Page 1

Technical Bulletin

Bulletin No: Effective Date: Cancels: Page: 1 of

Subject:

This bulletin is in reference to Bendix® BA-921® and BA-922® compressors installed on Detroit Diesel DD15™

and DD13™ engines. These compressors contain an Energy Saving System (ESS) within the cylinder head

that may require servicing while the compressor is still covered under warranty. The life expectancy of the

ESS varies according to the vehicle vocation and duty cycle. High air usage systems will result in reduced

life of the compressor ESS. In such cases, the ESS can be diagnosed for leakage and replaced if necessary .

This bulletin details the proper diagnostic and replacement procedures for the ESS. Failure to follow these

procedures may result in a denied warranty claim if the ESS portion of the compressor, submitted

for warranty consideration, is deemed causal. Note that if excessive carbon is present in the discharge

fi tting of the compressor, with a fi lm greater than 10% of the inside diameter, the entire compressor should

be replaced.

If the nature of the compressor issue, or complaint, is any of the following; the ESS is the likely source

(assuming that checks for other system malfunctions have been carried out).

(A) ESS leaking when pressurized (D) Compressor not unload

(B) Compressor safety valve popping off (E) System will not build air pressure

(C) Air dryer purge valve and compressor (F) System slow to build

cycling rapidly (G) Compressor leaking air

TCH-001-060

1-13-2011

ESS REPLACEMENT FOR BENDIX® BA-921® & BA-922® COMPRESSORS - REVISED

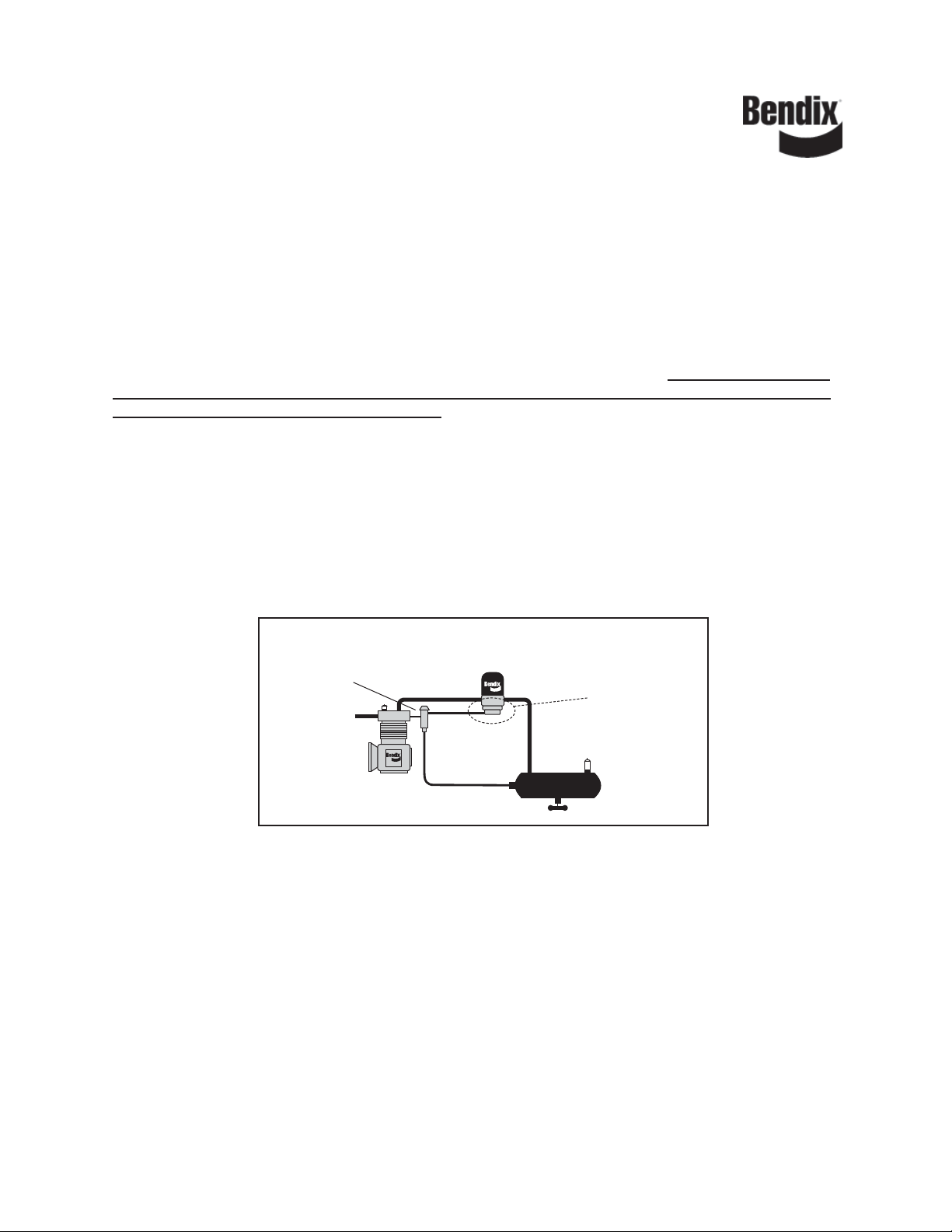

Closed Room Compressor Typical System

TCH-001-060 dated 12-2-2010

4

Governor Unloader

Por t

Governor

Reservoir Port

Compressor

DIAGNOSING THE UNLOADER SYSTEM FOR PROPER OPERATION AND PRESSURE SETTING

When performing any service, be sure to follow all safety guidelines outlined in the BA-921

compressor service data sheets, SD-01-690 or SD-01-700, or instruction sheet as applicable.

1. Using shop air, pressurize the unloader line to 120 psi and check for leaks in this line. Remove the air

pressure and ensure the unloader line is properly seated in the governor fi tting. Using shop air, check the

unloader line, again, for leaks. If there are no leaks, return the vehicle to service. If a leak is still present,

go to step 2.

2. Remove the compressor from the vehicle and closely inspect for any non-ESS related issues. If there are

non-ESS issues, submit the compressor for warranty consideration.

3. If there aren’t any obvious non-ESS related issues, service the ESS using the ESS service replacement

kit as outlined in this bulletin.

Air Dryer

Purge Valve

Cycling

Supply

Reservoir

®

or BA-922®

Continued...

Page 2

Bulletin No: Page: 2 of

TCH-001-060

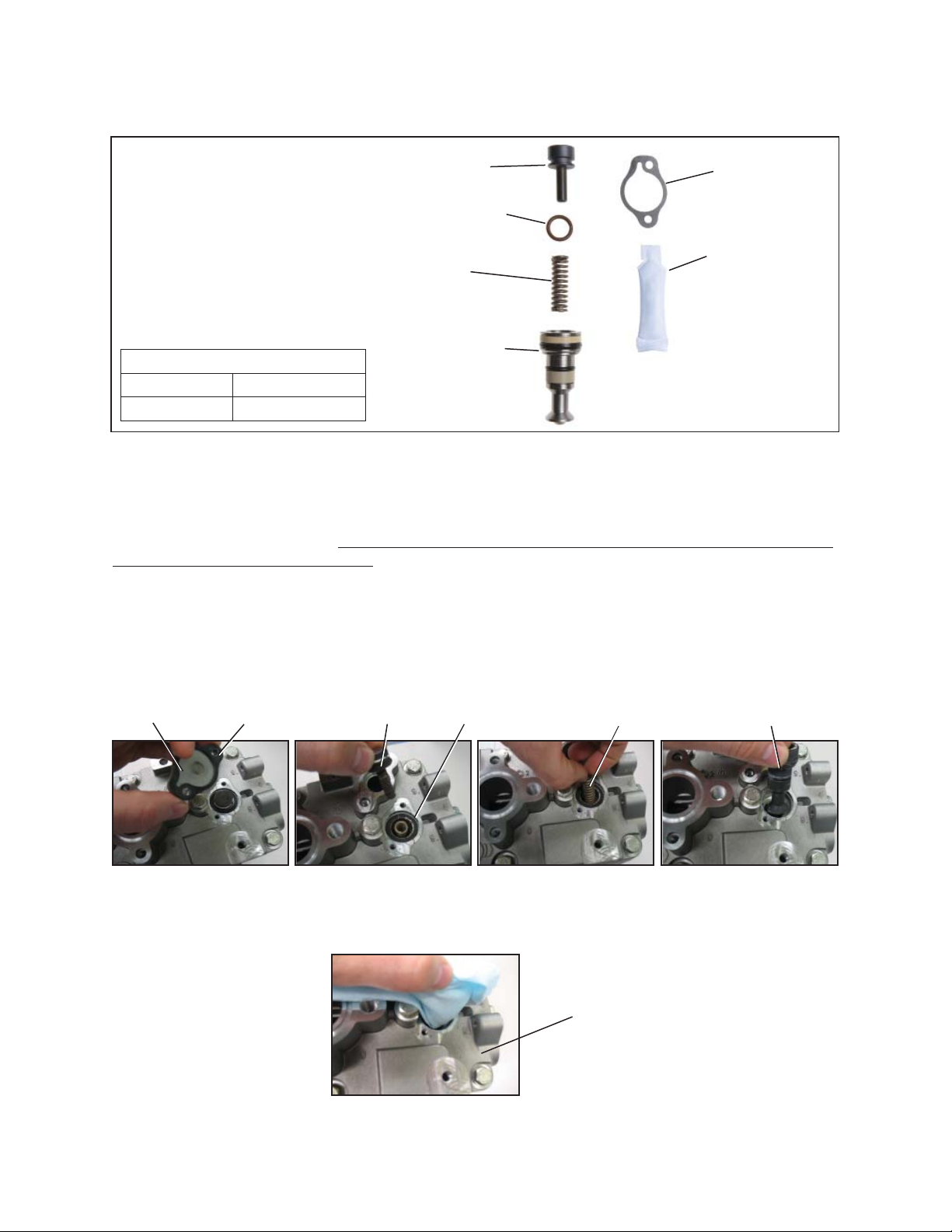

ESS SERVICE REPLACEMENT KIT CONTENTS

4

Balance Piston

Balance Piston O-ring

Spring

ESS Piston Assembly

Gasket

Lubricant

ESS Kit Part Nos

Bendix Detroit Diesel

K046477 A000 130 5819

THE FOLLOWING GUIDELINES ARE FOR REFERENCE. THE ESS SERVICE REPLACEMENT KIT

CONT AINS ADDITIONAL INSTRUCTIONS.

ESS REMOVAL AND CLEANING

Refer to the illustrations below. If the compressor being serviced is under warranty, retain the removed

components for warranty consideration.

Note: The Bendix

®

BA-922® compressor uses two ESS assemblies. Perform steps 1 through 3 for each

ESS assembly.

1. Using a T25 Torx head screwdriver, remove the ESS cover plate screws and ESS cover plate from the

compressor cylinder head.

2. Remove the balance piston, balance piston o-ring, spring, and ESS piston assembly from the cylinder

head.

Cover Plate

Gasket

Balance Piston

Balance Piston O-ring

Spring

ESS Piston Assembly

3. Thoroughly clean the cylinder head and ESS cover plate; removing all dirt, carbon, grease, gasket materials

and any foreign matter from the ESS piston cavity.

.

Cylinder Head

Page 3

Bulletin No: Page: 3 of

TCH-001-060

4

ESS INSTALLATION

Use the entire contents of this kit and only use the lubricant provided. Proper lubrication is extremely important

in the installation and the entire tube of lubricant must be used. Use the illustrations provided with each

step as a guide.

1. Lubricate the balance piston as shown. Be sure to thoroughly lubricate the o-ring groove.

Balance Piston

Balance Piston

Properly Lubricated

2. Lubricate the balance piston o-ring and install it on the balance piston. Be sure to not twist or tear the

o-ring during installation.

Balance Piston O-ring

3. Lubricate the entire ESS piston assembly as shown below.

ESS Piston Assembly

4. Insert the spring into the ESS piston assembly housing.

ESS Piston Assembly

O-ring Installed on the

Balance Piston

ESS Piston Assembly

Properly Lubricated

Spring

ESS Piston Assembly

with Spring

Page 4

Bulletin No: Page: 4 of

TCH-001-060

4

5. Slide the stem of the balance piston in the inside diameter of the spring as shown below.

Spring

Balance Piston

and O-ring

ESS Assembly

6. Install the ESS assembly into the compressor cylinder head as shown in the following illustrations. If

additional lubricant is available in the tube, add it to the outside of the ESS assembly before installation.

ESS Piston

Assemby

ESS Port

7. Install the new gasket on the boss of the ESS port, aligning the gasket with the boss contours and holes.

Place the cover plate over the gasket and secure it to the cylinder head with the two T25 Torx head screws

that were previously removed. While pushing down on the cover, tighten the screws manually with a

screw driver. Once the screws can’t be turned further, use a torque-meter to achieve the recommended

tightening torque of 7 ± 1.5 Nm.

Gasket

Torx Head

Screws

Cover Plate

8. If servicing a BA-922

®

compressor, repeat steps 1 through 7 for the installation of the second ESS assembly .

9. Reinstall the compressor on the vehicle. Refer to the service data sheet for additional guidelines and

compressor test procedures.

10. If the compressor is under warranty , submit the removed components for warranty consideration following

your normal warranty processes.

For additional assistance call

contact the Bendix Tech Team @

1-800-AIR-BRAKE

(1-800-247-2725)

or TechT eam@Bendix.com

© 2011 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • All rights reserved • 1/2011 Printed in U.S.A.

Loading...

Loading...