Page 1

®

Bendix® A2LS™ Hydraulic Drum Brakes w/Parking

DIRT SHIELD

SD-20-6608

CROSS-OVER PIPE

RETAINING SPRING

WHEEL CYLINDER END

SHOE RETURN SPRING

EXPANDER END SHOE

RETURN SPRING

WHEEL CYLINDER

EXPANDER

FIGURE 1 - A2LS™ AUT OMA TIC ADJUSTING TWO LEADING SHOE DRUM BRAKE

DESCRIPTION

The A2LS™ drum brake is a hydraulically operated duo-duplex

brake with an automatic adjustment and parking brake

feature. The A2LS™ drum brake (automatic adjust, two

leading shoes) provides two leading shoes in either direction

of drum rotation and an automatic adjustment of the brake

shoes to compensate for lining wear.

GASKET

SHOE HOLD-DOWN CLIP (NOT

FITTED TO EARLY BRAKES)

The single web brake shoes are located by slots in the wheel

cylinder tappet head, the expander input tappet/piston and

abutment tappet, and are retained by the shoe return springs.

As with all Bendix automatic adjusting brakes, provision is

made for manual override of the automatic adjuster. This

should only be needed for initial adjustment of the shoes to

a specific drum clearance, or to back off shoes to enable a

lipped drum to be removed.

CROSS-OVER

PIPE

CAP SCREWS

GROMMETS

Both the wheel cylinder unit and expander unit have cast

integral brake mounting lugs, each taking the brake torque

load. The wheel cylinder unit contains two single acting

hydraulic cylinders with automatic adjusters. The expander

unit contains a double acting hydraulic cylinder with a park

brake wedge expander . Wheel cylinder and expander units

have either a 1-5/8 inch (41,3mm) or 1-3/4 inch (44,5mm)

diameter bore depending upon vehicle brake requirements.

The units are hydraulically connected together with a bridge

pipe or crossover tube.

The brake assembly incorporates an integral backing plate

(dirtshield) to protect the brake from excessive water and

dirt intrusion. The backing plate (dirtshield) contains a steady

post for each brake shoe to insure that lining material is

kept parallel to the drum braking surface. Both brake shoes

are free to slide on their abutment faces against the backing

plate (dirtshield) and are therefore able to centralize

themselves to the drum. Lining material is 3/4 inch (19,1 1

mm) thick in the center of the shoe tapering to approximately

5/8 inch (15,9 mm) at each end. Lining inspection holes and

1

Page 2

manual override access holes are covered by rubber

grommets.

INPUT/

TAPPET

WHEEL

CYLINDER

PISTONS

PISTON

(ARROW INDICATES DIRECTION OF DRUM ROTATION)

TORQUE

LOAD

TORQUE

LOAD

WHEEL

CYLINDER

PISTONS

FIGURE 2 - SERVICE BRAKE APPLICA TION

ABUTMENT

ROLLER/TAPPET

PISTON

TAPPET

OPERATION

On brake pedal application, hydraulic fluid pressure is

delivered to the wheel cylinder and expander unit. This

hydraulic pressure forces the wheel cylinder pistons

outwards, Figure 2, moving the brake shoes against the

drum. At the same time hydraulic pressure also forces the

input tappet piston and abutment tappet in the expander

unit outward, moving the opposite end of the brake shoes

toward the drum. The expander input tappet/piston pushes

against one shoe, and the roller tappet/piston pushes on

the expander abutment tappet and through this to the other

shoe.

(ARROW INDICATES DIRECTION OF DRUM ROTATION)

FIGURE 4 - REVERSE DRUM ROTA TION

When the brake shoe lining contacts the drum the shoes

are forced around, sliding on the abutments, in the direction

Of drum rotation. In the forward direction, Figure 3, the torque

load from one shoe is taken by the wheel cylinder piston

bottoming in its bore in the wheel cylinder, and from the

opposite shoe by the expander abutment tappet resting

against the expander unit body. In the reverse direction,

Figure 4, the torque load from one shoe is taken by the

other wheel cylinder piston bottoming in its bore in the wheel

cylinder, and from the opposite shoe by the expander input

tappet/piston head resting against the expander body. In

this way, regardless of forward or reverse drum rotation,

the brake will always be a two leading shoe brake.

P ARKING BRAKE APPLICA TION

On application of the parking brake, the spring actuator

screwed into the back of the expander unit housing pushes

the wedge assembly forward. As the wedge assembly moves

TORQUE

LOAD

FIGURE 3 - FORWARD DRUM ROT A TION

2

TORQUE

LOAD

WEDGE

ASSEMBLY

FIGURE 5 - P ARKING BRAKE APPLICA TION

Page 3

PISTON

DRIVE RING

SEAL

SPRING

ADJUSTER

ADJUSTER

SHAFT HELIX

DRIVE RING

FIGURE 6 - WHEEL CYLINDER ASSEMBL Y CUT -AW A Y

forward, the wedge rollers force the expander abutment tappet

and roller tappet/piston apart, Figure 5, and directly, or

through the expander input tappet/piston the brake shoes

are forced against the drum. In parking brake operation the

brake assembly is a one leading and one trailing shoe brake,

in either forward or reverse drum rotation.

AUTOMATIC ADJUSTMENT OF BRAKE SHOES

In the A2LS™ drum brakes, automatic adjustment is

controlled by the wheel cylinder units. Adjuster assemblies

within the wheel cylinder units control the clearance between

the drum and brake shoe by the back-lash built into each

adjuster mechanism. During braking application, when no

adjustment is required, brake shoe travel takes place within

the back-lash available. As the linings wear and the dist ance

between the lining and drum exceeds the predetermined

clearance, travel of the piston exceeds the back-lash available

and adjustment of the brake shoe is automatically made.

Each wheel cylinder piston has an adjuster mechanism

screwed into it (Figure 6). The rotation of this adjuster relative

to the piston adjusts the brake shoes according to the

amount of lining wear. The adjuster shaft has a fast helix

thread; onto this is mounted a drive ring having a

corresponding thread with an axial clearance (back-lash)

built in.

MANUAL OVERRIDE

WHEEL

The adjuster drive ring is held in light contact with its seat in

the cylinder body by the drive ring spring. The brake shoe

tip engaging in the piston tappet head, and a spring between

the adjuster shaft assembly and the face of the adjuster

bore, insure that a back-lash is maintained on the mating

threads of the adjuster shaft and piston.

When the brake pedal is applied, hydraulic fluid pressure

causes the piston to move outwards, lifting the adjuster shaft

AT REST

SHOE RETURN

SPRING LOAD

DRIVE

RING

SEATED

DRIVE

RING

ADJUSTER

SCREW

PISTON AND ADJUSTER

(SCREW MOVE OUT)

ADJUSTER

SCREW

SEATED

FIGURE 7 - ADJUSTER OPERA TION

NORMAL APPLICATION

(NO ADJUSTMENT REQUIRED)

SPRING LOAD

DRIVE

RING

SEATED

ADJUSTER

SCREW

DRIVE

RING

3

Page 4

BRAKE APPLICATION

(ADJUSTMENT REQUIRED)

DRIVE RING-LIFTED OFF

SEATING-ROTATES RIDES

DOWN HELIX AND RE-SEATS

FIGURE 8 - ADJUSTER OPERA TION

BRAKES HELD ON (DRIVE RING

ALREADY SETTLED IN NEW

POSITION)

DRIVE RING

RE-SEATED

off its seat in the cylinder body. If the movement of the

adjuster shaft helix through the adjuster drive ring is less

than the axial clearance (back-lash), no rotation of the

adjuster shaft takes place. (Figure 7)

When the movement of the adjuster shaft helix through the

adjuster drive ring is greater than the axial clearance, rotation

of the drive ring relative to the adjuster shaft will occur . (Figure

8) As the adjuster shaf t helix passes through the drive ring,

the drive ring, lightly loaded by the drive ring spring, will

rotate in its seat in the cylinder body . As the brake pedal is

released, the brake shoe return springs cause the brake

shoe to push the piston and adjuster shaft assembly back

through the cylinder.

As the axial tolerance between the adjuster shaft helix and

adjuster drive ring is taken up, the load on the drive ring

helix forces it onto its seat. The resultant friction keeps it

from further rotation. As the piston and adjuster continue

through the cylinder, the adjuster shaft helix is forced to

rotate through the drive ring. (Figure 9) This rotation of the

adjuster shaft, relative to the piston, unscrews the adjuster

shaft from the piston, increasing the overall length of the

adjuster and piston assembly . This in turn reduces the brake

shoe lining to drum clearance.

The automatic adjustment rate is variable; each application

of the brake takes up only a percentage of the excess shoe

to drum clearance. This avoids over adjustment when the

drums get hot and expand.

Note: Due to manufacturing tolerances, it is unlikely that all

brake shoes will run at the same clearances. No

detrimental effect will result and no attempt should be

made to standardize these clearances.

MANUAL OVERRIDE MECHANISM

The manual override mechanism is used to override the

automatic adjuster to set the initial shoe to drum clearance.

This initial adjustment is made after new brake shoes have

been installed, or other maintenance work has been

performed requiring the removal of the brake drum. This

adjustment ‘is necessary to avoid excessive movement of

the wheel cylinder pistons and to achieve a correct and

stabilized running clearance.

The manual override is also used to un-adjust the brakes

when removing the drum when a lipped drum condition

exists.

IMPORT ANT! PLEASE READ:

BRAKES HELD ON (DRIVE RING

ALREADY SETTLED IN NEW POSITION)

SHOE RETURN

SPRING LOAD

DRIVE RING

RE-SEATED

FIGURE 9 - ADJUSTER OPERA TION

4

DRIVE RING

SEATED

RETURN STROKE

ADJUSTMENT COMPLETED

The manual override should not be used as an

alternative to the auto-adjuster. It is essential that the

auto-adjust mechanism be kept in good operating

condition to insure safe and reliable brake operation.

PREVENTIVE MAINTENANCE

The A2LS™ drum brakes normally do not require any service

except when new linings are being installed. The automatic

adjusters eliminate the need for any periodic adjustment of

the brakes. To insure safe operation of the brakes, the

following service checks should be performed.

The following is a recommended time table; the actual times

may vary depending upon the use of the vehicle and the

type of operation and condition the vehicle is exposed to.

LINE HAUL VEHICLES

Every 50,000 miles (80,000 km), six months, or 900

operating hours, whichever occurs first, perform the service

checks outlined in this manual.

Page 5

CITY DELIVERY

Every 15,000 miles (24,000 km), two months, or 300

operating hours, whichever occurs first, perform the service

checks outlined in this manual.

SERVICE CHECKS

With the vehicle on a level surface, block the wheels to

prevent movement of the vehicle.

1. Remove one or more of the lining inspection plugs.

Check the thickness of the brake linings.

2. Activate the brake pedal. Observe the brake shoes

through the inspection holes and make sure that the

brake shoes move against the drums smoothly and

promptly. Release the brake pedal and make sure the

brake shoes retract promptly and smoothly .

3. Apply the parking brake. Observe the brake shoes

through the inspection hole and make sure the brake

shoes engage the drum.

4. Check all hydraulic fittings and the surface of the

backing plate (dirtshield) for any evidence of hydraulic

fluid leakage.

5. Refer to the vehicle manual for service checks of other

brake related items.

WARNING!

When working on or around brake systems and

components, the following precautions must be

observed:

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around brake systems and

components, the following precautions must be

observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

When working around or under the vehicle, stop

the engine and remove the key from the ignition.

Always keep hands away from chambers as they

may apply as system pressure drops. Always wear

safety glasses.

2. When working in the engine compartment, the

engine should be shut off and the ignition key

should be removed. Where circumstances require

that the engine be in operation, extreme caution

should be used to prevent personal injury resulting

from contact with moving, rotating, leaking, heated

or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to the use of those tools.

4. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

5. If the vehicle is equipped with an air over hydraulic

brake system or any auxiliary pressurized air

system, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

6. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or pipe plug unless you are certain all

system pressure has been depleted.

7. Never exceed manufacturer’s recommended

pressure.

8. Never attempt to disassemble a component until

you have read and understand all recommended

procedures. Some components contain powerful

springs and injury can result if not properly

disassembled. Use only proper tools and observe

all precautions pertaining to use of those tools.

9. Use only genuine Bendix® replacement parts,

components and kits.

A. Use only components, devices and mounting

and attaching hardware specifically designed

for use in hydraulic brake systems.

B. All replacement hardware, tubing, hose,

fittings, etc. must be of equivalent size, type

and strength as the original equipment.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

ADJUSTMENT

OPENING

FIGURE 10 - REAR VIEW OF THE BACKING PLA TE

(DIRTSHIELD)

™

5

Page 6

REMOVAL

BRAKE SHOE REMOV AL

The removal, disassembly, cleaning and reassembly

instructions presented are primarily for reference.

Disassembly, particularly of the wheel cylinders and

expanders, should not be attempted without the proper

maintenance kits on hand. Damage to some parts may

occur as a result of disassembly. Maintenance kits are

available from your local authorized Bendix parts outlet.

1. Park the vehicle on a level surface and prevent vehicle

movement by a means other than with the parking brake.

Shut off engine.

2. Manually cage all hydraulic spring actuators, raise the

axle and remove the wheels and tires using the procedure

recommended by the vehicle manufacturer’s

maintenance manual.

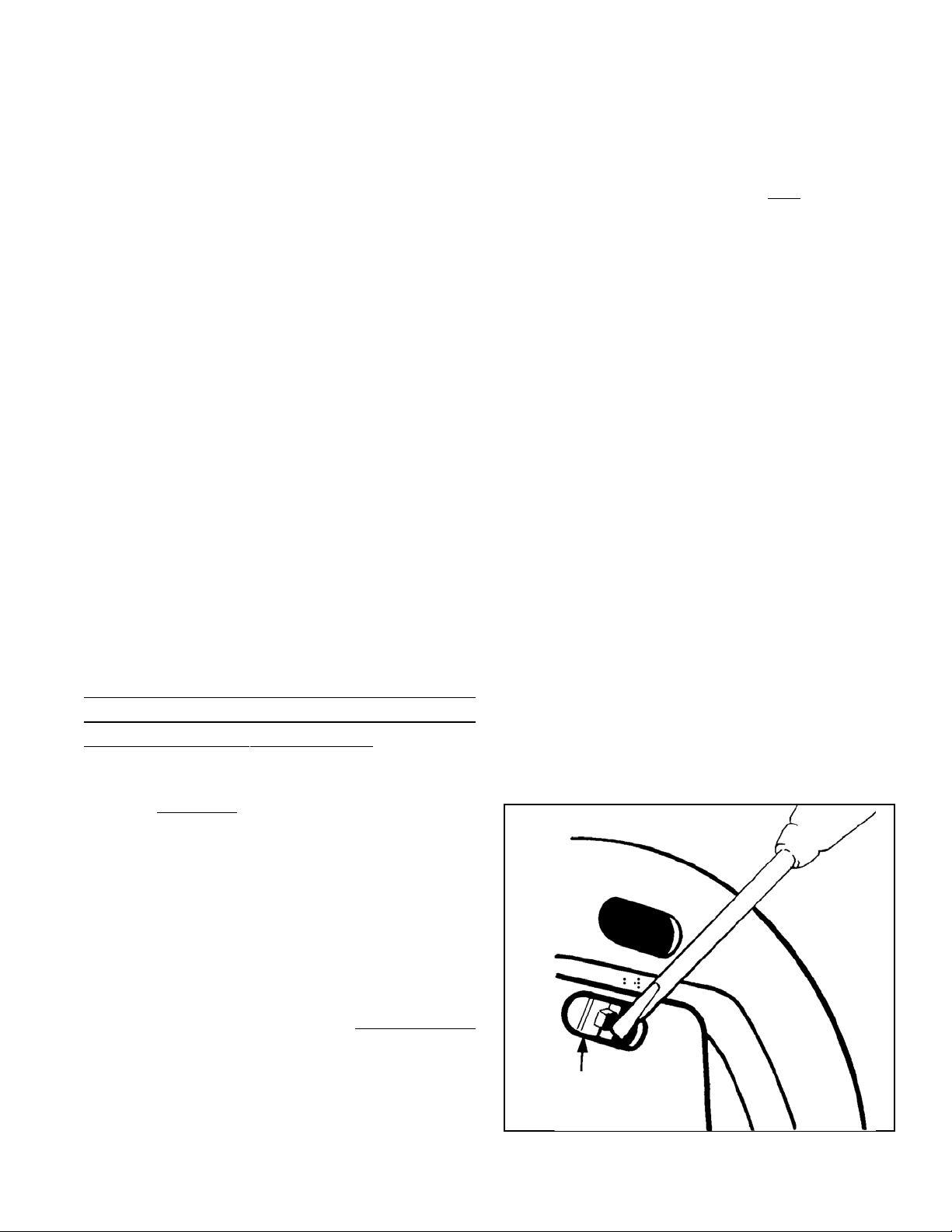

3. Un-adjust the vehicle brake shoes as follows:

A. Remove the rubber grommets from the manual

override access holes marked “ADJ” in the backing

plate (dirtshield), and insert a blunt screwdriver , or

adjusting tool, until it engages the manual override

wheel. Refer to Figure 10.

B. Using the backing plate (dirtshield) as a fulcrum,

Figure 1 1, turn the override wheel in a CLOCKWISE

direction, as viewed from the override wheel end until

the lining clears the lip in the drum. Watch the lining

through the lining inspection hole, Figure 26.

C. Repeat this procedure with the other brake shoe and

remove the drum. IMPORTANT: Do not apply

service or park brake after drums have been

removed.

DO NOT ALLOW SPRING END

TO ENGAGE INSIDE HOLE

FIGURE 12 - SHOE RETURN SPRING REMOVAL

SPRING REMOVAL TOOL MADE

FROM 0.375 IN. DIA. TOOL STEEL

COUNTER CLOCKWISE

TO ADJUST UP

CLOCKWISE TO

DE-ADJUST

FIGURE 11 - ADJUSTING ADJUSTER MECHANISM

6

A = 3/8 IN. (9.5 mm)

B = 1/2 IN. (12.7 mm)

C = 0.1 IN. (2.54 mm)

D = 0.15 IN. (3.8 mm)

E = 0.2 IN. (5 mm)

FIGURE 13

1 IN.

3/4 IN.

1/8 IN. THK.

A

1 IN.

D

C

B

3/8 IN. DIA.

E

Page 7

CLOCKWISE TO

DE-ADJUST

FIGURE 14 - DE-ADJUSTING ADJUSTER MECHANISM

PUSH DOWN

4. Place the recessed end of a 3/8 inch (9,53 mm) square

drive socket extension over the end of the wheel cylinder

end shoe return spring, Figure 12. Tap the end of the

socket extension until the hook end of the spring passes

through the brake shoe web.

5. Shape a length of drill rob, or equivalent tool steel, into a

tool as shown in Figure 13.

6. Insert the end of the tool into the loop on the end of the

shoe return spring. Using the expander unit body as a

fulcrum, unhook the spring from the brake shoe web,

Figure 25. Be careful not to damage the rubber dust

boot. Note: The brake shoe return spring is hooked into

the back side of the shoe web.

7. Ease the shoes from under the shoe hold down clips

(where fitted) and remove the back shoes.

8. Remove the tappet head and manual override assemblies

from the wheel cylinder units.

9. T o rapidly un-adjust the adjusters, fit a piece of 3/4 inch

(19,05 mm) heater hose inside a suitable 12 point socket,

Figure 14, on either a speedbrace or ratchet drive. Place

the heater hose over the piston neck and fully wind back

the adjusters as shown in Figure 14. A load must be

applied to the wheel cylinder piston while winding back

the adjusters.

Note: T o avoid locking the auto-adjuster mechanism in the

fully un-adjusted position, wind out each wheel cylinder

piston one complete turn after fully un-adjusting the

pistons.

10.Inspect the wheel cylinder unit and expander unit for

leaks. Lift the dust boots at their inner diameters from

the tappets and pistons. If fluid escapes when the dust

boots are lifted, the wheel cylinder or expander must be

removed for service. Follow the instructions in this

manual for wheel cylinder unit and expander unit removal

and service.

1 1. If there is no evidence of brake fluid leakage in the wheel

cylinder unit or expander unit, install new dust boots (if

necessary). Refit the tappet head and manual override

assembly to the wheel cylinder. Temporarily install an

elastic band around the wheel cylinder adjuster pistons

to prevent them form becoming displaced.

WHEEL CYLINDER AND EXPANDER

UNIT REMOVAL

1. Disconnect the hydraulic inlet hose and bridge pipe

from the wheel cylinder and expander unit.

2. If the expander unit is being removed at this time, remove

the parking brake chamber from the expander body

and backing plate (dirtshield). Refer to the vehicle

service manual.

3. Remove the fixing bolts that secure the wheel cylinder

and expander to the backing plate (dirtshield) and

remove the units.

4. Move the wheel cylinder and expander to a clean work

bench for service.

TAPPET HEAD AND

MANUAL OVERRIDE

WHEEL ASSEMBLY

DUST BOOT

PISTON

SEAL

ADJUSTER SHAFT

ASSEMBLY

SPRING & LOCATOR

ASSEMBLY

TAPPET HEAD

MANUAL

OVERRIDE

WHEEL

GASKET

FIGURE 15 - WHEEL CYLINDER

7

Page 8

FERRULE

FIGURE 16 - REMOV AL OF PIN FROM WEDGE

DUST BOOT

PIN

SPRING

DISASSEMBLY

BRAKE SHOES

Bendix brake shoes and linings are available as sets with

new factory lining installed. If the brake shoes are in good

condition, neither worn nor bent, new lining may be installed

on the old brake shoes. For lining installation procedures,

and brake shoe inspection procedures, refer to Bendix

publication; The Brake Block Manual Part 11, Form No.

BW-1257R.

WHEEL CYLINDER DISASSEMBLY

Before proceeding, clean the exterior of the wheel cylinder

and make sure the work area, tools, and hands are clean.

Place a clean sheet of paper on the work bench surface.

1. Clamp the wheel cylinder unit in a bench vise with padded

jaws.

INPUT TAPPET/

PISTON

SPRING & LOCATOR

HYDRAULIC SEALS

ROLLER TAPPET/

PISTON

TAPPET SEAL

HOUSING

STOP PIN

BLEED

SCREW

WASHER

RETURN SPRING

FERRULE

PIN

CIRCLIP (SNAP RING)

WEDGE SEAL- &

RETAINING RING

ASSEMBLY

WEDGE ASSEMBLY

ABUTMENT TAPPET

FIGURE 17 - EXP ANDER UNIT

8

GASKET

DUST BOOT

Page 9

2. Remove the tappet head and manual override assembly

from the wheel cylinder body , Figure 15. Sep arate the

tappet head from the manual override wheel.

3. Using a blunt screwdriver, pry the dust boots from the

housing and discard.

4. Carefully blow out both piston assemblies from the

cylinder housing using low pressure shop air. Remove

the small spring and locator assembly .

5. Unscrew the adjuster shaft assembly from the piston.

Note: Do not dismantle the adjuster shaft assembly.

6. Using a small screwdriver, with the end rounded and

polished, pry the seal from the piston, taking care not

to score the seal groove or piston surface.

EXPANDER DISASSEMBLY

Before proceeding, clean the exterior of the expander unit

and make sure the work area, tools, and hands are clean.

Place a clean sheet of paper on the work bench surface.

1. Place the expander unit in a bench vise with padded

jaws.

2. Compress the wedge return spring and remove the pin,

Figure 16. Slowly release the spring pressure and remove

spring along with the ferrule.

3. Use snap ring pliers to compress and remove the circlip

(snap ring), Figure 17.

4. Remove the dust boots from both ends of the expander

housing and discard. Note: The dust boots should not

be reused and must be replaced.

5. Remove the abutment tappet, input tappet/ piston and

stop pin from the housing.

6. Remove the wedge assembly, wedge seal, retaining ring

assembly and washer.

7. Push the roller tappet/piston from the housing in the

direction of the input tappet/piston, Figure 17. Note: Do

not slide the roller tappet/piston past the wedge turret.

8. Remove the bleed screw.

9. Using a small screwdriver, with the end rounded and

polished, pry the seals and o-ring from the input and

roller tappet/piston taking care not to score the seal

grooves or piston surface.

Clean all rubber parts that are to be reused with clean DOT

4 heavy duty brake fluid. Place on clean sheet of paper to

dry.

Inspect all of the parts that are to be reused as outlined

below. Replace those part s that are damaged or excessively

worn.

1. Wedge assembly. Check the wedge shaft and wedge

surfaces for scoring. Check the rollers for scoring, pits,

cracks, and flat spots. Check the roller cage for fatigue

cracks.

2. Abutment Tappet. Check the abutment tappet for any

nicks, burrs or corrosion. Check the brake shoe web

slot for any burrs or damage. Smooth with a fine emery

cloth or clean.

3. T appets/ Pistons. Check the outer surfaces for scoring,

pits, or nicks. Check the seal ring and o-ring grooves for

any nicks, burrs, or corrosion. Check the brake shoe

web slot of the expander input tappet/piston. Check the

inside of the piston for damaged threads. Smooth with a

fine emery cloth or clean as required.

DOT 4 FLUID

DOT 4 FLUID

DOT 4 FLUID

GREASE

GREASE

CLEANING AND INSPECTION

Discard all of the old parts that are to be replaced with

parts furnished in the repairs kits.

Clean all of the metal parts with unused DOT 4 brake fluid

or suitable solvent. Do not use gasoline or hot water solution

on metal parts.

GREASE

FIGURE 18 - EXP ANDER LUBRICATION POINTS

9

Page 10

TAPPETS LOCATED OVER WEDGE,

CAGE & ROLLER ASSY.

STOP PIN

FIGURE 19 - EXPANDER TAPPET LOCATION

Note: Normal wear pressure marks should not be mistaken

for scoring. Some discoloration of the piston diameter

may be apparent; this is a normal result of brake

actuation over a long period of operation and should

be ignored.

4. Adjuster Shaft Assembly. Check for damaged threads.

Check the helix for burrs, corrosion, or missing teeth.

Check that the adjustment shaft turns easily in the piston

for the full length of the threads. Smooth with a fine

emery cloth or clean as required.

5. Manual Override. Check the teeth of the manual override

for wear or damage.

6. Housings. Examine the cylinder bores for signs of

corrosion, ridges, or score marks.

Note: Provided the cylinder bore surfaces are in perfect

condition, new seals, and if necessary , new pistons

may be used to rebuild the existing housings. If there

is any doubt as to the condition of the cylinders, new

wheel cylinder and expander units must be installed.

INPUT TAPPET/PISTON

SEAL POSITION

O-RING

ROLLER TAPPET/

PISTON

ABUTMENT TAPPET

FIGURE 20 - EXP ANDER WEDGE

10

7. Backing Plate (dirtshield). Clean the backing plate with

a damp cloth and wire brush to remove any dirt or

corrosion from the surface of the backing plate.

IMPORT ANT! PLEASE READ:

Do not use an air hose to blow dust out of the backing

plate (dirtshield). Never inhale dust from asbestos

brake lining. Asbestos dust, when inhaled, can be

dangerous to your health. Use a vacuum with a filter

to remove dust carefully from the backing plate and

drum.

8. Brake Drum. Inspect the drum for scores and cracks.

Refer to the vehicle service manual for inspection and

resurfacing procedures. Wipe drum clean with a cloth

dampened in Bendix Metal Clene. Do not contaminate

the braking surface of the drum with grease or brake

fluid.

REASSEMBL Y

ASSEMBLE EXPANDER UNIT

Each Bendix drum brake repair kit contains a tube of

synthetic based grease that is recommended for all internal

expander parts (abutment tappet, roller tappet, piston, and

the wedge and roller assembly). This packaged grease, or

an approved substitute synthetic based grease, must be

used, and an adequate amount must be applied. Refer to

Figure 18 for identification of those parts being lubricated

with either the synthetic based grease or DOT 4 brake fluid

during assembly .

Use all of the parts supplied in the Bendix repair kit to replace

the old parts removed from the cylinders.

1. Clamp the expander housing in a bench vise with padded

jaws.

2. Thoroughly smear the wedge, cage, wedge seal and

roller assembly with the greased supplied. Fit the wedge

seal and retaining ring assembly as close to the cage

as possible.

3. Insert the wedge assembly into the expander housing

and retain with a new circlip.

4. Turn the expander housing in the vise to enable the

abutment tappet to be installed. Fit the dust boot to the

abutment tappet. Grease the inside of the dust boot and

the outside diameter and ramp face of the abutment

tappet with the grease supplied.

5. Insert the abutment tappet assembly into the housing

bore until it engages with the wedge cage and roller,

Figure 19. Install the dust boot to the end of the housing.

6. Smear the o-ring with the grease supplied and fit onto

the roller tappet/piston. Lubricate the piston seal with

new DOT 4 brake fluid and install the seal as shown in

Figure 20, with the lip of the seal facing outward toward

the pressure side. Liberally grease the ramp face and

Page 11

DUST BOOT

FIGURE 21 - WHEEL CYLINDER

SCREW ON FULLY AND UNSCREW ONE

PISTON

COMPLETE TURN

SEAL

12. Install the brake shoes following procedures under Brake

Shoe Installation in this manual. Refer to the vehicle

service manual for procedures to bleed the air from the

brake system. Af ter bleeding, manually readjust the brake

shoe to drum clearance as necessary. Refer to Brake

Shoe Adjustment in this manual.

ASSEMBLE WHEEL CYLINDER UNIT

Use all of the parts supplied in the Bendix repair kit to replace

the old parts removed from the cylinder .

1. Lubricate the piston seal, Figure 15, with new DOT 4

brake fluid and install the seal onto the piston with the

lip facing inwards, Figure 21.

Install the dust boot to the piston and smear the inside

of the dust boot with the grease furnished in the kit.

OVERRIDE

WHEEL

FIGURE 22 - PISTON ADJUSTER

insert the assembly into the bore of the housing until it

engages the wedge cage and rollers, Figure 16. Install

and tighten the stop pin to 16 ft. lbs. (23,3 N.m).

7. Fit the dust boot to the input tappet/piston, lubricate the

piston seal with new DOT 4 brake fluid and install the

seal onto the piston with the lip facing inward, Figure

20. Grease the inside of the dust boot with the grease

supplied and install the input tappet/piston assembly into

the housing bore until it rests on the roller tappet/piston.

Fit the dust boot to the end of the housing.

8. Turn the expander housing in the vise to enable the

wedge return spring to be installed. Locate the spring

ferrule on the spring and compress the spring over the

wedge stem until the pin can be inserted, Figure 16.

Release the spring carefully .

Note: Push in wedge assembly slightly and center it inside

the housing.

9. Install the bleed screw.

10. Install the expander to the backing plate (dirtshield) using

a new gasket, Figure 1, and secure in place with fixing

bolts.

1 1. Refer to the vehicle service manual and stall the parking

brake chamber. Install bridge pipe and hydraulic hose.

RETAINER

RING

GROOVE

IN PISTON

OLD STYLE

OVERRIDE WHEEL

RETAINER RING

GROOVE IN PISTON

HAS BEEN ELIMINATED

NEW STYLE

FIGURE 23 - NEW AND OLD STYLE PIST ON AND OVERRIDE

WHEEL

11

Page 12

LEFT HAND

BRAKE ASSEMBLY

GREEN ON LH

BRAKE YELLOW

ON RH BRAKE

FIGURE 24 - POSITION OF BRAKE SHOE RETURN SPRINGS

RED ON LH &

RH BRAKES

Note: A new design piston may be used to replace the piston

in older style brakes but the override wheel must also

be changed. Although it would be permissible to fit an

old style piston into a new style brake, it would be a

retro-grade step and is not recommended. Ensure that

the tappet head assemblies are located securely on

the piston necks.

IMPORT ANT : Do not turn the manual override wheel.

5. Repeat the above procedure for the other wheel cylinder.

6. Install the wheel cylinder unit to the backing plate

(dirtshield) using a new gasket, Figure 1, and secure in

place with fixing bolts. Install the bridge pipe and

hydraulic brake hose.

7. Install the brake shoes following procedures under Brake

Shoe Installation in this manual. Refer to the vehicle

service manual for procedures to bleed the air from the

brake system. After bleeding, manually readjust the

brake shoe to drum clearance as necessary. Refer to

Brake Shoe Adjustment in this manual.

BRAKE SHOE INSTALLATION

2. Lubricate the adjuster shaft with DOT 4 brake fluid and

screw the adjuster shaft fully into the piston assembly ,

then unscrew one full turn, Figure 22.

3. Install the spring and locator assembly into the adjuster

shaft assembly. Lubricate the piston assembly with new

DOT 4 brake fluid and install the piston assembly into

the cylinder housing. Fit the dust boot onto the housing.

4. Install a new retainer into the override wheel and install

the override wheel and tappet head onto the piston. On

old style A2LS™ drum brakes, the override wheel had an

internal retainer ring which also locates in a groove in

the neck of the piston, Figure 23. The latest override

wheel still uses the retainer ring but it is positioned further

up the override wheel. The groove in the piston neck has

been deleted.

High temperature grease should be used on those external

parts that require lubrication (slots on the pistons and

tappets, and on the steady posts).

Always install new brake shoes in axle sets. When installing

new brake shoes also install new shoe return springs.

1. Lightly smear the abutment ends of the brake shoes

and steady posts with high temperature grease. Keep

the grease away from all hydraulic components and

the shoe linings. Refer to Figure 24 for correct position

of the replacement brake shoes and shoe return springs.

Note: The color of the spring identifies its position in the

brake assembly .

FIGURE 25 - USING TOOL TO A TT ACH SPRING

12

LINING

INSPECTION

HOLE

SPRING TOOL

(REFER

FIGURE 13)

BRAKE LINING

FIGURE 26 - BRAKE SHOE INSPECTION HOLE

Page 13

RED - Park brake expander end on both LH and RH brakes.

GREEN - Wheel cylinder end on LH brakes.

YELLOW - Wheel cylinder end on RH brakes.

2. Remove the elastic bands from around the wheel cylinder

used to retain the pistons for assembly .

3. Push the abutment ends of the brake shoes into the

slots on the piston and tappets.

4. Attach the swan neck end, end opposite the loop in the

spring, of each return spring to the brake shoe web as

shown in Figure 25. Using the tool, Figure 13, hook the

other end of the return spring into the shoe web.

5. Install the brake drums.

6. Repeat with opposite wheel.

7. Ensure that the wedge stem is centralized.

8. Fit spring brake chambers to brakes per vehicle service

manual.

9. If new wheel cylinders or expander units were installed,

or the brake system drained, refer to the vehicle service

manual and bleed the brake system.

BRAKE SHOE ADJUSTMENT

1. Manually adjust both wheel cylinders through the

adjusting holes, Figure 10, until the shoe to drum

clearance is less than .76 mm (.030"). Check the shoe

to drum clearance by using a feeler gauge through the

lining inspection holes, Figure 26.

2. Apply the foot brake pedal to centralize the brake shoes

and release. Recheck the shoe to drum clearance; if

not 0.51 to 0.76 mm (0.020" to 0.030") manually adjust

the wheel cylinder until those dimensions are reached.

3. Replace all rubber grommets previously removed from

the backing plate (dirtshield).

Note: Due to manufacturing tolerances, it is unlikely that all

shoes on an axle will run at the same drum clearances.

No detrimental effects will result from this condition,

and no attempt should be made to standardize the

clearance.

4. Correct and full adjustment will only occur with the drum

rotating; i.e., with the vehicle moving. Pumping the brake

pedal with the vehicle stationary will not achieve proper

adjustment.

5. Refit road wheels.

6. Rotate each wheel to insure that the hydraulicsystem

has fully released parking brakes.

7. Apply parking brake and check that the wheels cannot

be rotated by hand.

8. Jack down vehicle. Run engine and release parking

brakes. Drive vehicle slowly and check service and

parking brakes, finally road test.

FINAL CHECK

IMPORT ANT! PLEASE READ:

Before test driving any vehicle, first check the hydraulic

fluid level in the master cylinder.

1. Check the hydraulic fluid level of the brake master

cylinder. If the fluid level is more than 1/4 inch (6,35 mm)

from the top of the reservoirs, fill the reservoirs with DOT

4 heavy duty hydraulic brake fluid.

2. Depress the brake pedal several times to seat the brake

shoes against the drums. Recheck the fluid level of the

master cylinder reservoirs.

3. Check the brake pedal travel by pushing the brake pedal

as far down as possible. If the brake pedal free play

exceeds recommended dimensions, or brake warning

light is lit, refer to the vehicle service manual.

4. With the vehicle on a level surface in a parking or service

area, start the engine and apply the parking brake; test

for operation.

5. With the vehicle moving at slow speed, make a series of

light snubs and follow with a series of normal service

stops before making a panic stop. Make sure the service

brakes stop the vehicle in an even and straight line,

without any pulling to either side.

6. Accelerate the vehicle to a speed of 20 mph (32 km/h)

then apply the service brakes. A 30 ft. (92,4 m) stop with

the service brake from 20 mph (32 km/h) is recognized

as being satisfactory .

IMPORT ANT : Run engine and release park brake. Wind

the park brake chamber spring release bolts in place

until they bottom firmly in the unit. They should be

torqued to the vehicle manufacturer’s

recommendations.

13

Page 14

DRUM BRAKE TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

1. Low Pedal. 1. Excessive clearance between 1. Adjust brakes.

drums and linings.

2. Automatic adjusters not 2. Make several forward and

working. reverse stops; if pedal does not

come up, repair automatic

adjusters.

3. Bent or distorted brake shoes. 3. Replace shoes and linings in axle

sets.

4. Leak in hydraulic system. 4. Refer to vehicle service manual.

5. Air in hydraulic system. 5. Bleed system; refer to vehicle

service manual.

6. Low brake fluid. 6. Fill master cylinder. If

necessary , bleed system. Refer

to vehicle service manual.

7. Weak brake hoses. 7. Refer to vehicle service manual.

2. S pringy or spongy 1. Bent or distorted brake shoes. 1. Replace shoes and linings in

pedal. axle sets.

2. Shoes not centered in drums. 2. Make certain shoe webs are

seated in tappet or piston slots.

3. Cracked or thin drums. 3. Replace drums in axle sets.

4. Air in hydraulic systems. 4. Bleed system; refer to vehicle

service manual.

5. Weak brake hoses. 5. Refer to vehicle service manual.

6. Drums out of round. 6. Refinish, or replace if wear

exceeds limits.

3. Hard pedal. 1. Grease or brake fluid on linings. 1. Replace grease seal, wheel

cylinder, or exp ander as

necessary . Replace brake shoes

in axle sets.

2. Glazed linings. 2. Sand lining surfaces or replace

shoes and linings in axle sets.

3. Damaged or distorted shoes. 3. Replace brake shoes in axle sets.

4. Scored, barrel-shaped, or 4. Refinish or replace drums in

bell-mounted drums. axle sets.

5. Defective master cylinder or 5. Refer to vehicle service manual.

other brake system components.

4. Grabby brakes. 1. Incorrect or distorted shoes. 1. Replace with correct shoes in

axle sets.

2. Incorrect linings or lining loose 2. Replace with correct shoes

on shoes. in axle sets.

3. Grease or brake fluid on linings. 3. Repair grease seal, wheel

cylinder, or exp ander as

necessary . Replace brake shoes

in axle sets.

4. Shoes not centered in drums. 4. Adjust steady post.

5. Loose or distorted backing plate 5. Tighten or replace backing plate

(dirtshield). (dirtshield).

14

Page 15

DRUM BRAKE TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

6. Scored, hard spotted or out of 6. Refinish or replace drums in

round drums. axle sets.

7. Rough or corroded master 7. Refer to vehicle service manual.

cylinder bore.

8. Binding brake pedal linkage. 8. Refer to vehicle service manual.

9. Faulty power brake unit. 9. Refer to vehicle service manual.

5. V ehicle pulls to one 1. Incorrect or distorted shoes. 1. Replace with correct shoes in

side. axle sets.

2. Incorrect linings or linings loose 2. Replace with correct shoes in

on shoes. axle sets.

3. Grease or brake fluid on linings. 3. Replace grease seal, wheel

cylinder or expander as

necessary . Replace brake shoes

in axle sets.

4. Shoes not centered in drums. 4. Adjust steady post.

5. Loose or distorted backing plate 5. Tighten or replace backing plate

(dirtshield). (dirtshield).

6. Scored, hard spotted, or out of 6. Refinish or replace drums in

round drums. axle sets.

7. Water on linings. 7. Apply brakes several times to

dry linings.

8. Sticking wheel cylinder piston. 8. Replace or repair wheel cylinder.

9. Faulty suspension parts. 9. Refer to vehicle service manual.

6. Noise and chatter . 1. Bent, damaged, or incorrect 1. Replace with correct shoes in

shoes. axle sets.

2. Worn linings. 2. Replace with correct shoes in

axle sets.

3. Broken shoe return spring. 3. Replace shoe return springs.

4. Rough, grooved, or dry shoe 4. Smooth shoe abutment surfaces

abutment surfaces or steady and steady post with emery

post on dirtshield. cloth and lubricate with brake

lubricant.

5. Cracked or threaded drums. 5. Replace drums in axle sets.

7. Pulsating brake 1. Out of round drums. 1. Refinish or replace drums in

pedal. axle sets.

2. Bent axle. 2. Refer to vehicle service manual.

3. Worn or damaged wheel 3. Refer to vehicle service manual.

bearings.

4. Defective master cylinder. 4. Refer to vehicle service manual.

5. Brakes overadjusting. 5. Adjust brake shoes and repair

automatic adjuster if necessary .

8. Decreasing pedal 1. Weak or broken shoe return 1. Replace shoe return springs.

travel. spring.

2. Sticking wheel cylinder piston. 2. Repair or replace defective wheel

cylinder.

15

Page 16

DRUM BRAKE TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

9. One brake drags. 1. Weak or broken shoe return 1. Replace shoe return springs.

spring.

2. Improper brake shoe 2. Adjust brake shoes and repair

adjustment. automatic adjuster if necessary .

3. Defective wheel cylinder. 3. Repair or replace wheel cylinder .

4. Bent or distorted brake shoe. 4. Replace brake shoes in axle sets.

10. Parking brake will 1. Defective expander unit. 1. Repair or replace expander unit.

not engage.

2. Binding wedge assembly. 2. Repair or replace wedge.

3. Parking brake actuator not 3. Refer to vehicle service manual.

working.

16

BW1601 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2004 Printed in U.S.A.

Loading...

Loading...