Page 1

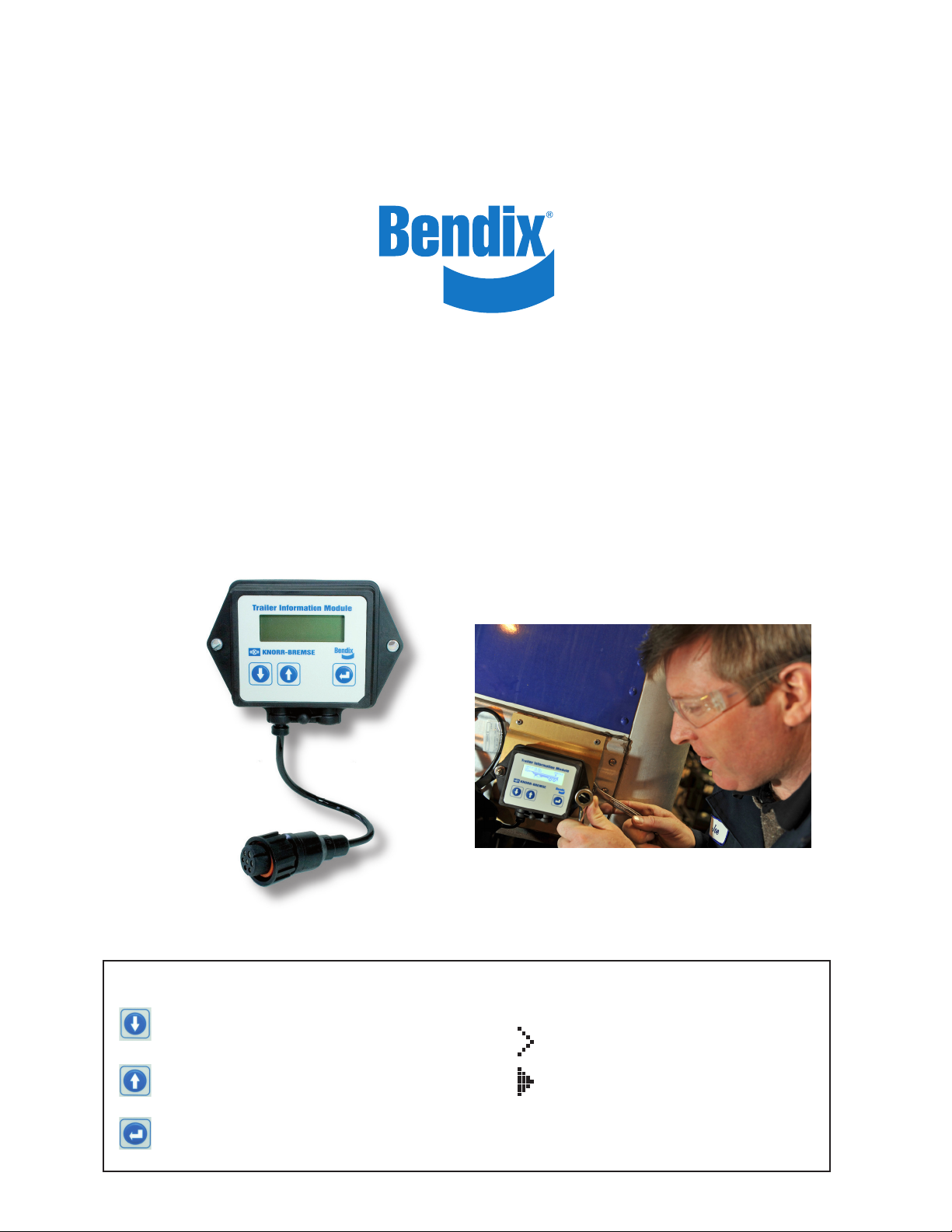

Bendix® Trailer Information Module (TIM™) G2

User Manual

User Manual

Navigation Buttons

Moves menu cursor down. Short hold jumps down one position, long hold

jumps to end of list (Exit).

Moves menu cursor up. Short hold jumps up one position, long hold jumps to

top of list.

Selects menu item at cursor position.

Cursor Function display

Menu point has no sub menu.

Menu point contains a sub menu or an item that may be modifi ed.

Navigation Buttons and Functionality

User Manual

Navigation Buttons

Moves menu cursor down. Short hold jumps down one position, long hold

jumps to end of list (Exit).

Moves menu cursor up. Short hold jumps up one position, long hold jumps to

top of list.

Selects menu item at cursor position.

Navigation Buttons and Functionality

User Guide

Press to move the cursor down one level.

Hold down to jump to the final level. (Exit)

Press to move the cursor up one level.

Hold down to jump up to the top of the list.

Select the chosen menu item.

Using the Navigation Buttons

The cursor is at a point with no sub menu.

The cursor is at a point with a sub menu or

an item that may be modified.

Page 2

DISPLAYS

With the ignition “ON”

The display is automatically activated. All menus are

available.

™

Bendix TIM

™

TABS-6

DISCLAIMER

For information

only! Press any key

to continue.

or

SUPPLY: 11.9V 58368LB

ODO: 127MI

or or

Initial Menu

<Active DTCs >

ODO: 127mi

Load Rear: 58420lb

Inst. Test Missing

Advanced ABS

or

Scroll until

“Main Menu”

TPMS symbol

(where used)

Initial Menu

Inst. Test Missing

TPMS Info

Main Menu

Exit

Main Menu

Stored DTCs

Distance & Serv.

Operating Info

System Info

With the ignition “OFF”

The display is off, push any navigation button for one second to

activate the display. Only limited menus are available.

Initial Menu

<Active DTCs >

ODO: 127mi

or or

DISCLAIMER

For information

only! Press any key

to continue

or

BATTERY MODE

For information

only! Values are

read from memory!

or or

Bendix TIM

™

TABS-6

Advanced ABS

or

™

Main Menu

Exit

Scroll until “Main Menu”

Main Menu

Stored DTCs

Distance & Serv.

Operating Info

ECU Info

+

SAFE MAINTENANCE PRACTICES

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following general precautions

should be observed at all times:

1. Park the vehicle on a level surface, apply the parking brakes, and

always block the wheels. Always wear safety glasses. Where

specically directed, the parking brakes may have to be released,

and/or spring brakes caged, and this will require that the vehicle be

prevented from moving by other means for the duration of these tests/

procedures.

2. Stop the engine and remove ignition key when working under or

around the vehicle. When working in the engine compartment, the

engine should be shut off and the ignition key should be removed.

Where circumstances require that the engine be in operation,

EXTREME CAUTION should be used to prevent personal injury

resulting from contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or assemble a

component until you have read and thoroughly understand the

recommended procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake system,

or any auxiliary pressurized air systems, make certain to drain the

air pressure from all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with a Bendix® AD‑IS® air dryer

system or a dryer reservoir module, be sure to drain the purge

reservoir.

5. Following the vehicle manufacturer’s recommended procedures,

deactivate the electrical system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing pressure; it

may whip. Never remove a component or plug unless you are certain

all system pressure has been depleted.

8. Use only genuine Bendix® brand replacement parts, components

and kits. Replacement hardware, tubing, hose, ttings, etc. must

be of equivalent size, type and strength as original equipment and

be designed specically for such applications and systems.

9. Components with stripped threads or damaged parts should be

replaced rather than repaired. Do not attempt repairs requiring

machining or welding unless specically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make certain all components

and systems are restored to their proper operating condition.

11. For vehicles with Automatic Traction Control (ATC), the ATC function

must be disabled (ATC indicator lamp should be ON) prior to

performing any vehicle maintenance where one or more wheels on

a drive axle are lifted off the ground and moving.

Page 3

MENU OVERVIEW

Initial Menu Main Menu

Repeat until

Trailer Information Module

<Active DTCs >

ODO: Omi

Load Rear: lb

Inst. Test Missing

<Active DTCs >

ODO: 0mi

Load Rear: lb

Inst. Test Missing

TPMS Info

2

3

Main Menu

Exit

“Main Menu”

Trailer Information Module

+

1

Stored DTCs

Distance & Serv.

Operating Info

System Info

Stored DTCs

Distance & Serv.

System Config

Operating Info

System Info

ECU Info

TIM Info

Exit

Stored

DTCs

Active DTCs:

<none>

DTCs:

Inactive

<none>

Clear DTCs

Exit

Date Based

Year:

Month:

Day:

Save & Exit

Exit

Distance & Serv.

ODO: mi

Trip: mi

Reset Trip

Srv Date:

Srv mi:

Set Next Service

Exit

Set Next Service

Date Based

Distance Based

Exit

Distance Based

Srv mi:

Save & Exit

Exit

System Config.

ABS Config.:

ECU Orient.:

RSP:

Exit

Operating Info

Info Total

Info Period

Exit

Info Total

ABS Events

RSP Interventions

Brake History

System Powering

Exit

TPMS Setup

Enter conf. Mode

Learn Sensor

Delete Sensor

Vehicle param.

Axle param.

Altitude comp:

Change password

Leave conf. Mode

Exit

3

5

5

5

5

5

6

5

5

System Info

TPMS Setup

Load Info

Pressure Info

Tilt Angle:

Wheel Speeds

Air Gap Speeds

Installation Test

Exit

Info Period

Period mi:

ABS Events:

RSP Interventions

Brake History

System Powering

Reset Period Data

Exit

Load Info

Front Axle Group

4

Bogie Load:

Rear Axle Group

Exit

3

4

Set LCD Contrast

LCD Contrast:

Save & Exit

Exit

Pressure Info

Dem P4:

Dem CAN:

Susp P42:

Pcyl P21:

Pcyl P22:

Res P1:

Exit

ECU Info

Part num:

SW:

Exit

Installation Test

Start Inst. Test

Install Check

Reserv. Press

S-A Sensor:

S-E Sensor:

S-C Sensor:

S-D Sensor:

S-F Sensor:

S-B Sensor:

Demand Press:

Tilt Angle:

Exit

TIM Info

Lang.:

Set LCD Contrast

Manufacturing Info

Exit

Manufacturing Info

Part num:

K001966XXXXXX

SW:

Serial:

ManufDate:

Exit

Wheel Speeds

S-A Sensor:

S-E Sensor:

S-C Sensor:

4

S-D Sensor:

4

S-F Sensor:

S-B Sensor:

Exit

4

4

Language

English (US)

N.Am. French

N.Am. Spanish

Exit

4

4

4

4

Airgap Speeds

S-A Sensor:

S-E Sensor:

S-C Sensor:

S-D Sensor:

S-F Sensor:

S-B Sensor:

Exit

4

4

4

4

RSP Intervention

Test Puls:

Step 1:

Step 2:

Step 3:

Exit

Appl vs Dem Values

<22psi:

22-36psi:

36-58psi:

>58psi:

Exit

Brake History

Appl vs Dem Values

Over Pressures

Exit

Over Pressures

Dem >130psi:

Res >130psi:

Exit

System Powering

ConstPower:

Stop Lamp:

Exit

Enter conf. Mode

Password:

Match password

Exit

1

Displayed only if active faults are available

2

Displayed only if installation test is missing

3

Displayed onlyifTirePressure Monitoring System (TPMS) is configured

4

Displayed only if included by vehicle ABS configuration

5

Displayed onlyif TPMS configuration mode entered

6

Displayed onlyif TPMS configuration mode not entered

6

Vehicle param.

FAL% CIP:

SAL % CIP:

Over Temp:

Exit

5

Change password

Password:

New passw.:

Save new passw.

Exit

5

Menu choices in green are not available in BATTERY MODE

Page 4

Initial Menu

a) Setting next service distance to

Reset Trip

Srv Date 18-01-10

Srv Mi: 6240mi

Set Next Service

Active DTCs:

S-C O/C.

S-D O/C.

Module Error

Main Menu

Stored DTCs

Distance & Serv.

Operating Info

System Info

+

1x

Date Based

Distance Based

Exit

Srv Mi: 0mi

Save & Exit

Exit

+

5x

+

1x

Srv Mi: 6250mi

Save & Exit

Exit

NOTE: “*” inactive, buttons and

revert to normal function

+

1x

Next service

distance has been

succesfully set in

ECU.

Indicates cursor buttons and

are now used to change ‘mi’ values

“

*

”

Srv Mi:

*

0mi

Save & Exit

Exit

2x

= 6250 mi

+

END

Main Menu

Stored DTCs:

Distance & Serv.

Operating Info

System Info

Overview of DTC

S-C Open circuit or

Shorted to Battery

DTC:

000D00

+

1x

DTC Detail

Scroll

Occurrence count:

4

First detection:

0mi

Scroll

Main Menu

System Info

ECU Info

TIM Info

Exit

+

Scroll to “TIM Info”

Lang.: US English

Scr Saver: Load

Set LCD Contrast

Manufacturing Info

US English

N.Am. French

N.Am. Spanish

Exit

+

1x

Langue: N.Am. French

Eco ecran Charger

Régl Contraste LCD

Info Fabricant

Info Fabricant

Test Affichage

Test Touche

Sortie

Scroll to “Sortie” (Exit)

END

2008-03-15 19:43.44

Last detection:

0mi

2008-03-31 10:11.47

END

6,250 miles (mi)

EXAMPLES

b) Display current Diagnostic

Trouble Code (DTC) status

c) Changing the language

default

d) Installation test

<Active DTCs>

ODO: 127mi

Load Rear: 58420lb

Inst. Test Missing

Scroll to “Inst. Test Missing”

Installation test

is missing! To

start it browse to:

Main Menu->

Start Inst. Test

Install. Check:

Reserv. Press:

S-C Sensor:

SECURE Trailer

against movement!

During this test

all its brakes may

+

3x

Scroll and follow

instructions on the

screen

all its brakes may

be released automatically! Press

ENTER to confirm

matically! Press

ENTER to confirm

you have secured

the Trailer.

Confirm that all

non connected

ports are plugged

then press ENTER.

Confirm that pneumatic connections

are secure, then

press ENTER.

2x

= Confirm

= Confirm

= Confirm

Confirm that

cables are securely

clipped, then

press ENTER.

Confirm that wheel

speed sensors have

been set, then

press ENTER.

Confirm that the

Truck‘s parking

brake is applied

then press ENTER.

Confirm that the

Trailer‘s parking

brake is NOT active

then press ENTER.

BW2867 © 2011 Bendix Commercial Vehicle Systems LLC, a member of the Knorr‑Bremse Group. 10/11. All Rights Reserved.

= Confirm

= Confirm

= Confirm

= Confirm

(if reservoir pressure > 6Bar)

Start Inst. Test

Install. Check:

Reserv. Press:

S-C Sensor:

Install. Check:

Reserv. Press:

S-C Sensor:

S-D Sensor:

Overview of wheel

location, “Confirm”

2x

Accelerate selected

wheel to 3mph

2x

Overview of wheel

location, “Confirm”

Accelerate selected

wheel to 3mph

Reserv. Press:

S-C Sensor:

S-D Sensor:

Demand Press:

S-C Sensor:

S-D Sensor:

Demand Press:

Tilt Angle:

Installation test

has been successfully executed.

Please switch igni-

fully executed.

Please switch ignition OFF-ON to

memorize status.

Start Inst. Test

Install. Check:

Reserv. Press:

S-C Sensor:

Fully apply the brake

pedal, then release it

o

< 5

TEBS mounting angle

within tolorance

2x

END

Loading...

Loading...