Page 1

®

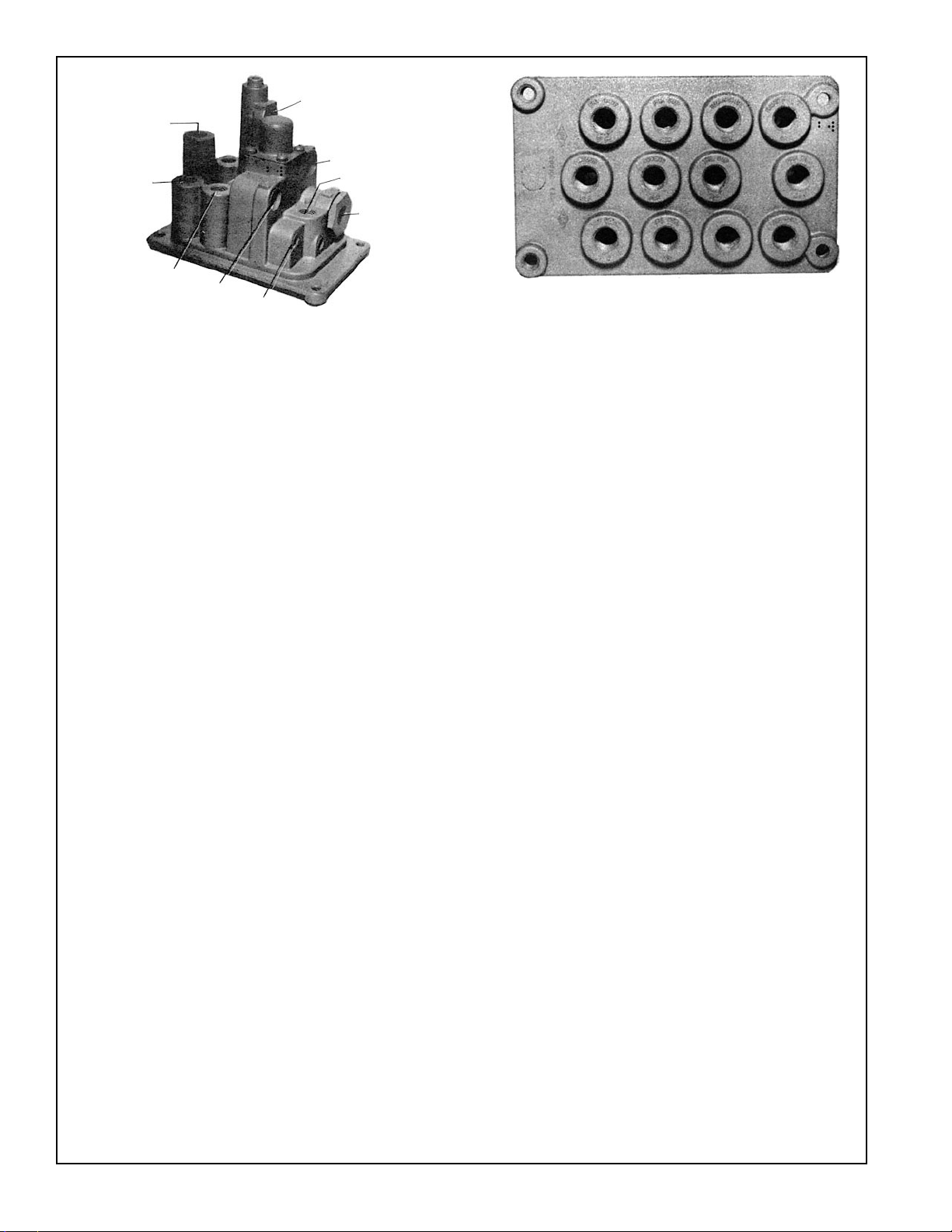

Bendix® VM-3™ Firewall Manifold

DESCRIPTION

The VM-3™ is a control manifold serving as a manifold unit

for air passages between cab and engine compartment and

housing a double check valve and PR-4

valve.

OPERATION

1. The double check valve receives supply air from the rear

(primary) supply system, through port No. 3 on Fig. 1,

and front (secondary) supply system, through port No.

1 on Fig. 1, and delivers whichever is higher in pressure

to the spring brake system and through another port to

the trailer supply through the dash mounted PP-7™ tractor

protection control valve.

2. The PR-4™ pressure protection valve receives supply air

from the front (secondary) supply port and supplies

protected air to three ports, one on the engine side and

two on the cab side. The PR-4™ valve will deliver air to

these ports only after the front supply system has built

up to at least 60 psi.

3. Supply air for the trailer control hand valve is taken from

a port inside the cab supplied from the rear (primary) air

supply.

The location and function of the various ports are shown in

Fig. 1 for the engine side of the VM-3™ manifold and in Fig.

2 for the cab side. The chart shown on Fig. 1 explains the

purpose and function of each port on the engine side and

the chart shown on Fig. 2 the cab side.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

™

pressure protection

SD-03-3410

NO.3

NO.9

NO.2

NO.8

NO.7

NO.6

NO.5

FIGURE 1 - ENGINE SIDE

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

NO.4

NO.1

™

1

Page 2

NO.8

NO.9

NO.3

NO.2

NO.4

NO.1

1234

5

67

8

NO.7

NO.6

NO.5

ENGINE SIDE FIGURE 1

Port Ident. on

No. Casting Function

1 Frt. Sup. Supply from No. 2 circuit reservoir.

Blue

2 Park Sup. Delivers air from double check valve

Red area to spring brake relay valve (R-8).

3 Rear Sup. Supply from No. 1 circuit reservoir.

Green

4 Rad. Fan Delivers protected air supply from

Blk. PR-4 valve. Suggested use - air

operated fan clutch.

5 Diff. Lock Connects directly to port No. 9 (Fig.

Blk. 2) in cab. Suggested use - manifold

connection to differential lockout

mechanism. This is a 90

0

pass-through

passage.

6 Trl. Sup. Connects directly to port No. 10 in

Yel. cab. Suggested use - deliver air from

trailer supply valve (such as BW PP-7)

to trailer. This is a 90° pass-through

passage.

7 (None) Connects directly to port No. 11 in

cab. Suggested use - any auxiliary

manifold function. This is a straight

through passage.

8 Air Rest. Connects directly to port No. 12 in

Blk. cab. Suggested use - air cleaner

restriction gauge. This is a straight

through passage.

9 Prk. Del. Connects directly to port No. 8 (Fig.

Red 2) in cab. Suggested use - deliver air

from park control valve to spring

brake control valve (SR-1™ valve).

This is a straight-through passage.

10 Spg. Brk. Connects to secondary circuit reservoir

Rest. - Grn. and to port No. 4 (Fig. 2) in cab.

Suggested use - supplies secondary

reservoir air to the balance port of the

SR-1 spring brake control valve.

910

11 12

CAB BULKHEAD SIDE FIGURE 2

Port Ident. on

No. Casting Function

1 Frt. Gauge Connects to gauge for No. 2 circuit

Blue reservoir.

2 Prk. Sup. Supplies air from double check valve

Red to park control valve.

3 Rear Gauge Connects to gauge for No. 1 circuit

Green reservoir.

4 Hand Brake Supplies air from No. 2 circuit reservoir

Supply to trailer hand control valve in

Green cab. Connects with No. 10 on engine

5 Access Supplies protected air from PR-4

side.

Blk. to any accessory control in cab.

6 Access Supplies protected air from PR-4

™

valve

™

valve

Blk. to any accessory control in cab.

7 Trl. Sup. Supplies air from double check valve

Red to trailer supply valve (tractor

protection).

8 Prk. Del. Receives air from delivery of park

Red control valve to deliver to SR-1

™

spring

brake control valve. Connects with No.

9 on engine side.

9 Diff. Lock Receives air from delivery of differen-

tial lockout control valve. Connects

with No. 5 on engine side.

10 Trl. Del. Receives air from trailer supply valve

(tractor protection) to supply trailer.

Connects to No. 6 on engine side.

11 (None) Auxiliary manifold for any accessory

function connects to No. 7 on engine

side.

12 Air Rest. Suggested use - air cleaner restriction

Blk. gauge. Connects with No. 8 on engine

side.

2

Page 3

3

1

2

3

FIGURE 3

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the VM-3

manifold should be inspected every year or 3600 operating

hours, whichever comes first, for proper operation. Should

the VM-3™ manifold not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

4

FIGURE 4

SERVICE CHECKS

OPERATING AND LEAKAGE CHECKS

1. Start engine and charge both sides of dual system.

2. Stop engine, drain the front brake reservoir and disconnect

tube fitting at port No. 1 in Fig. 1, identified as Frt.

Sup. - Blue. Excessive leakage would indicate a faulty

double check valve.

3. Restore and recharge both systems. Drain the rear brake

reservoir and disconnect the fitting at port No. 3 in Fig.

1, identified as Rear Sup. - Grn. Excessive leakage would

indicate a faulty double check valve.

4. After closing the drain cock and restoring the plumbing

for the front reservoir remove the fitting at port No. 4 in

Fig. 1. Start the engine and observe front dash gauge.

Stop the engine when the gauge shows 40 psi. Excessive

leakage from port No. 4 would indicate a faulty PR-4

valve. Restart engine and observe front gauge. Air should

start to blow from port No. 4 at 60-75 psi, indicating

PR-4™ valve is operating correctly. With engine shut off,

PR-4™ valve should close and retain at least 60 psi in

front reservoir.

If the VM-3™ manifold does not function as described above

™

or leakage is excessive, it is recommended that it be returned

to the nearest Bendix authorized distributor for an exchange

or a replacement unit. If this is not possible, the unit can be

repaired with genuine Bendix parts in which case the following

should prove helpful. A field maintenance kit is available under

pc. no. 289062.

™

3

Page 4

DISASSEMBLY

ASSEMBLY

Block the wheels and drain the air brake system. Remove

air lines and remove manifold from vehicle.

Remove the large cap nut at port No. 1 and remove the

double check shuttle.

™

Remove the four machine screws from the PR-4

valve cover.

(Caution - the cover is spring loaded.) Remove the PR-4

valve piston assembly. Do not attempt to remove the retaining

ring and stem from the piston.

Before assembly, lubricate all o-rings, bores and mating

surfaces with BW-650M lubricant pc. no. 291126 (Dow

Corning 55M). Replace any worn or deteriorated o-rings and

shuttle, item 2 in Fig. 5, if necessary.

Install shuttle in guide in body and install cap nut

™

After cleaning and lubricating, assemble the PR-4™ valve

section, replacing o-ring item 3 and inlet exhaust valve item

4 in Fig. 6 as required.

Replace valve on vehicle and check per operating and

leakage tests.

BW1576 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 4/2004 Printed in U.S.A.

4

Loading...

Loading...