Page 1

®

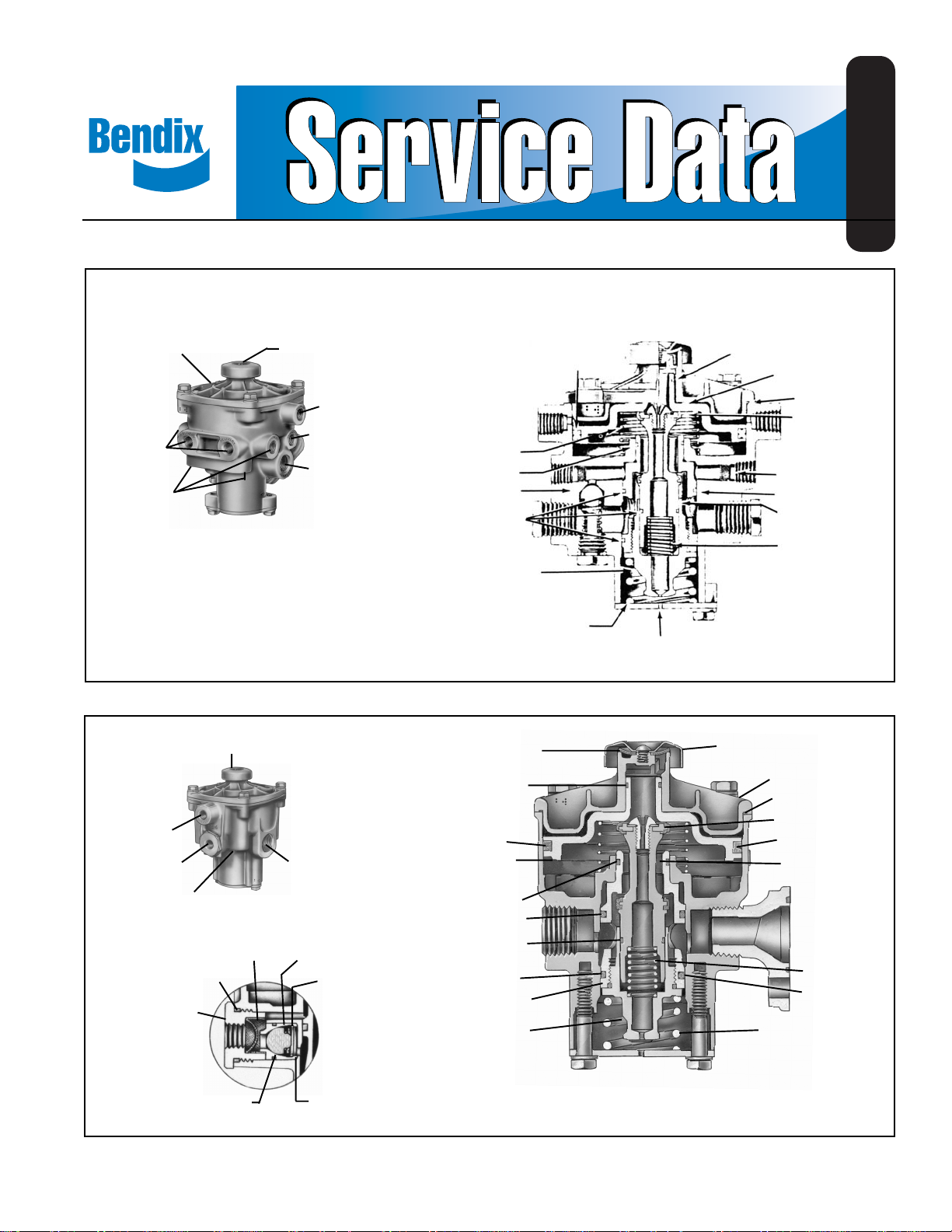

Bendix® RE-4™ Relay Emergency Valve

SD-03-1150

COVER

DELIVERY

PORTS (3)

DELIVERY

PORTS (3)

FIGURE 1 - RE-4

SERVICE

PORT

EMERGENCY

PORT

DELIVERY

PORTS (4)

CAP NUT

(20)

EXHAUST COVER

SERVICE

PORTS

EMERGENCY

PORTS (2)

RESERVOIR

PORTS

™

RELAY EMERGENCY VALVE (OLD STYLE)

EXHAUST

FILTER

PISTON TURN

RESERVOIR

PORTS (2)

O-RING

(22)

FILTER

(21)

CHECK

VALVE (24)

CHECK VALVE

SPRING (25)

SPRING

O-RING

CHECK VALVE

O-RINGS

EMERGENCY

PISTON CAP

NUT

EXHAUST

DIAPHRAGM (17)

O-RING (19)

SPRING (15)

O-RING (4)

O-RING (3)

O-RING (12)

O-RING (2)

EMERGENCY

PISTON (5)

EMERGENCY

PISTON CAP

NUT (6)

QUAD

RING

SPRING

O-RING

RELAY PISTON

GROMMET

EXHAUST

VALVE

EMERGENCY LINE

FILTERS (2)

EMERGENCY

PISTON

INLET VALVE

SPRING

COVER PLATE VENT

EXHAUST COVER (16)

TOP COVER (11)

O-RING (13)

EXHAUST VALVE (9)

RELAY PISTON (14)

INLET VALVE

BODY (10)

VALVE

SPRING (7)

O-RING (8)

EMERGENCY

SPRING (1)

CHECK VALVE

FIGURE 2 - RE-4

O-RING

SEAT (23)

™

RELAY EMERGENCY VALVE

(26)

1

Page 2

DESCRIPTION

The relay emergency valve is normally used in trailer braking

systems. It is a dual function valve, combining the functions

of a relay valve and an emergency valve.

RESERVOIR

SERVICE LINE

EMERGENCY LINE

FIGURE 3 - TYPICAL RELAY-EMERGENCY VALVE

TRAILER PIPING

The relay function is identical to that of a relay valve, serving

the trailer air brake system as a remote controlled brake

valve. Control (service) pressure from the towing vehicle is

routed through the trailer service line and on to the relay

portion of the valve.

The emergency function of the valve automatically applies

full trailer reservoir air pressure to the trailer chambers

when the trailer supply pressure falls below a predetermined

minimum.

For ease of service the valve features an “insert” cartridge

consisting of the inlet/exhaust valve and emergency piston.

Removal of the insert can usually be accomplished without

line removal.

The valve may be flange or reservoir mounted, and identified,

convenient porting locations of delivery, service, emergency

(supply) and reservoir ports are provided. (Note: Reference

Figures 1 and 2, two configurations of the RE-4™ valve are

shown). The older configuration (Figure 1) contained a total

of 13 ports. Check valve access was via a pipe plug on the

bottom of the valve. The newer and current configuration

contains 8 ports and check valve access is via a side cap

nut Interior components of both valves are identical.

RELAY

EMERGENCY

VALVE

SLACK

ADJUSTER

DRAIN

COCK

BRAKE CHAMBER

charged. This application is continued until the trailer supply

(emergency) line is charged to 60-65 psi, at which time the

application is automatically released. The trailer reservoir

continues to be charged to full operating pressure.

SERVICE APPLICATION

During normal service braking operation, the valve serves as

a relay valve, synchronizing tractor service (application) air

pressure with trailer service (application) air pressure as the

service foot brake valve on the tractor is operated. If the

tractor is equipped with a trailer hand control (TC) valve, the

trailer brakes can also be applied independently of the tractor

brakes.

EMERGENCY APPLICATION

(TRAILER AIR SYSTEM CHARGED TO NORMAL

OPERATING PRESSURE)

Venting the trailer supply line to atmosphere will cause the

emergency portion of the relay emergency valve to apply full

trailer reservoir pressure to the trailer air chambers.

If the trailer supply line pressure is reduced to approximately

20 psi due to leakage or conditions other than above, a

graduated trailer air chamber application will occur. The rate

of this brake application will depend upon the rate of pressure

loss in the supply line.

If the trailer is not equipped with parking actuators (such as

spring brakes), the trailer wheels should be blocked to

prevent trailer movement in the event reservoir pressure

would be depleted.

TO RELEASE AN EMERGENCY APPLICATION

Recharge trailer air system or:

A. For trailers equipped with standard brake chambers,

block wheels and drain trailer reservoir.

B. For trailers equipped with spring brake chambers, block

wheels and mechanically release spring brake chambers

via the mechanical release mechanism. (For specific

instructions, refer to manufacturer’s service literature.)

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

OPERATION

INITIAL CHARGING

When a tractor is connected to a trailer and the service and

emergency lines are opened (via the tractor protection

system), the valve permits charging the trailer reservoir to

approximately the same air pressure as that of the tractor

reservoir. Under initial charge conditions, the valve applies

trailer service air chambers as the trailer emergency line is

2

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the valve

should be inspected every 6 months or 1500 operating hours,

whichever comes first, for proper operation. Should the valve

not meet the elements of the operational tests noted in this

document, further investigation and service of the valve may

be required.

Page 3

OPERATING AND LEAKAGE TEST

REMOVING AND INSTALLING

Check tractor dash air gauge against a test gauge known to

be accurate prior to performing these tests. Connect tractor

air lines to the trailer on which this valve is to be tested.

Block wheels or otherwise hold both vehicles by a means

other than air brakes during these tests.

1. Start these tests with no air pressure in the tractor or

trailer air brake system. Open cut-out cocks, if installed,

and place tractor protection control valve in normal

position. As system pressure ascends and the trailer

emergency line is charged, note that the trailer brakes

are applied. Trailer brake application should completely

release as trailer emergency line pressure reaches

approximately 60-65 psi.

2. Fully charge tractor and trailer air brake systems. Make

several service brake application and check for prompt

braking response at all trailer wheels. With brakes

released and system reservoir pressure stabilized at

90-100 psi, with engine stopped, a two minute check

should result in no more than a six pound pressure drop

for the combination vehicle system. If this check indicates

possible excessive leakage of valve, soap suds should

be applied to cover plate, cover plate vent, and exhaust

port of valve to detect possible inlet valve, inlet valve guide

o-ring and emergency piston o-ring leakage. A combined

leakage as indicated by a 1” soap bubble in not less

than 5 seconds is permissible. No leakage is permissible

at pipe plugs or fittings.

3. Make and hold a full service brake application with system

reservoir pressure stabilized at 100-120 psi with engine

stopped. A two minute check should result in no more

than an eight (8) psi pressure drop for the combination

vehicle system. If this check indicates possible excessive

leakage of valve, soap suds should be applied to cover

plate, cover plate vent, and exhaust port to detect exhaust

valve, valve guide o-ring, emergency piston o-ring and

relay piston o-ring leakage. A combined leakage as

indicated by a 1” soap bubble in not less than 2 seconds

is permissible. Release the service brake application.

4. With tractor and trailer air brake system fully charged,

place the tractor protection control valve to “Emergency”

position or close the supply line cut-out cock on the

tractor and uncouple the trailer emergency line coupling.

Note that trailer brakes apply promptly. Check leakage

at valve, and at the emergency line coupling. Reconnect

and recharge tractor and trailer air brake system, noting

that trailer brakes release at a maximum of 65 psi trailer

emergency line pressure as the trailer air brake system

is recharged to full normal operating pressure.

5. With tractor and trailer air brake system fully charged,

stop engine. Reduce pressure by making a series of

applications and note that trailer brakes apply

automatically at approximately 40 psi tractor reservoir

pressure or at the automatic emergency setting of the

tractor protection equipment, if installed.

If the valve does not function as described, or leakage is

excessive, it is recommended that it be replaced with a new

or remanufactured unit or repaired with genuine Bendix parts

available at Bendix outlets.

REMOVING

1. Block trailer wheels.

2. Drain trailer systems air reservoirs.

3. Identify and disconnect air lines from valve. (Note: the

emergency piston and valve assembly, generally referred

to as the “insert” can be removed without line removal.

To remove the insert, remove cover plate and pull insert

out.)

4. Remove mounting bolts, then valve.

INSTALLING

If valve will be flange mounted directly to steel, it is

recommended that a flange gasket be utilized to prevent

electrolytic action between the unlike metals.

If the valve is adapter or nipple mounted directly to a reservoir,

it is recommended that “Never Seez” lubricant be applied to

the threads before installation. This will prevent galling of

the threads and make removal easier.

1. Clean and inspect all connecting lines and hoses for

cracks, deterioration or damage. Replace as necessary.

2. Mount valve securely.

3. Connect all lines and hoses to valve.

DISASSEMBLY

1. Remove capscrews, lockwasher, then cover plate and

emergency spring (1) from bottom of valve.

2. Remove insert (5) through bottom of valve (keep insert

centered during removal to avoid damage to exhaust

valve.

(Note: If new insert is to be installed omit steps 3-8).

3. Remove three o-rings (2) (3) & (4) from insert.

4. Using wrench flats provided, remove emergency piston

cap nut (6) from emergency piston (5). Use care to avoid

damaging finished diameters.

5. Remove valve spring (7) and emergency piston cap nut

o-ring (8).

6. Remove Phillips head screw, lockwasher and exhaust

valve (9) from inlet valve body (10).

7. Remove inlet body from emergency piston.

8. Remove inlet valve o-ring (12) from inlet valve body. Mark

cover and body to assure proper positioning when

assembling.

9. Remove capscrews, lockwashers then top cover (11) from

body. Remove o-ring (13) from cover.

10. Remove relay piston (14) and piston return spring (15)

from body.

11. Remove screw from exhaust cover (16) and remove

exhaust diaphragm (17).

12. Remove seal ring (18) and o-ring (19) from relay piston.

3

Page 4

13. Remove emergency-supply cap nut (20).

14. Remove filter (21) and o-ring (22) from cap nut.

15. Remove check valve seat (23), check valve (24), and

check valve spring (25). Remove o-ring (26).

CLEANING AND INSPECTION OF PARTS

Wash all metal parts in mineral spirits.

Wipe rubber parts dry.

Inspect all parts for wear, damage or deterioration.

Clean or replace all filters. Replace all rubber parts and any

other parts not considered serviceable by these inspections

with Genuine Bendix parts.

ASSEMBLY

NOTE: All torques specified are assembly torques and can

be expected to fall off after assembly. Do not

retorque after initial assembly torques fall. For

assembly, hand wrenches are recommended.

Prior to assembly, lubricate all o-rings and mating

surfaces with Dow-Corning 55-M pneumatic grease

(Bendix Pc. No. 291126).

1. Install o-ring (13) on top cover (11).

2. Install seal ring (18) and o-ring (19) on piston (14).

3. Install piston return spring (15) in body. Install relay piston

in cover; it should be a neat, sliding fit.

4. Install top cover/piston assembly. Torque cap screws to

100 inch pounds.

5. Install exhaust diaphragm (17), cover (16) and retaining

screw.

Note: If new insert is to be installed omit steps 6-12.

6. Install three o-rings (2) (3) & (4) on the emergency piston

insert and o-ring (12) on the inlet valve body (10).

7. Install valve spring (2) in inlet valve body (10) and slide

inlet valve body into the emergency piston cap nut (6).

Use care to avoid damaging the inlet valve o-ring.

8. Install emergency piston cap nut o-ring (8).

9. Install emergency piston cap nut in emergency piston

and tighten. Torque to 200-250 in. lbs.

10. Install exhaust valve (9) on inlet valve body using

lockwasher and Phillips head screw. (Bead on rubber

and recess in valve surface should face head of screw).

Torque to 80-120 in. lbs.

11. Install insert assembly in valve body.

12. Install emergency piston spring (1).

13. Install cover plate, lockwashers and cap nuts. Torque

cap nuts to approximately 100 in. lbs.

14. Install check valve (24) and check valve spring (25) in

check valve seat (23).

15. Install check valve o-ring (26) in body and install check

valve seat with check valve in body.

16. Install filter (21) and o-ring (22) on cap nut (20) and install

cap nut in body. Torque to 75-175 in. lbs.

17. Install plugs in unused ports.

18. Check valve as outlined in “Operating and Leakage

Check” sections before placing vehicle in service.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

™

4

BW1433 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

Loading...

Loading...