Page 1

Bendix® EC-60™ ABS Controller Checklist

• This checklist only takes a few minutes.

Follow all General Safety Guidelines (see back page.)

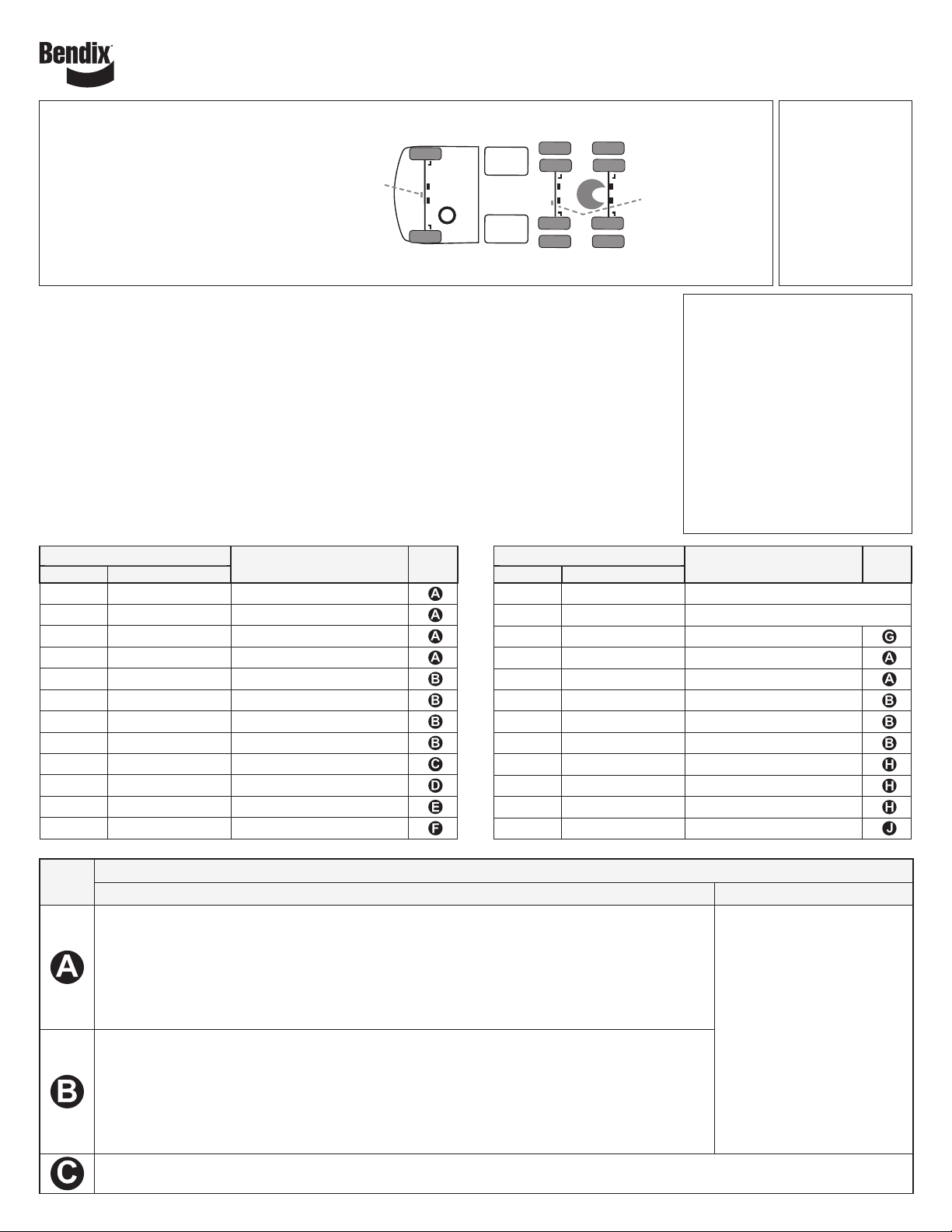

Step 1: What equipment does

the vehicle have?

Total of checked boxes:

........ Wheel Speed Sensors (WSSs),

c R. Steer A xle WSS

c R. Steer A xle PMV

c Steer

Axle

ATC

Valve

c R. Drive Axle WSS

c R. Drive Axle PMV

c R. Add’l Axle WSS

c R. Add’l Axle PMV

(Locations var y for PMVs

and ATC valves)

c Drive Axle ATC Valve

........ Pressure Modulator Valves (PMVs).

........ Automatic Traction Control Valves (ATCs).

c L. Steer A xle WSS

c L. Steer A xle PMV

c L. Drive A xle WSS

c L. Drive A xle PMV

c L. Add’l Axle WSS

c L. Add’l Axle PMV

Step 2: What Blink Code (BC) numbers are showing as active?

We recommend that you use Bendix® ACom® Diagnostics Software (with associated RP1210 harnesses,

etc.) to look up the BCs, but the blink code switch may also be used — see the info in the right column.

Use the BC Event History feature in ACom Diagnostics to view any recurring or intermittent BCs that

are not currently active, but may need attention. (visit www.bendix.com for a free software download)

Record here the BCs found:

(For example, 13-25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3: For blink codes starting with 13 followed by a second code of 1 through 7, 9 through 17, or

19 through 24, replace the ECU (go to Step 5).

Step 4: For each BC, use the tables below and take the actions suggested for the code; typically the

steps shown will resolve the issue. See the Service Data Sheet for complete troubleshooting information,

and for any other BCs not listed. Only go to Step 5 (over) in cases where the troubleshooting suggested,

and any actions the technical help line(s) recommend, do not resolve the issue.

Blink Codes (BC)

1st code 2nd code

2 any Left Steer Axle WSS

3 any Right Steer Axle WSS

4 any Left Drive Axle WSS

5 any Right Drive Axle WSS

7 any Left Steer Axle PMV

8 any Right Steer Axle PMV

9 any Left Drive Axle PMV

10 any Right Drive Axle PMV

11 7 Transmission / Hill Start Link

11 Any (except 7) J1939

12 4, 5 Retarder Relay or Hill Start Lamp

12 24, 25, or 26 Hill Start Solenoid

Description

Go To

Action

Blink Codes (BC)

1st code 2nd code

13 1- 7, 9 -17, 19-2 4 Go to Step 5

13 8, or 18 ECU (16) or (19) - Call the Tech Team

13 25 ECU “VIN Check”

14 any Left Additional A xle WSS

15 any Right Additional A xle WSS

16 any Left Additional Axle PMV

17 any Right Additional Axle PMV

20 any Trailer PMV

21 any Steering Angle Sensor

22 any Yaw Rate Sensor

23 any Lateral Acceleration Sensor

24 6 Brake Demand

Bendix Technical

Help Line:

1‑800‑AIR‑BRAKE,

(1-800-247-2725)

option 2-1,

Mon. - Fri.,

8 a.m. - 6 p.m. EST.

How to use the dash Blink Code

switch to retrieve active BCs:

1. Wait at least two seconds after

“ignition on.”

2. Toggle the blink code switch once.

3. After a pause of 3.5 seconds, the ECU

will begin responding with active BCs.

For example twelve blinks, pause, ve

blinks = 12-5. There is a long pause

before any fur ther BCs.

Note:

• Depress and release the BC switch

three times to clear BCs.

• Depress and release the BC switch

two times to see inactive BCs.

Description

Go To

Action

Action

Key Troubleshooting Steps for the Blink Codes Shown Above

Quick Checks to Make Next Steps

c Verify that the number of WSSs found in step 1 match the stored conguration

c Verify, for the wheel end identied in the description, that all WSS electrical connections and

wiring, from the wheel end through to the ECU, are properly installed and free from damage

c Check that the WSS’s face is touching the exciter ring/tone ring face

c Verify 1500-2500 ohms across sensor leads. Reading: ........ ohms*

c While turning the wheel at 0.5 revs/sec, verify a minimum of 0.25 AC volts across the sensor

leads. Reading: ........ volts* (* Out of range? – go to BW2453 WSS inspection guide.)

c Verify that the number of modulators found in step 1 match the stored conguration

c Verify, for the wheel end identied in the description, that all PMV electrical connections and

wiring, from the wheel end through to the ECU, are properly installed and free from damage

c Verify 9.8 to 11.0 ohms from the release to hold. (12 volt systems.) Reading: ........ ohms

c With the brakes applied**, verify the chuff test runs at power-up (vehicle cannot be moving). Listen

for the sequence: right steer; left steer; right drive; left drive; right add’l; left add’l

** Do not apply the brakes when testing the BC “20 -any” trailer PMV blink code

The ECU is expecting the transmission to be congured for Hill Start, but is not receiving the correct message from the transmission.

Contact the OEM support line

• Clear the Blink Codes (BCs)

• Is the same BC back?

c Yes – see the

Service Data sheet

Troubleshooting section

and/or contact the Bendix

Tech Team

c No – follow the actions

above for any other

remaining BCs

Page 2

Action

Key Troubleshooting Steps for the Blink Codes Shown Above

Quick Checks to Make Next Steps

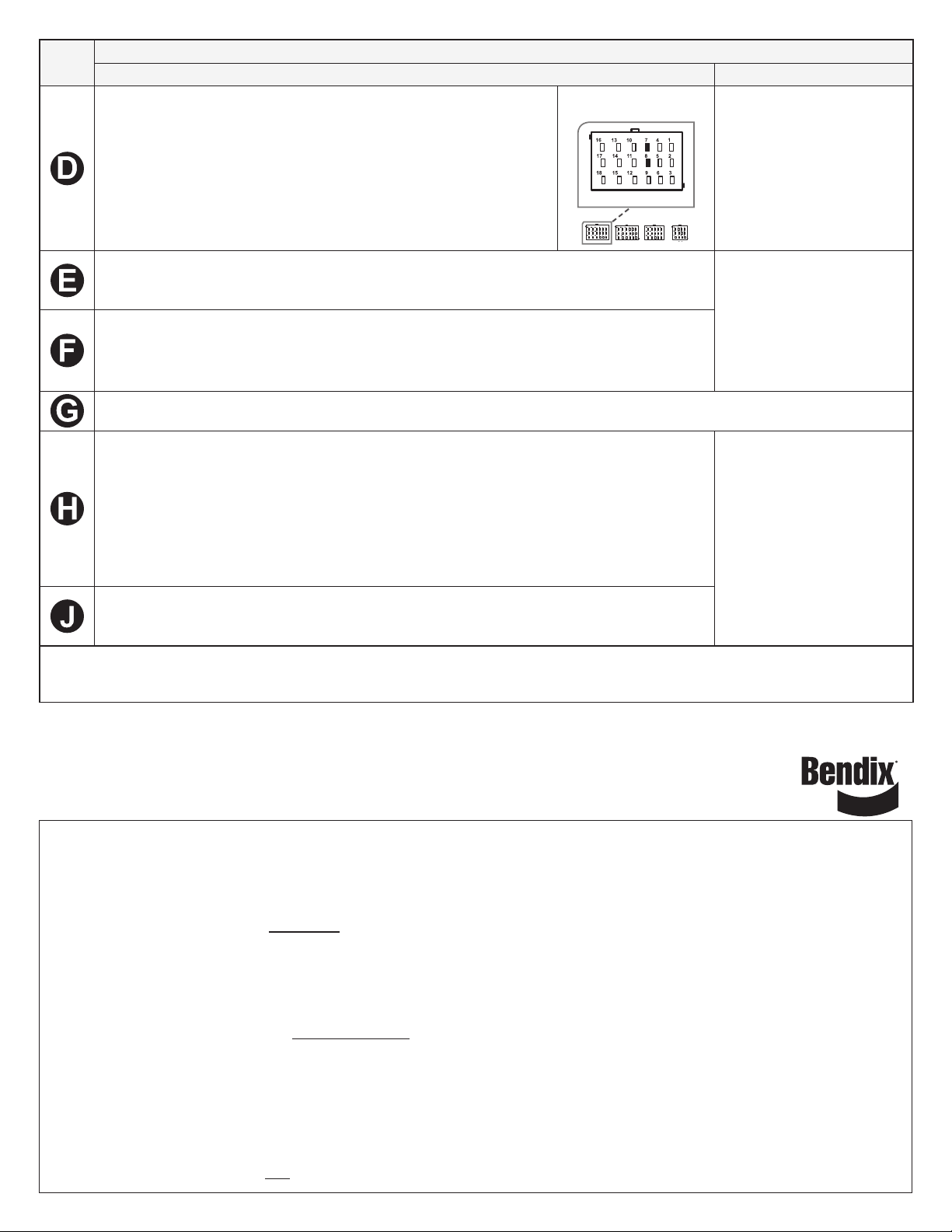

c Verify that the wiring and connections are free from damage

c With the vehicle power off, remove the X-1 connector from the ECU.

Verify the resistance between pins 7 and 8 is 60 ohms.

Reading: ........ ohms (Incorrect? – investigate harnesses and connectors)

c With vehicle power on, remove the X-1 connector. Verify the voltage

between pin 7 and ground, and also pin 8 and ground is 2.5 Vdc.

Readings: (pin 7) ........ Vdc, (pin 8) ........ Vdc

(Incorrect? – investigate harnesses and connectors)

(Looking into the wire

harness connector)

X1

• Clear the Blink Codes (BCs)

• Is the same BC back?

c Yes – Contact the OEM

support line for vehiclelevel troubleshooting

c No – follow the actions

above for any other

remaining BCs

c If there is a Hill Start dash switch installed, inspect the Hill Start lamp and switch wiring; if not,

inspect for the retarder relay wiring for damage.

c Verify that the resistance between the solenoid pins is approximately 7 to 8 ohms. (12 volt

systems.) (Incorrect? – replace the solenoid, go to Next Steps)

c Inspect the Hill Start solenoid for disconnected or damaged wiring and check the harness for

continuity.

• Clear the Blink Codes (BCs)

• Is the same BC back?

c Yes – see the Service Data

sheet and/or contact the

Bendix Tech Team

c No – follow the actions

above for any other

remaining BCs

Obtain the VIN stored in the ABS ECU, the VIN stamped on the vehicle, and the VIN stored in the engine controller. Next contact

the OEM support line: the ABS ECU BC is for a mismatched VIN ‑ this indicates the wrong ABS ECU has been installed

c Verify all wiring and connectors are free from damage. When BOTH Blink Code 21-8 AND Blink

Code 22-5 are reported, this is usually a wiring issue (check the harness for continuity).

c If 21‑8 alone, unplug the Steering Angle Sensor (SAS) connector harness and test with a replacement

SAS. If the BC clears, replace the SAS, and re‑calibrate with ACom® Diagnostics

c If 22‑5 alone, unplug the Yaw Rate Sensor (YRS) connector harness and test with a replacement

YRS. If the BC clears, replace the YRS, and re‑calibrate with ACom® Diagnostics

c Any remaining sensor BCs, clear BCs and re-calibrate with ACom® Diagnostics

c If BC returns, contact the Bendix Tech Team

c Calibrate the brake demand sensor by fully applying the brakes for three seconds

c Verify the sensor installation has not changed from the original OE conguration

• Clear the Blink Codes (BCs)

• Is the same BC back?

c Yes – see the

Service Data sheet

Troubleshooting section

and/or contact the Bendix

Tech Team

c No – follow the actions

above for any other

remaining BCs

c Verify all wiring and connectors are free from damage

Reference Documents - Ser vice Data sheets:

SD-13-4863 EC-60™ ABS/ATC standard & premium controllers, SD-13-4869 EC-60™ ABS/ATC ESP Advanced controllers

Go to www.bendix.com for free downloads of Service Data Sheets and Warranty Policies and to order copies of the SD sheets

Step 5: (If necessary.) Replace the ECU. If it is still under warranty coverage, le a claim and include: (a) the returned part, (b) a copy of this

document and (c) a print-out of the ACom® Diagnostics report.

VIN #: ___________________________________________________________________ Claim #: _____________

Vehicle Make: ________________________________________Model: _______________ Mileage: _____________

®

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW THESE

INSTRUCTIONS TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following general

precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking brakes, and always

block the wheels. Always wear safety glasses.

2. Stop the engine and remove ignition key when working under or around

the vehicle. When working in the engine compartment, the engine should

be shut off and the ignition key should be removed. Where circumstances

require that the engine be in operation, EXTREME CAUTION should be

used to prevent personal injury resulting from contact with moving, rotating,

leaking, heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or assemble a component

until you have read and thoroughly understand the recommended

procedures. Use only the proper tools and observe all precautions

pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake system, or any

auxiliary pressurized air systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work on the vehicle. If the vehicle

BW2832 ©2011 Bendix Commercial Vehicle Systems LLC. 04/11. All Rights Reserved. Printed in USA.

is equipped with a Bendix

module, be sure to drain the purge reservoir.

5. Following the vehicle manufacturer ’s recommended procedures, deactivate

the electrical system in a manner that safely removes all electrical power

from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing pressure; it may

whip. Never remove a component or plug unless you are certain all system

pressure has been depleted.

8. Use only genuine Bendix® brand replacement parts, components and kits.

Replacement hardware, tubing, hose, ttings, etc. must be of equivalent

size, type and strength as original equipment and be designed specically

for such applications and systems.

9. Components with stripped threads or damaged parts should be replaced

rather than repaired. Do not attempt repairs requiring machining or welding

unless specically stated and approved by the vehicle and component

manufacturer.

10. Prior to returning the vehicle to service, make certain all components and

systems are restored to their proper operating condition.

11. For vehicles with Automatic Traction Control (ATC), the ATC function must

be disabled (ATC indicator lamp should be ON) prior to performing any

vehicle maintenance where one or more wheels on a drive axle are lifted

off the ground and moving.

AD‑IS® air dryer system or a dryer reservoir

Loading...

Loading...