Page 1

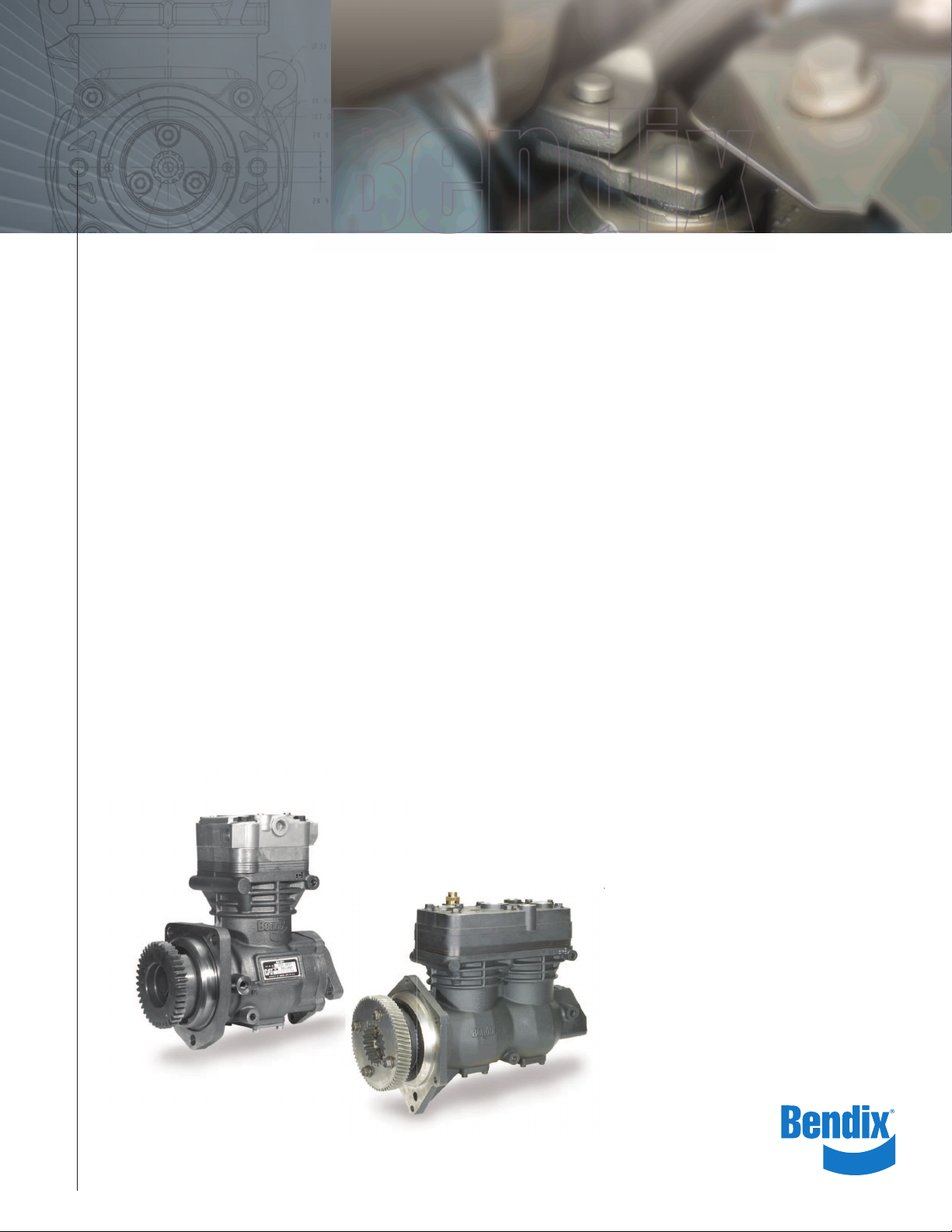

Bendix remanufactured compressor.

Th

Bendix®

Compressors

Engineered to perform better, so your fleet performs better.

Frequently Asked Questions:

®

Bendix® BA-921

and BA-922

®

Air Compressors.

1. Why shouldn’t I just buy from the other manufacturer

since they claim to be an authorized Bendix compressor

remanufacturer?

Bendix does not authorize any other manufacturers

to remanufacture Bendix compressors. Bendix is the

only authorized remanufacturer of genuine Bendix

compressors. The only genuine Bendix compressor

facility is in Huntington, Indiana.

2. I’ve purchased Bendix compressors rebuilt by other

manufacturers and I didn’t have a problem. Why?

Consider yourself lucky! Knock-off rebuilders don’t

have the quality systems and expertise to deliver robust

remanufactured compressor products each and every

time. You can expect this from Bendix; and we deliver on

it. Our analysis indicates that anything short of a genuine

Bendix remanufactured compressor leaves you vulnerable

to degraded performance and durability. Additionally, the

genuine Bendix warranty and support back each genuine

Bendix remanufactured compressor.

3. How can I guarantee that I have a genuine Bendix

compressor?

First, make sure you are dealing with an authorized Bendix

distributor or dealer. You can visit our Web site at

www.bendix.com for a list of authorized Bendix

distributors or dealers in your area. Or talk to your Bendix

account manager for the name of the distributor or dealer

nearest you. Second, always check the compressor’s

nametag for the Bendix logo and the words, “REMFD.

BY BENDIX IN THE USA.”

4. What is the difference between ‘remanufactured’ and

‘rebuilt’?

A rebuilt compressor is just that – re-built. Generally,

a rebuilder takes an old compressor back from a

manufacturer, tears it down, cleans it, reassembles and

paints it, then puts a nametag on it and makes sure it

turns over. The genuine Bendix process re-manufacturers

the compressor. Our focus on quality and engineering

excellence means that each component within the

compressor is inspected and either remanufactured

or replaced to ensure it meets the original Bendix and

OEM specifi cations. And, if technology advances have

been made since the part was originally produced, we

automatically build them into the remanufactured part.

That means a remanufactured compressor is

not only as good as the original – it may be

even better.

Bendix® BA-921

®

Bendix® BA-922

®

Page 2

Bendix®

Printed on recycled paper

Compressors

5. How can you justify the price difference when I can buy the

same compressor down the street for 25% less?

Even though competitors’ rebuilt compressors may look

the same – or similar – as genuine Bendix remanufactured

compressors on the outside, they’re not. You’re not

buying the same compressor. Bendix puts each and

every compressor through a rigorous process from the

moment it enters our Huntington facility until it leaves

as a genuine Bendix remanufactured compressor –

guaranteeing you a high-quality compressor. Rebuilders

can charge less since it costs less to simply ‘clean-up’

a compressor. Bendix remanufactures. And, you have

a team of qualifi ed individuals and programs available

to support you after you purchase a genuine Bendix

compressor, including one of the strongest warranty

programs in the industry. A rebuilder can’t provide that

kind of support.

6. Why do I care who rebuilt the compressor if it fi ts the

application and pumps air? What else do I need?

Reliability. Durability. Without the Bendix remanufacturing

process you have no assurance that the compressor

will last over the long haul. Only Bendix guarantees

that each and every component is inspected and then

remanufactured or replaced to original equipment

standards. The others just can’t do that.

7. I’ve been using rebuilts for years and have had very few

problems; but when I did have one, warranty was approved,

no questions asked.

Consider yourself lucky! It’s a gamble. Next time you may

fi nd yourself sitting on the side of the road. Only Bendix

has the knowledge to remanufacture Bendix compressors

to original equipment standards.

8. What percentage of components in genuine Bendix

remanufactured compressors are replaced with new?

All of the wear components in every genuine

remanufactured compressor are replaced with new. The

remaining components are either remanufactured to

original proprietary specifi cations or replaced with new.

9. How can I be sure that the materials some rebuilders use

aren’t better than the original Bendix material selections?

Bendix only uses genuine replacement components that

have been engineered and tested to meet the company’s

stringent product requirements. Using materials other

than the original can compromise the performance of the

compressor. Material selection is a critical part of product

engineering. Material analysis and component engineering

involves understanding the material’s wear characteristics

throughout the compressor’s operating environment.

The long-term performance of alternate materials is

unknown. Specifi cally regarding piston rings, we’ve seen

compressors seized because of material incompatibility.

10. Does Bendix have equipment or technology to check the bore

for roundness or being perfectly square to other cylinders?

Yes. Bendix checks for cylindricity (roundness), and

perpendicularity using state-of-the-art bore and air

gauging, in addition to monitoring the process with

CMM equipment.

11. Does the Bendix process produce a “Cross-hatch” pattern

during honing to minimize oil loss past the rings?

Yes. The “Cross-hatch” pattern is referred to as the

hone pattern. Bendix re-hones each and every genuine

remanufactured compressor. This process provides the

optimal combination of surface fi nish, piston and rings,

minimizing the compressor’s oil carryover.

For more information refer to the Bendix® Compressor Anatomy of a Legend (BW2878),

call 1-800-AIR-BRAKE (1-800-247-2725) or visit www.bendix.com today.

Bendix Commercial Vehicle Systems LLC • 901 Cleveland Street • Elyria, Ohio 44035 • www.bendix.com • 1-800-247-2725

BW2978 ©2014 Bendix Commercial Vehicle Systems LLC, a member of Knorr-Bremse Group • 02/14 • All Rights Reserved

Loading...

Loading...