Page 1

Bendix® SMS-9700™ Accessory Solenoid Manifold

SD-03-10432

NORMALLY

CLOSED (NC)

SOLENOID

(BLACK)

ELECTRICAL

CONNECTOR STYLE

FOR LATCHING

(GRAY) OR NC

(BLACK) SOLENOIDS

DELIVERY

PORT

EXHAUST

PORT

PUSH-TO-CONNECT

RINGS

COMMON RAIL

LATCHING

BANK (GRAY)

ELECTRICAL

CONNECTOR FOR

NO (NATURAL)

SOLENOIDS

NORMALLY

OPEN (NO)

SOLENOID

(NATURAL)

SUPPLY PORT

MOUNTING

HOLES

COMMON RAIL

SUPPLY PORT

ELECTRICAL

CONNECTOR

Normally Closed Function (NC) - No air passes through

the valve when electrical current is not present.

Normally Open Function (NO) - Air passes through the

valve when electrical current is not present.

LATCHING

BANK (GRAY)

FIGURE 1 - BENDIX® SMS-9700™ ACCESSORY SOLENOID MANIFOLD

DESCRIPTION

The Bendix® SMS-9700™ accessory solenoid manifold is

a bank of low air fl ow solenoids used to control devices

such as suspension dump, differential locks, transmission

controls and other piloted chassis functions. Each solenoid

is controlled by an electrical switch inside the cab of the

vehicle.

Identifying the type of solenoid is essential for servicing

and troubleshooting. Note that the individual solenoids in

the bank can be replaced, but not repaired.

BENDIX® SMS-9700™ ACCESSORY SOLENOID

MANIFOLD

The SMS-9700 accessory solenoid manifold is a stackable

assembly with up to fi ve normally open (NO), normally

closed (NC), or latching solenoid banks that can control

various accessories. These banks can be identifi ed by

the electrical connector type and/or color (black, gray or

natural), and delivery port pairings. See Figure 1.

The push-to-connect (PTC) rings come in a variety of colors

and are used for OE installation purposes and do not depict

features, or function, of the solenoid valve.

1

Page 2

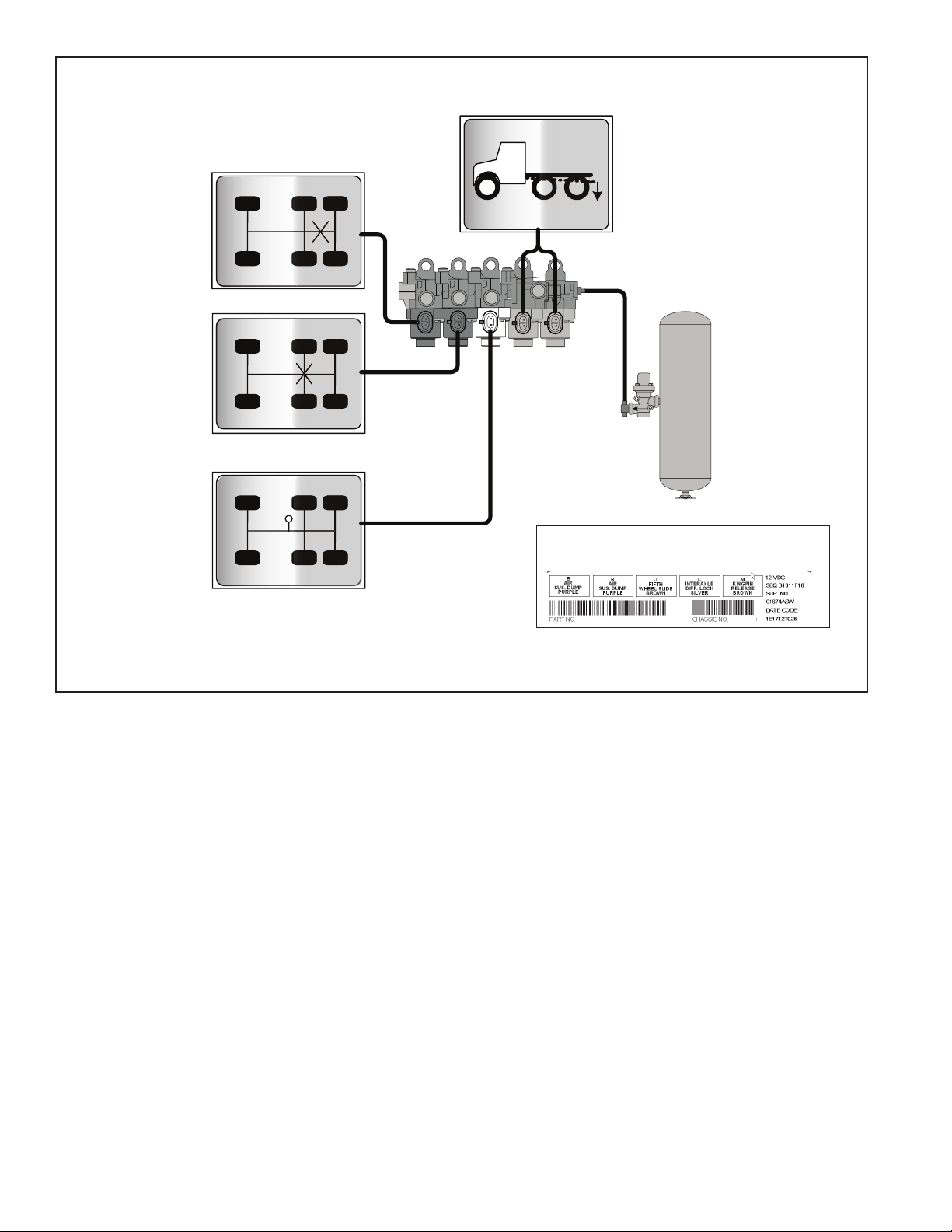

INTERAXLE

LOCK SWITCH

DIFFERENTIAL

LOCK SWITCH

PTO SWITCH

TYPICAL

IN-CAB SWITCHES

SUSPENSION DUMP SWITCH

BENDIX® SMS-9700™ ACCESSORY

SOLENOID MANIFOLD

PRESSURE

PROTECTION

VALV E

SUPPLY

RESERVOIR

FIGURE 2 - TYPICAL SYSTEM CONFIGURATION

OPERATION

Because these solenoid valves are used for auxiliary

air functions, a pressure protection valve, such as a

Bendix® PR-3™ valve, must be installed to protect the

air brake system. The solenoids will deliver, exhaust,

or latch air pressure to provide various functions on the

air brake vehicle. See Figure 2 for a typical system

configuration.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. The

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions; as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum,

the solenoid should be inspected every six (6) months or

Sample identifi cation label located on the back of the

solenoid mounting bracket. Each OE manufacturer will

have different labeling requirements.

1500 operating hours, whichever comes fi rst, for proper

operation. Should the solenoid not meet the elements

of the operational tests noted in this document, further

investigation and service of the valve may be required.

SERVICE CHECKS

These service instructions are a general guideline, and

should be consulted in conjunction with the OEM's service

manual.

ALERT: When servicing accessory solenoid valves that

control safety critical accessories (i.e., fi fth wheel lock,

king pin release, etc.), ensure that all components of the

redundant / backup system (i.e., two-step release system)

are functioning as intended by the original equipment

manufacturer.

When the in-cab switches are pressed to activate or

deactivate an accessory, the solenoids will promptly

exhaust (NO), apply (NC), or pulse (latching) air pressure to

an auxiliary device. Continuous exhausting of air pressure

should not occur.

2

Page 3

LEAKAGE CHECKS

With the air system fully charged, coat the exhaust ports

of the solenoid with a soap solution. A 1-inch bubble in

three (3) seconds is permitted (175 SCCM).

If the solenoid does not function as described above, or if

leakage is excessive, it is recommended that it be replaced

with a genuine Bendix

®

service replacement.

REMOVAL

1. Prior to removing a solenoid, apply the parking brakes

and drain all the vehicle reservoirs. Refer to the General

Safety Guidelines in this manual before performing any

service.

2. Identify, mark, and disconnect all air lines to the

solenoid. Push-to-connect fi ttings require the collar

to be pressed toward the valve body before the nylon

line can be pulled. Note that the braided hose version

(Arctic) uses compression fi ttings.

END CAP

LOCKING TAB

LOCKING TAB

O-RING - 2

BODY BOLT

COMMON RAIL

SUPPLY PORT

STRAIGHT -

3/8" PTC

SUPPLY END CAP CONFIGURATIONS -

THESE END CAPS ARE USED WHEN

A 3/8" NYLON AIR LINE IS USED TO

SUPPLY THE MANIFOLD

FIGURE 3 - SERVICING THE BENDIX® SMS-9700™ SOLENOID MANIFOLD

NON-REMOVABLE

FASTENER

90° ELBOW

3/8" PTC

3

Page 4

3. Identify, mark, and disconnect all electrical connector(s)

from the solenoid(s).

4. Remove the mounting bolt(s) and remove the

solenoid(s) from the vehicle.

DISASSEMBLY

The Bendix® SMS-9700™ solenoids can not be serviced

or repaired, they can only be replaced with service

replacement solenoids. Refer to Figure 3.

1. The SMS-9700 solenoids are fastened together with

a twist-to-lock feature. To disassemble the banks,

remove the body mounting bolt and twist the banks

slightly to separate. Note that only body bolts are

designed to be removed. Other fasteners are designed

to prevent removal.

2. If the solenoid being serviced is the last unit in a bank

(opposite the supply port), it will have an end cap

attached. This end cap is secured in the same manner

as a solenoid and can be removed using the same

procedure.

CLEANING & INSPECTION

Once apart, the banks interconnecting o-ring seals can

be serviced and the solenoid banks replaced. Internal

solenoid components are not serviceable.

ASSEMBLY

1. Lubricate the solenoid body o-rings before reassembly

of the banks.

2. Align the solenoid locking stem, then twist the banks

until line-to-line contact is made. Using the body bolts,

fasten the assemblies together. Torque the bolts to

25-30 inch pounds.

INSTALLATION

1. Install the valve on the vehicle by tightening the

mounting bolts to 150-200 inch pounds.

2. Reconnect the air lines and electrical connectors.

3. Charge reservoirs, check for operation and leakage.

BW2901 © 2012 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • All Rights Reserved • 09/12

4

Loading...

Loading...