Page 1

Dana®Spicer®Brakes

16.5" Series S-Cam Cast

XTRALIFE

XTRALIFE II

TM

TM

P-Series

Service Manual BRSM-0890 October 1997

For the most current information, visit the Roadranger web site at www.roadranger.com

Page 2

Page 3

TABLE OF CONTENTS

Identification ..................................................................... 2

Brake Components (Standard/Xtralife) ...................... 3

Brake Components (Cast Series).................................. 4

Brake Components (XL II Series) .................................. 5

Brake Components (“P” Series) .................................... 6

General Precautions ......................................................... 7

Preventative Maintenance ............................................... 9

Brake Disassembly ............................................................ 11

Inspection of Parts ........................................................... 12

Brake Assembly ................................................................. 15

Trouble Shooting Charts................................................. 18

Reline Procedure ............................................................... 21

GENUINE SPICER SER VICE PARTS

Should a brake assembly require replacement component parts, it is recommended that Spicer

Brake Service Parts be used. Spicer Brake Service Parts are manufactured under the same rigid

specification as are original equipment brake components. This assures the customer who uses

genuine Spicer service parts, maximum reliability for a Spicer Brake assembly. They may be

obtained through your vehicle manufacturer. The use of non-original Spicer service parts may

cause premature compontent failure and may void the warranty.

The items included in this book are currently being offered as service parts at the time of

printing. The part numbers and illustrations are provided specifically for reference purposes

only. Therefore, Spicer reserves the right to update this manual without notice or liability.

i

Page 4

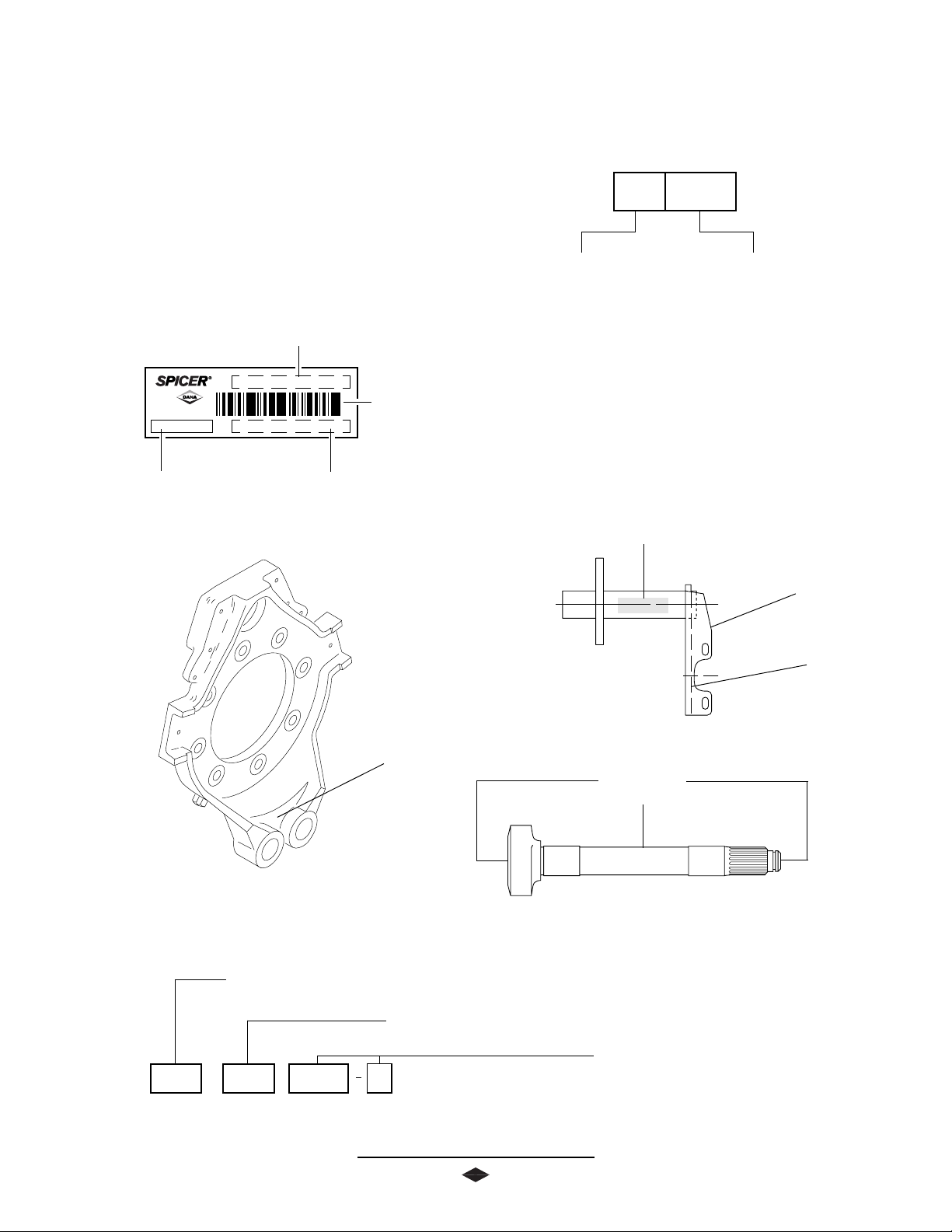

The brake assembly may be identified by a tag which is

located on the camshaft bracket cylinder, near the

grease fitting.

IDENTIFICATION

JULIAN DATE CODE

The mylar brake assembly tag contains the following:

Dana assembly number, bar coded customer assembly

number, and a numeric customer assembly number.

DANA

ASSEMBLY NUMBER

CUSTOMER

BAR CODE

NUMBER

Brake Assembly Tag

BUILD DATE

(APR 1997 AND LATER)

CUSTOMER

ASSEMBLY

NUMBER

97 170

DAY OF YEARMODEL YEAR

Two other markings that may be used to identify a

Spicer Brake assembly are located on the assembly's

components. "Spicer" will be cast into the spider

assembly just above the anchor pins. Also, the inside of

the chamber bracket arm contains the following stamped

part information: "Spicer", julian date code, and the part

number.

BRAKE ASSEMBLY TAG

CHAMBER

BRACKET ARM

STAMPED PART

INFORMATION

Camshaft Bracket

"SPICER"

Spider

MODEL IDENTIFICATION NUMBERING SYSTEM

Model (165 = 16.5" Brake)

(150 = 15" Brake)

165 WD 000 0

STAMPED PART

INFORMATION

(IN ONE OF THESE AREAS)

Camshaft

Alphabetical Code

(i.e., WD = Brake Assembly)

Sequential Assembly

Numbers

2

Page 5

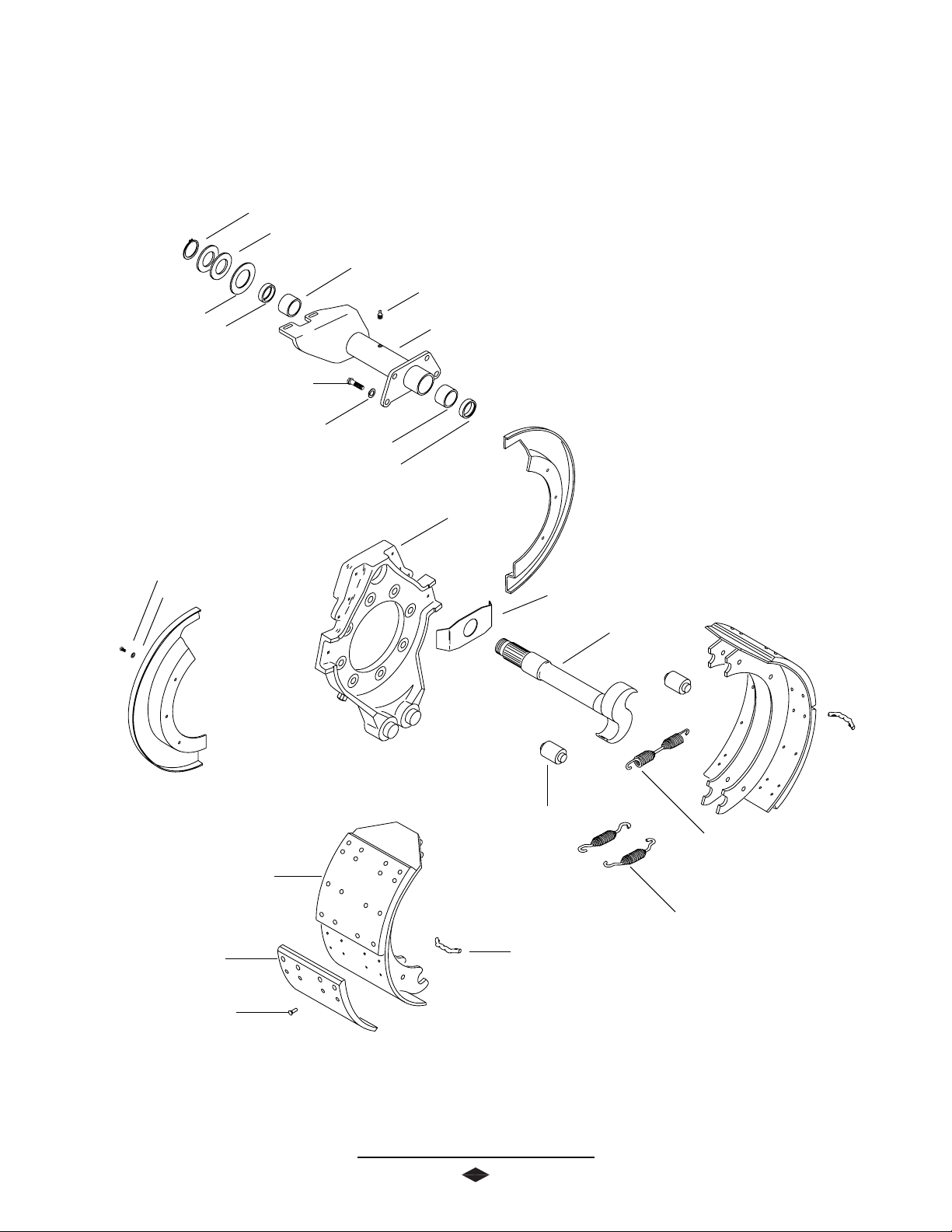

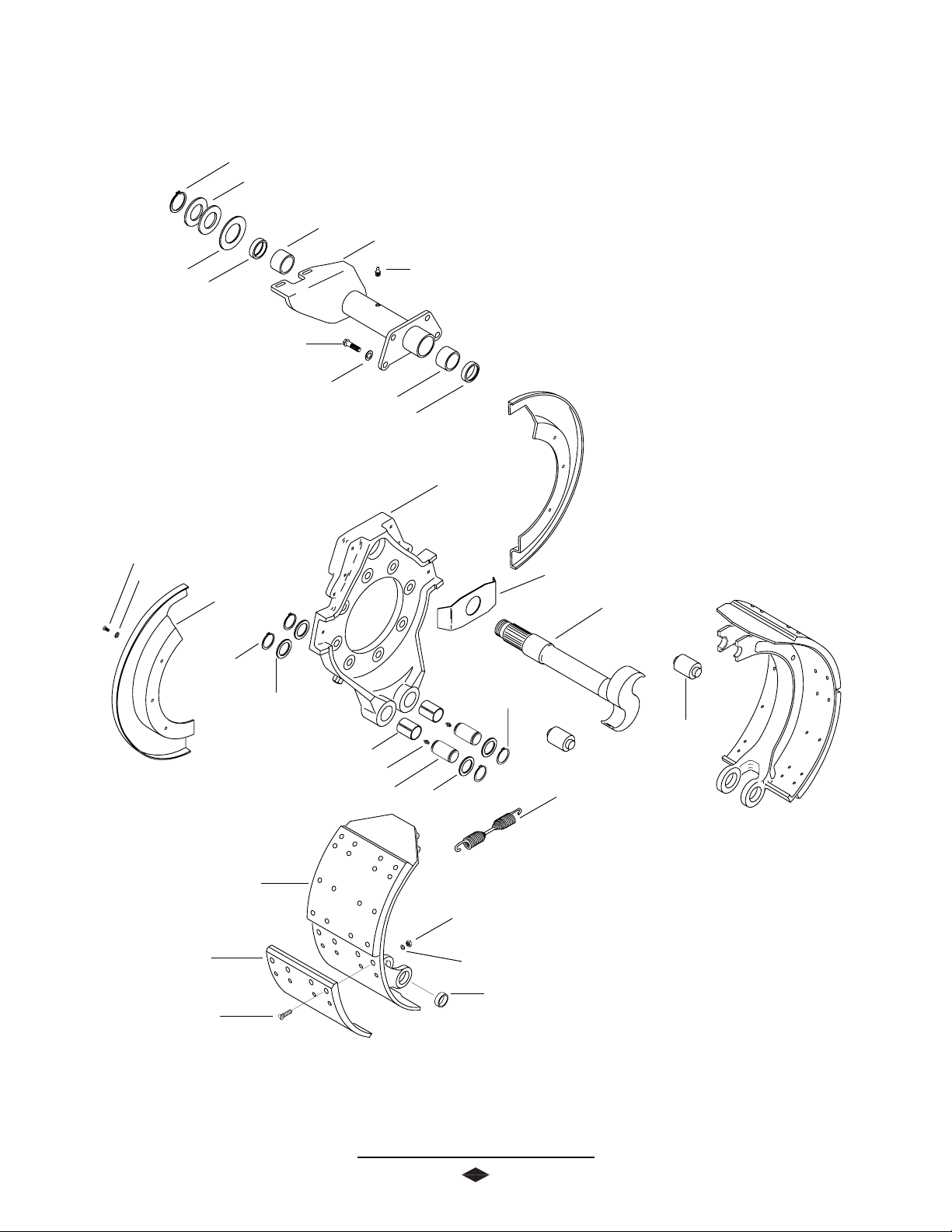

BRAKE COMPONENTS

ST ANDARD/ XTRALIFE 16.5"

Retaining Ring

Camshaft Adjusting

Washers (Shims)

Camshaft Bushing

Steel Spacer

Grease Seal

Bracket Mounting Bolt

(70 - 80 Lb-Ft)

(95 - 108 N-m)

Lock Washer

Camshaft Bushing

Grease Seal

Grease Fitting

Air Chamber

Bracket Assembly

Dustshield Mounting Bolt

3/8 in. - 16

(20 - 28 Lb-Ft)

(27 - 38 N-m)

Lock Washer

Shoe and Lining

Assembly

Lining

Spider

Steel Spacer Plate

Camshaft

Cam Roller

Shoe Return Spring

Retainer Springs

Return Spring Pin

Brake Lining

Rivet

3

Page 6

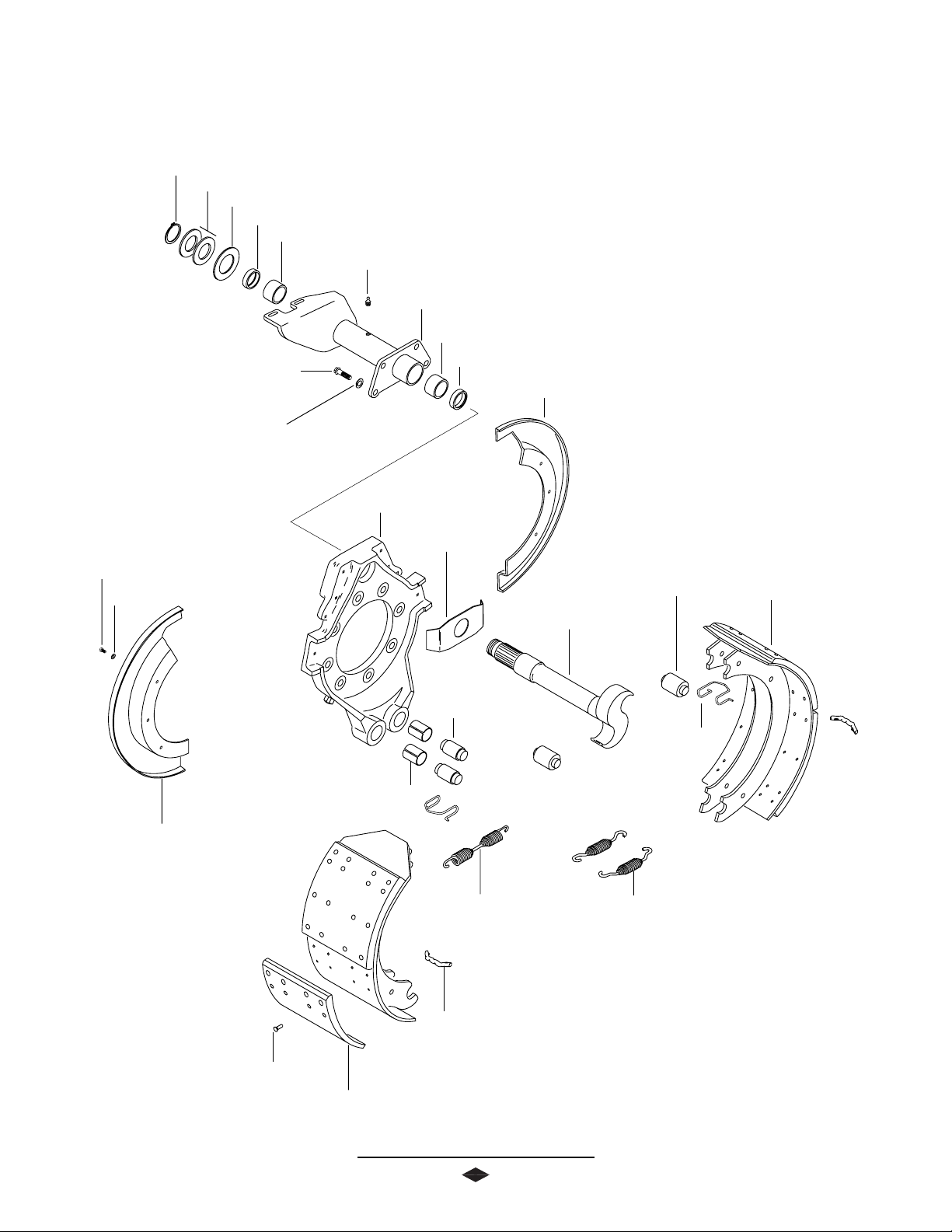

Retaining Ring

Camshaft Adjusting

Washers (Shims)

BRAKE COMPONENTS

16.5" CAST SHOE SERIES

Steel Spacer

Grease Seal

Bracket Mounting Bolt

(70 - 80 Lb-Ft)

(95 - 108 N-m)

Dustshield Mounting Bolt

3/8 in. - 16

(20 - 28 Lb-Ft)

(27 - 38 N-m)

Lock Washer

Dust Shield Half

Anchor Pin

Retainer Clip

Lock Washer

Washer

Camshaft Bushing

Air Chamber

Bracket Assembly

Grease Fitting

Camshaft Bushing

Grease Seal

Spider

Steel Spacer Plate

Camshaft

Anchor Pin

Retainer Clip

Shoe and Lining

Assembly

Lining

Brake Lining

Bolt

Anchor Pin Bushing

Grease Fitting

Anchor Pin

Washer

Cam Roller

Shoe Return Spring

Brake Lining Nut

(15-17 Lb-Ft)

(20-23 N-m)

Lock Washer

Brake Lining

Bronze Bushing

4

Page 7

BRAKE COMPONENTS

16.5" XL II SERIES BRAKE

Retaining Ring

Camshaft Adjusting Washer

Steel Spacer

Grease Seal

Camshaft Bushing

Grease Fitting

Bracket Mounting Bolt

(70 - 80 Lb-Ft)

(95 - 108 N-m)

Lock Washer

Spider

Dustshield Mounting Bolt

3/8 in. - 16

(20 - 28 Lb-Ft)

(27 - 38 N-m)

Lock Washer

Camshaft Bracket

Camshaft Bushing

Grease Seal

Steel Spacer Plate

Dust Shield (Half)

Camshaft

Cam Roller

Shoe and

Lining Assembly

Dust Shield (Half)

Brake Lining Rivet

Anchor Pin Bushing

Lining

Anchor Pin

Shoe Return Spring

Return Spring Pin

5

Cam Roller

Retainer Clip

Shoe Retainer Spring

Page 8

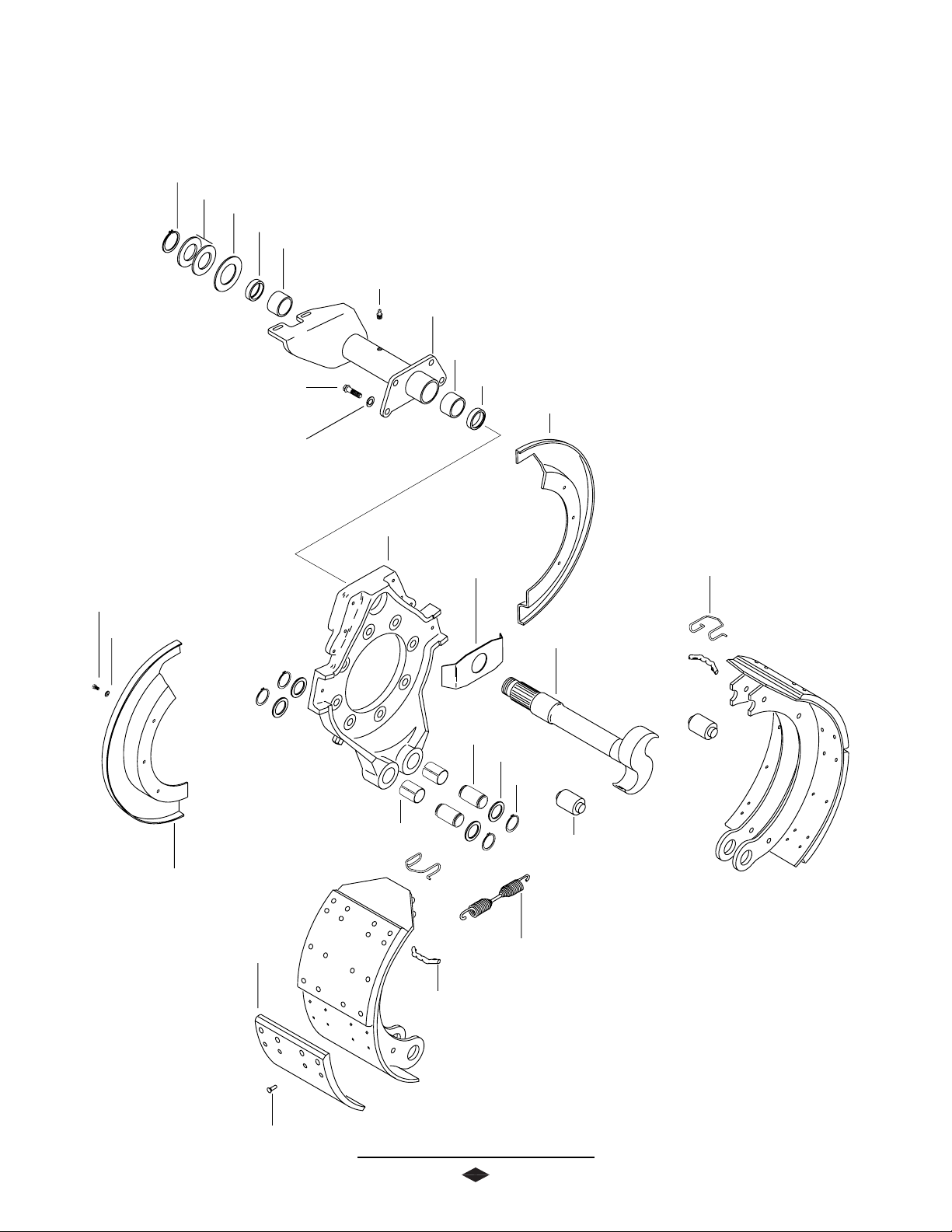

Retainer Ring

Camshaft Adjusting Washer

Steel Spacer

Grease Seal

Camshaft Bushing

BRAKE COMPONENTS

16.5" P SERIES BRAKE

Grease Fitting

Camshaft Bracket

Camshaft Bushing

Bracket Mounting Bolt

(70 - 80 Lb-Ft)

(95 - 108 N-m)

Dustshield Mounting Bolt

3/8 in. - 16

(20 - 28 Lb-Ft)

(27 - 38 N-m)

Lock Washer

Lock Washer

Anchor Pin Bushing

Spider

Grease Seal

Steel Spacer Plate

Anchor Pin

Washer

Snap Ring

Dust Shield (Half)

Cam Roller

Retainer Clip

Camshaft

Cam Roller

Dust Shield (Half)

Lining

Brake Lining Rivet

Shoe Return Spring

Return Spring Pin

6

Page 9

GENERAL PRECAUTIONS

IMPORIMPOR

IMPOR

IMPORIMPOR

READ THIS SECTION BEFORE STREAD THIS SECTION BEFORE ST

READ THIS SECTION BEFORE ST

READ THIS SECTION BEFORE STREAD THIS SECTION BEFORE ST

ANY SERANY SER

ANY SER

ANY SERANY SER

All Spicer original equipment or service parts for

steering and drive axle brakes are manufactured using

non-asbestos brake lining. It is recommended that

original Spicer service parts be used when brake maintenance is necessary.

SAFETY PRECAUTIONS

Proper service and repair of vehicle components is

important to the safe and reliable operation of all motor

vehicles. This applies particularly to brakes such as the

ones described in this manual. The procedures recommended and described in this manual are tested,

effective methods for performing service operation.

Follow each procedure closely, making use of both the

text and pictures. Some of these service procedures

show the use of certain tools designed especially for the

operation being performed. It is not mandatory that

these tools be used; they are shown only as preferred

means of performing the operation. It is not practical to

anticipate and advise the service trade of all possible

alternate service methods, and of all possible hazardous

consequences that could result from any particular

method. Accordingly, anyone who uses a service

procedure or tool different than shown must insure that

their safety, and that the vehicle’s safety will not be

jeopardized by the service method selected.

VICE PROCEDURESVICE PROCEDURES

VICE PROCEDURES

VICE PROCEDURESVICE PROCEDURES

TT

ANTANT

T

ANT

TT

ANTANT

ARAR

TINGTING

AR

TING

ARAR

TINGTING

Never remove a component or pipe plug unless you

are certain all system pressure has been depleted.

3.3.

3. Never exceed recommended air pressure and always

3.3.

wear safety glasses when working with air pressure.

Never look into air jets or direct them at anyone.

4.4.

4. Never attempt to disassemble a component until

4.4.

you have read and understand recommended

procedures. Some components contain powerful

springs and injury can result if not properly

disassembled. Use only proper tools and observe

all precautions pertaining to use of those tools.

5.5.

5. Use only genuine Spicer replacement parts and

5.5.

components.

A. A.

A. Only components, devices, mounting and

A. A.

attaching hardware specifically designed for use

in air brake systems should be used.

B. B.

B. Replacement hardware, tubing, hose, fittings, etc.

B. B.

should be of equivalent size, type, length and

strength as the original equipment.

C. C.

C. Make certain that when replacing tubing or hose,

C. C.

all supports, clamps or suspending devices that

were originally installed by the vehicle manufacturer are reinstalled.

CA CA

UTION:UTION:

CA

UTION:

CA CA

UTION:UTION:

brbr

akak

e se s

yy

stst

br

ak

brbr

akak

prpr

ecautions should be observecautions should be observ

pr

ecautions should be observ

prpr

ecautions should be observecautions should be observ

1.1.

1. Always block vehicle wheels. Stop engine when

1.1.

2.2.

2. Never connect or disconnect a hose or line con-

2.2.

ems and componentems and component

e s

y

st

ems and component

e se s

yy

stst

ems and componentems and component

working under a vehicle. Depleting vehicle air

system pressure may cause vehicle to roll. Keep

hands away from chamber push rods and slack

adjusters; they may automatically apply as system

pressure drops.

taining air pressure. It may whip as air escapes.

When wWhen w

When w

When wWhen w

orking on or arorking on or ar

orking on or ar

orking on or arorking on or ar

s, the follos, the follo

s, the follo

s, the follos, the follo

ed:ed:

ed:

ed:ed:

ound airound air

ound air

ound airound air

wingwing

wing

wingwing

6.6.

6. Devices with stripped threads or damaged parts

6.6.

should be replaced. Repairs requiring machining

should not be attempted.

CAUTION

BRAKE LININGS CONTAIN NON-ASBESTOS FIBERS

BREATHING BRAKE DUST MAY BE HAZARDOUS TO YOUR HEALTH AND

MAY CAUSE SERIOUS RESPIRATORY OR OTHER BODILY HARM.

AVOID CREATING DUST

DO NOT REMOVE BRAKE DRUM WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT WORK ON LININGS WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT REPLACE LININGS WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT ATTEMPT TO SAND, GRIND, CHISEL, FILE, HAMMER OR ALTER BRAKE

LININGS IN ANY MANNER WITHOUT PROPER PROTECTIVE EQUIPMENT.

FOLLOW 0.S.H.A. STANDARDS FOR PROPER PROTECTIVE DEVICES TO BE USED

WHEN WORKING WITH BRAKE MATERIALS.

7

Page 10

PREPARATION

GENERAL PRECAUTIONS (CONTINUED)

1.1.

1. Park vehicle on a level surface and prevent

1.1.

movement by means other than the brakes.

2.2.

2. If equipped with spring brakes, cage the spring on

2.2.

all axles to be worked on.

3.3.

3. Raise the axle, to be worked on until the tires

3.3.

clear the ground. Support axle with heavy duty

jack stands.

4. "Back-off " slack adjuster by turning adjusting nut

until the brake shoes are fully retracted.

CACA

UTION: RUTION: R

CA

UTION: R

CACA

UTION: RUTION: R

aa

ssemblssembl

a

ssembl

aa

ssemblssembl

ing ning n

ut.ut.

ing n

ut.

ing ning n

ut.ut.

WW

ARNING: NeARNING: Ne

W

ARNING: Ne

WW

ARNING: NeARNING: Ne

onlonl

y by b

onl

y b

onlonl

y by b

ockwockw

ell Autell Aut

ockw

ell Aut

ockwockw

ell Autell Aut

y ty t

o be ro be r

o be r

o be ro be r

vv

er wer w

v

er w

vv

er wer w

emoemo

emo

emoemo

y t

y ty t

y a jack. Alwy a jack. Alw

y a jack. Alw

y a jack. Alwy a jack. Alw

o Slacks ro Slacks r

o Slacks r

o Slacks ro Slacks r

vv

ed befored befor

v

ed befor

vv

ed befored befor

ork under a vork under a v

ork under a v

ork under a vork under a v

aa

yy

s use a jack sts use a jack st

a

y

s use a jack st

aa

yy

s use a jack sts use a jack st

e turning the adjuste turning the adjust

e turning the adjust

e turning the adjuste turning the adjust

equirequir

e the pae the pa

equir

e the pa

equirequir

e the pae the pa

ehicle supporehicle suppor

ehicle suppor

ehicle supporehicle suppor

and.and.

and.

and.and.

tt

t

tt

wlwl

wl

wlwl

eded

ed

eded

--

-

--

5.5.

5. Remove wheels and drums using the procedures

5.5.

specified in the vehicle maintenance manual.

WW

ARNING: The long tARNING: The long t

W

ARNING: The long t

WW

ARNING: The long tARNING: The long t

aa

sbesbe

stst

os haos ha

os ha

os haos ha

e ee e

e e

e ee e

s nos no

s no

s nos no

forming service on brforming service on br

forming service on br

forming service on brforming service on br

xposurxposur

xposur

xposurxposur

a

sbe

st

aa

sbesbe

stst

dust when perdust when per

dust when per

dust when perdust when per

ExEx

cece

ssivssiv

Ex

ce

ssiv

ExEx

cece

ssivssiv

tt

ory damage or oory damage or o

t

ory damage or o

tt

ory damage or oory damage or o

erm effecterm effect

erm effect

erm effecterm effect

t been det been de

t been de

t been det been de

e te t

o bro br

akak

e t

o br

ak

e te t

o bro br

akak

ther bodilther bodil

ther bodil

ther bodilther bodil

Safety glasses should be worSafety glasses should be wor

Safety glasses should be wor

Safety glasses should be worSafety glasses should be wor

at all times when assemblingat all times when assembling

at all times when assembling

at all times when assemblingat all times when assembling

or disassembling brakes.or disassembling brakes.

or disassembling brakes.

or disassembling brakes.or disassembling brakes.

s of es of e

s of e

s of es of e

tt

ermined. Aermined. A

t

ermined. A

tt

ermined. Aermined. A

e dust mae dust ma

e dust ma

e dust mae dust ma

y harm.y harm.

y harm.

y harm.y harm.

xposurxposur

xposur

xposurxposur

vv

oid croid cr

v

oid cr

vv

oid croid cr

akak

e ae a

ssembliessemblie

ak

e a

ssemblie

akak

e ae a

ssembliessemblie

y cause ry cause r

y cause r

y cause ry cause r

e te t

o non-o non-

e t

o non-

e te t

o non-o non-

eaea

tingting

ea

ting

eaea

tingting

ee

spirspir

e

spir

ee

spirspir

nn

n

nn

s.s.

s.

s.s.

a-a-

a-

a-a-

8

Page 11

PREVENTATIVE MAINTENANCE

A schedule should be eA schedule should be e

A schedule should be e

A schedule should be eA schedule should be e

adjustment, inspection and lubricaadjustment, inspection and lubrica

adjustment, inspection and lubrica

adjustment, inspection and lubricaadjustment, inspection and lubrica

ule is deule is de

ule is de

ule is deule is de

ee

xperience and the txperience and the t

e

xperience and the t

ee

xperience and the txperience and the t

BRAKE DRUMS

tt

ermined frermined fr

t

ermined fr

tt

ermined frermined fr

stst

ablished for periodicablished for periodic

st

ablished for periodic

stst

ablished for periodicablished for periodic

tion. This sched-tion. This sched-

tion. This sched-

tion. This sched-tion. This sched-

om vom v

ehicle oehicle o

om v

ehicle o

om vom v

ehicle oehicle o

ype of operype of oper

ype of oper

ype of operype of oper

wner/operwner/oper

wner/oper

wner/operwner/oper

aa

tiontion

a

tion.

aa

tiontion

aa

tt

oror

ss

a

t

or

s

aa

tt

oror

ss

Inspect for heat checks, grooves, hot spots, glazing,

cracks, and out of round. Drums which are glazed,

grooved, or have moderate heat checking may be

resurfaced and returned to service. The drum should

not be used if it exceeds the manufacturer’s recommended maximum diameter stamped on the drum.

BRAKE ADJUSTMENT

Brakes should be adjusted whenever the air chamber

push rod stroke exceeds the maximum distance accord-

FF

igurigur

ing to the chart shown in

e 2e 2

F

igur

e 2. To determine if

FF

igurigur

e 2e 2

brake adjustment is required measure the push rod

FF

igurigur

e 3e 3

stroke with the brakes applied as shown in

page 1page 1

page 1

page 1page 1

0.0.

0.

0.0.

F

igur

FF

igurigur

e 3

e 3e 3

onon

on

onon

CA CA

CA

CA CA

a contina contin

a contin

a contina contin

ee

xtxt

ends arends ar

e

xt

ends ar

ee

xtxt

ends arends ar

rr

eplaced. eplaced.

r

eplaced.

rr

eplaced. eplaced.

UTION:UTION:

UTION:

UTION:UTION:

uous length of four incheuous length of four inche

uous length of four inche

uous length of four incheuous length of four inche

ound the edge of the drum should beound the edge of the drum should be

ound the edge of the drum should be

ound the edge of the drum should beound the edge of the drum should be

See FSee F

See F

See FSee F

Drums displaDrums displa

Drums displa

Drums displaDrums displa

igurigur

e 1.e 1.

igur

e 1.

igurigur

e 1.e 1.

FF

igurigur

F

igur

FF

igurigur

ying heaying hea

ying hea

ying heaying hea

e 1e 1

e 1

e 1e 1

t checks witht checks with

t checks with

t checks witht checks with

s or mors or mor

s or mor

s or mors or mor

e ande and

e and

e ande and

RECOMMENED AIR BRAKE ACTUATOR SERVICE STROKE

Chamber Size

Type

Standard Chamber Long Stroke Chamber

Rated Stroke Max Readjust Stroke Rated Stroke Max Readjust Stroke

12 1.75 1.38 2.00 1.50

16 2.25 1.75 2.50 2.00

20 2.25 1.75 2.50 2.00

24 2.25 1.75 2.50 2.00

30 2.50 2.00 2.75 2.25

36 3.00 2.25 - -

Source: The Maintenance Council RP 635

FF

igurigur

e 2e 2

F

igur

e 2

FF

igurigur

e 2e 2

9

Page 12

PREVENTATIVE MAINTENANCE

MEASURING PUSH ROD STROKE

1.1.

1. Measure the distance between the air chamber

1.1.

mounting face and the center of the clevis pin,

with brakes released.

2.2.

2. Make an 70-90 PSI application and hold it.

2.2.

Measure the distance between the air chamber and

the mounting face and the center of the clevis pin.

3.3.

3. Subtract measurement A from measurement B. If

3.3.

this measurement equals or exceeds the maximum

readjust stroke the brakes need to be adjusted.

See FSee F

igurigur

igur

igurigur

e 3.e 3.

e 3.

e 3.e 3.

See F

See FSee F

4.4.

4. If adjustment is required, spin the wheel slowly and

4.4.

adjust the slack adjuster just enough for wheel to

spin freely. Be sure to adjust brakes equally on

each axle.

5.5.

5. Apply and release brakes and observe slack

5.5.

adjusters. Both slacks on each axle should respond

rapidly and in unison during application and

release.

6.6.

6. Drive vehicle at a low speed in a safe area and

6.6.

check for brake effectiveness prior to putting back

in service.

BRAKE LUBRICTION

Lubricate the camshaft thru the grease fitting on the

camshaft bracket with the chassis lube specified by the

vehicle manufacturer. Lube once every six months or at

every chassis lubrication.

BRAKE RELINE

The life of the brake lining is dependent on many factors

such as the material of the lining, type of operation the

vehicle is used for, geographic terrain, maintenance

practice of the shop, and the driver of the vehicle. If

driving conditions require frequent braking, lining

replacement will be required more often.

FOR RIVET LINING

Reline when thickness of lining is 1/4 " at thinnest

point, or 1/16" above rivet head.

FOR CAST SHOES WITH BOLTED LININGS

Reline when lining is below wear indicator line or

thickness is .31" at the thinnest point or 1/16" above

bolt head.

BRAKE OVERHAUL

As often as necessary to maintain satisfactory brake

performance. When overhauling the brakes, provide equal

service to both the left and right side of an axle.

AA

A

AA

BB

B

BB

A.A.

A. Released Position

A.A.

B. B.

B. Applied Postion

B. B.

F F

igurigur

e 3e 3

F

igur

e 3

F F

igurigur

e 3e 3

10

Page 13

BRAKE DISASSEMBL Y

CAST SHOE & "P" SERIES

1.1.

1. Insert sturdy lever between end of shoe and spider.

1.1.

Pry shoe away from cam until cam rollers can be

removed. Repeat procedure for opposite shoe.

2.2.

2. Unhook shoe return spring by pushing shoes

2.2.

together, allow tension on spring to be reduced.

3.3.

3. Discard shoe return spring and replace with new at

3.3.

time of reassembly.

4.4.

4. Remove snap ring from anchor pin and push anchor

4.4.

pin through.

NONO

TE: TTE: T

NO

NONO

nono

no

nono

5.5.

5. Remove brake shoe and place on floor. Repeat

5.5.

ap lightlap lightl

TE: T

ap lightl

TE: TTE: T

ap lightlap lightl

t push out with fingert push out with finger

t push out with finger

t push out with fingert push out with finger

y with bry with br

y with br

y with bry with br

..

.

..

aa

ss drift if anchor pin willss drift if anchor pin will

a

ss drift if anchor pin will

aa

ss drift if anchor pin willss drift if anchor pin will

procedure for opposite shoe.

ST ANDARD, XL, & XLII SERIES

1.1.

1. Insert sturdy lever between end of shoe and spider.

1.1.

Pry shoe away from cam until cam rollers can be

removed. Repeat procedure for opposite shoe.

2.2.

2. Unhook shoe return spring by pushing shoes

2.2.

together, allow tension on spring to be reduced.

SLACK ADJUSTER REMOV AL

1.1.

1. Disconnect clevis from slack adjuster arm by

1.1.

removing the clevis pin or pins depending on type

of slack adjuster.

2.2.

2. Remove retaining ring and shims from splined end

2.2.

of camshaft.

3.3.

3. Remove slack adjuster from the camshaft.

3.3.

CA CA

UTION: UTION:

CA

UTION:

CA CA

UTION: UTION:

rr

emoemo

vv

e. Serious damage te. Serious damage t

r

emo

v

e. Serious damage t

rr

emoemo

vv

e. Serious damage te. Serious damage t

or the camshaft splineor the camshaft spline

or the camshaft spline

or the camshaft splineor the camshaft spline

CAMSHAFT REMOV AL

1.1.

1. Before removing camshaft check to see if cam bushings

1.1.

need replacement.

2.2.

2. Remove spacer from between slack adjuster and cam

2.2.

Do noDo no

t hammer on slack adjustt hammer on slack adjust

Do no

t hammer on slack adjust

Do noDo no

t hammer on slack adjustt hammer on slack adjust

o the slack adjusto the slack adjust

o the slack adjust

o the slack adjusto the slack adjust

s mas ma

y ry r

ee

y r

y ry r

sult.sult.

e

sult.

ee

sult.sult.

igurigur

igur

igurigur

e 4 on Pe 4 on P

e 4 on P

e 4 on Pe 4 on P

s ma

s mas ma

See F See F

See F

See F See F

er and/er and/

er and/

er and/er and/

age 1age 1

age 1

age 1age 1

2.2.

2.

2.2.

er ter t

er t

er ter t

oo

o

oo

shaft bracket.

3.3.

3. Grasp camshaft at the camshaft head and pull in the

3.3.

outward direction to remove.

4.4.

4. Clean and inspect camshaft splines and head.

4.4.

3.3.

3. Discard shoe return spring and replace with new at

3.3.

time of reassembly.

4a.4a.

SS

TT

ANDAND

T

AND

TT

ANDAND

ARD & XLARD & XL

ARD & XL

ARD & XLARD & XL

4a.

4a.4a.

S

SS

Remove shoes by rotating the bottom shoe off the

anchor pin to release the tension on the two

retaining springs.

4b.4b.

XLII SERIESXLII SERIES

4b.

XLII SERIES

4b.4b.

XLII SERIESXLII SERIES

Remove snap ring from anchor pin and push anchor

pin through.

5.5.

5. Remove the two retaining springs and discard.

5.5.

6.6.

6. Remove shoes from spider.

6.6.

AIR CHAMBER/ CAMSHAFT BRACKET

ASSMEBLY REMOVAL

1.1.

1. Remove two nuts and washers that secure brake cham-

1.1.

ber to camshaft bracket.

2.2.

2. Remove brake chamber and temporarily set it aside.

2.2.

CA CA

UTION: UTION:

CA

UTION:

CA CA

UTION: UTION:

the air linethe air line

the air line

the air linethe air line

3.3.

3. Remove four bracket mounting bolts and lock washers.

3.3.

4.4.

4. Remove bracket assembly from spider.

4.4.

11

ss

s

ss

Do noDo no

Do no

Do noDo no

t let le

t the air chamber hang bt the air chamber hang b

t le

t the air chamber hang b

t let le

t the air chamber hang bt the air chamber hang b

yy

y

yy

Page 14

BRAKE DISASSEMBL Y (CONTINUED)

SPIDER REMOV AL

1.1.

1. Mark the postion of the spider on the axle (L.H. or

1.1.

R.H.) and the orientation on the axle flange by

making a reference mark on the spider and flange.

See FSee F

igurigur

igur

igurigur

e 4.e 4.

e 4.

e 4.e 4.

See F

See FSee F

2. 2.

2. Remove the spider to axle mounting bolts.

2. 2.

3. 3.

3. Remove spider.

3. 3.

DUST SHIELD REMOVAL

1.1.

1. Mark dust shields (upper left, lower right, etc-

1.1.

prior to removal.

2.2.

2. Detach dust sheild by removing the six cap screws

2.2.

using a 9/16" socket. Do not remove dust shield

unless there is apparent damage.

FF

igurigur

F

igur

FF

igurigur

e 4e 4

e 4

e 4e 4

INSPECTION OF P A R TS

AIR CHAMBER BRACKET ASSEMBL Y

1.1.

1. Check assembly for bent chamber bracket, broken

1.1.

welds, cracks, and correct alignment.

2.2.

2. Inspect camshaft bushings for signs of wear.

2.2.

Bearing surfaces should be smooth and free of any

pitting or fractures. Insert camshaft and measure

looseness up and down side to side at both ends

with a dial indicator. If more than .030” movement,

See FSee F

igurigur

replace bushings and/or camshaft.

See F

See FSee F

igur

igurigur

e 5.e 5.

e 5.

e 5.e 5.

FF

igurigur

e 6e 6

F

igur

e 6

FF

igurigur

e 6e 6

NONO

TE: If it is deTE: If it is de

NO

TE: If it is de

NONO

TE: If it is deTE: If it is de

rr

eplacement, boeplacement, bo

r

eplacement, bo

rr

eplacement, boeplacement, bo

should be rshould be r

should be r

should be rshould be r

brbr

akak

ee

s has ha

br

ak

e

s ha

brbr

akak

ee

s has ha

XL, and XLII SERIES brXL, and XLII SERIES br

XL, and XLII SERIES br

XL, and XLII SERIES brXL, and XLII SERIES br

the brthe br

onze bushing aonze bushing a

the br

onze bushing a

the brthe br

onze bushing aonze bushing a

CAMSHAFT

1.1.

1. Inspect camshaft spline and body for chips and

1.1.

excessive deformation. Replace as necessary.

See FSee F

See F

See FSee F

tt

ermined thaermined tha

t

ermined tha

tt

ermined thaermined tha

th camshaft bushings and sealsth camshaft bushings and seals

th camshaft bushings and seals

th camshaft bushings and sealsth camshaft bushings and seals

eplaced. All CASeplaced. All CAS

eplaced. All CAS

eplaced. All CASeplaced. All CAS

vv

e bre br

onze cam bushings. The Sonze cam bushings. The S

v

e br

onze cam bushings. The S

vv

e bre br

onze cam bushings. The Sonze cam bushings. The S

s an ops an op

s an op

s an ops an op

igurigur

e 6.e 6.

igur

e 6.

igurigur

e 6.e 6.

t a bushing rt a bushing r

t a bushing r

t a bushing rt a bushing r

T SHOE and P SERIEST SHOE and P SERIES

T SHOE and P SERIES

T SHOE and P SERIEST SHOE and P SERIES

akak

ee

ak

akak

e

ee

s use ns use n

s use n

s use ns use n

ylon bushings withylon bushings with

ylon bushings with

ylon bushings withylon bushings with

tion.tion.

tion.

tion.tion.

equirequir

equir

equirequir

TT

ANDAND

T

AND

TT

ANDAND

ee

ss

e

s

ee

ss

ARD,ARD,

ARD,

ARD,ARD,

FF

igurigur

F

igur

FF

igurigur

e 5e 5

e 5

e 5e 5

2.2.

2. Inspect cam head for cracks, and its roller surfaces

2.2.

for flat spots, brinneling, or ridges.

NONO

TE: UnTE: Un

12

NO

TE: Un

NONO

TE: UnTE: Un

outout

-of-squar-of-squar

out

-of-squar

outout

-of-squar-of-squar

shaftshaft

s.s.

shaft

s.

shaftshaft

s.s.

usual wusual w

usual w

usual wusual w

ear paear pa

tt

tt

ear pa

ear paear pa

e condition. Re condition. R

e condition. R

e condition. Re condition. R

erns which maerns which ma

t

t

erns which ma

tt

tt

erns which maerns which ma

y indicay indica

y indica

y indicay indica

eplace damaged cam-eplace damaged cam-

eplace damaged cam-

eplace damaged cam-eplace damaged cam-

tt

e ane an

t

e an

tt

e ane an

Page 15

INSPECTION OF P A R TS

SPIDER

1.1.

1. Inspect for cracked or broken surfaces on the

1.1.

spider at the cam, anchor pins, and mounting bolt

holes. Replace any spider with visible damage. Do

not attempt to weld or repair the spiders.

FF

igurigur

e 7e 7

igur

igurigur

e 7

e 7e 7

..

.

..

F

FF

XLII, P, & CAST SHOE SERIES

2a2a

2a. Check the inside diameter of the anchor pin hole

2a2a

SeeSee

See

SeeSee

with bushing in place. Diameter must not exceed

1.282”. Replace bushing if necessary.

STANDARD & XL SERIES

2b.2b.

2b. The anchor pins are staked into the spider and are

2b.2b.

not serviced separately. If the pins are loose or

grooved more than .030 inch, the spider assembly

must be replaced.

SHOES AND LINING

STANDARD, XL, XL II AND P SERIES

1.1.

1. Check shoes for bent shoe ribs, cracks in shoe

1.1.

table welds or ribs, and elongated rivet holes.

Replace shoes if any of these conditions exist.

FF

igurigur

e 9.e 9.

F

igur

e 9.

FF

igurigur

e 9.e 9.

2.2.

2. Measure the shoe span by loosely installing the

2.2.

SeeSee

See

SeeSee

anchor pin and cam roller in the appropriate ends

of the shoe rib. If the distance from center of

anchor pin to center of cam roller exceeds 12.76

inches replace shoe.

3.3.

3. Check linings and replace when any of the following

3.3.

conditions exist: See page 21 for reline procedure.

A.A.

A. Total lining thickness at thinnest point is 1/4"

A.A.

or less, or 1/16" above the rivets.

B. B.

B. Linings are cracked or worn in an unusual or

B. B.

odd pattern. For example: lining wear tapered

from side to side across the shoe table. Un

usual wear pattern can indicate damage to

foundation brake parts.

FF

igurigur

e 7e 7

F

igur

e 7

FF

igurigur

e 7e 7

ROLLERS AND ANCHOR PINS, BUSHINGS

1.1.

1. Inspect rollers and anchor pins for flat spots,

1.1.

galling, broken or cracked surfaces. Replace as

See FSee F

igurigur

necessary.

See F

See FSee F

igur

igurigur

FF

F

FF

e 8.e 8.

e 8.

e 8.e 8.

igurigur

igur

igurigur

e 8e 8

e 8

e 8e 8

C. C.

C. Rivet holes are elongated in lining or shoes.

C. C.

D. D.

D. Lining is oil soaked.

D. D.

E. E.

E. Linings can be moved by hand because of loose

E. E.

rivets.

FF

igurigur

e 9e 9

F

igur

e 9

FF

igurigur

e 9e 9

13

Page 16

INSPECTION OF P AR TS (CONTINUED)

SHOES AND LINING

CAST SHOE TYPE

1.1.

1. Check shoes for cracks and elongated bolt holes.

1.1.

2.2.

2. Measure the shoe span by loosely installing the

2.2.

anchor pin and cam roller in the appropriate ends

of the shoe rib. If the distance from center of

anchor pin to center of cam roller exceeds 12.76

inches replace shoe.

3.3.

3. Check linings, replace when any of the following

3.3.

conditions exist.

A. Total lining thickness at thinnest point is .31” or

less than 1/16” above screw head. Also, if the

material is worn beyond the wear groove on the

side of the lining.

B.B.

B. Linings are cracked or worn in an unusual or

B.B.

odd pattern. For example: lining wear tapered

from side to side across the shoe table. Un

usual wear pattern can indicate damage to

foundation brake parts.

BRAKE DRUMS

1.1.

1. Inspect drums for cracks, heat checking, glazing,

1.1.

grooving, severe out-of-round condition or bell

mouthing

IndicaIndica

tt

Indica

IndicaIndica

or Ror R

t

or R

tt

or Ror R

m

ust no

mm

ust noust no

eading) eading)

eading) Replace any drums that are

eading) eading)

t e

t et e

x

xx

ceed .0ceed .0

ceed .0

ceed .0ceed .0

22

2

22

5 T5 T

5 T

5 T5 T

.I.R. (T.I.R. (T

.I.R. (T

.I.R. (T.I.R. (T

oo

tt

alal

o

t

al

oo

tt

alal

mm

ust noust no

t et e

xx

cracked. The drum should not be used if it exceeds

the manufacturer’s recommended maximum

diameter stamped on the drum.

2.2.

2. Measure the drum I.D. to be sure the maximum limit

2.2.

allowed (stamped on drum) has not been exceeded

due to wear or machining.

CA CA

CA

CA CA

a contina contin

a contin

a contina contin

ee

xtxt

end arend ar

e

xt

end ar

ee

xtxt

end arend ar

rr

eplaced. eplaced.

r

eplaced.

rr

eplaced. eplaced.

UTION:UTION:

UTION:

UTION:UTION:

uous length of four incheuous length of four inche

uous length of four inche

uous length of four incheuous length of four inche

ound the edge of the drum should beound the edge of the drum should be

ound the edge of the drum should be

ound the edge of the drum should beound the edge of the drum should be

See FSee F

See F

See FSee F

Drums displaDrums displa

Drums displa

Drums displaDrums displa

igurigur

e 1e 1

e 1

e 1e 1

0.0.

0.

0.0.

igur

igurigur

ying heaying hea

ying hea

ying heaying hea

s or mors or mor

s or mor

s or mors or mor

t checks witht checks with

t checks with

t checks witht checks with

e ande and

e and

e ande and

C.C.

C. Screw holes are elongated.

C.C.

D.D.

D. Lining is oil soaked.

D.D.

E.E.

E. Lining can be moved by hand. (loose bolts)

E.E.

TRANSIT BRAKE (CAST SHOE ONLY) DRUM/

LINING CROSS REFERENCE CHART

1.1.

1. When installing new drums always use standard

1.1.

thickness lining. If used drums are rebored carefully measure inside diameter (in several places) of

rebored drum.

LINING MAXIMUM THICKNESS (IN) DRUM DIA. (IN) AT RELINE

.867” (Standard Thickness)

.927” (1X Oversize)

.987” (Premium Thickness)

FF

igurigur

e 1e 1

e 1

e 1e 1

00

0

00

F

igur

FF

igurigur

2.2.

2. Refer to the chart below for proper oversized lining

2.2.

required based on drum measurements.

CA CA

CA

CA CA

22

1, R1, R

2

1, R

22

1, R1, R

UTION:UTION:

UTION:

UTION:UTION:

NeNe

Ne

NeNe

eline Preline Pr

eline Pr

eline Preline Pr

vv

er shim brer shim br

v

er shim br

vv

er shim brer shim br

ocedurocedur

ocedur

ocedurocedur

e, for more, for mor

e, for mor

e, for more, for mor

akak

e linings. See pagee linings. See page

ak

e linings. See page

akak

e linings. See pagee linings. See page

e dee de

tt

ail.ail.

e de

t

ail.

e dee de

tt

ail.ail.

16.500”- New

16.620”

Over 16.620”

CAUTION: Maximum discard

diameter is 16.750”

14

Page 17

BRAKE ASSEMBL Y

CHAMBER BRACKET ASSEMBLY

Seal Installation

NONO

TE: BoTE: Bo

NO

NONO

dirdir

dir

dirdir

th lip seals point the sameth lip seals point the same

TE: Bo

th lip seals point the same

TE: BoTE: Bo

th lip seals point the sameth lip seals point the same

ection, lip tection, lip t

ection, lip t

ection, lip tection, lip t

oo

ww

arar

d the slack adjustd the slack adjust

o

w

ar

d the slack adjust

oo

ww

arar

d the slack adjustd the slack adjust

erer

er

erer

Lip SealLip Seal

Lip Seal

Lip SealLip Seal

Lip Seal

Lip SealLip Seal

Slack ASlack A

djustdjust

Slack A

Slack ASlack A

CA CA

CA

CA CA

instinst

alled corralled corr

inst

alled corr

instinst

alled corralled corr

lip of the seal thalip of the seal tha

lip of the seal tha

lip of the seal thalip of the seal tha

entent

er the opening firer the opening fir

ent

er the opening fir

entent

er the opening firer the opening fir

instinst

alled in the oppositalled in the opposit

inst

alled in the opposit

instinst

alled in the oppositalled in the opposit

entent

er laer la

ent

er la

entent

er laer la

brbr

ackack

br

ack

brbr

ackack

using four cap scrusing four cap scr

using four cap scr

using four cap scrusing four cap scr

77

0-80-8

0 Lb-Ft.0 Lb-Ft.

7

0-8

0 Lb-Ft.

77

0-80-8

0 Lb-Ft.0 Lb-Ft.

er Ender End

djust

er End

djustdjust

er Ender End

UTION:UTION:

UTION:

UTION:UTION:

st. st.

st.

st. st.

ee

t and the cam tube at and the cam tube a

e

t and the cam tube a

ee

t and the cam tube at and the cam tube a

The lip of the grThe lip of the gr

The lip of the gr

The lip of the grThe lip of the gr

ectlectl

y ty t

ectl

y t

ectlectl

y ty t

t is instt is inst

t is inst

t is instt is inst

See FSee F

igurigur

See F

igur

See FSee F

igurigur

ee

e

ee

AA

ctuactua

tt

or Bror Br

ackack

ee

A

ctua

t

AA

ctuactua

tt

and Cam Tand Cam T

and Cam T

and Cam Tand Cam T

FF

igurigur

F

igur

FF

igurigur

o pro pr

o pr

o pro pr

st. The lip of the seal thast. The lip of the seal tha

st. The lip of the seal tha

st. The lip of the seal thast. The lip of the seal tha

e end of the cam tube me end of the cam tube m

e end of the cam tube m

e end of the cam tube me end of the cam tube m

e 1e 1

e 1

e 1e 1

ww

s and lockws and lockw

w

s and lockw

ww

s and lockws and lockw

tt

or Br

ack

e

t

or Bror Br

ackack

ee

tt

ubeube

ube

ubeube

e 1e 1

11

e 1

1

e 1e 1

11

ee

vv

ent posssible damage. Theent posssible damage. The

e

v

ent posssible damage. The

ee

vv

ent posssible damage. Theent posssible damage. The

alled in the spider end malled in the spider end m

alled in the spider end m

alled in the spider end malled in the spider end m

11

. Inst. Inst

1

11

all the chamberall the chamber

. Inst

all the chamber

. Inst. Inst

all the chamberall the chamber

ssemblssembl

ssembl

ssemblssembl

aa

a

aa

Lip SealLip Seal

End CamEnd Cam

End Cam

End CamEnd Cam

SpiderSpider

Spider

SpiderSpider

eaea

se seals mse seals m

ea

se seals m

eaea

se seals mse seals m

y onty ont

o the spidero the spider

y ont

o the spider

y onty ont

o the spidero the spider

shersher

s. Ts. T

sher

s. T

shersher

s. Ts. T

oror

or

que t

oror

ust beust be

ust be

ust beust be

t ist is

t is

t ist is

ustust

ust

ustust

que tque t

que tque t

oo

o

oo

ustust

ust

ustust

If removed, reinstall the dust shields. Tighten the six cap

screws and lockwashers to 20-28 Lb-Ft of torque.

SPIDER

1.1.

1. Use a wire brush to remove heavy contamination

1.1.

from the spider mounting flange, knuckle, spider,

brake drum exterior, and chamber mounting

bracket.

2.2.

2. Install the spider and chamber bracket assembly

2.2.

onto the axle flange. Be sure spider is properly

oriented, as noted during disassembly. Tighten

mounting fastener to manufacturer's specifications.

Left Hand CamLeft Hand Cam

Left Hand Cam

Left Hand CamLeft Hand Cam

FF

igurigur

e 1e 1

e 1

e 1e 1

22

2

22

F

igur

FF

igurigur

CA CA

UTION:UTION:

CA

UTION: Left Hand and Right Hand does

CA CA

UTION:UTION:

Right Hand CamRight Hand Cam

Right Hand Cam

Right Hand CamRight Hand Cam

not

establish which side of the vehicle the cam goes on. Left

and right are used to identify the two different types of

cams only.

2.2.

2. Place steel spacer plate over splined end and slide

2.2.

next to cam head.

pagepage

s 3-6)s 3-6)

page

s 3-6)

pagepage

s 3-6)s 3-6)

3.3.

3. Coat bushing, seals, journals and camshaft spline

3.3.

(See br(See br

(See br

(See br(See br

akak

e componente component

ak

e component

akak

e componente component

s ons on

s on

s ons on

with light film of chassis lube.

IMPORIMPOR

IMPOR

IMPORIMPOR

4.4.

4. Carefully install camshaft through the chamber

4.4.

TT

ANTANT

T

ANT

TT

ANTANT

: Do no: Do no

: Do no

: Do no: Do no

t coat coa

t "S" cam head.t "S" cam head.

t coa

t "S" cam head.

t coat coa

t "S" cam head.t "S" cam head.

bracket tube, from spider end. Cam must rotate

freely when turned by hand.

IMPORIMPOR

IMPOR

IMPORIMPOR

seals.seals.

seals.

seals.seals.

TT

ANTANT

T

ANT

TT

ANTANT

: Be car: Be car

: Be car

: Be car: Be car

eful noeful no

eful no

eful noeful no

t tt t

o damage the gro damage the gr

t t

o damage the gr

t tt t

o damage the gro damage the gr

eaea

ea

eaea

sese

se

sese

SPICER S-CAM BRAKE RETURN SPRINGS

Br Br

akak

Br

Br Br

e Seriee Serie

ak

e Serie

akak

e Seriee Serie

ss

s

ss

RR

ee

turn Springs P/N & Colorturn Springs P/N & Color

R

e

turn Springs P/N & Color

RR

ee

turn Springs P/N & Colorturn Springs P/N & Color

Standard 165WJ110 Dark Blue

XL & Cast Shoe 165WJ115 White

XLII 165WJ129 Light Blue

CAMSHAFT

1.1.

1. Prior to reassembly, verify the part number is

1.1.

correct there are L.H. and R.H. camshafts and they

See FSee F

igurigur

e 1e 1

can not be interchanged.

See F

See FSee F

igur

igurigur

e 1

e 1e 1

2.2.

2.

2.2.

15

Page 18

BRAKE ASSEMBL Y (CONTINUED)

BRAKE SHOE ASSEMBLY

ST ANDARD, XL & XL II SERIES

1.1.

1. Install new return spring pins:

1.1.

A. StA. St

andarandar

andar

andarandar

d Seried Serie

d Serie

d Seried Serie

A. St

A. StA. St

ribs with mallet.

B. XL SerieB. XL Serie

B. XL Serie

B. XL SerieB. XL Serie

inner pin and outer pin.

2.2.

2. Apply a thin film of Lubriplate 630-A grease or its

2.2.

equivalent to the anchor pin.

3.3.

3. Install new brake retaining springs in the anchor

3.3.

end of shoes. Place the top shoe onto the spider

by engaging the open slots on the end with the

retaining springs onto the anchor pin. Place

opposite end of the shoe against the S-cam. Swing

the lower shoe, with springs attached, back until

slots in the shoe engage the anchor pin. Rotate the

shoe toward the S-cam. Lower shoe may require

support while completing assembly.

ss

s- Wireform pin installed in shoe

ss

ss

s- 2 piece kit assembly consisting of

ss

the S-cam and the slots in the end of the brake

shoe. Make sure the cam rollers are in the lowest

position on the cam. Repeat procedure for opposite side.

CAST SHOE SERIES

1.1.

1. Apply a thin film of Lubriplate 630-A grease or its

1.1.

equivalent to the anchor pin.

2.2.

2. Place snap ring on anchor pin end with grease

2.2.

fitting. Place thin spacer onto anchor pin.

3.3.

3. Align anchor pin end of cast shoe with spider bore.

3.3.

4.4.

4. Install anchor pin through backside of shoe and

4.4.

spider. Repeat procedure for opposite shoe.

4a.4a.

StSt

andarandar

4a.

St

4a.4a.

StSt

to aid in assembly. Place the one hook of the brake

shoe return spring onto the return spring pin.

Hold shoes firmly against the S-cam. Push the

other hook of the brake shoe return spring over the

opposite return spring pin until it snaps in place.

4b.4b.

XL/XL II SerieXL/XL II Serie

4b.

XL/XL II Serie

4b.4b.

XL/XL II SerieXL/XL II Serie

shoe return spring onto the return spring pin

located between the shoe ribs. Hold both shoes

against the S-cam head. Push the other hook of

the return spring over the opposite shoe spring pin

until it snaps in place.

5.5.

5. Apply a thin film of Lubriplate 630-A grease or its

5.5.

equivalent to the cam roller journal, and the roller

side only. Do not put grease on the end of the

roller which contacts the cam head.

6.6.

6. Insert sturdy lever between end of shoe and the

6.6.

return spring pin.

the cam until cam rollers can be installed between

andar

andarandar

d Seried Serie

d Serie

d Seried Serie

ss

s- Utilize leg on shoe return spring

ss

ss

s- place the one hook of the brake

ss

See FSee F

igurigur

e 1e 1

See F

See FSee F

33

igur

e 1

3. Pry away from

igurigur

e 1e 1

33

FF

igurigur

e 1e 1

e 1

e 1e 1

33

3

33

SeeSee

See

SeeSee

F

igur

FF

igurigur

5.5.

5. Place thin spacer onto opposite side of anchor pins

5.5.

and install snap rings.

6.6.

6. Hook shoe return spring by pushing shoes to-

6.6.

gether. The cast shoe does not have a separate

return spring pin. The spring hook-up feature is

designed into the shoe casting.

77

..

7

. Insert sturdy lever between end of shoe and spider.

77

..

Pry shoe away from cam until cam rollers can be

installed. Repeat procedure for opposite side.

FF

igurigur

e 1e 1

igur

igurigur

e 1

e 1e 1

3.3.

3.

3.3.

F

FF

16

Page 19

BRAKE ASSEMBL Y (CONTINUED)

“P” SERIES

11

1. Install new return spring pins.

11

2.2.

2. Align lower end of fabricated shoe with spider bore.

2.2.

3.3.

3. Place snap ring on anchor pin end with grease

3.3.

fitting. Place thin spacer onto anchor pin.

4.4.

4. Install anchor pin through backside of shoe and

4.4.

spider.

5.5.

5. Apply a thin film of Lubriplate 630-A grease or its

5.5.

equivalent to the anchor pin.

6.6.

6. Place thin spacer onto opposite side of anchor pin

6.6.

and install snap ring.

77

..

7

. Hook shoe return spring by pushing shoes to-

77

..

gether.

8.8.

8. Insert sturdy lever between end of shoe and spider.

8.8.

Pry shoe away from cam until cam rollers can be

installed. Repeat procedure for opposite side.

See FSee F

See F

See FSee F

igurigur

igur

igurigur

e 1e 1

e 1

e 1e 1

4.4.

4.

4.4.

NONO

TE: Due tTE: Due t

NO

TE: Due t

NONO

TE: Due tTE: Due t

adjustadjust

adjust

adjustadjust

manman

ufacturufactur

man

ufactur

manman

ufacturufactur

aa

ssemblssembl

a

ssembl

aa

ssemblssembl

FF

igurigur

e 1e 1

F

igur

e 1

FF

igurigur

e 1e 1

o the mano the man

o the man

o the mano the man

erer

s and brs and br

er

s and br

erer

s and brs and br

er’er’

s specificas specifica

er’

s specifica

er’er’

s specificas specifica

y and final adjustment.y and final adjustment.

y and final adjustment.

y and final adjustment.y and final adjustment.

y combinay combina

y combina

y combinay combina

akak

e chambere chamber

ak

e chamber

akak

e chambere chamber

tions and prtions and pr

tions and pr

tions and prtions and pr

44

4

44

tions of slacktions of slack

tions of slack

tions of slacktions of slack

s, follos, follo

s, follos, follo

w vw v

w v

w vw v

ocedurocedur

ocedur

ocedurocedur

s, follo

ehicleehicle

ehicle

ehicleehicle

ee

e

ee

s fors for

s for

s fors for

SLACK ADJUSTER ASSEMBL Y

1.1.

1. Reinstall thick camshaft flatwasher.

1.1.

2.2.

2. Install new slack adjuster, shims, and a new snap

2.2.

ring (In that sequence) into the splined end of the

camshaft.

3.3.

3. Adjust camshaft end play of the camshaft to

3.3.

between .005" and .045" by using the appropriate

number of shims. Make sure the snap ring is seated

into the groove at the end of the splined camshaft.

BRAKE LUBRICA TION

1.1.

1. Lubricate the camshaft bushings by filling the

1.1.

camshaft tube with lube through the zerk fitting

provided. Fill until grease is forced out in the area

of the slack adjuster. Grease should not appear at

the cam head end. If it does, the seal has not been

properly installed, or the old seals should be

replaced.

3.3.

3. Spin the wheel slowly and adjust the slack adjuster

3.3.

until wheel will no longer turn. Back off slack

adjuster just enough for wheel to spin freely. Be

sure to adjust brakes equally on each axle.

4.4.

4. Apply the release brakes and observe slack adjust-

4.4.

ers. Both slacks on each axle should respond

rapidly and in unison during application and

release.

5.5.

5. Drive vehicle at a low speed in a safe area and

5.5.

check for brake effectiveness prior to putting back

in service.

2.2.

2. Reinstall brake drums and wheels. Torque and

2.2.

adjust wheel bearings to manufacturer’s specifications.

17

Page 20

FOUNDATION BRAKE TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

A.A.

A. Adjust brake.

1.1.

1. Degraded brake

1.1.

performance.

2.2.

2. Slow brake

2.2.

application.

3.3.

3. Slow brake release.

3.3.

A.A.

A. Too much push rod free travel.

A.A.

B.B.

B. Severely glazed or worn out linings.

B.B.

C.C.

C. Grease or oil on linings.

C.C.

D.D.

D. Worn, seared, heat checked, cracked

D.D.

drums.

E.E.

E. Push rod length too long.

E.E.

FF

..

F

. Air chamber in wrong position.

FF

..

G.G.

G. Broken or bent parts.

G.G.

H.H.

H. Flat spots on cam or rollers.

H.H.

A.A.

A. Cam shaft bushings binding.

A.A.

A.A.

A. Binding cam shaft and bushing.

A.A.

B.B.

B. Weak or broken shoe return

B.B.

spring.

C.C.

C. Flat spotted cam or rollers.

C.C.

A.A.

B.B.

B. Deglaze linings or replace.

B.B.

C.C.

C. Replace linings.

C.C.

D.D.

D. Replace part.

D.D.

E.E.

E. Adjust clevice, shorten push rod length

E.E.

FF

..

F

. Reposition.

FF

..

G.G.

G. Replace part.

G.G.

H.H.

H. Replace flat-spotted parts.

H.H.

A.A.

A. Clean and lubricate. Check for seal

A.A.

leakage.

A.A.

A. Clean and lubricate.

A.A.

B.B.

B. Replace part.

B.B.

C.C.

C. Replace flat-spotted parts.

C.C.

4.4.

4. Grabbing or pulling.

4.4.

A.A.

A. Grease, oil, or dirt on linings.

A.A.

B.B.

B. Glazed linings.

B.B.

C.C.

C. Brake linings not a balanced set,

C.C.

different friction codes, or lining brand.

D.D.

D. Loose or broken linings.

D.D.

E.E.

E. Brake drum out-of-round.

E.E.

FF

..

F

. Defective brake drum.

FF

..

G.G.

G. Clevis pin or camshaft binding at one

G.G.

or more wheels.

H.H.

H. Defective slack adjuster.

H.H.

I.I.

I. Uneven brake adjustment (side to side).

I.I.

J.J.

J. Broken or bent parts.

J.J.

K.K.

K. Loose spider or drum mounting bolts.

K.K.

L.L.

L. Different air chamber size or slack

L.L.

adjuster length (side to side).

A.A.

A. Replace lining.

A.A.

B.B.

B. Deglaze lining or replace.

B.B.

C.C.

C. Replace linings.

C.C.

D.D.

D. Replace linings.

D.D.

E.E.

E. Turn, per manufacturer's specifications.

E.E.

FF

..

F

. Replace part.

FF

..

G.G.

G. Clean and lubricate.

G.G.

H.H.

H. Replace part.

H.H.

I.I.

I. Adjust brakes.

I.I.

J.J.

J. Replace part.

J.J.

K.K.

K. Inspect and replace as necessary.

K.K.

L.L.

L. Use same size and type both ends of

L.L.

the axle.

18

Page 21

BRAKE SHOE & LINING TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

1.1.

1. Poor lining to drum

1.1.

contact.

2.2.

2. Linings tapered

2.2.

across width.

3.3.

3. Unequal wear on

3.3.

same brake.

A.A.

A. Bell-mouth drum.

A.A.

B.B.

B. Bent brake spider.

B.B.

C.C.

C. Bent or stretched brake shoe.

C.C.

D.D.

D. Undersize linings.

D.D.

E.E.

E. Loose wheel bearing.

E.E.

FF

..

F

. Improper lining grind.

FF

..

A.A.

A. Bell-mouth drum.

A.A.

B.B.

B. Bent brake shoe.

B.B.

C.C.

C. Bent brake spider.

C.C.

D.D.

D. Loose wheel bearings.

D.D.

A.A.

A. Mismatched lining friction codes.

A.A.

B.B.

B. Stretched shoe.

B.B.

C.C.

C. Flat spots on cam or roller.

C.C.

D.D.

D. Worn anchor pin.

D.D.

E.E.

E. Worn camshaft or bushings.

E.E.

A.A.

A. Replace part.

A.A.

B.B.

B. Replace part.

B.B.

C.C.

C. Replace part.

C.C.

D.D.

D. Replace linings.

D.D.

E.E.

E. Correct as required.

E.E.

FF

..

F

. Regrind linings to drum

FF

..

radius minus .015"

A.A.

A. Replace parts.

A.A.

B.B.

B. Replace parts.

B.B.

C.C.

C. Replace part.

C.C.

D.D.

D. Correct as required.

D.D.

A.A.

A. Replace linings.

A.A.

B.B.

B. Replace parts.

B.B.

C.C.

C. Replace flat-spotted parts.

C.C.

D.D.

D. Correct as required.

D.D.

E.E.

E. Replace part.

E.E.

4.4.

4. Unequal wear side

4.4.

to side brakes,

same axle.

5.5.

5. Wear on edge of

5.5.

lining.

6.6.

6. Glazed linings

6.6.

(hard & shiny).

A.A.

A. Mismatched lining friction codes.

A.A.

B.B.

B. Seized or binding camshaft.

B.B.

C.C.

C. Brake drum surface

C.C.

in poor condition.

D.D.

D. Loose wheel bearing.

D.D.

E.E.

E. Relining one brake.

E.E.

A.A.

A. Wrong width lining.

A.A.

B.B.

B. Holes improperly drilled in lining.

B.B.

C.C.

C. Wrong drum, or improperly machined.

C.C.

D.D.

D. Loose wheel bearing

D.D.

E.E.

E. Improper wheel bearing or cone.

E.E.

FF

..

F

. Bent brake shoe.

FF

..

G.G.

G. Bent brake spider.

G.G.

H.H.

H. Worn axle spindle.

H.H.

A.A.

A. Overheating, due to unbalanced

A.A.

braking system.

B.B.

B. Wrong type linings for service

B.B.

involved.

A.A.

A. Replace linings.

A.A.

B.B.

B. Clean and lubricate.

B.B.

C.C.

C. Replace or turn I.D.

C.C.

D.D.

D. Correct as required.

D.D.

E.E.

E. Reline both brakes together.

E.E.

A.A.

A. Replace linings.

A.A.

B.B.

B. Replace linings.

B.B.

C.C.

C. Replace or turn I.D.

C.C.

D.D.

D. Correct as required.

D.D.

E.E.

E. Correct as required.

E.E.

FF

..

F

. Replace part.

FF

..

G.G.

G. Replace part.

G.G.

H.H.

H. Correct as required.

H.H.

A.A.

A. Correct as required.

A.A.

B.B.

B. Replace linings.

B.B.

19

Page 22

BRAKE SHOE AND LINING TROUBLESHOOTING CHART

77

..

7

. Scored or grooved

77

..

linings and drum.

8.8.

8. Loose lining.

8.8.

9.9.

9. Cracked lining at

9.9.

rivet holes.

11

0.0.

1

0. Elongated rivet

11

0.0.

holes.

A.A.

A. Scored or worn drum, not

A.A.

machined at reline.

B.B.

B. Abrasive material between

B.B.

lining and drum.

A.A.

A. Improper size rivets (too long, too

A.A.

short, improper diameter).

B.B.

B. Improper crimping of rivet.

B.B.

C.C.

C. Enlarged rivet holes in shoe.

C.C.

D.D.

D. Incorrect lining hole size or counter

D.D.

bore depth.

E.E.

E. Rust build up on shoe table.

E.E.

A.A.

A. Wrong type rivets.

A.A.

B.B.

B. Rivets not properly crimped.

B.B.

C.C.

C. Dirt or rust on shoe table.

C.C.

D.D.

D. Wrong size lining counter bore.

D.D.

A.A.

A. Loose rivets.

A.A.

A.A.

A. Replace or re-machine.

A.A.

B.B.

B. Clean, remove dirt and debris.

B.B.

A.A.

A. Re-rivet.

A.A.

B.B.

B. Re-rivet.

B.B.

C.C.

C. Replace part.

C.C.

D.D.

D. Replace linings.

D.D.

E.E.

E. Clean, remove rust and paint shoe.

E.E.

A.A.

A. Replace part.

A.A.

B.B.

B. Replace lining.

B.B.

C.C.

C. Clean, remove dirt and debris.

C.C.

D.D.

D. Replace linings.

D.D.

A.A.

A. Replace shoe and lining.

A.A.

BRAKE DRUM TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

A.A.

A. Out round brake drum.

1.1.

1. Brake drum heat

1.1.

checked.

2.2.

2. Excessive scoring

2.2.

of drum.

A.A.

B.B.

B. Eccentric mounting of drum.

B.B.

C.C.

C. Loose wheel bearing.

C.C.

D.D.

D. Glazed linings.

D.D.

E.E.

E. Improper friction materials for duty

E.E.

cycle of vehicle.

FF

..

F

. Overworked brake.

FF

..

G.G.

G. Driver abuse.

G.G.

H.H.

H. Wrong drum, too light.

H.H.

A.A.

A. Defective brake lining.

A.A.

B.B.

B. Abrasive material between lining and

B.B.

drum.

C.C.

C. Soft drum.

C.C.

D.D.

D. Excessive lining wear, rivets contact

D.D.

ing drum.

A.A.

A. Turn, per manufacturer’s specifications.

A.A.

B.B.

B. Inspect wheel and drum and replace

B.B.

C.C.

C. Correct as required.

C.C.

D.D.

D. Replace linings.

D.D.

E.E.

E. Consult vehicle manufacturer.

E.E.

FF

..

F

. Check proper brake balance.

FF

..

G.G.

G. Correct as required.

G.G.

H.H.

H. Replace part.

H.H.

A.A.

A. Replace linings.

A.A.

B.B.

B. Clean, remove dirt and debris.

B.B.

C.C.

C. Check hardness on flange.

C.C.

D.D.

D. Replace lining.

D.D.

defective part.

E.E.

E. Drum not turned at last reline.

E.E.

FF

..

F

. Build up of abrasives in rivet holes.

FF

..

20

E.E.

E. Turn per manufacturer’s specifications.

E.E.

FF

..

F

. Blow out debris.

FF

..

Page 23

Bolts/Rivets Removal

When removing bolts/rivets from the brake shoes, be

careful to avoid doing any damage to the holes in the

shoe. Do not use a chisel to shear them off. The force

will elongate the bolt/rivet holes. Neglecting any

elongated holes may result in a loose fitting installation.

If holes are burred, they should be filed down flush with

the shoe table.

Cleaning the Shoe

Rust often developes on the surface of the shoe table

under the brake lining or blocks. During every reline job,

shoe tables should be cleaned thoroughly. The best

procedure is to steam clean the entire shoe or put it into

a degreaser.

RELINE PROCEDURE

FF

igurigur

e 1e 1

igurigur

e 1

e 1e 1

66

6

66

F

igur

FF

After cleaning the shoe, the shoe should be scraped

clean of rust and scale. Any burrs or nicks should be

filed smooth. At the same time, the entire shoe should

be examined to see if it is worn or bent.

Shoe Inspection

The shoe should be either reconditioned or discarded.

It is also necessary to check for flat spots on the shoe

that can be caused by cleaning away the rust from the

area that was under the block previously. This can cause

a mismatch of shoe and lining arcs. After the shoe is

cleaned and inspected, it should be given a coating of

rust preventative paint. Treatment of a new, unpainted

shoe is also suggested to prevent the initial rusting

problem.

Lining Installation

IMPORIMPOR

IMPOR

IMPORIMPOR

TT

ANTANT

T

ANT

TT

ANTANT

: Ne: Ne

vv

er shim the brer shim the br

: Ne

v

er shim the br

: Ne: Ne

vv

er shim the brer shim the br

akak

e linings.e linings.

ak

e linings. Brake

akak

e linings.e linings.

noise may result because of cracked and/or loose lining

since a tight installation is not possible with shims. The

inside surface of the correct arc to match the shoe table,

and the rivet/bolt holes in the linings will only line up

with holes in the shoes when they are in direct contact.

Prior to riveting/bolting be sure the holes in the lining

blocks and the shoes are exactly matched.

The sequence of riveting/bolting should be such that

the center of the block is attached first and then the

See page 2 See page 2

ends.

See page 2

See page 2 See page 2

2 for bolting sequence.2 for bolting sequence.

2 for bolting sequence.

2 for bolting sequence.2 for bolting sequence.

The installation should be checked by attempting to

insert a .006" feeler gage between the lining and shoe

table. It should not be possible to insert the feeler gage

See F See F

igurigur

e 1e 1

anywhere along the edge.

See F

See F See F

igur

igurigur

6.6.

e 1

6. The only

e 1e 1

6.6.

exception is at each end and beyond the last row of

rivets/bolts. A slightly larger clearance may exist in

these areas.

Riveting Application

Some brake failures result from the use of rivets which

are too short, too long, or the wrong diameter. Incorrect setting of the riveting machine may induce other

types of failures.

The solid portion of the rivet should end just at the

inner surface of the shoe. The hollow portion of the

rivet should extend past the inner surface of the shoe.

The proper size rivet must be used to completely fill the

hole.

1/2 1/2

1/2

1/2 1/2

USE ONLUSE ONL

USE ONL

USE ONLUSE ONL

Y 1Y 1

Y 1

Y 1Y 1

0-80-8

0-8

0-80-8

RIVETSRIVETS

RIVETS

RIVETSRIVETS

Brass plated steel rivets are recommened. The riveting

machine must be adjusted so that the roll of the rivet is

complete, but the rivet should not split. Always use a

roll set, never a star set, when riveting brake linings. A

star set does not compress the rivet and expand it to fill

the hole. Consequently, the lining may work loose in

service.

21

Page 24

RELINE PROCEDURE

Bolting Application

Use 3/8 inch diameter copper alloy bolts.

Torque bolts to 15-17 Lb-Ft (20-23 N-m)

Follow the sequence below for the bolt application only.

16.5 x 6 inch

15

11

7

9

5

1

3

10

12

17

8

4

2

6

11

13

20

3

10

1

7

5

16.5 x 10 inch

14

19

12

16

18

6

8

2

4

9

22

Page 25

Page 26

Copyright Eaton and Dana Corporation,

2002. EATON AND DANA CORPORATION

hereby grants its customers, vendors, or

distributors permission to freely copy,

reproduce and/or distribute this document

in printed format. THIS INFORMATION IS

NOT INTENDED FOR SALE OR RESALE, AND THIS NOTICE MUST REMAIN

ON ALL COPIES.

The Roadranger® System is an unbeatable combination of the best

products from Eaton and Dana -- partnering to provide you the most

advanced, most trouble-free drivetrain in the industry. And it's

backed by the Roadrangers -- the most experienced, most expert,

most accessible drivetrain consultants in the business. Visit our web

site at www.roadranger.com. For spec'ing or service assistance,

call 1-800-826-HELP (4357) 24 hours a day, 7 days a week,

(Mexico: 001-800-826-HELP (4357)) for more time on the road.

BRSM-0890

05/04 PDF

Printed in USA

Loading...

Loading...