Page 1

®

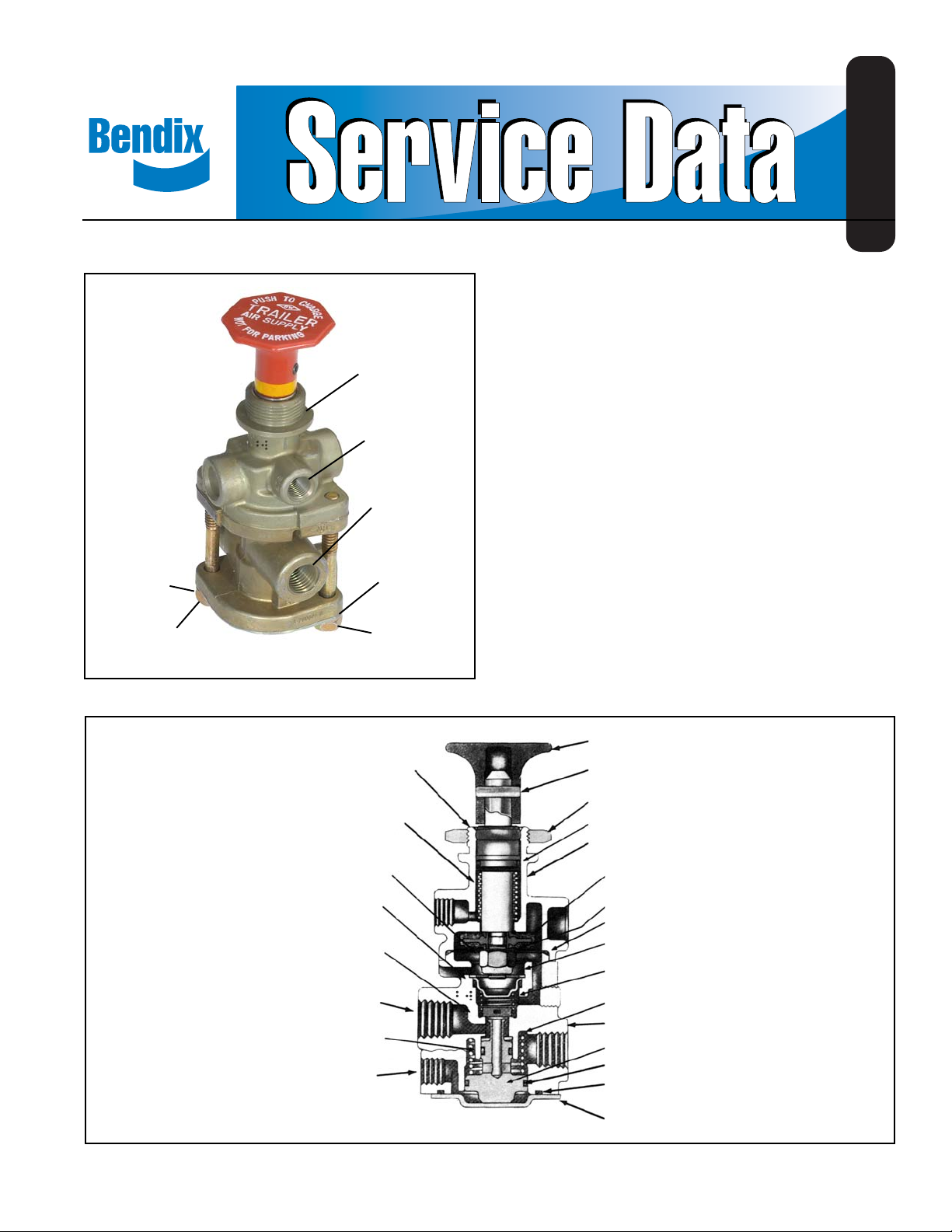

Bendix® PP-7™ Trailer Supply Valve

NUT & THREAD

1/8 P.T.

SUPPLY

EXHAUST

SD-03-3617

FUNCTION AND DESCRIPTION

The PP-7™ trailer supply valve provides in cab control for the

tractor protection system and functions in conjunction with

the park control valve. It is responsible for synchronizing the

tractor and trailer parking and emergency brakes.

It is essentially a combination of two non-modulating, onoff control valves in a single, compact package.

Each of the four pipe tapped ports of the PP-7™ valve are

identified with cast in, raised letters. The supply and control

ports have 1/8 inch N.P.T.F . dry seal pipe threads while the

delivery and exhaust ports have 1/4 inch N.P.T .F. dry seal

pipe threads.

LOCK

WASHER

CAP SCREW

FIGURE 1 - EXTERIOR

(17) PLUNGER

(18) PLUNGER

RETURN

SPRING

HEX LOCK NUT (15)

(12) O-RING

(13) INLET &

EXHAUST

VALVE

1/4 P.T. DELIVERY

(9) O-RING

1/8 P.T. CONTROL

LOCK

WASHER

CAP SCREW

GENERAL OPERA TION

The PP-7 trailer supply valve is a panel mounted, push-pull

operated control valve. The button of the PP-7™ valve must

be manually depressed, but will automatically pop out and

exhaust if supply air is below 40 p.s.i. Fifty p.s.i. or greater

supply air pressure is required for the button to remain in

BUTTON (2)

SPIROL

PIN (1)

THIN NUT

O-RING (19)

BODY

INLET & EXHAUST

(16) VALVE

RETAINING RING (10)

SEALING RING (3)

O-RING RETAINER (11)

INLET & EXHAUST (14)

VALVE SPRING

SPRING (7)

LOWER BODY

PISTON (6)

O-RING (8)

O-RING (5)

FIGURE 2 - SECTIONAL

END PLATE (4)

1

Page 2

PP-7

Control

Valve

™

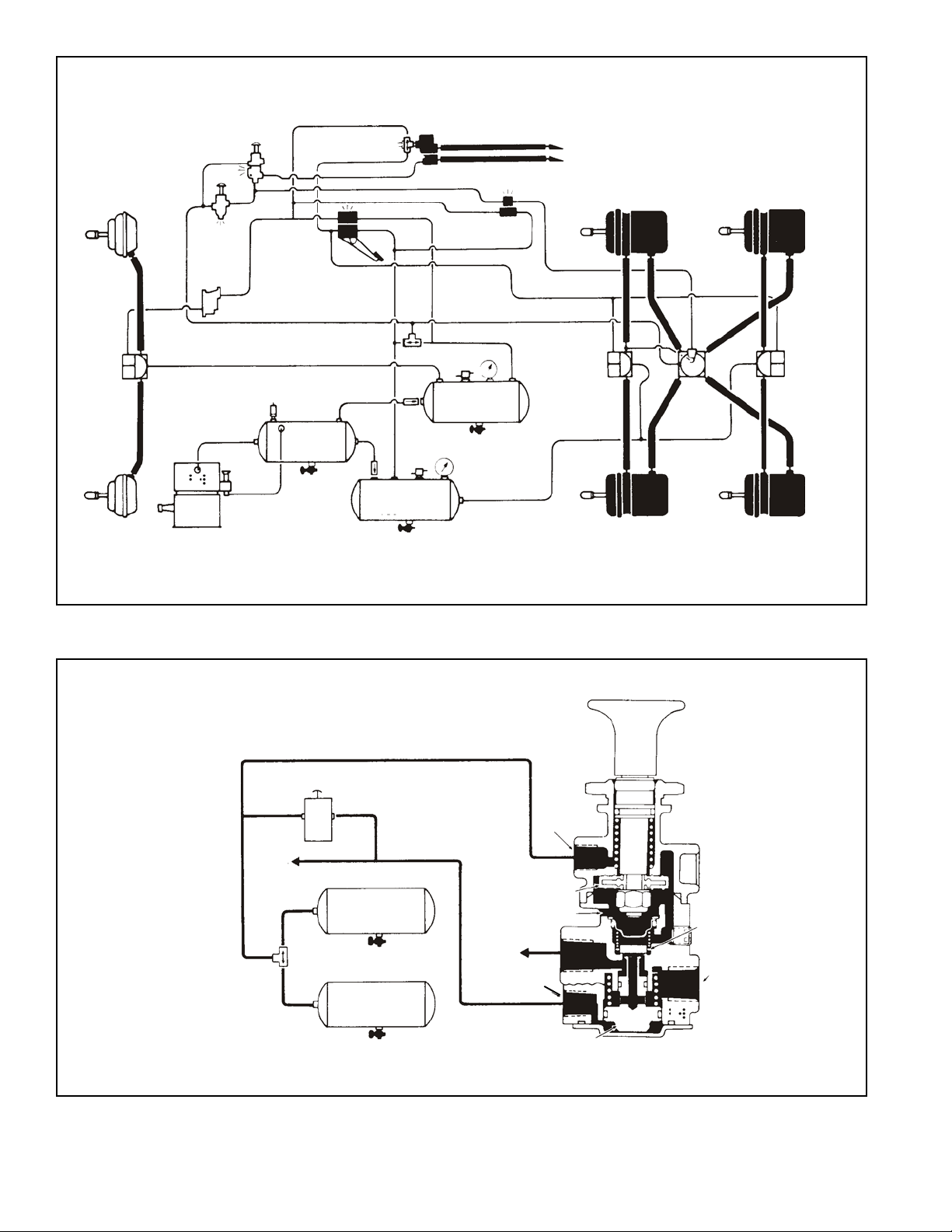

TRACTOR DUAL AIR BRAKE SYSTEM

™

TP-3

Tractor Protection

DS-1

Park

Control

LQ-3

Modulator

FIGURE 3 - PIPING DIAGRAM

™

Valve

Double Check

Supply

Reservoir

™

E-7

Dual

Brake Valve

Valve

#1 Service

Reservoir

SR-1™ Spring

Brake Valve

LP-3™ Low

Pressure Indicator

#2 Service

Reservoir

SB-3

R-8

™

SB-3

RELAY

VALVE

SB-3 SB-3

PP-7™ VALVE LESS THAN 50 PSI

SYSTEM PRESSURE

To

Parking

Brakes

Double

Check

Valve

FIGURE 4 - PP-7

™

TRAILER SUPPL Y V ALVE LESS THAN 50 PSI SYSTEM PRESSURE

Park

Control

Valve

#1 Service

Reservoir

#2 Service

Reservoir

Inlet & Exhaust

Exhaust Vent

To Tractor

Protection

Control Port

Supply

Port

Plunger

Control Inlet

and Exhaust

Exhaust

Port

Control

Piston

2

Page 3

PP-7™ VALVE SYSTEM FULLY CHARGED

Park

Control

Valve

To

Parking

Brakes

#1 Service

Reservoir

Double

Check

Valve

FIGURE 5 - PP-7™ TRAILER SUPPL Y V AL VE SYSTEM FULL Y CHARGED

#2 Service

Reservoir

Plunger

Inlet & Exhaust

Exhaust Vent

To Tractor

Protection

Control Port

Supply

Port

Control Inlet

and Exhaust

Exhaust

Port

Control

Piston

after it is depressed and it will remain in until supply air

pressure falls below 40 P.S.I. or until the valve is manually

actuated.

OPERATION - LESS THAN 50 P.S.I. SYSTEM

PRESSURE

With less than 50 P.S.I. system air pressure, the button of

the PP-7™ valve will be out and the park control valve will not

deliver air to the control port of the PP-7™ valve. In this

condition supply air cannot flow past the closed plunger inlet

and the plunger exhaust valve is off its seat. With no air

pressure on the control port, the control inlet is seated and

the exhaust passage through the control piston is open.

OPERATION - ABOVE 50 P.S.I. SYSTEM AIR

PRESSURE

When system air pressure is greater than 50 P .S.I., the button

of the PP-7™ valve can be depressed and will stay in. If the

vehicle is in the running condition, the park control valve will

be delivering system air pressure to the control port of the

PP-7™ valve. (See Note.)

With the button of the PP-7™ valve depressed, the plunger

inlet will be open and the exhaust valve will be seated, sealing

the exhaust vent. Supply air is permitted to flow through the

body to the control inlet and exhaust valve. With the park

control valve delivering full system pressure to the control

port of the PP-7™ valve, the control piston moves into contact

with the control valve, closing the exhaust passage through

the piston and opening the inlet. Opening the control inlet

permits supply air to flow out the delivery port of the PP-7

valve. (See Note.)

NOTE: If the vehicle is parked and system air pressure is

above 50 P.S.I., the park control valve will not be

delivering air to the PP-7™ valve control port and the

control inlet valve will be closed. In this case no air

will be flowing from the delivery port of the PP-7

valve.

OPERATION - MANUAL OR AUTOMATIC

EMERGENCY

MANUAL

In order to disconnect the tractor and trailer, the button of

the PP-7™ valve is pulled by the operator. Pulling the button

closes the plunger inlet and unseats the exhaust valve. Air

that was flowing out the delivery port returns to the PP-7

valve and is exhausted from the vent in the midsection of the

PP-7™ valve.

NOTE: If the parking brakes were applied prior to pulling

the PP-7™ valve button, no delivery air would be

present to exhaust. Delivery air would have been

exhausted when the parking brakes were applied.

See “Operation Park Application.”

AUTOMA TIC

In the event of trailer breakaway or a sudden complete failure

of the trailer supply line, the button of the PP-7™ valve will

pop out when air pressure in the supply line falls below 40

P.S.I.

™

™

™

3

Page 4

PP-7™ VALVE MANUAL EMERGENCY

Park

Control

Valve

To

Parking

Brakes

#1 Service

Reservoir

Double

Check

Valve

FIGURE 6 - PP-7™ TRAILER SUPPLY VAL VE MANUAL EMERGENCY

#2 Service

Reservoir

Inlet & Exhaust

To Tractor

Protection

Control Port

PP-7™ VALVE PARK APPLICATION

Supply

Port

Plunger

Exhaust Vent

Control

Piston

Control Inlet

and Exhaust

Exhaust

Port

Park

Control

Valve

To

Parking

Brakes

#1 Service

Reservoir

To Tractor

Double

Check

Valve

FIGURE 7 - PP-7™ TRAILER SUPPLY V AL VE PARK APPLICA TION

#2 Service

Reservoir

Protection

OPERATION - AUTOMATIC EXHAUST (NO

OVER RIDE)

If the driver holds the button of the PP-7™ valve in after supply

air pressure has dropped below the 40 P .S.I. automatic pop

out pressure, the control piston will move into the exhaust

position when control port pressure falls below 20 P .S.I.

Supply

Port

Plunger

Inlet & Exhaust

Exhaust Vent

Control Port

Control

Piston

Control Inlet

and Exhaust

Exhaust

Port

OPERATION - PARK APPLICATION

During a parking brake application, the park control valve

removes air pressure from the control port of the PP-7™ valve.

The button of the PP-7™ valve remains in.

With air pressure removed from the control port of the PP-7

valve, the control piston moves away from the control inlet

and exhaust valve. The inlet valve seats and the exhaust

passage through the control piston is open. Air at the delivery

port of the PP-7™ valve is exhausted at the exhaust port of

the PP-7™ valve.

™

4

Page 5

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the PP-7

valve should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

™

the PP-7

valve not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

OPERATING AND LEAKAGE CHECKS

T o perform the following test, an accurate vehicle test gauge

installed in a spare hose coupling is required. The vehicle

dash gauge(s) should be checked for accuracy against

the test gauge prior to making these tests.

1. Block or hold the vehicle by means other than the

service air brakes.

2. With the PP-7™ trailer supply valve button out and the

parking control valve in the exhaust, or brakes applied

position, build the air system pressure to governor

cut-out.

3. Apply a soap solution to the exhaust vent and the plunger

stem of the PP-7™ valve to check for leakage. Leakage

should not exceed a 1 inch bubble in 5 seconds at either

point.

4. Depress the control button of the PP-7™ valve and apply

a soap solution to the exhaust vent and the exhaust

port. Leakage should not exceed a 1" bubble in 5 seconds

at either point.

5. Install the test gauge and coupling on the trailer supply

coupling (tractor emergency hose coupling) at the rear

of the tractor.

6. Place the tractor parking control valve in the “brakes

released” position and observe an immediate rise in

pressure on the test gauge. The pressure registered on

the test gauge should equal dash gauge or system

pressure.

7. Apply a soap solution to the exhaust port of the PP-7

valve. Leakage should not exceed a 1" bubble in 5

seconds.

8. With the tractor air system at governor cut-out pressure,

shut off the engine and note the dash gauge pressure.

Quickly disconnect the test gauge and hose coupling

from the tractor-trailer supply line coupling. Leakage from

the tractor-trailer supply line should cease immediately

and button of the PP-7™ valve should be out. Dash gauge

air pressure after the performing of the preceding test

should be within approximately 10 P.S.I. of the initial

pressure.

9. Reconnect the test gauge to the tractor-trailer supply

line and depress the button of the PP-7™ valve. Open

the drain cocks of No. 1 and No. 2 service reservoirs

slightly . Note at what pressure (descending) the button

of the PP-7™ valve pops out and exhausts the

tractor-trailer supply line. This should occur between

™

20-45 P.S.I. air system pressure.

If the PP-7™ trailer supply valve fails to function as described

or if leakage is excessive, it is recommended that it be

returned to the nearest Bendix authorized outlet for a factory

remanufactured valve. If this is not possible, the valve should

be repaired using only genuine Bendix replacement parts,

in which case the following should prove helpful.

NOTE: Maintenance piece number 287367 kit is available

for the PP-7™ trailer supply valve, which contains

all the necessary parts to completely repair it, from

any authorized Bendix outlet.

REMOV AL

1. Chock the vehicle wheels and drain all air system

reservoirs completely .

2. Disconnect all air lines leading to and from the PP-7

valve and mark them for proper reconnection.

3. Using a drift pin punch, remove the spirol pin (1) Fig. 2

which secures the button to the plunger. Remove the

button (2).

4. Using a 1-5/16 inch wrench, remove the special thin

nut which secures the PP-7™ valve to the panel and

remove the valve.

DISASSEMBL Y

1. Mark the upper and lower body halves to show their

relationship to each other.

2. Remove the two 1/4 inch-20 cap screws, that secure

the lower valve body to the upper valve body, using a

7/16 inch wrench. Separate the two body halves.

3. Remove and discard the square cut sealing ring (3)

between the upper and lower body halves.

4. Remove the end plate (4) and o-ring (5) from the lower

body and discard the o-ring.

5. Remove the control piston (6) and piston return spring

™

(7).

6. Remove the large (8) and small diameter o-rings (9) from

the piston and discard them.

7. Remove the internal truarc retaining ring (10) from the

lower body .

8. Remove the o-ring retainer (11) and remove and discard

the o-ring (12).

9. Remove the inlet exhaust valve (13) and return spring

(14).

™

5

Page 6

10.Using a 7/16 inch wrench remove the special hex nut

(15) from the plunger inlet exhaust valve and washer.

1 1. Remove the plunger inlet exhaust valve (16) and washer.

12.Remove the plunger (17) and plunger return spring (18)

from the body .

13.Remove and discard the plunger o-ring (19).

CLEANING AND INSPECTION

1. Clean all metal parts in a good commercial solvent

making sure all ports, passages, and bores are clean

and open.

2. Dry the parts thoroughly and inspect the plunger and

piston bores for scratches and nicks.

3. It is recommended that all non-metallic parts and springs

be replaced, using only genuine Bendix replacements.

ASSEMBLY

GENERAL

Prior to assembly all internal bores and all non-metallic parts

should be coated with a film of silicone lubricant, Bendix

piece number 291 126.

1. Install the control inlet exhaust valve (13) and return

spring (14) in the lower body .

2. Install the o-ring (12) in the body, then the o-ring retainer

(1 1) and the truarc retainer (10).

3. Install the end plate o-ring (5) in the oval groove in the

lower body .

4. Install the plunger o-ring (19) and place the plunger return

spring (18) and plunger (17) in the upper body .

5. Depress the plunger until the threaded portion extends

sufficiently to install the plunger inlet and exhaust valve

(16), the valve washer and special hex nut (15). T orque

the special hex nut to 30-40 inch pounds.

6. Install the square cut seal ring (3) in the upper body .

7. Install the large (8) and small diameter o-rings (9) on the

control piston (6).

8. Place the upper and lower bodies together taking care

to align the marks made during disassembly .

9. Install the control piston return spring (7) and control

piston in the lower body .

10.Install the end plate (4) on the lower body and secure it

with the two 1/4 inch-20 cap screws.

1 1. T orque the cap screws to 30-40 inch pounds.

12.Reinstall the rebuilt valve on the vehicle in the reverse

manner in which it was removed.

TESTING THE REBUILT VALVE

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

™

T est the rebuilt unit using the operation and leakage checks

outlined in this manual.

6

BW1579 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

Loading...

Loading...