Page 1

Technical Bulletin

Bulletin No: TCH-002-010 Effective Date: 6/2/08 Cancels: N/A Page: 1 of 2

Subject: Retrofi tting Wide-Based Tires: Increased Vibration Requires

Improved Air Chamber Bracket Supports

This Bulletin addresses vehicles originally

equipped with dual tires on the drive axles which

are retrofitted with “wide-based” tires (also

referred to as “Super Singles”).

T est data has shown that retrofi tting “wide-based”

tires can result in higher vibrational loading of

vehicle drive axles and wheel ends. As a result,

the air chamber bracket supports are potentially

exposed to vibrations and stresses beyond their

original design capabilities.

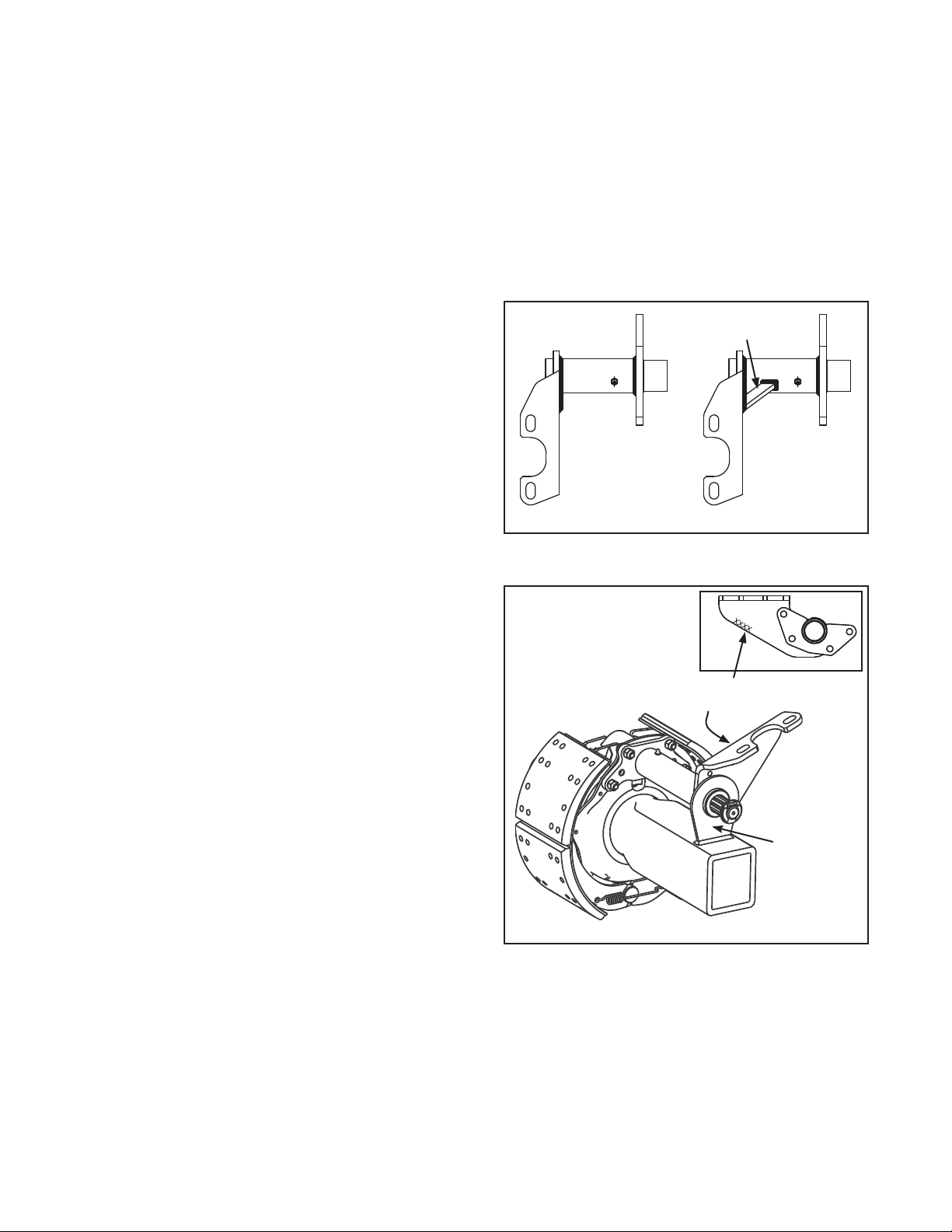

Example of

Air Chamber

Bracket without

Gusset

GUSSET

Example of

Air Chamber

Bracket with

Gusset

As with all retrofi ts, Bendix recommends that

the installer confi rm with the vehicle Original

Equipment Manufacturer (OEM) that the changes

to be made to the vehicle are approved and obtain

from the OEM any vehicle modifi cations that are

required (e.g. suspension clearances, etc.) before

proceeding.

When vehicles equipped with Bendix foundation

brake components are retrofi tted with wide-based

tires, Bendix requires the vehicles to be further

equipped with:

• Air chamber brackets with gussets (see

Figure 1). If the air chamber brackets do not

have gussets, they must be replaced with

Bendix approved air chamber brackets with

gussets. Identify the part number stamped

into the support arm (see Figure 2 for location)

and refer to BW7253 for the proper gusseted

replacement.

• Bendix “Marion” air chamber bracket supports

or other Bendix approved air chamber bracket

supports, welded to the axle, are required (see

Figure 2).

Failure to make all necessary changes when

retrofitting wide-based tires will void the

®

warranty on all Bendix

foundation brake

products equipped on the vehicle.

FIGURE 1 - EXAMPLES OF AIR CHAMBER BRACKETS

WITH AND WITHOUT GUSSETS

AIR CHAMBER BRACKET

PART NUMBER STAMPED HERE

“MARION”

AIR CHAMBER

BRACKET

SUPPORT

(TYPICALLY

820188)

FIGURE 2 - EXAMPLE OF “MARION” AIR CHAMBER

BRACKET SUPPORT

WARNING: Follow all standard industry

safety guidelines when welding, including

disconnection of batteries.

(Continued over)

Page 2

Bulletin No: TCH-002-010 Effective Date: 6/2/08 Cancels: N/A Page: 2 of 2

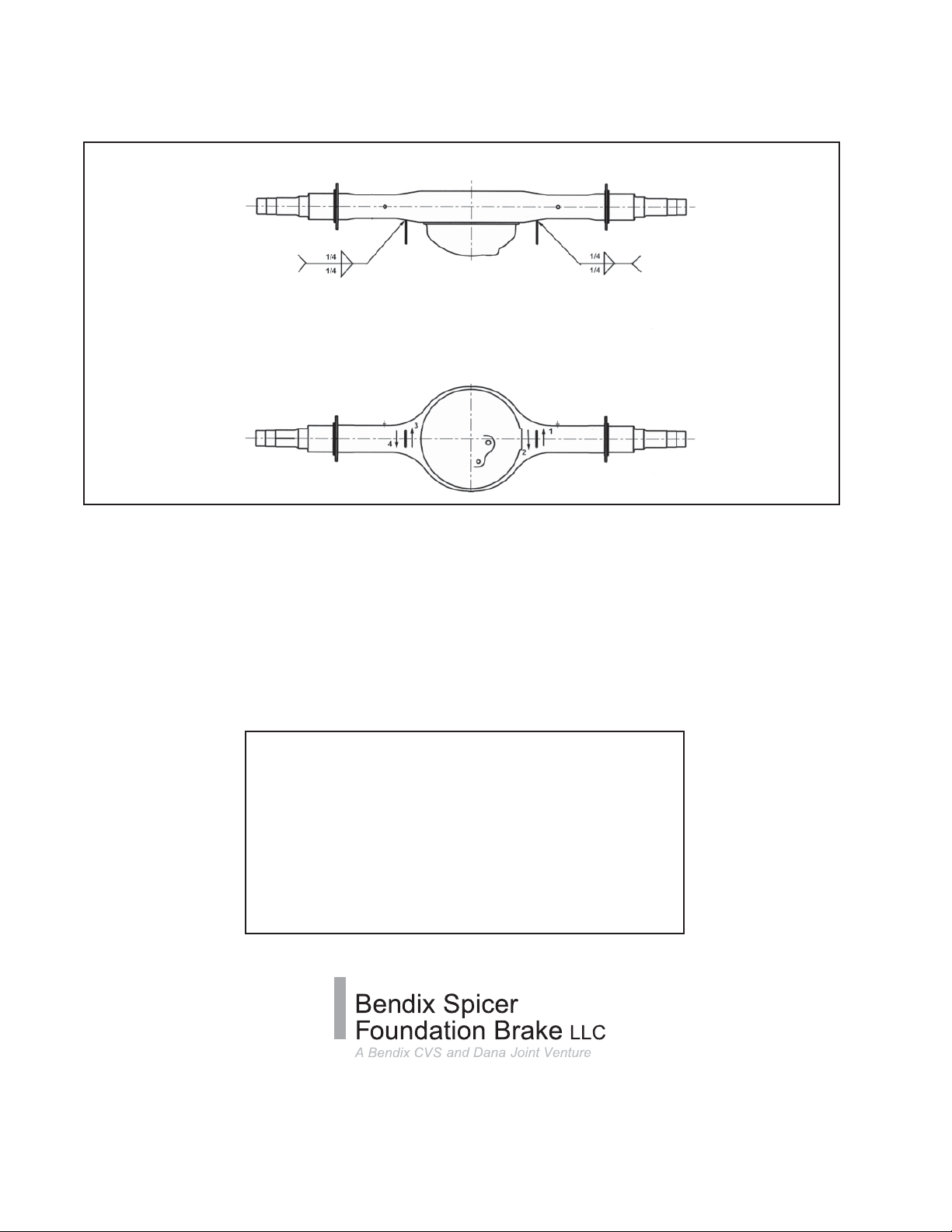

FIGURE 3 - EXAMPLE OF SUPPORT WELD ARRANGEMENT

Whenever available, use the axle manufacturer’s recommendations for welding the additional “Marion”

brackets - the welding notes below are shown for reference only (See Figure 3):

0

• E70T-5 FCA W or ER70S-6 GMAW Single Pass Process 60

F (15.50C) Minimum

Pre-Heat Temperature

• Maximum Fit up gap of 0.16 inch (4mm)

• The order of welding may be reversed or started on the opposite side

• The direction of welding may be completely reversed

Reference:

Application Guideline Catalog - BW7260

Illustrated Parts List - BW7253

Available from the Literature Center at www.bendix.com

and also from www.Roadranger.com.

Questions or changeover information:

Call 1-800-Air-Brake (1-800-247-2725)

© 2008 Bendix Spicer Foundation Brake LLC 6/08. All Rights Reserved. Printed in U.S.A.

Loading...

Loading...