Page 1

Bendix® SS-1™ Shut-Off Valve

SD-03-4010

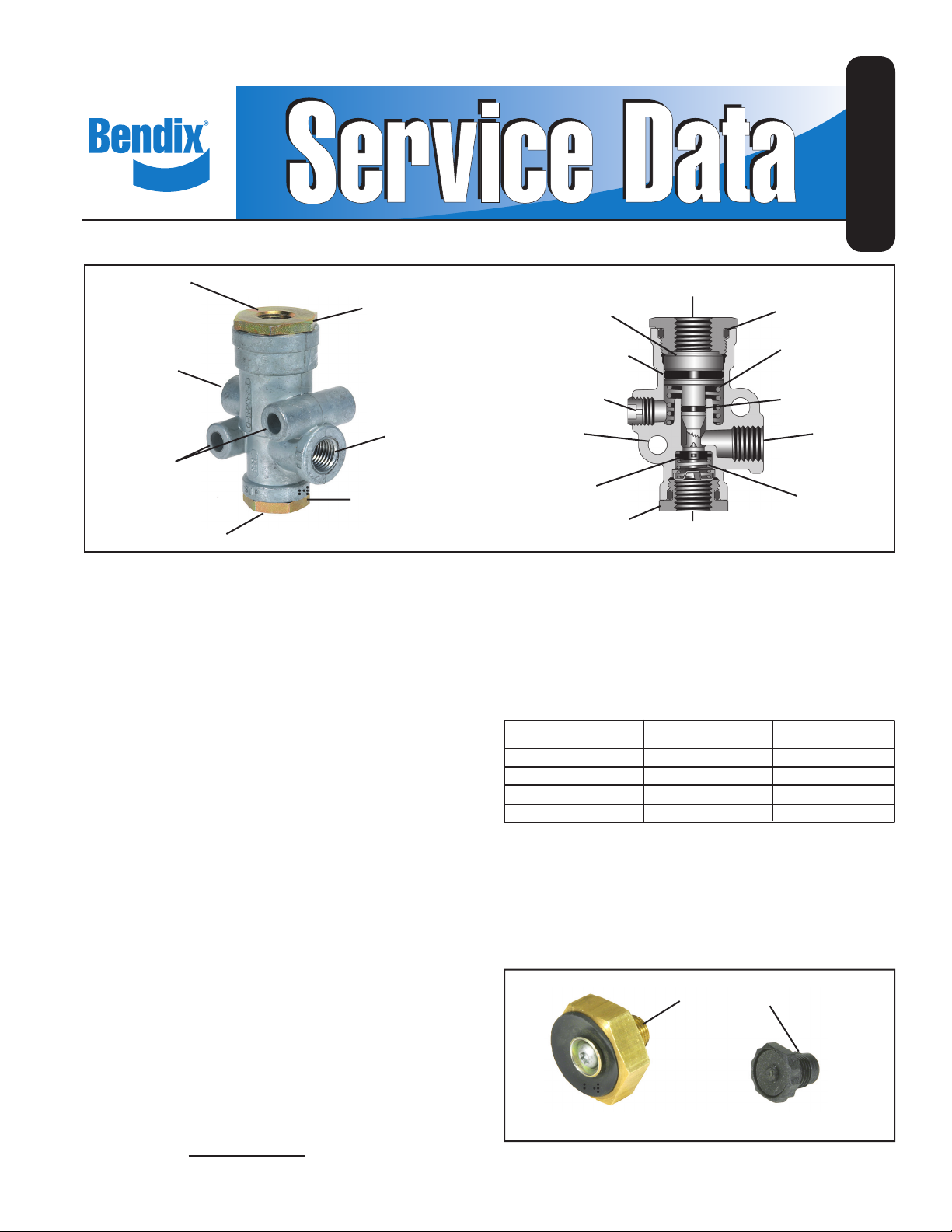

CONTROL

PORT

VENT PORT

MOUNTING

HOLES

SUPPLY

PORT

FIGURE 1- SS-1™ SHUT-OFF VALVE

CONTROL PORT

CAP NUT

DELIVERY

PORT

SUPPLY PORT

CAP NUT

DESCRIPTION

The SS-1™ shut-off valve (fi gure 1) is a pilot operated,

air controlled, on-off, non-graduating, non-exhausting

pneumatic control valve. The valve is primarily used to

delay, sequence, or control airfl ow from various devices in

the air brake system. It can be operated either in a pilot or

automatic mode using different air connection methods.

1/4" P.T.

CONTROL PORT

PISTON

PISTON O-RING

VENT PLUG WITH

1/8" P.T. VENT

MOUNTING

HOLE

INLET VALVE

CAP NUT O-RING

1/4" P.T.

SUPPLY PORT

CAP NUT O-RING

PISTON RETURN

SPRING

PISTON O-RING

1/4" P.T.

DELIVERY

PORT

INLET VALVE

SPRING

Two .28 inch mounting holes are provided in the die cast

zinc body for panel or frame mounting. Two steel hex cap

nuts at the ends of the cylindrical valve body retain the

internal components. All air connection ports contain pipe

threads. Lettering embossed in the valve body identifi es

two of the four ports in the valve. Refer to the chart below

and fi gure 1.

The SS-1™ valve is a general purpose valve used in a

variety of applications on trucks, buses, tractors, trailers

and converter dollies. It is offered in a variety of pressure

settings to accommodate applications where automatic

operation is required. The most common application of

the SS-1

™

valve is in the tractor protection system of a

truck tractor.

™

Important Note: The SS-1

shut-off valve is

application specifi c due to its pressure settings. It is

therefore important to use the proper part number

when replacement is required. IN ADDITION: The

SS-1™ shut-off valve and SV-1™ synchro valves are

identical in appearance and similar in operation but

have substantial internal differences and must not

be confused or used interchangeably. The SV-1™

synchro valve incorporates an internal exhaust passage

through its piston, which allows delivery pressure to

be vented to atmosphere while the SS-1™ does not.

Refer to Service Data Sheet, SD-03-4020, for more

information on the SV-1™ synchro valve. Service Data

Sheets can be obtained by calling 1-800-AIR-BRAKE

or by visiting www.bendix.com on the Internet.

Air Connection Body Ident. Thread Size

Supply SUP 1/4” P.T.

Delivery DEL 1/4” P.T.

Control NONE 1/4” P.T.

Vent NONE 1/8” P.T.

IMPORTANT: A vented, socket head vent plug is

installed in some SS-1

™

valves, however, an exhaust

check valve should be installed in the threaded vent

™

port when the SS-1

valve is mounted outside the cab

in unprotected environments. See Figure 2.

1/8" PIPE THREAD

Note: Either style may be installed in the SS-1™ valve

FIGURE 2 - EXHAUST CHECK VALVE STYLES

1

Page 2

OPERATION

GENERAL

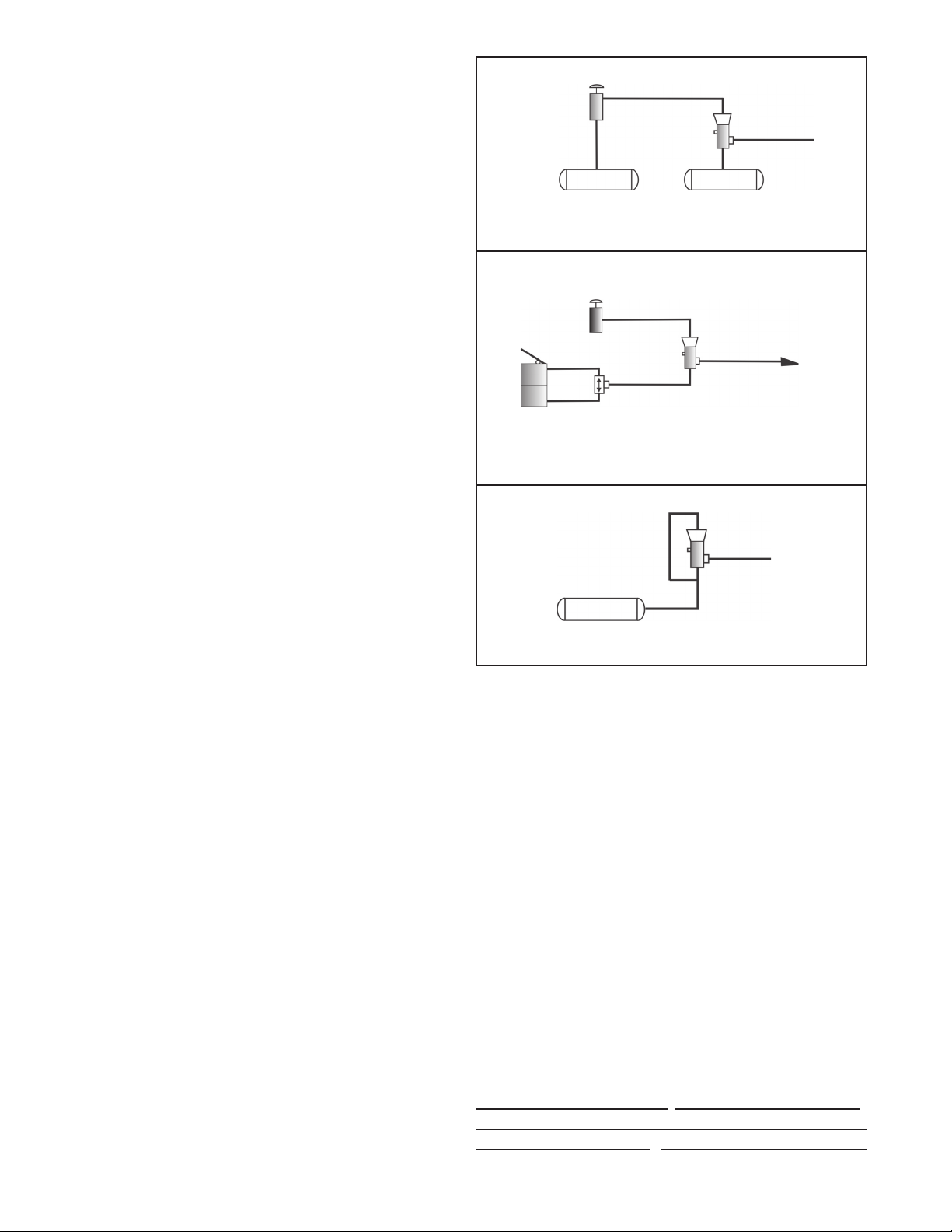

Because the SS-1™ shut-off valve is a general purpose

valve, it can be connected in the air system in a variety of

ways to accomplish its intended function. Figure 3 displays

only three of the many different connection methods that

can be used.

™

In general, the SS-1

system to function as a pilot operated, remote mounted,

on-off valve or it can be connected in a manner that allows

the valve to operate automatically at preset pressures as

system pressure increases or decreases. Figure 3 displays

examples of air system connections. Two examples of

connections that result in pilot operation are shown and one

that illustrates automatic operation. It should be noted that

since the SS-1™ valve is a pressure sensitive valve, under

certain air system conditions it might temporarily operate in

an automatic fashion even in a system where its intended

function is that of a pilot on-off valve. Regardless of how

the SS-1™ shut-off valve is connected, the internal valve

operation is the same.

valve can either be connected in the

CONTROL VALVE

CON

DEL

SUP

RESERVOIR

SS-1

™

VALV E

RESERVOIR

Pilot Operation

TRACTOR PROTECTION

CONTROL VALVE

CON

DEL

SUP

HOSE COUPLING

"GLAD HAND"

BRAKE VALVE

™

VALV E

SS-1

DOUBLE

CHECK VALVE

Pilot Operation - Tractor Protection Application

PILOT (controlled remotely by another valve)

With no air pressure present at the control port, supply port

air pressure, if present, along with the inlet valve spring hold

the inlet valve on its seat in the body. The piston is held

away from the inlet valve by the piston return spring.

When suffi cient air pressure is applied to the control port,

the control piston moves against the resistance of its return

spring. As the control piston moves, it contacts the valve

and continued piston movement drives the inlet valve from

its seat and allows supply air to fl ow through the body and

out the delivery port.

When air pressure is removed from the control port, the

piston return spring moves the piston away from the inlet

valve. As the piston moves, the inlet valve re-seats itself

preventing airfl ow to the delivery port.

If air pressure at the supply port remains constant (is not

reduced) then delivery port pressure remains equal to

supply port pressure provided that devices connected to

it do not dissipate delivery port pressure.

If supply port pressure is removed (after control pressure

is removed), then delivery port air pressure will hold the

inlet valve away from its seat against the force of the inlet

valve return spring. Air present at the delivery port will fl ow

through the valve body in the reverse direction, from the

delivery port, past the inlet valve, and into the supply port.

Flow will continue until the delivery port pressure (which

acts upon the area of the inlet valve) is reduced and equal

to the force exerted by the inlet valve spring. When delivery

port pressure and spring force are equal, the inlet valve

re-seats in the body and air pressure remaining in the

delivery line is “trapped” between the closed inlet valve and

air devices connected to the delivery port. The amount of

2

CON

SS-1™ VALV E

RESERVOIR

DEL

SUP

Automatic Operation - Common Control & Supply

FIGURE 3 TRACTOR PROTECTION SYSTEM

air pressure “trapped” is dependant upon the specifi c part

number of the valve. Valves used in a tractor protection

system application will “trap” less than 5 psi while other

SS-1™ valves will “trap” approximately 10 psi.

AUTOMATIC (self actuating at a preset pressure)

Automatic operation of the SS-1™ shut-off valve occurs

when the pressure at the supply and control port is the

same. This is referred to as “common control and supply”

and can be accomplished by connecting the valve’s control

port to its supply port using a pipe or tubing tee. With

common control and supply pressure, the valve opens

(delivers air) on ascending air pressure and closes on

descending pressure. The pressures at which delivery

and closure occur differ for various part numbers. Opening

and closing pressures are specifi ed for the various part

numbers. It should be noted that as supply and control

pressure descends delivery pressure will also decrease

but will not be completely removed. Refer to the “Pilot”

operation in this section.

Important: Consult Bendix® cataloging and/or Bendix®

Engineering for specifi c opening and closing control

pressures when the SS-1™ valve is used in the automatic

Page 3

mode. When using the SS-1™ shut-off valve in this

manner, the control signal ramp rate should be limited

by orifi cing or other methods. Please contact Bendix®

Engineering with specifi c application requirements.

PREVENTIVE MAINTENANCE

Important: Review the Bendix® Warranty Policy before

performing any intrusive maintenance procedures.

The warranty may be voided if intrusive maintenance

is performed during the warranty period.

No two vehicles operate under identical conditions, as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum,

the SS-1™ valve should be inspected every 6 months or

1500 operating hours, whichever comes fi rst, for proper

operation.

Should the SS-1™ valve not meet the elements of

the operational tests noted in this document, further

investigation and service of the system or valve may be

required.

If the SS-1™ valve fails to function as described or leakage

is excessive, it should be replaced with a genuine Bendix®

service unit of the same part number, available at Bendix®

authorized parts outlets.

WARNING!

PLEASE READ AND FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following general

precautions should be observed at all times. Always wear

safety glasses.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels.

2. Stop the engine and remove ignition key when working

under or around the vehicle. When working in the engine

compartment, the engine should be shut off and the

ignition key should be removed. Where circumstances

require that the engine be in operation, EXTREME

CAUTION should be used to prevent personal injury

resulting from contact with moving, rotating, leaking,

heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended procedures.

Use only the proper tools and observe all precautions

pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake

system, or any auxiliary pressurized air systems, make

certain to drain the air pressure from all reservoirs

before beginning ANY work on the vehicle. If the

vehicle is equipped with an AD-lS® air dryer system or

a dryer reservoir module, be sure to drain the purge

reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power from

the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has

been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware, tubing,

hose, fi ttings, etc. must be of equivalent size, type

and strength as original equipment and be designed

specifi cally for such applications and systems.

9. Components with stripped threads or damaged parts

should be replaced rather than repaired. Do not

attempt repairs requiring machining or welding unless

specifi cally stated and approved by the vehicle and

component manufacturer.

10. Prior to returning the vehicle to service, make certain all

components and systems are restored to their proper

operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

OPERATING AND LEAKAGE TESTS

OPERATING TESTS

General

Two accurate air gauges are necessary to perform these

tests. Depending upon installation, it may be necessary to

remove the valve to properly test it. When testing valves

installed in an automatic application the correct opening

pressures of the valve should be known before beginning

tests; consult vehicle manual. Refer to fi gure 3 and use the

appropriate Operational test.

Pilot

1. Install an accurate gauge in the supply line and the

other gauge in the delivery line.

2. With full system pressure present at the supply port of

the SS-1™ valve, apply and release full system pressure

to the control port and note that delivery pressure

increases to supply port pressure with no perceptible

lag.

3

Page 4

3. With full system pressure present at the control port,

remove all pressure from the supply port. Note that

delivery port pressure is reduced to 10psi or less.

Important Note: Depending upon part number and

valve application on the vehicle, delivery port pressure

may be required to be reduced to less than 5psi. When

used in tractor protection systems, delivery pressure

is generally required to be less than 5psi in this test.

Consult the vehicle manual for specifi cations.

2. Apply 120 psi to the supply port only. Apply soap

solution to the exhaust port. Leakage must not exceed a

1" bubble in less than 5 seconds (100 sccm). Excessive

leakage would indicate a faulty inlet valve or inlet valve

seat.

If the SS-1™ valve does not function as described or if

leakage is excessive, it is recommended that it be replaced

with a new unit available from authorized genuine Bendix®

parts outlets.

Automatic

1. Install an accurate gauge in the common control and

supply line; install another gauge in the delivery line.

2. Gradually increase air pressure to the common supply

and control line. Note when pressure is fi rst registered

on the delivery line gauge and record the common

control and supply pressure at that point. Compare the

recorded pressure with specifi cations in vehicle manual

or for the valve part number being tested. The recorded

pressure should be plus or minus 7psi of the specifi ed

pressure.

3. Apply full system pressure to the common control and

supply and note that delivery pressure increases to

supply port pressure with no perceptible lag.

4. Remove all pressure from the common control and

supply. Note that delivery port pressure is reduced to

10psi or less.

Important Note: Depending upon part number and

valve application on the vehicle, delivery port pressure

may be required to be reduced to less than 5psi.

LEAKAGE TESTS - ALL TYPES

1. With 120 psi air pressure present in supply, control and

delivery ports:

Apply a soap solution around control port cap

nut and supply port cap nut. No leakage is

permitted.

Apply soap solution to the exhaust port; leakage

must not exceed a 1" bubble in less than 5

seconds (100 sccm). Excessive leakage would

indicate faulty piston o-rings.

REMOVING AND INSTALLING

REMOVING

1. Read the Warning Section previously presented in this

manual and make certain to block and hold vehicle by

means other than air brakes.

2. Drain the air brake system completely.

3. Clean the exterior of the SS-1™ shut-off valve, as well

as the fi ttings and air lines attached to the valve.

4. Identify the air lines to facilitate reinstallation, disconnect

the lines, remove and retain the mounting bolts, and

then the valve.

5. Remove the exhaust check from the vent port if the

shut-off valve was so equipped.

INSTALLING

1. Mount the SS-1™ valve securely using the mounting

hardware retained during removal.

2. Using the identifi cation made during removal, connect

the air lines to the SS-1™ valve.

3. Install the exhaust check valve if the SS-1™ shut-off

valve was so equipped.

4. Perform tests as outlined in the "Operating and Leakage

Tests" section before placing the vehicle back into

service.

4

BW2539 © 2006 Bendix Commercial Vehicle Systems LLC. All rights reserved. 1/2006 Printed in U.S.A.

Loading...

Loading...