Page 1

®

Bendix® TP-5™ Tractor Protection Valve

DESCRIPTION

SD-03-3655

The Bendix® TP-5™ tractor protection valve is a panel or cross

member mounted unit designed to replace the Bendix® TP-3®

valve plus two additional double check valves and quick

release functions. It may be used in conjunction with the

Bendix® MV-3® module or independently. It contains a service

line shut-off valve with exhaust function, a service line quick

release valve and two double check valves.

OPERATION

The function of the TP-5™ valve is to receive all pneumatic

signals pertinent to the operation of the trailer brake system,

transmit the same to the trailer and also to protect the

tractor air supply in case of separation of the connecting

lines to the trailer.

TRACTOR PROTECTION PORTION

Air from the trailer supply control valve in the cab, such as

the MV-3® module, enters at the trailer supply delivery port

and passes out the trailer supply port and simultaneously

acts upon the service line shut-off piston moving the

service line inlet valve off its seat and opening the service line

3/8" PTC

REAR SERVICE

1/4" PTC

STOP

LIGHT

SWITCH

3/8" NPT

TRAILER CONTROL

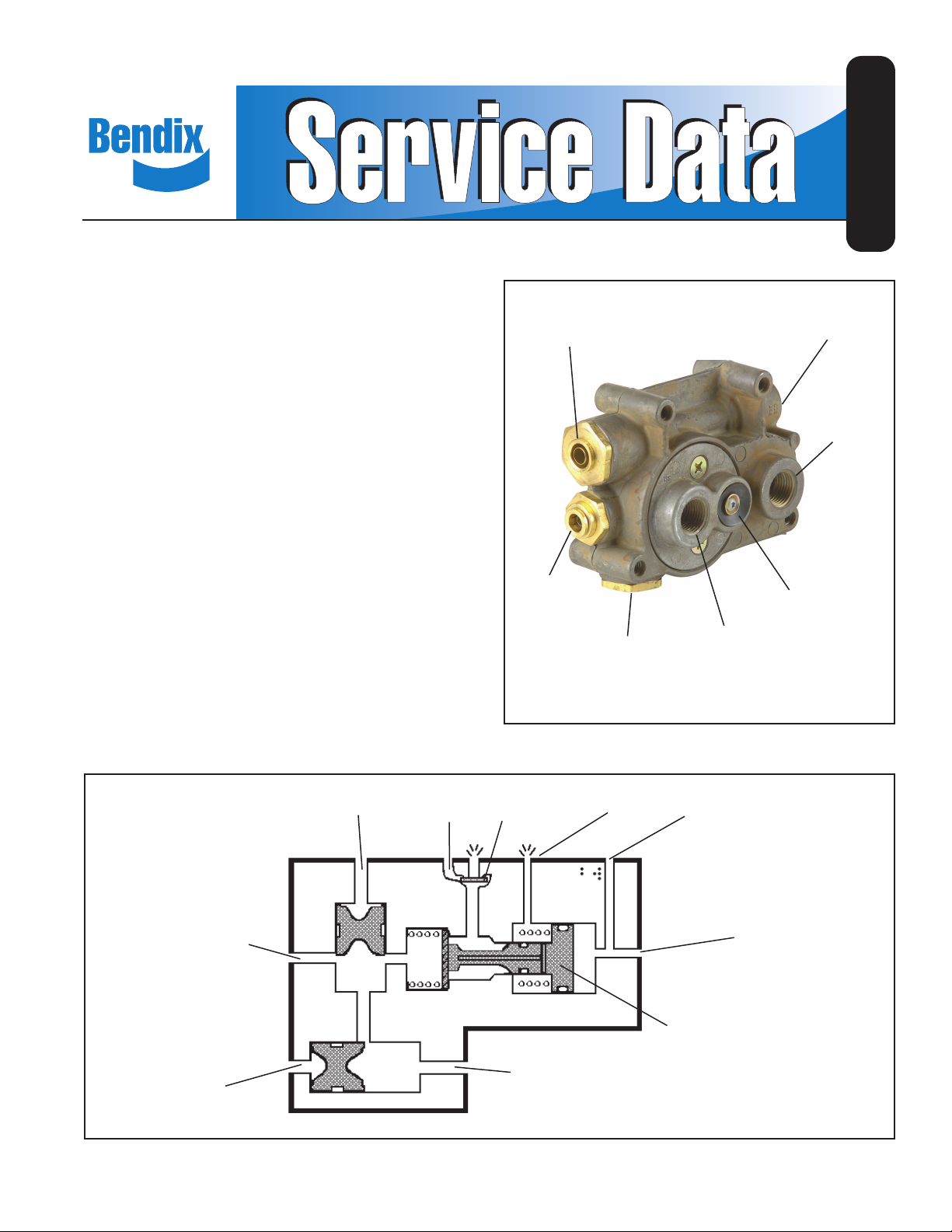

FIGURE 1 - BENDIX® TP-5™ TRACTOR PROTECTION

VALVE EXTERIOR

1/2" NPT

TRAILER

SERVICE

3/8" NPT

FRONT SERVICE

1/2" NPT

TRAILER

SUPPLY

EXHAUST

FROM TC VALVE

STOP LIGHT

SWITCH

FROM REAR

SERVICE

FIGURE 2 - BENDIX® TP-5™ TRACTOR PROTECTION VALVE SCHEMATIC DIAGRAM

TO TRAILER

SERVICE

SERVICE

LINE QRV

FROM FRONT

SERVICE

VENT

TO TRAILER

SUPPLY

(EMERGENCY)

FROM TRAILER

SUPPLY VALVE

(E.G. MV-3® MODULE)

SERVICE LINE

SHUT-OFF

PISTON

1

Page 2

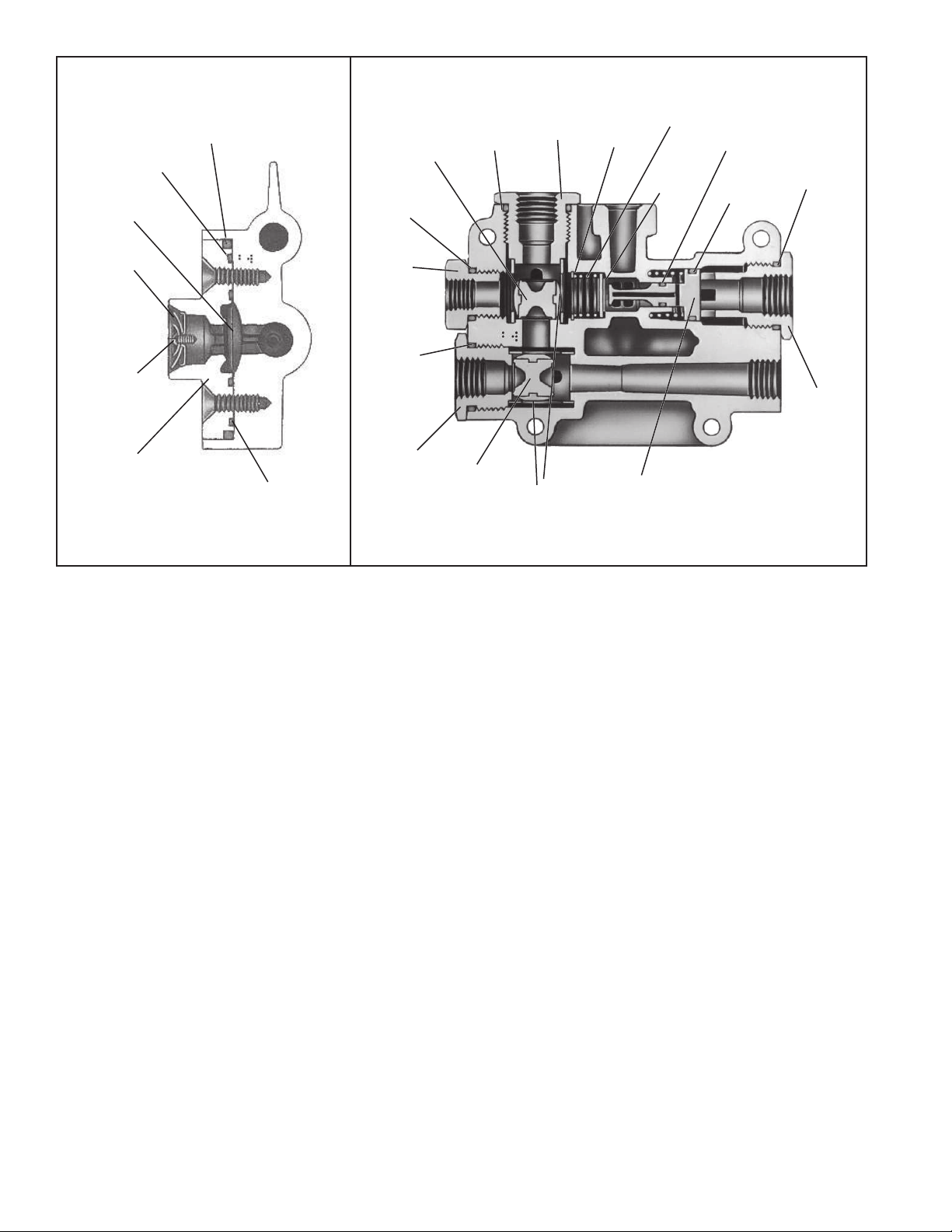

O-RING

(4)

DIAPHRAGM

(1)

O-RING

(3)

INSERT

O-RING

(5)

(9)

O-RING

(7)

CAP

NUT

(13)

RETAINING

RING

(15)

SPRING

(16)

VALVE

(2)

O-RING

(6)

O-RING

(5)

O-RING

(7)

EXHAUST

CHECK

VALVE

DIAPHRAGM

(8)

#6

TORX/

PN

SCREW

(17)

COVER

(18)

O-RING

(4)

FIGURE 3 - BENDIX® TP-5™ TRACTOR PROTECTION VALVE

END SECTIONAL VIEW

CAP

NUT

(10)

O-RING

(7)

CAP

NUT

(11)

DOUBLE

CHECK

SHUTTLE

passage (see Figure 2). With common air to the supply side

and service side of the manifold the valve should open at

approximately 45 psi.

If the Bendix

®

MV-3® tractor supply valve is manually or

automatically moved to the exhaust position, the service

line shut-off valve will close at approximately 10 psi and

the exhaust passage in the plunger will vent the trailer

service line.

DOUBLE CHECK VALVES

The two double check valves in the Bendix® TP-5™ valve,

as seen in schematic view Figure 2, serve to pick up the

highest pressure service signal from either the tractor front

brake circuit, rear brake circuit or TC valve signal, operating

the trailer brakes accordingly. The stop light switch port

also picks up this signal and actuates the stop light switch.

SERVICE LINE QUICK RELEASE VALVE

The trailer service line port is located in the cover, as seen

in Figure 3. This cover also houses a quick release valve.

Diaphragm (Item 1 in Figure 3) seals off the exhaust port

on application and upon release of service line application,

permits the trailer service line air to exhaust through the

exhaust port, thus permitting faster release times for trailer

brake release.

CAP NUT

DOUBLE

(9)

CHECK

GUIDES

(14)

FIGURE 4 - BENDIX® TP-5™ TRACTOR PROTECTION VALVE

SIDE SECTIONAL VIEW

SERVICE LINE

SHUT-OFF

PISTON

(19)

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions; as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the TP-5

valve should be inspected every 6 months or 1500 operating

hours, whichever comes fi rst, for proper operation. Should

the TP-5™ valve not meet the elements of the operational

tests noted in this document, further investigation and

service of the valve may be required.

A maintenance kit is available under part number 289061.

For the latest service parts and kits, refer to the Bendix

Quick Reference Catalog (BW1114) available for order or

download at www.bendix.com.

SERVICE CHECKS

OPERATING AND LEAKAGE CHECKS

1. Charge the air brake system to governor cut-out, block

the wheels, and place tractor protection control valve

in the emergency position.

(12)

™

2

Page 3

2. Disconnect the trailer service line hose coupling. Make

a trailer hand control valve application. Cover the 1/16

inch vent hole in the service line shut-off valve area of

the Bendix® TP-5™ valve body. Check for leakage at

hose coupling and at exhaust port at the TP-5™ valve.

Excessive leakage at either port indicates a faulty inlet

valve, item 2 on Figure 4.

3. With the hand control valve still applied, turn the ignition

on and check for the stop light function.

4. Release the hand control valve application and place

the tractor protection valve in the normal position.

5. Connect the tractor service hose coupling to a test

gauge, re-apply the hand control valve and note that

there is pressure at the service hose coupling.

6. Check for leakage at the service line quick release

valve. Excessive leakage would indicate a defective

diaphragm (1). See Figure 3.

7. With the service line pressure still applied through the

hand control valve, check for leakage at the brake valve

exhaust. Excessive leakage indicates a defective

double check valve shuttle.

8. Check for leakage at the 1/16 inch vent hole. Leakage

indicates either o-ring (6) or o-ring (5) on the service

line shut-off piston (19) is defective. Note the same size

o-ring is identifi ed as (5) is also used on cap nut (10).

9. Release the hand control valve application and re-check

for leakage at the vent hole. If the leakage continues,

the large o-ring (5) is the cause for the leak and if the

leakage stops, the smaller o-ring (6) is the cause of the

leak.

10. Make and hold a foot brake application. Check for

leakage at exhaust of hand control valve. Excessive

leakage indicates a faulty double check valve shuttle.

3

Page 4

11. Release the foot brake application, disconnect the line

®

from primary service brake circuit at Bendix

TP-5™

valve delivery port (PCD) and block off the end of the

line from the brake valve. Make a foot brake application

and observe for leakage at the PCD delivery port.

12. Reconnect the primary circuit line and reverse the

procedure with the secondary circuit line (SCD).

Excessive leakage in either (11) or (12) indicates a faulty

double check valve shuttle. Restore the secondary circuit

connection to the TP-5

™

valve.

If the valve does not function as described above, or

leakage is excessive, the valve should be exchanged or

replaced at the nearest authorized Bendix Parts distributor.

If this is not possible the following should prove helpful.

DISASSEMBLY

1. Block the wheels and drain the air brake systems.

2. Remove all air lines and the stop light switch from the

manifold and remove the unit from the vehicle.

3. Remove the four cap nuts, (items 10, 11, 12, and 13)

from the body. Identify the cap nuts to their respective

ports before removing. Remove the o-ring (3 of item 7

and one of item 5). See Figure 4.

4. Remove the double check guides (14) and double check

shuttles (9).

5. Reach into the port marked BLK-SLS with a set of snap

ring pliers and remove the snap ring (15), spring (16),

and valve (2).

6. Remove the two screws which hold the cover (18)

to the body. Remove the two small o-rings (4) and

one large o-ring (3). Remove the quick release valve

diaphragm (1). See Figure 3.

7. Remove the 6-32 pan head screw (17) and remove the

exhaust check valve diaphragm (8).

CLEANING AND INSPECTION

1. Clean all metal parts in mineral spirits and dry them

completely.

2. Inspect all parts for excessive wear or deterioration.

Inspect valve seats for nicks or burrs. Check the valve

spring for cracks or corrosion.

3. Inspect the bores of the valve housing for deep scuffi ng

or gouges.

Replace all parts that were discarded and any parts not

found to be serviceable during inspection, using only

genuine Bendix replacement parts.

ASSEMBLY

Before assembling the TP-5™ valve, lubricate all o-rings,

o-ring grooves, body bores and rubbing surfaces with

Bendix silicone lubricant (Pc. No. 291126) or equivalent.

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to prevent the

sealant from entering the valve itself. Apply the

sealant beginning with the second thread back

from the end.

1. Re-install inlet valve (2), spring (16) and lock ring (15)

in body. See Figure 4.

2. Install shuttle guides (14) and shuttles (9) and their

respective cap nuts (10) and (11).

3. Install the o-rings (5) and (6) on the service line shutoff plunger (19), and install spring (20), plunger and

corresponding cap nut (12) with o-ring (7).

4. Position the quick release valve diaphragm in the body

(18) and the o-rings (3) and (4) on the cover and install

the cover in its cavity in the body. See Figure 3.

5. Replace the exhaust seal diaphragm (8) in the cover.

TESTING

Test the re-assembled valve per Operating and Leakage

Checks.

4

BW1575 © 2011 Bendix Commercial Vehicle Systems LLC • 5/2011• All rights reserved.

Loading...

Loading...