Page 1

Premium wheel-end brake products

BBeennddiixx®®EESSDD--222255™™AAiirr DDiisscc BBrraakkee

SS ee rr vv ii cc ee MM aa nn uu aa ll

Page 2

Table of Contents

General Information

Model Identifi cation . . . . . . . . . . . . . . . . . . . . . . . 2

Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifi cations

Disc Brake ESD225. . . . . . . . . . . . . . . . . . . . . . . 4

Tightening Torque. . . . . . . . . . . . . . . . . . . . . . . . . 5

Wear Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of Operation

Actuation/Release of the Brake . . . . . . . . . . . . . . 6

Self-Adjusting Adjustment . . . . . . . . . . . . . . . . . . 6

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . 10

Service Instructions

Service Intervals. . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking Pads. . . . . . . . . . . . . . . . . . . . . . . . 12

Checking Brake Disc. . . . . . . . . . . . . . . . . . . 12

Checking Sliding Function. . . . . . . . . . . . . . . 13

Checking Play in the Slide Pins. . . . . . . . . . . 13

Checking Boots for Slide Pins. . . . . . . . . . . . 14

Checking Bellows for Adjustment Screws . . . 14

Operating Test . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Initial Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 16

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjustment Mechanism. . . . . . . . . . . . . . . . . 16

Slide Pins and Bushings . . . . . . . . . . . . . . . . 16

Replacing Disc Brake

Removing Disc Brake Caliper . . . . . . . . . . . . . . 19

Replacing Disc Brake Caliper . . . . . . . . . . . . . . 19

Replacing Slide Pins, Slide Bushings, and Boots

Removing Slide Pins, Slide Bushings,

and Boots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Slide Bushings and Slide Pins . . . . . 22

Replacing Boots in Caliper. . . . . . . . . . . . . . . . . 23

Replacing Brake Chamber

Removing Brake Chamber. . . . . . . . . . . . . . . . . 25

Replacing Brake Chamber. . . . . . . . . . . . . . . . . 25

Replacing Spring Brake Chamber

Removing Spring Brake Chamber. . . . . . . . . . . 26

Replacing Spring Brake Chamber . . . . . . . . . . . 27

Replacing Rotor

Removing Rotor. . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing Rotor. . . . . . . . . . . . . . . . . . . . . . . . . 28

Rotor Runout Check. . . . . . . . . . . . . . . . . . . . . . 28

Cleaning and Inspection. . . . . . . . . . . . . . . . . . . 29

Rotor Resurfacing . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table of Contents

Replacing Pads

Removing Pads . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacing Pads . . . . . . . . . . . . . . . . . . . . . . . . . 17

Initial Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 18

1

Page 3

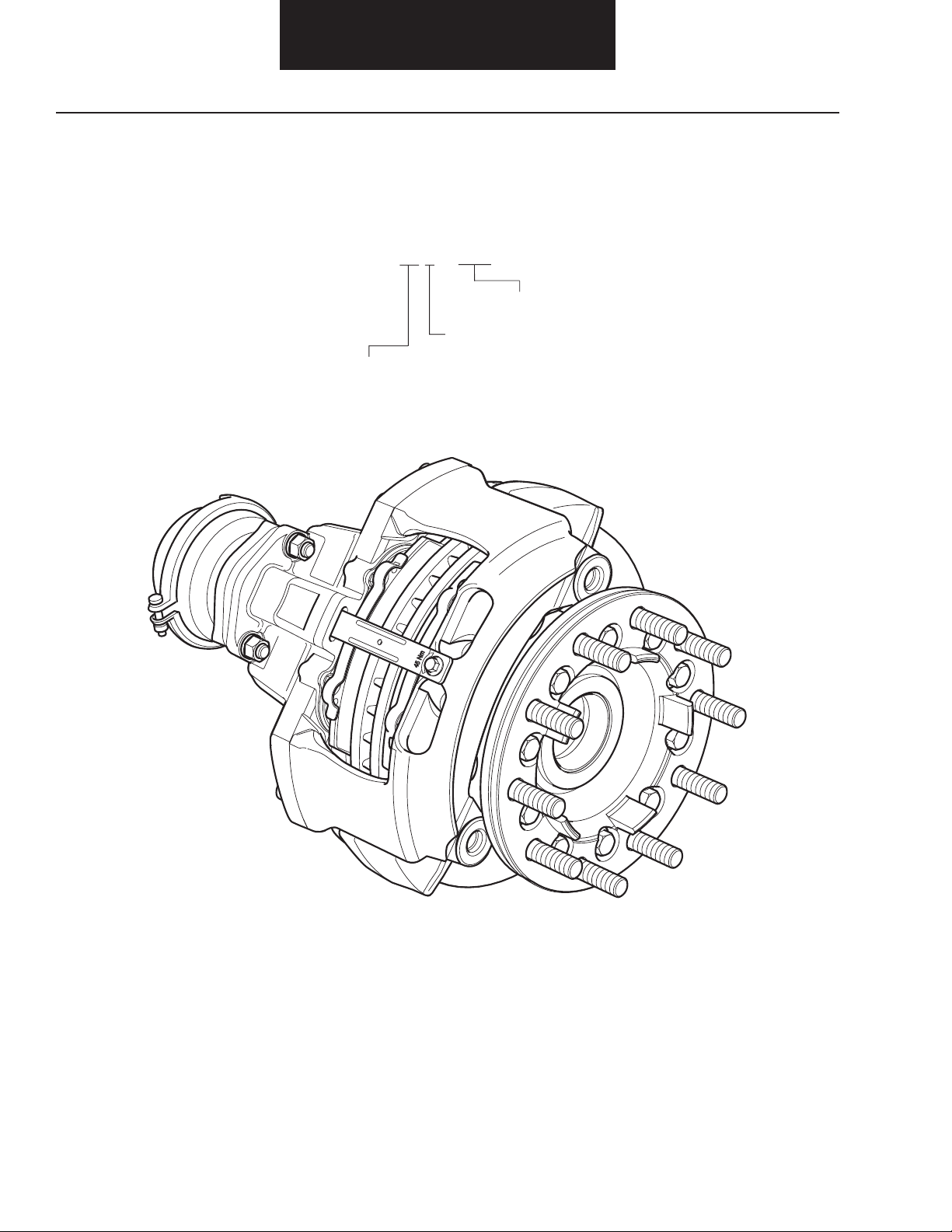

Model Identifi cation

General Information

Bendix® ESD - 225

Wheel Size

Disc Brake

Extended Service

™

2

Page 4

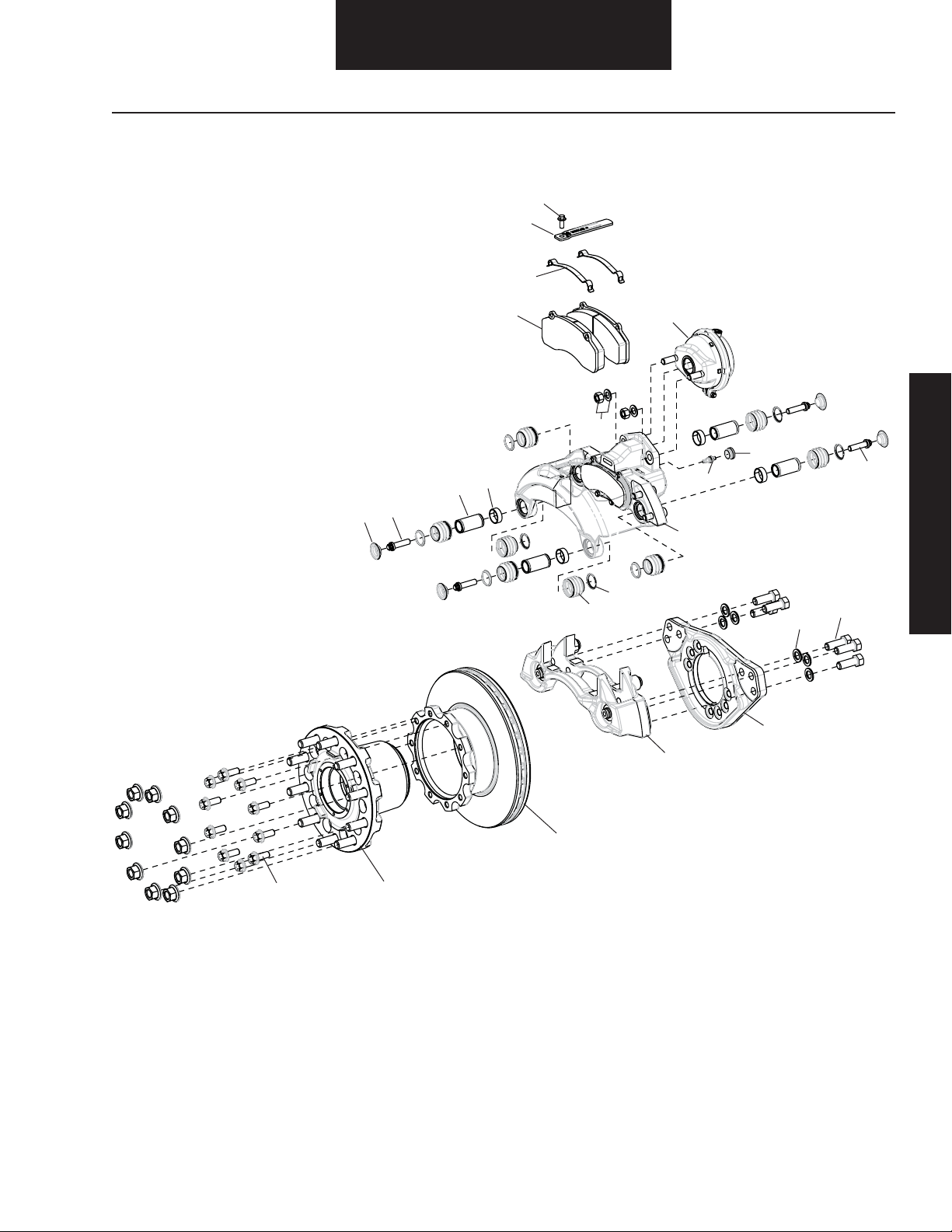

Product Identifi cation – Exploded View

General Information

5

6

7

13

14

Exploded view of conventional hub rotor

12

8

21

11

10

9

20

2

General Information

22

23

4

17

1

19

18

1 – Torque plate

2 – Carrier

4 – Caliper Assy.

5 – Retaining bar screw

6 – Retaining bar

7 – Pad retaining spring

8 – Pads

9 – Slider boot

10 – Boot retaining ring

11 – Slider bushing

12 – Slide pin

25

24

26

13 – Slider pin bolt

14 – Slider pin cap

17 – Flat washer

18 – Hex head screw (torque plates to frame)

20 – Air chamber

21 – Air chamber nut & air chamber washer

22 – Actuator plug

23 – Actuator assembly extension

24 – Rotor

25 – Rotor mounting cap screw

26 – Hub

3

Page 5

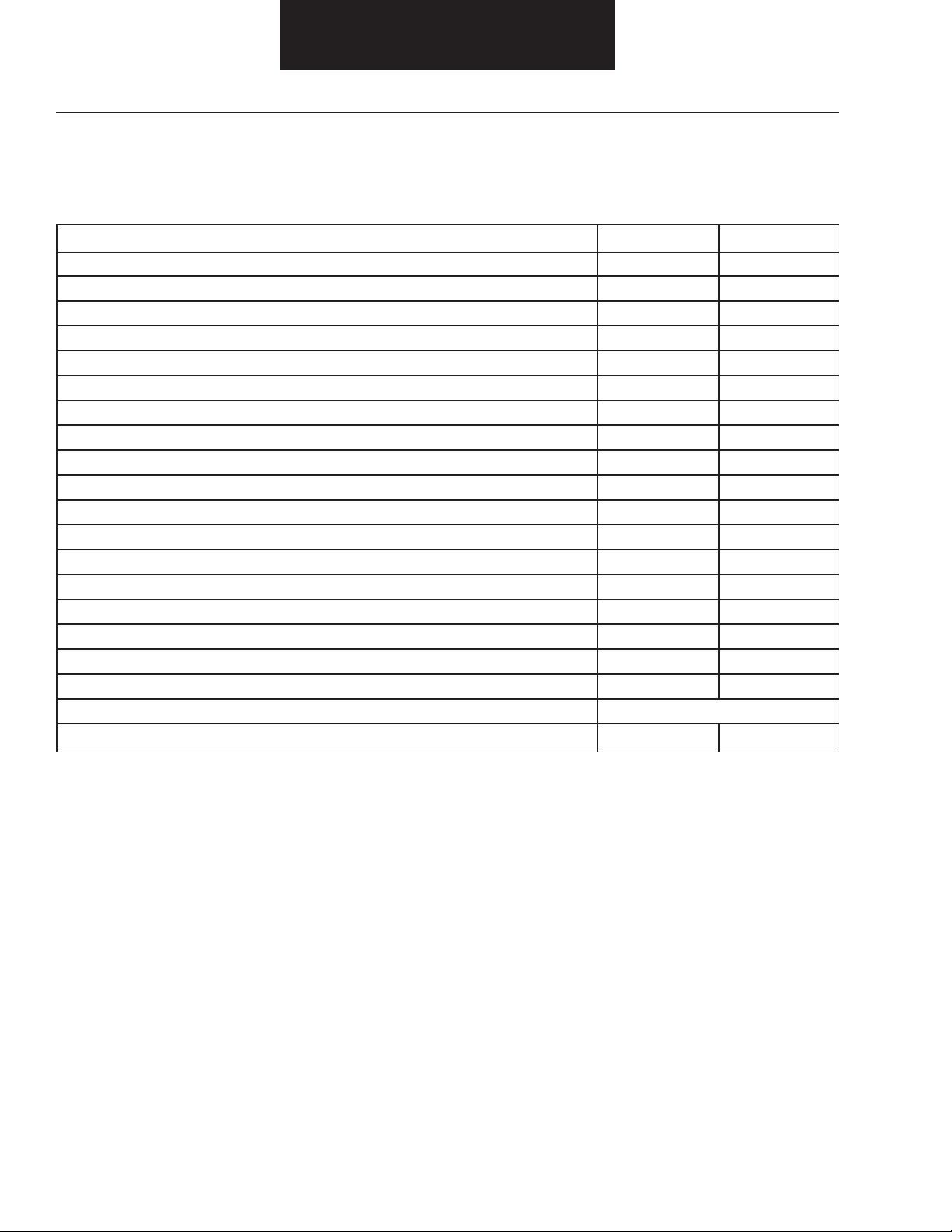

Specifi cations

Specifi cations

Disc Brake ESD225

METRIC STANDARD

Max. brake chamber force 13.9 kN 3124.8 lbf.

Wheel size 571.5 mm 22.5 in.

Number of actuating pistons 2 2

Number of slide pins 4 4

Threshold force 28N 6.3 lbf.

Brake chamber stroke requirements min. 57 mm min. 2.2 in.

max. 65 mm max. 2.6 in.

Mechanical advantage 15:8:1 15:8:1

Max. adjustment distance brake lining 58 mm 2.3 in.

Lining thickness (friction material), new 22 mm 0.9 in.

Backplate thickness 8 mm 0.3 in.

Running clearance brake lining to brake disc 0.6 - 0.8 mm 0.02 - 0.03 in.

External diameter brake disc 430 mm 16.9 in.

Thickness brake disc, new 45 mm 1.8 in.

Thickness brake disc, worn 41 mm 1.61 in.

Effective radius 172.6 mm 6.8 in.

Swept area, brake disc 1808 cm2 280.2 cm

Lining area (per pad) 187 cm2 29.0 cm

Grease (GGLB - NGLI +350°F/+177°C to -35°F/-37°C Standard Chassis Grease

Weight, disc brake, approximately . (Exc. brake disc/pads/chamber and sensor) 42.0 Kg 112.5 lb.

2

2

4

Page 6

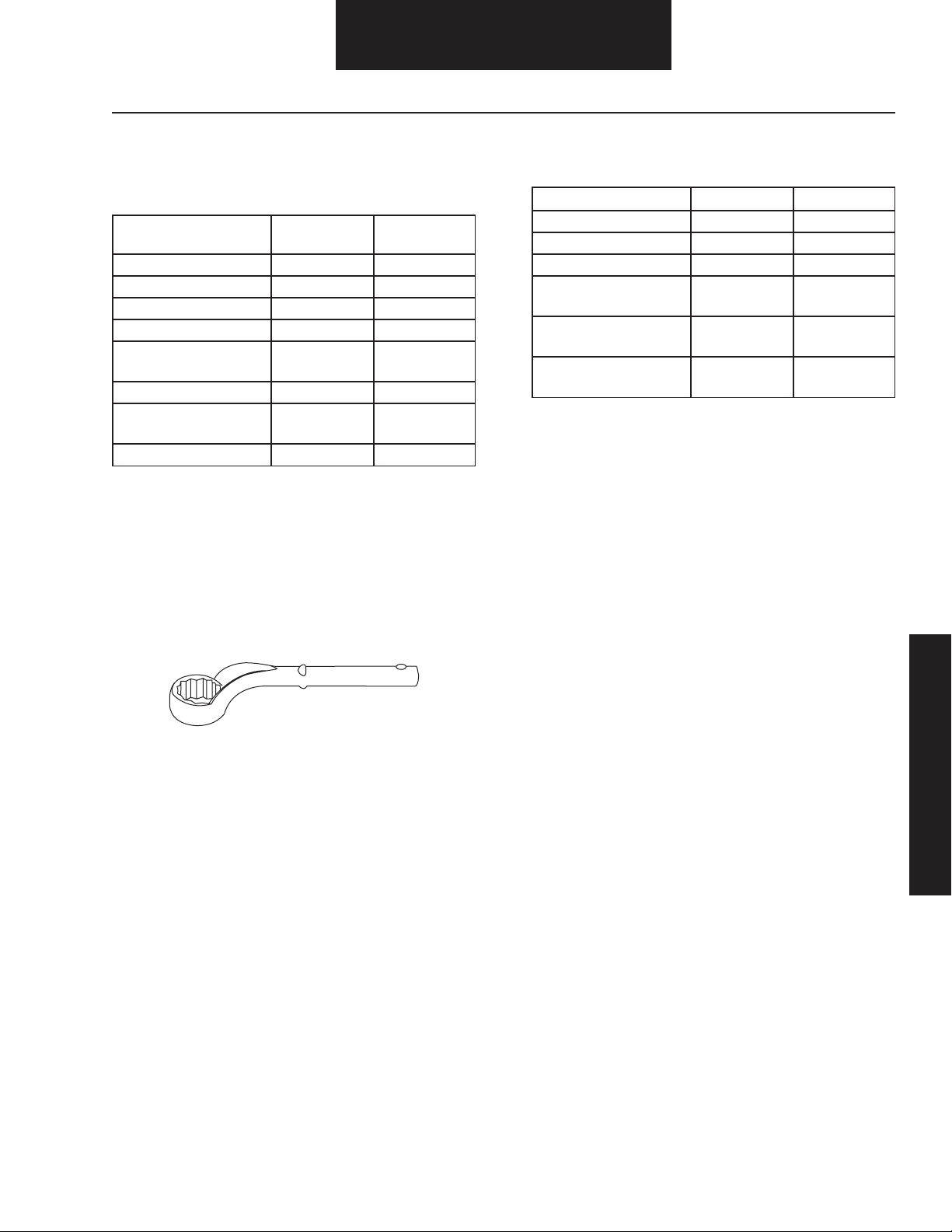

Specifi cations

Tightening Torque Wear Limits

Torque fasteners to specifi cations in table.

Torque Torque

Fastener N•m lbs. ft.

Frame Mounting Screw* 447 to 474 330 to 350

Slide Pin Screw 187 to 200 138 to 148

Retaining Bar Screw 42 to 48 31 to 35

Actuator Mounting Screw 24 to 30 18 to 22

Bridge Mounting Screw 100 +/-10 +50º 74 +/-7 +50º

+/-2º turn +/-2º turn

Air Chamber 176 130

Rotor to Iron Hub 339 to 373 250 to 275

(use Loctite 266)

Rotor to Aluminum Hub 190 +/- 19 140 +/- 14

* Use the Snap-on™ Torque Wrench Heavy Duty Offset 13/16"

(30mm) Box Adapter (part number XM300B) with the Snap-on™

400 lbs. ft. Torque Wrench (part number TQR400).

Snap-on™ Customer Service – 877-740-1900

METRIC STANDARD

Pads, min. lining thickness 3 mm 0.12 in.

Pads, max. uneven wear 1 mm 0.04 in.

Slide pins, max. play 1 mm 0.04 in.

Brake disc, max. wear per 2 mm 0.08 in.

side

Brake disc, max. lateral 0.5 mm 0.02 in.

runout

Brake disc, max. 0.1 mm (DTV) 0.004 in.

thickness variation

Specifi cations

5

Page 7

Description of Operation

Description of Operation

Actuation/Release of the Brake

On braking, the lever is actuated by the brake chamber. The

external and internal radii of the inner part of the lever do not

have a common center, which means that the crossbar is moved

axially in the direction of the brake disc. The force is transferred

from the crossbar via adjustment screws and thrust plates to the

inner pad. When the pad comes into contact with the brake disc,

the caliper is moved on slide pins so that the outer pad also

comes into contact with the brake disc.

When the brake is released, the return spring forces the

crossbar back into its rest position, so that the design clearance

between pad and brake disc is achieved.

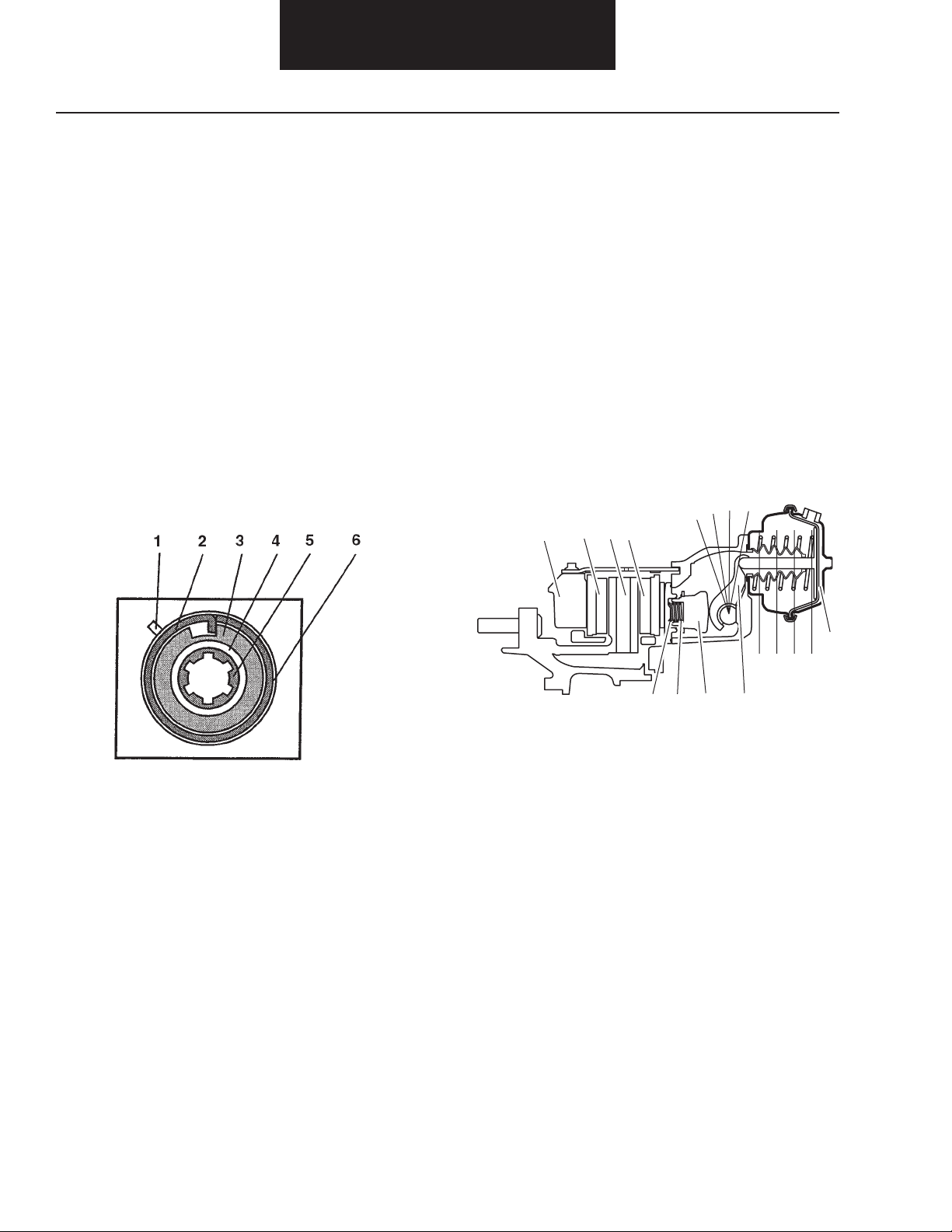

Self-Adjusting Adjustment

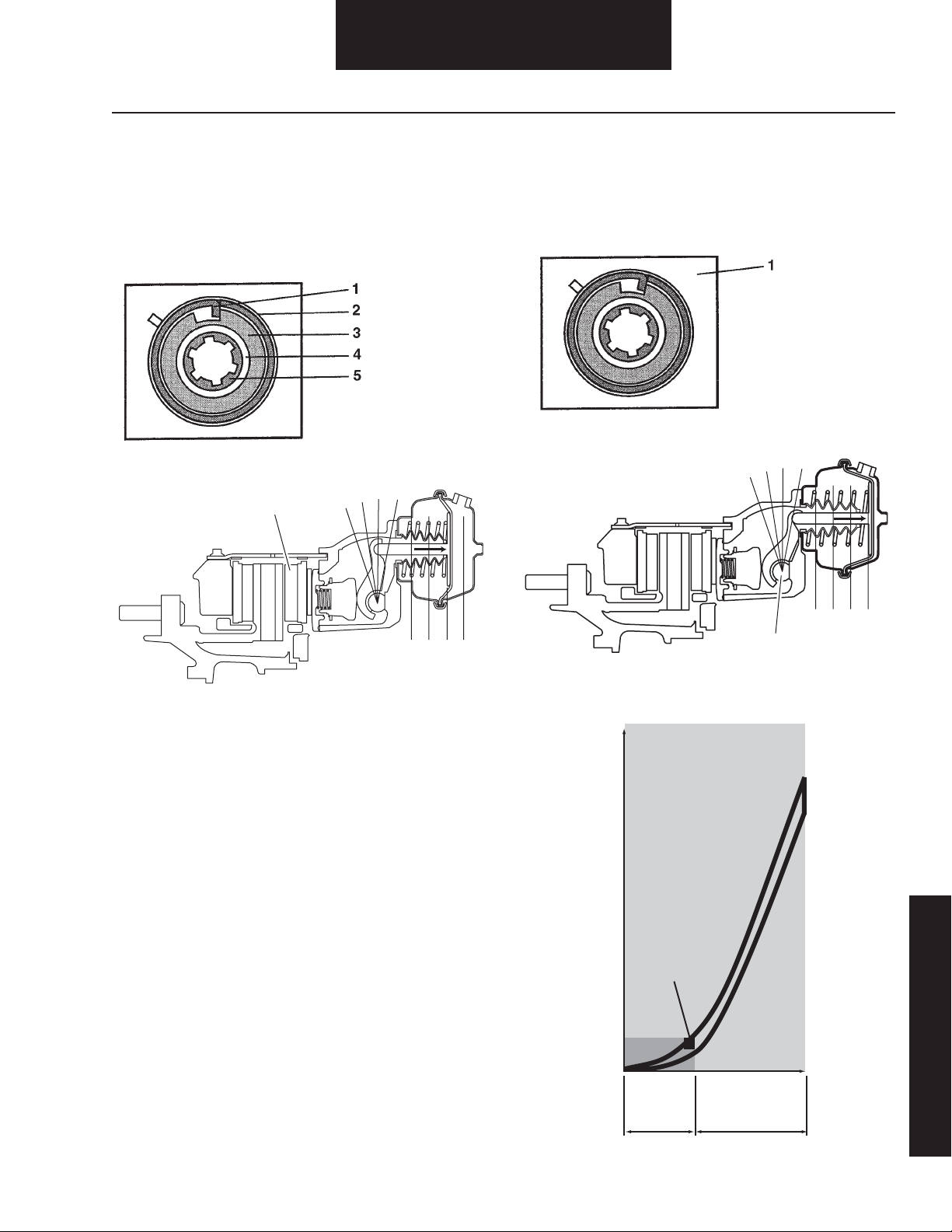

The brake operates according to the clearance principle. The

brake sequence is divided into three phases: Design Clearance

- C, Excess Clearance - Ce (which is to be adjusted out), and

Elasticity - E.

The housing of the adjuster is held in position against the

internal radius of the lever by a guide pin. The adjuster housing

consequently follows the movement of the lever. The rotational

motion is transferred from housing to adjustment spring which in

turn, after passing the design clearance, transmits the motion of

the companion sleeve, friction spring and hub.

e

C

C

1234

E

3/3

2/3

1/3

9

1 – Guide pin 4 – Friction spring

2 – Adjustment spring 5 – Hub

3 – Companion Sleeve 6 – Adjuster housing

56 7 8

1 – Caliper 6 – Return spring

2 – Outer pad 7 – Crossbar

3 – Brake disc 8 – Lever

4 – Inner pad 9 – Brake chamber

5 – Thrust plates

6

Page 8

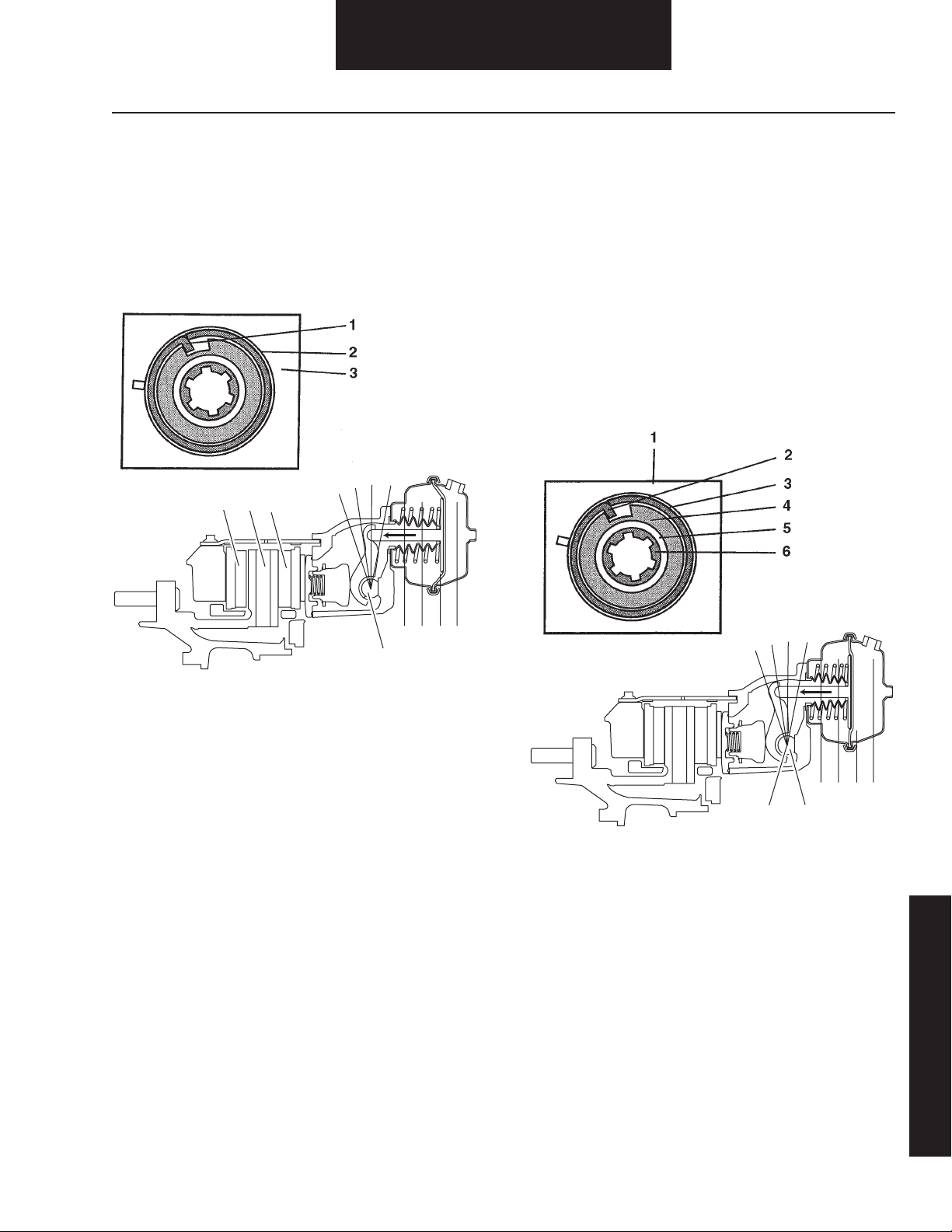

Application

Description of Operation

C - During the movement through C, the design clearance is

measured between the pad and brake disc by the adjuster.

There is a predetermined clearance between the tongue of the

adjustment spring and the slot in the companion sleeve, which

determines the free stroke before the adjustment.

e

C

C

5

4

6

E

3/3

2/3

1/3

7

Ce - If excess clearance remains after the mechanism has

moved radially in accordance with the design clearance C, the

adjuster, synchronization shaft, pinions, crown wheels, adjusting

shaft/readjustment shaft and the adjustment screws are turned.

The rotation of the adjustment screws means that a percentage

of the measured excess Ce is removed.

In the adjuster, the turning movement is transferred from the

housing via the adjustment spring, companion sleeve, and

friction spring to hub, which engages with the synchronization

shaft.

C

e

C

E

1 – Adjustment spring 5 – Brake disc

2 – Companion sleeve 6 – Inner pad

3 – Adjuster 7 – Adjuster

4 – Outer pad

3/3

2/3

8

7

1 – Adjuster 5 – Friction spring

2 – Adjuster spring 6 – Hub

3 – Housing 7 – Synchronization shaft

4 – Companion sleeve 8 – Adjuster

1/3

Description of Operation

7

Page 9

Description of Operation

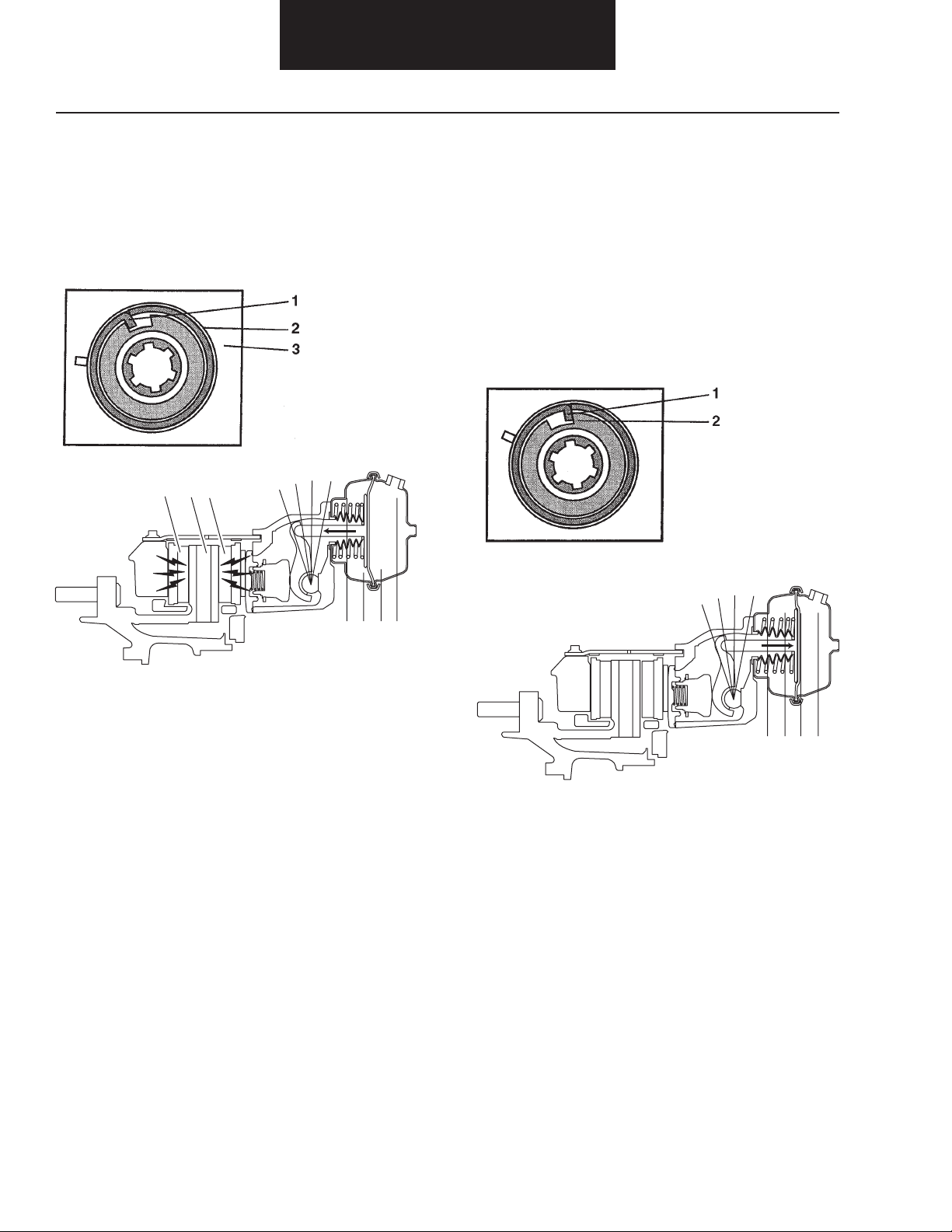

E - When the two (2) pads come into contact with the brake

disc, the braking sequence enters elasticity phase E, the torque

rises and the adjuster stops adjusting. The continued rotational

movement, which now occurs in the adjuster is allowed by

rotating the housing in relation to the adjustment spring.

C

e

C

5

4

6

E

3/3

2/3

1/3

Release

The fi rst part of the return stroke passes through C followed by

movement corresponding to E and Ce. During the return stroke,

the return spring ensures that the crossbar travels back.

C - During the fi rst part of the return stroke, transmitted force

decreases and the tongue of the adjustment spring changes

fl ank in the slot of the companion sleeve.

C

e

E

C

1 – Adjustment spring 4 – Outer pad

2 – Rotating housing 5 – Brake disc

3 – Adjuster 6 – Inner pad

1 – Adjustment spring

2 – Companion sleeve

3/3

2/3

1/3

8

Page 10

Description of Operation

E - The next part of the return stroke corresponds to E. The

housing of the adjuster, the adjustment spring and companion

sleeve are rotated in relation to the hub, which is stationary.

Movement between companion sleeve and hub is allowed by

the friction spring.

e

C

6

C

E

Ce - During the last part of the return stroke (Ce), the rotational

movement continues in the adjuster as described under E until

the mechanism has reached its resting position. The friction

springs on the adjustment screws prevent the mechanism from

backing off.

C

e

E

C

3/3

1 – Adjustment spring 4 – Friction spring

2 – Rotating housing 5 – Hub

3 – Companion sleeve 6 – Inner pad

2/3

1/3

1 – Adjuster

Brake torque

Adjustment

phase (Ce)

3/3

2/3

1/3

1

Description of Operation

Free stroke Elasticity

9

Page 11

Safety Instructions

Safety Instructions

• Always follow the vehicle manufacturer's safety instructions

when working on a vehicle.

• Follow the vehicle manufacturer's instructions for jobs which are

not described in this manual.

• Follow local safety regulations.

• The work must be carried out by trained personnel.

!

DANGER

AVOID CREATING DUST

POSSIBLE CANCER AND LUNG

DISEASE HAZARD

• Sudden release of tensioned springs, such as the spring brake

part of the brake chamber and the return spring of the disc

brake, may cause injury.

• Use recommended tools only.

• Release pressure from lines and components before opening

them.

• Chock at least one of the vehicle's wheels to prevent involuntary

movement of the vehicle.

• Before releasing the vehicle back in service, perform a brake

operational check and test drive the vehicle to make sure that

the brakes are working correctly.

While Bendix Spicer Foundation Brake LLC does

not offer asbestos brake linings, the long-term

effects of some non-asbestos fi bers have not

been determined. Current OSHA Regulations

cover exposure levels to some components of

non-asbestos linings but not all. The following

precautions must be used when handling these

materials.

1. AVOID CREATING DUST. Compressed air or dry

brushing must never be used for cleaning brake

assemblies or the work area.

2. BENDIX SPICER FOUNDATION BRAKE LLC

RECOMMENDS THAT WORKERS DOING

BRAKE WORK MUST TAKE STEPS TO MINIMIZE

EXPOSURE TO AIRBORNE BRAKE LINING

PARTICLES. Proper procedures to reduce

exposure include working in a well ventilated area,

segregation of areas where brake work is done,

use of local fi ltered ventilation systems or use of

enclosed cells with fi ltered vacuums. Respirators

approved by the Mine Safety and Health

Administration (MSHA) or National Institute for

Occupational Safety and Health (NIOSH) should

be worn at all times during brake servicing.

10

3. Workers must wash before eating, drinking or

smoking; shower after working, and should not

wear work clothes home. Work clothes should be

vacuumed and laundered separately without

shaking.

4. Material safety data sheets on this product, as

required by OSHA, are available from Bendix

Spicer Foundation Brake LLC.

Page 12

Service Instructions

Service Instructions

Service Intervals

Check the following items regularly every 6 months. Refer to the

sections as listed below.

• Check brake pads

• Check brake disc

• Check caliper sliding function

• Check operation

WARNING: Refer to Safety Instructions. The vehicle

!

manufacturer's instructions must also be followed.

Clean the disc brake of dirt and dust. Use the specifi ed type of

dust-removal equipment to clean, not compressed air, inhaling dust

particles may be harmful to health.

If the disc brake is equipped with a spring brake chamber, ensure

that the spring is caged in accordance with the manufacturer's

instructions.

Service Instructions

11

Page 13

Checking Pads

Service Instructions

Measure the distance from the backplate to the wearing surface

of the pad.

The minimum permitted lining thickness (friction material), per

D.O.T. (Department of Transportation) standards, is currently

3 mm (.12 in). (The lining thickness of a new pad is 22 mm

(0.9 in.).) Replace the pads if they are worn out.

Check that the pads are evenly worn by measuring at four

different points on the pad. A maximum of 1 mm [0.04 in.] of

uneven wear is allowed. Also, the inner and outer pads must

be worn equally. In the event of uneven wear, check the sliding

function of the caliper on the slide pins. See "Checking Sliding

Function".

IMPORTANT: Driving with light braking may result in increased

wear on the inner brake lining.

To replace the pads, see the section on "Replacing Pads".

Checking Brake Disc

Measure the thickness of the brake disc. Minimum thickness of

the brake disc is 41 mm (1.61 in.).

Measure the lateral runout of the brake disc as

follows.

1. Attach a magnetic stand, complete with a dial indicator on the

frame.

2. Place the tip of the dial indicator on the face of the brake disc.

3. Rotate the brake disc. Max. runout 0.5 mm

[0.02 in.].

IMPORTANT: Do not include the wheel bearing play in the

measurement.

1. If the brake disc has a worn edge, the measurement can be

performed using two (2) spacers.

2. Reduce the measured dimension by the total thickness of the

two (2) spacers.

1

2

1 – Spacers

2 – Brake disc

1

1 – Carrier

3

2

2 – Brake disc

3 – Dial indicator

Refer to WESM-0060 for bearing adjustment

procedures. Endplay not to exceed .005 in.

Also check the brake disc for cracks and wear tracks.

12

Page 14

Service Instructions

Checking Sliding Function Checking Play in the Slide Pins

This check is done after the pads have been removed. See the

section on "Replacing Pads".

Check the sliding motion of the caliper on the slide pins. If the

caliper does not slide freely on the pins, make sure the movement is not obstructed by external dirt or foreign objects.

1

Measure the play in the outer slide pins as follows. The

maximum amount of play is 1.0 mm [0.04 in.].

1. Attach a magnetic stand, complete with a dial indicator to

the frame.

2. Put the tip of the dial indicator on caliper at point 2, see

below.

3. Rock the caliper and read the dial.

4. Repeat this measurement procedure inside the brake disc for

the inner slide pins and measure at point 5, see below.

5

2

Service Instructions

6

4

3

1 – Caliper

1

1 – Outer slide pin 4 – Carrier

2 – Dial indicator tip 5 – Measure point

3 – Inner slide pin 6 – Dial indicator

13

Page 15

Service Instructions

Checking Boots for Slide Pins Checking Bellows for Adjustment Screws

Check the protection caps and rubber boots of the slide pins

[two (2) per slide pin]. If there are signs of cracks or other

damage on the rubber bellows and protection caps, they

must be replaced.

If action is required, see the section on "Replacing Slide Pins,

Slide Bushings and Boots".

2

1

1 – Slide pin protection cap

2 – Slide pin rubber boots

1. Using an 8 mm socket, rotate the readjustment shaft until the

protection springs are fully visible.

IMPORTANT: Thrust plates should not exceed 50 mm

[1.97 in.] from the cover.

2. Inspect the protection springs. The protection springs must be

replaced if there are signs of cracks or other damage.

3. Pull back the protection springs and inspect the rubber

bellows. The rubber bellows must be replaced if there are

signs of cracks or other damage.

4. Turn back the readjustment shaft. Do not tighten the shaft.

If action is required, see section "Replacing Disc Brake".

3

2

1

14

Max.

50 mm

[2.2 in.]

1 – Thrust plates

2 – Cover

3 – Protection springs

Page 16

Service Instructions

Operating Test

1. Lift and support the axle in accordance with the vehicle

manufacturer's instructions.

!

WARNING: Follow the Safety Instructions. The vehicle

manufacturer's instructions must also be followed.

2. Check that the wheel can be turned freely.

3. Remove the plug.

4. Release the brake by turning the readjustment shaft using

an 8 mm socket (3/4 turn).

Note: The brake can be released in the counterclockwise

direction.

5. Position disc brake with the brake chamber at the top

and viewed from the side on which the hexagon of the

readjustment shaft is accessible, turn the readjustment

shaft counterclockwise.

Service Instructions

6. Leave the wrench in the same position.

7. Activate the brakes fi ve (5) times. The wrench must move on

each brake application which shows that the self-adjustment

is working.

IMPORTANT: Movement of the wrench must not be

obstructed. If the wrench moves to and fro or does not move

at all, the caliper is defective and must be replaced.

See the section on "Replacing the Disc Brake".

Release

Counterclockwise

x5

15

Page 17

Service Instructions

Initial Adjustment Lubrication

1. Check that the brake disc can be turned freely.

1

1 – Brake disc

2. Using an 8 mm socket, turn the readjustment shaft clockwise

(Do not force) until both pads touch the brake disc.

3. Loosen the readjustment shaft 1/2 turn counterclockwise to

obtain a basic clearance between the pads and the brake

disc.

WARNING: Follow the Safety Instructions. The vehicle

!

manufacturer's instructions must also be followed.

General

To obtain maximum service life, it is important to use only the

specifi ed lubricants for the lubrication points concerned.

Apply the correct amounts. To prevent the lubricant from being

dispersed or causing damage during the natural movements

of the brake (e.g., on friction surface of pads, on brake disc, in

boots and bellows, etc.), do not apply excessive amounts of

lubricant.

Adjustment Mechanism

The adjustment mechanism is lubricated and sealed for life in

the factory.

Slide Pins and Bushings

Lubricate the slide pins and bushings sparingly during assembly.

See the section of "Specifi cations" for selection of the lubricant.

Use only the specifi ed lubricant.

4. Check that the brake disc can be turned freely.

5. Remove the wrench.

6. Fit the plug into the adjustment access hole on the

readjustment shaft. Make sure it is securely installed.

!

WARNING: To prevent damage to the adjusting

mechanism, never use an impact wrench. Do not

exceed 150 lbs. in. or damage to the adjuster

extension may occur.

Note: In order to obtain correct clearance between the brake

disc and the pads, the mechanism itself will perform

the fi nal fi ne-adjustment during a number of braking

applications.

7. Lower the axle, remove the support and the wheel chocking

in accordance with the vehicle manufacturer's instructions.

16

Page 18

Replacing Pads

Removing Pads Replacing Pads

• Always replace pads on both sides of the axle at the same time.

!

WARNING: Follow the Safety Instructions. The vehicle

manufacturer's instructions must also be followed.

• Chock the wheels on an axle that is not to be raised.

• Lift the axle, support and remove the wheels in

accordance with the vehicle manufacturer's instructions.

!

WARNING: Clean the disc brake of dirt and dust. Use the

specifi ed type of dust-removal equipment for cleaning. Do

not use compressed air. Inhaling dust particles may be

harmful to your health.

!

WARNING: If the disc brake is equipped with a spring

brake chamber, make sure that the spring is caged in

accordance with the manufacturer's instructions.

1. Remove the plug of the readjustment shaft.

2. Use an 8 mm socket to back off the brake adjuster. Turn the

readjustment shaft counterclockwise to release the brake. Do not

tighten.

IMPORTANT: To prevent damage to the adjusting mechanism,

never use an impact wrench.

1. Using an 8 mm socket, turn counterclockwise until the

readjustment shaft is fully retracted.

IMPORTANT: Do not tighten.

2. Check that the pad contact surfaces in the disc brake are

clean. Replace pads. Replace pad springs, retainer bar and

secure with retainer cap screw. Torque retainer cap screw to

45± 3 N•m [33.2 ± 2.2 lbs. ft.].

Replacing Pads

3. Remove the retainer bar cap screw.

4. Remove the retaining bar. Hold the pad springs to prevent them

from jumping out.

5. Check the following (refer to section):

• Brake Disc

• Sliding Function

• Play in the Slide Pins

• Boots for Slide Pins

• Bellows for Adjustment Screws

17

Page 19

Initial Adjustment

Replacing Pads

1. Check that the brake disc can be turned freely.

2. Using an 8 mm wrench, turn readjustment shaft until both

pads touch brake disc. Then loosen 1/2 turn to obtain a basic

clearance between pads and brake disc. Check that the brake

disc can be turned freely. Remove the socket or wrench.

1

1 – Brake disc

Note: In order to obtain correct clearance between

brake disc and pads, the adjusting mechanism

itself will perform the fi nal fi ne-adjustment

during a number of braking operations.

3. Fit plug into access hole readjustment shaft (see Item 1 in the

illustration below).

1

2

1 – Readjustment shaft

2 – Brake disc

CAUTION: Never use an impact wrench, as this could

!

damage the adjusting mechanism.

18

Page 20

Replacing Disc Brake

Removing Disc Brake Caliper

WARNING: Be sure to follow all safety instructions

!

including the blocking of wheels and proper lifting and

support of axle.

!

WARNING: Do not use compressed air.

!

WARNING: If disc brake is equipped with a spring

brake, make sure the spring is properly caged.

1. Remove air chamber from caliper and secure. Do not let the

air chamber hang by just the air hose.

2. Remove retaining bar.

3. Remove brake pads.

4. Re-install retaining bar and secure with fastener.

5. Connect lifting strap and suitable lifting device around retainer

bar.

6. Remove attachment bolts to torque plate.

Replacing Disc Brake Caliper

1. Place caliper assembly on torque plate.

2. Lubricate attachment bolts with anti-seize compound.

3. Fit bolts through torque plate to caliper and tighten to snug

fi t.

4. Torque bolts to 330-350 lbs. ft. (407-448 N•m). If torque

wrench is not available, tighten bolt to snug fi t (mark fl at of

bolt to torque plate then tighten bolt one more fl at). This will

be the approximate torque value.

1 Flat

(60 deg.)

5. Verify adjustment shaft is fully retracted.

IMPORTANT: Do not tighten.

1 – Readjustment shaft

7. Remove caliper.

6. Install Air Chamber. See page 25.

1

7. Check that the pad contact surfaces are clean.

Replacing Disc Brake

8. Install new pads.

9. Replace retaining bar and secure fastener.

10. Perform initial adjustment. See "Initial

Adjustment" on page 16.

Note: Make sure that the sliding function of the air chamber

does not pull on the ABS sensor. Chamber/caliper must be free

to slide inboard 20 mm (0.78 in.).

19

Page 21

Replacing Slide Pins, Slide

Bushings, & Boots

Removing Slide Pins, Slide Bushings, and

Boots (Frame)

1. Put the disc brake assembly in a vise. 3. Remove the four (4) bolts for the slide pins using Torx E 18

socket.

3

2

2. Remove protection caps using a hammer and chisel. If the

inner part of the protection cap remains in the slide pin,

remove this using an internal bearing puller.

Note: Protection caps must never be reused.

1

1

1 – Slide pins 3 – Carrier

2 – Caliper

4. Retract the slide pins suffi ciently to remove frame from caliper

2

by alternately pushing frame to and fro. If slide pins are

seized in the frame, cut threads internally in slide pins using

an M16x2 thread tap.

3

WARNING: To prevent injury, only grip from outside.

!

1 – Protection cap 3 – Caliper

2 – Carrier

20

Page 22

Replacing Slide Pins, Slide

Bushings, & Boots

CAUTION: Do not use gripping tools, as the sealing

!

surfaces of the slide pins may be

damaged.

1 – Carrier 2 – Caliper

5. Clean parts of dirt and dust.

WARNING: Use the specifi ed type of dust removal

!

equipment to clean–not compressed air. Inhaling dust

particles may be harmful to health.

8. Remove the four (4) slide bushings (which are of a split

design) using a small screwdriver. Begin at the split.

IMPORTANT: Do not damage the fi tting surfaces.

1

1

2

2

1 – Slide bearings (4)

2 – Caliper

6. Press the four (4) slide pins out of the caliper.

7. Remove the eight (8) boots by carefully prying them out.

IMPORTANT: Do not damage the fi tting surfaces.

1

2

1 – Caliper

2 – Bellows (8)

Replacing Slide Pins, Slide

Bushings, & Boots

21

Page 23

Replacing Slide Pins, Slide

Bushings, & Boots

Inspection Replacing Slide Bushings and Slide Pins

1. Check that the fi tting surfaces for slide bushings and boots

are damage free.

1

2

1 – Caliper

2 – Slide pins (4)

1. Fit four (4) new slide bushings in caliper.

2. Lubricate slide bushings sparingly with grease.

3. Lubricate slide pins with grease and press them into

position in the slide bushing. Use Haldex tool #81921

(1-800-643-2374).

1

22

1 – Slide bearings (4)

4. Slide pins must slide easily in the slide bushings so that

caliper can "fl oat" over carrier.

1

2

1 – Caliper

2 – Slide pins

Page 24

Replacing Boots in Caliper

Replacing Slide Pins, Slide

Bushings, & Rotors

Replacing Slide Pins, Slide

Bushings, & Rotors

1. Install boot in caliper. Use Haldex tool #81922

(1-800-643-2374).

2. Press the outer part of boot into position in the groove in slide

pin and secure with boot ring.

3

4

2

1

1 – Caliper 3 – Boot

2 – Slide pin 4 – Boot ring

WARNING: To prevent injury, only grip from outside.

!

1

2

1 – Lift carrier

2 – Caliper

7. Apply anti-seize compound to the threads of the four (4) bolts

and screw them into position. Tighten with torque wrench

(Torx E 18 socket) to specs on page 5.

8. Tap new protection caps into position in the outer ends of the

slide pins using a 17 mm socket and extension.

3. Clean the contact surfaces between the brake pads, frame,

caliper and on thrust plates. Use wire brush. Do not grind.

4. Apply anti-seize compound to the inner surfaces of the slide

pins facing the frame.

5. Push slide pins out so that frame can be fi tted into caliper.

6. Life frame into position in caliper and press slide pins into

position. Take care not to damage boots.

1

Extension

Socket

1 – New protection caps

23

Page 25

9. Check the following (refer to section):

• Installing disc brake

Note: Always use new bolts.

• Installing air chamber

• Installing pads

• Adjust brakes

• Perform brake operating test

Replacing Slide Pins, Slide

Bushings, & Boots

24

Page 26

Replacing Brake Chamber

Removing Brake Chamber

1. Remove the air hose. Remove the two (2) nuts holding brake

chamber.

2. Remove brake chamber.

3. Check through the aperture in the brake chamber attachment

fl ange that no moisture/corrosion is present. If it is, replace

caliper.

Replacing Brake Chamber

1. Check that the new brake chamber is of the correct type.

(There must be inner bushings on the push rod.)

Replacing Brake Chamber

1 – Hose

2 – New brake chamber

4. If action is required, see "Removing Disc Brake Caliper" on

page 19.

2. Fit the pipe fi tting to the new brake chamber.

3. Check that the mounting faces of the brake chamber and

caliper are clean.

4. Lubricate the end of the push rod with grease.

5. Fit the new brake chamber with nuts and washers and

tighten to 130 lbs. ft. (176 N•m).

6. Install the air hose to the brake chamber.

7. With the service brake applied, check brake chamber hose

and connections for tightness and damage.

8. Install the wheels in accordance with the vehicle

manufacturer's instructions.

9. IMPORTANT: Make sure that the contact surfaces between

the wheels and hub are clean and free of distortion. follow

the vehicle manufacturer's instructions on tightening torques.

10. Check that the brake hoses do not pinch during full wheel

articulation.

11. Remove the axle support and the wheel chocks and lower

the axle in accordance with the vehicle manufacturer's

instructions.

25

Page 27

Replacing Spring Brake Chamber

Removing Spring Brake Chamber

WARNING: Follow the Safety Instructions. The vehicle

!

manufacturer's instructions must also be followed.

• Activate the spring caging mechanism of the spring brake

chamber so that the spring is held in it compressed position.

See vehicle manufacturer's instructions.

• Apply the parking brake.

1. Remove the air hose connectors of the service and parking

brake.

2. Remove the two (2) nuts holding the spring brake chamber.

3. Remove spring brake chamber.

4. Check through the aperture in the brake chamber attachment

fl ange that no moisture/corrosion is present. If so, replace

caliper.

5. Lubricate the end of the push rod with grease.

26

Page 28

Replacing Spring Brake Chamber

Replacing Spring Brake Chamber

1. Check that the new spring brake chamber is of the correct

type.

Note: There must be an inner boot at the push rod.

1 – New spring brake chamber

2. Check that the parking spring is caged in accordance with

the manufacturer's instructions.

3. Install the pipe fi ttings to the new spring brake chamber.

4. Check that the mounting faces of the spring brake chamber

and the caliper are clean.

5. Lubricate the end of the push rod with grease.

6. Fit the new spring brake chamber with nuts and washers.

Torque to specs on page 5.

7. Fit the air hoses to the spring brake chamber.

IMPORTANT: Do not swap the air hoses.

8. Apply air pressure (min. 6 bar [87 psig]) to the parking brake.

Uncage the parking spring.

9. With the service brake applied and the parking brake

released, check the air hoses and connectors of the spring

brake chamber for tightness and damage.

10. Install the wheels in accordance with the vehicle

manufacturer's instructions.

IMPORTANT: Make sure that the contact

surfaces between the wheels and hub are

clean and free of distortion. Follow the vehicle

manufacturer's instructions on tightening torques.

11. Check that the brake hoses do not pinch during full wheel

articulation.

12. Remove the axle support and the wheel chocks and lower

the axle in accordance with the vehicle manufacturer's

instructions.

Replacing Spring Brake Chamber

27

Page 29

Removing Rotor

Replacing Rotor

1. Remove the caliper assembly. See "Removing Disc Brake

Caliper" on page 19.

2. Remove the wheel/hub/rotor assembly from the vehicle

following the recommended procedures in WESM-0060.

3. Remove ABS tone ring (aluminum hubs only).

4. Remove rotor fasteners.

5. Remove rotor from wheel/hub.

1

!

CAUTION: Never release a vehicle from brake service

without verifying safe brake operation.

Rotor Runout Check

1. With rotor installed on vehicle, position dial indicator with

contact on 90º to rotor face.

1

1 – Rotor

Replacing Rotor

1. Prior to rotor installation, clean and inspect wheel bearings

and replace seals following instructions in WESM-0060.

2. Inspect torque plate for cracks and obvious damage.

Replace as required.

3. Check fasteners and tighten as required to OEM

recommended torque specs.

4. Position rotor on mounting surface of wheel/hub.

5. Install fasteners and tighten to torque specifi cations.

6. Re-install ABS tone ring (if previously removed).

7. Install wheel/hub and rotor assembly following the

recommended procedures in WESM-0060.

8. Install caliper assembly. See page 19.

9. Perform brake operation check.

2

1 – Rotor

2 – Dial indicator

2. Rotate rotor through at least two full revolutions and check

lateral runout.

3. Record maximum runout indicated.

4. Repeat Steps 1-3 for the opposite rotor face.

5. If total indicated runout on either face is:

• less than .5 mm (0.21 in.) - rotor is good.

• more than .5 mm (0.21 in.) - resurface or replace rotor.

Note: Disc Thickness Variation (DTV) maximum .1 mm (.004 in.)

measure around rotor.

28

Page 30

Replacing Rotor

Cleaning and Inspection

1. Wire brush circumference of rotor to remove dirt and rust, and

then clean rotor in a non-toxic, greaseless cleaner.

CAUTION: Use of a petroleum-based cleaning solvent

!

may leave a residue which could

damage lining material.

2. Visually inspect rotor for heat checks, cracks, grooving, or

scoring beyond a depth of .030". If the rotor is:

• cracked - replace rotor.

• heat checked, but no cracks - reuse rotor.

Note: Many heat checks are similar in appearance to cracks.

If in doubt, a crack is defi ned as a "surface split"

radiating into or from an edge of the rotor and/or

over 75% in length.

• grooved or scored -

- less than .030" - reuse rotor as is

- more than .030" - resurface rotor

Rotor Resurfacing

1. The rotor should be resurfaced by mounting in an appropriate

brake lathe and removing the least amount of material

possible to ensure a smooth face.

2. Depending on the amount of braking surface scoring present,

every effort should be made to remove equal amounts from

each rotor face.

Note: Before installing on the vehicle, ensure that the rotor is

clean and re-inspected. After installing on vehicle, verify

that the lateral runout is within specifi cation. See "Rotor

Runout Check" section.

Good Rotor:

More than 43 mm (1.7 in.)

Replace Rotor:

Less than 43 mm (1.7 in.)

3. Measure thickness of area between rotor faces. The rotor

must be replaced if thickness is less than 41 mm (1.61 in.).

1

Replacing Rotor

29

Page 31

Troubleshooting

Troubleshooting

WARNING: Refer to Safety Instructions. The vehicle manufacturer's instructions must also be followed.

!

Symptoms Actions

No or low braking effect • Are brake pads worn away?

• Is brake pad to disc clearance OK?

• Is brake disc OK?

• Is air pressure in brake chamber correct? (Measure with pressure gauge at brake chamber.)

• Change pads.

• Carry out initial adjustment + perform function test.

• Change brake disc (See vehicle manufacturer's instructions.)

• Take action in accordance with vehicle manufacturer's instructions.

Brake drags/does not release • Does air pressure in brake chamber remain after brake has been released? (< 1 psi OK)

completely • Is spring brake (if fi tted) completely released when parking brake is off?

• Is brake pad to disc clearance OK?

• Are pads able to move freely in carrier?

• Is sliding function of brake caliper OK?

• Is wheel bearing or wheel bearing clearance OK?

• See vehicle manufacturer's instructions for troubleshooting air system.

• Carry out initial adjustment + perform function test.

• Remove pads, clean pads, carrier and caliper.

• Check slide pins/bushings.

• See vehicle manufacturer's instructions.

Vehicle pulls to one side • Are pads worn out on one side?

• Is brake pad to disc clearance OK?

• Are pads able to move freely in carrier?

• Is the pressure the same in both brake chambers of the axle in braking?

(Measure with pressure gauge at the brake chambers.)

• Replace pads.

• Carry out initial setting and perform function test.

• Remove pads, clean pads, carrier and caliper.

• See vehicle manufacturer's instructions for troubleshooting air system.

Noise/vibrations from the • Are pads about to move freely in carrier?

brake • Are the disc brake and its components attached to the axle as per specifi cation?

• Non-permitted cracks/tracks in brake disc?

• Is brake disc runout within spec?

• Remove pads, clean pads, carrier and caliper.

• See section on "Replacing slide pins and bushings".

• See vehicle manufacturer's instructions for troubleshooting air system.

30

Page 32

FFoorr mmoorree iinnffoorrmmaattiioonn,, ttaallkk ttoo yyoouurr BBeennddiixx oorr RRooaaddrraannggeerr

rreepprreesseennttaattiivvee,, ccaallll 11--886666--661100--99770099 oorr vviissiitt

w

901 Cleveland Street • Elyria, Ohio 44035 • 1-866-610-9709 • www.foundationbrakes.com

BW

7273 ©2008 Bendix Spicer Foundation Brake LLC • 01/08 • All Rights Reserved • Printed in U.S.A.

The Roadranger®System features

®

brand foundation brakes.

Bendix

Loading...

Loading...