Page 1

Manual

VMD460-NA

Network and system protection (NS protection) for monitoring

the power feed-in of power generation systems

Software version: D398 V1.1x

Display software version: D403 V2.2x

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 2

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Gruenberg • Germany

Postfach 1161 • 35301 Gruenberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender-de.com

Web: http://www.bender-de.com

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. How to use this documentation effectively ................................................ 7

1.1 How to use this manual ................................................................................. 7

1.2 Technical support: Service and support .................................................. 8

1.3 Workshops .......................................................................................................... 9

1.4 Delivery conditions, guarantee, warranty and liability .................... 10

2. Safety ................................................................................................................ 11

2.1 Intended use ................................................................................................... 11

2.2 Electrically skilled person ........................................................................... 11

2.3 General safety instructions ........................................................................ 12

3. Function ........................................................................................................... 13

3.1 Device features .............................................................................................. 13

3.2 Description of function ............................................................................... 14

3.2.1 Calculating the average value of overvoltage

(VDE-AR-N 4105, CEI 0-21, C10/11) ......................................................... 14

3.2.2 Self test, automatic ....................................................................................... 14

3.2.3 Manual self test .............................................................................................. 15

3.2.4 Remote-Trip (RTG / RT1) ............................................................................. 15

3.2.5 Malfunction and messages ........................................................................ 16

3.2.6 Delay times ton and toff ............................................................................. 17

3.2.7 Password protection .................................................................................... 17

3.2.8 Factory setting ............................................................................................... 17

3.2.9 Erasable history memory ............................................................................ 17

3.2.10 Passive islanding detection (df/dt) ......................................................... 18

VMD460-NA_D00001_01_M_XXEN/08.2013

3

Page 4

Table of Contents

4. Installation, connection and commissioning ........................................... 19

4.1 Unpacking ........................................................................................................ 19

4.2 Back-up fuses .................................................................................................. 19

4.3 Notes on mounting ...................................................................................... 20

4.4 Block diagram ................................................................................................. 20

4.5 Dimension diagram VMD460-NA ............................................................ 21

4.6 DIN rail mounting: ......................................................................................... 21

4.7 Screw mounting ............................................................................................ 21

4.8 Wiring diagram .............................................................................................. 22

4.8.1 VDE-AR-N 4105, BDEW, C10/11 ................................................................ 22

4.8.2 CEI 0-21 ............................................................................................................. 24

4.8.3 Details regarding the digital inputs (D1…D4, RT1) .......................... 27

4.9 Standards, selectable ................................................................................... 27

4.10 Commissioning .............................................................................................. 27

4.11 Trigger circuit test by the system erector ............................................. 28

5. Operation and configuration ...................................................................... 29

5.1 Getting to know the user interface ......................................................... 29

5.2 Various displays ............................................................................................. 30

5.2.1 Standard display ............................................................................................ 30

5.2.2 Info display ...................................................................................................... 31

5.2.3 Alarm display .................................................................................................. 31

5.2.4 Menu display ................................................................................................... 31

5.2.5 Toggling between the displays ................................................................ 32

5.3 INFO button ..................................................................................................... 33

5.4 Menu button ................................................................................................... 33

5.4.1 Alarm/meas. values ...................................................................................... 34

5.4.2 History ............................................................................................................... 35

5.4.3 Settings ............................................................................................................ 37

5.4.4 System ............................................................................................................... 38

4

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 5

Table of Contents

5.4.5 Info ......................................................................................................................40

6. Maintenance ................................................................................................... 41

7. Selectable default settings ........................................................................... 43

7.1 VDE-AR-N 4105 .............................................................................................. 44

7.2 CEI 0-21 ............................................................................................................. 46

7.3 BDEW-guideline ............................................................................................. 49

7.4 C10/11 ............................................................................................................... 52

8. Technical data VMD460-NA ......................................................................... 55

8.1 Standards, approvals and certifications ................................................ 59

8.2 Ordering information .................................................................................. 59

INDEX ..................................................................................................................... 61

VMD460-NA_D00001_01_M_XXEN/08.2013

5

Page 6

Table of Contents

6

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 7

1. How to use this documentation effectively

1. 1 How to use this manual

This operating manual will concern qualified experts in electrical engineering

and user of the product and must be kept ready for referencing in the immediate vicinity of the device.

In order to make it easier for you to find specific text passages or references in

this manual and for reasons of comprehensibility, important information is

emphasised by symbols. The meaning of these symbols is explained below:

The warning symbol indicates a potential dangerous

situation that may result in bodily injury and/or damage

to property.

Observe the associated safety instructions.

Information intended to assist the user to make optimum

use of the product are marked with the Info symbol.

Although great care has been taken in the drafting of this operating manual,

it may nevertheless contain errors and mistakes.

The Bender Group cannot accept any liability for injury to persons or damage

to property resulting from errors or mistakes in this manual.

Each of the registered trademarks which appears in this document remains

the property of its owner.

VMD460-NA_D00001_01_M_XXEN/08.2013

7

Page 8

How to use this documentation effectively

1. 2 Technical support: Service and support

For commissioning and troubleshooting Bender offers you:

First level support

Technical support by phone or e-mail for all Bender products

Questions about special customer applications

Commissioning

Troubleshooting

Tel.: +49 6401 807-760*

Fax: +49 6401 807-259

only available in Germany: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.com

Repair service

Repair, calibration, update and replacement service for all Bender products

Repair, calibration, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices for faulty or incorrectly delivered

Bender devices

Extended warranty for Bender devices with in-house repair service

resp. replacement devices at no extra cost

Tel.: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (commercial matters)

Fax: +49 6401 807-789

E-mail: repair@bender-service.com

Please send the devices for repair to the following address:

Bender GmbH, Repair Service,

Londorfer Strasse 65,

35305 Gruenberg,

Germany

8

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 9

How to use this documentation effectively

Field service

On-site service for all Bender products

Commissioning, parameter setting, maintenance, troubleshooting for

Bender products

Analysis of the electrical installation in the building (power quality test,

EMC test, thermography)

Practical training courses for customers

Tel.: +49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (commercial matters)

Fax: +49 6401 807-759

E mail: fieldservice@bender-service.com

Internet: www.bender-de.com

*Available from 7.00 a.m. to 8.00 p.m. on 365 days of the year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m

1. 3 Workshops

Bender would be happy to provide training in respect of the use of the universal measuring device.

Current dates of training courses and workshops can be found

on the Internet at

http://www.bender-de.com/en/know-how/seminars.

VMD460-NA_D00001_01_M_XXEN/08.2013

9

Page 10

How to use this documentation effectively

1. 4 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender apply.

For software products, the "Softwareklausel zur Überlassung von StandardSoftware als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen

Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie"

(software clause in respect of the licensing of standard software as part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband

Elektrotechnik- und Elektronikindustrie e.V. (German Electrical and Electronic

Manufacturers' Association) also applies.

Conditions of sale and delivery can be obtained from Bender in printed or

electronic format.

10

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 11

2. Safety

2. 1 Intended use

The voltage and frequency monitoring relay VMD460-NA is used for system

and network protection (NS protection) of CHPs, wind, hydroelectric and photovoltaic systems feeding power into the grid.

If inadmissible voltage and frequency values occur on the supply side, the

VMD460-NA has the task of disconnecting the power generation system from

the distribution network by means of a coupling switch.

The voltage and frequency monitoring relay is to be installed and connected

directly at the central meter panel.

The VMD460-NA utilises a separate supply voltage connection.

Power generation systems with an output of > 6 kW

require a separate asymmetry monitoring.

2. 2 Electrically skilled person

Only electrically skilled persons are authorised to install and commission this

device. Electrically skilled persons are those who have the relevant education,

knowledge and experience, as well as knowledge of the relevant safety standards and who are able to perceive risks and to avoid hazards which electricity

can create when work activities are carried out on electrical installations. The

electrically skilled person is specially trained for carrying out work activities in

his specific working environment and has a thorough knowledge of the relevant standards and regulations. In Germany, an electrically skilled person

must meet the requirements of the accident prevention regulation BGV A3. In

other countries the applicable regulations have to be observed and followed.

VMD460-NA_D00001_01_M_XXEN/08.2013

11

Page 12

Safety

2. 3 General safety instructions

Bender devices are designed and built in accordance with the state of the art

and accepted rules in respect of technical safety. However, the use of such devices may introduce risks to the life and limb of the user or third parties and/

or result in damage to Bender devices or other property.

Danger of electric shock!

Touching live parts will cause danger of electric shoc k with fatal

consequences. All work activities on electrical installations as

well as installation activities, commissioning activities and

work activities with the device in operation may only be carried

out by electrically skilled persons!

Only use Bender equipment:

– as intended

– in perfect working order

– in compliance with the accident prevention regulations and guide-

lines applicable at the location of use

Eliminate all faults immediately which may endanger safety.

Do not make any unauthorised changes and only use replacement

parts and optional accessories purchased from or recommended by

the manufacturer of the equipment. Failure to observe this requirement can result in fire, electric shock and injury.

If the device is overloaded by overvoltage or a short-circuit current

load, it must be checked and replaced if necessary.

If the device is being used in a location outside the Federal Republic of

Germany, the applicable local standards and regulations must be complied with. European standard EN 50110 can be used as a guide.

Device-specific safety information

After commissioning, the essential settings of the

VMD460-NA have to be protected against unauthorised

changes by a password.

If the password protection is not used, the device has

to be sealed.

12

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 13

3. Function

3.1 Device features

Straightforward commissioning by means of default basic programs

for national standards and regulations

Single-fault safety

Monitoring of the connected coupling switches

Islanding detection df/dt (ROCOF)

Service Interface RS-485 (software update)

Test function with determination of the disconnection time

Test button for the trigger circuit

The last 300 distribution network faults can be recalled with

time stamp/real-time clock

Continuous monitoring of the phase voltage and line-to-line voltage

Special connection conditions after an infringement of a limit value

Language selection (German, English, Italian)

Backlit graphics LC display

Password protection for device setting

Remote shutdown via ripple control signal receiver

Sealable enclosure

VMD460-NA_D00001_01_M_XXEN/08.2013

13

Page 14

Function

3.2 Description of function

The power generation system is only allowed to connect to the public grid

when the country-specific connection conditions are met. Mains voltage and

mains frequency must be within the defined tolerance range.

The devices utilise several separately adjustable measuring channels for:

Voltage drop protection U <, U<<

Rise-in-voltage protection U >>, U10> / U> (depending on standard)

Frequency decrease protection f <, f<<

Frequency increase protection f >, f>>

This satisfies the requirements for static and dynamic network monitoring.

In case of infringements of a limit value or a remote trip signal, the relay K1

(and K2, if necessary) switch and the alarm LEDs light. Reconnection to the

grid is carried out when the national connection conditions to the grid are

met. Pressing the test button ensures that the relays are checked and the required test (trigger test) of the relays K1 and K2 is carried out.

3.2.1 Calculating the average value of overvoltage

(VDE-AR-N 4105, CEI 0-21, C10/11)

The overvoltage U10 is determined by averaging the last 10-minute measuring interval. Always the highest 10-minute average value value U10> of each

of the three voltages monitored between L1-N, L2-N, L3-N will be indicated.

3.2.2 Self test, automatic

The device runs a continuous self test during which internal malfunctions are

detected and shown on the display as error codes. The alarm relays are not

switched during this test.

14

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 15

Function

3.2.3 Manual self test

The self test cannot be started unless the power generation system has been

started by the VMD460-NA (both alarm LEDs off) and the contact monitoring

is installed and activated.

Start of the manual self test:

1. Press the test button in the standard display (> 1.5 s) or

2. select "TEST" from the menu display

The alarm relays K1 and K2 switch during the self test and open resp. close the

contacts 11/12/14 and 21/22/24.

The self test continues to run until the defined disconnection time t

undervoltage condition has elapsed.

Both coupling switches are switched off during the self

test.

at

off

During the self test, the times are measured until the switching command for

the coupling switches (t

(t

) trip. These periods are automatically indicated by alarm displays

off (TOTAL)

off (DEVICE)

for the measuring channels 15 (t

available in the "Alarm/meas. value" menu.

) is activated or until the coupling switches

off (TOTAL)

) and 16 (t

off (DEVICE)

). They are also

3.2.4 Remote-Trip (RTG / RT1)

The activation of this function is optional and can be used to separate the

power generation system from the supply network remotely via an external

contact. After activating the remote control, the coupling switch will be

switched after ≤ 50 ms.

This function can be deactivated in the "Settings / General / Remote Trip = off"

menu, if not required.

VMD460-NA_D00001_01_M_XXEN/08.2013

15

Page 16

Function

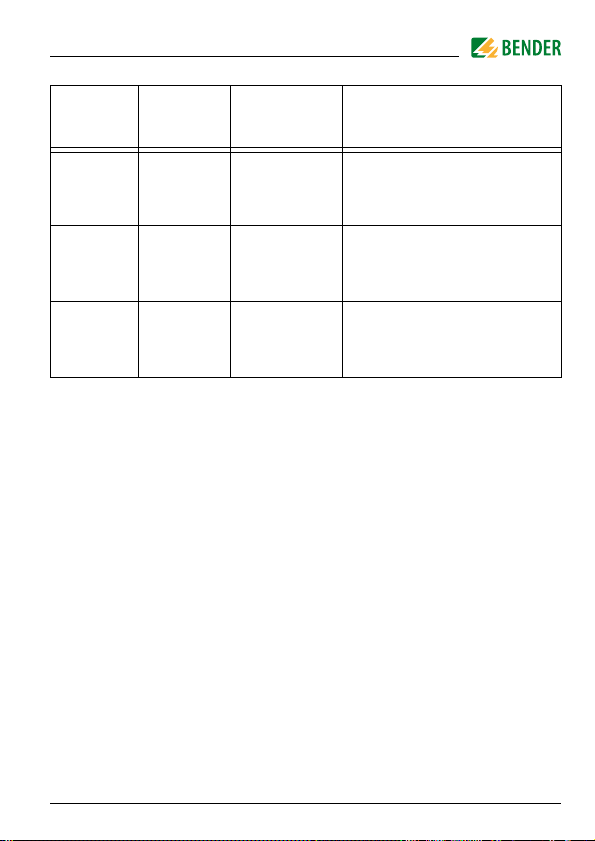

3.2.5 Malfunction and messages

In case of malfunctions or messages, the power

generation system will be separated from the supply

network.

In the case of an internal malfunction or an error in the operation of the coupling switches, both alarm LEDs will flash. The error code or the message in

plain text is indicated on the display.

If several faults or messages occur simultaneously, they will be displayed alternately at four-second-intervals.

In the case of an internal error, make a note of the error code "xx" and contact

the Bender Service.

Code/

Message

1…20

contact

monit. K1

contact

monit. K2

16

LED Meaning Remedy

Both LEDs

flash

Both LEDs

flash

Internal error

Error:

Contact

monitoring

K1

Error:

Contact

monitoring

K2

Make a note from the error

code "xx“ and contact the

Bender Service.

After rectifying the the fault

at the coupling switch/main

switch (e.g. manual connection of the backup switch),

the fault is automatically

cleared. Should, however, a

fault have occurred three

times within 30 seconds, normal operation must be

started again after fault rectification by pressing the

"RESET" button (in the standard display).

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 17

Function

Code/

Message

23

Remote

trip

Enter

norm

3.2.6 Delay times t

Delay time for connection t

When all voltage and frequency values measured, meet the conditions for

connection during the delay time for connection, the alarm LEDs will go out

and the alarm relays will switch.

Response delay t

Minimum period for an error to exist until the alarm relays will switch.

LED Meaning Remedy

Both LEDs

flash

Both LEDs

light continuosly

Both LEDs

light continuosly

off

Internal error

Remote trip

active

No norm

selected

and t

on

off

on

Make a note from the error

code "xx“ and contact the

Bender Service.

Activate RTG/RT1 or deactivate the input via the menu

(off)

Select the application norm

from the menu.

3.2.7 Password protection

By default, the password protection is deactivated (off).

3.2.8 Factory setting

After activating the factory setting, all previously changed settings are reset to

delivery status.

3.2.9 Erasable history memory

The device utilises a history memory for failsafe storing of up to 300 data

records (date, time, channel, event code, measured value).

VMD460-NA_D00001_01_M_XXEN/08.2013

17

Page 18

Function

3.2.10 Passive islanding detection (df/dt)

The VMD460-NA uses a passive method for islanding detection (three-phase

voltage and frequency monitoring).

df/dt

The monitoring of the rate of change of frequency "ROCOF" (df/dt) is an

islanding detection function.

If a section of the network is disconnected by the energy provider, it may happen that the power generation systems located in this section unintentionally

feed this section of the network.

Underfrequency and overfrequency monitoring might not be sufficient to detect this dangerous, uncontrollable state, since the generators try to keep the

frequency at the nominal frequency level.

Due to the unbalance between generated and consumed energy, however,

the frequency fluctuates around the nominal frequency. If this happens at a

certain minimum speed, this is an indication of islanding, hence the power

generation system will be disconnected by the VMD460-NA.

As soon as the rate of change of frequency is below the response value

hysteresis and t

nected.

has expired, the power generation system will be recon-

on

t

off

Response delay: the time during which a limit value

(df/dt) must be violated until the power generation

system is disconnected by the VMD460-NA.

t

on

Delay time, if df/dt disconnected the system.

Measuring window Period of time used to calculate the average of the fre-

quency changes. The bigger the measuring window is

selected the less sensitive will the df/dt function be.

18

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 19

4. Installation, connection and commissioning

Danger of electric shock!

Make sure that the installation area is disconnected

from any electrical source .

Consider the data on the rated voltage and supply

voltage as specified in the technical data!

4.1 Unpacking

Unpack all the parts supplied with the system. Avoid sharp-edged tools

that may damage the content of the packaging.

Compare your order with our delivery note to check that you have

received all products in full. The article numbers and type designation

printed on the nameplates provide an easy means of uniquely identifying each device.

Check all parts supplied for any evidence of damage in transit.

Equipment damaged in transit must not be used. If a device has sus-

tained damage, please contact Bender. Details of who to contact are

indicated on the delivery documents.

When storing the devices in an environment where the temperature is

wintry and cold:

Leave the devices to stand for 3 to 4 hours at room temperature before

connecting the power supply. When the devices are moved from a cold

to a warm environment, condensation will be evident on all parts.

Putting damp devices into operation risks damaging electrical components and there is a danger of electric shock on contact.

4.2 Back-up fuses

Equip the supply voltage of all system components with fuses. IEC 60364-4-43

requires protective devices to be used to protect the component in the event

of a short circuit. We recommend the use of 6 A fuses.

VMD460-NA_D00001_01_M_XXEN/08.2013

19

Page 20

Installation, connection and commissioning

4.3 Notes on mounting

Danger of electric shock!

Make sure that the installation area is disconnected

from any electrical source .

Consider the data on the rated voltage and supply

voltage as specified in the technical data!

The length of the connecting cable of the device

connections DG1/2, D1, D2, DG3/4, D3, D4, RTG and

RT1 is to be limited to 3 m.

To ensure the VMD460-NA's functionality aft er a power

failure, it is recommended to use an external UPS.

The devices are suitable for the following types of installation:

Standard distribution panels according to DIN 43871 or DIN rail mount-

ing according to IEC 60715

Screw mounting using M4 screws

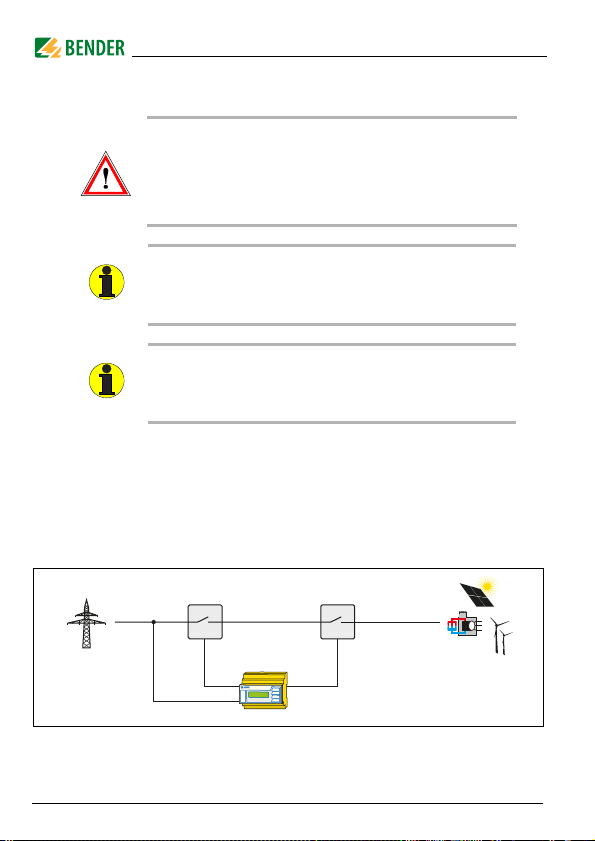

4.4 Block diagram

Coupling switch

Public grid

VMD460

Coupling switch

Power generation system

Fig. 4.1: Block diagram of a central NS protection with coupling switches

20

VMD460-NA_D00001_01_M_XXEN/08.2013

G

Page 21

Installation, connection and commissioning

4.5 Dimension diagram VMD460-NA

All dimensions in mm

Fig. 4.2: Dimension diagram and drawing for screw fixing

4.6 DIN rail mounting:

Snap the rear mounting clip of the device into place in such a way that a safe

and tight fit is ensured.

4.7 Screw mounting

1. Use the tool to move the rear mounting clips (a second. mounting clip

required, see ordering information) to a position that it projects

beyond the enclosure.

2. Then fix the device using two M4 screws.

VMD460-NA_D00001_01_M_XXEN/08.2013

21

Page 22

Installation, connection and commissioning

12

3

4

5

6

7

4.8 Wiring diagram

Connect the device according to the wiring diagram depending on the applicable standard.

4.8.1 VDE-AR-N 4105, BDEW, C10/11

Coupling switch 1 Coupling switch 2

L1

L2

L3

N

U

S

6 A

6 A

A1

A2 L1 L2 L3

6 A 6 A

6 A

DG1/2

D1

11 21

14N

D2

2412 22

Power

generation

system

K1 K2

LINETRAXX®

A B RTGRT1D4D3

VMD460

1112142122

DG1/2

DG3/4

DG3/4

24

L3L2L1

D2

D1

V

D4ND3

RTG

RT1

Fig. 4.3: Wiring diagram VMD460-NA (VDE-AR-N-4105, BDEW, C10/11)

22

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 23

Installation, connection and commissioning

Key

No. Element Function

A1, A2

1

L1, L2, L3, N Power supply connection

2

K1, K2 Relay connections

3

DG1/2,

D1, D2

4

RTG, RT1

5

A, B Service interface

6

R

on/off

7

DG3/4, D3, D4not to be used in accordance with VDE-AR-N 4105,

* Explanation: NC (in non-operating state closed)

Supply voltage U

Contact monitoring coupling switch

DG1/2: GND

D1: feedback signal contact K1

D2: feedback signal contact K2

(feedback signal contacts optionally NC/NO/off)*

RTG: GND

RT1: Remote trip input (optionally NC/NO/off))*

Activate or deactivate the terminating resistor of the

service interface (120

BDEW, C10/11

NO (in non-operating state open)

off (switched off)

(see ordering information)

s

Ω )

Single-fault safety

In o rder to en sure s ingl e-fault safe ty, t he VDE -AR- N 410 5 has t o be r ealised for

the power generation system. A single fault in the actuation circuit must not

prevent a disconnection of the power generating system from the grid.

The monitoring circuit for grid disconnection of power generation systems is

to be installed at the point of supply. The relays used K1 and K2 are to be connected according to the wiring diagram.

Use the contact monitoring function to prevent the

sticking of contacts!

VMD460-NA_D00001_01_M_XXEN/08.2013

23

Page 24

4.8.2 CEI 0-21

12 4

3

6

7

8

5

Installation, connection and commissioning

LINETRAXX®

Backup

< U

VMD460

D2

Coupling switch 1

DG1/2

1112142122

D1

DG1/2

V

D1

11 21

K1 K2

24

L3L2L1

D2

14N

L1

L2

L3

N

U

S

6 A 6 A

A1

A2 L1 L2 L3

DG1/2

6 A 6 A 6 A

D4ND3

A B RTGRT1D4D3

DG3/4

DG3/4

RT1

RTG

Power

generation

system

2412 22

24

Fig. 4.4: Wiring diagram VMD460-NA (CEI 0-21)

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 25

Installation, connection and commissioning

Key

No. Element Function

A1, A2

1

L1, L2, L3, N Power supply connection

2

DG1/2,

D1, D2

3

K1, K2 Relay connections

4

DG3/4,

D3, D4

5

RTG, RT1

6

A, B Service interface

7

R

on/off

8

* Explanation: NC (in non-operating state closed)

Supply voltage U

Contact monitoring coupling switch

DG1/2: GND

D1: feedback signal contact K1

D2: feedback signal contact K2 (Backup)

(optionally NC/NO/off ) *

Digital inputs (external monitoring)

DG3/4: GND

D3: Local control (CEI 0-21 8.6.2.1.1)**

D4: External signal (CEI 0-21 8.6.2.1.2)**

(optionally NC/NO/off )*

RTG: GND

RT1: Remote trip input (optionally NC/NO/off)*

Activate or deactivate the terminating resistor of the

service interface (120

NO (in non-operating state open)

off (switched off)

(see ordering information)

s

Ω )

** For evaluation of the inputs D3 and D4, the mode has to be set accordingly in

the menu:

VMD460-NA_D00001_01_M_XXEN/08.2013

25

Page 26

Installation, connection and commissioning

Example for N/O:

Connection D3, menu: „local“ (D4 will not be evaluated)

D3:

local control

open 49.5…50.5 0.1 s 81.S1

closed 47.5…51.5 0.1 s 81.S2

Example for N/O:

Connection D4, menu: „extern“ (D3 will not be evaluated)

D4:

external signal

open 49.5…50.5 0.1 s 81.S1

closed 47.5…51.5 4 s; 1 s 81.S2

In the case of a failure of the coupling switch 1 (K1), the contact

monitoring function will cause the backup relays to switch (K 2).

f [Hz]

f [Hz]

Disconnection

time

Disconnection

time

Norm CEI0-21

Norm CEI0-21

26

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 27

Installation, connection and commissioning

4.8.3 Details regarding the digital inputs (D1…D4, RT1)

low : < 4 V DC

high : > 6 V DC

U

= 30 V DC

max

1

V1

24

2

DC

Source

Dx: D1, D2, D3, D4, RT1

DGx: DG1/2, DG3/4, RTG

Q1

Open

Collector

Relais

Kontakt

I < 5 mA

Dx

DGx

GND

Fig. 4.5: Block diagram (simplified representation)

4.9 Standards, selectable

The VMD460-NA includes the following standards:

VDE-AR-N 4105

CEI 0-21

BDEW

C10/11

Menu: "Settings" --> "General" --> "Norm".

4.10 Commissioning

Danger of electric shock!

Improper connection can lead to injury to persons and damage

to the device!

Prior to commissioning make sure that the device is properly

connected!

12V

R1

D1

µC

VMD460-NA_D00001_01_M_XXEN/08.2013

27

Page 28

Installation, connection and commissioning

Initial commissioning

When commissioning the device for the first time

Select a language (English, German, Italian).

Select a standard (VDE-AR-N 4105, CEI 0-21, BDEW, C10/11).

In addition, you have to set the date and the time.

You can only change settings in the menus after settings listed above have

been carried out.

The contrast of the LC display can be adjusted to any

ambient brightness.

Select the contrast ratio from an infinite loop display. After

reaching a black display, the contrast setting process starts

again with a white display. Simultaneously press and hold

down the buttons "INFO" and "MENU" until the display text is

clearly readable.

When switching to another application standard, the

associated factory settings will be loaded.

Existing user-defined settings will not be saved when

switching from one standard to another.

4.11 Trigger circuit test by the system erector

During commissioning, the system erector has to check the correct function

of the trigger circuit NS protection/coupling switch, as illustrated in the wiring

diagram in this operating manual, consisting of K1/K2 and coupling switch 1/

coupling switch 2.

Press the test button to activate the coupling switch.

Successful activation must be visualised by the coupling switch.

Contact monitoring of the coupling switch (optional, depending on

the standard)

Note the information about recurrent tests on page 41.

28

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 29

5. Operation and configuration

1

2

3

4

5

6

7

5.1 Getting to know the user interface

LINETRAXX®

Key

No. Element Function

Power On LED, green;

ON

1

ALARM1

ALARM2

2

3

lights when the power supply is available and the device is

in operation;

flashes in case of system fault alarm (external watchdog)

Generation system disconnected:

Both LEDs light (yellow) in the case of limit value violation

and

of voltage, frequency, remote disconnection df/dt

(optional), asymmetry (optional);

Both LEDs flash (yellow) in the case of an internal device

error or a contact monitoring fault;

Only ALARM 1 lights: Delay time for connection t

Backlit LC display

VMD460-NA_D00001_01_M_XXEN/08.2013

VMD460

V

active

on

29

Page 30

Operation and configuration

L1-N 229.9V L1-L2 397.2V

L2-N 229.5V L2-L3 401.9V

L3-N 232.9V L3-L1 400.1V

U10 57.3V f 50.00Hz

Standard display: Toggling between standard display and

Info

device information

ESC

4

5

RESET Standard display: (> 1.5 s) Acknowledgement of fault

6

MENU

7

Menu display: To exit the parameter setting menu without

storing; to go to the next higher menu level

Standard display: A manual test is carried out using the

TEST

test button (> 1.5 s), during which both alarm relays are

triggered (trigger test for testing the coupling switches). In

addition, fault simulation will be carried out (disconnection

time documented)

Menu display: Arrow up button for parameter change and

scrolling

messages from contact monitoring

Menu display: Arrow down button for parameter change/

scrolling

Standard display: Toggling between standard, menu and

alarm display

Menu display: button

Jump to parameter settings; saving the changed parameters

5.2 Various displays

5.2.1 Standard display

In the standard display, phase voltages, line conductor voltages, the maximum 10-minute average value (depending on standard) and the frequency

are indicated on the display.

30

Fig. 5.1: Standard display

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 31

Operation and configuration

VMD460-NA

22.02.13 12:34

Software: Dxxx

Date:18.02.13

ALARM 2/3

Undervoltage

U

(N-1)

: 180.3V

Addr.:1 Chan.:1

Exit

1. Alarm/meas. values

2. History

3. Settings

5.2.2 Info display

Device-specific information is available in the info display.

Fig. 5.2: Info display

For detailed information refer to page 33.

5.2.3 Alarm display

Type and source of alarms are indicated on the alarm display in plain text format.

Fig. 5.3: Al arm displ ay

Explanation: In the example above, the second message of three is being indicated (2/3). The address "Addr" currently is of no significance. The alarm is

outputted on measuring channel 1 and can be accessed via channel number 1

in the "Alarm/meas. values" menu.

5.2.4 Menu display

Alarms, currently measured values as well as the history memory can be called

up via the menu display. Settings can also be changed in this display.

VMD460-NA_D00001_01_M_XXEN/08.2013

Fig. 5. 4: Menu display

31

Page 32

Operation and configuration

5.2.5 Toggling between the displays

You can toggle between the different displays by using the four device buttons. Depending on the type of display (standard display, alarm display, menu

display, info display), the meaning of the buttons is different. The picture below illustrates which button is to be pressed for accessing the individual display. First, it is necessary to determine whether an alarm exists or not.

Without alarm With alarm

ESC

info

display

MENU

standard

dispaly

ESC

menu

display

INFO

MENU

ESC

ESC

info

display

MENU

standard

display

MENU

alarm

display

menu

display

Fig. 5.5: Toggling between the displays (with or without alarm)

32

VMD460-NA_D00001_01_M_XXEN/08.2013

INFO

ESC

MENU

Page 33

Operation and configuration

5.3 INFO button

Dev ice i nfor matio n in c lear t ext f ormat (I nfo d ispl ay) ca n be call ed up with the

"INFO" button. For this purpose press the "INFO" button in the standard display once. Scroll through the individual lines using the arrow buttons :

Device type

Current date, current time

Address BMS-Bus

Software version (measurement technique)

Date of software (measurement technique)

Software version (display)

Date of software (display)

Manufacturer of the device

Address of the manufacturer

Internet address of the manufacturer

Return to standard display via "ESC" resp. .

5.4 Menu button

Toggling between the standard, alarm and menu display (see page 32).

The individual entries in the menu display can be accessed using the arrow

buttons :

The menu display provides the following submenus

Exit

1. Alarm/meas. values

2. History

3. Settings

4. System

5. Info

VMD460-NA_D00001_01_M_XXEN/08.2013

33

Page 34

Operation and configuration

5.4.1 Alarm/meas. values

For detailed information about the value, select the "Alarm/meas. values"

menu item (select the menu item using ).

Select the individual entries by means of the buttons.

Exit

1. U(1-N): Value

2. U(2-N): Value

3. U(3-N): Value

4. U10: Value

5. U(1-2): Value

6. U(2-3): Value

7. U(3-1): Value

8. Frequency: Value

9. df/dt: Value

10. Status*

11. T(ON) : Value

12. Asymmetry: Value

13. Vect. shift**: Value

14. Phase sequ.: Value

15. T(OFF)TOTAL: Value

16. T(OFF)DEVICE: Value

For each of these entries you can check whether an alarm exists or not:

= no alarm

= alarm

* Measuring channel 10: The text depends on the existing message. If several

messages exist, the individual messages appear automatically on the display

every four seconds.

34

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 35

Operation and configuration

History No. 297

Start: 01.02.13 / 15:57:00

Quit:

End: 01.02.13 / 16:07:03

Measuring channel 15: Indicates the total time passed during the self test

between the simulation of 0 V on L1 to the disconnection of coupling

switch 1.

Measuring channel 16: Indicates the total time passed during the self test

between the simulation of 0 V on L1 to the disconnection command for

coupling switch 1.

** not used

5.4.2 History

The fail-safe history memory stores up to 300 events (alarms, tests) with information about alarms and acknowledgements and the time the event happened. If the history memory is full, the oldest entry will be deleted in the

event of an alarm to create space for the new entry (FIFO principle).

For details about erasing the entire history memory manually, refer to

"Chapter 5.4.4 System" on page 38.

Fig. 5. 6: Histor y (overview)

Key

Line 1: Event number

Line 2: Event start: Date/time

Line 3: Acknowledgement of the event: Date/time

Line 4: Event end: Date/time

Possibilities:

1. If you are searching for an event that occurred at a specific time, use the

arrow buttons to scroll to the required entry.

2. Call up details: Use the button to call up the current history memory

entry.

VMD460-NA_D00001_01_M_XXEN/08.2013

35

Page 36

Operation and configuration

History No. 297

Undervoltage

Min. 21 V/max.198 V

Addr.:2 Chan.:1

Fig. 5.7: History (detail)

Key

Line 1: Data record number

Line 2: Alarm status and alarm text (e.g. undervoltage, transformer error,…)

= no alarm

= alarm, fault

Line 3: Minimum and maximum measured value after the occurrence

of an alarm

Line 4: RS-485 address and measuring channel of the device sending

the message

36

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 37

Operation and configuration

Please enter

password:

0 0 0

5.4.3 Settings

Response values for NS protection may only be changed in

consultation with the network operator!

Settings can be password protected. If the password is activated (enabled), all

settings continue to be displayed. When an attempt is made to change settings, the password entry screen appears automatically:

Once a valid password has been entered, access will be granted to settings in

all menus (except the Service menu) until menu mode is exited.

If you can't remember your password, contact the Bender Service.

In principle, all preset response values can be changed, if this should be necessary. The values can be changed in the third level of the menu (column

"twice ") using .

There are two different ways to exit the setting menu:

Save and exit: „ “

Exit without saving: "ESC"

The menu structures in the settings contain different entries for each individual standard. These are listed in detail in "Chapter 7. Selectable default set-

tings".

VMD460-NA_D00001_01_M_XXEN/08.2013

37

Page 38

Operation and configuration

5.4.4 System

The following table gives an overview of the menu structure. The values can

be changed in the third level of the menu (column "twice ") using .

There are two different ways to exit the system menu:

Save and exit: „ “

Exit without saving: "ESC"

Menu: System

1. History Exit

2. Language Exit

3. Clock Exit

38

once twice

Delete

Delete

Cancel

English

English

Italiano

Format

Date

Time

CEST

d.m.y

m-d-y

Toggling between the date elements

Toggling between hour and

minute with

auto

off

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 39

Operation and configuration

Menu: System

4. Password Exit

5. Interface

6. Alarm addresses Exit

7. TEST Cancel

8. RESET Cancel

9. Test

communication

10. External devices Exit

11. Factory setting Cancel

once twice

Password

Status

Exit

Address

Address xxx

TEST

RESET

Exit

1. Chan.

List of the

devices connected

Factory settings

* * *

Toggling between positions with

off

on

1…90

1: MASTER

2…90: Slave

1…150: off/on

Test will be carried out

Reset will be carried out

Channel (1…12)

1: Own address

2…150: External devices

Restore factory settings

VMD460-NA_D00001_01_M_XXEN/08.2013

39

Page 40

Operation and configuration

5.4.5 Info

The following table gives an overview of the information to be called up.

Scroll through the individual lines using the arrow buttons :

Device type

Current date, current time

Address BMS-Bus

Software version (measurement technique)

Date of software (measurement technique)

Software version (display)

Date of software (display)

Manufacturer of the device

Address of the manufacturer

Internet address of the manufacturer

40

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 41

6. Maintenance

Repeat test of the trigger circuit by the system operator

The system operator must ensure that the equipment required for parallel

operation with the low-voltage network is always in proper technical condition. To this end, it is required to have an electrically skilled person check the

protective devices for proper functioning at regular intervals. This requirement is deemed to be satisfied for normal and environmental conditions if the

test intervals mentioned in BGV A3 are adhered to. The repeat test shall include at least the following:

Check of the environmental conditions (pollution, mechanical or isola-

tion damage).

A tripping control of the coupling switch.

Press the "TEST" button to trigger the coupling switch.

Tripping must be visualised by the coupling switch.

The trigger circuit NS protection/coupling switch, in the wiring diagram of this

operating manual consisting of K1/K2 and coupling switch 1/coupling switch

2, separates the power generation system from the public low-voltage grid.

By checking the trigger circuit regularly, sticking of the contactors can be

detected at an early stage.

VMD460-NA_D00001_01_M_XXEN/08.2013

41

Page 42

Maintenance

42

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 43

7. Selectable default settings

Response values for NS protection may only be changed in

consultation with the system operator!

The following standards are implemented in the factory settings of the

VMD460-NA:

VDE-AR-N 4105

CEI 0-21

BDEW guideline

C10/11

In preparation

– G59/2

– G83/2

– DIN V VDE V 0126-1-1

The following tables give an overview about the menu structure for each preset standard. The values can be changed in the third level of the menu

(column "twice ") using .

The respective menu item can be exited with

ESC (= without saving changed parameters)

(= saving the changed parameters)

When switching to another application standard, the

associated factory settings will be loaded.

Existing user-defined settings will not be saved when

switching from one standard to another.

VMD460-NA_D00001_01_M_XXEN/08.2013

43

Page 44

7.1 VDE-AR-N 4105

4105 Menu :

Settings

Exit

General Exit

Volt age Exit

once twice

norm

coupling

U(L-N)

U(L-L)

t SHORT INT.

t (ON) SHORT INT. 1 s…60 min 5 s

t (ON) NORMAL 1 s…60 min 60 s

Remote Trip

U>> off/100…130 % 115 %

U> off/100…130 % 110 %

U (ON) MAX off/100…130 % 110 %

U (ON) MIN off/1…100 % 85 %

U< off/1…100% 80 %

CEI021

4105

1 AC

3N AC

3 AC

50…250 V

87…433 V

1…300 s

6…60.0 min

N/C

N/O

off

Selectable default settings

Fac tor y

setting

3N AC

U(L-N) 230 V

3 s

off

44

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 45

Selectable default settings

4105 Menu :

Settings

Frequ ency Exit

df/dt Exit

Asymmetry Exit

Relay Exit

once twice

f> off/50.00…65.00 Hz 51.50 Hz

f (ON) MAX off/50.00…65.00 Hz 50.05 Hz

f (ON) MIN off/45.00…60.00 Hz 47.50 Hz

f< off/45.00…60.00 Hz 47.50 Hz

Mode off/on off

Resp. value 0.1…9.9 Hz/s 1.0 Hz/s

Hysteresis 1.0…50.0 % 20.0 %

Meas. window 0.05…1.0 s 200 ms

T (OFF) 0.04…30.0 s 100 ms

T (ON) 1 s…60 min 60 s

Mode off/on off

Resp. value 1.0…50.0 % 5.0 %

Hysteresis 1.0…50.0 % 20.0 %

T (OFF) 0.04…30.0 s 100 ms

Relay mode

N/C

N/O

Fac tor y

setting

K1: N/C

K2: N/C

VMD460-NA_D00001_01_M_XXEN/08.2013

45

Page 46

Selectable default settings

4105 Menu :

Settings

once twice

Digital Input Exit

Relay mode N/C; N/O; off

* not used in VDE-AR-N 4105

7.2 CEI 0-21

CEI 0-21 menu:

Settings

Exit

General Exit

1)

Analysis of digital input D4 (external signal)

2)

Analysis of digital input D3 (local control)

once twice

norm

coupling

U(L-N)

U(L-L)

Mode

T (ON) 0.04…30.0 s 70 ms

Remote trip N/C; N/O; off N/C

CEI021, 4105, BDEW,

C10/11

3N AC

1 AC

3 AC

50…250 V

87…433 V

1)

2)

off/extern

/local

Fac tor y

setting

D1: N/C

D2: N/C

D3: off*

D4: off*

Fact ory

setting

3N AC

U(L-N) 230 V

off

46

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 47

Selectable default settings

CEI 0-21 menu:

Settings

Volt age E xit

Frequency Exit

once twice

U>> (59.S2) off/100…130 % 115 %

T (OFF) (59.S2) 0.04…30.0 s 200 ms

U> (59.S1) off/100…130 % 110 %

T (OFF) (59.S1) 0.04…30.0 s 3.00 s

U< (27.S1) off/1…100 % 85 %

T (OFF)(27.S1) 0.04…30.0 s 400 ms

U<< (27.S2) off/1…100 % 40 %

T (OFF)(27.S2) 0.04…30.0 s 200 ms

f> (81>.S1) off/50.00…65.00 Hz 50.50 Hz

T (OFF) (81>.S1) 0.04…30.0 s 100 ms

f< (81<.S1) off/45.00…60.00 Hz 49.50 Hz

T (OFF) (81<.S1) 0.04…30.0 s 100 ms

f> (81>.S2) off/50.00…65.00 Hz 51.50 Hz

f< (81<.S2) off/45.00…60.00 Hz 47.50 Hz

Tlc (OFF) (81>.S2) 0.04…30.0 s 100 ms

Tlc (OFF) (81<.S2) 0.04…30.0 s 100 ms

Tex (OFF) (81>.S2) 0.04…30.0 s 1.00 s

Tex (OFF) (81<.S2) 0.04…30.0 s 4.00 s

Fac tor y

setting

VMD460-NA_D00001_01_M_XXEN/08.2013

47

Page 48

Selectable default settings

CEI 0-21 menu:

Settings

df/dt Exit

Asymmetry Exit

Relay Exit

Digital Input* Exit

once twice

Mode

Resp. value 0.1…9.9 Hz/s 1.0 Hz/s

Hysteresis 1.0…50 % 20%

Meas. window 0.05…1 s 200 ms

T (OFF) 0.04…30.0 s 100 ms

T (ON) 1 s…60 min 60 s

Mode off/on off

Resp. value 1.0…50.0 % 5.0 %

Hysteresis 1.0…50.0 % 20.0 %

T (OFF) 0.04…30.0 s 100 ms

Relay mode

Relay mode

off

on

N/C

N/O

N/C

N/O

off

Fact ory

setting

off

K1: N/C

K2: N/O

D1: N/C

D2: off

D3: N/O

D4: N/O

*D1: Coupling switch K1

D2: Coupling switch K2 (Backup)

D3: local control

D4: external signal

48

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 49

Selectable default settings

7.3 BDEW-guideline

BDEW menu:

Settings

Exit

General Exit

Volt age Exit

once twice

norm

coupling

U(L-N)

U(L-L)

t (ON) 1 s…60 min 30 s

Remote Trip N/C; N/O; off off

U>> off/100…130 % 120 %

T (OFF) 0.04…30.0 s 100ms

U> off/100…130 % 108 %

T (OFF) 1 s…60 min 60 s

U (ON) MAX off/100…130 % 108 %

U (ON) MIN off/1…100% 95 %

U< off/1…100% 80 %

T (OFF) 0.04…30.0 s 2.40 s

U<< off/1…100% 45 %

T (OFF) 0.04…30.0 s 300 ms

CEI021, 4105, BDEW,

C10/11

1 AC

3N AC

3 AC

50…250 V

87…433 V

Fac tor y

setting

3N AC

U(L-N) 230 V

VMD460-NA_D00001_01_M_XXEN/08.2013

49

Page 50

Selectable default settings

BDEW menu:

Settings

Frequency Exit

df/dt Exit

once twice

f>> off/50.00…65.00 Hz off

T(OFF) 0.04…30.0 s 100 ms

f> off/50.00…65.00 Hz 51.50 Hz

T (OFF) 0.04…30.0 s 100 ms

f (ON) MAX off/1…65 Hz 50.05 Hz

f (ON) MIN off/45.00…60.00 Hz 47.50 Hz

f< off/45.00…60.00 Hz 47.50 Hz

T (OFF) 0.04…30.0 s 100 ms

f<< off/45.00…60.00 Hz off

T (OFF) 0.04…30.0 s 100 ms

Mode off/on off

Resp. value 0.1…9.9 Hz/s 1.0 Hz/s

Hysteresis 1.0…50.0 % 20.0 %

Meas. window 0.05…1 s 200 ms

T (OFF) 0.04…30.0 s 100 ms

T (ON) 1 s…60 min 60 s

Fac tor y

setting

50

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 51

Selectable default settings

BDEW menu:

Settings

Asymmetry Exit

Relay Exit

Digital Input* Exit

* not used in BDEW

once twice

Mode off/on off

Resp. value 1.0…50.0 % 5.0 %

Hysteresis 1.0…50.0 % 20.0 %

T (OFF) 0.04…30.0 s 100 ms

Relay mode

Relay mode

N/C

N/O

N/C

N/O

off

Fac tor y

setting

K1: N/C

K2: N/C

D1: off

D2: off

D3: off*

D4: off*

VMD460-NA_D00001_01_M_XXEN/08.2013

51

Page 52

7.4 C10/11

Selectable default settings

C10/11 menu:

Settings

Exit

General Exit

once twice

norm

coupling

U(L-N)

U(L-L)

t SHORT INT. 1 s…60 min 3 s

t (ON) SHORT INT. 1 s…60 min 5 s

t (ON) NORMAL 1 s…60 min 60 s

Remote Trip N/C; N/O; off off

CEI021, 4105, BDEW,

C10/11

1 AC

3N AC

3 AC

50…250 V

87…433 V

Fac tor y

setting

3N AC

U(L-N) 230 V

52

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 53

Selectable default settings

C10/11 menu:

Settings

Volt age Exit

Frequ ency Exit

once twice

U>> off/100…130 % 115 %

T (OFF) 0.04…30.0 s 100 ms

U> off/100…130 % 110 %

T (OFF) 0.04…30.0 s 100 ms

U (ON) MAX off/100…130 % 110 %

U (ON) MIN off/1…100% 85 %

U< off/1…100% 80 %

T (OFF) 0.04…30.0 s 100 ms

U<< off/1…100% off

T (OFF) 0.04…30.0 s 100 ms

f>> off/50.00…65.00 Hz off

T (OFF) 0.04…30.0 s 100 ms

f> off/50.00…65.00 Hz 51.50 Hz

T (OFF) 0.04…30.0 s 100 ms

f (ON) MAX off/50.00…65.00 Hz 50.05 Hz

f (ON) MIN off/45.00…60.00 Hz 47.50 Hz

f< off/45.00…60.00 Hz 47.50 Hz

T (OFF) 0.04…30.0 s 100 ms

f<< off/50.00…65.00 Hz off

T (OFF) 0.04…30.0 s 100 ms

Fac tor y

setting

VMD460-NA_D00001_01_M_XXEN/08.2013

53

Page 54

Selectable default settings

C10/11 menu:

Settings

df/dt Exit

Asymmetry Exit

Relay Exit

Digital Input* Exit

once twice

Mode off/on on

Resp. value 0.1…9.9 Hz/s 1.0 Hz/s

Hysteresis 1.0…50.0 % 20.0 %

Meas. window 0.05…1 s 200 ms

T (OFF) 0.04…30.0 s 100 ms

T (ON) 1 s…60 min 60 s

Mode off/on off

Resp. value 1.0…50.0 % 5.0 %

Hysteresis 1.0…50.0 % 20.0 %

T (OFF) 0.04…30.0 s 100 ms

Relay mode

Relay mode

N/C

N/O

N/C

N/O

off

Fac tor y

setting

K1: N/C

K2: N/C

D1: N/C

D2: N/C

D3: off*

D4: off*

* not used in C10/11

54

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 55

8. Technical data VMD460-NA

( )* = factory setting

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Rated insulation voltage ....................................................................................................................................... 400 V

Overvoltage category.....................................................................................................................................................III

Rated impulse voltage/pollution degree..............................................................................................................6 kV/2

Protective separation (reinforced insulation) between.................(A1, A2) - (L1, L2, L3, N) - (11, 12, 14, 21, 22, 24)

(D1, D2, D3, D4, DG1/2, DG3/4, RTG, RT1)-(A1, A2, L1, L2, L3, N)

Voltage test according to IEC 61010-1:

(N, L1, L2, L3) - (A1, A2), (11, 12, 14, 21, 22, 24) ............................................................................................ 3.32 kV

Supply voltage

Rated supply voltage U

....................................................................................................................................................................DC / 50/60 Hz

Operating range U

............................................................................................................................................................... DC / 40…70 Hz

Power consumption at AC 230 V .....................................................................................................< 7,5 VA /< 3,5 W

Measuring circuit

Nominal system voltage U

Nominal system voltage U

Rated frequency f

Response values

Type of distribution system .............................................................................................................. 1 AC: 230 V, 50 Hz

................................................................................................................................................3(N)AC: 400/230 V, 50 Hz

Relative uncertainty, voltage .........................................................................................................U ≤ 280 V: ≤ ±1 %

.............................................................................................................................................................U > 280 V: ±3 %

Resolution of setting voltage.................................................................................................................................... 1 %

Rated frequency ..................................................................................................................................................... 50 Hz

Relative uncertainty, frequency...................................................................................................................... ≤ ±0.1 %

Resolution of setting f ......................................................................................................................................... 0.05 Hz

................................................................................................................ AC/DC 100…240 V

s

...........................................................................................................................AC/DC 75…300 V

s

max. ................................................................................................................9 VA / 3,5 W

(r.m.s. value) (L-N) ..................................................................................... AC 0…300 V

n

(r.m.s. value) (L-L) ..................................................................................... AC 0…520 V

n

(Un > 20 V) ................................................................................................................... 45…65 Hz

n

VMD460-NA_D00001_01_M_XXEN/08.2013

55

Page 56

Technical data VMD460-NA

Recording of measurement values, condition for connection

L-N, L-L ..........................................................................................................................................................0…1.3 U

<f .................................................................................................................................................................. 45…60 Hz

>f .................................................................................................................................................................. 50…65 Hz

Recording of measurement value, condition for disconnection

L-N, L-L ..........................................................................................................................................................0…1.3 U

<f .................................................................................................................................................................. 45…60 Hz

>f .................................................................................................................................................................. 50…65 Hz

df/dt..........................................................................................................................................................0.1…9,9 Hz/s

Time response

Delay time for connection t

Resolution of setting t

.......................................................................................................................................................................>10 s: 1 s

Operating time, voltage t

Operating time, frequency t

Recovery time t

............................................................................................................................................. ≤ 300 ms

b

............................................................................................ 40 ms…30 s / 1…3600 s

on

..............................................................................................................................< 10 s: 0.1 s

on

.............................................................................................................................. ≤ 15 ms

ae

.......................................................................................................................... ≤ 1 5 ms

ae

Digital inputs

Monitoring of potential-free contacts or voltage inputs:....................................closed = low; 0…4 V; I

........................................................................................................................................... open = high; > 6…≤ 30 V

< –5 mA

in

D1 ..........................................................................................................................................feedback signal contact K1

D2 ..........................................................................................................................................feedback signal contact K2

D3 ....................................................................................................................................................local control (mode)

D4 ................................................................................................................................................external signal (mode)

RT1..................................................................................................................................................................remote trip

DG1/2, DG3/4, RTG................................................................................................................................................... GND

max. length of the connecting cables of digital inputs ............................................................................................ 3 m

Displays, memory

Display .......................................................................................................... LC display, multi-functional, illuminated

Display range measured value ................................................................................................................. AC 0…520 V

Operating uncertainty, voltage ......................................................................................................U ≤ 280 V: ≤ ±1 %

.............................................................................................................................................................U > 280 V: ±3 %

Operating uncertainty, frequency ..................................................................................................................≤ ±0.1 %

n

n

56

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 57

Technical data VMD460-NA

History memory for the last 300 messages ............................................................... per data record measured values

Password.....................................................................................................................................on/off / 0…999 (off*)

Switching elements

Number of changeover contacts............................................................................................................... 2 x 1 (K1, K2)

Operating mode............................................................................................................. N/C operation / N/O operation

Electrical service life under rated operating conditions....................................................10.000 switching operations

Contact data acc. to IEC 60947-5-1:

Utilisation category ............................................................. AC 13 ......... AC 14........ DC-12........ DC-12....... DC-12

Rated operational voltage .................................................. 230 V ......... 230 V ........... 24 V......... 110 V....... 220 V

Rated operational current ........................................................ 5 A ............. 3 A ............. 1 A.......... 0.2 A ........ 0.1 A

Minimum contact rating ............................................................................................................ 1 mA at AC/DC ≥ 10 V

Environment/EMC

EMC ................................................................................................................................... DIN EN 60255-26 / CEI 0-21

Operating temperature.............................................................................................................................-25…+55 °C

Classification of climatic conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) ........................................................3K5 (except condensation and formation of ice)

Transport (IEC 60721-3-2) ................................................................2K3 (except condensation and formation of ice)

Long-term storage (IEC 60721-3-1) .................................................1K4 (except condensation and formation of ice)

Classification of mechanical conditions acc. to IEC 60721:

Stationary use (IEC 60721-3-3) ..............................................................................................................................3M4

Transport (IEC 60721-3-2) ..................................................................................................................................... 2M2

Storage (IEC 60721-3-1) ........................................................................................................................................ 1M3

Connection

Connection type...................................................................................screw-type terminals (or push-wire terminals)

Connection properties:

Rigid ............................................................................................................................... 0.2…4 mm

Flexible ...................................................................................................................... 0.2…2.5 mm

2

(AWG 24…12)

2

(AWG 24…14)

Stripping length..............................................................................................................................................8…9 mm

Tightening torque..................................................................................................................................... 0.5…0.6 Nm

VMD460-NA_D00001_01_M_XXEN/08.2013

57

Page 58

Technical data VMD460-NA

Other

Operating mode ............................................................................................................................continuous operation

Mounting ..................................................................................................................................................... any position

Degree of protection, built-in components (DIN EN 60529) ................................................................................. IP30

Degree of protection, terminals (DIN EN 60529) ................................................................................................... IP20

Enclosure material ....................................................................................................................................polycarbonate

Flammability class ........................................................................................................................................... UL94 V-0

DIN rail mounting acc. to................................................................................................................................. IEC 60715

Screw fixing ......................................................................................................................... 2 x M4 with mounting clip

Software version .......................................................................................................................................... D398 V1.1x

Weight.................................................................................................................................................................≤ 360 g

( )* = factory setting

58

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 59

Technical data VMD460-NA

8. 1 Standards, approvals and certifications

The VMD460-NA fulfils the requirements of the following standards:

VDE-AR-N 4105 (Technical minimum requirements for the connection

to and parallel operation with low-voltage distribution networks)

CEI 0-21 (Regola tecnica di riferimento per la connessione di utenti

attivi e passivi alle reti BT delle imprese distributrici di energia elettrica)

C10/11(Prescriptions techniques spécifiques de raccordement d'instal-

lations de production décentralisée fonctionnant en parallèle sur le

réseau de distribution; June 2012)

BDEW(Technische Richtlinie Erzeugungsanlagen am Mittelspannung-

snetz; Bundesverband der Energie- und Wasserwirtschaft e.V., Berlin,

June 2008)

VMD460-NA is certified by Bureau Veritas.

8. 2 Ordering information

Device type

VMD460-NA-D-2

Nominal voltage U

3(N) AC, 400/230 V,

50 Hz

Supply voltage U

n

AC/DC 100…240 V

DC / 50/60 Hz

Mounting clip for screw mounting (1 piece per device, accessories)

Device version with push-wire terminals on request.

VMD460-NA_D00001_01_M_XXEN/08.2013

Art. No.

S

B 9301 0045

B 9806 0008

59

Page 60

Technical data VMD460-NA

60

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 61

INDEX

A

Alarm display 31

Automatic self test

B

Button

- INFO

33

- MENU

33

- RESET

30

- TEST

30

14

- Info

31

- Menu

31

- Toggling between the displays

E

Electrically skilled person 11

Enter button

F

Factory setting 17, 27

H

How to use this manual 7

30

32

C

Calculating the average value of overvolt-

age

14

CEI 0-21

- Settings

46

- Wiring diagram

Central NS protection with coupling switch

20

Conditions for connection

D

Description of function 14

df/dt

18

Display

- Alarm

VMD460-NA_D00001_01_M_XXEN/08.2013

24

14

31

I

INFO button 33

Info display

31

Installation and connection

Intended use

Islanding detection, passive

L

LEDs 29

M

Maintenance 41

Malfunction

Manual self test

Measured values

11

16

15

34

19

18

61

Page 62

MENU button 33

Menu display

Mounting clip for screw mounting

N

Network and system protection 11

O

Operation and configuration 29

Ordering information

P

Password protection 17

Preset function

R

Remote-Trip 15

RESET button

Response delay ton

S

Service 8

Single-fault safety

Standard display

Support

T

Technical data 55

TEST button

Time delays

31

59

14

30

17

27

30

8

30

16

59

- Wiring diagram

W

Wiring diagram 22

Work activities on electrical installations

workshops

9

22

12

V

VDE-AR-N 4105

- Settings

62

44

VMD460-NA_D00001_01_M_XXEN/08.2013

Page 63

Page 64

D0000101MXXEN

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Gruenberg • Germany

Postfach 1161 • 35301 Gruenberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender-de.com

Web: http://www.bender-de.com

Loading...

Loading...