Page 1

Technical Bulletin

Bulletin No.: PRO-03-02 Effective Date: 10/30/69 Cancels: N/A Page: 1 of 9

Subject: 1970 FORD “L SERIES” MODEL DUAL AIR BRAKE

SYSTEM

The purpose of this bulletin is to generally familiarize you with the dual air brake system

standard on all 1970 “L Series” Ford Trucks. Both four wheel and six wheel systems are

offered with either wedge or S Cam foundation brakes. We have attached lithos of these

systems (SA 8042-63 used for six wheel, SA 8042-64 for four wheel) for your reference.

These systems provide a modulated emergency application of the Spring Brake

Actuators and a full spring application for parking. In addition to normal service braking.

Three new Bendix Commercial Vehicle Systems LLC devices are used in these

systems:

1. E-7 Dual Brake Valve

2. R-7 Modulating Valve

3. VM-1 Control Valve Manifold

Page 2

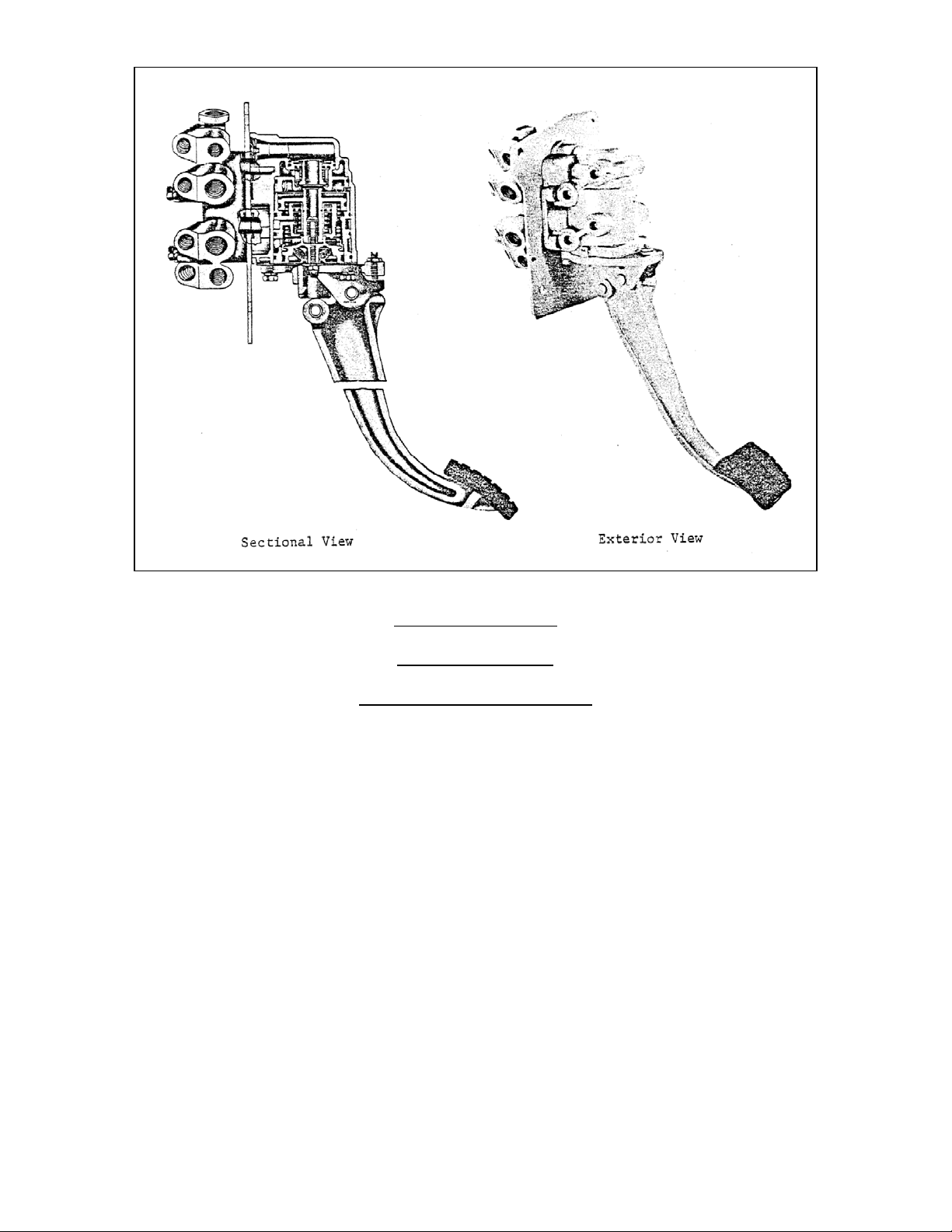

E-7 Dual Brake Valve

B-W Pc. No. 282410

Ford Part No. DOHA 2A 270-C

1. The E-7 Dual Brake Valve is a suspended pedal, firewall mounted, foot operated

dual brake valve with two separate supply and delivery circuits for service and

emergency braking. An air manifold is bolted to the back of the valve to

accommodate the piping. Sealing of the ports between the manifold and valve is

accomplished with the use of o-rings.

The E-7 Dual Brake Valve is similar in operation to that of the E-4 Dual Brake Valve

in that the primary portion of the valve is mechanically operated by the pedal, and the

secondary portion of the valve is pneumatically actuated by primary circuit delivered

air pressure acting on a relay piston.

If loss of primary air supply occurs, extended treadle travel and mechanical force will

actuate the secondary portion of the E-7 Dual Brake Valve. The primary circuit of the

brake valve is supplied by No. 1 Reservoir, and the secondary circuit is supplied by

No. 2 Reservoir.

Page 3

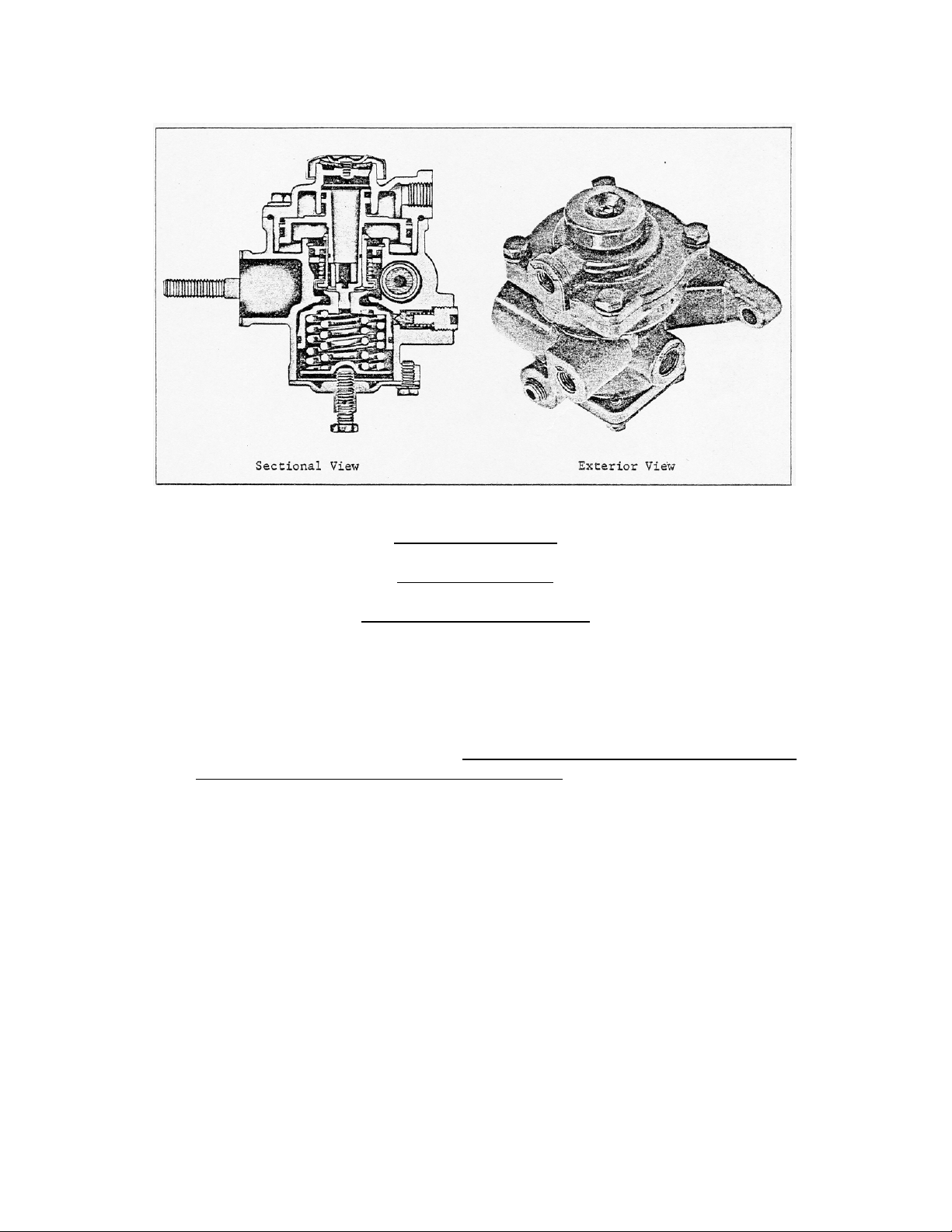

R-7 Modulating Valve

B-W Pc. No. 283036

Ford Part No. DOHA 2B431-A

2. The R-7 Modulating Valve performs four functions:

A. Modulates spring brake actuator applications should a failure occur in the service

brake system. If a loss of air should occur in the primary delivery circuit of the

Dual Brake Valve, the R-7 Modulating Valve exhaust air from the spring hold-off

cavity of the spring brake actuator, resulting in an application on that axle which

is proportionate to the braking on the other axles. If a loss of air should occur in

the secondary delivery circuit of the Dual Brake Valve, rear axle braking is

assured because the primary circuit supplies rear axle service brakes; therefore,

the Spring Brake Actuators will not be actuated.

B. Provides for quick release of the spring hold-off cavity of the Spring Brake

Actuators, allowing a fast application of the Spring Brake Actuators.

C. Limits hold-off pressure to the Spring Brake Actuators. This hold-off pressure can

be adjusted by the adjusting screw on the Modulating Valve.

D. Prevents compounding of push rod forces when the Spring Brake Actuators are

in the applied position.

Page 4

VM-1 Control Valve Manifold

B-W Pc. No. 283039

Ford Part No. DOHA 1B200-C

3. The VM-1 Control Valve manifold is located on the engine side of the firewall and is

bolted to an air manifold which extends through the firewall. Sealing of the ports

between the VM-1 manifold and the air manifold is accomplished by o-rings.

The manifold houses three valves that serve the trailer braking system. The valves are:

A. The SS-1 Valve (Service Line Shut-Off) which operates in conjunction with the

dash mounted PP-3 Tractor Protection Control Valve to manually or

automatically close and retain sufficient air pressure in the tractor to apply

service brakes.

B. A Double Check Valve which permits either primary or secondary circuit air

pressure from the Dual Brake Valve to normally actuate trailer service brakes.

C. A Double Check Valve which permits use of the TC-2 Trailer Control Valve to

control only trailer brakes.

In addition to ports necessary for the function of the above described valves, the VM-1

Manifold also provides ports for installation of the Service Stop Light Switch, front axle

Limiting Control Valve and TE-1 Trailer Emergency Stop Light Switch.

Page 5

SYSTEM DESCRIPTION

Service Brakes

The service brakes in this system are split across the dual circuit Brake Valve to supply

the rear axle from the primary circuit and the front axle from the secondary circuit. Note

that the trailer service brakes are supplied by both circuits via the Double Check Valve in

the VM-1 manifold. The service reservoirs are of a common volume, and all accessories

are supplied from the secondary (No. 2) service reservoir.

Emergency Brakes

The emergency brakes are considered to be the remaining intact circuit of the dual

circuit system. Both service reservoirs are protected by PR-2 Pressure Protection

Valves, so that a single failure anywhere will retain 85 P.S.I. in at least one reservoir.

If the secondary Brake Valve supply is lost, only the front axle brakes are lost; the tractor

rear and trailer service brakes are applied as the emergency brakes. If the primary

Brake Valve supply pressure is lost, the front axle and trailer brakes can be applied, but

the rear axle service brakes cannot be applied, however, rear axle braking is

accomplished by the function of the R-7 Modulating Valve which exhausts the spring

hold-off cavity pressure, thereby allowing the Spring Brake Actuators to apply.

Parking Brakes

A full parking application can be made by moving the parking valve control handle to the

”park” position, which exhausts the R-7 Modulating Valve supply and the spring hold-off

cavities of the Spring Brake Actuators.

If a service application is made when the Spring Brake Actuators are in the applied

position (Spring hold-off cavities vented), the double check valve in the R-7 Modulating

Valve allows recharging the spring hold-off cavities, thereby preventing compounding of

push rod forces.

Referring to lithos SA 8042-63 and SA 8042-64, compressor discharge is piped to No. 1

Reservoir protected by a Single Check Valve. No. 2 Reservoir is supplied by the No. 1

Reservoir, and a complete loss of air in either No. 1 or No. 2 Reservoir is prevented by

PR-2 Pressure Protection Valves which are set to close automatically at 85 P.S.I.

The Parking Control Valve is supplied from a point between No. 1 and No. 2 Reservoirs

to minimize automatic application of the Spring Brake Actuators. If loss of air in No. 1

Reservoir occurs, the Parking Brake Control Valve is supplied from No. 2 Reservoir

through Single Check Valve (both PR-2 Valves close upon loss of air in either reservoir),

if loss of air in No. 2 Reservoir occurs, the Governor (which has cut-in pressure set at

approximately 100 PSI) allows the Compressor to re-supply No. 1 Reservoir to the PR-2

Pressure Protection Valve opening pressure (approx. 95 PSI) therefore, the PR-2 Valve

protecting No. 1 Reservoir provides a supply for the Parking Brake Control Valve. The

delivery of the Parking Brake Control Valve is piped to the supply port of the R-7

Modulating Valve. Thus, with the Parking Brake Control Valve in the “Release” position,

the Spring Brake Actuators are released. As stated before, the purpose of this piping

arrangement is to minimize automatic application of the Spring Brake Actuators.

Page 6

The primary circuit of the Dual Brake Valve is supplied by No. 1 Reservoir, and the

secondary circuit is supplied by No. 2 Reservoir. Both supply circuits have Low

Pressure Indicators.

The primary service circuit actuates the rear axle service brakes, and supplies the

balance port of the R-7 Modulating Valve. The secondary circuit actuates front axle

Brake Chambers, and supplies the control port of the R-7 Modulating Valve. Either

primary or secondary service circuits will actuate the Stoplight Switch.

Should a service brake application be made while the full spring parking force is applied,

primary circuit air is delivered to the balance port of the R-7 Modulating Valve Double

Check Valve and re-supplies the spring cavities; this reduces the spring force by an

amount equal to the service application and prevents compounding of push rod forces.

To summarize, these systems have the following principal features:

1. During normal operation, the Spring Brake Actuators are held in the released

position by air pressure supplied to the Parking Brake Control Valve and the R-7

Modulating Valve. The Parking Brake Control Valve is supplied from either or both

Service Reservoirs; the two sources of supply air minimize automatic applications.

2. To park the vehicle, the Parking Control Valve is placed in the “Park” position, which

exhausts the air from the Spring Brake Actuators.

3. During normal service braking, air from the two circuits of the Dual Brake Valve is

delivered to the R-7 Modulating Valve and there will be no effect upon the Spring

Brake Actuators. Braking will be through the normal action of air pressure on the

diaphragms of the front, rear and trailer axle Brake Chambers.

4. Should the primary circuit of the Dual Brake Valve fail, there would be no air

pressure to actuate the service brakes on the rear axle, however, the air pressure

delivered by the secondary circuit of the Dual Brake Valve to the R-7 Modulating

Valve would cause the R-7 Modulating Valve to exhaust air from the Spring Brake

Actuators and provide rear axle braking a well as normal service braking to the front

axle and the trailer.

5. Should the secondary circuit of the Dual Brake Valve fail, the primary circuit will

provide normal service brakes to the rear axle and trailer. The Spring Brake

Actuators and Front Axle Brake Chambers will not be actuated.

6. Regardless of which circuit of the Dual Brake Valve might fail or malfunction for any

reason, a signal will be sent back to the trailer because both circuits of the Dual

Brake Valve supply the trailer service line through the Double Check Valves which

are housed in the VM-1 Manifold.

7. The Parking Control Valve, and the PP-3 Tractor Protection Control Valve serves as

a secondary emergency brake control, and can be actuated in the event of treadle

failure.

Page 7

It is of interest to note that the color coded Synflex Nylon Tubing is used to pipe the air

brake system on the Ford “L Series.” Color coding is as follows:

Red: Secondary System – Green: Primary System – Orange: Spring Brake System

In the near future, Service Data and Instruction Sheets will be released on the E-7 Dual

Brake Valve, R-7 Modulating Valve and VM-1 Control Valve Manifold, describing in

detail, operation, maintenance, and disassembly and assembly procedures. Information

regarding maintenance kits and Repair Exchange piece numbers will also soon be

released.

Page 8

Page 9

Loading...

Loading...