Page 1

Genuine Bendix Valves

Tests show that some knock-off valves may be potentially hazardous or inferior to genuine Bendix parts

Comprehensive testing by Bendix Commercial Vehicle Systems continues to show that some knock-off brake

valves not only fall short of Bendix specifi cations, but can lead to safety hazards through inferior production

quality. The following is an example of a recent test on a knock-off valve product purchased off the shelf

compared to the Bendix

®

E-6™ brake valve:

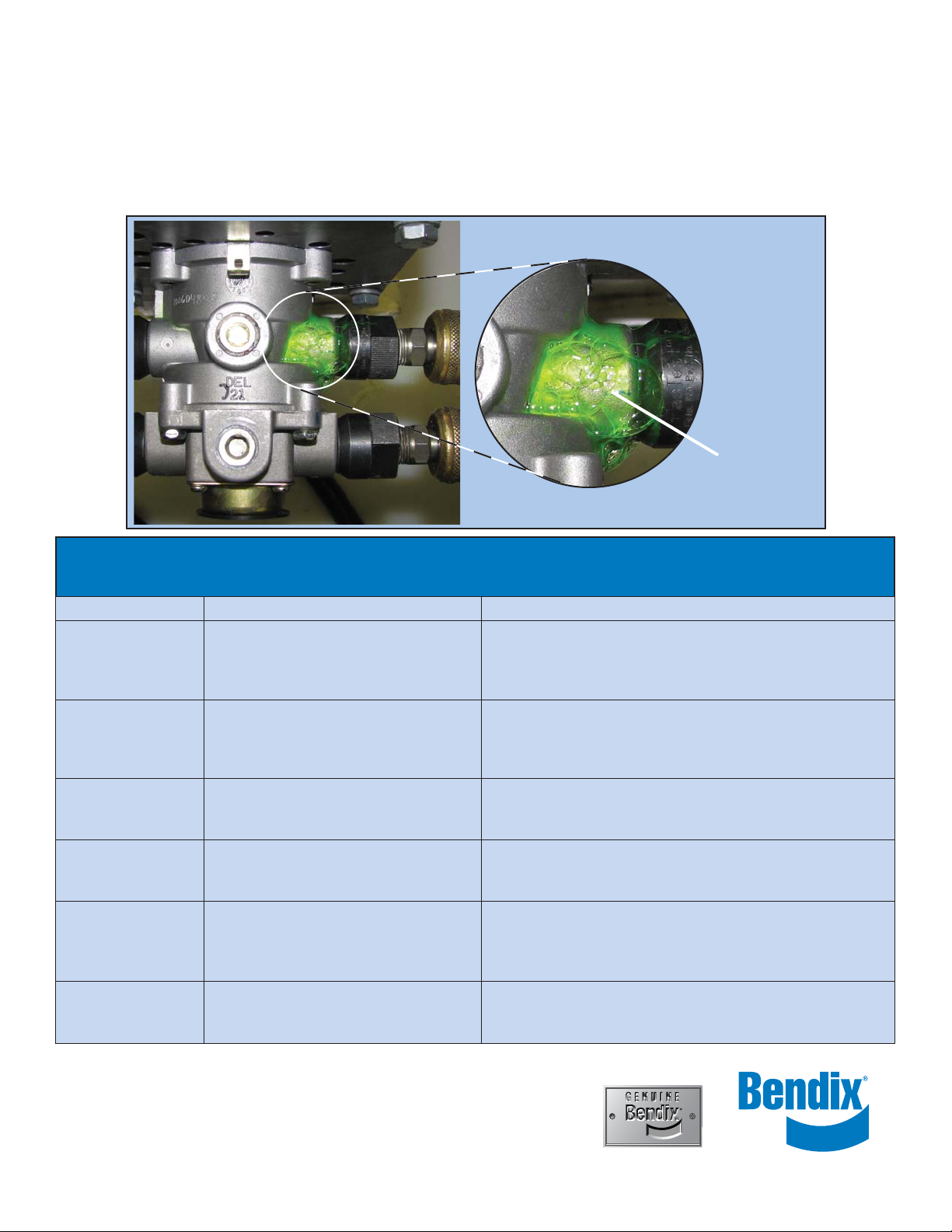

Test Showing

Non-Genuine

Knock-off

Valve

Leakage

Cracks in

Housing Result in

System Air Leakage

After thousands of hours of testing the knock-off and the Bendix brake valve

in identical conditions, the results are in.

Test Category The Results The Potential Impact To Your Vehicle

Too high of a pressure differential can cause the primary circuit to

Safety

Feel

Durability

Machined Surface

Finish

Corrosion

Protection

O-Ring Quality

Pressure differential at double

the allowable OEM spec

Inconsistent and poor

quality graduating springs

Valve bodies cracked before the

test was complete

Machined surface fi nish did not meet OEM

specifi cations when the tested product was

new out of the box

No corrosion protection material was found

on outer castings. Material used

on internal components failed 50% sooner

than OEM protective coatings

7 out of 8 O-rings in the valve were 50%

stiffer than Bendix specifi cations allow

open long before the secondary circuit, causing longer stopping

distances, and accelerated wear of other critical brake components

(friction material, drums, seals).

Inconsistent spring tension means the driver loses the ability

to lightly apply the brakes. The valve acts more like an instant

on-off switch instead of providing the expected gradual braking

capability.

Weak or thin body castings not only cause internal component

misalignment, but also make the valve more susceptible to cracking

or may even result in a complete valve rupture.

Signifi cantly reduced component life, decreased durability and loss

of valve function. Rough surfaces will cause O-rings to wear and

may cause premature air leaks.

Untreated and uncoated exterior and interior surfaces mean

premature corrosion along with sharply decreased durability,

greater susceptibility to cracking and possible brake valve failure.

Hard or stiff O-rings may lead to premature wear, and may result

in air leaks, shorter component life, and substantially poorer

performance.

Your air brake system is not the place to cut corners. Inferior

design or materials can, and frequently do, affect the performance,

durability and long-term reliability of your braking system. Protect

your vehicle by using only genuine Bendix

®

parts. Talk to your

Bendix Account Manager, call 1-800-AIR-BRAKE, (1- 800-247-2725)

or visit www.bendix.com today.

BW2627 ©2007 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • 05/07 • All Rights Reserved.

™

Loading...

Loading...