Page 1

Operator’s Manual

1

Page 2

2

Page 3

OPERATOR’S MANUAL

SMARTIRE™ TIRE PRESSURE MONITORING SYSTEM BY BENDIX CVS

Thank you for purchasing the SmarTire

TPMS onboard, your vehicle is equipped with a wireless communication network allowing seamless

integration of wireless sensing technology.

The SmarTire

™

TPMS application is an advanced tire pressure monitoring system specifically designed

for commercial vehicles. The system constantly monitors the pressure and temperature of each tire on

your vehicle in order to provide real-time, on-demand tire status information and to warn the driver of a

tire-related problem before it becomes dangerous.

SMARTIRE

™

TPMS:

Extends tire life,

Reduces maintenance costs and time,

Maximizes fuel economy by ensuring tires are properly inflated,

Reduces vehicle downtime, and

Reduces accident risk caused by a tire blowout or tire fire.

FEATURES OF SMARTIRE

™

:

Temperature compensated alert: know when your tires are at risk no matter how long you’ve

been driving.

Real-time tire information while you drive.

Tire alerts provide instant visual and optional audible alert of a tire problem.

3 types of alerts: Pressure Deviation Alert, Critical Low Pressure Alert, and High Temperature

Alert.

Can be linked to the J1939 communication network for seamless vehicl e integration.

IMPORTANT NOTICE: PLEASE READ

SmarTire

™

tire sensors can be broken when mounting and dismounting a tire unless

specific instructions are followed. If tire work is done by a non-Bendix authorized facility,

please let them know that a tire pressure monitoring system is installed on the vehicle

before they remove a tire from a wheel.

™

Tire Pressure Monitoring System (TPMS). With SmarTire™

3

Page 4

WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when working under or around the vehicle. When

working in the engine compartment, the engine should be shut off and the ignition key should be

removed. Where circumstances require that the engine be in operation, EXTREME CAUTION

should be used to prevent personal injury resulting from contact with moving, rotating, leaking,

heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or assemble a component until you have read and

thoroughly understand the recommended procedures. Use only the proper tools and observe all

precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from all reservoirs before beginning ANY work on

the vehicle. If the vehicle is equipped with an AD-IS

®

air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system

in a manner that safely removes all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a

component or plug unless you are certain all system pressure has been depleted.

8. Use only genuine Bendix

®

replacement parts, components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent size, type and strength as original equipment and

be designed specifically for such applications and systems.

9. Components with stripped threads or damaged parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make certain all components and systems are restored to

their proper operating condition.

11. For vehicles with Automatic Traction Control (ATC), the ATC function must be disabled (ATC

indicator lamp should be ON) prior to performing any vehicle maintenance where one or more

wheels on a drive axle are lifted off the ground and moving.

4

Page 5

TABLE OF CONTENTS

SmarTire

SmarTire™ TPMS: ....................................................................................................................3

Features of SmarTire™:............................................................................................................ 3

IMPORTANT NOTICE: PLEASE READ .................................................................................. 3

WARNING! Please read and follow these instructions to avoid personal injury or death:.......4

™

Tire Pressure Monitoring System by Bendix CVS...................................................... 3

Section A: System Overview .............................................................................7

1.0 System Overview................................................................................................................... 8

1.1 System Components.......................................................................................................... 8

1.2 Maintenance Tools............................................................................................................. 9

1.3 How Does The SmarTire™ TPMS System Work?............................................................ 10

1.4 Why is Temperature Monitoring Important?.....................................................................10

2.0 Tire Maintenance................................................................................................................. 13

Section B: System Programming....................................................................14

3.0 Configuring & Customizing Your SmarTire™ System .......................................................... 16

3.1 Pre-Configured Settings................................................................................................... 16

3.2 SmarTire™ Sensor Learn Instructions.............................................................................. 16

Section C: SmarTire™ Display Operation........................................................23

4.0 Display Overview: Alerts..................................................................................................... 24

4.1 Power, Mounting, and Environmental Requirements....................................................... 24

4.2 J1939 Connector Pin Descriptions................................................................................... 24

5.0 Using SmarTire™ TPMS....................................................................................................... 25

5.1 Getting Started................................................................................................................. 25

5.2 Checking Tire Temperature, Pressure, and Pressure Deviation ..................................... 25

5.3 Audible and Visual Alerts ................................................................................................. 26

5.4 Reacting to Audible and Visual Alerts.............................................................................. 28

5.5 Diagnostic Trouble Code Message Overview.................................................................. 29

5.6 Setup Mode – For Use When SmarTire™ Diagnostics Software Is Not Available........... 30

Section D: System Installation - Electrical .....................................................39

6.0 System Installation: Electrical.............................................................................................. 40

6.1 Tools Required................................................................................................................. 40

6.2 Getting Started................................................................................................................. 40

6.3 Step 1: Installing the Receiver and Display...................................................................... 43

6.4 Step 2: Assembling and Installing the Antenna(s)........................................................... 47

6.5 Wireless Gateway Receiver Specifications...................................................................... 50

6.6 SmarTire™ Display Specifications.................................................................................... 51

6.7 Vehicle Wiring Harness: Light.......................................................................................... 53

6.8 Wiring Harness: Trailer.....................................................................................................54

Section E: System Installation – Tire Sensors...............................................55

7.0 System Installation: Tire Sensors ........................................................................................ 56

7.1 Sensor Overview.............................................................................................................. 56

IMPORTANT NOTICE: PLEASE READ ................................................................................ 56

7.2 Tools Required................................................................................................................. 57

7.3 Tire Sensor Installation..................................................................................................... 57

7.4 Re-Mounting Tires After a Sensor has been Installed..................................................... 58

7.5 Removing a Tire That Has a SmarTire™ Sensor Installed............................................... 61

7.6 Tire Sensor Specifications................................................................................................ 62

5

Page 6

Section F: Troubleshooting .............................................................................63

8.0 Troubleshooting Guide......................................................................................................... 64

8.1 SmarTire™ Gauge Display Q&A....................................................................................... 64

8.2 SmarTire™ Receiver Q&A ................................................................................................ 66

8.3 SmarTire™ System Q&A................................................................................................... 68

8.4 Diagnosing a Defective, Missing, or Misplaced sensor.................................................... 72

8.5 SmarTire™ Hand Tool Troubleshooting............................................................................ 73

8.6 Quick Reference Guide to SmarTire™ System Troubleshooting...................................... 74

Appendix 1: Replacement Parts......................................................................75

9.0 Replacement Parts .............................................................................................................. 76

Appendix 2: System Scope of Use & Alerts ...................................................77

10.0 System Scope of Use and Alerts....................................................................................... 78

10.1 System Installation and Usage....................................................................................... 78

10.2 Use of Chemicals...........................................................................................................78

10.3 Reacting to Alerts........................................................................................................... 78

10.4 FCC Notice.....................................................................................................................78

6

Page 7

S E C T I O N

SmarTire™ Tire Pressure Monitoring System

by Bendix CVS

Section A: System Overview

7

Page 8

1.0 SYSTEM OVERVIEW

1.1 SYSTEM COMPONENTS

The Wireless Gateway Receiver forms the "brain" of the

SmarTire

™

platform. The receiver captures data transmissions

from tire sensors mounted on each wheel which is then analyzed

against programmed user-defined settings and, if it determines

that a tire is under-inflated or running over temperature, an alert is

triggered. Robust and weatherproof in design, the Wireless

Gateway Receiver can be conveniently mounted directly to the

vehicle's chassis. It also interfaces with the vehicle's J1939

network for seamless integration.

Real-time tire pressure and temperature information is available to

the driver on demand via the SmarTire

™

display. If the system

detects a tire that is under-inflated or overly hot, the display will

alert the driver to the condition before it becomes dangerous.

Industrially designed for the harsh environment of a commercial

truck tire, the tire sensor measures internal tire pressure and

temperature every 12 seconds and transmits data every three to

five minutes. If the system detects a pressure change of 3 PSI

(0.206 bar) or greater, it breaks its regular schedule and transmits

data immediately. Each tire sensor is mounted in a break away

cradle so that in the event of in-field damage, the sensor remains

unbroken.

Tire sensors are mounted to the surface of the rim using a

stainless steel strap. Installed by Bendix on hundreds of

thousands of wheels world wide, strap mounting is the most

reliable and universal method of sensor installation available.

Wireless signals from tires on the front axle are captured by the

wireless gateway directly. Signals from the rear axles and the

trailer are captured by an antenna mounted at the rear of the

vehicle. An external antenna ensures signal reception reliability so

that SmarTire

™

TPMS always has up-to-date tire status

information accessible at the push of a button.

When a tire problem occurs on a towed trailer, the trailer lamp will

clearly indicate it to the driver. The lamp illuminates at the first

sign of trouble, as well as flashes to indicate the type of problem

found.

8

Page 9

1.2 MAINTENANCE TOOLS

Maintaining tires in the yard is just as important as real-time tire

information for the driver, but most TPMS systems don't take

maintenance personnel into account. The SmarTire

tool acts like an 'electronic billy-club' allowing maintenance personnel to

wirelessly 'ping' a tire to measure its pressure and temperature. The

SmarTire

diagnostic time in order to keep every tire rolling safely and cost

effectively. (Maintenance Tool comes with a separate manual).

The LF Tool allows the user to wirelessly 'ping' a tire and can be used

instead of a Hand Tool to add tires to the system configuration, either

during the initial setup or when tires are changed.

™

universal hand

™

hand tool improves inflation accuracy and reduces

9

Page 10

1.3 HOW DOES THE SMARTIRE

™

TPMS SYSTEM WORK?

1. The SmarTire

™

Wireless Gateway receiver creates a wireless bubble around a vehicle

allowing various sensing technologies to seamlessly interact.

2. Tire sensors mounted on each wheel measure tire pressure and temperature every 12

seconds and wirelessly transmit tire data every three to five minutes.

3. Industrially designed for the rugged requirements of a commercial vehicle chassis, the

wireless gateway can monitor up to 20 wheel positions and is able to handle the most

complex commercial and off-highway vehicle configurations.

4. Real-time tire pressure and temperature information is available to the driver on demand

via the SmarTire

simple to use interactive gauge that provides real-time tire status information, the

SmarTire

™

™

display. Ranging from a simple illuminated light to an easy to read and

display will alert the driver to a low pressure or high temperature condition

before it becomes dangerous.

5. Trailer tires can also be monitored using a stand-alone system and/or trailer lamp.

6. The SmarTire

maintenance personnel to wirelessly ‘ping’ a tire to measure its real-time tire pressure.

The SmarTire

™

universal hand tool acts like an ‘electronic billy-club’ allowing

™

maintenance hand tool improves inflation accuracy and reduces

diagnostic time in order to keep every tire rolling cost effectively.

1.4 WHY IS TEMPERATURE MONITORING IMPORTANT?

THE PRESSURE TEMPERATURE RELATIONSHIP

Tire manufacturers specify that tire pressures should be checked and adjusted when a tire is

“cold”, but most people may not know why, or even what a “cold tire” is. The temperature of a tire

actually has a significant impact on its inflation pressure.

According to tire manufacturers, a tire is considered to be “cold” when its temperature is 65°F

(18°C). The inflation values provided by vehicle manufacturers, fleet maintenance personnel or

industry published load inflation tables are called ‘Cold Inflation Pressures’ (CIP) because they

represent the correct amount of pressure a tire should be inflated to when it is “cold”. The reason

that tires have cold inflation pressures set at specific temperatures is because a tire’s pressure

will change relative to its temperature.

Air naturally expands when heated and contracts when cooled. Inside a contained vessel such as

a tire, this expansion and contraction causes a change in contained air pressure. As a tire heats

up, its pressure will naturally increase and as it cools down, its pressure will naturally decrease.

10

Page 11

For example, a tire inflated to a CIP of 105 PSI at 65°F will increase in pressure to 125 PSI at

152°F and decrease in pressure to 97 PSI at 32°F. The SmarTire

™

tire monitoring system

considers these changes in temperature and pressure as part of normal operation and adapts

accordingly to provide more accurate information while helping to prevent false alerts.

Tire manufacturers never recommend inflating a tire to less than the specified cold inflation

pressure. In extreme cases, the beads of a commercial tire can unseat if its pressure gets too low

resulting in a catastrophic tire failure.

Always refer to the vehicle manufacturer’s recommendations for minimum cold inflation

pressures.

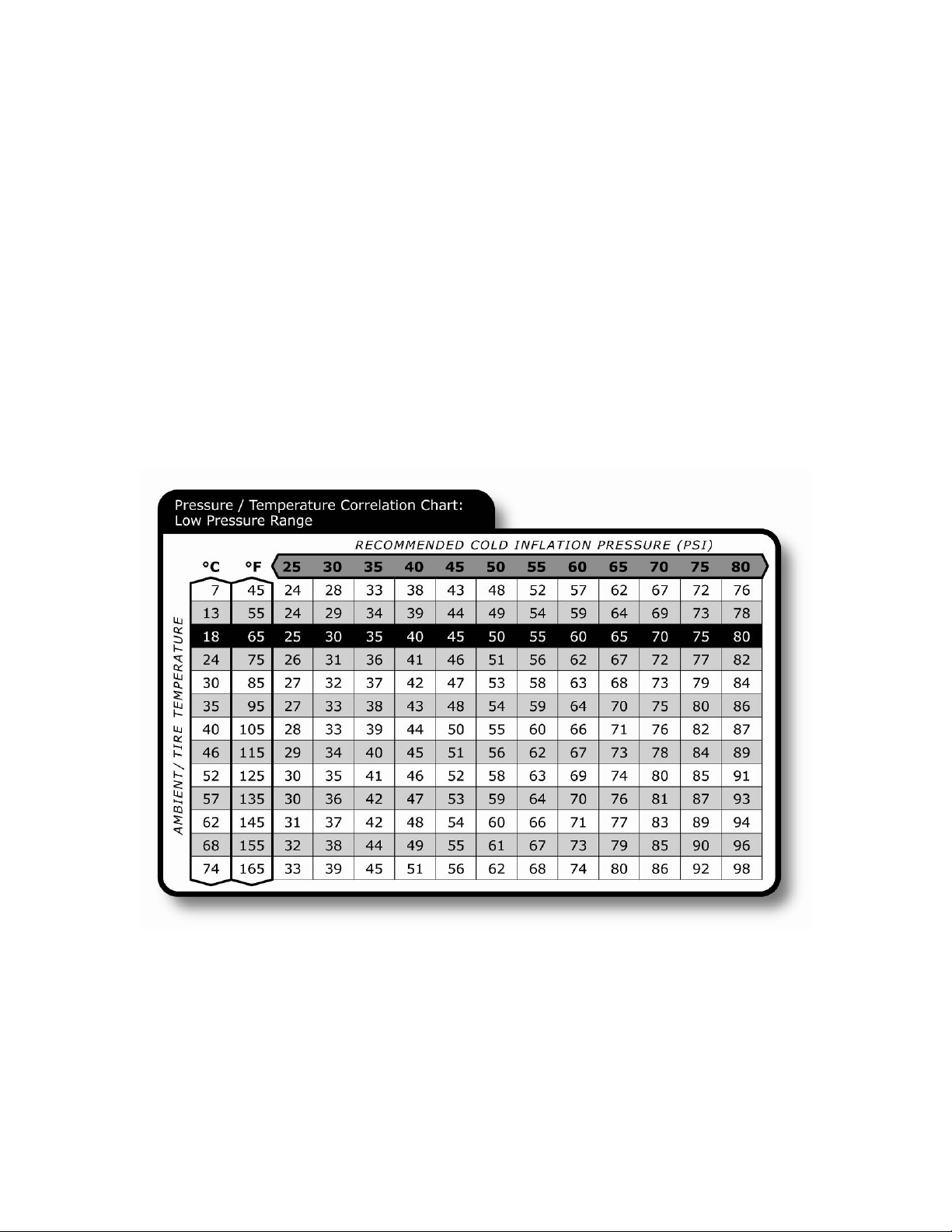

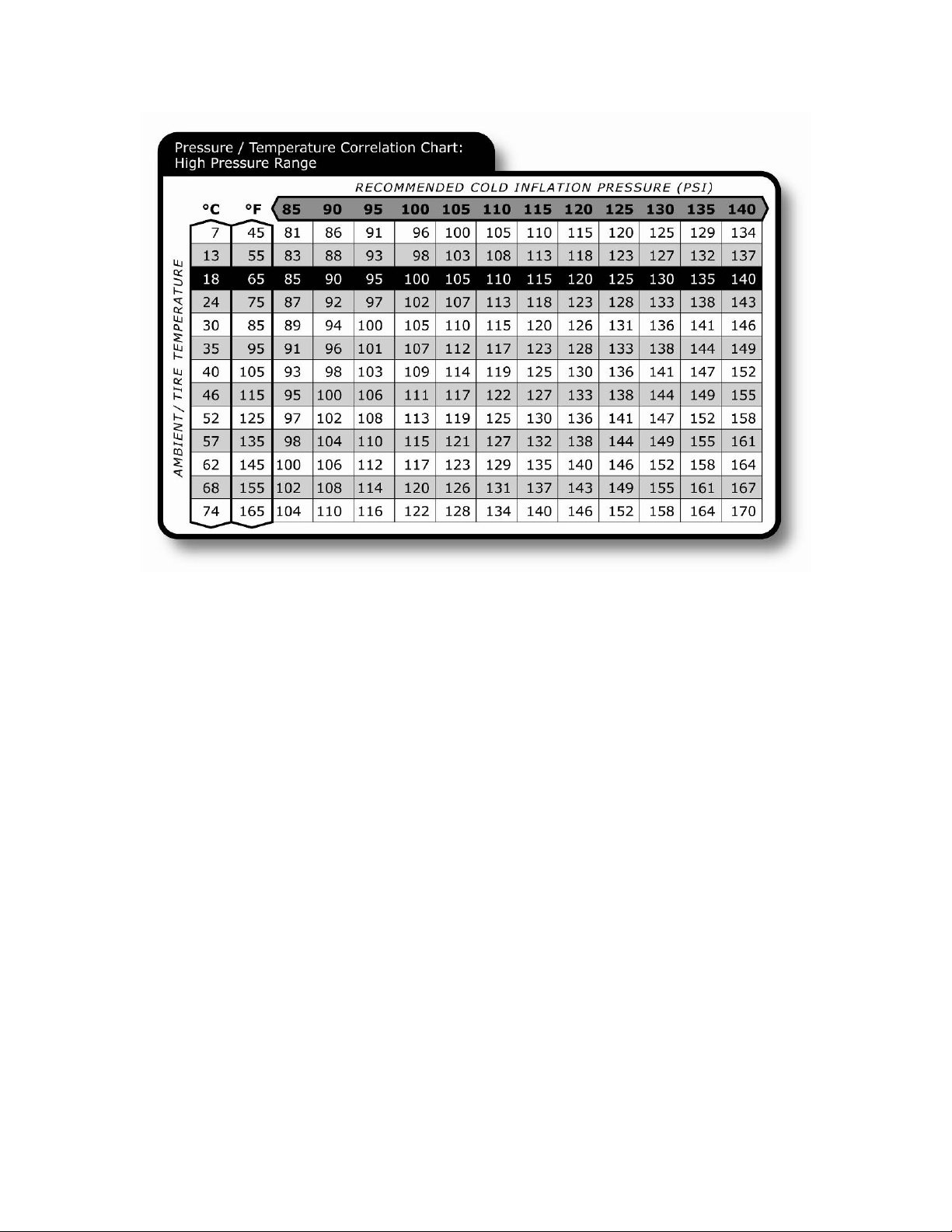

The charts below illustrate the equivalent inflation values for a series of cold inflation pressures at

various temperatures. The temperature values represent the temperature of the air contained

inside the tire. This temperature can be estimated for a cold tire using the outside, ambient

temperature.

11

Page 12

The charts above are to be used as a guide only. Always refer to the tire / v ehicle

manufacturer’s recommendations for minimum cold inflation pressures.

Thermal Equilibrium

As a vehicle moves, its tires naturally heat up due to friction from the road and the flexing of its

side-walls. Weight, vehicle speed and a tire’s starting inflation pressure all have an impact on how

much and how quickly heat is generated.

As the tire generates heat, its pressure increases, causing a reduction in side-wall flexing. Less

side-wall flexing and road resistance combined with air rushing past the tire as the vehicle moves

effectively counteracts the conditions that cause the tire to heat up. As a result, the temperature

increase tapers off until the tire reaches a point of balance called Thermal Equilibrium.

Tire “Thermal Equilibrium” is the point where the heat being generated is equal to the heat being

dissipated. Tires are designed with the principles of temperature and pressure in mind in order for

them to achieve Thermal Equilibrium. Once a properly inflated tire reaches Thermal Equilibrium, it

will operate at its peak; providing the best performance, handling, tire life and fuel economy.

SmarTire

™

TPMS Temperature Compensation

Since a tire’s contained air pressure naturally increases as a vehicle moves, it can be difficult to

tell if a hot tire is under-inflated. Without some form of temperature compensation, a hot tire that

is under-inflated might appear to be fine because its contained air pressure is at or above its cold

inflation pressure (CIP).

For example, a tire correctly inflated to a CIP of 105 PSI at 65°F will reach thermal equilibrium

when its temperature increases to 152°F and its pressure increases to 125 PSI. A tire starting at

95 PSI at 65°F (10 PSI under inflated) would have to reach 202°F for it to reach thermal

12

Page 13

equilibrium (125 PSI). The tire will then be running 50°F hotter than it should be, causing more

tire wear and the potential for a catastrophic failure or tire fire.

When checked using a handheld gauge or a tire monitoring system that does not measure

operating temperature, this 10 PSI under-inflated tire can appear to be normal. When equipped

with tire sensors that mount inside the tire, SmarTire

™

TPMS measures both tire pressure and

temperature in order to provide “Temperature Compensated” pressure deviation values and

alerts. By measuring the operating temperature of a tire and comparing it to the cold inflation

pressure (CIP) value programmed into the system, the SmarTire

™

system will know what a tire’s

pressure is supposed to be in relation to its operating temperature.

The system is able to warn the driver of an under-inflated tire even if that tire’s actual contained

air pressure is at or above its CIP.

The advantages of temperature compensation are even more dramatic when a tire has a slow

leak. A tire that is constantly losing pressure will not be able to reach thermal equilibrium because

the contained air simply can not expand enough to generate the required pressure, regardless of

how hot the tire becomes. Since the leak is slow, the tire may appear over an extended period of

time to be properly inflated when it is actually dangerously under-inflated and operating well

above its temperature capacity.

As air leaks from the tire, increased side-wall flexing and rolling resistance cause the tire’s

temperature and pressure to increase. The pressure increase will soon plateau and begin to

slowly decrease while the tire’s temperature continues to increase. Eventually, the tire will

become so hot that its structure will degrade and then fail in the form of a blow-out and / or tire

fire.

2.0 TIRE MAINTENANCE

Proper tire maintenance is critically important for keeping tires rolling smoothly. When properly

maintained and inflated, tires will provide shorter stopping distances, better vehicle handling in

emergency situations and better fuel economy.

Maintenance Tips for Long Tire Life:

Keep tires properly inflated at all times.

Visually inspect tires for injuries prior to each trip.

Match dual tires for size and keep pressures within 5 PSI (0.344 bar).

Re-tread tire before wear causes excessive belt damage or fatigue.

13

Page 14

S E C T I O N

SmarTire™ Tire Pressure Monitoring System

by Bendix CVS

Section B: System Programming

14

Page 15

IMPORTANT

READ THESE INSTRUCTIONS PRIOR TO INSTALLATION

This SmarTire

Sensors have been PRE-ASSIGNED TO WHEEL POSITIONS and are identified on each

Default values have been assigned to each axle for the following:

™

kit is pre-programmed and ready to use, subject to your application:

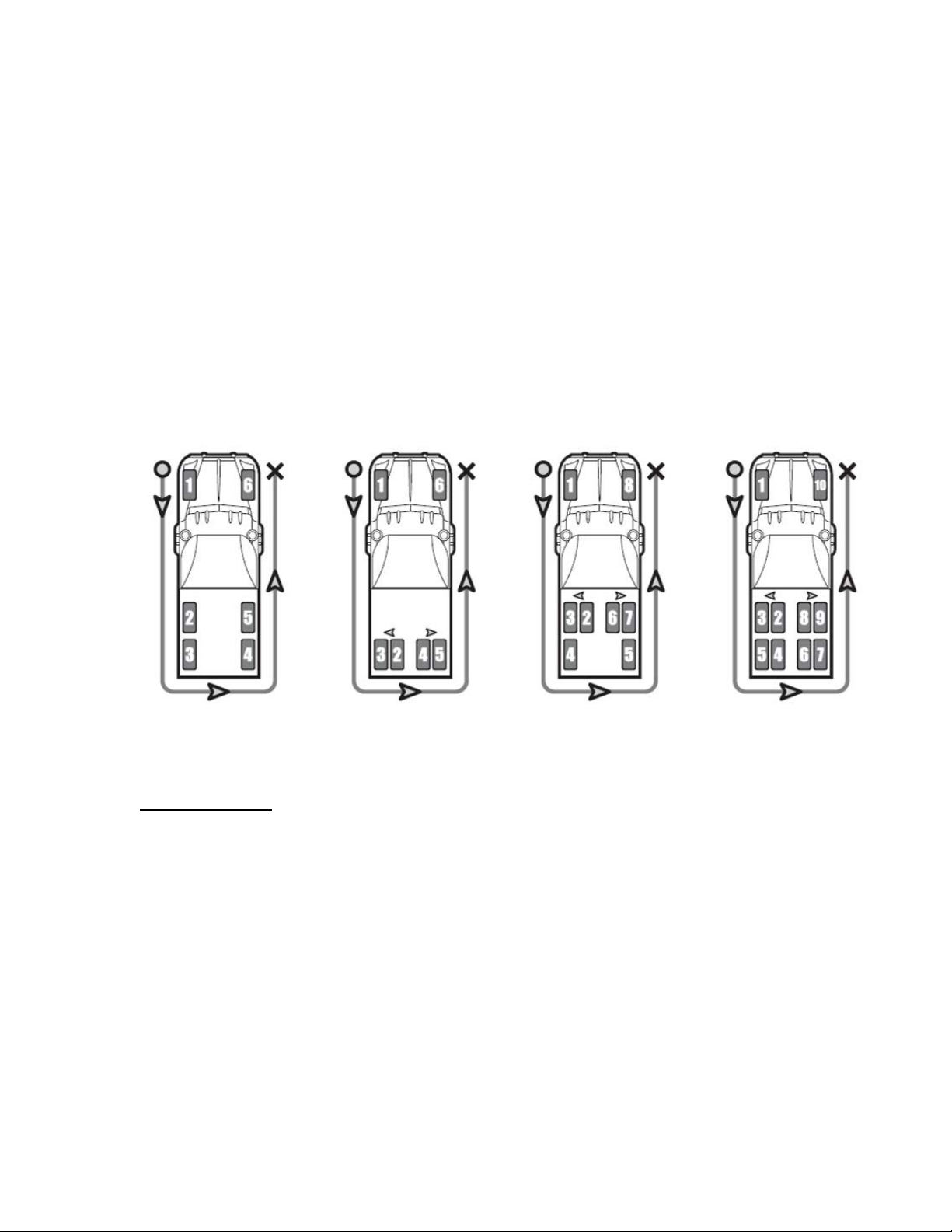

unit with a position label (P1, P2, P3, etc.) – install the sensors as per the diagram below.

o Cold Inflation Pressure (CIP) – 100 PSI

o First Alert Level (FAL) – set to a deviation of ±15% from CIP

o Second Alert Level (SAL) – set to -20% from CIP

o High temperature alert (optional) – ITEC specific kits set to OFF, all other kits

set to 85°C

Installation steps:

1. Install the receiver, display, antenna and harnesses on the vehicle, following the

instructions in “Section D – Installation Electrical” section of the SmarTire

2. Install the sensors in the pre-programmed locations as above, following the instructions in

“Section E – Installation Tire Sensors” section of the SmarTire

3. Adjust any system parameters as required, following “Section B – System

Programming” section of the SmarTire

™

manual.

™

manual.

™

manual.

15

Page 16

3.0 CONFIGURING & CUSTOMIZING YOUR SMARTIRE™ SYSTEM

During the installation process, the default settings for SmarTire

the vehicle by the installer. At any time, alert thresholds can be made more or less sensitive and

system settings can be adjusted to accommodate vehicle changes and use.

Replacing vehicle tires or installing the system on a new vehicle may also require adjustment of

pre-configured settings. The following section describes how to adjust the pre-configured settings

of your SmarTire

™

TPMS.

3.1 PRE-CONFIGURED SETTINGS

Generally, the SmarTire

™

TPMS is pre-configured with the default settings listed below.

Depending on your vehicle, your system may have a different initial setup.

Cold Inflation Pressure (CIP):

o 6-Wheel (4x2 Configuration)

Steer Axle: 100 PSI (6.89 bar)

Drive Axle: 100 PSI (6.89 bar)

o 10-Wheel or 6-Wheel with Super Singles

Steer Axle: 100 PSI (6.89 bar)

Drive Axle: 100 PSI (6.89 bar)

First Alert Level (FAL) Pressure Deviation Alert: CIP +/- 15%

Second Alert Level (SAL) Critical Low Pressure Alert: CIP -20%

High Temperature Alert: 185°F (85°C)

Default cold inflation pressure settings should always be customized to the vehicle. Check the

vehicle’s owner’s manual, placard or the industry published load inflation table to determine the

recommended cold inflation pressure settings. Bendix recommends setting the Second Alert

Level (SAL) critical low pressure alert at 20% below the recommended cold inflation pressure for

your vehicle. Bendix also does not recommend changing the First Alert Level (FAL) pressure

deviation alert setting.

3.2 SMARTIRE

™

SENSOR LEARN INSTRUCTIONS

This section contains the instructions to program vehicle sensors into the SmarTire

using the SmarTire

™

Diagnostic Tool software.

3.2.1 Equipment

Hardware

On-Vehicle J1939 Diagnostic Port

J1939 CAN Adaptor (e.g. Vansco DLA, USBLink)

SmarTire

J1939 Wireless Gateway Receiver

(Optional) LF Initiator; SmarTire

™

Vehicle Harness

™

Maintenance Hand Tool; or SmarTire™ LF Tool

Software

SmarTire

™

Diagnostic Software (Version 1.0.25 or higher – download at

http://www.smartire.com/support/manuals)

PC with Microsoft Windows XP

™

TPMS should be customized to

™

system

16

Page 17

3.2.2 Communications Setup

To setup communications over J1939:

1. Connect the Gateway connector on the SmarTire

™

harness to the vehicle’s Gateway.

2. Connect the J1939 Diagnostic port of the harness to your PC-to-CAN adaptor (i.e.

RP1210A).

3. Connect the harness’ VIN1 and GND1 wires to 12-24VDC.

4. Apply power to the hardware.

5. Run SmarTire

™

Diagnostic Tool.exe on your PC.

6. Select your J1939 Adaptor on the menu bar. If it doesn’t appear in the Adaptor dropdown list, ensure you have the appropriate drivers installed on your computer.

7. Click ‘Connect J1939’ to start the interface communicating over J1939.

17

Page 18

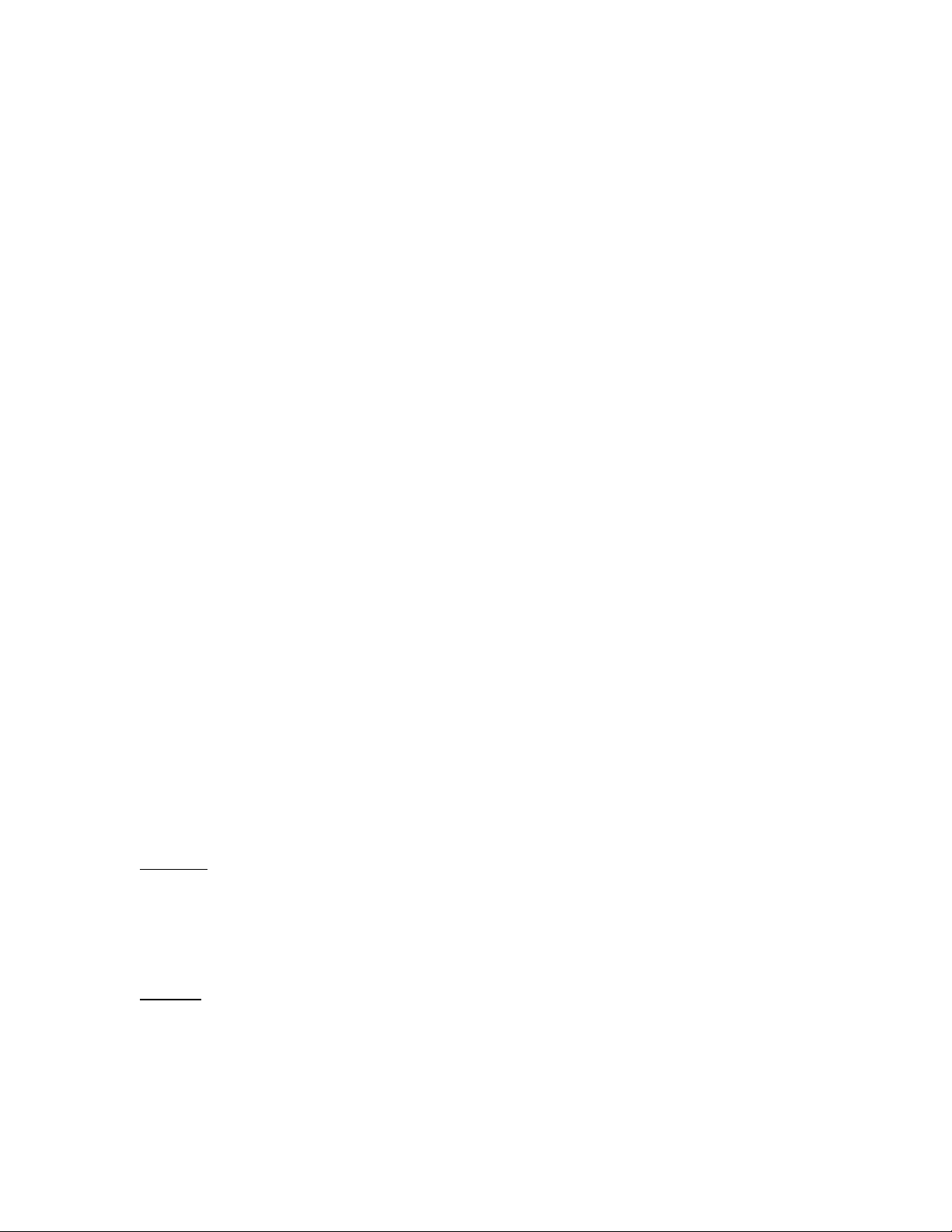

8. If the adaptor is correctly installed and identified, the TPM system details will be filled in

at the bottom of the screen with information from the SmarTire

™

Wireless Gateway.

3.2.3 Configuring Your Vehicle

There are two steps to having the Gateway Receiver learn your vehicle’s configuration:

1. Axle/Tire configuration

2. Sensor Programming

Axle/Tire Configuration

During this step, we must tell the Gateway Receiver how many tires there are on the vehicle and

their locations. Also, we will program the Cold Inflation Pressures (CIP) and Alert Levels. The

alert levels can be changed at anytime later without affecting the vehicle layout, but it is best to

put a default value in at this time.

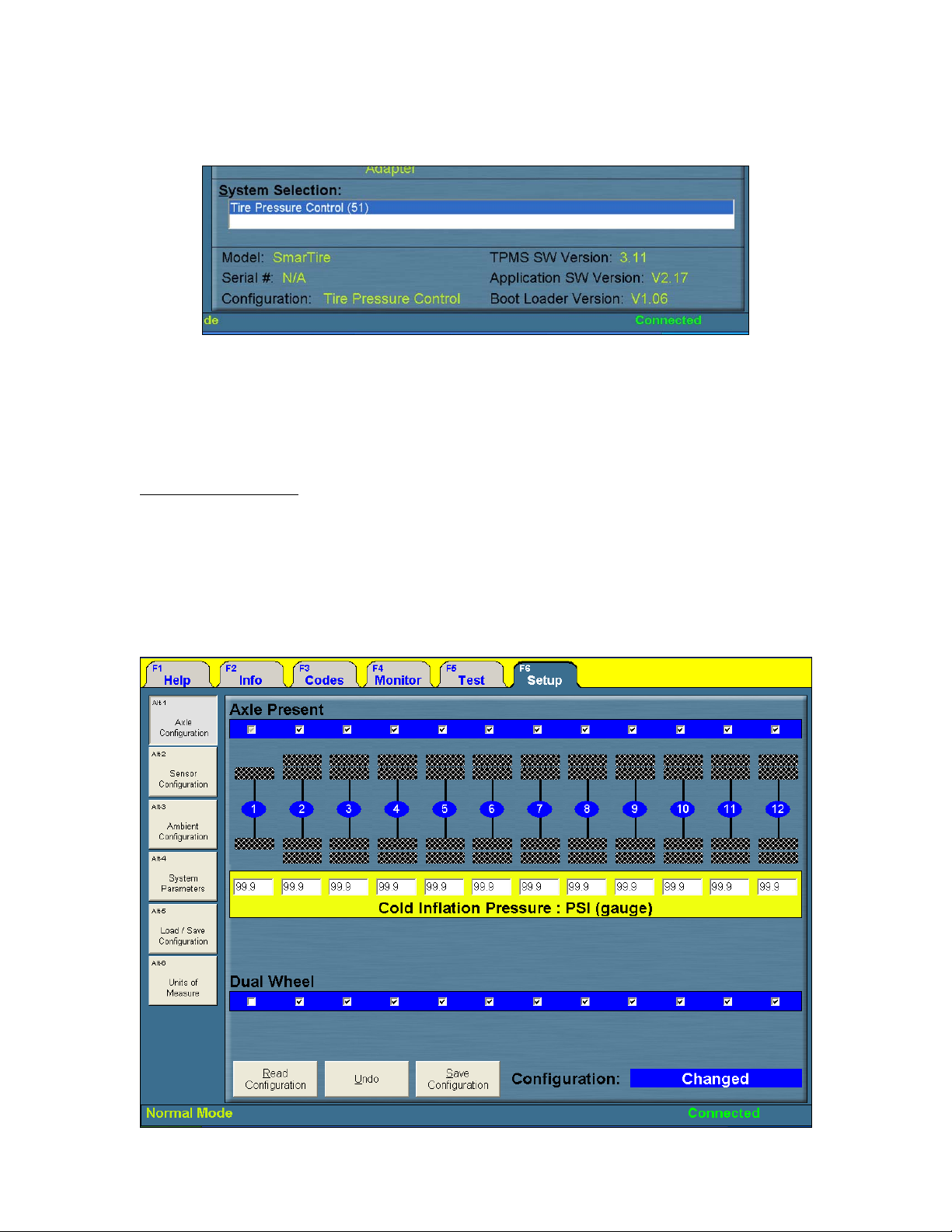

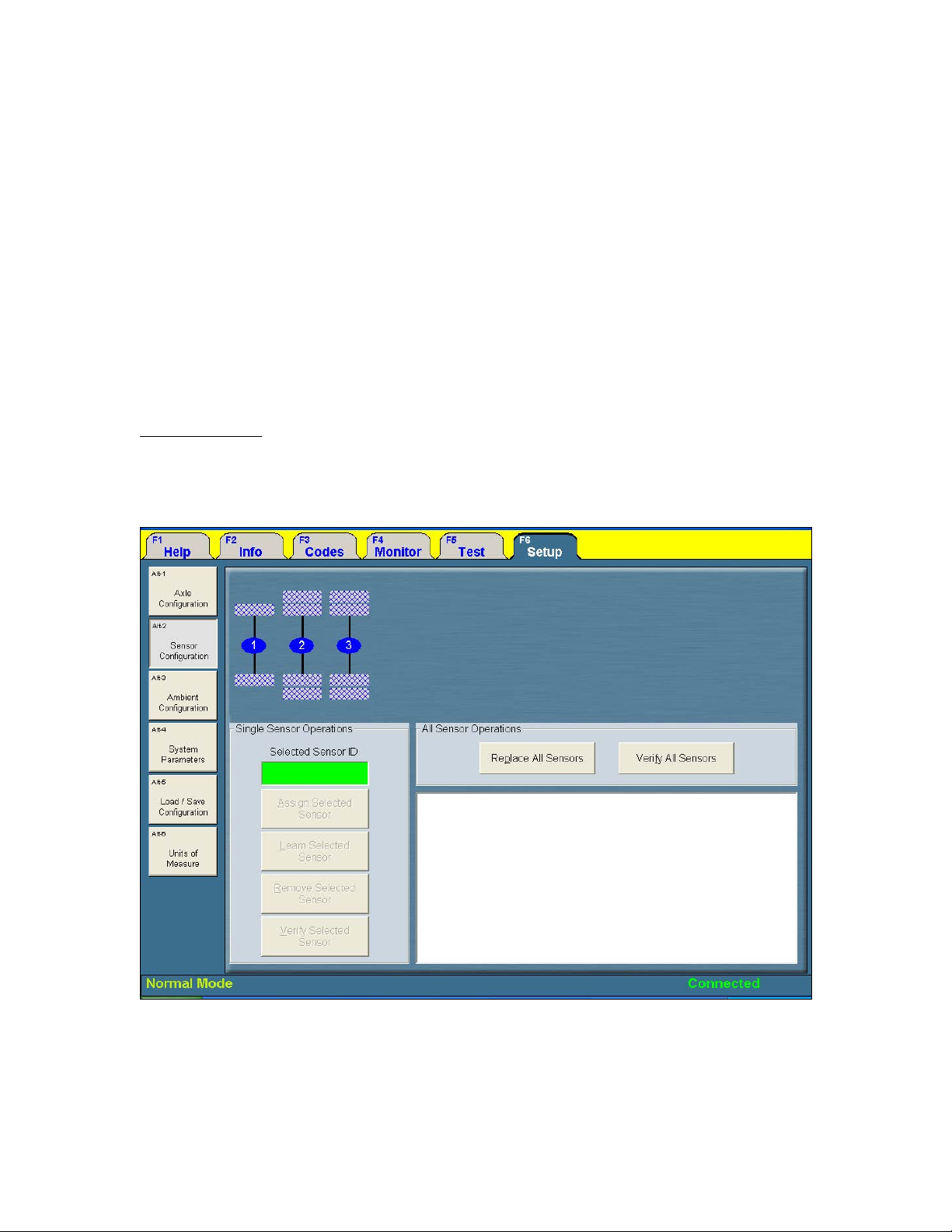

1. With the SmarTire

™

Diagnostic Tool setup and running, click on the Setup tab (or press

the F6 key).

18

Page 19

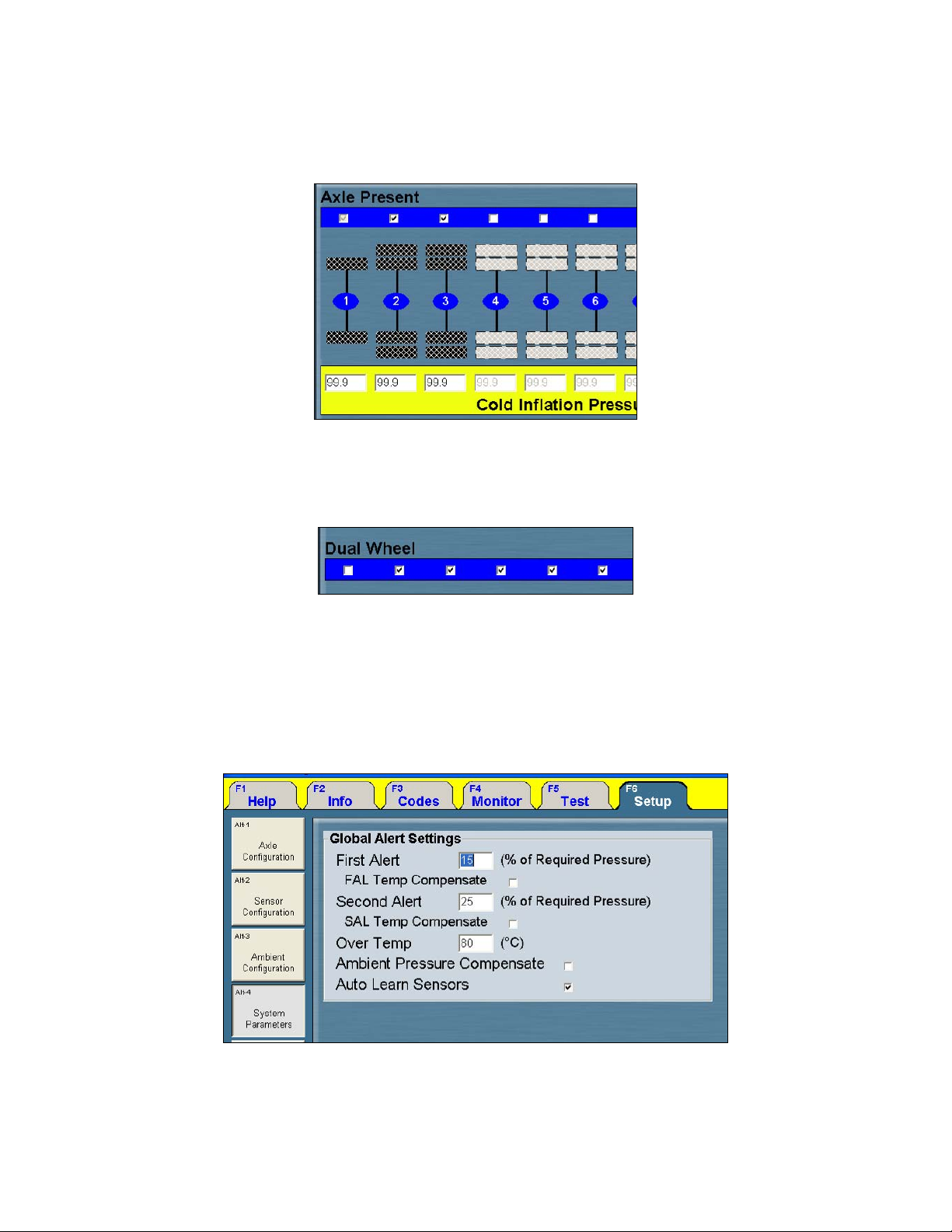

2. To specify how many axles are present on the vehicle, click on the check mark after the

last axle on your vehicle. Darkened axles and tires are active and can be programmed.

Grayed out axles and tires are disabled.

3. Next, ensure that all active axles have the correct number of tires assigned. Use the

‘Dual Wheel’ check box under each axle to configure this. Note: Steps two and three

must be carried out each time the software is restarted, regardless of the saved

configuration in the receiver.

4. When you’ve completed setting up the vehicle’s axles, adjust the CIP values for each

axle. If you would like to change the units being displayed, click the ‘Units of Measure’

button on the left side of the window (or press ALT-6).

5. Now we will check the Alert levels to ensure they are the right values for your system.

Click the ‘System Parameters’ button (or press ALT-4). Bendix recommends that you

use the default values that came programmed with the Wireless Gateway, but you can

change them here if desired.

6. Click the Axle Configuration button (or press ALT-1) to return to the Axle Configuration

screen.

19

Page 20

7. To save the settings you’ve entered into the Wireless Gateway Receiver, click ‘Save

Configuration’ on the Axle Configuration screen.

To save the settings for use on another vehicle, click the ‘Load/Save Configuration’ button (or

press ALT-5). On this screen, click ‘Save Configuration’ and choose the filename and location to

save this file. Included in the saved file is:

Axle layout

Axle CIP levels

Alert Levels

All Sensor IDs

Once you’ve saved a configuration, when you start the Diagnostic Tool the next time, you must

simply go to the ‘Load/Save Configuration’ screen and click ‘Load Configuration’ to restore the

complete profile you were working on previously. You can then proceed to programming the

sensors into the new Gateway Receiver.

Learning Sensors

After setting up or loading a profile, you can begin programming sensors into the Gateway.

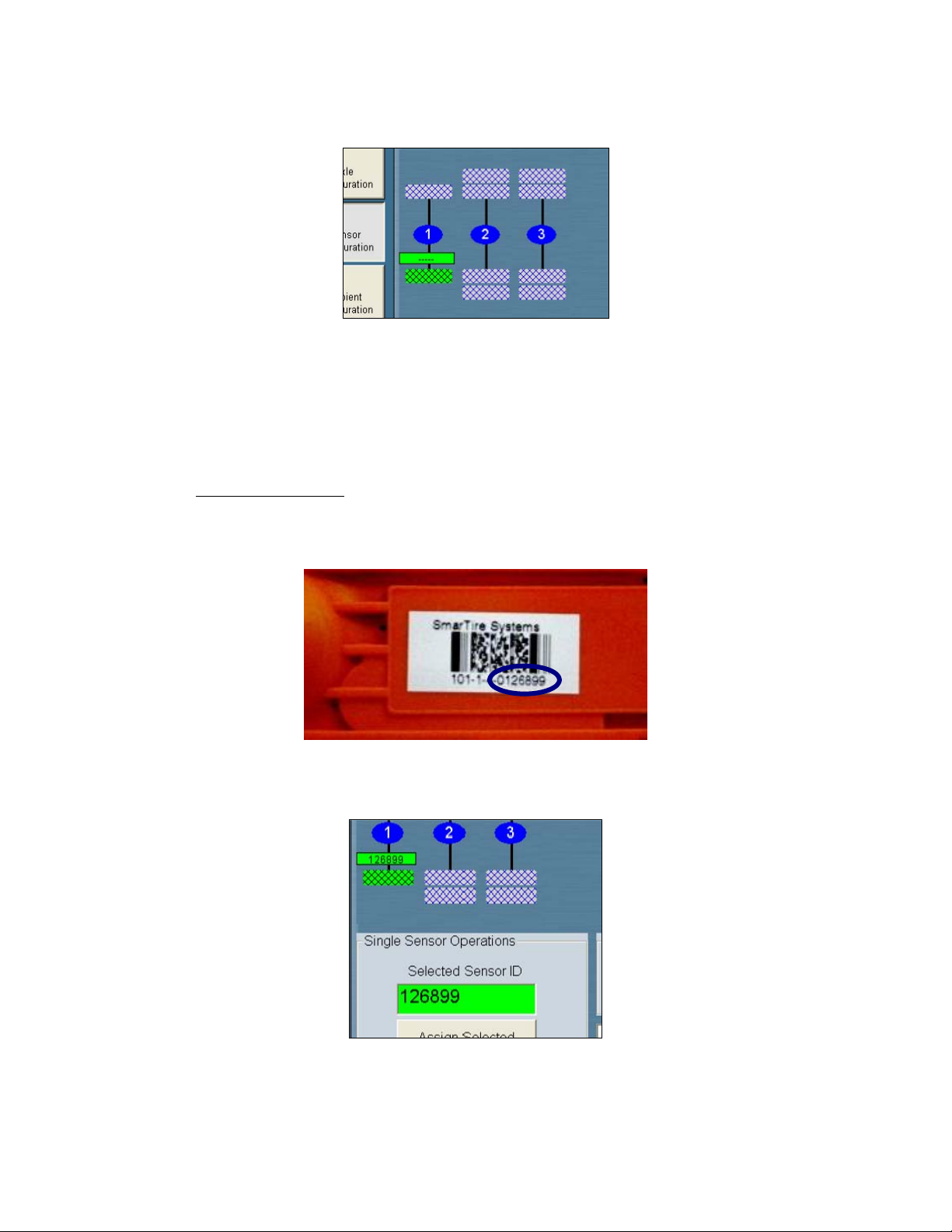

1. On the Setup tab, select the ‘Sensor Configuration’ button.

20

Page 21

2. Select the tire you wish to program.

3. Each sensor has a unique ID that the Gateway Receiver uses to identify it. You can

either enter this ID into the Gateway Receiver manually, or trigger the sensor to identify

itself and have the Gateway Receiver automatically learn it.

Having the Gateway Receiver identify the sensor is a slower method than manually

entering the ID, but it is particularly useful if a sensor has already been installed in a tire.

Manual Sensor Learn

a. To do a manual sensor learn enter the ID of the sensor into the green dashed

text box. The ID for the sensor is the 7 digit code on the top label of the sensor

(i.e. 101-1-4-#######).

b. Now click ‘Assign Selected Sensor’. The sensor ID will then appear on the tire

map.

21

Page 22

Gateway Sensor Learn

a. To have the Gateway Receiver detect a sensor’s ID, click the ‘Learn Selected

Sensor’ button in the SmarTire

™

Diagnostics Software.

b. You now need to trigger a Learn transmission from the tire within the next two

minutes (or press ESC to cancel). This can be done using the LF Initiator Tool,

LF Tool, or Maintenance Hand Tool.

Press the Learn button with the device in the appropriate position shown below.

Check the manual for the tool you are using to select the Learn function.

c. Once triggered, it can take up to 30 seconds for the Gateway to receive the

transmission and complete the learn process. When successful, the sensor icon

in the tire map will turn green and the detected ID will be displayed.

4. Perform the above steps for each sensor on the tire map.

5. Sensor programming is now complete and the sensors are stored on the Gateway

receiver.

22

Page 23

S E C T I O N

SmarTire™ Tire Pressure Monitoring System

by Bendix CVS

™

Section C: SmarTire

Display Operation

23

Page 24

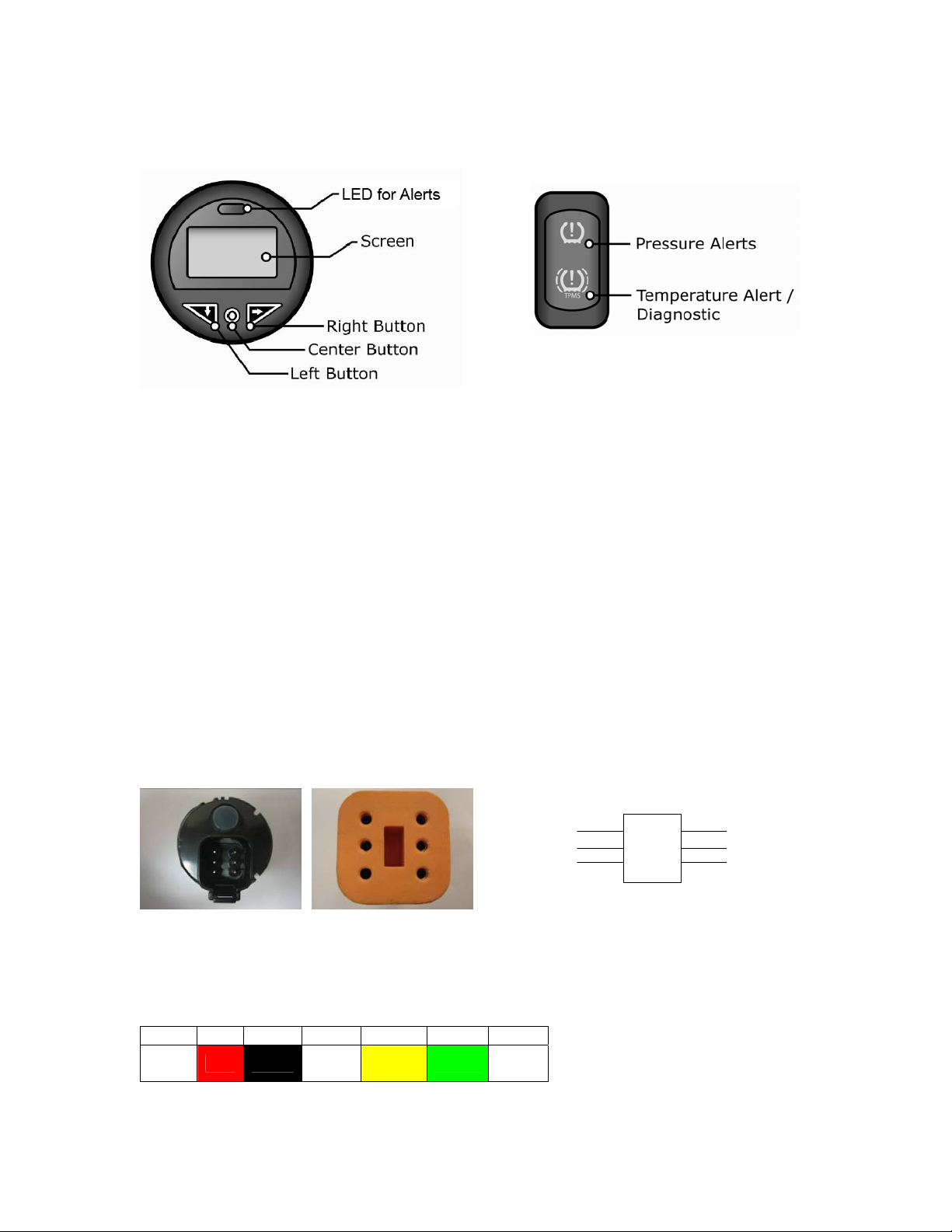

4.0 DISPLAY OVERVIEW: ALERTS

SMARTIRE

™

Display Dual Light Display

Note: If you are using a 3

rd

party display to view SmarTire™ information, please refer to the

respective user manual or contact your vehicle vendor for instructions.

4.1 POWER, MOUNTING, AND ENVIRONMENTAL REQUIREMENTS

Operating voltage range 8.5 – 36V

Typical current consumption (with no external loads) 30mA

Connector type: 1062-16-0122-Deutsch

Lock: W6S-Deutsch

Plugs: DT06-6S-Deutsch

SAE J1939 protocol compliant, 250 kbps

Overall depth of unit (back of bezel to the end of the connector): 2.55 in.

Bezel thickness: 0.240 in (6.069 mm).

Bezel diameter: 2.29 in (58.166 mm).

Panel Cutout: Std SAE 2 in. gauge panel cutout

Mounting (clamp ring and wave spring): 0.050 to 0.130 in (1.27 mm to 3.302 mm).

4.2 J1939 CONNECTOR PIN DESCRIPTIONS

(Buzzer) Output

CAN - L

CAN - H

Check the back of the 6-pin Deutsch connector for numbering.

Line Colors versus Pin Numbers for Standard SmarTire

™

Harnesses (White wires are

labeled for Display connector):

Pin 1 2 3 4 5 6

Line

Color

Red Black White Yellow Green White

6 1

5 2

4 3

Vin

GND

Backlight

24

Page 25

5.0 USING SMARTIRE™ TPMS

5.1 GETTING STARTED

When the vehicle’s ignition switch is turned on, the SmarTire

™

system will power up and the

display will indicate that the system is Initializing. During initialization, the display receives vehicle

configuration data and tire pressure/temperature parameters from the receiver. After

approximately 10 seconds, the display will show the “TPMS Ready” screen indicating that the

system is ready to receive tire data from the sensors. When showing the TPMS Ready screen,

the display will show TPMS Ready and a tire icon. If a Dual Light Display or Trailer Lamp is

installed, they will flash once as the SmarTire

™

system is powered up to indicate their TMPS

Ready status.

4.1

When the vehicle is driven over 14 mph (24 km/h), the tire sensors will activate and SmarTire

TPMS will begin to receive tire data. While the vehicle is in motion, the sensors will measure tire

pressure and temperature every 12 seconds and transmit tire data approximately every 3 - 5

minutes.

If an Alert icon (triangle with an exclamation mark) is displayed on

the TPMS Ready screen, a tire pressure or temperature condition

has been detected and should be investigated / corrected before the

vehicle is driven. Bendix recommends that tire pressure and

temperature conditions always be corrected before a vehicle is

driven to ensure the safety of the driver, vehicle and cargo.

If the TPMS ready screen shows an alert icon but no tire icon, the

display has not received any tire programming information from the

receiver.

NOTE: Standard tire sensors transmit data once every 15

minutes while stationary. They contain a motion switch and will send data regularly once

the vehicle reaches a speed of approximately 14 mph (22 km/h).

5.2 CHECKING TIRE TEMPERATURE, PRESSURE, AND PRESSURE DEVIATION

At the push of a button, SmarTire

™

TPMS will provide the driver with real-time tire pressure and

temperature information for each tire on their vehicle. Please check tires only when the vehicle is

stopped and in a safe location. Never check tire status when the vehicle is in motion and the

driver’s attention is on the road.

SmarTire

™

TPMS displays tire status information by axle using various axle screens. Each axle

programmed in the display has a corresponding axle screen. The diagram on the next page

outlines the different screen elements of the axle screens.

™

25

Page 26

To check your tire pressure, temperature, and pressure deviation:

1. Starting from the TPMS Ready screen, press the right button once and the display will

show the first axle screen starting at the front of the vehicle with one tire position

highlighted. The pressure, temperature and pressure deviation information displayed is

for the selected tire.

2. To move to the next wheel on the vehicle, press the right button once. The next tire in

sequence will be highlighted and its pressure, temperature and pressure deviation

reading will be displayed. Each time the right button is pushed, the next tire in sequence

will be selected and its information displayed. Pressing the right button when the last tire

on the axle is selected will re-select the first tire on that axle.

3. To move to the next axle on the vehicle, press the left button once. Once again, pressing

the right button will scroll the display to the next tire on that axle. Each time the left button

is pressed the display will show the next axle on the vehicle. When the left button is

pressed from the last axle screen programmed in the display, the first axle will once again

be shown.

4. Repeat steps 1, 2 and 3 until all desired wheel positions and axles have been checked.

5. To exit back to the “TPMS Ready” screen, press the center button once.

5.3 AUDIBLE AND VISUAL ALERTS

Pressure Deviation Alert

The Pressure Deviation Alert is the first indicator of an underinflated tire. If a tire deviates 10% from its “proper” inflation

pressure, the driver is alerted to the condition by an indicator light

and an audible alarm (optional). SmarTire

™

calculates a tire’s

“proper” inflation pressure by first mathematically calculating the

amount of pressure that is supposed to be in the tire based on its

operating temperature and its cold inflation pressure setting, and

then comparing this calculated value to the actual, measured

pressure value of the tire. The pressure deviation value that is

displayed is the difference between the actual pressure and the

calculated “correct” pressure. This temperature compensation

calculation enables SmarTire

™

TPMS to provide pressure deviation

values and alerts even when a tire is hot.

26

Page 27

The default setting triggers the pressure deviation alert when a tire is 10% under- or over-inflated.

This setting can be customized by the user. The alert can also be customized to be a fixed

pressure alert rather than a temperature compensated alert. The units of measure can also be

customized to PSI, bar, or kPa. The acronym for the Pressure Deviation Alert is FAL for First Alert

Level.

Critical Low Pressure Alert

The Critical Low Pressure Alert is the second indication of an underinflated tire. It alerts the driver when a tire’s pressure falls 20% below

the programmed Cold Inflation Pressure (CIP) value. This visual and

audible (optional) alert is intended to alert the driver to a critical tire

condition in order for them to take immediate precautions.

Unlike the Pressure Deviation Alert, the default setting for the Critical

Low Pressure Alert does not include the temperature compensation

calculation. As such, if a tire’s pressure falls below the default

setting, the tire is critically under-inflated and should be addressed

immediately.

Like the Pressure Deviation Alert, the default settings for the Critical

Low Pressure Alert can be customized by the user. The alert can also be set to be temperature

compensated. The acronym for the Critical Low Pressure Alert is SAL for Second Alert Level.

High Temperature Alert

The High Temperature Alert warns the driver when a tire’s

temperature exceeds 195°F (90°C). High tire temperatures are

typically caused by under-inflation and the SmarTire

™

system will

usually provide a Pressure Deviation Alert and a Critical Low

Pressure Alert well in advance of a High Temperature Alert. If

triggered on its own, the High Temperature Alert can be an indication

of an alternative problem, such as a dragging brake or a bearing

failure. Like the other two alerts, the default High Temperature Alert

setting can be customized by the user. The acronym for the high

temperature alert is Over Temp.

Sensor Diagnostic Trouble Code Alert

A Sensor Diagnostic Trouble Code Alert will be issued for any

programmed sensor that has not reported its data to the Gateway

receiver within 35 minutes of the last transmission. Sensor

Diagnostic Trouble Code Alerts are self-clearing as soon as data is

received from the given sensor. Prolonged Sensor Diagnostic

Trouble Codes can indicate damaged or missing sensors and should

be examined further.

27

Page 28

Low Sensor Battery Alert

A Low Sensor Battery Alert will be displayed for a given sensor when

it is near the end of its battery life. Typically, a low sensor battery

alert will be triggered when the battery reaches 2.1 Volts and below.

The sensor should be replaced as soon as possible to avoid a

continuous sensor Diagnostic Trouble Code from being issued by

the same tire location.

No Tires Programmed Alert

The “No Tires Programmed” message will be displayed after the

startup sequence if the Gateway receiver unit has not been

programmed with any axle and wheel configurations. The Gauge’s

Profile Definition mode or the SmarTire

be used to program new axle and tire combinations into the receiver.

A SmarTire

™

LF Hand tool is also required for this step.

™

Diagnostics software can

5.4 REACTING TO AUDIBLE AND VISUAL ALERTS

It is important to always react to the audible and visual alerts provided by the SmarTire

™

TPMS

system. When an alert is triggered, immediately bring the vehicle to a stop in a safe location in

order to asses the nature of the problem. Tire conditions should always be corrected before the

vehicle is driven.

SmarTire

When a SmarTire

™

Gauge

™

tire alert is triggered, the indicator light will illuminate, an audible alarm will

sound (optional), and an icon will appear on the TPMS Ready screen. To access the alert, press

the left button once. For both pressure alerts, the affected tire and axle will be indicated along

with a number indicating the amount of pressure the tire has lost. The same will be shown for the

high temperature alert except the number will indicate the temperature of the affected tire. Below

are images that show on the screen for each alert.

Pressure Deviation Critical Low Pressure High Temperature

28

Page 29

Dual Light Display

Light

Appearance Alarm

On Solid Critical Low Pressure

Top

Flashing Pressure Deviation

Off No Alarm

On Solid High Temperature

Sensor or System

Bottom

Flashing

Diagnostic Trouble

Code

Off No Alarm

Trailer Lamp

Appearance Alarm

On Solid Critical Low Pressure

Flashing Rapidly Pressure Deviation

Flashing (Twice,

then long delay)

Sensor or System

Diagnostic Trouble Code

5.5 DIAGNOSTIC TROUBLE CODE MESSAGE OVERVIEW

The chart below outlines the six diagnostic trouble code messages that can be displayed by

SmarTire

™

TPMS.

Message Cause & Solution

SENSOR

DIAGNOSTIC

TROUBLE CODE

NO TIRES

PROGRAMMED

AMB SENSOR

DIAGNOSTIC

TROUBLE CODE

Cause: No signal has been received from a sensor for 35 minutes. If

the SENSOR diagnostic trouble code persists after the vehicle is driven,

then a signal reception problem has been detected.

Solution: This problem is frequently due to the removal of the tire with

the programmed sensor. If the correct tire is still installed, this may be

caused by a malfunctioning antenna, sensor or receiver. Contact your

authorized dealer for assistance.

Cause: Indicates the receiver was not programmed with any tire

locations during the initial programming stage.

Solution: The SmarTire

™

Diagnostics Tool will need to be interfaced to

the Wireless Gateway for proper tire programming. Contact your

authorized dealer for additional information.

Cause: The Ambient Pressure sensor has not been received for 35

minutes.

Solution: A default ambient pressure value of 14.7 PSI (1.013 bar) or

the last received ambient reading will be substituted until new ambient

data is received. This may be caused by a malfunctioning antenna,

sensor or receiver. Contact your authorized dealer for assistance.

29

Page 30

Message Cause & Solution

ERROR – RE-ENTER

VALUE

Cause: The value being entered was not accepted due to increased

network traffic.

Solution: The user will be returned to the original menu upon pressing

any button in order to re-enter the value.

SENSOR

DIAGNOSTIC

TROUBLE CODE Dual Light Display &

Trailer Lamp Only

(lower light flashes

twice followed by a 5

second pause,

repeated)

SYSTEM

DIAGNOSTIC

TROUBLE CODE Dual Light Display &

Trailer Lamp Only

Cause: No signal has been received from a sensor for 35 minutes as a

result of a broken sensor or wireless reception issue. If the diagnostic

trouble code is intermittent, it is usually caused by inconsistent

reception. If the diagnostic trouble code is consistent after the vehicle is

driven, the sensor may be broken.

Solution: This problem is frequently due to the removal of the tire with

the programmed sensor. If the correct tire is still installed, reception

quality and/or sensor functionality must be diagnosed. Contact your

authorized dealer for assistance.

Cause: Improper programming, program corruption, electrical problems,

and component failures can cause a system diagnostic trouble code.

Solution: Contact your authorized dealer for assistance if this diagnostic

trouble code persists for more than an hour of driving the vehicle.

5.6 SETUP MODE – FOR USE WHEN SMARTIRE

™

DIAGNOSTICS SOFTWARE IS NOT

AVAILABLE

SmarTire

™

TPMS can be configured by accessing its Setup Mode. Follow the steps below to

access the Setup Mode:

1. The Setup Mode can only be accessed from the TPMS Ready screen. Press the center

button repeatedly until the TPMS Ready screen is displayed (screen shows TPMS Ready

and tire icon).

2. Press and hold the center button for two seconds and the display will show a password

entry screen. NOTE: If the password function has not been activated, the setup mode will

be entered directly.

3. To enter a password, press the left button to scroll the first digit from 9 to 0. When the

correct digit is displayed, press the right button to move to the next digit in sequence.

4. Repeat step three until all four digits are entered correctly and then push the right button

to enter the password. If the password is correct, the display will enter Setup Mode. If the

password is incorrect, the display will indicate that the wrong password was entered and

return to the password entry screen.

30

Page 31

Below is a list of menu items available in Setup Mode and their application:

Menu Item Application

Change Units Use this menu item to change the units of measure from imperial to metric

or from PSI to Bar to kPa.

Vehicle Params Use this menu item to adjust alert thresholds.

Axle Params Use this menu item to program the cold inflation pressures (CIP) per axle.

Altitude Adjust Use this menu item to add or remove altitude compensation (requires

ambient pressure sensor).

Screen Contrast Use this menu item to increase or decrease screen contrast.

Buzzer Use this menu item to customize the audible alert (requires audible alert

module).

Learn Sensors Use this menu item to program new sensors into the receiver or change the

wheel position assigned to a sensor.

Profile Definition Use this menu item to select the number of axles and wheels per axle for a

new vehicle profile definition. This menu item will also overwrite the

existing definition and relearn all sensors after a new profile definition has

been completed.

Change Password Use this menu item to change the password for accessing the setup mode.

To scroll to the next menu item on the list, press the left button. To select a menu item, press the

right button. Below is a description of each menu item.

5.6.1 Changing the Units of Measure

The default "units of measure" setting is usually customized for the region in which the SmarTire

™

system was sold. Use the steps below to customize the units of measure.

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Change Units” is highlighted. Then

press the right button to select the function.

3. Temperature and Pressure options will then be displayed along with the corresponding

unit of measure. Press the left button to scroll between Temperature and Pressure and

press the right button to select the highlighted option for customization.

4. Press the left button to scroll between the different units of measure options. For

pressure, the options are PSI, Bar, and kPa. For temperature, the options are degrees

Fahrenheit and degrees Celsius.

5. Select the desired option by pressing the right button and the display will revert to the

Temperature and Pressure option screen.

6. Repeat steps 3 – 5 should further customization be required.

7. To save the changes and exit the “Change Unit” function, press the center button once.

Press the center button again to exit Setup Mode.

31

Page 32

5.6.2 Changing the Alert Thresholds

The “Vehicle Parameters” (vehicle params) function is used to adjust the default thresholds for

the pressure deviation, critical low pressure and high temperature alerts. The acronyms for each

alert along with the instructions for alert threshold customization are outlined below:

Pressure Deviation Alert = FAL: First Alert Level

Critical Low Pressure Alert = SAL: Second Alert Level

High Temperature Alert = Over Temp

Follow the instructions below to customize the thresholds for each alert:

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Vehicle Params” is highlighted. Then

press the right button to select the function.

3. The alert thresholds for each alert will be displayed. Press the left button to highlight an

alert and the right button to select it for customization.

4. Press the left button to increase the number or the right button to decrease the number

until the desired value is shown. Hold down either button to quickly increase or decrease

the number. When the desired value is displayed, press the center button to save the

value.

5. Repeat steps 3 and 4 to continue customizing the alert thresholds until all values are

programmed correctly.

6. To save the changes and exit the “Vehicle Params” function, press the center button

once. Press the center button again to exit Setup Mode.

NOTE: The High Temperature Alert setting applies to all axle locations.

5.6.3 Changing the Cold Inflation Pressure (CIP) Value for Each Axle

The “Axle Parameters” (axle params) function is used to adjust the default cold inflation pressure

setting for each axle on the vehicle. Follow the instructions below to modify the CIP values for

each axle:

1. Enter the Setup Mode using the steps outlined in section 5.6.

32

Page 33

2. When in the Setup Mode, press the left button until “Axle Params” is highlighted. Then

press the right button to select the function.

3. The first axle will then be displayed along with its CIP value. Press the left button to scroll

to each programmed axle on the vehicle. Each time the left button is pressed, the axle

designator will change to the next axle in sequence and the CIP for that axle will be

displayed. Press the right button to select the axle for programming.

4. Press the left button to increase the number or the right button to decrease the number

until the desired value is shown. Hold down either button to quickly increase or decrease

the number. When the desired value is displayed, press the center button to save the

value.

5. Repeat steps 3 and 4 to continue customizing the CIP values for each axle until all axles

are programmed correctly.

6. To save the changes and exit the “Axle Params” function, press the center button once.

Press the center button again to exit Setup Mode.

5.6.4 Altitude Compensation (Optional)

SmarTire

™

TPMS can be made to compensate for the pressure changes caused by elevation. To

compensate for elevation, the system uses an ambient pressure sensor. The primary use of this

feature is for off-highway equipment located in elevations other than sea level for extended

periods of time. Unless an ambient pressure sensor has been installed on the vehicle, the Altitude

Adjust setting should be set to “OFF”. Follow the instructions below to modify the Altitude Adjust

setting:

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Altitude Adjust” is highlighted. Then

press the right button to select the function.

3. The display will then show “Altitude Comp” with either ON or OFF highlighted. Press

either the left or right buttons to scroll between the ON and OFF setting.

4. When the desired setting is highlighted, press the center button once to save the value.

Press the center button again to exit Setup Mode.

33

Page 34

5.6.5 Display Contrast

Follow the instructions below to modify the contrast of the display:

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Screen Contrast” is highlighted. Then

press the right button to select the function.

3. The display will then show “Contrast Adjust” and a bar indicating the level of contrast.

Press the right button to increase the contrast and the left button to decrease the

contrast. Each time the right button is pushed, an additional box on the contrast bar will

darken and the contrast will increase. Each time the left button is pushed, one less box

on the contrast bar will be dark and the contrast will decrease.

4. When the desired level of contrast is attained, press the center button once to save the

setting. Press the center button again to exit Setup Mode.

5.6.6 Audible Alert Settings

SmarTire

™

TPMS has an optional Audible Alert (part number 255.0077) to compliment the Visual

Alert light that is triggered during a tire pressure or temperature alert. If the system was installed

with the audible alert module, the alert can be disabled and customized by the user. Follow the

instructions below to modify the audible alert settings:

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Buzzer” is highlighted. Then press

the right button to select the function.

3. The display will then show a “Startup” setting and an “Alarm” setting along with their

preset values. Press the left button to scroll between the two programmable functions

and the right button to select the function for programming.

4. Once selected, press the down button to scroll between setting the function to ON or

OFF. When the “Startup” function is set to ON, SmarTire

™

TPMS will make a noise on

start up. When the Alarm function is set to ON, the system will emit an audible alarm

when an alert is trigger ed. When the desired value is displayed, press the right button to

select it.

5. Repeat steps 3 and 4 until all settings are correct. To save the new settings, press the

center button once.

6. Press the center button again to exit Setup Mode.

34

Page 35

5.6.7 Learning Sensors into the Wireless Gateway Receiver

In order for the display to show information specific to a given tire location, the Wireless Gateway

Receiver is programmed with a sensor ID number for each sensor on the vehicle and each

number is associated with a specific wheel position. Every sensor has a unique ID number

specific to it so that when fully programmed, the SmarTire

™

system will recognize only sensors

associated with the vehicle and will know the specific wheel positions for each sensor.

If a wheel is moved to a different location on the vehicle or a sensor is broken and needs to be

replaced, the Wireless Gateway Receiver must be reprogrammed. Otherwise, when a tire alert is

generated, the display will not show the correct wheel position for the affected tire. When

programming a single sensor ID number into the Wireless Gateway Receiver, use the “Learn”

function as described below. When programming more than one sensor ID number or performing

a tire rotation, use the “Walk-Around Learn” function in the SmarTire

Maintenance Tool manual) and/or SmarTire

™

Diagnostics Tool.

™

Maintenance Tool (see

Exercise caution when proceeding with the following

steps! Loss of power to the SmarTire™ TPMS during

Learn Sensor operations will cause sensor location to be

deleted. Do not proceed without the use of SmarTire™ LF

Tool or SmarTire™ Maintenance Tool!

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in Setup Mode, scroll to the “Learn Sensors” menu item. Press the

right button to select the Learn Sensor function.

3. The first axle on the vehicle and “Select Tire To Learn” will then be

displayed. Press the right button to scroll to the next tire on the axle and

the left button to move to the next axle on the vehicle.

4. When the desired wheel position is highlighted, press and hold the center

button for two seconds to delete the ID stored for that tire. The screen will

then show “Deleting Tire” and the selected wheel position will flash.

5. When the ID for the selected tire has been deleted, the screen will show

“Learn in Progress”. The sensor inside the tire for the wheel position to be

programmed must now be provoked to transmit its ID. This can be done

using the SmarTire

Initiator.

A. If using an LF Initiator Tool (obsolete):

Turn the LF Initiator ‘ON’ (push switch upward)

Hold the LF Initiator pointed towards the tire’s sidewall adjacent to sensor’s

location approximately 2" away from the tire’s surface. The sensor should be

located at the valve stem with a rim label indicating its location. Do not touch the

side of the tire or the edge of the rim.

Press “Learn” button once & hold LF Initiator tool in position for 5 seconds (until -

diagnostic light turns off). Do not hold down the “Learn” button.

™

Maintenance Hand Tool, SmarTire™ LF Tool, or LF

35

Page 36

B. If using the SmarTire™ LF Tool:

Turn the SmarTire

™

LF Tool ON by pressing and holding the On/Off/Mode Select

button for 2 seconds.

Press the On/Off/Mode Select button once more to toggle the tool mode to the

Learn sensor function. The LED under the head with the question mark must

now be ON.

Point the SmarTire

™

LF Tool towards the tire’s sidewall adjacent to sensor’s

location approximately 2" away from the tire’s surface. The sensor should be

located at the valve stem with a rim label indicating its location. Do not touch the

edge of the rim with the tool.

Press and release the Initiate/Learn button once & hold the LF Initiator tool in

position for 5 seconds until 4 rapid beeps are heard. Do not hold down the

Initiate/Learn button.

C. If using the SmarTire

Turn the SmarTire

™

Maintenance Tool:

™

Maintenance Tool ‘ON’ (Press and release the red button).

Button functionality:

o Left Button: Initiate Function

o Center Button: Setup Menu

o Right Button: Learn Function

Hold the SmarTire

™

Maintenance Tool pointed towards the tire’s sidewall

adjacent to sensor’s location approximately 2" away from the tire’s surface. The

sensor should be located at the valve stem with a rim label indicating its location.

Do not touch the side of the tire or the edge of the rim.

Press right button (learn function) once & hold tool in position until the screen is

updated. Do not continue to press the button.

6. When completed correctly, the screen will show “Learn Complete”.

Repeat steps 3 – 5 until all wheel positions are programmed. If the

screen shows:

Learn Time Out: A Learn transmission was not provoked

fast enough and the system timed out. Repeat the Learn

process.

Duplicate Sensor ID: The sensor ID that was programmed to the wheel position

is also programmed to another wheel position.

7. When all wheel positions are correctly programmed, press the center button once to save

the changes and exit the “Learn” function. Press the center button again to exit Setup

Mode.

36

Page 37

5.6.8 Selecting a new Vehicle Profile Definition

If the vehicle profile definition changes, for example, in the event of converting from a rear duallywheel axle to single, wide-base tires; this option gives access to change the number of axles

used on the vehicle and the amount of tires mounted per axle.

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Profile Definition” is highlighted.

Then press the right button to select the function.

3. Select the number of axles required for the vehicle profile by

pressing the left button. Press the right button after selecting the

number of axles to gain access to the axle definition screen.

4. Using the left button, select the axle that needs to be defined as a

single, dually or spare tire axle. Press the right button to open the

axle profile screen.

5. Press the left button to toggle the axle profile option from single to

dually or S for Spare. Once you have selected the required axle

profile, press the center button to save your selection and return to

the axle selection screen.

6. Repeat steps 4 and 5, until all axles have been given a profile.

Press the center button to exit the axle selection screen. This will

prompt the “Ready to Learn All Tires?” confirmation screen. Press

the left button to select ‘Yes’ or press the right button to select ‘No’.

If ‘No’ is selected, the profile will remain unchanged from the

original and any button can be pressed again to exit to the Setup

menu.

7. If ‘Yes’ is selected in step 6, the “Overwrite Existing Profile?”

screen is entered. Pressing the left button for ‘No’ will exit the

Vehicle Profile Definition mode, with no changes to the current

profile. Press any button after the notice appears, to exit back to

the Setup menu. Pressing the right button for ‘Yes’ will initialize the

new profile and erase all previous axle and wheel combinations.

This process can take several minutes and the display will prompt

not to cycle power for the system during this time.

8. The display will now enter the Walk Around Learn Mode for the

axle and tires previously selected in the profile definition process.

Each tire will be marked in black for learn in a specific order. To

learn the marked tire into the system, follow steps 5 to 7 in the

Learn Mode procedure under section 5.6.7.

9. After all locations have been learned successfully, the gauge will

restart and the new vehicle profile definition will be in effect. In the

event that the process had to be canceled or power was lost to the

system, the gauge will assign placeholder IDs to each unlearned

location. After restarting, each of the previously missed locations

can be accessed individually via the Learn Sensor menu and be

reprogrammed.

37

Page 38

5.6.9 Changing the Password

A four digit, numerical password is required to enter the Setup Mode. The default password is

‘0000’. Follow the instructions below to customize the password:

1. Enter the Setup Mode using the steps outlined in section 5.6.

2. When in the Setup Mode, press the left button until “Change Password” is highlighted.

Then press the right button to select the function.

3. The display will then show “Enter Password” and four digits. Before a new password can

be set, the original password must be confirmed. To enter a password, press the left

button to scroll the first digit from 9 to 0. When the correct digit is displayed, press the

right button to move to the next digit in sequence.

4. Repeat step three until all four digits are entered correctly and then push the right button

to enter the password.

5. If the password that was entered was correct, the display will show “Enter New

Password” and four digits. Again, press the left button to scroll the first digit from 9 to 0.

When the desired digit is displayed, press the right button to move to the next digit in

sequence.

6. Repeat step five until all four digits are entered as desired and then push the right button.

7. The screen will then prompt to “Save Password” with a choice of YES or NO. If the

password entered is correct, press the right button to save it as the new password. Press

the left button or the center button to reject the password and enter a new one.

8. Press the center button once to exit to the Setup menu and again to exit Setup Mode.

38

Page 39

S E C T I O N

SmarTire™ Tire Pressure Monitoring System

by Bendix CVS

Section D: System Installation - Electrical

39

Page 40

6.0 SYSTEM INSTALLATION: ELECTRICAL

6.1 TOOLS REQUIRED

Installing the Receiver

1. Two ¼ -20 (M6X1) flange head cap screws with lock washers and nuts

2. Wrenches for tightening cap screw

Installing the Display

1. Power drill & 2 1/8" (54mm) hole saw

2. 1 Ring terminal 22-18 AWG, stud size 8-10 for grounding*

Installing the Antennas

1. Power drill & bits *

2. Silicone sealant *

3. 1" open ended wrench or crescent wrench

4. 2 small self-tapping screws for antenna bracket to fit 3/16" holes*

5. 15 medium sized, black cable ties

6. Electrical tape

* Tool may not be required

6.2 GETTING STARTED

Like all integrated systems, the installation location of each component is dependant upon the

location of the other components in the system. As such, it is best to select the overall location of

each component before starting.

The following diagrams show common vehicle system configurations:

Truck with Trailer

1. Dash-mounted display connects to Wireless Gateway Receiver.

2. Wireless Gateway Receiver connects to underside of vehicle.

3. Antenna at rear axle(s) connects to Wireless Gateway Receiver.

nd

4. 2

Wireless Gateway Receiver mounts to the trailer at its rear axle(s).

5. Trailer lamp mounts within view of the driver and connects to the Wireless Gateway

Receiver.

6. Sensors mount to the wheels.

40

Page 41

Straight Trucks, Buses, OTR Vehicles

1. Dash-mounted display connects to Wireless Gateway Receiver.

2. Wireless Gateway Receiver connects to underside of vehicle.

3. Antenna at rear axle(s) connects to Wireless Gateway Receiver.

4. Sensors mount to the wheels.

6.2.1 Guidelines and Best Practices

Use the guidelines below to help select the best installation location for the Wireless Gateway

Receiver and the antenna(s). Guidelines are also provided for routing antenna cables.

Antenna Placement

DO:

Choose a location for the antenna that is within the allowable cable length for connection

to the Wireless Gateway Receiver (e.g. 40 ft antenna cable will not reach a straight-line

point 40 ft away on a given vehicle).

Choose a location in which the antenna whip does not contact the vehicle. The antenna

should only contact the vehicle at its mounting base.

Orient the antenna so that it has clear line of sight to the tires. If it is pointed downward, a

minimum of 1.5 feet (46 cm) is required between the tip of the antenna and the ground. If

it is pointed upward, it can not be shielded by any metal on the underside of the vehicle.

In general, a horizontal antenna orientation along the center line of the vehicle yields the

best results.

When placing the antenna near the front axle, choose a location that offers protection in

the driving direction e.g. if placed on the front cross member, face the antenna rearward

on the rear-most vertical side of the cross member.

When placing an antenna near or on suspension supports, make sure there is enough

room to allow the suspension to travel to its full compression.

DO NOT:

Do not place the antenna near large concentrations of metal e.g. steel I-beam support,

axle differentials, etc.

Do not place antenna near large concentrations of electrical wiring, generators, amplifiers

or pre-existing transceiver assemblies (e.g. GPS/Telematics systems, CB Radio, Data

Loggers, etc).

Do not place the antenna on or near moving parts such as steering linkages, drive shafts,

or suspension assemblies.

41

Page 42

Avoid placing the antenna close to the ground or having it point downwards – instead

face the antenna horizontally or point it up into the vehicle if the ground clearance is less

than 1.5 ft (46 cm).

Antenna Cable Routing

DO:

Choose the proper cable length for the given antenna location.

Protect the cable from heat and sharp edges e.g. keep adequate distance from exhaust

pipes and avoid potential chafing on sharp metal.

Route the cable along existing cable tree on the underside of vehicle (i.e. along I-beams

for tractor trailer).

Provide some slack in the cable (a few feet depending on vehicle application) at each

end point of cable / antenna to allow for slight repositioning if needed.

Route “head first” for hole-through & magnetic mount antennas when passing cable

through frame holes and tight access points (route small cable end first always).

Apply cable ties every 2 feet (61 cm) to ensure secure attachment – avoid chafing by not

over tightening.

Secure antenna cable with cable ties on both sides of the connectors for extensions,

splitters and antenna mounts.

Make sure all connections are properly locked and secured.

For TNC Hex heads, apply 17 to 23 inch-pounds of torque.

DO NOT:

Do not strain the cable and its connectors if length barely reaches – choose a longer

cable (chassis-flex during driving may tear an already tight cable).

Do not subject the cable to sharp bends – try to allow for a natural cable path flow.

Do not route over or under moving parts like steering linkages and shoc k mounts.

Do not over-tighten cable ties.

Receiver Placement

For outside mounting, Wireless Gateway Receiver must be properly secured via bolt-on

faceplate, heavy duty straps, or custom mount.

Mount the Wireless Gateway Receiver ‘away’ from forward driving direction e.g. if

possible, have object between receiver box and open road surface such as a cross

member.

Preferred mounting orientation to shed water is vertical (Connector side facing down ).

Apply the same precautions described under “Antenna Placement” since Wireless

Gateway Receiver has built-in antenna.

Caution: Make sure all power input lines are fitted with 5

Amp fuses for proper protection of the SmarTire™ system

components. If the Gateway Receiver, Gauge, and

Diagnostics port are hooked to the same power line, only

one 5 Amp fuse is required before the line branches to

each part.

42

Page 43

6.3 STEP 1: INSTALLING THE RECEIVER AND DISPLAY

1. The Wireless Gateway Receiver has a built-in antenna capable of receiving wireless

signals from various sensor types, including tire sensors. It should be externally mounted

to the vehicle’s chassis or frame rail near the front of the vehicle and in a position as

close to the vehicle’s centerline as possible. The Receiver can be mounted with the

connectors facing downwards or upwards (to protect cables from ground effects damage)

and it must always be within clear line of sight of the front wheels.

Using the integrated bolt holes and two ¼ -20 (M6X1) Flange Head Cap screws, attach

the receiver to the vehicle. The supplied mounting plate (PN 264.0318) can be used with

existing bolts / bolt holes to mount the receiver (see picture). Torque to 7-10 FT/LBS (13

Nm). For location testing, heavy-duty safety straps may also be temporarily used.

Note: To protect the receiver input cables from any ground effects damage it is also permissible

to mount the receiver upside down as seen below (cables exiting out the top):

2. With the vehicle’s power turned OFF, connect the wiring harness to the main connector

on the receiver (see P1 in vehicle wiring harness: Light – 260.0309 diagram). Route the

J1939 bus and power line through the chassis towards the driver’s cab and dashboard

area. Identify Power line VIN and Ground line GND in the vehicle wiring harness diagram

and connect the power line to a 5 Amp fuse protected, ignition keyed 12 or 24 Volt

power source. Ensure that this power source is properly grounded through the GND

line.

For more information, please refer to the circuit diagram in your vehicle specific manual.

3. Run the display cable (see P5 in vehicle wiring harness: Light – 260.0309 diagram) from

the wiring harness to the desired location on the dash or consol (may require drilling a

hole in the dash). For systems using a 2" SmarTire

™

display, use the dashboard lock ring

and metal spring to secure the display in the dash (may require the cutting of a 2-1/8" (54

mm) port hole in the dash – see picture, also cut a small notch into the bottom of the hole

to create a turn stop. Insert the gauge so that the tab at the bottom fits into the notch. If

the lock ring cannot be engaged, either remove the metal spring completely or bend it flat

43

Page 44

for a better fit. For systems using a dual-light display, identify connector P7 in the vehicle

wiring harness diagram - 260.0275 (not included under section 5 of the SmarTire

manual). Use a spare rocker switch on the dashboard to situate the dual-light display.

4. Connect P5 of the Light vehicle wiring harness to the back of the 2" SmarTire

™

Display /