Page 1

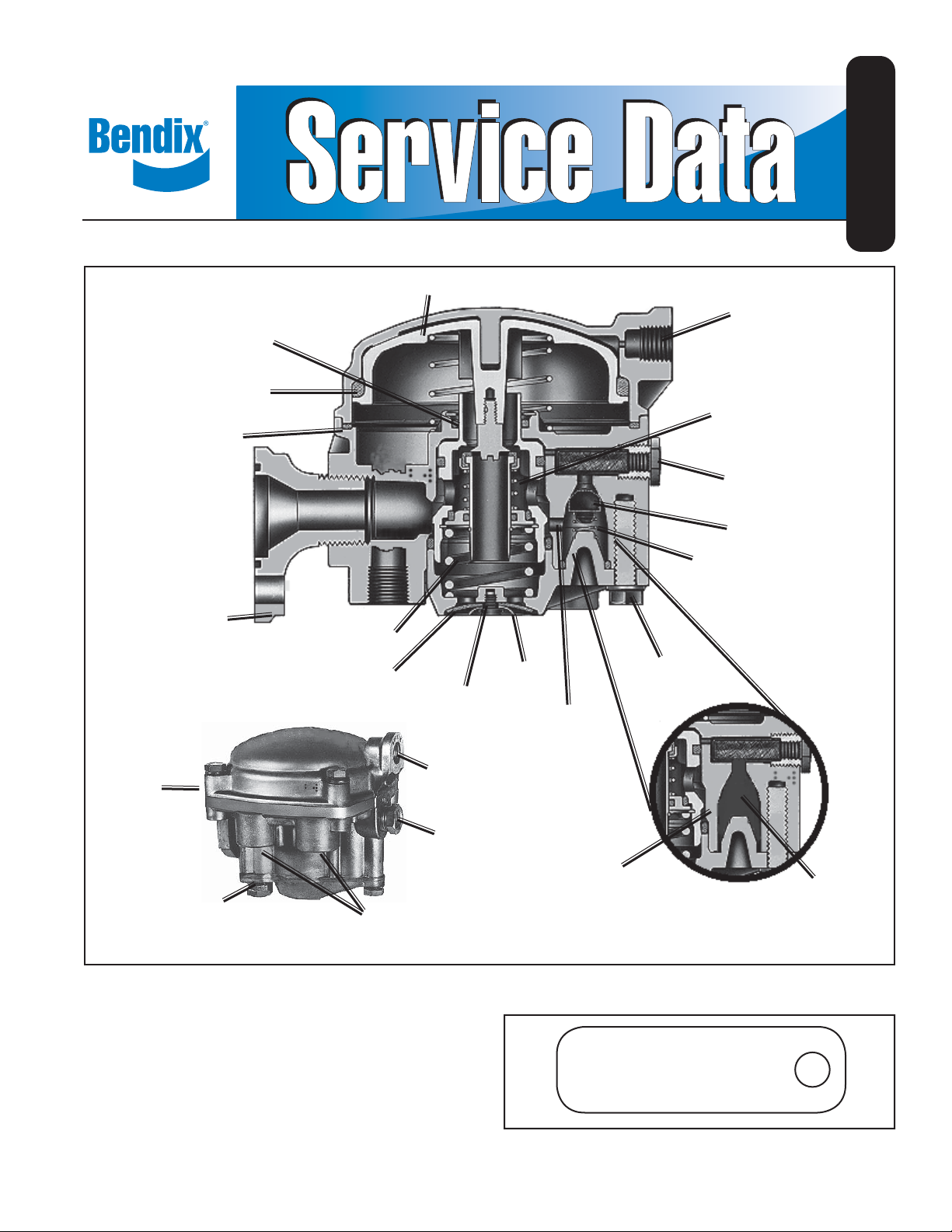

Bendix® RE-6™ and RE-6NC™ Relay Valves

RELAY PISTON

EMERGENCY

PISTON

SD-03-1151

SERVICE

PORT

O-RING

SEALING

RING

™

RE-6

Valve

MOUNTING

FLANGE

RE-6™ & RE-6NC™

Valves

RESERVOIR

PORT (2)

™

RE-6NC

ID TAG ATTACHED

SEE (FIGURE 2)

VALVE

SPRING

DIAPHRAGM

DELIVERY PORTS

(4)

SCREW

SERVICE

PORT

EMERGENCY

PORT

WASHER

CHECK VALVE

DELIVERY

PASSAGE

CHECK VALVE

DELIVERY

PASSAGE NOT

PRESENT

CAP

SCREW

INLET AND

EXHAUST

VALVE

EMERGENCY

SUPPLY PORT

CHECK VALVE

SPRING

RE-6NC

Valve

™

CHECK

VALVE

NOT

PRESENT

FIGURE 1 RE-6™ & RE-6NC™ RELAY VALVES

RE-6™ VALVE DESCRIPTION

The RE-6™ valve is used in dolly and trailer brake systems.

It is a dual function valve, combining the functions of a relay

valve and an emergency valve.

The relay function is identical to that of a relay valve, a

remotely controlled brake valve. Control pressure from the

towing vehicle is routed through the trailer service line and

RE-6NC SPECIAL

XXXXXX

SVC. REPL. XXXXXX

FIGURE 2 RE-6NC™ RELAY VALVE SPECIAL

IDENTIFICATION TAG

1

Page 2

CONTROL LINE

Service Brake Chamber

Slack Adjuster

Trailer Gladhand

FRONT

SUPPLY LINE

R-12P

Valve

™

Single Check

Valve

Reservoir

Bulkhead

™

SV-4

Valve

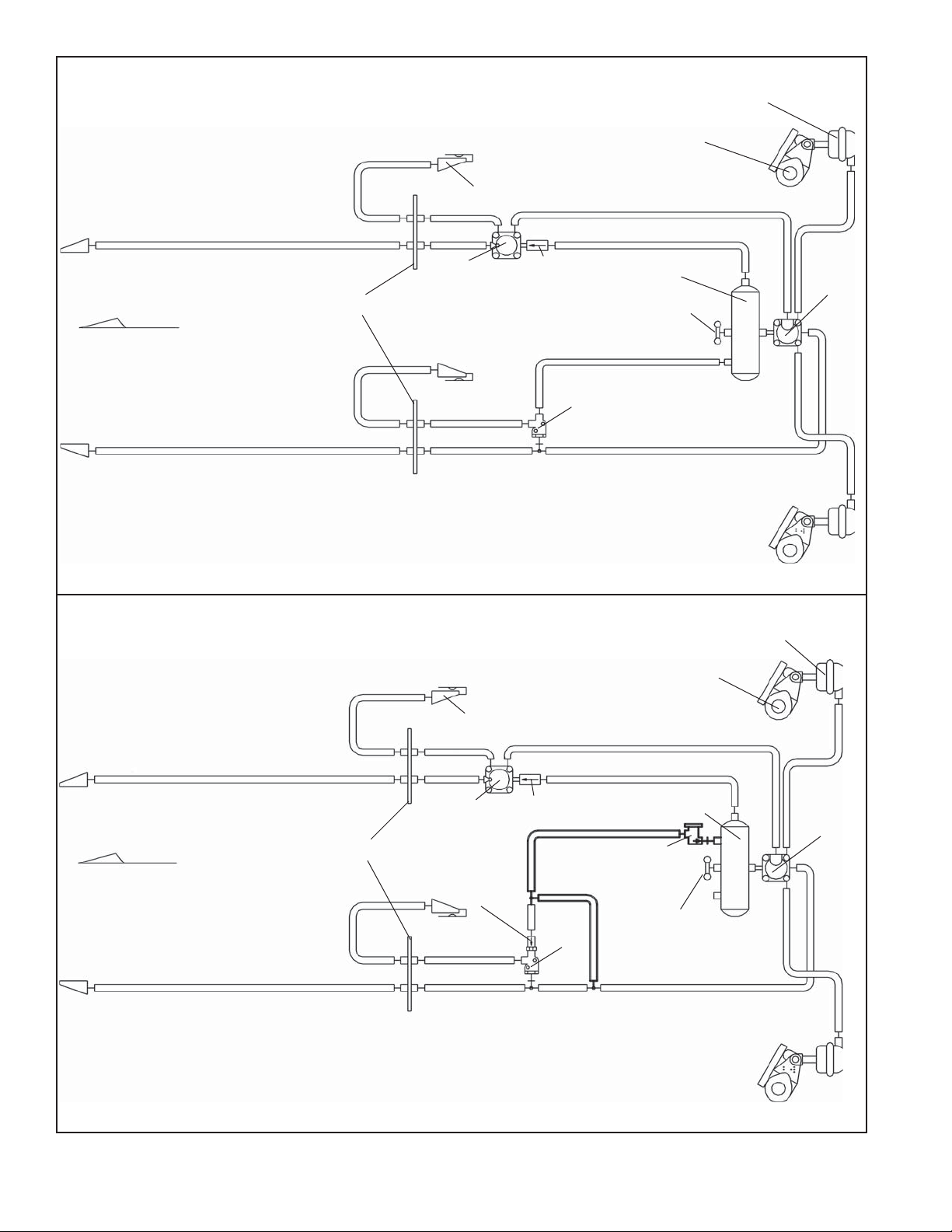

RE-6™ RELAY VALVE DOLLY SYSTEM CONFIGURATION

Trailer Gladhand

Drain

Valve

Service Brake Chamber

Slack Adjuster

RE-6

Valve

™

CONTROL LINE

™

R-12P

Valve

FRONT

Bulkhead

Single Check

Valve

SUPPLY LINE

RE-6NC™ RELAY VALVE DOLLY SYSTEM CONFIGURATION

FIGURE 3 - RE-6™ & RE-6NC™ RELAY VALVES SYSTEM CONFIGURATION

2

Single Check

Valve

™

SV-4

Valve

Reservoir

™

PR-3

Valve

Drain

Valve

™

RE-6NC

Valve

Page 3

on to the relay portion of the valve. The emergency function

of the valve automatically applies full trailer reservoir air

pressure to the trailer chambers when the trailer supply

pressure falls below a predetermined minimum value.

™

The RE-6

/RE-6NC™ relay emergency valve may be

fl ange or reservoir mounted. Ports are clearly identifi ed for

delivery, service, emergency (supply) and reservoir lines.

RE-6NC™ VALVE DESCRIPTION

The RE-6NC™ valve is a special non-charging relay

emergency valve. It is used on dollies to comply with

FMVSS 121. The RE-6NC™ valve eliminates the need for

a protected reservoir to provide the release air for the trailer

spring brakes when the following requirements are met:

- The trailer supply line must be 70 psi minimum with any

leakage-type service system failure.

- The parking brake must not drag at trailer supply line

pressures above 70 psi.

The relay function of the RE-6NC™ valve is identical to that

of the RE-6™ valve, serving the dolly or trailer system as

a remote controlled brake valve. The emergency function

of the valve automatically applies full trailer reservoir air

pressure to the trailer or dolly chambers when the trailer

supply pressure falls below a predetermined minimum

value. The major difference between the RE-6™ and the

RE-6NC™ valve is that the RE-6NC™ valve allows supply

pressure (initial charge) to release the spring brakes before

the dolly or trailer reservoir(s) is fi lled.

RE-6™ & RE-6NC™ VALVE SYSTEM

CONFIGURATION

In the RE-6™ valve dolly system, the supply air fl ows to the RE-

6™ valve, passes through the valve, holding the chambers in

the apply position while simultaneously fi lling the reservoir.

In the RE-6NC

supplied through the RE-6NC

valve system. The supply air fl ows to the RE-6NC™ valve,

acts upon the emergency piston, pushing the emergency

piston toward the inlet / exhaust valve seat. System

pressure in the chambers and reservoir are still at 0 psi in the

RE-6NC

™

In the RE-6NC

PR-3™ valve, which will allow the air to fl ow on to the

reservoir at a pressure setting of about 70 psi. The major

difference between the RE-6™ valve and the RE-6NC™

valve is that the RE-6NC™ valve does not require the

system to charge the reservoir to a predetermined psi

before drive away is allowed. Refer to Figure 3.

™

valve dolly system, reservoir air is not

™

valve, as it is in the RE-6™

valve system, allowing for faster trailer pull-away .

™

valve system, air is also fl owing to the

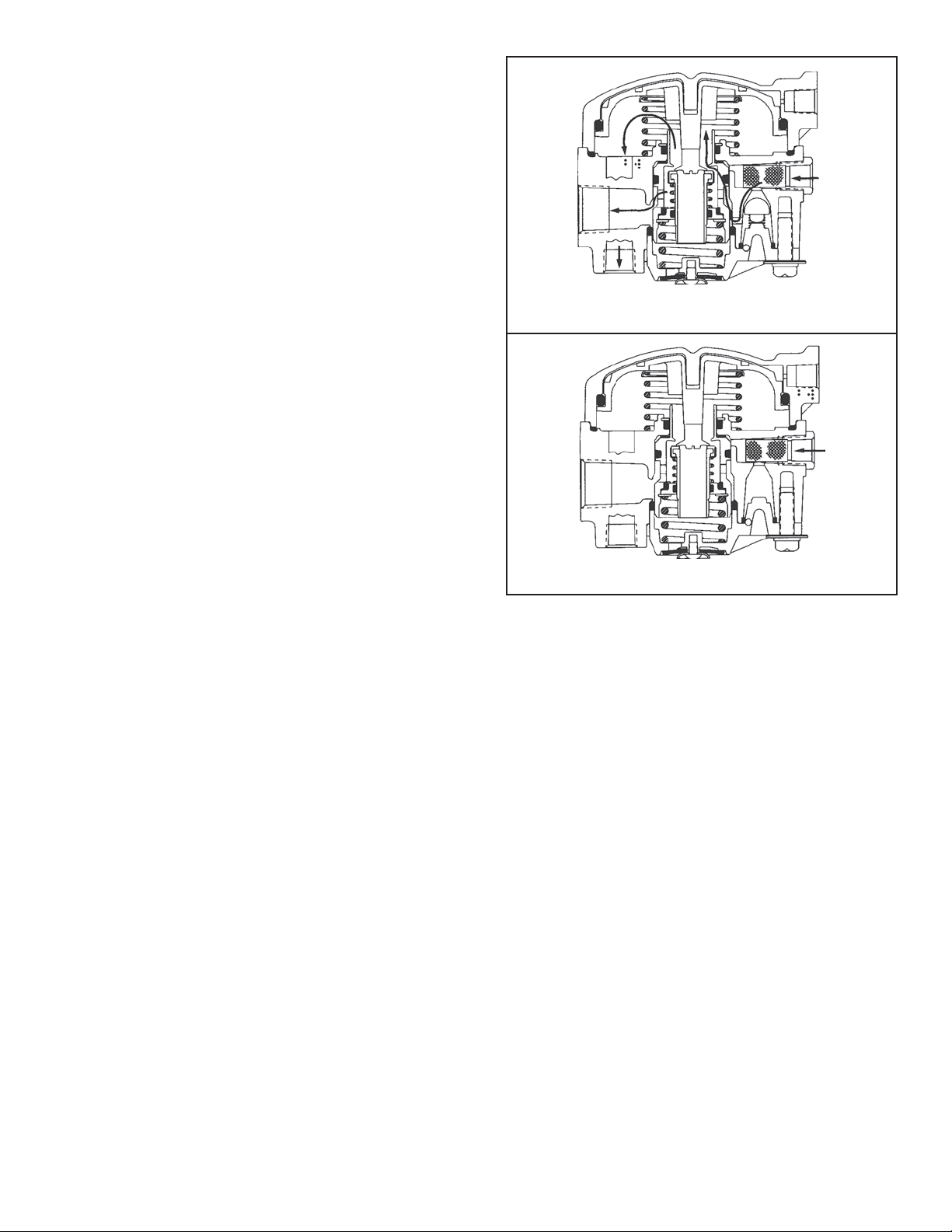

EMERGENCY

SUPPLY

RESERVOIR

45 PSI

CHAMBERS

45 PSI

45 PSI

RE-6™ Relay Valves

45 PSI

0 PSI

0 PSI

RE-6NC

FIGURE 4 RE-6

BELOW 45 PSI

CHARGING THE RE-6™ & RE-6NC™ VALVES

BELOW 45 PSI

When the air brake system is charging below 45 psi,

emergency supply air enters the RE-6™ and RE-6NC™

valves emergency port. In the RE-6™ valve the air acts on

the check valve and the emergency piston. In the RE-6NC™

valve the air acts on the emergency piston, because there

is no check valve present. This allows for faster drive away

(reference FMVSS 121 regulation). In the RE-6™ valve, the

supply air is forced past the check valve, fl owing through

the emergency piston shoulder and past the inlet / exhaust

valve. The air fl ows to the upper portion of the valve,

underneath the relay piston and out to the service brake

chambers while simultaneously fi lling the reservoir with the

same air that is passing through the emergency piston. In the

RE-6NC™ valve, air is only acting upon the emergency

piston. The check valve is not present. In replacement

of the check valve, the RE-6NC™ valve uses a reservoir

control valve (the Bendix® PR-3™ valve), to allow the

reservoir to be fi lled. The PR-3™ valve is totally separate

from the RE-6NC™ valve, but is necessary for proper

operation of the RE-6NC™ valve. Air acts on the PR-3™

valve piston, but will not fl ow on to the reservoir until about

70 psi. Refer to Figure 4.

™

& RE-6NC™ RELAY VALVES CHARGING

™

Relay Valves

3

Page 4

RESERVOIR

45<>60 PSI

EMERGENCY

SUPPLY

45<>60 PSI

RESERVOIR

60 PSI

EMERGENCY

SUPPLY

60 PSI

45<>60 PSI

CHAMBERS

HOLDING

RE-6™ Relay Valve

45<>60 PSI

0 PSI

0 PSI

RE-6NC™ Relay Valve

FIGURE 5 RE-6™ & RE-6NC™ RELAY VALVES CHARGING

HOLD POSITION

RE-6™ & RE-6NC™ VALVES CHARGING HOLD

POSITION

In the RE-6™ valve, as pressure increases in the reservoir,

the emergency piston is being pushed toward the seat on

the inlet and exhaust valve. When the emergency piston

reaches the seat of the inlet / exhaust valve, air is trapped

between the new seal and the chambers, holding the

chambers in the apply position. The check valve in the

RE-6™ valve will continue to remain open, charging

the reservoir. In the RE-6NC™ valve, air is acts on the

emergency piston, but there is still 0 psi in the reservoir

and the chambers. Air is also acting on the piston in the

PR-4™ valve, but still has not reached the opening pressure

of 70 psi. Refer to Figure 5.

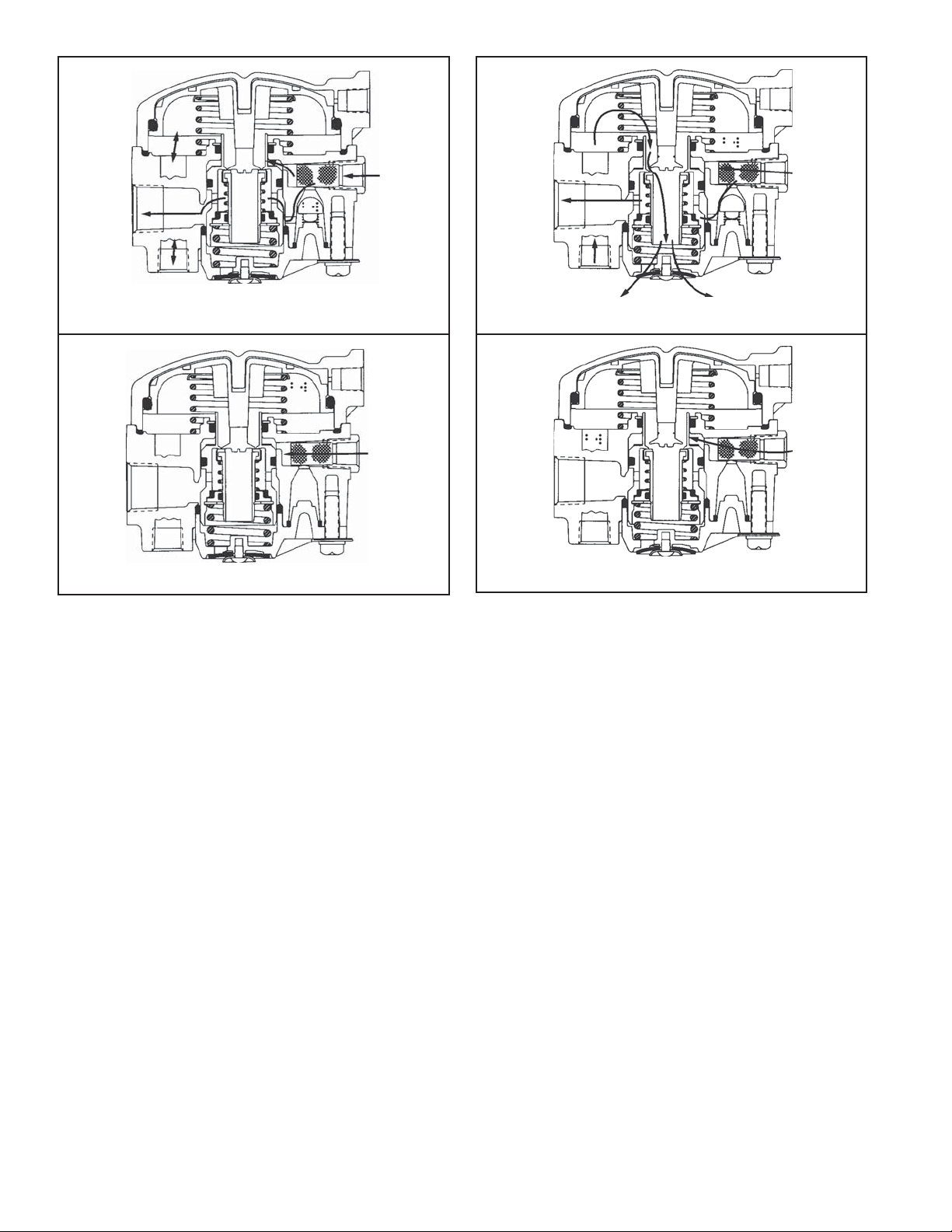

CHARGING THE RE-6™ & RE-6NC™ VALVES

ABOVE 60 PSI

In the RE-6™ valve, as pressure increase beyond 60 psi, the

emergency piston and the inlet / exhaust valve, move from

the seat of the primary piston, opening the exhaust valve to

atmosphere allowing the service chambers to be exhausted.

The air will fl ow from the service chambers, back through

the RE-6™ valve and out the exhaust of the RE-6™ valve,

CHAMBERS

0 PSI

RE-6™ Relay Valve

60 PSI

0 PSI

0 PSI

RE-6NC™ Relay Valve

FIGURE 6 RE-6™ & RE-6NC™ RELAY VALVES CHARGING

ABOVE 60 PSI

allowing drive away . In the RE-6NC™ valve, air is still acting

upon the emergency piston, but there is no pressure in the

reservoir and the chambers. The emergency piston and

inlet / exhaust valve have moved to the exhaust position,

opening the exhaust portion of the valve to atmosphere.

The PR-3™ valve remains closed until reaching 70 psi,

allowing air to fl ow to the reservoir. Refer to Figure 6.

CHARGING THE RE-6NC™ VALVE ABOVE 70 PSI

Once system pressure reaches 70 psi, the PR-3™

reservoir control valve will open charging the reservoir(s).

Simultaneously the emergency piston and inlet / exhaust

valve of the RE-6NC™ valve is kept away from the seat

of the primary piston (keeping the exhaust valve open to

atmosphere). This is the major difference between the

RE-6™ valve and the RE-6NC™ valve. The RE-6NC™ valve

allows for quicker drive away , since the reservoir does not

need to be fi lled before the brakes are released. Refer to

Figure 7.

4

Page 5

RE-6™ & RE-6NC™ VALVES SERVICE

APPLICATION

During normal, service braking operation, the valve serves

as a relay valve, synchronizes tractor service (application)

SERVICE

HOLD

5 PSI

EMERGENCY

RESERVOIR

70 PSI

SUPPLY

70 PSI

RE-6NC™ Relay Valve

FIGURE 7 RE-6NC

PSI

air pressure with trailer service (application) air pressure

as the service foot brake valve on the tractor is operated.

If the tractor is equipped with a trailer hand (TC) valve, the

trailer brakes can be applied independently of the tractor

™

RELAY VALVE CHARGING ABOVE 70

SERVICE

BRAKE

APPLICATION

10 PSI

CHAMBER

HOLD 5 PSI

FIGURE 9 RE-6

HOLD

™

& RE-6NC™ RELAY VALVES SERVICE

NO AIR FLOW

enough to allow the inlet / exhaust valve to re-seat on the

emergency piston and close the inlet / exhaust valve. Air

is trapped between the seal of the emergency piston and

inlet / exhaust valve and the service chambers, making the

service brake application. The entrapment of air constitutes

the holding position of the valve. At this time, no air is

fl owing through the valve. Refer to Figure 9.

CHAMBER

APPLICATION

10 PSI

FIGURE 8 RE-6™ & RE-6NC™ RELAY VALVES SERVICE

APPLICATION

brakes. Air is applied to the control port of the RE-6™ and

RE-6NC™ valves, acting on the primary piston and moving

the inlet / exhaust valve away from the seat on the

emergency piston. Service application allows air to fl ow

from the reservoir, past the shoulder (on the emergency

piston) to the underside of the relay piston and on to the

service chambers to apply the brakes. Refer to Figure 8.

RE-6™ & RE-6NC™ VALVES SERVICE HOLD

Air is still being applied to the control port of the RE-6™

and RE-6NC™ valves, but the relay piston has moved

0 PSI

FIGURE 10 RE-6™ & RE-6NC™ RELAY VALVES SERVICE

EXHAUST

RE-6™ & RE-6NC™ VALVES SERVICE EXHAUST

When air is removed from the control port of the RE-6™ and

RE-6NC™ valves, the relay piston moves upward. As the

air is let off the control port, the relay piston moves from

its seat on the inlet / exhaust valve, opening the exhaust

path to atmosphere. Air fl ows from the service chambers,

past the relay piston, through the emergency piston and

inlet / exhaust valve to atmosphere past the diaphragm.

Refer to Figure 10.

5

Page 6

RE-6™ & RE-6NC™ VALVES EMERGENCY

APPLICATION

(Trailer air system charged to normal operating pressure).

Venting the emergency supply line to atmosphere will

cause the emergency portion of the relay emergency

valve to apply full trailer reservoir pressure to the trailer

service chambers. If the emergency supply line pressure

is reduced to approximately 20 psi, a graduated trailer

air chamber application will occur. The rate of this brake

application will depend upon the rate of pressure loss in

the emergency supply line.

TO RELEASE AN EMERGENCY APPLICATION

™

RE-6

Charge the trailer air system or:

A. For trailers equipped with standard brake chambers,

B. For trailers equipped with spring brake chambers,

& RE-6NC™ VALVES

block wheels and drain trailer reservoir.

block wheels and mechanically release spring brake

chambers via the mechanical release mechanism (for

specifi c instructions, refer to manufacturers service

literature.)

In an emergency , air would be removed from the emergency

™

supply line port of the RE-6

and RE-6NC™ valves, allowing

the emergency piston to return to its released position.

EMERGENCY

FALLING

FROM FULL

SYSTEM

PRESSURE

FULL SYSTEM

PRESSURE

FIGURE 11 RE-6

APPLICATION

™

& RE-6NC™ RELAY VALVE EMERGENCY

SUPPLY LINE

When the emergency piston moves back to its released

position, the seal is open between the emergency piston

and the inlet / exhaust valve. The open valve allows air to

fl ow from the reservoir, past the shoulder in the emergency

piston, past the inlet / exhaust valve, past the underside

of the relay piston moving on to the service chambers

creating an emergency application. Full reservoir pressure

will be applied to the service chambers and will not be

removed until the pressure in the emergency port of the

RE-6™ or RE-6NC™ valve reaches at least 60 psi. When

the emergency port pressure reaches any pressure above

60 psi, the emergency piston and inlet / exhaust valve will

move from the seat of the relay piston allowing the service

chambers to exhaust the air. Refer to Figure 11.

If the dolly is not equipped with parking actuators (such as

spring brakes), the wheels should be blocked to prevent

trailer movement.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO A VOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with an

®

AD-IS

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power

from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

air dryer system or a dryer reservoir module,

6

Page 7

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fi ttings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifi cally for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifi cally stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the valve

should be inspected every 6 months or 1500 operating

hours, whichever comes fi rst, for proper operation. Should

the valve not meet the elements of the operational tests

noted in this document, further investigation and service

of the valve may be required.

SERVICE CHECKS

1. Remove any accumulated contaminants. Visually

inspect the valve's exterior for excessive corrosion

or physical damage. Repair/replace the valve as

necessary.

2. Inspect all air lines connected to the valve for signs

of wear or physical damage. Repair/replace as

necessary.

3. Test air line fi ttings for excessive leakage and tighten

or replace as necessary.

OPERATIONAL AND LEAKAGE TESTS

1. Block the vehicle's wheels and fully charge the air

system.

2. Apply and release the service brakes several times

and check for prompt response of the brakes at all

appropriate wheels.

3. With the air system fully charged, apply a soap solution

to the RE-6™ or RE-6NC™ valve’s exhaust port.

Leakage of a 1" bubble in 5 seconds is permissible.

4. Make and hold a full brake application and again

apply a leak check solution to the RE-6

valve’s exhaust. Leakage of a 1" bubble in 3 seconds

is permissible.

5. With the brakes still applied, apply a leak check solution

around the valve where the cover meets the body . No

leakage at this point is permitted.

If the valve does not function as described; or if leakage is

excessive, repair the valve or replace it at any authorized

parts outlet.

™

or RE-6NC™

REMOVAL

1. Identify, mark or label all air lines and their connections

to the RE-6™ or RE-6NC™ valve. Scribe a line across

the body of the valve, including the valve cover.

When the assembly process is reached, the line will

serve as a reference to the position of the valve cover

on the valve body. Disconnect the air lines.

2. Remove the RE-6™ or RE-6NC™ valve from the

vehicle.

INSTALLATION

1. Use the mounting bracket provided with the valve, or,

if securing the valve to a reservoir, use a Schedule 80

(heavy wall) short couple, pipe nipple.

2. Reconnect all air lines to the valve using the identifi cation

made during removal.

3. Test all air fi ttings for excessive leakage and tighten

as needed. Also, perform OPERATIONAL AND

LEAKAGE TESTS before placing the vehicle back into

service.

DISASSEMBLY

The following procedure is for reference only. Always

have the appropriate maintenance kit on hand, and use its

instructions in lieu of those presented here. Refer to Figure

12 throughout. CAUTION: The RE-6™ & RE-6NC™ valve

may be lightly clamped in a bench vise during disassembly .

However, over-clamping will cause damage to the valve

and result in leakage and/or malfunction. If a vise is used,

position the valve so the jaws bear on the supply ports on

opposing sides of the valve's body.

1. Remove the four screws that secure the cover to the

body, set aside, and then slowly remove the cover.

2. Remove and discard the sealing ring(6) from sealing

ring grove located at the top of the valve body.

3. If a spring(5) is present (positioned between the bottom

side of the relay piston and the upper portion of the

valve body) set aside for the assembly process.

4. Remove the relay piston(3) from the valve body. It may

be necessary to tap the valve body lightly in order to

dislodge the relay piston from the valve cover.

5. Remove and discard the large o-ring(2) on the relay

piston.

6. Remove and discard the exhaust valve seat(4) from

the relay piston.

7

Page 8

7. Remove and discard o-ring(7) from under the crimpedon retaining ring located in the upper portion of the valve

body.

8. Turn the valve over, holding the exhaust cover , remove

the 3 cap screws(27) from the exhaust cover(22).

Remove the spring(20) and set the cap screws and

spring aside for the assembly process.

9. Remove and discard the small o-ring(19) from the

exhaust cover (located on the check valve post).

™

10. The RE-6NC

valve will not have a check valve(17)

and spring(18).

11. Remove and discard the check valve (17) and spring(18)

in the RE-6™ valve.

12. Remove and discard the diaphragm(23) from the

exhaust cover. Set screw(25) and washer(24) aside

for the assembly process.

13. Remove the emergency piston(9) and inlet / exhaust

valve(10) assembly by pushing the assembly through

the valve body , from the relay piston side of the valve.

The whole assembly will come out of the valve body

as one unit.

14. Remove and discard o-ring(8) located in the grove of

the emergency piston.

15. Remove and discard o-ring(21), which creates the

seal between the emergency piston and the exhaust

cover.

16. Remove valve retainer(16) with appropriate pliers and

set aside for the assembly process.

17. Remove and discard all internal parts. Valve guide(15),

o-rings(13&14), spring(12), valve retainer(11), inlet /

exhaust valve(10).

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Wash all non-metallic components in a soap and water

solution. Dry thoroughly.

3. Inspect interior and exterior of all metal parts for severe

corrosion, pitting, and cracks. Superfi cial corrosion

and/or pitting on the exterior of the body and cover is

acceptable. Replace the entire valve if the body or

cover interior show signs of corrosion or pitting.

4. Inspect each non-metallic component for cracks, wear,

or distortion. Replace the valve if these conditions are

found.

5. Make certain the air channel running from the cover

through the top surface of the body to the supply port

is clear and free of obstruction.

6. Inspect the pipe threads in the body. Make certain they

are clean and free of thread sealant.

7. Inspect all air line fi ttings for corrosion. Replace as

necessary. Remove all old thread sealant before

reuse.

8

ASSEMBLY

Before assembly , lubricate all o-rings, seals, and pistons as

well as body and cover bores, using the lubricant provided

in the maintenance kit. Use all of the lubricant, and spread

it evenly on the rubbing surfaces.

1. Install o-ring(8) into the grove on the emergency

piston(9).

2. Install the inlet / exhaust valve assembly into the

emergency piston. Packaged as 1 unit.

3. With Tru-Arc pliers, install valve retainer(16), making

certain it is in the grove in the emergency piston.

4. Install the emergency piston(9) (including the inlet /

exhaust valve assembly just installed) into the valve

body.

5. Install the spring(20) in body.

6. Install o-ring(19) on to the check valve post, located on

the exhaust cover.

7. Install the diaphragm(23) on to the exhaust cover,

securing it with the screw(25) and washer(24) set aside

in the disassembly process.

™

8. For the RE-6

spring(18) on to the check valve(17) and drop into the

check valve cavity . The spring will fi t in groove on the

exhaust cover (making sure spring is positioned in the

center of the cavity). If changing the RE-6NC™ valve,

discard the check valve(17) and spring(18).

9. Install o-ring(21) into channel between the valve body

and emergency piston.

10. Turn the valve over and install o-ring(7) in the channel

under the crimped-on retaining ring located in the upper

portion of the valve body. (This must be done before

the exhaust cover is installed because the emergency

piston will cover this o-ring).

11. Turn the valve back over and install the exhaust

cover(22). Install cap screws and lock washers, torque

to approximately 100 inch pounds.

12. Turn the valve over and install the sealing ring(6) in

the grove located at the top of the valve body.

13. Apply the adhesive sealant to the seat(4) threads and

install in to the relay piston.

14. Install the o-ring(2) around the relay piston(3).

15. Insert the relay piston(3) into the valve cover(1) and

push the piston to the top of the cover.

16. If so equipped, install the piston return spring(5).

17. Install the cover to body, making certain the scribe

marks line up marked in the "REMOVAL" section.

18. T orque the cap screws to approximately 100 inch

pounds.

19. Perform OPERA TIONAL AND LEAKAGE TESTS before

returning the vehicle to service.

valve, install the small check valve

Page 9

O-RING (2)

O-RING (7)

BODY

COVER (1)

O-RING (8)

EMERGENCY

PISTON (9)

INLET & EXHAUST

VALVE (10)

RELAY PISTON (3)

SPRING (5)

SEALING RING (6)

A

SEAT (4)

VALVE RETAINER (11)

SPRING (12)

O-RING (13)

O-RING (14)

VALVE GUIDE (15)

VALVE RETAINER (16)

CHECK VALVE (17)

SPRING (18)

O-RING (19)

CHECK VALVE

POST

EXHAUST

COVER (22)

DIAPHRAGM (23)

WASHER (24)

INLET

EXHAUST

VALVE

ASSEMBLY

SEE NOTE 1

SPRING (20)

O-RING (21)

LOCKWASHER

(26)

CAP SCREW

SCREW (25)

FIGURE 12 EXPLODED VIEW

Note 1: The OE production valve does not have this valve retainer. The maintenance kit includes the retaining ring to hold together

the inlet/exhaust valve. The inlet/exhaust valve comes as one piece in the maintenance kit.

(27)

9

Page 10

OPERATION

Air fl ow in the normal direction moves the check valve

from its seat, and the fl ow is unobstructed. Flow in the

reverse direction is prevented by the seating of the ball or

wafer-type disc, which is caused by a drop in up-stream

air pressure and assisted by the spring.

PREVENTATIVE MAINTENANCE

Every six months, 1,800 operating hours or every 50,000

miles inspect all parts.

Replace any check valves leaking or showing signs of wear

or deterioration. Check for proper operation.

OPERATION & LEAKAGE CHECKS

NOTE: Depending upon installation, it may be easier or

necessary to completely remove check valves so that the

following checks may be made.

With air pressure present at outlet side of check valve and

the inlet side open to atmosphere, coat the open end of

the check valve with soap suds; a 1" bubble in 5 seconds

is permissible.

If the check valve does not function as described, or

leakage is excessive, it is recommended that it be replaced

with a new genuine Bendix part available at any Bendix

parts outlet.

REMOVAL

Block and hold vehicle by means other than air brakes.

Completely drain all reservoirs.

Disconnect air lines at single check valve and remove.

DISASSEMBLY/ASSEMBLY

Note: There are no Disassembly/Assembly procedures for

SC-3™ valves. They are non-serviceable items. If a valve

does not meet the Operational and Leakage tests, it should

be replaced at any authorized Bendix parts outlet.

TESTING AND TROUBLESHOOTING

Perform “Operating and Leakage Checks”.

10

Page 11

11

Page 12

12

BW1570 © 2007 Bendix Commercial Vehicle Systems LLC. All rights reserved. 7/2007 Printed in U.S.A.

Loading...

Loading...