Page 1

®

Bendix® TP-2™ Tractor Protection Valve

SD-03-3651

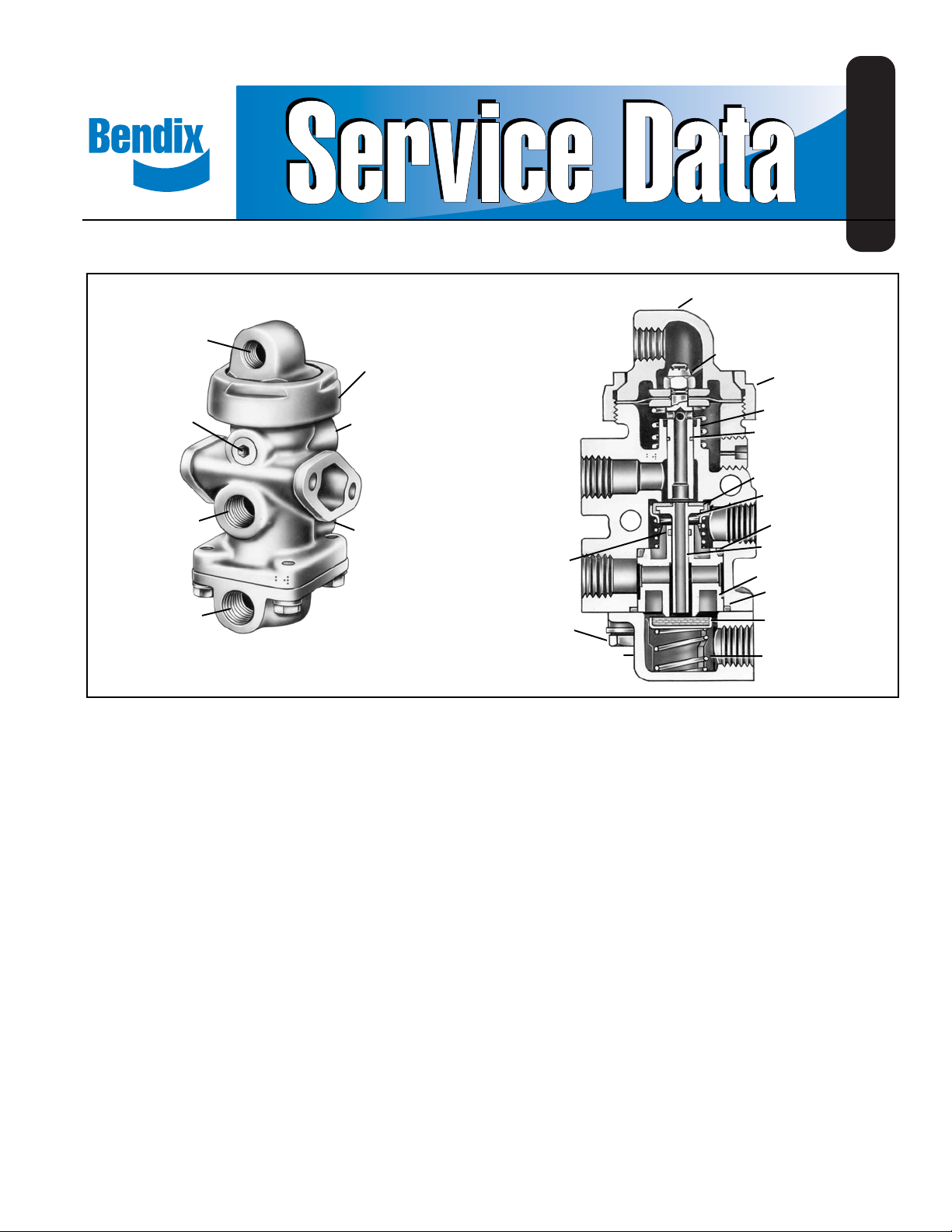

CONTROL CAP (13)

CONTROL PORT

CAP NUT

EXHAUST PORT

TRACTOR

SERVICE

PORT

TRACTOR

EMERGENCY

PORT

FIGURE 1 - TRACTOR PROTECTION SYSTEM

TRAILER

SERVICE

PORT

TRAILER

EMERGENCY

PORT

DESCRIPTION

The Bendix® TP-2™ tractor protection valve functions as a

set of remote controlled cut-out cocks, protecting the tractor

air supply should a loss of air occur in the trailer side

(delivery) of the valve. The TP-2™ valve is a three line system

as compared to the TP-3™ valve which is a two line system.

The valve is normally piped as shown in Figure 2. Lines

delivering service and supply (emergency) pressure to the

trailer are routed through the valve. A third control Iine comes

from the on-off control valve in the cab.

With the control valve in the “normal” (on) position and

reservoir pressure at approximately 50 psi, the valve will

open and service and emergency air is permitted to pass

through the valve. With the control valve in the emergency

position (off) position the vaIve is closed and service and

emergency lines on the trailer (delivery) side of the valve

are open to atmosphere through the vaIve’s exhaust port.

The valve will automatically close and vent delivery lines to

atmosphere should air pressure drop below a safe operating

EXHAUST VALVE PLUNGER AND

DIAPHRAGM ASS’Y (14)

CAP NUT (12)

EXHAUST PLUNGER

SPRING (15)

O-RING (16)

VALVE

RETAINER (7)

SPRING (8)

O-RING (10)

SERVICE AND EXHAUST

(11) O-RING

VALVE SEAT (5)

(1) CAP SCREW

(2) COVER

VALVE (6)

O-RING (9)

EMERGENCY

VALVE (3)

EMERGENCY VALVE

SPRING (9)

minimum pressure (approx. 40 psi), thus retaining and

protecting the tractor air brake system against complete

loss of air.

NOTE: With a TP-2™ valve system it should be noted that

the pneumatic logic for the legally required automatic

function is incorporated in the TP-2™ valve whereas

in the current TP-3™ valve system the logic is in the

supply valve in the cab. Consequently a TP-2™ valve

should never be replaced by a TP-3™ valve unless

the on-off control valve in the cab is replaced with

either a PP-3™ or PP-7™ trailer supply valve.

OPERATION - NORMAL POSITION

With air pressure at approximately 50 psi at the control

port, the diaphragm and plunger assembly is depressed

and the plunger contacts the service and exhaust valve

surface sealing the exhaust passage through the center of

the plunger. Continued travel of the plunger moves the service

valve off its seat, opening the service passage from the

1

Page 2

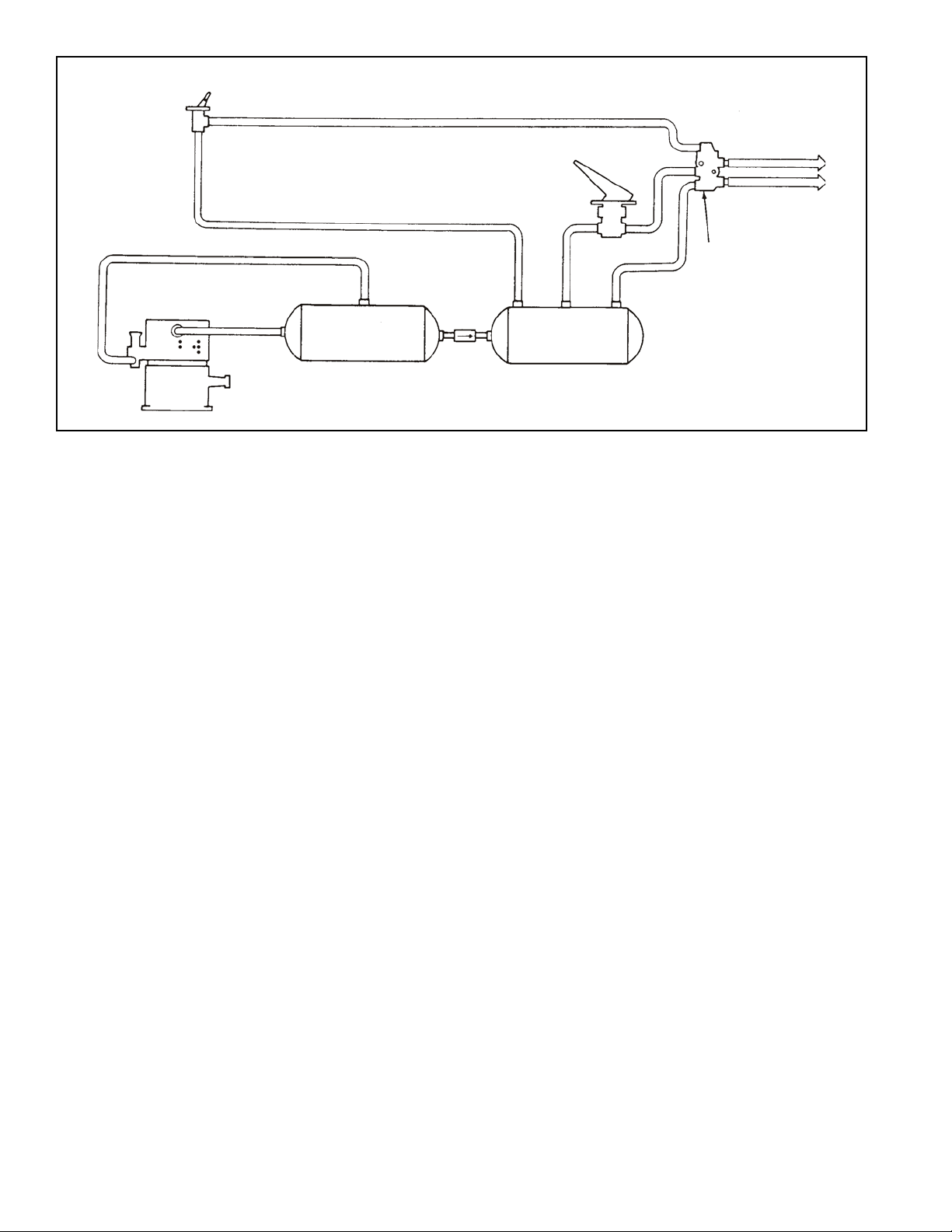

CONTROL

VALVE

COMPRESSOR

BRAKE

VALVE

TRAILER

SERVICE LINE

TRAILER

EMERGENCY

LINE

TRACTOR

PROTECTION

VALVE

NO. 1

RESERVOIR

FIGURE 2 - TRACTOR PROTECTION SYSTEM

tractor service port to the trailer service port. The stem of

the service and exhaust valve contacts the emergency valve,

sealing the exhaust passage. Continued travel of the service

and exhaust valve plunger moves the emergency valve off its

seat and allows air to flow from the tractor emergency port

to the trailer emergency port.

EMERGENCY POSITION

If air pressure in the control port (and on top of the diaphragm

and plunger assembly) drops below approximately 40 psi,

the combined forces of the exhaust plunger spring, the

service and exhaust valve spring and the emergency valve

spring will return the diaphragm and plunger assembly

allowing the service and exhaust valve and the emergency

valve to close. Further flow of air through either the service

or emergency ports is stopped. The loss in air pressure

which would precede such action would be indicated to the

driver, either visually or audibly by the low pressure warning

device, before such action would occur.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions; as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the TP-2

valve should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

the TP-2™ valve not meet the elements of the operational

NO. 2

RESERVOIR

CHECK

VALVE

tests noted in this document, further investigation and service

of the valve may be required.

OPERA TING AND LEAKAGE CHECK

NOTE: To make the following operating and leakage

checks,an accurate test gauge installed in spare

hose coupling is required. The vehicle dash gauge

should be checked for accuracy against the test

gauge prior to making these tests.

1. Block and/or hold the vehicle by means other than air

brakes during these test.

2. Drain vehicle reservoirs. Then close drain cocks.

3. Disconnect vehicle emergency and service hose

couplings and connect assembled hose coupling and

test gauge in tractor emergency hose coupling.

4. Start engine and build up system pressure.

5. As pressure in system builds up there should be no

pressure reading on test gauge. When system pressure

reaches 30 psi on dash gauge, make and hold a foot or

hand valve application and observe that no air escapes

at the open service hose coupling.

6. When system pressure reaches 40 to 60 psi, valve should

open and pressure reading show on test gauge. Allow

system to build up to 100 psi and shut off engine.

7. With soap solution coat exhaust port of the Tractor

Protection V alve. Leakage of a 1" bubble in 3 seconds

is permissible (175 SCCM).

™

8. Place the tractor protection control valve in the

“Emergency” position and note that emergency line

pressure drops promptly to zero on test gauge.

Disconnect coupling and test gauge.

2

Page 3

9. With soap solution:

A. Coat emergency line coupling. Leakage of a 1"

bubble in 5 seconds is permissible (100 SCCM).

B. Coat service line coupling. Make and hold a full hand

or foot valve application. Leakage of a 1" bubble in 5

seconds is permissible (100 SCCM).

10.Connect the coupling and test gauge to the emergency

line hose coupling. Place the tractor protection control

valve to “Normal” position. (If necessary , re-start engine

and build system pressure.) With ignition switch “on”

slowly drain tractor air brake system observing that low

pressure indicator occurs at prescribed pressure (normally

at approximately 60 psi) observe that the emergency

Iine will be vented by the tractor protection valve between

45 to 33 psi (test gauge will drop to 0 psi.)

If the TP-2™ tractor protection valve does not function as

described or if leakage is excessive, it is recommended

that it be replaced with a new or remanufactured unit, or

repaired with genuine Bendix parts, available at Bendix

outlets.

REMOVING AND INSTALLING

REMOVING

1. Block and/or hold vehicle by a means other than air

breaks. Drain air system reservoirs.

2. Identify lines and hoses so that correct lines are

reconnected to proper ports when reinstalling.

3. Remove lines; remove valve.

INSTALLING

1. Mount valve, checking to make certain control cap is

properly positioned. If it is necessary to re-position cap,

refer to No. 3 of “Assembly Instructions.”

2. Connect lines making certain proper lines are

connected to correct ports.

DISASSEMBLY

Important: Mark position of control port and tractor

emergency port location in relation to body in such a manner

that mark will not be obliterated during cleaning of parts.

Three (3) springs in valve should be carefully marked as to

their proper location in valve as valve is disassembled.

1. Remove four (4) cap screws (1) Figure 1, lock washers,

and cover (2) from valve.

2. Remove emergency valve (3) and emergency valve

spring (4) from cover.

3. Remove valve seat (5) service and exhaust valve (6),

valve retainer (7), spring (8).

4. Remove o-rings (9), (10), and (11).

5. Remove cap nut (12) and control cap. (13).

6. Remove exhaust valve plunger and diaphragm assembly

from body. (14).

7. Remove exhaust plunger spring (15) from body.

8. Inspect bores in valve body to be sure they are not

damaged or out of round. Clean body , control cap and

cover.

CLEANING AND INSPECTION

1. Clean all metal parts in mineral spirits and dry them

completely.

2. Inspect all parts for excessive wear or deterioration.

Inspect valve seats for nicks or burrs. Check the valve

spring for cracks or corrosion.

3. Inspect the bores of the valve housing for deep scuffing

or gouges.

Replace all parts that were discarded and any parts not

found to be serviceable during inspection, using only genuine

Bendix replacement parts.

ASSEMBL Y

Before assembling the TP-2™ valve, lubricate all o-rings,

o-ring grooves, body bores and rubbing surfaces with Bendix

silicone lubricant (Pc. No. 291 126) or equivalent.

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to prevent the

sealant from entering the valve itself. Apply the

sealant beginning with the second thread back from

the end.

1. Place in vise with control cap end up. Install o-ring (16)

in groove in the stem of the exhaust valve plunger and

diaphragm assembly (14).

2. Install exhaust plunger spring (15) in valve body and

install exhaust plunger and diaphragm assembly (14).

IMPORTANT: Both sides of diaphragm and clamping

surfaces of body and control cap must be

free of grease. Plunger should be a neat

sliding fit in bore.

3. Position control cap (13) and cap nut (12). Position control

cap to desired port angle (as marked during

disassembly). Install a short (4-6") 1/4" pipe nipple in

control port of cap. Apply pressure firmly on cap, holding

in position with pipe nipple and firmly tighten cap nut to

approximately 50 ft. lbs.

It is important that the cap not be allowed to turn while

tightening the cap nut. Remove pipe nipple from control

port.

4. Place valve in vise with control cap down.

5. Install o-ring (10) in valve body (smaller of two o-rings).

3

Page 4

6. Preassemble the following parts before installing in valve:

a. Install valve seat o-ring (11) in small bore of valve

seat making certain it is properly seated in groove.

Install spring (8) (the heavier of the two remaining

springs) over protrusion on small bore end of valve

seat.

b. Install valve retainer (7) on service and exhaust valve

(6). Install stem of service and exhaust valve through

center of spring and into small bore of valve seat.

7. Carefully install preassembled parts in body and hold in

place.

8. Position o-ring (9) in groove of body.

9. Position emergency valve spring (4) in cover (2) and place

emergency valve (3) (metal side of valve in contact with

spring) on top of spring.

10. Install cover (2) in desired port position (as marked during

disassembly.) Check to be certain o-ring (9) and

emergency valve (3) are in position.

11. Install cap screws and lockwashers and tighten to

approximately 100 in. lbs.

TESTING REBUILT TP-2™ TRACTOR

PROTECTION VALVE

Performance tests as outlined in “Operating and Leakage

Checks” section.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

EXTREME CAUTION should

ANY work on the

™

BW1436 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

4

Loading...

Loading...