electrical power input at

minimum power output

W 15 15 23

Electrical power input in

STAND BY mode

W 6 6 6

Electrical protection IP 20

Tab. no. 2 Thermal technical parameters of BENEKOV S boiler series with the combustion of wood

pellets

Boiler type

BENEKOV

S16

BENEKOV

S26

BENEKOV

S51

Nominal output kW 20 26 49

Adjustable power output kW 6,0 – 20 7,7 – 26 14,6 – 49

Fuel consumption kg . h-1 1,3 – 4,3 1,8 – 5,7 3,1 – 10,5

Output in attenuation kW 1,7 1,7 1,7

Fuel consumption in attenuation kg . h-1 0,4 0,4 0,4

Flue gas temperature: - at rated output °C 108 109 95

- at minimum output °C 73 69 61

Efficiency % 92,1 90,8 90,7

Mass flow rate of flue gas at the output

- at rated output kg . s-1 0,008 0,016 0,024

- at minimum output kg . s-1 0,004 0,006 0,011

Tab. no. 3 Parameters of standardized fuel storage containers to the boilers of BENEKOV S series

Boiler type

BENEKOV S16 BENEKOV S26

BENEKOV

S51

Silo diameter mm

1 200 2 000 1 200 2 000 2 500

Dimension of the filling

opening in the fuel container

mm octagon

φ 1200

octagon

φ 2000

octagon

φ 1200

octagon

φ 2000

octagon

φ 2500

Weight of the basic fuel

container module

kg 121 286 121 286 397

Weight of the additional fuel

container module

kg 30 48 30 48 60

Capacity of the basic fuel

container module

dm

3

740 2700 740 2700 4000

Capacity of 1 pc of the

additional fuel container

module

dm

3

500 1300 500 1300 2000

Firing time at rated output

with full basic container

module

h 143 523 80 293 236

6

3. Specified fuel for boilers

The fuels specified in tab.no.4 are prescribed (under guarantee) fuel types for BENEKOV series boilers.

Tab. no. 4 Prescribed fuel

Type of fuel

according to ČSN EN

303-5

Average

[mm]

Length

[mm]

Bulk

density

[kg/m3]

Water

content

[%]

Ash

content

[%]

Calorific

capacity

[MJ.kg-1]

C1 - wood pellets

φ 6 - 14

max. 30 600 - 650 max. 12 max. 1,5

min. 17

ATTENTION! Poor quality fuel can significantly affect performance and emission parameters of

the boiler.

The pellets must comply with the requirements of the standard ČSN EN 14961-2.

4. Boiler description

The design of BENEKOV S boilers meets the requirements of:

ČSN EN 303-5: 2013 - Heating boilers - Part 5: Heating boilers for solid fuels, hand and automatically

stocked, nominal heat output of up to 500 kW - Terminology, requirements,

testing and marking.

4.1. Boiler design

The main part of the boiler, based on a fuel understoking design, is the boiler body that is welded from

steel boiler plates. All parts of the boiler body at the interface of flue gases and heating water are

made of sheet metal with a thickness of 5 mm. In front of the boiler body there is a combustion

chamber with a burner; at the back of the boiler body there is a 3-draft multi-plate heat exchanger

providing the decisive transfer of heat from flue gases to the boiler water. The finned heat exchanger

is fitted with an automatic cleaner, which during operation of the boiler continuously cleans the heat

exchange surfaces.

The burner, based on a fuel understoking design, consists of a screw fuel feeder and a steel grate.

The fuel feeder consists of a trough for fuel supply, a channel for supplying combustion air and a

flexible interconnection that serves for pressure equalization under the fireplace and which prevents

smoke penetration into the fuel tank during the combustion process. The burner is fitted with a ceramic

reflector that directs the exhaust gas flow, reduces fly dust and thus facilitates complete combustion.

Under the combustion chamber there is an ash drawer and shaped bed for the eventual installation of

an ash remover.

Beside the boiler there is a screw feeder that transports fuel from the external container to the burner.

The feeder consists of two screw conveyors (feeding from the bunker + feeding into the boiler) with a

turnstile between them. This serves to create an air gap between the two screw conveyors and avoids

any ignition of fuel in the container. In addition, the cover of the feeder from the bunker that transports

fuel above the turnstile is fitted with an emergency fire extinguishing system.

Depending on the position of the fuel feed screw towards the boiler drum, the boiler is manufactured in

two versions:

• Right version - the fuel feeder is on the right of the boiler body when viewed from the front

• Left version - the fuel feeder is on the left of the boiler body when viewed from the front

Furthermore, according to the design of your boiler room, you can select three mounting positions for

feeding from the bunker to the boiler. A side design (see fig. No. 5 and 8), front design (see fig. No. 6

and 9) and rear design (see Fig. 7 and 10).

7

The combustion air fan/s is/are placed on the side of the boiler by the fuel container. The boiler’s

control unit regulates the amount of combustion air.

The inlet and outlet of heating water for connection to the heating system is located in the rear part of

the boiler. BENEKOV S16 and S26 have two outlets with internal thread G 1", BENEKOV S51 has two

outlets with internal thread G 6/4". The outlet with G 1/2" thread in the bottom part on the right is used

to install the drain cock. At the rear of the boiler on the top, there is a flue gas exhaust adapter leading

to the chimney.

The flue gas exhaust increases the chimney draft and is an integral part of the equipment of S series

boilers.

The boiler body, its lid and doors are insulated with non-toxic insulation that reduces losses by

dissipating heat to the surroundings.

The steel casing is provided with a quality powder paint colour finish.

8

Fig. no. 1 Front view of the BENEKOV S16 and S26 boiler

1. Boiler lid

2. Locking bolt of firing flap

3. Firing flap lever

4. Boiler control unit display

5. Door cover

6. Combustion air fan

7. Preparation for ash remover

8. Boiler body feet cover

9. Emergency fire extinguishing system

10. Cover limit switch of the bunker feeder

11. Feeding from the bunker

12. Turnstile

13. Turnstile chain

14. Overflow cleaning cap

15. Feeding to the boiler

16. Feeder foot

1

16

15

14

12

13

11

10

9

2

3

4

5

6

7

8

9

Fig. no. 2 Rear view of the BENEKOV S16 and S26 boiler

17. Cover of feeder from the bunker

18. Stirrer

19. Flexible blades of stirrer

20. Lambda probe

21. Flue gas exhaust

22. Drive of feeder from the bunker

23. Drive of feeder to the boiler

24. Control unit switchboard

25. Feeding to the boiler

26. Automatic heat exchanger cleaning drive

27. Inlet for filling and discharge of the boiler

26

25

23

24

22

21

20

17

18

19

27

10

Fig. no. 3 Front view of the BENEKOV S51 boiler

1. Boiler lid

2. Locking bolt of firing flap

3. Firing flap lever

4. Boiler body

5. Door cover

6. Door cover handle

7. Heat exchanger cleaning door

8. Preparation for ash remover

9. Boiler control unit display

10. Drive of feeder from the bunker

11. Cover of feeder from the bunker

12. Cover limit switch of the bunker feeder

13. Emergency fire extinguishing system

14. Primary air fan

15. Secondary air fan

16. Feeding to the boiler

17. Drive of feeder to the boiler

18. Turnstile chain

19. Feeding from the bunker

1

14

15

16 18

17 19

10 9

2

3

7

8

11

12

13

6

5

4

11

Fig. no. 4 Rear view of the BENEKOV S51 boiler

20. Stirrer bed

21. Stirrer

22. Flexible blades of stirrer

23. Feeder foot

24. Turnstile

25. Lambda probe

26. Flue gas exhaust

27. Control unit switchboard

28. Automatic heat exchanger cleaning drive

29. Inlet for filling and discharge of the boiler

20

27

26

25

22

23

24

21

28

29

12

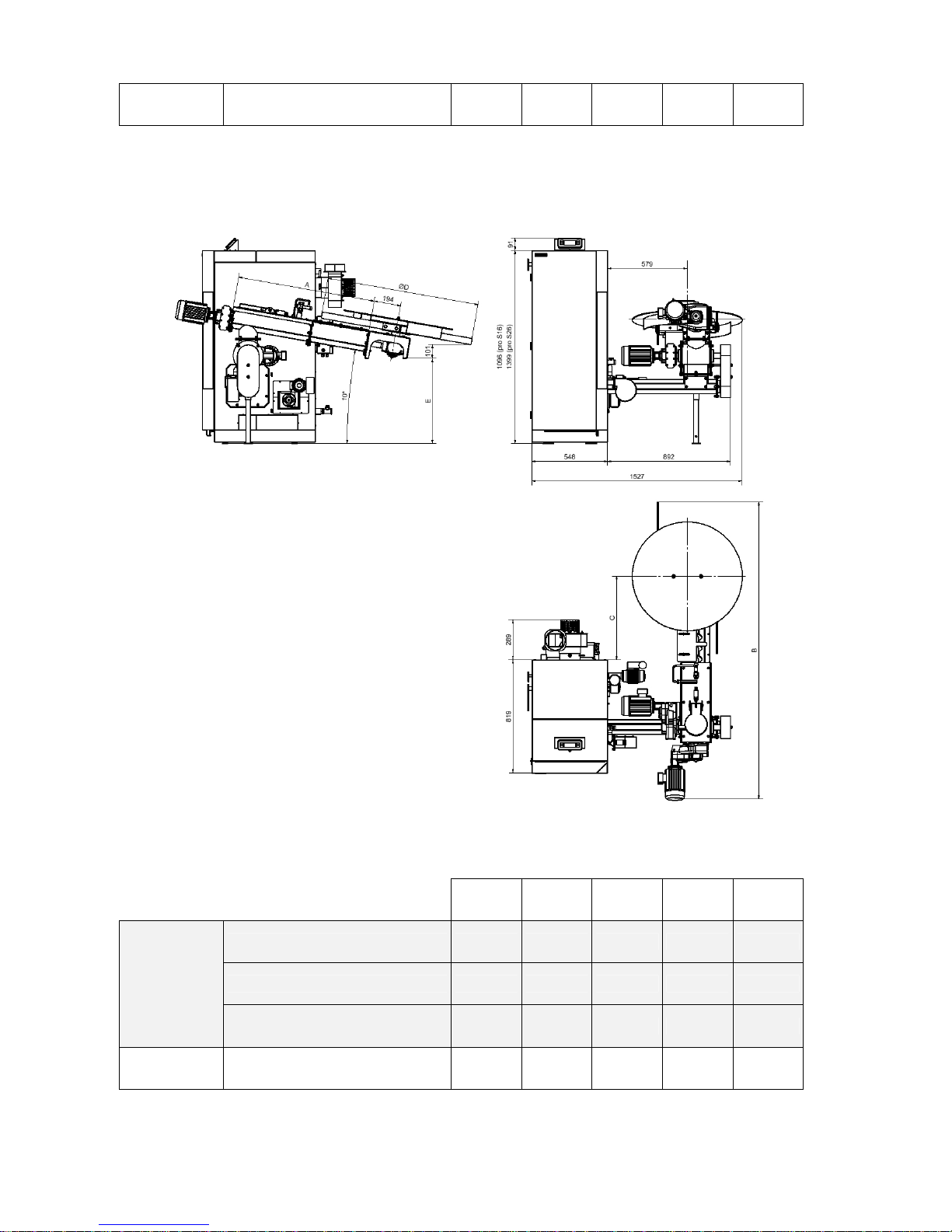

Fig. no. 5 Basic BENEKOV S16 and S26 boiler dimensions with lateral arrangement of feeding from

the bunker

Tab. no. 5 Parametric BENEKOV S16 and S26 boiler dimensions with lateral arrangement of feeding

from the bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Basic feeder arrangement

1000 2816 1732 1105 616

Feeder with extension of 1 m

2000 3801 2717 1105 442

Feeder

for container

φ 1200 mm

(740 dm3)

Feeder with extension of 2 m

3000 4786 3702 1105 268

Basic feeder arrangement

1400 3587 2126 1874 547

Feeder with extension of 1 m

2400 4572 3111 1874 373

Feeder

for container

φ 2000 mm

(2700 dm3)

Feeder with extension of 2 m

3400 5557 4096 1874 199

13

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

Fig. no. 6 Basic BENEKOV S16 and S26 boiler dimensions with front arrangement of feeding from the

bunker

Tab. no. 6 Parametric BENEKOV S16 and S26 boiler dimensions with front arrangement of feeding

from the bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Basic feeder arrangement

1000 2400 757 1105 616

Feeder with extension of 1 m

2000 3385 1742 1105 442

Feeder

for container

φ 1200 mm

(740 dm3)

Feeder with extension of 2 m

3000 4370 2727 1105 268

Basic feeder arrangement

1400 3171 1151 1874 547

Feeder

for container

φ 2000 mm

(2700 dm3)

Feeder with extension of 1 m

2400 4156 2136 1874 373

14

Feeder with extension of 2 m

3400 5141 3121 1874 199

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

Fig. no. 7 Basic BENEKOV S16 and S26 boiler dimensions with rear arrangement of feeding from the

bunker

Fig. no. 7 Parametric BENEKOV S16 and S26 boiler dimensions with rear arrangement of feeding

from the bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Basic feeder arrangement

1000 2144 603 1105 616

Feeder with extension of 1 m

2000 3129 1588 1105 442

Feeder

for container

φ 1200 mm

(740 dm3)

Feeder with extension of 2 m

3000 4114 2573 1105 268

Feeder

for container

Basic feeder arrangement

1400 2915 997 1874 547

15

Feeder with extension of 1 m

2400 3900 1982 1874 373

φ 2000 mm

(2700 dm3)

Feeder with extension of 2 m

3400 4885 2967 1874 199

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

Fig. no. 8 Basic BENEKOV S51 boiler dimensions with lateral arrangement of feeding from the

bunker

Tab. no. 8 Parametric BENEKOV S51 boiler dimensions with lateral arrangement of feeding from the

bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Arrangement with 2 m feeder

2000 4770 2812 2374 400

Arrangement with 3 m feeder

3000 5755 3797 2374 226

Arrangement with 4 m feeder

4000 6740 4782 2374 52

Feeder

for container

φ 2500 mm

(4000 dm3)

Arrangement with 5 m feeder

5000 7725 5767 2374 -122

16

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design

Fig. no. 9 Basic BENEKOV S51 boiler dimensions with front arrangement of feeding from the bunker

Tab. no. 9 Parametric BENEKOV S51 boiler dimensions with front arrangement of feeding from the

bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Feeder

for container

Arrangement with 2 m feeder

2000 4294 1643 2374 400

17

Arrangement with 3 m feeder

3000 5279 2628 2374 226

Arrangement with 4 m feeder

4000 6264 3613 2374 52

φ 2500 mm

(4000 dm3)

Arrangement with 5 m feeder

5000 7249 4598 2374 -122

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

Fig. no. 10 Basic BENEKOV S51 boiler dimensions with rear arrangement of feeding from the bunker

Tab. no. 10 Parametric BENEKOV S51 boiler dimensions with rear arrangement of feeding from the

bunker

A*

[mm]

B

[mm]

C

[mm]

D

[mm]

E

[mm]

Feeder

for container

Arrangement with 2 m feeder

2000 3851 1471 2374 400

18

Arrangement with 3 m feeder

3000 4836 2456 2374 226

Arrangement with 4 m feeder

4000 5821 3441 2374 52

φ 2500 mm

(4000 dm3)

Arrangement with 5 m feeder

5000 6806 4426 2374 -122

* Dimension "A" is specified by the client when ordering, based on the specific boiler room design.

4.2. Control and safety elements of the boiler

The control and regulation of the boiler is governed by a control unit - see separate instruction manual.

Safety components that monitor the safe operation of the boiler:

• The emergency thermostat is used to prevent the system from overheating. The manufacturer sets

the thermostat at 95°C, i.e. at a higher temperature than can be set on the boiler. The emergency

thermostat is positioned on the rear wall of the boiler in the CLIMATIX control unit cabinet.

• Thermal protection of the motor (thermal contact) is part of both fuel feeder motors and is used to

protect them from overheating in the case of fuel feeder blockage. It also retroactively stops the fan so

as to avoid burning of fuel in the container in the event of a fault. During normal operation, the motor

working temperature is up to 85 °C - such warming does not mean a failure.

• The turnstile is a device that mechanically separates the fuel between the screw conveyors (feeding

from the bunker + feeding into the boiler). In the event of re-ignition of fuel in the boiler feeding (e.g.

during long term power outage) the fuel in the tank does not ignite. Furthermore, the turnstile serves as

a partial fuel crusher. In the event of a longer piece reaching the turnstile, the turnstile crushes it into

smaller pieces.

• The cover limit switch of the bunker feeder shuts down the screw feeder and fan when the cover is

open. After proper closure both will return to normal operation.

• The emergency fire extinguishing system is another security feature preventing burning of fuel

through to the container. A temperature increase above 95 °C at the feeding out of the bunker results in

a thermostatic valve opening and the space being cooled with cooling water from the water main.

• The firing flap is located between the second and the third draft in the top part of the finned heat

exchanger and serves to regulate the flue gas temperature at the boiler outlet.

When operating the boiler when the flue gas temperature is higher than 100 °C the firing valve must be

closed, i.e. the firing flap lever on the side of the boiler must be rotated as much as possible upwards

(forwards) and secured with a locking screw. When firing (with cold chimney) or during long term

operation of the boiler at lower output it is recommended to operate the boiler with the firing valve

slightly open so that the flue gas temperature does not drop below 80 °C. In this case, the firing flap

lever must be rotated downward (backwards) and secured by a locking screw.

4.3. Boiler accessories

Standard accessories:

• Operating instructions and installation manual which includes a warranty card

• Operating instructions of the boiler control unit

• List of contracted service organizations

19

• Ash drawer

• Cleaning rake

• Automatic cleaning of heat transfer surfaces of the heat exchanger

• Flue gas exhaust - see fig. no. 15 and 16

Optional accessories:

• Automatic ignition - see fig. no. 11 and 12

• Ash remover - see fig. no. 13 and 14

• Rotary grate for combustion of less valuable fuels

• Basic container module with a diameter of 1200 mm (valid for BENEKOV S16 and S26)

• Basic container module with a diameter of 2 000 mm (valid for BENEKOV S16 and S26)

• Basic container module with a diameter of 2 500 mm (valid for BENEKOV S51)

• Additional fuel container module with a diameter of 1200 mm (valid for BENEKOV S16 and S26)

• Additional fuel container module with a diameter of 2 000 mm (valid for BENEKOV S16 and S26)

• Additional fuel container module with a diameter of 2 500 mm (valid for BENEKOV S51)

• 1 m extension of feeding from the bunker S26 (valid for BENEKOV S16 and S26) - see fig. no. 19

• 2 pieces of ceramic half-ring (valid for BENEKOV S51)

Optional accessories are not included in the basic price of the boiler.

Fig. no. 11 Automatic boiler ignition for S16 and S26

Fig. no. 12 Automatic boiler ignition for S51

Fig. no. 13 Boiler ash remover for S16 and S26

20

Fig. no. 14 Boiler ash remover for S51

Fig. no. 15 Boiler flue gas exhaust for S16 and S26

21

Fig. no. 16 Boiler flue gas exhaust for S51

Fig. no. 17 Basic fuel container module

Fig. no. 18 Additional fuel container module

Fig. no. 19 1 meter extension of feeding from the bunker S16 and S26

22

5. Boiler placement and installation

5.1. Regulations and directives

A boiler for solid fuels can be installed by an organization authorized to install these devices.

The installation must be made in accordance with the project subject to applicable regulations.

The heating system must be filled with water that meets the requirements of CSN 07 7401: 1992 and

importantly its hardness must not exceed the required parameters.

Tab. no. 12 Heating water parameters

Parameter Unit Value

Hardness mmol/l 1

Ca2+ mmol/l 0,3

Concentration of total Fe + Mn mg/l 0.3 (recommended value)

A) Regarding the heating system

ČSN EN 303-5:2013 Heating boilers - Part 5: Heating boilers for solid fuels, hand and

automatically stocked, nominal heat output of up to 500 kW - Terminology,

requirements, testing and marking.

ČSN 06 0310 2014 Heating systems in buildings - Design and installation

ČSN 06 0830:2014 Heating systems in buildings - Safety devices

ČSN 07 7401:1992 Water and steam for thermal energy equipment with working pressure up to

8 MPa

B) Regarding chimney

ČSN 73 4201:2010 Chimneys and flues - Design, implementation and connection of fuel

consumers

C) Regarding fire regulations

ČSN 06 1008:1997 Fire safety of heat installations

ČSN EN 13 501-1+A1:2010 Fire classification of construction products and building structures - Part 1:

Classification according to the results of response to fire tests

D) Regarding the electric network

ČSN 33 0165:1992 Regulations for electrical engineering. Marking of wires with colours or

numbers Executive provisions

ČSN 33 1500:1990 Regulations for electrical engineering. Revisions of electrical equipment

ČSN 33 2000-1 ed.2:2009 Low-voltage electrical installations - Part 1: Basic terms, determination of

basic characteristics, definitions

23

ČSN 33 2000-4-41 ed.2:2007 Low-voltage electric installations - Part 4-41: Protective measures to ensure

safety - Protection against electric shock

ČSN 33 2000-5-51 ed.3:2010 Electrical installations of buildings - Part 5-51: Selection and assembly of

electrical equipment - General requirements

ČSN 33 2000-7-701 ed.2:2007 Low-voltage electric installations - Part 7-701: Single-purpose equipment

and in special premises - Premises with tub or shower

ČSN 33 2030:2014 Electrostatics - Guidelines for the elimination of hazards due to static

electricity

ČSN 33 2130 ed.2:2009 Low-voltage electrical installations - Internal electrical wiring

ČSN 33 2180:1979 Regulations for electrical engineering ČSN. Connection of electrical devices

and appliances

ČSN 33 2350:1982 Regulations for electrical engineering. Regulations for electrical equipment in

difficult climatic conditions

ČSN 34 0350 ed.2:2009 Safety requirements for flexible cords and cord lines

ČSN EN 55 014-1 ed.3:2007 Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 1: Emissions

ČSN EN 55 014-2:1998 Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 2: Immunity - Product family

standard

ČSN EN 60079-14 ed.3:2009 Explosive atmospheres – Part 14: Design, selection and erection of electrical

installations

ČSN EN 60335-1 ed.2:2003 Electric appliances for household and similar purposes - Safety - Part 1:

General requirements

ČSN EN 60335-2-102:2007 Electric appliances for household and similar purposes - Safety - 2-102:

Particular requirements for appliances burning gas, oil and solid fuel

containing electrical connections

ČSN EN 60445 ed.4:2011 Basic and safety principles for man-machine interface, marking and

identification - Marking of conductors with colours or letters and numbers

ČSN EN 61000-3-2 ed.3:2006 Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic

current emissions (equipment with input phase current <= 16 A)

ČSN EN 61000-3-3 ed.2:2009 Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of voltage

fluctuations and flicker in low-voltage supply systems for equipment with

rated current <=16, not subject to conditional connection

E) Regarding noise

ČSN EN ISO 3746:2011 Acoustics - Determination of sound power levels and sound energy levels of

the sources of noise using sound pressure - Survey method with measuring

lateral surface over a reflecting plane

ČSN EN ISO 11202:2010 Acoustics - Noise emitted by machinery and equipment - Determination of

emission sound pressure levels at a work station and at other specified

locations using approximate environmental corrections

F) Regarding machine equipment

ČSN EN 614-1+A1:2009 Safety of machinery - Ergonomic design principles - Part 1: Terminology and

general principles

ČSN EN 953+A1:2009 Safety of machinery - Guards - General requirements for the design and

construction of fixed and movable guards

ČSN EN 1037+A1:2008 Safety of machinery - Prevention of unexpected start up

ČSN EN ISO 12100:2011 Safety of machinery – Basic concepts, general principles for design.

ČSN EN ISO 13857:2008 Safety of machinery - Safety distances to prevent danger zones being

reached by the upper and lower limbs

5.2. Boiler placement options

Boiler placement with regard to the electric network:

24

• The boiler must be positioned so that a plug socket (400V / 50Hz) is always accessible.

• The boiler is connected to the mains with a fixed and flexible power supply cord with standardized plug.

• Protection against electric shock must be made in accordance with valid ČSN EN standard (see chap.

5.1.)

Boiler placement with regard to fire regulations:

1. Positioning on a floor made of incombustible material

• Place the boiler on an incombustible thermally insulating pad exceeding the boiler floor plan on all

sides by 20 mm.

• If the boiler is located in the basement, it is advisable to place it on a substructure at least 50 mm

high. The boiler must stand horizontally so any unevenness of the substructure must be eliminated

by screwing or unscrewing the foot of the fuel container beneath the fuel screw feeder.

2. Safe distance from flammable materials

• The minimum allowable distance of the outer contours of the boiler and flue gas ducting from

flammable materials (see detailed specifications in ČSN EN 13 501-1+A1:2010) during installation

and operation of the boiler must be at least 400 mm.

Boiler positioning with regard to the necessary handling space:

• Basic environment AA5 / AB5 according to ČSN 33 2000-1 ed.2:2009

• The handling space left in front of the boiler must be at least 1000 mm

• Minimum distance between the rear part of the boiler and the wall must be 500 mm

• The gap on the side of the fuel container must be at least 500 mm

• The gap on the side of the boiler body must be at least 500 mm for the possibility to clean the convective

area of the heat exchanger and connection of the ash remover

• The gap above the fuel container must be at least 1000 mm (for BENEKOV S16 and S26 boilers) and

1400 mm (for BENEKOV S51 boiler) to allow full opening of the fuel tank cover.

Fig. No. 20 Placement of the boiler in the boiler room

Boiler positioning with regard to the chimney:

25

• The BENEKOV S16 and S26 boiler is connected to the chimney using a metal pipe with a diameter of

145 or 150 mm.

• The BENEKOV S51 boiler is connected to the chimney using a metal pipe with a diameter of 200 mm.

Fuel placement:

• Pellets are recommended to be stored in their original packaging from the manufacturer (PET bags or

"big bags") in a dry place.

• Do not store fuel behind the boiler or store it next to the boiler within a distance shorter than 400 mm.

• The manufacturer recommends keeping the min. distance between the boiler and fuel at 1000 mm or to

store the fuel in a different room away from the boiler.

The room where the boiler is installed must be provided with permanent intake and outlet of air for

combustion and ventilation. Air consumption of:

- BENEKOV S16 at nominal output is about 45 m3 . h-1

- BENEKOV S26 at nominal output is about 75 m3 . h-1

- BENEKOV S51 at nominal output is about 150 m3 . h-1

According to regulations, an authorized person must perform the connection of the heating system pipeline

or heater heating element pipeline.

NOTE: When connecting the boiler to the heating system the lowest point as close to the

boiler as possible must be equipped with a drain tap.

6. Commissioning of the boiler - instructions for contracted service

organizations

Commissioning can only be performed by a contracted service organization authorized to conduct

this activity.

6.1. Electric connection using via connectors

In the course of putting the boiler into operation there is no need to tamper with any electrical connection of

the boiler’s control unit. Wiring of electrical components of the boiler and peripheral devices (e.g. ash

remover, automatic ignition, etc.) is via the connectors, which allows for quick and easy disconnection from

(or connection to) the boiler control unit.

Depending on the variant and equipment the boiler may be fitted with connectors marked with the following

symbols:

- Fuel feed drive connector

- Fan connector

- Automatic ignition connector

- Ash remover connector

26

- Flue gas exhaust connector

- Circulation pump connector

- Room thermostat connector, respectively the equitherm control

- Spontaneous combustion sensor connector

- Lambda probe connector

- Limit switch connector

Spare connector plugs (e.g. for connecting a room thermostat, circulation pump, etc.) are placed in a

package in the ash tray drawer during transport from the factory. Prior to putting the boiler in operation it is

necessary to fit all these loose connector plugs to the boiler, even if they are not used.

When connecting the connectors you must avoid any confusion. Please connect the connector plugs and

sockets with the identical symbols.

Before connecting the room thermostat, respectively equitherm control, it is necessary to remove bridging

from the plug of the relevant connector. The room thermostat connector, respectively equitherm control can

only be connected to a thermostat with free potentialless contact (eg. SIEMENS REV, HONEYWELL CM…).

No external voltage can be connected to any of these terminals.

Fig. no. 21 Connection dimensions of BENEKOV S16 boiler

27

Fig. no. 22 Connection dimensions of BENEKOV S26 boiler

28

Fig. no. 23 Connection dimensions of BENEKOV S51 boiler

29

6.2. Verification activities before start-up

The following checks must be performed before start-up:

a) Filling the heating system with water

The water used for filling boiler and heating systems must be clear and colourless, without suspended

solids, oil and aggressive chemicals. Its hardness must comply with ČSN 07 7401: 1992 and it is

essential that in case the water hardness does not comply, it must be treated. Even multiple heating of

water with a higher hardness does not stop salt build-up on the walls of the exchanger. 1 mm of calcite

reduces the heat transfer from metal to water at the given point by approximately 10%.

Heating systems with an open expansion tank allow direct contact between the heating water and the

atmosphere. During the heating season the water expanding in the tank absorbs oxygen which increases

corrosion and at the same results in significant water evaporation. Refilling can only be performed with

water treated according to ČSN 07 7401:1992. The heating system must be thoroughly flushed in order to

wash out all impurities.

During the heating season it is necessary to maintain a constant volume of water in the heating system.

When refilling the heating system with water no air must be sucked into the system. The boiler and

heating system water must never be discharged or taken for use except in emergencies like repairs etc.

Water discharge and filling with new water increases the danger of corrosion and scaling.

If it is necessary to refill the heating system with water only do this when the boiler is cold to

prevent damage to the steel heat exchanger.

b) Heating system tightness

c) Connection of emergency fire-fighting equipment to the water distribution system

d) Connection to the chimney - must be approved by a chimney sweeping company

e) Ceramic reflector of BENEKOV S16 and S26 boilers (fig. no. 24, pos. 7) fitted into the combustion

chamber of the burner, i.e. laid on the obliquely welded beams (8) in the boiler body and attached to the

back wall of the combustion chamber.

Ceramic reflector of BENEKOV S51 boiler (fig. no. 25, pos. 7) fitted into the combustion chamber of the

burner, i.e. laid on the horizontally welded beams (8) in the boiler body and attached to the back wall of

the combustion chamber.

f) Electric connection

The assembly completion and heating test must be recorded in the "Guarantee certificate".

6.3. Putting into operation

1. Fire the boiler.

2. Bring the boiler to operating temperature. The recommended operating temperature of the output

heating water is 65 to 80 °C.

3. Check the boiler tightness again.

4. Carry out the heating test according to relevant standards (see the Guarantee certificate)

5. Acquaint the user with the boiler operation - see chapter 7.

6. Make a record in the Guarantee certificate.

30

Fig. no. 24 Section of the combustion chamber of the BENEKOV S16 and S26 boiler

Fig. no. 25 Section through the combustion chamber of the BENEKOV S51 boiler

1. Feeding to the boiler

2. Screw shaft

3. Grate

4. Secondary air tube

5. Ceramic reflector (1 pc)

6. Ceramic reflector beam

1. Feeding to the boiler

2. Screw shaft

3. Grate

4. Ceramic half-ring (2 pcs)

5. Distribution of secondary air

6. Ceramic reflector (2 pc)

7. Ceramic reflector beam

1

2

3

4

5

6

31

8.

7. Boiler operation by user

7.1. Making fire in the boiler

1. Check the water volume in the heating system.

2. Check whether the stop valves between the boiler and the heating system are open.

3. Check the circulation pump functionality.

4. Clean the burner and ash tray drawer.

5. Fill the container with prescribed fuel - see Chap. 3. If the container is equipped with a lid, close the

container after refilling in order to avoid potential false air intake into the burner through the screw

feeding device.

6. Connect the boiler to the mains (400V/50Hz) via power cord with plug.

7. Put the control unit into operation (see separate control unit instruction manual).

8. If the boiler is equipped with automatic ignition (optional), leave the boiler without intervention. The

control unit evaluates the status of the boiler and makes fire (see separate control unit instruction

manual). During the boiler firing and operation the door must be permanently closed.

9. If the boiler is not equipped with automatic ignition, it is necessary to make fire manually (see

separate control unit instruction manual). Using the control unit manual mode deliver the fuel into the

combustion chamber of the boiler. Leave the screw feeding device switched on until the fuel appears in

the burner (2 cm below the edge of the grate). Subsequently switch the screw off, place fire setting

material on the fuel (eg. paper, dry wood chips, PEPO, solid alcohol or other material intended for this

purpose), ignite it and let it flame up (approx 1-2 minutes). Then add a small amount of prescribed fuel

with a shovel to the fire setting material and switch on the fan. In the event that the fire is extinguished,

repeat the manual firing procedure. Close the door and let the fire flame up well (about 3-5 minutes).

1

2

3

4

5

6

7

32

7.2. Boiler operation

After fuel flame-up the boiler switches (see separate control unit instruction manual) to automatic operation,

which includes the fan, as well as cycling of the fuel screw feeder. The control unit display visualizes the

basic data regarding the boiler operation.

The boiler operation is automatic until the desired water temperature is reached. As soon as the required

water temperature is reached, the boiler automatically switches to the "attenuation" mode where it remains

until the temperature drops below the medium heating setpoint.

During a power outage (400 V, 50 Hz) the boiler control unit remembers its status and restores to this when

the power returns.

If the heating water temperature exceeds 95 °C, the emergency thermostat will respond to shut down the

boiler irrespective of the control unit. When you turn off the emergency thermostat the control unit indicates

overheating.

The emergency thermostat can be switched on only when the temperature falls below the set value by about

20 °C. This is done by unscrewing the black cap on the emergency thermostat and pushing the colour

button. The black cap must subsequently be restored to its place.

To prevent unwanted switching of the safety thermostat due to the thermal inertia of the boiler, it is

recommended to operate the boiler at outlet heating water temperatures up to 80 °C.

In case of repeated switching off of the boiler by the emergency thermostat, the boiler must be shut down

and the user must determine the cause of the repeated overheating.

7.3. Boiler shutdown

Before the boiler is shut down, it is necessary to use manual control to push the hot fuel from the feed area

of the boiler and burner into the ash tray drawer. This is not necessary for short repairs when an operator is

present.

IMPORTANT ADVICE:

• This appliance is not intended for use by persons (including children) whose physical, sensory

or mental disability or lack of experience and knowledge prevents them from using the

appliance safely.

• It is unacceptable to leave children unattended near the boiler when it is in operation.

• If there is a danger of combustible vapours or gases building-up in the boiler room or there is

work involving a temporary fire or danger of explosion (gluing of floorings, painting with

combustible paints, etc.) taking place in the boiler room, the boiler must be shut down before

beginning any work.

• When transporting fuel into the combustion chamber before firing, it is necessary to check the

amount of fuel in the burner visually, not by inserting hands into the burner. There is a risk of

injury from the rotating screw shaft.

• It is forbidden to fire the boiler using flammable liquids.

• Observation of the flame during boiler operation is possible by opening the door. If it is

necessary to open the door during boiler operation (e.g. for removal of ash from the ash tray

drawer), it should be noted there is an increased danger of sparks and smoke development in

the boiler room. If this happens the door must be closed immediately. The door must only be

opened with caution during boiler operation, i.e. slightly ajar at first then wait until the exhaust

gases from the combustion chamber are extracted and only then open it completely.

• During operation it is forbidden to overheat the boiler in any manner.

• It is not allowed to place any articles made of flammable materials on the boiler or within a

distance smaller than the safe distance from it (see chap. 5.2.).

33

• All flammable substances must be at a minimum distance of 1500 mm from the boiler when

removing ash from the boiler. The ashes must be put into incombustible containers with lids.

• When operating the boiler at a temperature below 60 °C, the steel boiler body is covered with

dew and so-called low-temperature corrosion occurs, which reduces its service life. Therefore,

the boiler must be operated at a temperature of 60 °C and higher.

• After the heating season, it is necessary to thoroughly clean the boiler including the flue gas

duct. The boiler room must be kept clean and dry.

• It is forbidden to interfere with the boiler structure and wiring.

• The boiler is operated with a fan.

• The boiler is operated at an overpressure at the flue gas outlet.

• The boiler operates in conditions without condensation.

7.4. Residual risks and their prevention

Risks arising during operation of the boiler under the conditions of expected use and logically foreseeable

misuse have been minimized using currently available technology.

Despite its design, structure and technical features, during the operating life of a boiler certain residual risks

remain.

These risks in particular result from inattention by the boiler operator and failure to observe safety

rules during operation.

To further reduce these risks and ensure your safety we bring to your attention certain residual risks that

cannot be removed by any technical design.

a) Electrical risks

Mounting, maintenance and repairs of electrical parts of the boiler must be carried out only by

professionally qualified personnel in accordance with applicable technical regulations and standards;

Supply wiring must comply with applicable regulations;

Power supply cable and wiring of the boiler must be regularly checked and maintained in the

prescribed condition;

In the event of any damage to electrical equipment, the boiler must be shut down, unplugged from

the mains and a qualified repair must be undertaken;

It is forbidden to interfere with the wiring of safety circuits, or perform any unauthorized interventions,

which are related to the equipment’s safety and reliability.

b) Thermal risks

The boiler must not be exposed to higher working pressures than prescribed;

It is forbidden to overheat the boiler;

The boiler must be protected against low-temperature corrosion by a suitable connection with an

automatic return temperature protection;

The boiler can burn only specified fuel;

It is prohibited to store flammable liquids near the boiler;

Minimize the risk of ignition by setting suitable attenuation parameters;

During boiler operation pay maximum attention to the risk of burns from sources of heat.

c) Risks posed by fuel handling

Handling fuel results in emission of solid particles. Therefore, the operator should wear appropriate

protective equipment according to the degree of dust generation;

Because it is a fuel, it is necessary to observe appropriate fire regulations and keep a suitable

portable fire extinguisher accessible.

d) Ergonomic risks

The boiler must stand horizontally in the boiler room;

It is forbidden to put hands into the screw feeder;

All doors, lids and covers must be completely closed during boiler operation.

34

8. Boiler maintenance

NOTE: Before performing maintenance and cleaning the boiler and/or feeder mechanism, it is

necessary to make sure the boiler is disconnected from the power supply (plug pulled out of the

socket). Risk of injury!

1.) It is necessary to ensure timely refuelling. If a small amount of fuel remains in the container, it must be

refilled immediately to prevent extraction of "false air" and a smoked container.

2.) If the boiler is correctly adjusted, the ash has the form of a fine grey powder, which accumulates in the

ash tray drawer. The combustion compartment has self-cleaning design and in the course of normal

operation the boiler’s ash tray drawer has to be emptied once or twice a week. It is necessary to use

protective gloves for this activity.

3.) In continuous operation of the boiler it is recommended to clean the heat transfer area of the combustion

chamber or the exchanger fins once a week. The heat transfer surfaces can be subject to clogging,

which can greatly affect the heat transfer and thus the efficiency of the boiler. Occasional cleaning of the

inside of the grate (on a monthly basis) should not be forgotten. Its clogging impairs the flow of

combustion air to the burner nozzles. The boiler must be shut-off by the main switch at least 1 hour

before cleaning the grate. After the heating season the entire boiler must be carefully and completely

cleaned.

4.) The minerals contained in the fuel can form hard deposits during operation in the area of the burner. This

can subsequently cause a complete blockage of the screw shaft of the feeding mechanism. To avoid the

risk of this phenomenon, it is recommended to check the burner zone at least monthly and in the event

of hard deposits, mechanically remove any stuck material.

5.) It is further recommended to perform occasional external cleaning of drives and fans. Cleaning must be

done using a dry brush. The boiler must be disconnected from the power supply during this time.

6.) A refractory ceramic reflector is located above the boiler burner. It does not require any special attention.

Any fly ash deposited on the surface of the reflector can be regularly removed, but it does not affect its

function.

7.) For a reliable operation of the turnstile during fuel feeding into the screw feeder, it is necessary to

maintain proper tension of the chain, i.e. the deflection in the middle between the sprockets must be in

the range of 6 to 10 mm. If the deflection is bigger, the chain must be replaced. When checking the

tension and handling of the chain the boiler must be shut down. Risk of hand injury!

8.) In case of a screw fuel feeder blockage the two motors are protected against damage by the thermal

contact (working temperature of the fuel feeder motor is up to 85 °C), which after exceeding the

critical temperature shuts down both feeder motors and the fan(s). If this happens, the boiler must be

shut down and repaired.

9.) Since pressurising occurs in the burner area during fan operation, it is necessary to ensure perfect

tightness of the boiler (boiler door, the top cover of the boiler body, etc.).

10.) Occasionally perform a visual check of the emergency fire-fighting equipment.

11.) In the event of an emergency (electricity outage for long periods, etc.) or if fuel burns through the

increase in temperature opens the thermostatic valve and any fuel is extinguished with water from the

water main. Before restarting the boiler it is necessary to remove wet fuel, and fire the boiler in a

standard manner (see chap. 7.1.).

12.) The gearboxes are filled with synthetic oil in compliance with factory standards therefore no further

maintenance is required.

35

9. Troubleshooting

If you have problems with the operation of the boiler, try some of the following solutions:

SYMPTOM CAUSE SOLUTION

The boiler is not

connected to the mains.

Connect the boiler to the mains (400V/50Hz) via

power cord with plug.

The display does not

show any data.

Boiler controller failure. Replace the boiler controller.*

Boiler drive cable Is

disconnected (or

damaged).

Connect (or replace) the boiler drive cable.*

Boiler drive is damaged. Replace the boiler drive.*

Screw feeding device

does not work.

There was a motor

overheating and thus the

motor thermal protection

was activated.

Let the motor cool, after cooling the motor will

restart automatically.

The fuel feeder contains

an obstacle (stone, etc.).

Demount the fuel feed screw and remove the

obstruction. Reassemble the feeder.*

The fuel contains a

substantial quantity of

dust.

Remove unsuitable fuel from the boiler, refill the

container with prescribed fuel.

Repeated activation of the

motor thermal protection.

The alignment of the

drive, screw shaft and

burner is not correct.

Disassemble the fuel screw feeder, clean and

reassemble it with emphasis on ensuring the

alignment of the individual components.*

The container does not

contain fuel.

Refill the container with prescribed fuel.

Overall wear of the screw

shaft.

Replace the screw shaft.*

The screw shaft rotates,

though the fuel is not

transported into the

combustion chamber.

The turnstile chain was

damaged.

Replace the turnstile chain.*

Boiler fan cable is

disconnected (or

damaged).

Connect (or replace) the boiler fan cable.* Boiler fan does not work.

The fan is damaged. Replace the boiler fan.*

The fan was clogged by

dust.

Clean the boiler fan.* The fan is noisy in

operation.

The fan bearings are

worn.

Replace the entire boiler fan.*

The fan does not rotate

during boiler modulation

at the lowest output

values.

The set values of the fan

speed are too low.

Increase the fan speed on the boiler controller

so as to guarantee its smooth operation.

Water from the

emergency fire-fighting

equipment leaked into the

fuel feeder.

The fuel burnt through to

the fuel feeder, which

activated the thermostatic

valve.

Remove wet fuel from the feeder, fill the

container with new dry fuel and start-up the

boiler.

Water from the

emergency fire-fighting

equipment leaks into the

fuel feeder.

The thermostatic valve on

the feeder leaks.

Replace the thermostatic valve.

The boiler is filled with wet

fuel.

Refill the container with dry fuel. The walls of the fuel tank

are covered with droplets

of water.

The temperature in the

boiler room is low (about

12 °C or less)

The boiler room requires a higher air

temperature (boiler room wall insulation,

installation of heating radiator to the boiler room,

etc.).

A short time passed after

firing in the boiler.

Let the boiler thoroughly flame up. The boiler cannot reach

the rated output during

operation.

Fuel dosing is set to a

lower output.

Adjust the fuel dosing according to the control

unit instruction manual.

36

The boiler uses nonprescribed fuel (high

humidity, lower calorific

capacity, etc.)

Refill the container with prescribed fuel.

The boiler is clogged with

soot.

Clean the heat transfer surfaces of the boiler

body.

The boiler is overheating. Reduce fuel dosage.

High chimney draft. Install a chimney flue draw limiter (this activity

must be performed by a specialized company).

Ceramic reflector is not

installed in the boiler

body.

Install a ceramic reflector according to the

instruction manual.

The flue gas temperature

is higher than specified in

the instructions.

The firing flap in the boiler

body is open.

Close the firing flap using the cleaner lever and

firing flap and secure it with a locking screw with

a plastic head.

Low chimney draft. Have a chimneysweeper check the value of the

chimney draft. If the measured value is less than

the value required (see instructions), it is

necessary to make adjustments to the chimney.

The boiler door and / or

the top cover of the boiler

body and / or the fuel tank

cover is not closed

properly.

Close the boiler door and / or the top cover of

the boiler body and / or the fuel tank cover

properly.

The sealing cord of the

boiler door and / or the

top cover of the boiler

body are worn

(damaged).

Replace the worn (damaged) sealing cords.*

Smoke appears in the

boiler room or fuel

container.

The fuel container is

empty.

Refill the container with prescribed fuel.

Low volume of

combustion air.

Increase the boiler fan output (see the control

unit instruction manual).

The boiler is overheating. Set the boiler output to nominal value (see the

control unit instruction manual).

The fan is damaged. Replace the boiler fan.*

The boiler body gets

clogged with soot after a

short time.

The grate is clogged with

ash and dust.

Clean the grate.

Caking ash on the grate. Other than prescribed fuel

is used for combustion.

Fill the container with prescribed fuel (see chap.

3).

Fuel dosing is not set

correctly.

Reduce the dosage of fuel in the burner (see the

control unit instruction manual).

Moist fuel is used for

combustion.

Refill the container with prescribed (dry) fuel.

Emergence of a

significant part of

unburned fuel in the ash

tray drawer.

The output of the fan is

adjusted incorrectly and

the air flow blows fuel out

of the burner.

Reduce the boiler fan speed (see the control unit

instruction manual).

* - This activity can only be performed by a service organization trained and authorized by BENEKOVterm

s.r.o.

10. Guidelines for sustained compliance with the environmental

parameters of the product

Continuous environmentally friendly operation of the boiler requires full compliance with the provisions of this

manual, especially:

37

• Burn only fuel whose parameters are guaranteed by the manufacturer for fuel within the range specified

in table 4, chap. 3.

• Comply fully with the provisions of chap. 7 and 8.

11. Instructions for product disposal after the end of its service life

Since the product is made of common metal materials, it is recommended to dispose of the respective parts

as follows:

- boiler body, casing - via KOVOŠROT

- other metal parts - via KOVOŠROT

- SIBRAL insulation material - standard waste

- ORSIL T insulation material - standard waste

- TECHROCK insulation material - standard waste

12. Guarantee and liability for defects

The manufacturer provides a warranty for the boiler for a period of 24 months from the date of sale to

the end user, assuming that it will be used and operated in accordance with the conditions specified

in the instruction manual.

The user is obliged to entrust the boiler installation, commissioning and troubleshooting, going beyond chap.

7 and 8 only to a professional contractual service accredited by the boiler manufacturer BENEKOVterm

s.r.o., otherwise the guarantee is void.

A precondition for the warranty is the installation of the boiler in the heating system so that the

temperature of the water returning to the boiler is monitored AUTOMATICALLY at a minimum value

of 53 °C. This can be achieved through a variety of hydraulic circuits depending on the controller

used in the boiler. More information - see "Technical documentation for installation of automatic

boilers."

The solution should be proposed by a designer, based on knowledge of the complete heating

system.

If the boiler is operated in accordance with the instructions provided in the "Boiler operating and instruction

manual", it does not need any special service interventions.

The "Certificate of quality and completeness of BENEKOV boiler" serves as a "Guarantee Certificate" after

having been completed by contractual service organization.

The boiler must be subjected to regular maintenance - see chap. 8.

The manufacturer shall not be responsible for any loss of profits, goodwill or contracts, or any

incidental, special or consequential damages arising in connection with the use or inability to use

this product.

Each notice of defect must be made immediately after its detection, always in writing or by

telephone. In the event of a claim it is always necessary to provide the serial number of the boiler.

The manufacturer shall not admit a claim if the above instructions are not followed.

The guarantee does not apply to cases caused by improper operation of the device, failure to comply

with the technical conditions of operation, normal wear and tear, wilful damage and damage to the

equipment which arose due to unavoidable and natural disasters (fire, water, theft, violent damage,

etc.).

No warranty applies unless the seller duly completed the warranty certificate.

38

The manufacturer reserves the right to make changes to the product, such as innovations, that may

not be included in this manual.

39

BENEKOVterm s.r.o.

Masarykova 402

CZ - 793 12 Horní Benešov

Tel.: +420 554 748 008, Fax :+420 554 748 008

E-mail: info@benekov.com, www.benekov.com

Issue: 2016/06

Loading...

Loading...