Page 1

Bendix Manual Slack Adjusters

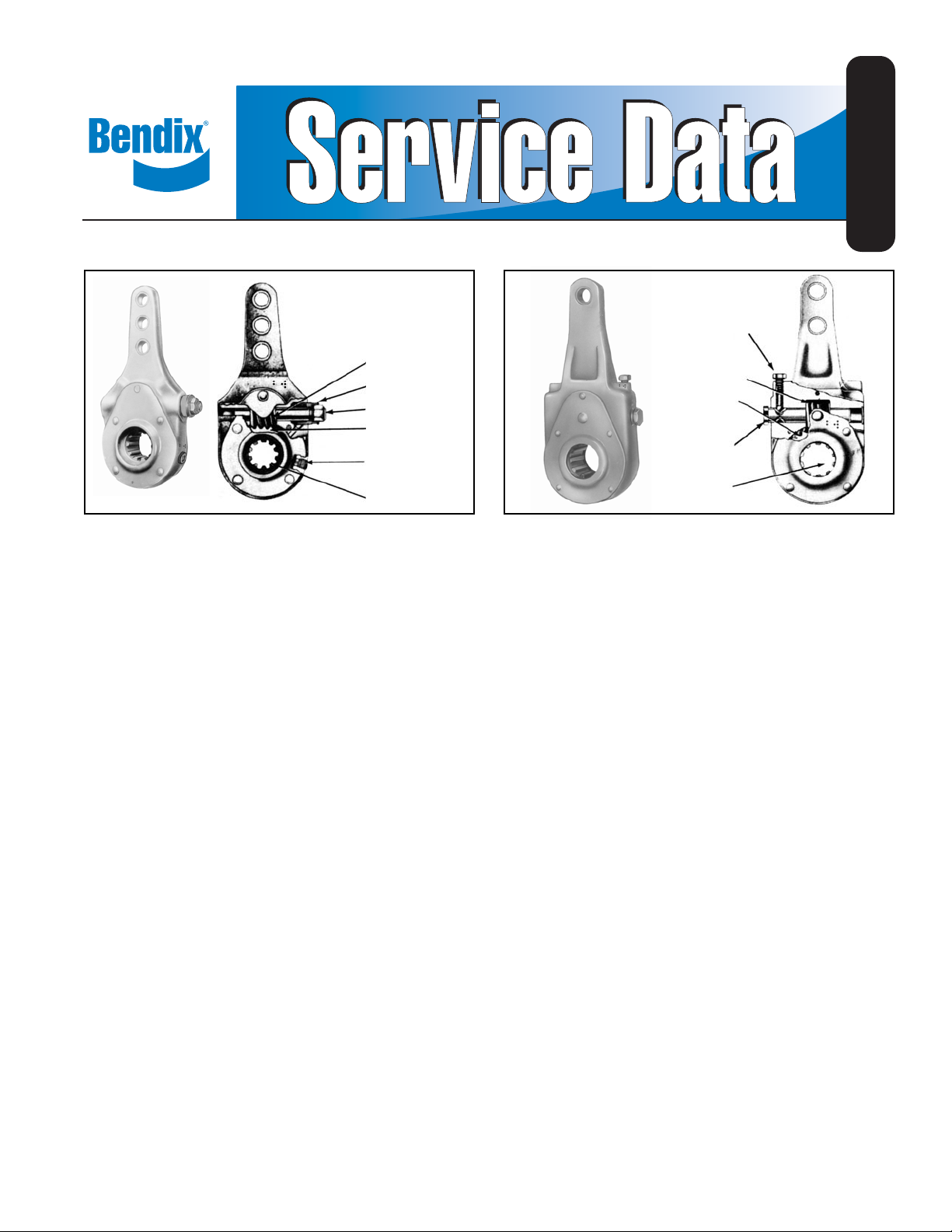

WORM GEAR

LOCK SLEEVE

ADJUSTING SCREW

(WORM SHAFT)

ADJUSTING GEAR

GREASE HOLE

SPLINE

FIGURE 1 - POSITIVE LOCK TYPE SLACK ADJUSTER

SD-05-1200

WORM SHAFT (LOCK

SCREW)

WORM GEAR

ADJUSTING

GEAR

ADJUSTING SCREW

(WORM SHAFT)

SPLINE

FIGURE 2 - BALL INDENT TYPE SLACK ADJUSTER

DESCRIPTION

In an s-cam type foundation brake, the final link between

the pneumatic system and the foundation brake is the slack

adjuster. The arm of the slack adjuster is fastened to the

push rod of the chamber with a yoke, and the slack adjuster

spline is installed on the brake cam shaft.

Primarily , the slack adjuster is a lever , converting the linear

force of the air chamber push rod into a torque which turns

the brake cam shaft and applies the brakes.

Standard slack adjusters contain four basic components;

the body, worm, gear and adjusting screw. The adjusting

screw is provided to adjust the slack caused by the wear of

the brake lining.

All slack adjusters utilize the worm and gear principle and,

fundamentally, differ only in torque limit specifications; A

type 20 slack adjuster has a limit of 20,000 inch pounds

torque, a type 30 slack adjuster has a limit of 30,000 inch

pounds torque, etc.

Slack adjusters are manufactured with various arm lengths

and various configurations; straight, offset, etc. to satisfy

various installation requirements. Splines are available in

several different types and sizes.

OPERA TION

When the brakes are applied, air pressure forces the air

chamber diaphragm and push rod to move; this rotates the

slack adjuster, which in turn rotates the cam shaft. This

causes the “S” cam to spread the brake shoes which contact

the brake drum.

When the brakes are released, air pressure is exhausted

from the air chamber. The chamber return spring and the

brake shoe return springs return the brake cam, cam shaft,

slack adjuster and chamber push rod to the released position.

ADJUSTING MECHANISM

The adjusting mechanism of a slack adjuster consists of an

adjusting screw (worm shaft), worm and slack adjuster worm

gear. T urning the adjusting screw nut on the end of the worm

shaft rotates the worm shaft and worm. The worm meshes

with and rotates the slack adjuster worm gear which is

connected to the brake cam by a splined cam shaft. The

turning of the slack adjuster worm gear rotates the cam

shaft and brake cam, spreading the brake shoes,

compensating for brake lining wear.

There are two types of adjusting mechanisms used on Bendix

slack adjusters currently manufactured. The light to medium

torque rated slack adjusters (Fig. 1) use a positive lock

mechanism consisting of a spring loaded lock sleeve, which

when positioned properly , engages the adjusting screw nut,

preventing the adjusting screw (worm shaft) from rotating.

The heavier torque rated slack adjusters (Fig. 2) utilize the

lock ball or plunger and worm shaft indent principle

adjustment lock. The lock ball or plunger must engage the

indent on the worm shaft after the adjustment is completed.

An audible metallic click can be heard when engagement is

made.

1

Page 2

Using the Positive Lock Slack Adjuster Mechanism: (Fig. 1)

Wipe the adjusting screw nut and locking sleeve area clean.

Position wrench or socket over the adjusting screw and

disengage the locking sleeve by depressing the lock sleeve.

Make the necessary adjustment by turning the adjusting

screw with the locking sleeve depressed.

When adjustment is completed, the adjusting screw nut

should be positioned so the locking sleeve engages the

adjusting screw nut, thus locking the adjusting screw in

place. DO NOT ATTEMPT TO TURN THE ADJUSTING

SCREW WITHOUT FULLY DEPRESSING THE LOCK

SLEEVE.

Using the Ball Indent Slack Adjuster Mechanism: (Fig. 2)

Before proceeding with adjustment, measure distance from

top of lock screw head to slack adjuster body.

T o adjust, back off lock screw (counter clockwise) and make

necessary adjustment by turning the adjusting screw. After

adjustment is complete, retighten lock screw, making certain

that lock ball is engaged on the plunger shaft. (Proper

engagement can be confirmed by checking the measurement

from the top of the lock screw head to the slack adjuster

body. It should be the same before and af ter the adjustment.)

PROCEDURE

Vehicle brakes should normally be adjusted using the vehicle

or brake manufacturer’s recommendations. If they are not

available, the following can be used:

1. Bring the vehicle to rest on a level surface and chock the

wheels.

2. Mechanically release (“cage”) the spring brakes.

BRAKE ADJUSTMENT CHECK

A. PREFERRED METHOD

Determine the brake chamber size. Make a 100 psi

application to the service brakes and measure the push rod

stroke. Using the chart (Fig. 3) compare the actual chamber

stroke to the recommended maximum stroke to determine

if brake adjustment is required.

CLAMP RING TYPE CHAMBER DATA

(Dimensions in inches)

Effective * With Brakes

Type (Sq. In.) Diameter Stroke Adjusted Readjusted

12 12 5-11/16 1-3/4 short as 1-3/8

16 16 6-3/8 2-1/4 possible 1-3/4

20 20 6-25/32 2-1/4 without 1-3/4

24 24 7-7/32 2-1/4 brakes 1-3/4

30 30 8-3/32 2-1/2 dragging 2

36 36 9 3 2-1/4

*Dimensions listed do not include capscrew head projections

for rotochambers and bolt clamp projections for clamp type brake

chambers.

Area Outside Max. Brakes Should Be

6 6 4-1/2 1-5/8 Should 1-1/4

9 9 5-1/4 1-3/4 be as 1-3/8

Max. Max. Stroke

Stroke at Which

Slack Adj. Arm Length Push Rod Movement (stroke)

“A” Dim. (in.) “B” Dim. (in.)

5 1-1/2

5-1/2 1-1/4

61

6-1/2 3/4

B

A

FIGURE 4

B. ALTERNA TE METHOD

Determine the slack adjuster arm length (Dim. A). Measure

push rod movement (stroke) by manually extending push

rod until brake shoes contact drum. Refer to chart (Fig. 4). If

Dim. “B” is greater than allowable stroke indicated brakes

need to be adjusted.

BRAKE ADJUSTMENT

A. PREFERRED METHOD

Raise the vehicle wheel that is to be adjusted off the ground

so that it turns freely. Turn the slack adjuster adjusting

mechanism until the brakes begin to drag. Adjustment is

then backed off until the wheel turns freely . This adjustment

method will result in the shortest possible actuator stroke

without the brakes dragging.

B. ALTERNA TE METHOD

Regardless of the brake chamber size or the slack arm length

adjust the slack adjuster so that there is 3/8" travel of the

push rod when manually extended to contact the brake shoes

to the brake drum. After adjustment, check for brake drag

by gently striking the brake drum with a hammer. When the

brake shoes are away from the drum, a ringing sound will be

heard. A dull sound indicates brake drag and requires

readjustment until the drag is eliminated.

NOTE: If the brakes cannot be adjusted per the above

instructions inspect the foundation brake and drum

for worn or damaged components.

PREVENTIVE MAINTENANCE

Every month, 8000 miles or 300 operating hours; check push

rod travel. Stroke should be short as possible without brakes

dragging or chamber rod binding. Adjust if necessary.

Every six months, 500,000 miles or 1800 operating hours;

lubricate slack adjuster with chassis lube N.L.G.I. grade 1

or 2. Apply a sufficient amount of grease to completely fill

body cavity.

FIGURE 3

2

Page 3

SLACK ADJUSTERS MOUNTED IN TENSION OR COMPRESSION

BRAKE

CHAMBER

SLACK

ADJUSTER

ADJUSTING

SCREW

TENSION

PROVIDED THE MAXIMUM TORQUE RATING IS NOT EXCEEDED, BENDIX SLACKS CAN BE MOUNTED IN EITHER DIRECTION AND

STILL MEET THE ENGINEERING TEST SPECIFICATION (50K CYCLES AT MAXIMUM RATED LOAD). COMPRESSION MOUNTING IS

RECOMMENDED AND WILL YIELD A LONGER SERVICE LIFE.

NOTE: Some Bendix slack adjusters were manufactured

without a lubrication provision in the body; however,

the slack adjuster may be lubricated through the

cover as follows:

1. Remove rubber plugs from both covers and discard.

2. Determine which side of slack adjuster is accessible for

lubrication and install washer (Pc. No. 230156) and

grease fitting (BW Pc. No. 244017) Alemite #1625 using

Alemite tool #5254 to press grease fitting firmly in place

in cover.

3. Install steel plug (Pc. No. 244400) in other cover, making

certain it is firmly in place.

4. Lubricate slack adjuster. Apply a sufficient amount of

grease to completely fill body cavity .

SERVICE TESTS

1. Apply brakes and check that slack adjusters rotate freely

and without binding.

2. Release brakes and check that slack adjusters return

to the released position without binding.

3. With brakes released, check that the angle formed by

the slack adjuster arm and actuator push rod is greater

than 90 degrees. All slack adjusters should be set at

this same angle.

4. With brakes applied, check that the angle formed by

the slack adjuster arm and actuator push rod is still

slightly greater than 90 degrees. All slack adjusters

should be set at this same angle.

REMOVA L AND INSTALLA TION

CAUTION: Before attempting to remove slack adjusters,

proper precautions should be taken so that an automatic

application of the actuators does not occur while removing

or installing slack adjusters, thus causing possible injury.

Decreasing air pressure can cause a sudden full brake

application without warning. Depending on type of system

on vehicle, it maybe necessary to drain all air reservoirs or

mechanically back off spring brake chambers.

BRAKE

CHAMBER

SLACK

ADJUSTER

ADJUSTING

SCREW

COMPRESSION

A. REMOVAL

1. Remove the chamber push rod yoke pin.

2. Remove the retaining mechanism from end of brake

cam shaft.

3. Rotate the slack adjuster by turning the adjusting nut.

4. Slide the slack adjuster off of the spline end of the brake

cam shaft.

B. INSTALLATION

1. Install slack adjuster on brake cam shaft so the

adjustment screw and grease fitting (if so equipped) are

accessible for servicing.

2. Install retaining mechanism on end of brake cam shaft

to hold slack adjuster in place.

3. Turn adjusting nut to line up yoke pin hole with arm

hole. Install yoke pin and cotter pin.

4. Refer to steps 3 and 4 under “Service Tests” and make

sure the proper adjustments are made after installing a

slack adjuster.

SLACK ADJUSTER REPLACEMENT

When replacing one type of slack adjuster with another type,

it is necessary to match or exceed the torque rating and

match the arm length, yoke pin diameter, offset spline

diameter and width. It is also necessary to make certain

that there is adequate clearance at release and full stroke.

DISASSEMBLY AND ASSEMBLY

NOTE: Disassembly and assembly instructions apply only

to assemblies with riveted covers. Assemblies with

welded covers are considered non-serviceable and

are replaced as an assembly .

TYPE 20 TO 30 WITH POSITIVE LOCK MECHANISM AND

RIVETED COVER DISASSEMBL Y

1. Remove rivets holding covers.

2. Remove welch plug.

3

Page 4

3. Before removing worm shaft, measure height from top of

adjusting screw to the slack adjuster body. This

measurement is important, as it serves as a reference

when the worm shaft is reassembled.

4. Press out worm shaft from worm by pressing in on the

end of the worm shaft opposite the adjusting screw nut.

5. Remove worm shaft, worm shaft lock and worm lock

spring.

6. Remove worm and slack adjuster worm gear from slack

adjuster body.

TYPE 35 WITH POSITIVE LOCK MECHANISM

DISASSEMBL Y

1. Remove retaining ring holding the cover, cover nut and

gear in place.

2. Remove set screw in worm nut.

3. Depress worm lock and remove lock nut pin.

4. Remove worm lock and worm lock spring.

5. Unscrew worm nut.

6. Remove worm shaft, worm and gear from slack adjuster

body.

7. Before removing worm shaft, measure height from top

of adjusting screw to the slack adjusted body. This

measurement is important, as it serves as a reference

when the worm shaft is reassembled.

8. Press out the worm shaft from worm by pressing on the

end of the worm shaft opposite the adjusting screw nut.

TYPE 35 AND TYPE 55 (WITHOUT RIVETED COVER) AND

BALL INDENT LOCK MECHANISM DISASSEMBL Y

1. Remove cam lock pin, cam lock, thrust washer , plunger

spring and plunger.

2. Bend up tab of lock washer and remove worm nut.

3. Remove retaining ring and cover .

4. Before removing worm shaft, measure height from the

top of adjusting screw to the slack adjuster body. This

measurement is important, as it serves as a reference

when the worm shaft is reassembled.

5. Remove worm and shaft and slack adjuster gear .

6. Remove plunger and plunger spring from body .

7. If worm gear is to be pressed from shaft, note dimension

from end of shaft to gear before proceeding.

TYPE 35, 40, 55 (WITH RIVETED COVER AND BALL

INDENT LOCK MECHANISM) DISASSEMBL Y

1. Remove rivets holding the covers.

2. Remove welch plug.

3. Before removing ball indent lock mechanism, measure

and note distance from top of lock screw head to slack

adjuster body .

4

4. Remove ball indent lock mechanism screw.

5. Remove spring and ball.

6. Before removing worm shaft, measure height from top of

adjusting screw to the slack adjuster body. This

measurement is important, as it serves as a reference

when the worm shaft is reassembled.

7. Press out worm shaft from worm by pressing on end of

worm shaft opposite the adjusting nut.

8. Remove worm and slack adjuster worm gear .

CLEANING AND INSPECTION

Wash all parts in mineral spirit s and dry. Inspect parts and

replace any part showing signs of wear or deterioration.

TYPE 20 TO 30 WITH POSITIVE LOCK MECHANISM

AND RIVETED COVER ASSEMBLY

1. Place worm and worm gear in slack adjuster body .

2. Position and press the worm shaft, worm shaft lock and

spring into the worm and slack adjuster body. The recess

in the worm shaft lock must be lined up with the pin in

the slack adjuster body before pressing into position.

Make certain that when pressing the worm shaft into

the body that the height measurement between the top

of the adjusting screw and slack adjuster body is the

same before and after removal.

3. Install covers and rivet securely.

4. Install new welch plug in body.

5. Lubricate as outlined in “Preventive Maintenance”

section.

TYPE 35 WITH POSITIVE LOCK MECHANISM

ASSEMBL Y

1. Press worm shaft into worm. Care should be exercised

to be sure the worm shaft is pressed into the proper

dimension.

2. Install the worm shaft, worm and gear in the slack

adjuster body .

3. Make certain that when pressing the worm shaft into

the body that the height measurement between the top

of the adjusting screw and slack adjuster body is the

same before and after removal.

4. Install worm lock guide pin in worm nut.

5. Screw the worm nut into slack adjuster body.

6. Install worm lock and worm lock spring over worm shaft

and adjusting screw nut.

7. Depress worm lock and install lock nut pin in adjusting

screw nut.

8. Install set screw in worm nut.

9. Assemble cover and cover nut to the body by installing

the retaining ring.

10. Lubricate slack adjuster as outlined in “Preventive

Maintenance” section.

Page 5

TYPE 35 AND TYPE 55 (WITHOUT RIVETED COVER) AND

BALL INDENT LOCK MECHANISM ASSEMBL Y

1. Install plunger spring and plunger in body.

2. Install slack adjuster gear in body.

3. If worm was removed from shaft, new worm should be

pressed on shaft noting dimension as instructed in No.

4 of disassembly procedure.

4. Install worm and shaft. Worm and shaft must be run in

so that the worm fully engages slack adjuster worm gear.

Make certain that when pressing the worm shaft into

the body that the height measurement between the top

of the adjusting screw and slack adjuster body is same

before and after removal.

5. Install cover and retaining ring in groove of body .

6. Install new lockwasher on worm nut in body and tighten.

Bend up at least 2 tabs of lockwasher, one of which

should fit in groove of body.

7. Install plunger spring, thrust washer and plunger in lock

hole.

8. Install cam lock in body. Install pin.

9. Lubricate slack adjuster, as outlined in “Preventive

Maintenance” section.

TYPE 35, 40, 55 (WITH RIVETED COVER AND BALL

INDENT LOCK MECHANISM) ASSEMBL Y

1. Place worm and worm gear in slack adjuster body .

2. Press the worm shaft into the worm. The indents in the

worm shaft must be lined up with the ball lock hole.

Make certain that when pressing the worm shaft into

the body that the height measurement between the top

of the adjusting screw and slack adjuster body is the

same before and after removal.

3. Install covers and rivet securely.

4. Install ball, spring and ball indent lock mechanism. Turn

adjusting screw, allowing ball to fully engage indent in

shaft. Check for full engagement by tightening lock

mechanism screw to same dimension as noted in step

#3 of “Disassembly” instructions.

5. Before installing welch plug, grease bottom of shaft.

Install new welch plug.

6. Lubricate slack adjuster as outlined in “Preventive

Maintenance” section.

TEST OF REBUILT SLACK ADJUSTERS

After lubricating rebuilt slack adjuster (see “Preventive

Maintenance” section), all moving parts of the slack

adjusters should rotate freely and not bind. With slack

adjuster installed in vehicle, refer to “Service Test” section.

Check that rebuilt slack adjuster functions properly .

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all electrical

power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all system

pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent size,

type and strength as original equipment and be

designed specifically for such applications and

systems.

®

5

Page 6

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

6

BW1453 © 2007 Bendix Commercial Vehicle Systems LLC All rights reserved. 3/2007 Printed in U.S.A.

Loading...

Loading...