Page 1

™

SmarT ire Trailer-Link

Tire Pressure Monitoring System

TPMS

Operator’s Manual

This booklet contains important operational and safety

information that benets you and subsequent owners.

Page 2

Sources of Additional Information about

your SmarTire

®

System by Bendix™ CVS

Consult the vehicle manufacturer’s documentation.

Visit www.bendix.com for free downloads of these

publications from the Literature Center at www.bendix.com.

BW2799 SmarTire Tire Pressure Monitoring System

(TPMS) Operator’s Manual

BW2809 SmarTire TPMS Hand Tool Manual

BW2820 SmarTire Low Frequency (LF) Tool Users Manual

BS2822 SmarTire TPMS Walk Around Card

or

Contact the Bendix Tech Team at

techteam@bendix.com or

1-800-AIR-BRAKE (1-800-247-2725, option 2).

Representatives are available

Mon. - Fri. 8:00 a.m. to 6:00 p.m. ET.

The trademarks used in this document, including Bendix™, are United States

trademarks owned by or licensed to Bendix Commercial Vehicle Systems LLC.

2

Page 3

About the SmarTire

®

TPMS and SmarTire Trailer-Link™ TPMS 5

Section A - System Overview 7

1 0 System Overview 7

1 1 System Components 7

1 2 Maintenance Tool 7

INDEX

1 3 How Does The SmarTire Trailer-Link

™

TPMS System Work? 8

1 4 Fundamentally, Why Is Temperature Monitoring Important? 9

2 0 Tire Maintenance 12

Section B - System Installation – Tire Sensors 14

3 0 System Installation: Tire Sensors

14

3 1 Sensor Overview 14

3 2 Tools Required 14

3 3 Tire Sensor Installation 15

3 4 Re-mounting Tires After A Sensor Has Been Installed 16

3 5 Removing A Tire That Has A SmarTire

®

Sensor Installed 20

3.6 Tire Sensor Specications 22

Section C: System Installation – Components and Programming 23

4 0 Installing The SmarTire Trailer-Link System 23

4.1 Conguring & Customizing Your SmarTire Trailer-Link System 27

4 2 SmarTire Trailer-Link Axle CIP Adjustment Instructions 28

Section D: SmarTire Trailer-Link Display Options 34

5 0 Trailer Information Display Options 34

5 1 Tractor SmarTire Dash Display

34

5 2 Tractor SmarTire Dash Display Alerts 35

5 3 Trailer-Link To SmarTire Dash Display Link-Up Procedure 35

5 4 Trailer Lamp Blink Codes 35

Section E: Additional Component Details 37

6 0 Trailer-Link System Component Details 37

6.1 Trailer-Link Module Specications 37

Section F: Troubleshooting 41

7 0 Troubleshooting Guide 41

7.1 SmarTire Gauge Display And Trailer-Link Module Q&A 41

7.2 SmarTire System Q&A

46

7 3 Diagnosing A Defective, Missing, Or Misplaced Sensor 46

7 4 SmarTire Hand Tool Troubleshooting 47

Appendix 1: Replacement Parts 48

8 0 Replacement Parts 48

Appendix 2: System Scope Of Use & Alerts 49

9 0 System Scope Of Use And Alerts 49

9 1 System Installation And Usage 49

9 2 Use Of Chemicals 49

9 3 Reacting To Alerts

49

9 4 FCC Notice 50

3

Page 4

GENERAL SAFETY GUIDELINES

brakes and always block the wheels. Always wear

WARNING! PLEASE READ AND

FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

guidelines should be observed AT ALL TIMES:

▲ Park the vehicle on a level surface, apply the parking

personal protection equipment.

▲ Stop the engine and remove the ignition key when

working under or around the vehicle. When working

in the engine com par tment , the engine sho uld be shut

off and the ignition key should be removed. Where

circumstances require that the engine be in operation,

EXT R E ME CAU T I ON sh ou l d be us ed to pre ven t per son a l

injury resulting from contact with moving, rotating,

leaking, heated or electrically-charged components.

▲ Do not attempt to install, remove, disassemble or

assemble a component until you have read, and

thoroughly understand, the recommended procedures.

Use only the proper tools and observe all precautions

pertaining to use of those tools.

▲ If th e wor k is be i ng pe r f o rme d on th e veh i cle ’s ai r br a ke

sy ste m , or an y aux i lia r y pres s uri zed ai r sy ste m s , ma k e

certain to drain the air pressure from all reservoirs

before beginning ANY wor k on th e veh icl e . If th e ve hic l e

is equipped with a Bendix

®

Bendix

DRM™ dryer reservoir module, or a Bendix

®

AD-IS® air dryer system, a

AD-9si® air dryer, be sure to drain the purge reser voir.

▲

Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a manner

that safely removes all electrical power from the vehicle

▲ Never exceed manufacturer’s recommended pressures.

▲ Never connect or disconnect a hose or lin e cont aining

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has

been depleted.

▲ Use only genuine Bendix

®

brand replacement parts,

components and kits. Replacement hardware, tubing,

hose, t tings, etc. must be of equivalent size, type

and strength as original equipment and be designed

speci cally for such applications and systems.

▲ Components with stripped threads or damaged par ts

should be replaced rather than repaired. Do not

attempt repairs requiring machining or welding unless

speci cally stated and approved by the vehicle and

component manufacturer.

▲ Pr i or to ret u r nin g the vehi c le to ser vic e, ma ke ce r t ai n all

componen ts and systems are restore d t o their proper

operating condition.

▲ For vehicles with Automatic Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to per forming any vehicle

ma int e na n ce wh ere one or mor e whe e ls on a dri ve ax l e

are lifted off the ground and moving.

▲ The power MUST be temporarily disconnected

from the radar sensor whenever any tests USING A

DYNAMOMETER are conducted on a Bendix

Advanced

™

-equipped vehicle.

▲ You should consult the vehicle manufacturer's

operating and service manuals, and any related

literature, in conjunction with the Guidelines above.

4

®

Wingman

®

.

®

Page 5

About the SmarTire® Tire Pressure Monitoring

System (TPMS) and SmarTire Trailer-Link™ TPMS

Full SmarTire® TPMS System Overview

Thank you for purchasing the Smar Tire T railer-Link™ Tire Pressure Monitoring

System (TPMS) by Bendix CVS. With SmarTire Trailer -Link TPMS onboard,

your vehicle is equipped w ith a wireless commun ication networ k allowing

seamless integration of wireless tire pressure sensing technology.

The SmarTire Trailer-Link TPMS system is an advanced tire pressure

monitoring system specically designed for commercial vehicle trailers. The

system monitors the pres sure and temperature of eac h trailer tire in or der

to provide real-t ime, tire status i nformat ion and to war n the dri ver of a tire related problem before it becomes dangerous.

Bendix SmarTire System Advantages

● Extends tire life;

● Reduces maintenance costs and time;

● Helps ma xi m ize fuel economy by ensuring that tir e s ar e pr oper ly inated;

● Reduces trailer downtime; and

● Reduces accident risk caused by a tire blowout or tire re.

System Features

● Tempe rature co mpensated al er ts: Know w hen your tires a re at risk no

matter how long you’ve been driving;

● Real-time tra iler tire information displayed on the d ash whenever the

tractor is equipped with the SmarTire TPMS system by Bendix CVS;

● Tire alert s provide instant visual warning of a tire proble m using the

tractor’s dash display or a trailer lamp;

● There are three t ypes of tire aler ts: Pressure Deviati on Aler t, Critic al

Low Pressure Alert, and High Temperature Alert;

● The SmarTire Trailer-Link system data can be sent through the tractor’s

J1939 communication network via the tractor-mounted SmarTire TPMS

for seamless vehicle integration; and

● The trailer tire data can be broadcast on the J1939 communication

network and accessed by telematics devices for back-ofce reporting

of tire data.

5

Page 6

IMPORTANT NOTICE: PLEASE READ

To prevent sensor dam age, when mounting and dismounting tires th at

have SmarTire

®

TPMS tire sensors, be sure that the maintenance facility

is aware that a tire pressure monitoring system is installed.

If any rims are reloc ated or replaced, be sur e to follow the SmarTire by

Bendix system guidelines to permit the system to re-learn the tire sensor

positions.

To moni to r your trailer tires with your exist in g S m a rTire by Bendix tractor

ECU, you must ensure that the SmarTire Trailer-Link

™

enable function

is set to ON in the SmarTire TPMS system tractor-mounted ECU (par t

number 200.0216).

Additionally, for tractors equipped with ECU part number 200.0184, in order

for the ECU to be able to communicate with the SmarTire T railer-Link ECU,

the ECU rmware MUST BE updated to new rmware. For instructions

on performing this update, please contact your Bendix account manager

or call 1-800 AIR-BRAKE (1-800-247-2725), option 2.

6

Page 7

Section A - System Overview

1.0 System Overview

1.1 System Components

Maintenance

Hand tool

Tire Sensors

and Cradles

Harnesses

Stainless Steel

Tire Straps

Figure 1 - System Components and Hand Tool

ECU. The Electronic C ontrol Uni t (ECU) of the SmarTire Trailer-Link™ Tire

Pressure Monitoring System receives data transmissions from individual tire

sensors mounted on each trailer wheel. The information received is compared

to user-dened settings. An alert is triggered if the system detects that a tire

is under-inated and/or above expected temperatures.

Where the tractor is equipped with Bendix

and alert s are communicated to a dash displ ay along with the tractor tire

information. A lter nately, where the tractor i s not equipp ed wit h a SmarTire

TPMS system, the Trailer-Link system alerts the dr iver using an optional

trailer-mounted lamp.

Sensors. De signed for the h arsh environment of a c ommercial t ruck tire,

each tire sensor is mounted in a break-away cradle for extra protection.

The tire sensor measur es internal tire pres sure and temperature ever y 12

(twelve) seconds and transmits data every three to ve minutes. If the system

detects a pressure c hange of 3 PSI (0.20 6 bar) or greater, it does not wait

until the next transmission, but will transmit the data immediately.

Sensor Straps. Sensors are mounted to th e surface of the rim usin g a

stainless steel strap, a reliable and universal method of sensor installation.

Harness. Designed to not require a sepa rate power supply, the harness

supplies trailer ABS system power to the SmarTire T railer-Link Tire Pressure

Monitoring System ECU.

1.2 Maintenance Tool

Maintaining tires in the yard is just as important as real-time tire information

for the driver, but many TPMS systems don’t include functi onality to help

yard maintenance personnel. The SmarTire universal hand tool acts like an

“electronic billy- club” allowing maintenance personnel to wirelessly ‘ping’

each tire to measure its pressure and temperature. The SmarTire hand tool

reduces diagnost ic time and helps keep every tir e rolling safely and costeffectively. (For the Maintenance Tool manual, see BW2809.)

7

Trailer-Link ECU

™

SmarTire® TPMS, the data

Page 8

1.3 How Does The SmarTire TrailerLink™ TPMS System Work?

Full SmarTire® TPMS System Overview

1. The SmarTire Trailer-Link™ ECU creates a wireless bubble around the

trailer, allowing it to sense and transfer trailer tire data to a SmarTire®equipped tractor.

2. Tire sensors mounted on each trailer wheel measure tire pressure and

temperature every twelve (12) seconds and wirelessly transmit tire data

every three to ve minutes.

3. Industrially-designed for the rugged requirements of a commercial trailer

chassis, the SmarTire T railer-Link ECU can monitor up to eight (8) wheel

positions when linked with a tractor with SmarTire TPMS, and more

when applied as a stand alone trailer TPMS. The total number of tires

monitored on both the tractor and trailer cannot exceed twenty.

4. When the tractor connects up to the trailer, the wireless transmissions of

the SmarTire Trailer-Link ECU will link up to the SmarTire tractor ECU.

Once the link up is achieved, the tractor SmarTire display will restart and

add the additional trailer axles to the tractor display . The new axles will

be indicated as trailer axles by showing a “T” in front of the axle number,

e.g. T1, T2, etc.

5. Real-time tire pressure and temperature information is available to the

driver on demand via the SmarTire TPMS tractor display, if equipped.

An easy-to-read and simple-to-use interactive gauge that provides realtime tire status information, the SmarTire display will alert the driver to a

low pressure or high temperature trailer tire condition before it becomes

dangerous.

6. Trailer tires can also be monitored using the system as a stand-alone

application connected to an optional trailer-mounted alert lamp.

7. The SmarTire maintenance hand tool is used to check trailer tire

pressures and temperatures during maintenance inspections. It can

also be connected directly to the SmarTire Trailer-Link ECU to set the

trailer axle Cold Ination Parameters (CIPs) and to congure trailer tire

sensor IDs. The SmarTire maintenance hand tool improves ination

accuracy and reduces diagnostic time in order to keep every tire rolling

cost-effectively. Please refer to Section 3.2 of this manual or BW2809

for detailed information on programming the SmarTire T railer-Link ECU

with the maintenance hand tool.

8

Page 9

1.4 Fundamentally, Why Is Temperature

Monitoring Important?

The Pressure/Temperature Relationship

Tire manufacturers specify that tire pressures should be checked and adjusted

when a tire is “col d”, but most people may not know why, or even what a

“cold tire” is. The temperature of a tire actually has a signicant impact on

its ination pressure.

According to tire manufacturers, a tire is c onsidered to be “cold” when

its temperature is 65°F (18°C). The ination values provided by vehicle

manufacturers, eet maintenance personnel, or industry-published load

ination tables are called ‘Cold Ination Pressures’ (CIP) because they

represent the correct amount of pressure a tire should be inated to when

it is “cold”. The reason that tires have cold ination pressures set at

specic temperatures is because a tire’s pressure will change relative to its

temperature.

Air naturally expands when h eated and contracts when c ooled. Inside a

contained vesse l such as a tire, this expansion and c ontraction causes a

change in contained air pressure. As a tire heats up, its pressure will naturally

increase and as it cools down, its pressure will naturally decrease.

For example, a tire inated to a CIP of 105 PSI at 65°F will increase in pressure

to 125 PSI at 1 52°F and decrease in pressure to 97 PSI at 32°F. The Smar Tire

Trailer-Link

and pressure as part of normal operation and adapts accordingly to provide

more accurate information while helping to prevent false alerts.

™

tire monitoring system considers these changes in temperature

Tire manufacturers never recommend inating a tire to less than the specied

cold ination pressure. In extreme cases, the beads of a commercial tire

can unseat if its pressure gets too low resulting in a catastrophic tire failure.

Always refer to the vehicle manuf acturer’s recomme ndations for minimum

cold ination pressures.

9

Page 10

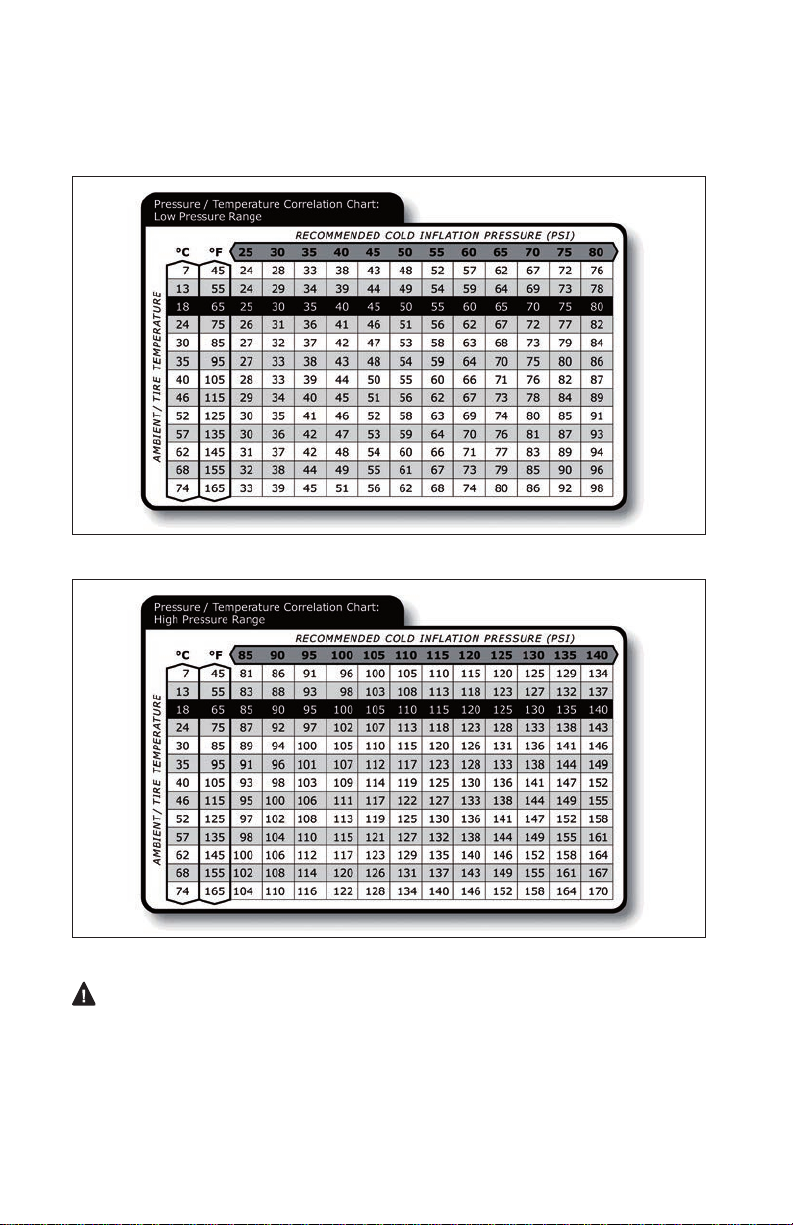

The charts below illustrate the equivalent ination values for a series of Cold

Ination Pressures (CIPs) at various temperatures. The temperature values

represent the temperature of the air contained inside the tire. This temperature

can be estimated for a cold tire using the outside, ambient temperature.

Chart 1

Chart 2

The c h a r ts above are to be u s e d as a gu i d e on l y. Al ways refer to th e

tire and/or vehicle manufacturer’s recommendations for minimum CIPs.

10

Page 11

Thermal Equilibrium

As a vehicle moves, its tire s naturally heat up due to f rict ion fro m the road

and the exing of its side-walls. Weight, vehicle speed and a tire’s starting

ination pressure all have an impact on how much, and how quickly, heat

is generated.

As the tire generate s heat, its pressure incre ases, causing a reducti on in

side-wall exing. Less side-wall exing and road resistance, combined with

air rushing past the t ire as the vehicle moves, effectively c ounteract the

conditions that cause the tire to heat up. As a result, the temperature increase

tapers off until the tire reaches a point of balance called “thermal equilibrium.”

Tire thermal equilibrium is the point where the heat being generated is

equal to the heat being dis sipated. Tires are design ed with the pr inciples

of temperature and pressu re in mind in order for them to ac hieve thermal

equilibrium. Once a properly inated tire reaches thermal equilibrium, it will

operate at its peak; providi ng the best per forman ce, handling, tire life and

fuel economy.

SmarTire Trailer-Link

™

TPMS Temperature Compensation

Since a tire’s contained air pressure naturally increases as a vehicle moves,

it can be difcult to tell if a hot tire is under-inated. Without some form of

temperature compensation, a hot tire that is under-inated might appear to

be ne because its contained air pressure is at, or above, its Cold Ination

Pressure (CIP).

For example, a tire correctly inated to a CIP of 105 PSI at 65°F will reach

thermal equilibrium when its temperature increases to 152°F and its pressure

increases to 125 PSI. A tire starting at 95 PSI at 65°F (10 PSI under inated)

would have to reach 202°F for it to reach thermal equilibrium (12 5 PSI). The

tire will then be running 50°F hotter than it should be, causing more tire wear

and the potential for a catastrophic failure or tire re.

When checked using a handheld gauge or a tire monitoring system that does

not measure operating temperature, this 10 PSI under-inated tire can appear

to be normal. When equi pped with tire s ensors that m ount inside the tire,

SmarTire Trailer-Link TPMS m easures both tire p ressure and temper ature

in order to provide “Temperature Compensated” pres sure deviation values

and alerts. By measuring the operating temperature of a tire and comparing

it to the CIP value programm ed into the system, the SmarTire Trailer-Link

system will know what a tire’s pressure is suppose d to be in relation to its

operating temperature.

The system is able to warn the driver of an under-inated tire even if t hat

tire’s actual contained air pressure is at — or above — its CIP.

11

Page 12

The advantages of temperature compensation are even more dramatic when

a tire has a slow leak. A tire t hat is constantly l osing pressure wi ll not be

able to reach ther mal equilibr ium bec ause the c ontained ai r simply ca nnot

expand enough to generate the required pressure, regardless of how hot the

tire becomes. Since the leak is slow, the tire may appear over an extended

period of time to be properly inated when it is actually dangerously underinated and operating well above its temperature capacity.

As air leaks from the tire, increased side-wall exing and rolling resistance

cause the tire’s temperature and pressure to increase. The pressure increase

will soon plateau and beg in to slowly d ecre ase while t he tire’s temperature

continues to increase. Eventually , the tire will become so hot that its structure

will degrade, and then fail in the form of a blow-out and/or tire re.

2.0 Tire Maintenance

Proper tire maintenance is critically impor tant for keeping tires rolling

smoothly. When properly maintained and inated, tires will provide shorter

stopping distances, better vehicle handling in emergency situations, improved

fuel economy and increased tire life.

Maintenance Tips for Long Tire Life:

● Keep tires properly inated at all times.

● Visually inspect tires for injuries prior to each trip.

● Match dual tires for size and keep pressures within 5 PSI (0.344 bar).

● Re-tread tire before wear causes excessive belt damage or fatigue.

12

Page 13

IMPO R TA NT

READ THESE INSTRUCTIONS PRIOR TO INSTALLATION

™

This SmartTire Trailer-Link

TPMS kit is pre-programmed and ready to use,

subject to your application:

● The sensors have been PRE-ASSIGNED TO WHEEL POSITIONS and

are identied on each unit with a position label (P1, P2, P3, etc.) – install

the sensors as shown in Figure 1.

● Default values have been assigned to each axle for the following

(depending on kit conguration):

◊ Cold Ination Pressure (CIP) – preset to 100 PSI

◊ First Alert Level (FAL) – preset to ±15% from expected (temperature

compensated)

◊ Second Alert Level (SAL) – preset to -20% from CIP

◊ High temperature alert – 185°F (85°C)

Figure 2

13

Page 14

Section B - System Installation – Tire Sensors

3.0 System Installation: Tire Sensors

3.1 Sensor Overview

The SmarTire® TPMS sensor monitors tire pressure and temperature every

twelve (12) seconds and transmits tire data every three (3) to ve (5) minutes.

If a pressure change of 3 PSI is detected, the sensor will not wait for the next

regular transmission and will transmit tire data immediately. The sensor has

an estimated battery life of ve (5) years.

3.1.1 Break Away Cradle

If proper care is n ot taken when removing or inst alling a tire on a rim th at

has a tire sensor installed, damage can occur. Each SmarTire tire sensor is

conveniently mounted in a break-away cradle so that if damage accidentally

occurs, the inexpensive cradle is broken instead of the sensor.

IMPORTANT NOTICE: PLEASE READ

Please read this section carefully and follow each step precisely to

ensure that you do not damage a sensor and that the sensors are

installed in the correct, pre-programmed locations.

SmarTire tire sensors can be broken when mounting and dismounting

a tire unless specic instructions are followed. If tire work is done

by an unauthorized facility, please let them know that a tire pressure

monitoring system is installed on the vehicle before they remove a tire

from a wheel.

Exercise caution and take precautions when cutting the steel strap

(See Section 3.3 step 2.). Beware of potential sharp edges!

Figure 3

3.2 Tools Required

Installing the Sensors

1. 5/16" or 8 mm hexagon driver

2. Metal cutter

3. Torque wrench

14

Page 15

4. Tire changing equipment

5. Tire balancing equipment

3.3 Tire Sensor Installation

1. Remove the wheel from the vehicle and then remove the tire.

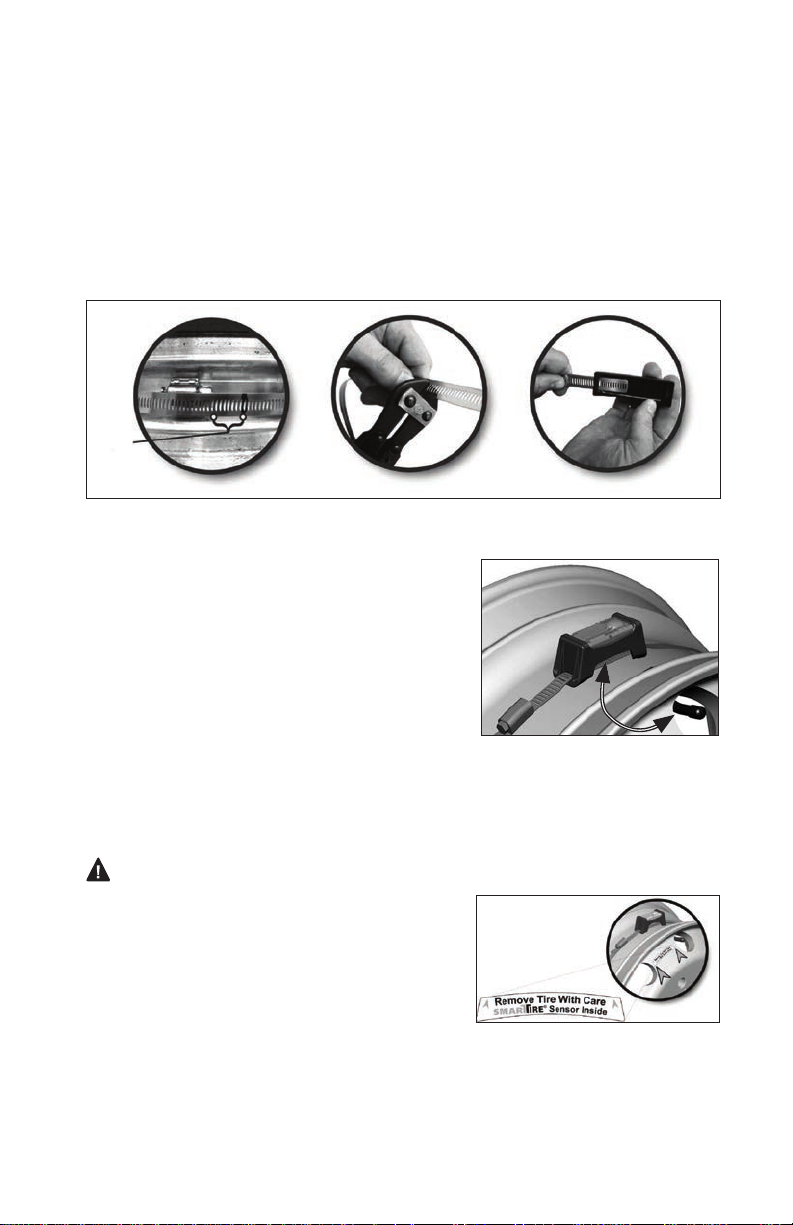

2. Wrap the strap around the rim in the lowest point of the drop center well

and mark it 1” (2.5 cm) past the worm gear. Cut the strap at the mark.

Excess strap MUST be removed or it will break-off and damage the tire.

3. Slide on the sensor.

1"

Figure 4

4. With the strap and sensor positioned in

the lowest point of the center well, feed

the end of the strap into the worm gear

and pull it tight. Orient the sensor so that

it is positioned at the valve with the worm

gear 4" (10 cm) away from the edge of

the sensor. The sensor MUST always

be installed at the valve in order to know

its approximate location after the tire has

been mounted.

Figure 5

5. Tighten the strap using a 5/16" (8 mm) hexagon driver until the sensor

can not be moved. Reference torque: 35 in-lbs (4 Nm).

CAUTION: Do not over tighten the strap.

6. Indicate the location of the sensor by

applying the supplied rim label to a

clean and dry location on the rim.

Figure 6 - The actual

label design may vary

15

Page 16

3.4 Re-mounting Tires After A Sensor Has Been Installed

Please read this section carefully and follow each step precisely to ensure you

do not damage the sensor when mounting the tire. If steps are not taken to

avoid the sensor located in the drop center well of the rim, it can be damaged

by tire beads as the tire is mounted.

3.4.1 Internal Tire Sensor Servicing

®

SmarTire

during the mounting or de-mounting process. Each sensor is mounted inside

a break-away cradle that is designed to absorb the impact of damage during

the tire mounting / de-mounting process. If damage occurs, the inexpensive

cradle will break instead of the tire sensor.

If a sensor cradle is da maged, it along with the mounting strap must be

replaced. Carefully remove the tire sensor from the damaged cradle, re-insert

it into a new cradle (Bendix par t number 26 4.00228 N), and then continue

the mounting process.

TPMS tire sensors are designed to be serviceable if damage occurs

16

Page 17

3.4.2 Re-Mounting Tires Using Tire Irons

To avoid damagin g the sensor, simply mount the tire e nsuring t hat the last

part of the bead to slip over the ange happens directly at the sensor. Start

at one end of the tire and work towards the opposite end with the tire oriented

so that the beads are rst pushed under the rim ange directly opposite the

sensor (1) and then worked over the ange toward the sensor (2). The bead

will nally slip over the rim ange at the sensor without contacting it (3).

Repeat for the remaining bead.

1 2 3

Figure 7

17

Page 18

3.4.3 Re-Mounting Commercial Tires

Using a Vertical Tire Machine

1. Place the rim on the machine so that the rim ange clamp is at the

12 o’clock position, the sensor is at the 2 o’clock position and the

mounting hook is at the 8 o’clock position.

Rim Flange Clamp

Sensor

Figure 8

2. Advance the wheel clockwise to pass both beads over the rim ange

simultaneously . The tire should mount onto the wheel without contacting

the sensor.

Mounting

Hook

Figure 9

3.4.4 Re-Mounting Commercial Vehicle Tires

Using A Center Post Tire Machine

1. Place the rim on the machine with the mounting shoe at the 9 o’clock

position and the sensor at the 5 o’clock position.

Mounting

Shoe

Figure 10

18

Sensor

Page 19

2. Place the tire on the rim with the bottom bead under the ange at the

6 o’clock position with the mounting shoe at the 9 o’clock position.

3. Advance the mounting shoe clockwise to pass the lower bead over the

rim ange.

4. Return the mounting shoe to the 9 o’clock position, depress the upper

bead under the rim ange at the 6 o’clock position and advance the

mounting shoe clockwise until the second bead is completely mounted.

3.4.5 Dual Wheel Assemblies

In order to accommodate SmarTire® TPMS system programming, dual wheels

MUST always be mounted on the vehicle with the valve stems 180° apart or

as close as possible to opposite each other.

Inboard TireOutboard Tire

Sensor

Valve Stem

Valve Stem

Sensor

Figure 11

3.4.6 Re-Mounting Light Truck Tires Using a Tire Machine

1. Place the rim on the turn-table of a tire mounting machine with the sensor

at the 7 o’clock position and the mount head at the 12 o’clock position.

2. Starting from the mount head, manually depress the bottom bead of the

lubricated tire on the rim and into the drop center well until its pinch point

is approximately 3” (7.5 cm) before the sensor.

(Note: The pinch point, also known as a “traction point” is the position

on the rim where the tire bead encounters resistance when trying to slip

over the rim ange.)

Figure 12

19

Page 20

3. Advance the turn-table clockwise using the mount head to guide the rest

of the bottom bead over the ange and on to the rim. When assembled

correctly, the bead will slip over the ange without contacting the sensor.

4. Repeat for the top bead. Do not allow the pinch point to slip as the rim

rotates or the sensor could be broken.

5. Finish the tire installation as normal (seat the beads, install the valve

core, inate to the recommended cold ination pressure, balance tires

and mount wheels in specied locations).

3.5 Removing A Tire That Has A

SmarTire

This section ou tlines the c orr ect metho ds for removing a ti re from a whe el

that is equipped with a S marTire® sensor. Instructions for usin g both tire

irons and a tire mounting machine are provided.

Please read these instr uctions caref ully and follow each step precis ely to

ensure you do not damage a sensor when dismounting the tire. If steps are

not taken to avoid the sensor located in the drop center well of the rim, it can

be crushed by the beads as the tire is removed.

®

TPMS Sensor Installed

3.5.1 Using Tire Irons

1. After removing the deated tire / wheel assembly from the vehicle, lay

the assembly on a oor mat and unseat both beads directly opposite

the sensor. The sensor should be located at the valve stem (the rim

mounted decal should also indicate the sensor’s location). Do not unseat

the bead at or near the sensor/valve stem.

Figure 13

2. Ensure that the mounting side of the wheel is facing upward and both

the bead and wheel ange are properly lubricated.

3. Starting near the sensor, lift the top bead over the wheel ange using tire

irons and progressively work away from the sensor until the top bead is

free. Be careful not to contact the sensor with the tire irons.

4. Again starting near the sensor, repeat the process for the bottom bead

until the tire is free from the wheel.

20

Page 21

3.5.2 Using a Tire Mounting Machine

1. After removing the deated tire / wheel assembly from the vehicle, unseat

the beads directly opposite the sensor and valve stem. The sensor should

be located at the valve stem (the rim mounted decal should also indicate

the sensor’s location). Do not break the bead at or near the sensor /

valve stem.

2. Position the lubricated tire / wheel assembly on the machine so that the

dismount head and the sensor are approximately aligned.

3. Lift the bead over the rim ange with the bead lifting bar and then advance

the assembly / dismount head clockwise to remove the top bead.

4. Repeat steps 2 and 3 to remove the bottom bead.

NOTE: This information sh ould be provided to tire installer s that are not

authorized SmarTire

®

TPMS distribut ion outlet to ensure a sensor is not

broken when a tire is dismounted.

21

Page 22

3.6 Tire Sensor Specications

Tire Sensor (with cradle)

Power Internal Lithium Battery

Weight 1.89 oz (58.7 g)

Dimensions 3.58 x 1.65 x 1.34 in. (91 x 42 x 34 mm)

Operating Temperature

(-40º C to 125º C)

Pressure Accuracy at 0ºC

to 50º C

Maximum Cold Ination

Pressure

Maximum Sensing

Pressure

Battery Life 5 years operational, 5 year shelf

Table 3

-40º F to 257º F

+/- 2.39 PSI (0.65 bar)

160 PSI (11.03 bar)

188 PSI (13.0 bar)

22

Page 23

Section C: System Installation –

Components and Programming

4.0 Installing The SmarTire

®

Trailer-Link

™

System

What follows are the steps to install the SmarTire® T railer-Link™ TPMS system

components fo r trailers built af ter 1998 with integrated p ower supply lines

and ABS modules already equipped. Installation of the TPMS sensors onto

wheels is excluded in this section. For additional harness, component, and

sensor installation details, refer to Sections B and E.

CAUTION: It is recommended to install all Trailer TPMS sensors

in their pre-assigned locations prior to completing the actions below

and in accordance with the sensor mounting instructions in Section B.

Step 1. For a multi -ax le trailer, use Figure 3 to identi fy the ide al SmarTire

T railer -Link ECU mounting location. To do so, picture a line drawn from the

left front trailer tire to the rear right trailer tire, and a line drawn from the front

right to the rear left tire. Where the lines intersect is the approximate mounting

location of the provided SmarTire T railer-Link bracket and ECU. For a single

axle trailer, place the ECU slightly in front of the axle.

Figure 14

T o ensure optimal signal reception, make sure the distance between any tire

and the SmarTire Trailer-Link ECU does not exceed six (6) feet.

Step 2. To install the SmarTire Trailer-Link ECU mounting bracket, nd a

at surface at or near the location indicated in Figure 3, and use a minimum

of three hex bolts to secure t he bracket against the surf ace. Trailer c ross

members are ideal for mounting the bracket. For dimensions of the mounting

bracket, please refer to Section D.

Step 3. Mount the Sm arTire Trail er-Link ECU against t he br acket by using

the two hex bolt sets provided. Ensure that the ECU module’s at top is

facing parallel to th e trailer tires, with the har ness connector f acing away

from the driving direction. See mounting example below; arrow shows driving

direction of the trailer.

23

Page 24

Figure 15

Step 4 . Find the ABS power supply on the underside of the trailer. This power

supply is usually loc ated just ahead of the t railer ax les along t he frame, or

directly next to the A BS modu le. Free the connec tor of any dirt an d debris

and wipe down the ABS connection joint with a dry cloth before moving on.

Lift the plast ic lockin g tab slightly to pul l the ABS p ower splice c onnectio n

apart. Be careful as this tab can break off easily if pushed up too far.

Step 5 . Interconnect the SmarTire

®

T railer-Link™ ABS-Power Splice Harness

(Part No: K075867) with the or i g inal ABS power supply. Ensure the locking

tab is re-engaged and that the connector plugs are greased with the supplied

dielectric grease.

P1 & 2 - ABS Power Splice Connections

P1 PIN# P2 PIN # Designation Color

A A Brake Light Power White

B B Ignition Power Red

E E Ground Black

Detail B-B

D

A

Packard plug

CEB

P1

Packard Plug

C C Aux. I/O Blue

D D Indicator Lamp Brown

15 Inch

B

B

Detail A-A

A

P3

P3 - ABS Power Splice Connection

P3 PIN # Designation Color

A

2 Brake Light Pwr. White

3 IGN. Power Red

1 Ground Black

Packard Recpt

Detail C-C

E

CB

D

C

A

Packard Recpt

P2

C

Figure 16 - SmarTire Trailer-Link™ TPMS ABS Power Splice (Part No: K075867)

24

Page 25

Step 6. After installin g the ABS Power Splic e harnes s, connec t the 3 -pin

power connector, (P3 in Figure 16) to the Smar Tire T railer -Link™ TPMS Wiring

Harness, (P3 in Figure 17). Then route the harness along the underside of the

trailer, taking care to avoid any slider mounts and su s pension compo n e nts.

Secure the har ness every fo ot with zip ties. C onnect t he other end of the

harness, P1 in Figure 17 to the SmarTire Trailer-Link ECU.

P3 - ABS Power Splice Interconnection

P3 PIN # Designation Color Optional Color

2 Brake Light Power White White

1 Ground Black Ye llo w

DTM06-12SA-E007

A

P1

A

P1

Detail A-A

12

11

DEUTSCH

10

9

8

7

3 Ignition Power Red Red

1

2

3

4

5

6

12 Inch

P5

Bullet Connector

64 Inch

36 Inch

DTM06-3S-E007

P2

Delphi Fuse

P3

Detail B-B

P3

B

B

8 Inch

B

A

P4

C

P4

Detail C-C

P1 - DTM06 -12SA-E007

14

P1 -

Pin #

Designation Wire Color

Optional

1 RS232-Transmit Blue Black

2 Not Used Sealing Plug ---

3 Brake Light Power Orange White

4 Not Used Sealing Plug ---

5 Not Used Sealing Plug ---

6 Ignition Power Red Red

7 Not Used Sealing Plug ---

Color

P4 - Serial Port with LED Diagnostic

P4

Designa-

PIN#

tion

RS232-

2

Transmit

RS232-

3

Receive

1 Ground Black* Yell ow

32

DTM06-4S-E007

Optional

Color

Blue Black

White White

8 LED - Diagnostic Brown Brown

9 Not Used Sealing Plug ---

10 Lamp Driver Purple Purple

11 Ground Black Ye llo w

4

Diagn.

Splice Required into main GND wire

*

Brown Brown

LED-

12 RS232-Receive White White

Figure 17 - 6 ft SmarTire® Trailer-Link™ TPMS Harness Part No: K075868

25

C

Color

Page 26

In some cases, the supplied 6ft harness may not be sufcient for your

installation. If this is the case, there is an optional 15 ft SmarTire T railer-Link™

TPMS Harness Part No: K075869 available. Please contact your distributor

to order this part.

Step 7. Route the 4-pin diagnostic LED line to the side of the trailer or slider

and secure the line ever y foot wit h zip ties. Ensure th e Bendix diagno stic s

LED Cap part numbe r K0758 66 is placed over the end of the diagnosti c

connector, P4 in Figure 17 when not used with the Maintenance Han d too l.

Connec t th e trailer to po w e r and watc h fo r the LED t o light u p br i ey to conrm

the SmarTire Trailer-Link ECU is functional. Refer to the blink code table in

Section C for more information.

Step 8 . If needed, adjust the Cold Ination Pressure (CIP) of each axle using

the SmarTire

®

Maintenance Hand to ol (09 0.0011) and diagnosti cs har nes s

part number K092501 as described in Section 3.1 to complete the installation.

If the optional trai ler warn ing lamp is not inst alled, pl ease use th e supplied

dielectric grease and ll the trailer lamp output connector (P5 in Figure 17)

with grease to protect it from corrosion. For instructions on how to install the

optional trailer warning lamp, continue to step 9.

Optional Step 9. Using the lamp output

connector (P5 in Figure 17) a trailer lamp may

also be installed at the n ose of the trailer to

provide trailer TPM S alerts regardless if th e

tractor is equipped with a SmarTire TPMS

unit. Extend a p ower line from t he conn ector

to the lamp (standard 12-24V lamp with max

one (1) Amp draw can be used, n ot provided

by Bendix) and ground the lamp to the trail er

chassis at its mounting point. Place the

provided Trailer Lamp alert sticker underneath

the trailer lamp. See Section C for blink codes.

Figure 18

CAUTION: A 5-Amp fuse is included with all SmarTire Trailer-Link

TPMS harnesses. If the fuse needs to be replaced, use a maximum

5-Amp fuse to protect the SmarTire Trailer-Link ECU.

26

Page 27

4.1 Conguring & Customizing Your

SmarTire Trailer-Link

™

System

During the installation process, the default settings for SmarTire T railer-Link

™

TPMS should be customized to the trailer by the installer. Using the Smar Tire

T railer-Link Diagnostics Software within Bendix® ACom® Diagnostics 6.6 (or

higher), alert thre sholds can be made more or les s sensitive and system

settings can be adjusted to accommodate trailer changes and use.

Replacing trailer tires or installing the system on a new trailer may also require

adjustment of pre-congured settings. The following section describes how

to adjust the pre-congured settings of your SmarTire Trailer-Link TPMS.

4.1.1 Pre-Congured Settings

Generally, the SmarTire Trailer-Link TPMS is pre-congured with the default

settings listed be low. Depending on your vehic le, your system may have a

different initial setup.

● Cold Ination Pressure (CIP):

◊ 4-Wheel (2-axle Conguration)

• Trailer Axle 1&2: 100 PSI (6.89 bar)

◊ 8-Wheel (2-axle Conguration)

• Trailer Axle 1&2: 100 PSI (6.89 bar)

● First Alert Level (FAL) Pressure Deviation Alert: CIP ±15% (temperature

compensated)

● Second Alert Level (SAL) Critical Low Pressure Alert: CIP -20%

● High Temperature Alert: 185°F (85°C)

Default cold ination pressure settings should always be customized to the

trailer. Check the trailer’s placard or the industry published load ination

table to determine the recommended cold ination pressure settings. Bendix

recommends setting the Second Alert Level (SAL) critical low pressure alert

at 20% below the recommended cold ination pressure for your trailer. Bendix

also does not rec ommend changing the First Aler t Level (FAL) pressure

deviation alert setting as well as the High T emperature Alert setting of 185F .

To make chang es to the FA L, SAL, and High Temperature settings refer

to the SmarTire Trailer-Link Diagnostics settings within Bendix ACom

Diagnostics. For programming sensor IDs and changing the axle CIP using

the Maintenance Hand tool, see the instructions that follow. These instructions

can also be found in the Maintenance Hand tool manual (BW2809).

27

Page 28

4.2 SmarTire Trailer-Link™ Axle Cold Ination

Pressure (CIP) Adjustment Instructions

4.2.1 Equipment

™

● SmarTire Trailer-Link

®

● SmarTire

TPMS Maintenance Hand tool Kit 090.0011

4.2.2 Trailer CIP Programming Procedure

The default CIP programmed into the SmarTire Trailer-Link ECU is 100 PSI

for all axles. Each axle can be congured to have a unique CIP. If the case

arises where dif fere nt CIP values are require d, the following p rogrammin g

procedure should be used.

Perform the following steps:

1. Power up the SmarTire Trailer-Link ECU. In most cases the trailer will

need to be connected to a tractor in order to receive power. The diagnostic

LED on the SmarTire T railer-Link harness can be viewed at power up to

ensure that the ECU has power.

2. Using the Maintenance Hand Tool, press and hold the Setup

until a list of menu items appear.

3. Select the Trailer CIP menu item and press the Return

4. Use the Up

and Down arrow buttons to congure the system for the

total number of axles installed on the trailer. A maximum of 5 axles can

be congured. When the correct number of axles is selected, press the

Return button.

Diagnostic Harness Kit K092501

button

button

Figure 19

5. Next, adjust the CIP value for each axle. The default value of 100 PSI

will be shown on the screen (if imperial units are selected).

Figure 20

Use the Up and Down arrow buttons to adjust the value of the CIP.

Holding down the arrow buttons will cause the values to increment at

an increasing rate. Press the Return/Right button to advance to the

next axle.

28

Page 29

6. When the Cold Ination Pressure (CIP) values have been adjusted to

the desired setting, press and hold the Return button for 3 seconds

until the programming screen bellow is displayed.

Figure 21

7. Using the SmarTire Trailer-Link™ programming cable (Part Number

K092501), connect the tool to the SmarTire Trailer-Link harness.

Figure 22

8. Press the Check button to initiate programming. Y ou may also press

the Return button to return to the CIP adjustment screen or press the

button to return to the main menu.

9. Once programming has been initiated, the following screen is shown:

Figure 23

10. After successful programming, the following screen is shown:

Figure 24

11. Press the Return button to exit to the main menu.

12. In the case of a programming error, the following screen is shown:

Figure 25

If this occurs, ensure the SmarTire T railer-Link ECU is powered and the

connection from the tool to the SmarTire T railer-Link harness is correct.

Press the Check

button to retry the operation, press the Return

button to return to the CIP adjustment screen in step 5, or press the

button to abort the programming and return to the main menu.

29

Page 30

4.2.3 Trailer Sensor ID Walk-Around Learn Procedure

™

The following steps are only to be used for the SmarTire Trailer-Link

ECU.

When the tires are rotated or replaced on a trailer equipped with a SmarTire

tire pressure monitoring system, the trailer TPMS module must be taught the

new position of each sensor ID code. The Walk-Around Learn procedure is

used to activate each sensor in its new location, store the sensor information

and download this information into the SmarTire Trailer-Link ECU.

The SmarTire Maintenance Hand Tool (P/N 090.0011) will learn and store the

location of eac h sens or as t he use r walks around t he t raile r in a U-Shape d

pattern, starting at the left side (looking forward) front most tire location (see

Figure 28). If this is a dual tire axle, start with the inner tire location. The new

location information (ID codes) for each sensor collected is then uploaded to

the SmarTire Trailer-Link receiver.

1. Power up the SmarTire Trailer-Link receiver. In most cases the trailer

will need to be connected to a tractor in order to receive power. The

diagnostic LED on the SmarTire Trailer-Link harness can be viewed at

power up to ensure that the ECU has power.

2. Using the Maintenance Hand Tool, press and hold the Setup

button

until a list of menu items appear.

3. Select the Walk-Around Learn

4. Use the Up

and Down arrow buttons to select the number of tires

icon and press the Return button.

on the trailer.

Figure 26

5. When the correct number of tires is selected, press the Return button

to initiate the walk around learn procedure.

Figure 27

30

Page 31

6. Using the SmarTire

®

TPMS Maintenance Hand Tool, go to the rst tire to

be programmed and proceed to activate each of the trailer’s tire pressure

sensors in the proper order. Starting on the left side (road side) of the

trailer at the forward axle, begin by activating the inner tire and proceed

to work counterclockwise from inner to outer tire. Work in a U-shaped

pattern around the trailer ending with the right side (curb side) forward

outer tire. If using wide-based single tires, simply start at the forward

left side tire and work in a U-Shaped pattern around the trailer ending

with the right side forward tire. Some examples are shown below:

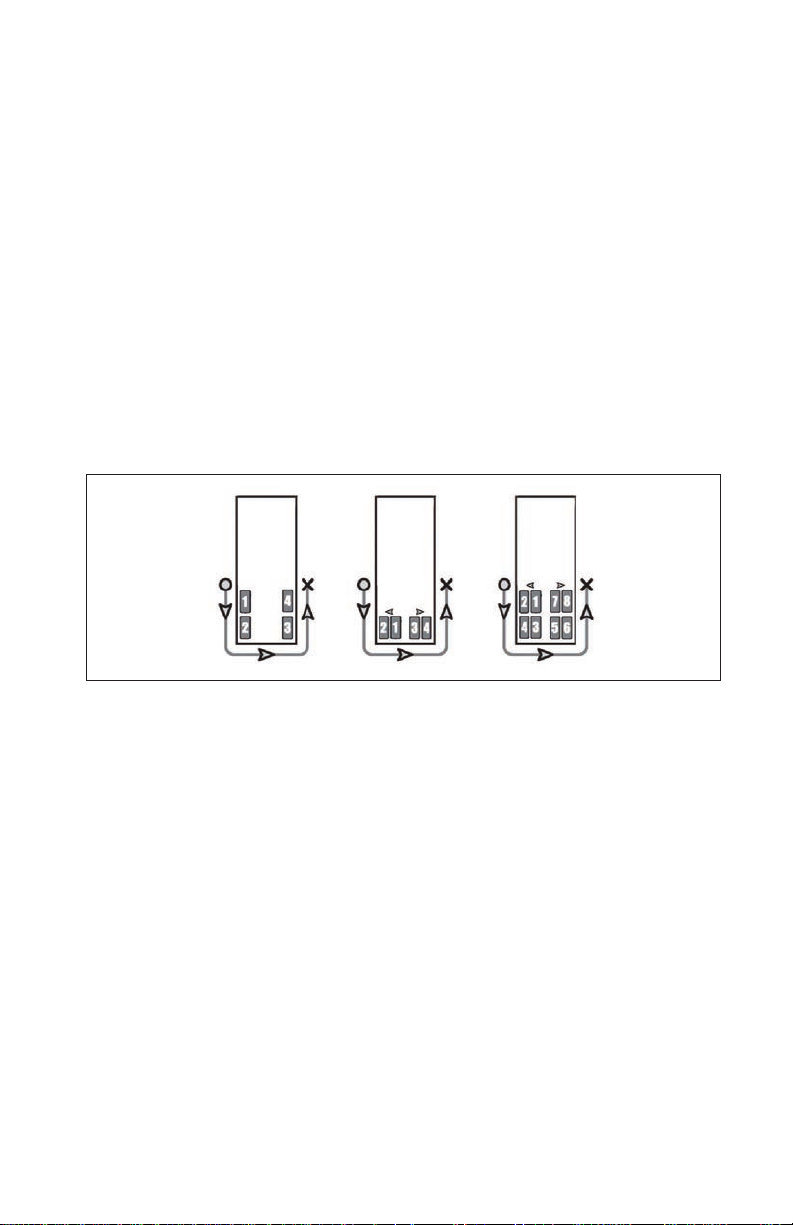

Figure 28

7. T o activate the tire pressure sensor , hold the SmarTire Maintenance Hand

T ool’s antenna against the tire’ s upper sidewall in-line with the valve stem.

Press the Learn

Button to learn the ID code of the sensor. In most

cases, the Maintenance Hand Tool is able to receive signals from the

inner tire on the dual tire conguration as well. To program the inner tire,

hold the tool in line with the circumferential position of the valve stem of

the inner wheel, as indicated below:

Inboard TireOutboard Tire

Sensor

22-24 inch LF

Field Range

Figure 29 - Initiating Transmissions From Dual Wheels

Valve Stem

If the sensor is not programmed from this position, you many also place the

tool between the dual tire assemblies and activate the sensor by placing the

antenna near the tire sidewall, in -line with t he inner valve stem. Pressing

button will abort the Walk-Around Learn procedure.

the

31

Page 32

8. Once the tool has learned the tire pressure sensor ID for the given

position, it briey displays the received ID code and automatically

switches to the next tire position.

Figure 30

Figure 31

Press the Learn button to initiate the next tire sensor. Repeat until all

the tires have been learned into the tool. At this point you may also press

the Up and Down arrow buttons to select and view any previously

learned wheel positions. If needed, you may also reprogram a tire

position by simply selecting a previously learned position and pressing

the Learn button. Any previously learned sensor ID codes will be

replaced by the new ID code for that position.

9. If a sensor failed to activate, the following screen will be displayed (Figure

32). If this occurs, ensure that the tool is placed at the correct position

around the tire and retry the sensor activation by pressing the Learn

button.

Figure 32

10. If, while learning a particular wheel position, a tire pressure sensor ID

code is received that is already used in a different position, the following

“Duplicate ID” error screen is displayed.

Figure 33

Pressing the button will delete the received ID and the screen will

go to the previously learned position. Press the Learn button to learn

the tire sensor into the position again.

11. After the last tire position has been learned into the tool, press the Down

arrow button. The tool is now ready to transmit this information to the

SmarTire T railer-Link™ receiver.

Figure 34

12. Using the SmarTire Trailer-Link programming cable (Part Number

K092501), connect the tool to the SmarTire Trailer-Link harness.

32

Page 33

Figure 35

13. Press the Check button to begin downloading the new tire sensor

IDs into the SmarTire Trailer-Link™ receiver.

Figure 36

14. In the case of a programming error, the following screen is shown:

Figure 37

15. If this occurs, ensure the SmarTire T railer-Link™ ECU is powered and the

connection from the tool to the SmarTire T railer-Link harness is correct.

Press the Check

button to retry the operation, press the Return

button to return to the learn procedure screen in step 5, or press the

button to abort the learn procedure and return to the main menu.

16. If the tool screen reverts back to the screen for entering the number of

tires, then the number of tires entered does not match the number of

tires currently programmed into the SmarTire Trailer-Link receiver.

Figure 38

Make sure the number of tires entered o n the tool matche s the number of

tires being monitor ed by the SmarTire Trailer- Link rec eiver and t hen retur n

to Step 4 and repeat the Walk-Around Learn procedure.

33

Page 34

Section D: SmarTire Trailer-Link™ TPMS Display Options

5.0 Trailer Information Display Options

5.1 Tractor SmarTire Dash Display

When the SmarTire Trailer- Link™ TPMS system is combined w ith a tractor

equipped with the SmarTire® TPMS system, the trailer tires will be added in

the form of ‘T’ axles following the last tractor axle on the 2-inch SmarTire dash

display. The dash gauge will reboot shortly after the wireless connection is

established wit h the SmarTire Trailer-Link system and t he new trailer axl e

positions will be displayed for the tractor. T o become more familiar with the

functions of the S marTire dash display, refer to Section C of the Sm arTire

Operator’s Manual BW2799 before continuing on in this section.

CAUTION: The tractor dash display cannot be used to make any

SmarTire Trailer-Link system parameter adjustments or to change the

sensor conguration programmed into the SmarTire Trailer-Link ECU!

These parameters are stored directly in the SmarTire Trailer-Link ECU

and must be congured by connecting to the SmarTire Trailer-Link ECU

as described in Section 4.1.

Ensure the SmarTire Trailer-Link Enable function is set in the SmarTire

tow-vehicle-mounted ECU part number 200.0216.

For tractors equipped with the part number 200.0184 ECU to be able

to communicate with the SmarTire Trailer-Link ECU, the ECU rmware

MUST BE updated to new rmware. For instructions on performing

this update, please contact your Bendix account representative or call

1-800-AIR-BRAKE (1-800-247-2725).

Figure 39

34

Page 35

5.2 Tractor SmarTire® TPMS Dash Display Alerts

After the SmarTire Trailer-Link™ connection has been established, the same

three tire alerts, rst level pressure, second level pressure and temperature

alerts w ill be reported from the t railer that are reported fr om the tractormounted Smar Tire® TPMS system. In addition, trailer tire sensor Diagnostic

Troub le Co des (DTCs) and low batter y alerts will also b e repo r te d. Please

note, alert levels congured in the tractor TPMS ECU do not override the

settings in the SmarTire Trailer-Link ECU. For example, if the tractor has its

rst level alert set to 10% -- but the SmarTire Trailer-Link ECU is congured

for a 15% rst level alert – the driver will see trailer tire alerts based on the

15% gure stored in the Trailer-link ECU.

Pressure Deviation Critical Low Pressure High Temperature

Figure 40

5.3 SmarTire Trailer-Link™ To SmarTire TPMS

Dash Display Link-Up Procedure

The SmarTire

connections. There are three options available and can be congured with

the Bendix ACom 6.6 (or later) diagnostic software.

1. Disabled: In this mode Trailer Linking is disabled and trailer tires will not

show up on the dash display.

2. Automatic Learn Mode: In this mode the SmarTire ECU will try and auto

detect the attached trailer. In this mode the SmarT ire T railer-Link should

link up within 30 seconds but could take as long as 5 minutes.

3. Dedicated Trailer Mode. In this mode the ID code of a particular trailer

can be programmed into the SmarTire ECU. This mode is normally used

if the tow vehicle always pulls the same trailer. Link-up in this mode

should take 30 seconds.

When the tractor drops a trailer, it will unlink from the SmarTire ECU in 9

minutes at which time the dash display will remove the trailer tires.

®

ECU must be congured to allow SmarTire Trailer-Link

5.4 Trailer Lamp Blink Codes

If an optional traile r lamp i s inst alle d and c o nnec ted v ia th e lamp o utput o n

the SmarTire T railer-Link ECU, the following table shows the blink codes that

will be displayed by the system in the event of an active Diagnostic Trouble

Code (DTC) condition. The SmarTire T railer-Link lamp alerts will be displayed

for one (1) minute after system power-up and then will either show the lamp

on — or off — depending on status of the system.

35

Page 36

TPMS Lamp Alerts

(repeated for 1 Minute

after Start-up, then ON

or OFF depending on

Priority)

5x Blinks

High

Temperature

& then

ON after 1

min.

4x Blinks

Critical Low

Pressure

& then

ON after 1

min.

Minor Over

or Under

Pressure

Sensor

Diagnostic

Trouble

Code (DTC)

Setup

Diagnostic

Trouble

Code (DTC)

Table 4

2x Blinks

& then

OFF after

1 min.

1x Blink

& then

OFF after

1 min.

3x Blinks

& then

OFF after

1 min.

Cause and Solution

Contain e d Ai r Temperature is ove r 85 C /185F –

Stop and allow tire to cool down, assess cause

of temperature increase, possible brake,

wheel bearing, or pressure issue

Tire Pressure has dropp ed bel ow the c rit ica l

threshold (-20% default), stop and check for

punctures, bead leaks, valve leaks, etc. and

air up the tire

The minor over- or under-pressure thresho ld

has been reached, have the tire serviced

during the next maintena nce check, set the

recommended pressure and compensate for

changes in ambient temperature (see temp

chart in Section A)

Data from a TPMS sensor has not been

received for 35 min. This may be rel ated to

the signal rece ption of t he senso r. Continue

to drive to clear the DTC. If the Diagno stic

Trouble Code (DTC) persists, check the

programming and functionality of all trailer

TPMS sensors by using the Maintenance

Hand tool 09 0.0011 and replace sensors if

unresponsive

™

The SmarTire T railer -Link

ECU is not properly

programmed and is unable to connect. Check

the programming using the Maintenance

Too l, Diagnostics Sof tware and Diagnosti cs

Harness K092501

36

Page 37

Section E: Additional Component Details

6.0 SmarTire Trailer-Link

™

System Component Details

6.1 SmarTire Trailer-Link Module Specications

6.1.1 Power, Mounting, and Environmental Requirements

● Operating voltage range 9 – 36V

● Typical current consumption (with no external loads) 30mA

● 5A fuse is required bet ween the m ain power line of the tr ailer link and

the vehicle battery

● Frequency 433.92 MHz

● Modulation type: OOK

● Design protected for FSK

● 500 kHz Band Width

● Sensitivity (OOK) at 433.92 MHz : -112 dBm

● Internal antenna only

● Uses standard Deutsch enclosure

● Tested to SAE J1455 Specications

● Operating temperature range: -40C to +85C

● Survivability temperature range: -40C to +85C

● Sealed to IP67

● Preferred mounting orientation to shed water is vertical (Connector side

facing rear of trailer, away from driving direction)

● Preferred Mounting hardware: ¼ -20 (M6X1 ) Flange Head CAPSCREW,

torque to 7-10 FT/LBS (13 Nm)

● The SmarTire Trail er-Link ECU has an internal antenna and should be

mounted free of any metal (only half the enclo sure should be c overed

by the chassis or metal bracket)

37

Page 38

6.1.2 SmarTire Trailer-Link™ Module

Dimensions in Inches/[mm]

4 7 in (119 5 mm)

5 28 in

(134 mm)

Figure 41

6.1.3 SmarTire Trailer-Link Module

Connector Pin Description

Position Signal

1 RS232-TX

2 NOT USED

3 BRAKE LIGHT-L

4 NOT USED

5 NOT USED

6 VIN

7 NOT USED

8 LED-DIAG

9 NOT USED

10 LAMP DRIVER

11 GROUND

12 RS232-RX

Figure 42 - PIN-OUT TABLE

1 43 in (36 4 mm)

4 0 in (102 mm)

38

Page 39

D-SUB-MALE

1

6

2

P2

7

3

Detail A-A

8

4

9

5

P2

P1

D-SUB-FEMALE

5

9

4

P1

8

3

7

Detail B-B

2

6

1

Figure 43

6.1.4 SmarTire Trailer-Link™ TPMS Diagnostics

Interface Harness Part No: K071016

A

B

10 Inch

TPMS TOOL

A

PC

B

72 Inch

P3

Detail C-C

14

11

2

Back View

7

3

P3

C

DTM04-4P

C

39

Page 40

Figure 44

6.1.5 SmarTire Trailer-Link™ Mounting Bracket

Part No: K092801 (dimensions in inches)

1 2 in

12 in

3 in

40

Page 41

Section F: Troubleshooting

7.0 Troubleshooting Guide

7.1 SmarTire

®

TPMS Gauge Display And

SmarTire Trailer-Link™ Module Q&A

7.1.1 Q: The SmarTire Trailer-Link™ module does not connect to the

tractor. How can the SmarTire Trailer-Link module be diagnosed

further?

A: In the event that the SmarTire T railer-Link ECU does not connect with the

SmarTire vehicle-mounted TPMS system, follow these steps:

1. Check to make sure the SmarTire T railer-Link ECU and vehicle-mounted

TPMS ECU power up during start up. The red diagnostics LED (P/N

K075866) on the SmarTire Trailer-Link harness should light up during

power-up to conrm that power is being supplied to the SmarTire Trailer-

Link ECU.

2. Ensure the SmarTire Trailer-Link Enable function is set in the SmarTire

tow-vehicle-mounted ECU part number 200.0216 and that the tow-vehicle

ECU is loaded with TPMS rmware part number is 248.0091 min. version

1.02 and CAN rmware part number 248.0092 min. version 1.03. Use

Bendix ACom 6.6 (or later) Diagnostics to verify the software version on

the vehicle-mounted ECU.

3. Check the SmarTire Trailer-Link harness to ensure all connections are

secure. Ensure the locking tab on the ABS-power splice is engaged as

well as the main connector on the SmarTire Trailer-Link ECU module.

4. Cycle power to restart the link-up process and reset the ECUs.

5. If the SmarTire T railer-Link ECU still does not connect with the SmarTire

vehicle-mounted TPMS system please refer to 7.1.4 for further

Diagnostics.

41

Page 42

7.1.2 Q: The gauge only displays dashes for the trailer tire information;

there is no pressure, temperature, or deviation value.

®

A: After th e wireless link between the trac tor SmarTire

™

the SmarTire Trailer-Link

module has been established and the gauge has

TPMS ECU and

rebooted, trailer tire sensor data will be displayed within ve (5) to eight (8)

minutes on the gauge.

T o facilitate the quicker display of tire information, use the SmarTire LF Tool

or SmarTire Maintenance Hand tool and initiate each of the tires that have not

reported to the Gauge. On the SmarTire TPMS Maintenance Hand tool, press

the left-most button as you point the tool’s antenna into the tire sidewall above

the valve stem (default sensor location). Remember, that both the SmarTire

LF Too l and Sm arTire Maintenance Hand to ol a re c ap able of ac t ivating t he

inner tire on a dual tire assembly from the outboard tire position. For use of

the SmarTire LF Tool, please refer to manual BW2820.

In cases where no transmissions were received from a specic tire, move the

Hand tool ve (5) inches in a clockwise or counterclockwise direction and try

again. Should the problem persist, a defective, missing, or misplaced sensor

may need to be diagnosed – see Section 7.3.

Inboard TireOutboard Tire

Sensor

Figure 45

22-24 inch LF

Field Range

Valve Stem

42

Page 43

7.1.3 Q: When the Gauge rst powers up, the alert lamp is blinking and

a triangle with an exclamation mark is displayed. A few minutes later

the alert cl ears and the display retur ns to normal. Was there an alert?

A: During the start up sequence, the

Gauge may clear itsel f of a previous al er t

condition or i ssue a momentar y alert i f a

tire sensor has not reported in.

Figure 46

As soon as the tir e sensors report their late st readings and they do not

constitute an alert condition, the Gauge will clear the alert.

Ensure that the user keeps an eye on the par tic ular alert until it is cle ared.

If the alert does not clear itself, the user may indeed have an alert condition

that needs to be chec ked further. Updating the given tire po s ition with new

information by using the LF T ool or Maintenance Hand tool (press “Initiate”),

would clear the alert faster, unless an alert condition does exist or the sensor

is malfunctioning.

43

Page 44

7.1.4 Q: What additional diagnostic information is available?

A: The external LED part # K075866 is connected via the cable harness as a

separate plug. Please refer to Section C, 4.0, step 7 for details on installation

and location of this LED. The LED functions as described in the table below.

Flashing with pattern will have periods of 0.3 second on and 0.3 second off

repeating every 6 seconds. The number of high pulses in each 6–second

window will be determined by a code. For example if the ash code is 2, the

pattern will be 0. 3 second on, 0. 3 second of f, 0.3 second o n, 5.1 sec onds

off and repeating.

Alarms Priority External LED See

No Alarms 0 Off Second Level Low Pressure (SAL) 6 Pattern ashing

code: 4

SAL Cleared 0 Off First Level High Pressure (FAL_H) 4 Pattern ashing

code: 2

First Level Low Pressure (FAL_L) 3 Pattern ashing

code: 2

FAL Cleared 0 Off High Temperature 7 Pattern ashing

code: 5

High Temperature Cleared 0 Off Sensor Diagnostic Trouble Code (DTC) Set 2 Pattern ashing

code: 1

Sensor DTC Cleared 0 Off ROM To Both Copy Performed 10 Pattern ashing

code: 7

Set Up DTC 5 Pattern ashing

code: 3

Set Up DTC Cleared 0 Off Factory To Custom Copy Performed 9 Pattern ashing

code: 7

Custom To Factory Copy Performed 8 Pattern ashing

code: 7

Watchdog Reset 11 Pattern ashing

code: 8

Sensor Battery Low Alert 1 Pattern ashing

code: 6

Note

-

-

-

-

1

2

3

2

4

5

-

Table 5

44

Page 45

Notes for Table 5

Note 1: This Diagnostic Trouble Code (DTC) occurs when the SmarTire

Trailer-Link™ ECU has not received informatio n from a tire sensor for 35

minutes. Possible causes are:

1. A tire has been replaced and a tire sensor is no longer in range of the

ECU and is therefore no longer being received. In this situation the

missing sensor must be replaced and the ECU recongured to add this

new sensor.

2. There is poor radio frequency signal quality between the sensor and the

ECU. Check the installation of the ECU and ensure it is not mounted

close to any metal objects and is in the correct location as described in

Section C, 4.0.

3. There is a malfunctioning sensor in one of the vehicle’s tires. In this

situation the malfunctioning sensor must be replaced and the ECU

recongured to add this new sensor.

Note 2: This Diagnostic Trouble Code (DTC) is generated when the

conguration information within the ECU has become corrupt. During this

DTC the ECU’s conguration is restored to the default factory setting. If this

DTC occurs all sensors registered in the ECU will be lost and all programmable

settings restored to factory settings. The ECU must be re-congured to

become operational again.

Note 3: This DTC is active if there are no tire sensors registered in the ECU.

This could be caused if the ECU was never congured or corruption of the

conguration in f o r m a t i o n has oc c u r r e d as in Note 3. To co r re c t th i s si tuation,

tire sensors installed on the trailer must be learned into the ECU.

Note 4: This DTC is generated when the conguration information within the

ECU has become cor rupt. The ECU has re covered from thi s by restoring

the congurat i o n fr o m a ba c k u p co py. Nor m ally this DTC is self- c o r re c t e d by

the ECU but the conguration should be analyzed to make sure all settings

are correct.

Note 5: This DTC is generated when the ECU has restarted due to a software

related failure. If this DTC occurs o n a regular basis, the ECU should be

returned to Bendix for analysis.

45

Page 46

7.2 SmarTire® TPMS System Q&A

7.2.1 Q: A tr ai l e r ti r e co n t i n u e s to sh ow a deviation value/aler t al t h o u gh

it was aired up properly.

A: Set the Cold Ination Pressure value (CIP) for each trailer axle to make

sure it matches that of the intended ination value for the tire in question.

To do so, pleas e refer to Section C, 4.2.2 as well as the ination tables in

Section A under Section 1.4. If the CIP value is matched to the recommended

ination pressure for the vehicle and the prevailing ambient temperature but

the deviation value cont inues to show up, the tire is exhibi ting a slow leak .

Take appropriate steps to have the tire inspected for any damage or leaks.

7.2.2 Q: Pressure readings at a tire location do not change on the

gauge when air is added, or removed, to correct tire pressure, and a

new transmission has been received.

A: Whee l as sembli e s may have been re l o c ated/r otated on th e trailer wi thout

™

the SmarTire Trailer-Link

ECU having been updated. To correct this, follow

the steps in Section C, 4.2.3 in combination with the SmarTire® TPMS

Maintenance Hand tool to relearn sensors into their correct tire positions.

7.3 Diagnosing A Defective, Missing, Or Misplaced Sensor

In the event that a tire sensor does not r eport to the display af ter having

gone through the step s above, the following s ensor c hecks sho uld also be

performed:

a. Try to initiate the sensor opposite of

the valve stem. There are times when

the tire installer accidentally places the

sensor 180 degrees opposite of the

valve by misreading the instructions

(sensors are required to be placed 180

degrees opposite of each other for dual

wheel assemblies). Check for new data

on the gauge for the affected wheel

position.

b. If step a. was unsuccessful, try to initiate the sensor at the bottom of the

wheel, no matter where the valve stem is located. If this attempt updated

the display screen, rotate the wheel 180 degrees forward and initiate the

sensor again at the BOTTOM of the wheel. If the second initiation also

provided new data (cycle power between tries to empty the screen, not

necessary when using SmarTire Maintenance Hand tool), it is evidence

of a broken cradle and/or strap. The sensor is simply falling to the lowest

point in the wheel after each rotation. Remove the tire and replace the

cradle and strap. Depending on the damage done to the sensor itself,

Figure 47

46

Page 47

it may simply be pressed into a new cradle for reuse. Avoid reusing the

strap – worm gear could be damaged internally.

c. If points a. and b. did not yield any results, the sensor is either missing or

has been damaged. Remove the wheel carefully and inspect the inside

tire lining for any damage if the sensor, strap, and cradle are found to

have been damaged and non-operational. Replace strap, cradle, and

sensor. Program the new ID into the system using the SmarT ire

®

TPMS

Maintenance Hand tool as described in Section C, 4.2.3.

7.4 SmarTire® TPMS Hand Tool Troubleshooting

7.4.1 Q: The Tool does not power-up or turns off when the “Activate”

button is pressed.

A: Replace the batteries.

7.4.2 Q: No tire pressure sensor data is received.

A: Ma ke sure th e Ac t i vate A n t enna is h e l d within 6" of t h e ti re pressure s ensor

and positioned before the “Activate” button is momentarily pressed and that

the tool is held in th at posi tio n for at l east 3. 5 to 5 sec o nds. Try to activate

and receive tire pressure sensor data from another tire sensor.

Activate Antenna

On/Off

Button

Flash

Connector

Display Screen

Selection

Buttons

Figure 48

47

Page 48

Appendix 1: Replacement Parts

8.0 Replacement Parts

DESCRIPTION

Bolt Kit for Receiver Mounting Plate 090.0017 090.0017N

Bolt Kit for Mounting Trailer ECU to Plate 090.0020 090.0020N

SmarTire Trailer-Link

SmarTire

SmarTire LF Tool - 090.0021

Tire Sensor with Cradle 201.0007 201.0007N

6 ft SmarTire Trailer-Link TPMS Harness K075868 K095615

15 ft SmarTire Trailer-Link TPMS Harness K075869 K095616

SmarTire Trailer-Link TPMS Diagnostics Interface

Harness

SmarTire Trailer-Link ABS-Power Splice Harness K075867 K095614

Sensor Mounting Cradle – High 264.0228 264.0228N

SmarTire Trailer-Link Mounting Bracket K092801 K096638

Plate-style SmarTire Trailer-Link Mounting Bracket K068737 K092425

Rim Labels 269.0155 269.0155N

Strap for 22.5" Rims 264.0328 264.0328N

Strap for 24.5" Rims 264.0332 264.0332N

Sensor Replacement Kit for 22.5" Rims (Includes

Sensor, Strap and Rim Label)

Sensor Replacement Kit for 24.5" Rims (Includes

Sensor, Strap and Rim Label)

®

TPMS Maintenance Tool Kit - 090.0011

™

ECU 200.0189 200.0189N

OE Part

Number

- K092501

- 115.0003

- 115.0004

AM Bendix

Part Number

Table 6

Contact your local authorized Bendix distribution outlet for parts pricing.

Note: The parts in t he table above are for referenc e purpose s only during

ordering of spare and replacement components. The table does not represent

the contents of any kit.

48

Page 49

Appendix 2: System Scope Of Use & Alerts

9.0 System Scope Of Use And Alerts

This tire monitoring system does not in any way replace the need for regular

maintenance of the tire pressures and visual inspection of tires for damages.

9.1 System Installation And Usage

Warranty of the SmarTire® TPMS system requires that it has be en p ro p erly

installed and programmed by qualied personnel according to Bendix

specications. This includes all manuals and any supplementary installation

instructions included with system components.

9.2 Use Of Chemicals

Use of temporary re-sealing or re-ination products containing internal sealers

or propellants in any tire/wheel assembly may adversely affect the operation

of the Sensor/Transmitters and void the warranty.

9.3 Reacting To Alerts

CAUTION. When an alert is detected, reduce vehicle speed to an

appropriat e , safe level an d pr o c e ed to a safe stopping locat i o n or facili t y

where the tire can be inspected and serviced.

49

Page 50

9.4 Federal Communications Commission (FCC) Notice

This device com plie s with p ar t 15 of the FCC rule s. Ope rati on is subj ec t to

the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference

that may cause undesired operation. This equipment has been tested

and found to comply with the limits for a class B digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation.

If this equipment does c ause harmful interference to radio or television

reception, whic h can be determined by turn ing the equipment off an d on,

the user is encour aged to tr y to c orre ct the inter fe rence by one or m ore of

the following measures:

● Reorient or relocate the receiving antenna,

● Increase the separation between the equipment and receiver,

● Connect the eq uipment into an outlet on a c ircuit di ffer ent from that to

which the receiver is connected,

● Consult the dealer or an experienced radio/TV technician for help.

Changes or modications to this device without the express approval of

Bendix may void the user’s authority to use this device.

50

Page 51

51

Page 52

Log-on and Learn from the Best