Page 1

®

Bendix® WS-24™ AntiLock Wheel Speed Sensor

SD-13-4860

PREVIOUS MODEL WHEEL SPEED SENSORS

90° WS-24

SENSOR

™

STRAIGHT WS-24

SENSOR

CONNECTORS

PACKARD GT

150 SERIES

FIGURE 1 - WHEEL SPEED SENSORS AND CONNECTORS

PACKARD

METRIPACK

150.2 SERIES

DEUTSCH

DTM06 SERIES

PACKARD

METRIPACK 280

(FEMALE)

DESCRIPTION

The WS-24™ wheel speed sensor is an electromagnetic

device used to obtain vehicle speed information for an

antilock controller. When the wheel rot ates, the sensor and

an exciter ring (sometimes called a “rotor” or “tone” wheel)

generate a simple AC signal. This signal is sent to the

controller, which analyzes the data and commands the

antilock system accordingly.

™

SERIES

The WS-24™ sensor fit and function is

compatible with all previous Bendix models.

PACKARD

METRIPACK 280

SERIES (MALE)

DEUTSCH DT04

SERIES

EXCITER RING

STANDARD

ROUND TWO

PIN

MOUNTING

BLOCK

WHEEL

SPEED

SENSOR

Specifically, the speed sensor consists of a coil, pole piece,

and magnet. The exciter is a steel ring or gear-like device

that has regularly spaced high and low spots called "teeth."

The sensor is mounted in a fixed position, while the exciter

is installed on a rotating member so that its "teeth" move, in

close proximity, past the tip of the sensor.

™

The WS-24

sensor is available in both straight and right

angle versions, to accommodate axle/wheel space

limitations. (See Figure 1.)

FIGURE 2 - WHEEL END ABS COMPONENTS

OPERATION

The sensor's magnet and pole piece form a magnetic field.

As an exciter tooth passes by the sensor , the magnetic field

is altered, which generates AC voltage in the sensor coil.

Each time an exciter tooth and its adjacent space move

past the tip of the sensor, an AC voltage "cycle" is generated.

1

Page 2

P/N 5006849

P/N 5012878

PEAK TO PEAK

PREVIOUS

CLAMPING

SLEEVES HAVE

“BW” IN A

DIAMOND

FIGURE 3 - CLAMPING SLEEVES

CORRECT

CLAMPING

SLEEVES

HAVE “BX” IN

A SWOOSH

SYMBOL

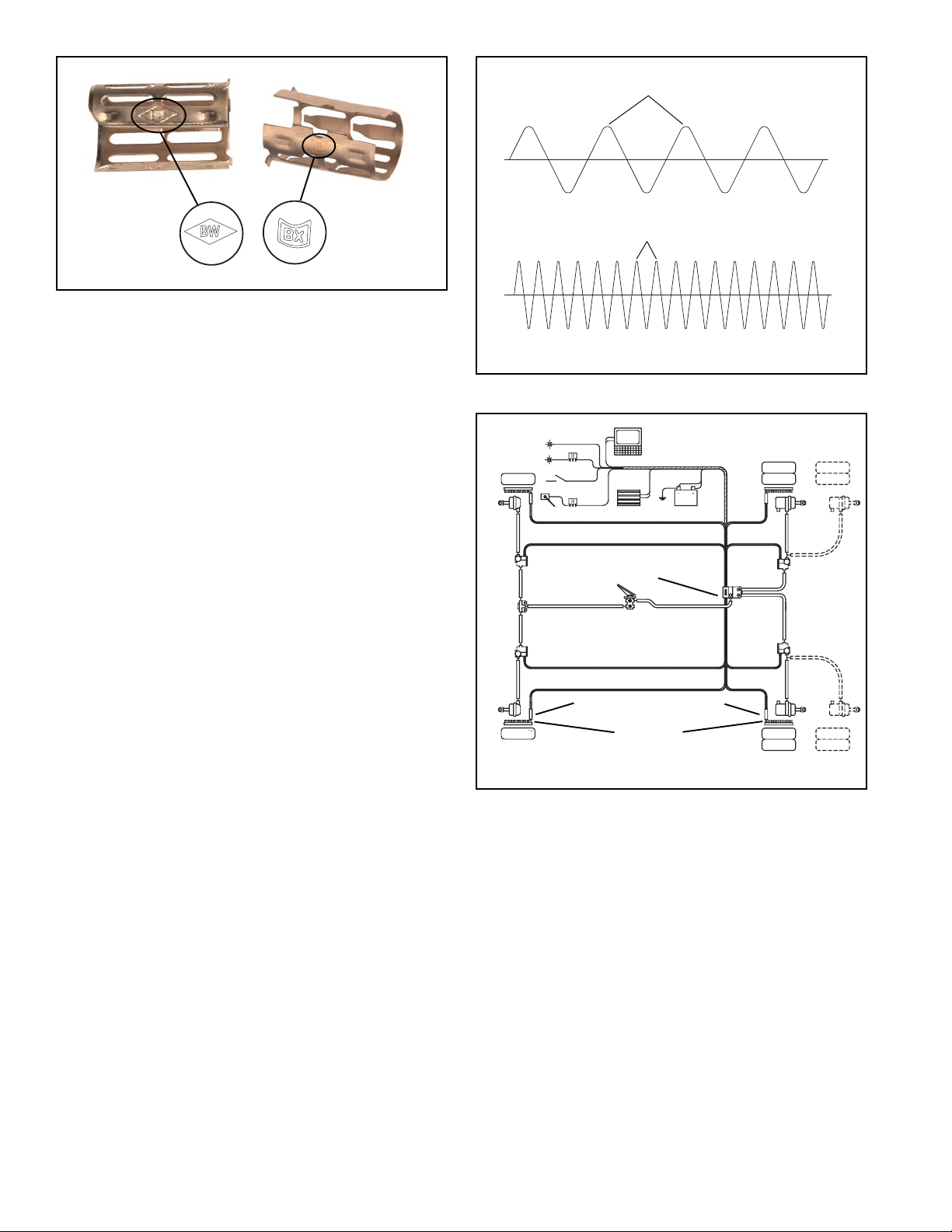

The number of AC cycles per revolution of the vehicle's

wheel depends on the number of teeth in the exciter, which

is programmed into the antilock controller. Using the

programmed data, the controller can calculate "vehicle

speed" by analyzing the frequency of AC cycles sent by the

speed sensor. (The frequency of AC cycles is directly

proportional to wheel speed.) See Figure 4.

AC voltage is also proportional to speed, but voltage is not

used to determine speed. It is only an indication of AC

signal strength. The amount of AC voltage generated by a

specific speed sensor depends on the distance, or "gap"

between the tip of the sensor and the surface of the exciter.

Voltage increases as the sensor gap decreases.

™

Typically , the WS-24

sensor is installed in mounting blocks

that are welded to the axle housing. (See Figure 2.)

™

WS-24

wheel speed sensors are protected by a stainless

steel sheath. They are designed to be used with berylliumcopper clamping sleeves (sometimes referred to as a

“retainer bushing”, “friction sleeve” or “clip”) (See Figure 3).

The clamping sleeve provides a friction fit between the

™

mounting block bore and the WS-24

™

Please note that WS-24

wheel speed sensors must use

sensor.

clamping sleeve p/n 5012878 instead of p/n 5006849 (used

for previous wheel speed sensors). Always use correct

clamping sleeves to avoid problems associated with reduced

retention force, such as sensor movement and resulting

ABS trouble codes.

™

The friction fit allows the WS-24

sensor to "slide" back

and forth under force but to retain its position when the

force is removed.

™

When the WS-24

sensor is inserted all the way into the

mounting block and the wheel is installed on the axle, the

hub exciter contacts the sensor, which pushes the sensor

back. Also, normal bearing play will "bump" the sensor away

from the exciter. The combination of these two actions will

establish a running clearance or air gap between the sensor

and exciter.

LOW SPEED

PEAK TO PEAK

HIGH SPEED

FIGURE 4 - SPEED SENSOR VOLTAGE CYCLE OUTPUT

ANTILOCK CONTROLLER

& RELAY

WS-24™ SPEED SENSORS

EXCITER

FRONT WHEEL

FIGURE 5 - TYPICAL ANTILOCK SYSTEM

WHEELS

REAR WHEELS

TECHNICAL INFORMA TION

Electrical connector 2 Pin.

Sensor resistance 1500-2500 ohms

Output voltage A t a minimum of 100Hz

(approximately 7 mph) the sensor

output across the leads should be

0.400 VAC.

Sensor gap 0 to 0.015 inch.

Sensor body Outer diameter is 0.627 inch.

Normal resistance 1500-2000 Ohms.

range across pins (Note: Previous model WS-20

at room temperature sensor was rated at 2000-2500

Ohms.)

™

2

Page 3

SPEED SENSOR MOUNTING

WS-24™ SPEED

SENSOR (90 DEG.)

HUB ASSEMBLY

FIGURE 6 - WS-24™ WHEEL SPEED

SENSOR INSTALLATION

BLOCK

100 TOOTH

(TYPICAL) SPEED

SENSOR EXCITER

RING

MOUNTING

BLOCK

BRAKE DRUM

MAX. GAP

(SENSOR TO EXCITER)

.015 INCHES

WS-24™ SPEED

SENSOR

100 TOOTH

EXCITER

RING

PREVENTIVE MAINTENANCE

1. Every 3 months; 25,000 miles; 900 operating hours; or

during the vehicle chassis lubrication interval, make the

visual inspections noted in "SERVICE CHECKS" below .

2. Every 12 months; 100,000 miles; or 3600 operating

hours, perform the OPERA TIONAL TEST in this manual.

SERVICE CHECKS

Check all wiring and connectors. Make sure connections

are free from visible damage.

Examine the sensor. Make sure the sensor, mounting

bracket, and foundation brake components are not

damaged. Repair/replace as necessary.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear

safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When working

in the engine compartment, the engine should be

shut off and the ignition key should be removed.

Where circumstances require that the engine be in

operation,

prevent personal injury resulting from contact with

EXTREME CAUTION should be used to

moving, rotating, leaking, heated or electrically

charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

ANY work on the

vehicle. If the vehicle is equipped with an

™

AD-IS

air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power from

the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all system

pressure has been depleted.

®

8. Use only genuine Bendix

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent size,

type and strength as original equipment and be

designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

3

Page 4

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make certain

all components and systems are restored to their

proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

REMOVAL

1. Unplug the cable assembly connector from its lead. Lift

the lock tab and pull on the connector until it disengages.

2. Gently pry the sensor and clamping sleeve from the

mounting block.

INSPECTION

Look for any visible damage to the sensor, cable assembly,

connector, mounting block, and foundation brake. Repair

or replace any damaged components. Make sure the block

is securely attached to the axle housing.

in use. (See the Service Data Sheet for the antilock

controller for this procedure.)

2. Proceed to the sensor in question and inspect its wiring

connector. Disconnect the connector and test the

resistance between the pins ON THE SENSOR.

Normal resistance range across pins at room temperature

should be 1500-2000 Ohms. (Note: Previous model

™

WS-20

Individually test the resistance of each pin to vehicle ground

and note there is NO CONTINUITY.

If the resistance readings are as shown, the wire harness

leading to the modulator may require repair or replacement.

Before attempting repair or replacement of the wire harness,

refer to the test procedures specified for the antilock

controller in use for possible further testing that may be

required to substantiate the wire harness problem. If the

resistance values are NOT AS ST A TED, replace the sensor .

Resistance could be as low as 1100 Ohms or as high as

3300 Ohms if wheel end has recently been exposed to

extreme temperature.

sensor was rated at 2000-2500 Ohms.)

SENSOR INST ALLA TION

1. For increased corrosion protection we recommend that

a high-temperature rated silicon- or lithium-based grease

be applied to the interior of the mounting block, the

sensor, and to a new clamping sleeve.

2. Install the new clamping sleeve fully into the block, with

the retaining tabs toward the inside of the vehicle.

3. Gently push (DO NOT STRIKE) the sensor into the

mounting block hole until it bottoms out on the face of

the tone ring. Secure the cable lead wire to the knuckle/

axle housing 3-6 inches from the sensor.

4. Apply a moderate amount of dielectric non-conductive

grease to both the sensor connector and harness

connector.

5. Engage the connectors, and push together until the lock

tab snaps into place.

NOTE: It is important for the wheel bearings to be adjusted

per the manufacturer's recommendations.

Excessive wheel end play can result in antilock

function shutdown in cases where the sensor is

pushed too far away from the tone ring.

ELECTRICAL TESTING

1. Before testing the speed sensor, its location on the

vehicle should be confirmed using the Troubleshooting

or Start Up procedure for the specific antilock controller

OPERA TIONAL TESTING

To test sensor operation, one of two tests can be done.

TEST 1

Drive the vehicle in a safe area to a minimum speed of 15

mph. Be sure to apply the vehicle brakes several times.

Then stop the vehicle and check the LED display on the

Bendix controller. If the dash light is out and the sensor

LED(s) are not illuminated, the sensor is installed properly.

TEST 2

Disconnect the connector from the sensor's socket or from

the attached lead. Raise the vehicle wheel so it rotates

easily . Connect a volt-Ohm meter (set to read Volts AC) to

the pins on the sensor or lead and spin the wheel. If the

wheel is spun at 1/2 revolution per second the reading

should be greater than 0.250 VAC.

If the sensor fails to operate as described, check the wiring

from the controller to the sensor. Make sure all connectors

are properly and tightly installed. Check for frayed or

damaged wires and check and/or reset the sensor air gap

(distance from sensor tip to exciter ring) as described in

this manual. For additional troubleshooting information, see

the troubleshooting procedure for the specific antilock

system in use.

4

BW2364 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 9/2004. Printed in U.S.A.

Loading...

Loading...