Page 1

TROUBLESHOOTING THE

VACUUM HYDRAULIC BRAKE

SYSTEM

Troubleshooting The

Vacuum Hydraulic Brake System

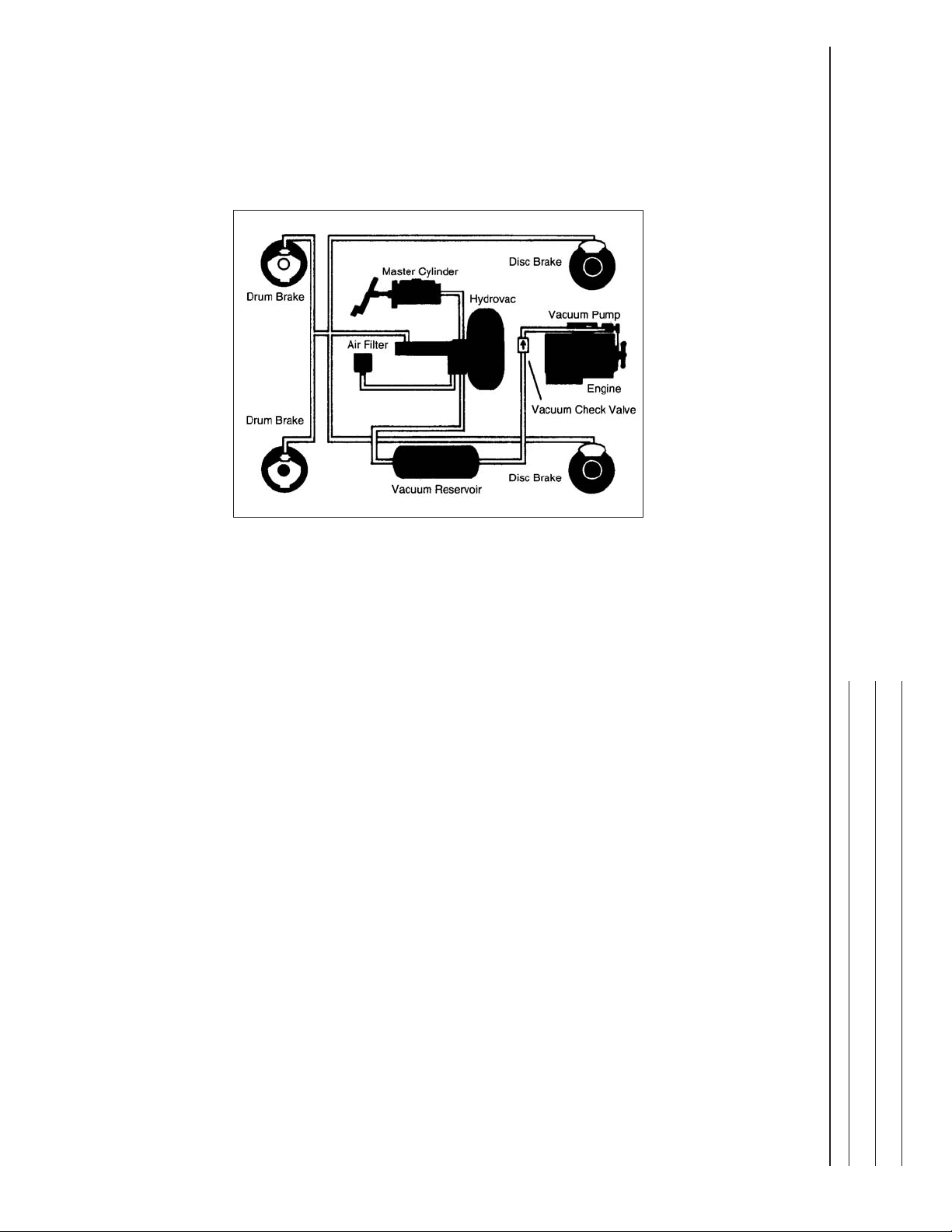

The three phases of tests presented here have been

designed to discover the presence of both vacuum and

hydraulic fluid leakage and sluggish performance of the

brakes. The entire system from the vacuum service to the

wheel cylinder or caliper can be easily checked in a relatively short period of time by performing these tests.

While in many cases a problem can be found and corrected early in the testing procedure, it is generally recommended that all three phases of testing be completed

to assure that the entire system is in good working order.

BEFORE GETTING STARTED

When working on or around brake systems and components, the following precautions should be observed:

1. Always block vehicle wheels. Stop engine when work-

ing under a vehicle. Keep hands away from chambers;

they may apply as system pressure drops.

2. Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

pipe plug unless you are certain all system pressure

has been depleted.

3. Never exceed recommended pressure and always

wear safety glasses.

4. Never attempt to disassemble a component until you

have read and understand recommended procedures.

Some components contain powerful springs and injury

can result if not properly disassembled. Use only proper tools and observe all precautions pertaining to use

of these tools.

5. Use only genuine Bendix replacement parts and

components.

To perform these tests it is necessary to obtain both a

vacuum and hydraulic pressure gauge. The hydraulic

gauge should be capable of readings up to 2000 P.S.I.

while the vacuum gauge should have a range up to 30

inches of mercury.

Please note that the tests presented here are performed with the vehicle stationary. They must not be

interpreted as overruling the importance and necessity of

functional dynamic controllability tests and other testing

required in assuring vehicle safety and performance.

A. Only components, devices and mounting and

attaching hardware specifically designed to use in

hydraulic brake systems should be used.

B. Replacement hardware, tubing, hose, fittings, etc.

should be of equivalent size, type and strength as

the original equipment.

6. Devices with stripped threads or damaged parts

should be replaced. Other than drums and rotors,

repairs requiring machining should not be attempted.

7. For cleaning brake parts, use only new DOT 4 brake

fluid, isopropyl alcohol or clear methylated spirits. Do

not use mineral base cleaning solvents such as gasoline, kerosene, carbon tetrachloride, acetone or paint

thinner - these will damage the rubber parts.

8. Bendix recommends that for optimum results and

safety, worn units should be replaced by new units. If,

however, it is decided to service a used component,

particular attention should be paid to the following, but

in any case of doubt replace the unit or seek professional advice.

DATE:

TRUCK

MECHANIC:

Page 2

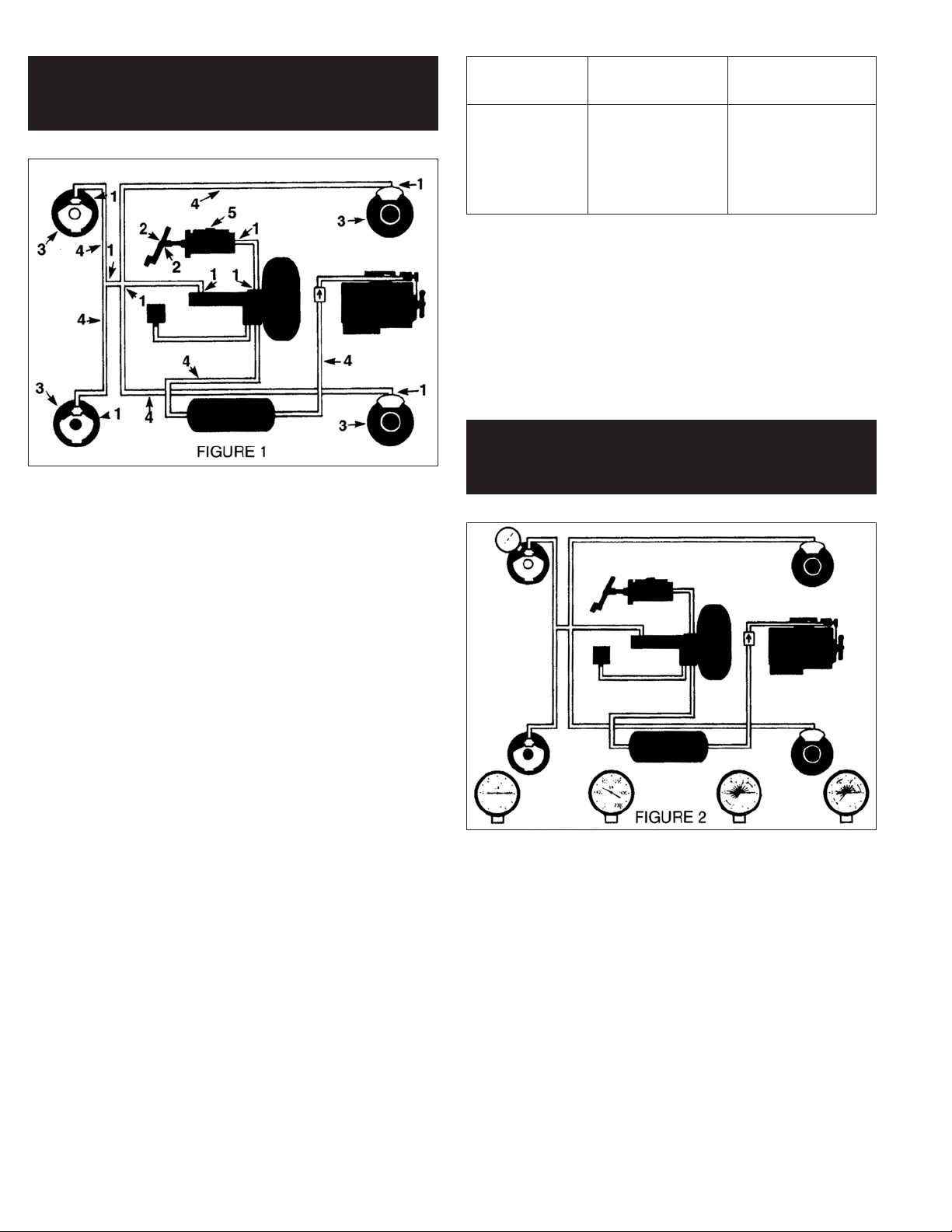

PHASE I – VISUAL

INSPECTION

GENERAL

Phase I visual inspection procedures should reveal the most common problems found in a hydraulic brake system. The inspection

steps are presented in the order in which they are most easily

performed.

Brake Fluid Boiling Point Boiling Point

Type Dry Wet

DOT #3 401°F 284°F

DOT #4 446°F 311°F

DOT #5 500°F 500°F

(silicone)

With the master cylinder cover off, have an assistant slowly make

a full brake application while observing the fluid in the reservoir.

CAUTION. Wear eye protection and do not allow fluid to contact

vehicle's painted finish. A small spurt or geyser at the beginning of

the brake application followed by continued fluid turbulence indi-

cates internal master cylinder leakage. Repair or replace. If the

fluid remains calm after initial spurt, continue to Phase II Testing.

PHASE II – HYDRAULIC

SYSTEM TESTS

INSPECTION

1. Look for signs of fluid leakage at connection points as well as

around wheel cylinder calipers, the master cylinder and

hydrovac. Inspect disc brakes caliper piston boots for tears or

deterioration.

2. Inspect the master cylinder pedal and linkage for binding, bending or damage. Lubricate rotating and sliding components with

a rubber compatible lubricant.

3. Inspect the foundation brakes for proper adjustment and adjust

if necessary.

4. Start engine and have assistant make several brake applications while visually inspecting all hydraulic and vacuum lines,

hoses, and clamps for kinking, chafing, damage, corrosion and

signs of collapsing or "ballooning".

5. Remove the master cylinder reservoir cover and check the fluid

level. Refill as necessary. While the cover is off, look for discoloration, cloudiness, and "gumming" of the fluid. Also look for

corrosion on any part in contact with the fluid. If any of these

conditions are found, the system should be drained, bled,

flushed and refilled with the proper type of brake fluid for the

application. DO NOT MIX HYDRAULIC FLUID AND BRAKE

FLUID. "GUMMING" OF FLUID AND DAMAGE TO COMPONENT SEALS WILL RESULT.

Federal Motor Vehicle Safety Standard #116 divides brake

fluids into three categories with the primary difference being the

fluid boiling points.

GENERAL

1. With the engine off and brakes not applied, install a 0-2000 p.s.i.

hydraulic gauge at the wheel cylinder or caliper and bleed air

from the gauge and its connecting line.

NOTES:

A. The gauge can usually be installed by removing the wheel

cylinder bleed screw.

B. When the vehicle is equipped with a dual or "split" brake sys-

tem, a gauge must be installed in each side of the system,

i.e.; one gauge in a front axle brake and one gauge in a rear

axle brake. Alternatively, the tests can be performed twice,

once for the front axle brakes and again for the rear axle

brakes.

Page 3

2. With the engine idling, apply and release the brakes several

times. Note that the pressure is registered on the gauge with the

brakes applied and that each time the brakes are released the

gauge returns to 0 p.s.i. NOTE: In systems where a residual

check valve is used the pressure will not return to 0 p.s.i.

Between 3 and 50 p.s.i. pressure will remain when the brakes

are released. RESIDUAL CHECK VALVES MUST NOT BE

USED TO HOLD PRESSURE ON A DISC BRAKE CALIPER.

3. With the engine idling make a rapid, full brake application and

hold it applied while observing one of four gauge reactions.

A. Pressure instantly rises to between 1000 and 2000 p.s.i.

and remains constant while brakes are applied.

Hydraulic System Okay

Problem is most likely in

Foundation Brakes

Check Foundation Brakes Mechanical Parts

Hydraulic System Okay

Problem is most likely in

Vacuum System or Booster

Perform Phase III Vacuum System Tests

C. Pressure rises slowly but remains constant while brakes

are held applied. Final pressure reading may be very low

or may be between 1000 and 2000 p.s.i.

Record pressure reading here if it is less than 1000 p.s.i.

______________________.

While applying and releasing brakes, inspect hydraulic

lines and hoses for kinks, bends, "ballooning" and

restrictions that may not have been found in Phase I

inspections. Replace as necessary.

For Example: (1) Drum or rotor condition

(2) Backing or anchor plate

condition

(3) Shoe and lining condition

(4) Correct lining friction

(5) Caliper sliding surfaces

(6) Worn, missing or damaged

part

(7) Wheel bearings

B. Pressure instantly rises and remains constant while

brakes are held applied but pressure does not reach a

minimum 1000 p.s.i.

Release brake application, then remove atmospheric air

hose from vacuum booster control valve. (NOTE: This is

the hose running between the booster and its externally

mounted filter generally found in the cab.) Make a full and

rapid brake application and again observe gauge at wheel.

Hydraulic pressure rises

instantly to between 1000

and 2000 p.s.i.

Repair or replace atmospheric air filter and/or

connecting hose fittings.

Return to beginning of

Step 3 and retest.

D. Pressure rises instantly to between 1000 and 2000 p.s.i.

but begins to drop while brakes are held applied.

Hydraulic pressure rises

slowly to same pressure

recorded above.

Perform Phase III Vacuum

System Tests

Page 4

Turn off engine. Make 10-15 full brake applications to get rid

of all vacuum. Make and hold a full brake application and

observe gauge at wheel. Pressure valve is not important.

Watch for a pressure drop.

There are two possible gauge results; proceed to the correct heading and continue testing.

A. Vacuum gauge reading is 16 inches of mercury or higher.

Vacuum reaching booster is okay.

Pressure rises instantly

and remains constant while

brakes are held applied.

Hydraulic system okay.

Vacuum leakage most likely

causing the pressure drop.

Perform Phase III Vacuum

System Checks.

Pressure rises instantly but

begins to fall while brakes

are held applied.

Vacuum system probably

not causing pressure drop.

Hydraulic leakage most

likely causing pressure

drop.

Perform Steps 1, 4, 5 of

Phase I Visual Inspection

again. Return to beginning

of Step 3 and retest.

PHASE III – VACUUM

SYSTEM TESTS

Shut off engine and note any change in vacuum gauge. The

following are maximum acceptable leakage limits:

1. Vacuum system with separate vacuum reservoir; a drop

of no more than 2" HG in 60 seconds.

2. Vacuum system without separate vacuum reservoir; a

drop of no more than 2" HG in 15 seconds.

Leakage is okay. Proceed to

Step 3 and continue testing.

Leakage NOT okay. To

pinpoint leakage source,

reinstall gauge at positions

indicated in Figure 3 and

retest at each position.

Begin at position #3 to test

hose between check valve

and vacuum source. Repair

or replace components

ahead of gauge when

unacceptable leakage is

noted. Continue testing

until leakage checks okay

at position #1.

GENERAL

1. Remove vacuum line from booster control valve section and

install a vacuum gauge with a range of 0-30 inches of mercury

in the end of the line. (Refer to Figure 3 Gauge Position #1.)

2. Start engine and allow to idle for several minutes to allow vacuum gauge reading to stabilize, then read gauge. Vacuum should

be a minimum of 16 inches of mercury. Record gauge reading

here _________________" HG for use later.

Leakage is okay. Proceed to

Step 3 and continue testing.

B. Vacuum gauge reading is less than 16 inches of mercury.

Insufficient vacuum is reaching the booster.

Page 5

Shut off engine. Connect vacuum gauge at the source of

vacuum on engine which is position #2 in Figure 3. Start

engine and idle. Vacuum registered on gauge should be

16 inches of mercury or higher. Record reading here:

_____________________" HG.

Vacuum less than 16 inches

of mercury. Repair engine or

replace vacuum pump if so

equipped, then retest

vacuum.

Remove gauge from

position #2 and reconnect

hose to vacuum source.

Reconnect vacuum gauge at position #1 as illustrated in

Figure 3.

Vacuum is 16 inches of

mercury or greater. Problem

is most likely restricted

lines/devices or excessive

leakage. Refer to Figure 3

and reinstall gauge at positions 3, 4, 5, 6 & 1 in that

order. Retest vacuum at

each position. If vacuum is

less than 16" HG at any

position, repair or replace

hose or component between

current and last gauge position. Continue testing until

16" HG or better is noted at

position #1.

3. Reinstall vacuum hose at control valve of booster and tee in

vacuum gauge. Start engine and build vacuum. Read gauge

and compare to gauge reading recorded in first part of Step #2.

(Refer to Figure 4.)

Reading is same, booster

okay.

With engine idling make 10 rapid brake applications and

note the time required for vacuum to recover. The following

are maximum acceptable limits.

A. Vacuum system with separate vacuum reservoir; vacuum

rise to 16" HG in 30 seconds or less.

B. Vacuum system without separate vacuum reservoir;

vacuum rise to 16" HG in 15 seconds or less.

Recovery time is acceptable.

Remove gauge and return

vehicle to service.

Reading is lower. Booster is

leaking vacuum. Repair or

replace and retest.

Recovery time not

acceptable. Check hose,

clamps, fittings. Repair

or replace if required

and retest.

Retest vacuum system beginning with Step #1.

Page 6

NOW – The most complete stock of original equipment replacement parts for all

medium truck and school bus hydraulic brake systems.

SEE YOUR BENDIX PARTS OUTLET FOR:

POWER BRAKE

• Hydrovacs

• Vacuum Pumps

• Hydromax

• Air-paks

• Master Cylinders and

Repair Kits

• Power Brake Repair Kits

DISC BRAKE

• Calipers and Repair Kits

• Hardware Kits

• Rotors

• Disc Pads

• Pistons

Also

• Brake Hose & Tubing

• Fittings

• Brake Fluid

• Vacuum Hose

DRUM BRAKE

• Wheel Cylinders and

Repair Kits

• Detail Parts

• Anchor Supports

• Brake Lining

THE AIR AND HYDRAULIC BRAKE EXPERTS

BW1399 © 2003 Bendix Commercial Vehicle Systems LLC All rights reserved. 2/2003 Printed in U.S.A.

Loading...

Loading...