Page 1

Operating Manual

UNIMET® 300ST

Testing system for

electrical safety

Software version: 3.2 and later

TGH1365en/10.2012

Page 2

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Grünberg • Germany

Postfach 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-mail: info@bender-de.com

Web: http://www.bender-de.com

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. How to get the most out of this manual ............................................................. 5

1.1 About this operating manual .............................................................................................. 5

1.2 Technical support .................................................................................................................... 5

1.3 Explanation of symbols and notes ..................................................................................... 6

2. Safety instructions .................................................................................................. 7

2.1 Delivery ........................................................................................................................................ 7

2.2 Intended use .............................................................................................................................. 7

2.3 Skilled persons .......................................................................................................................... 7

2.4 General safety instructions ................................................................................................... 7

2.5 Delivery conditions, guarantee, warranty and liability .............................................. 8

3. System description ................................................................................................. 9

3.1 Function ...................................................................................................................................... 9

3.2 Standard-compliant tests .................................................................................................. 10

3.3 System components ............................................................................................................10

3.4 Controls .................................................................................................................................... 12

4. Operation and configuration ............................................................................. 13

4.1 Commissioning ...................................................................................................................... 13

4.1.1 Connecting a printer ............................................................................................................ 14

4.1.2 Connecting the keyboard and barcode scanner ....................................................... 14

4.2 Principle of operation .......................................................................................................... 14

4.2.1 Operating the device ........................................................................................................... 14

4.2.2 Operation via the keyboard .............................................................................................. 15

4.2.3 Reading in with the barcode reader .............................................................................. 15

4.3 Main menu .............................................................................................................................. 16

4.4 Test engineer catalogue ..................................................................................................... 16

4.5 Device settings ....................................................................................................................... 19

4.5.1 Test probe calibration ......................................................................................................... 20

4.5.2 Device type query ................................................................................................................. 21

4.5.3 Warm-up and cool-down period ..................................................................................... 21

4.5.4 Changing the company name ......................................................................................... 22

4.5.5 Time/date ................................................................................................................................. 22

TGH1365en/10.2012

3

Page 4

4.5.6 RS-232 parameters ................................................................................................................ 23

4.5.7 Buzzer On/Off ......................................................................................................................... 24

4.5.8 Summer time/winter time ................................................................................................. 24

4.5.9 Language/Sprache ............................................................................................................... 25

4.5.10 Firmware update ................................................................................................................... 25

4.6 Information .............................................................................................................................. 28

5. Testing and measuring ........................................................................................ 29

5.1 Testing via classification ..................................................................................................... 29

5.1.1 Classification ........................................................................................................................... 29

5.1.2 Tests ........................................................................................................................................... 33

5.1.3 Evaluating the test result .................................................................................................... 40

5.2 Recurrent test and device catalogue ............................................................................. 41

5.2.1 Collective printout ................................................................................................................ 42

5.2.2 Backing up the device catalogue .................................................................................... 43

5.3 Single test ................................................................................................................................. 49

Inhaltsverzeichnis

6. Maintenance and calibration ............................................................................. 51

6.1 Calibration ............................................................................................................................... 51

6.2 Changing the battery ........................................................................................................... 51

6.3 Error messages ....................................................................................................................... 51

6.4 Disposal .................................................................................................................................... 52

7. Data ......................................................................................................................... 53

7.1 Standards ................................................................................................................................. 53

7.1.1 Application standards ......................................................................................................... 53

7.1.2 Design standards ................................................................................................................... 53

7.2 Test steps .................................................................................................................................. 54

7.3 Technical specifications ...................................................................................................... 56

7.4 Ordering data ......................................................................................................................... 57

INDEX ...........................................................................................................................59

4

TGH1365en/10.2012

Page 5

1. How to get the most out of this manual

1.1 About this operating manual

This operating manual describes the UNIMET® 300ST with the software version indicated on the cover page. The functions and processes described may vary from those featured in other versions. It is

designed for electrically skilled persons working in electrical engineering and electronics.

Please read this operating manual before using the devices. This documentation must be kept in an

easily accessible location near to the device.

Although great care has been taken in the drafting of this operating manual, it may nevertheless

contain errors and mistakes. The Bender Group cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

Each of the registered trademarks which appears in this document remains the property of its owner.

1.2 Technical support

As a Bender customer, you will receive technical support and assistance in the event of queries relating to equipment you have purchased. Please contact our Service Department or your next Bender

agency for more information:

Service-Hotline:

0700-BenderHelp (Telefon und Fax)

Carl-Benz-Straße 8 • 35305 Grünberg • Germany

Tel: +49 6401 807-760 • Fax: +49 6401 807-629

E-Mail: info@bender-service.com • www.bender-de.com

TGH1365en/10.2012

5

Page 6

How to get the most out of this manual

Danger !

Warning

Caution

1.3 Explanation of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documentation:

This symbol indicates an immediate risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions

will result in death, serious physical injury or substantial damage to property.

This symbol indicates a potential risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions

may result in death, serious physical injury or substantial damage to property.

This symbol indicates a potentially dangerous situation.

Failure to observe the associated instructions and take appropriate precautions

may result in minor physical injury or damage to property.

This symbol indicates important information about the correct use of the equipment purchased.

Failure to observe the associated instructions can result in equipment malfunctioning or cause problems in the environment in which it is being used.

This symbol indicates tips for using the equipment and particular useful information. This type of information will help you to optimise your use of the equipment.

6

TGH1365en/10.2012

Page 7

2. Safety instructions

2.1 Delivery

Inspect the dispatch packaging and equipment packaging for damage, and compare the contents

of the package with the delivery documents. Equipment damaged in transit must not be used. If

equipment has been damaged in transit, contact Bender immediately.

Equipment may only be stored in areas where it is protected against dust, damp, spray water and

dripping water and where the specified storage temperatures can be assured.

The selling company’s "General conditions of sale and delivery" always apply.

2.2 Intended use

The UNIMET® 300ST has been designed exclusively for use in the area of application stipulated in the

chapter entitled "System description" on page 9.

Intended use also implies:

Observance of all instructions in this operating manual and

Compliance with any test intervals

Use which deviates from or is beyond the scope of these technical specifications is considered noncompliant. The Bender Group cannot accept any liability for damage resulting from such use.

2.3 Skilled persons

Only electrically skilled persons may work on Bender products. Personnel who are familiar with the

installation, commissioning and operation of the equipment and have undergone appropriate training are considered skilled persons. Such personnel must have read this manual and understood all

instructions relating to safety.

2.4 General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in

respect of technical safety. However, the use of such devices may introduce risks to the life and limb

of the user or third parties and/or result in damage to Bender devices or other property.

Only use Bender equipment:

– As intended

– In perfect working order

– in compliance with the accident prevention regulations and guidelines applicable at the loca-

tion of use

Eliminate all faults that may endanger safety immediately

Do not make any unauthorised changes and only use replacement parts and optional accesso-

ries purchased from or recommended by the manufacturer of the equipment. Failure to

observe this requirement can result in fire, electric shock and injury

Information plates must always be clearly legible. Replace damaged or illegible plates immedi-

ately.

TGH1365en/10.2012

7

Page 8

Safety instructions

2.5 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender apply.

For software products, the "Softwareklausel zur Überlassung von Standard-Software als Teil von

Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und

Leistungen der Elektroindustrie" (software clause in respect of the licensing of standard software as

part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband Elektrotechnik- und Elektronikindustrie e.V., the German Electrical and Electronic Manufacturers' Association) also applies.

Delivery and payment conditions along with a copy of the software clause can be obtained from

Bender in printed or electronic format.

8

TGH1365en/10.2012

Page 9

3. System description

3.1 Function

The UNIMET® 300ST is used to test electrical safety. It has been designed for following areas of use:

Hospital and care beds

"Prüfung nach Instandsetzung, Änderung elektrischer Geräte - Wiederholungsprüfung elek-

trischer Geräte" (Inspection after repair, modification of electrical appliances - Periodic inspection on electrical appliances) DIN VDE 0701-0702 (VDE 0701-0702):2008-06

with appropriate adapter

according to DIN VDE 0701-0702 and DIN EN 62353

* Use the DS32DCT three-phase current adapter to test devices not being in operation.

Use the DS32A three-phase current adapter to test devices during operation.

The test system supplies measurement results which it evaluates immediately in order to classify the

test as "passed" or "failed". The test sequence which follows classification contains a visual inspection

and a functional test in addition to the electrical tests. The test sequence can be carried out automatically or manually depending on the device under test.

The test results can be displayed on the screen, saved or printed out using an external printer. In the

event of unexpected results, the DUT can be inspected in more detail by carrying out a single test.

The device catalogue provides memory space for the test results from up to 600 tested beds or devices.

*

also protection class I and II three-phase electrical equipment

Tests can be transferred to a PC software program via the RS-232 interface. This software is included

with the UNIMET

®

300ST. For recurrent tests, the data stored in the PC software are transferred back

to the UNIMET® 300ST. The RS-232 interface is also used for any subsequent updates of the internal

operating software on the test system.

The test engineer catalogue can be beneficial if more than one person is working with the test system. Test engineers already registered on the system are simply selected from this folder. There is no

need to re-enter the name of the test engineer. The names of up to ten test engineers can be stored.

The LC display is backlit. For entering data, a standard keyboard or barcode reader can be connected

to the PS/2 interface.

UNIMET® 300ST has been designed solely for use with earthed systems. If the test

system is used other than as intended, i.e. on an IT system, the measured values

of any leakage currents will not be reproducible. The test result cannot be used.

Alternative measurements of leakage currents, however, carried out with the

UNIMET® 300ST in IT systems will deliver correct test results.

TGH1365en/10.2012

9

Page 10

System description

3.2 Standard-compliant tests

The UNIMET® 300ST carries out measurements and tests according to the following standards (see

also chapter "7.1 Standards"):

IEC 62353:2007-05

DIN EN 62353 (VDE 0751-1):2008-08

ÖVE/ÖNORM EN 62353:2009-01-01

DIN VDE 0701-0702 (VDE 0701-0702):2008-06

ÖVE E8701-1:03-01

The UNIMET® 300ST carries out the following measurements and tests:

Visual inspection

System voltage

Measurement of current consumption and calculation of power consumption

PE resistance for Protection Class I equipment

Insulation resistance

Equipment leakage current according to the differential measurement method or by direct

measurement

Equipment leakage current -Alternative method

Touch or PE conductor current according to the differential measurement method or by direct

measurement

Functional test

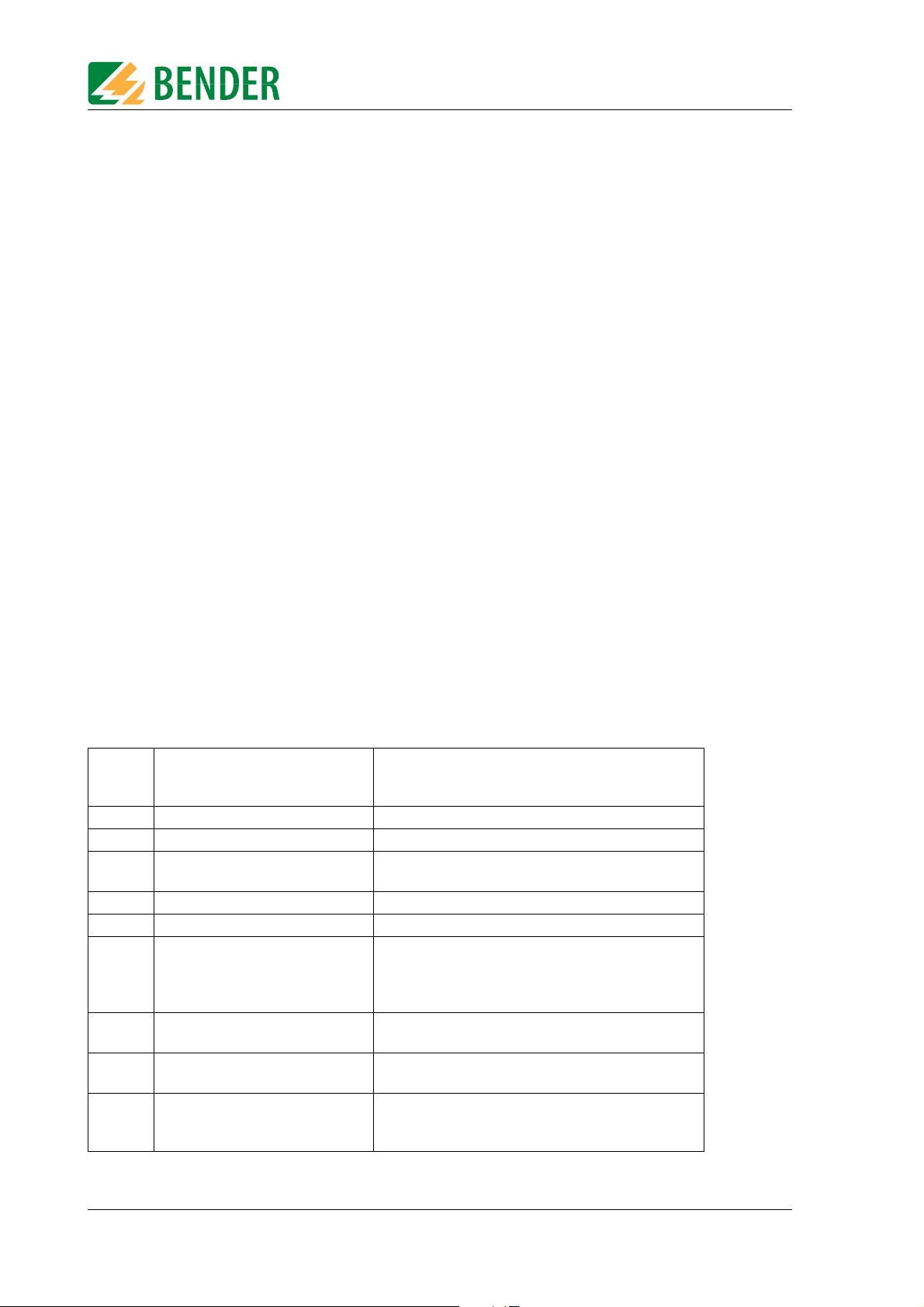

3.3 System components

The following accessories are supplied with the UNIMET® 300ST test system:

1 Carrying bag For the storage and transport of the test system

and its accessories. Accessories are kept in the side

pocket and the inside pocket.

2 Test probe For testing accessible parts of the DUT

3 Test terminal (safety claw grip) For connection to accessible parts of the DUT

4 Interface cable (null modem

cable)

5 Calibration certificate Proof of the calibration carried out in the factory

6 Technical device manual on CD Test system manual

7 UNIData300 PC software (CD) UNIData300 software for

8 VK701-6 Adapter Schuko

(German)

9 VK701-7 Adapter for non-

heating appliances

10 USB1.1 RS-232 converter Enables data exchange between the RS-232

Enables data to be exchanged between the test

system and a PC (RS-232 interface)

- backing up the device catalogue on a PC

- transferring a firmware update to the

UNIMET® 300ST

For testing extension cables and socket strips

For testing device connecting cables

interface of the UNIMET® 300ST and the USB port

of a PC (with installation CD)

10

TGH1365en/10.2012

Page 11

1

4

7

6

5

9

8

10

2

3

Side pocket

contains the accessories

Pos. 2, 3, 4, 8, 9, 10

Inside pocket

contains the accessories

Pos. 6, 7

System description

The test system and its accessories

TGH1365en/10.2012

Fig. 3.1: Accessories

11

Page 12

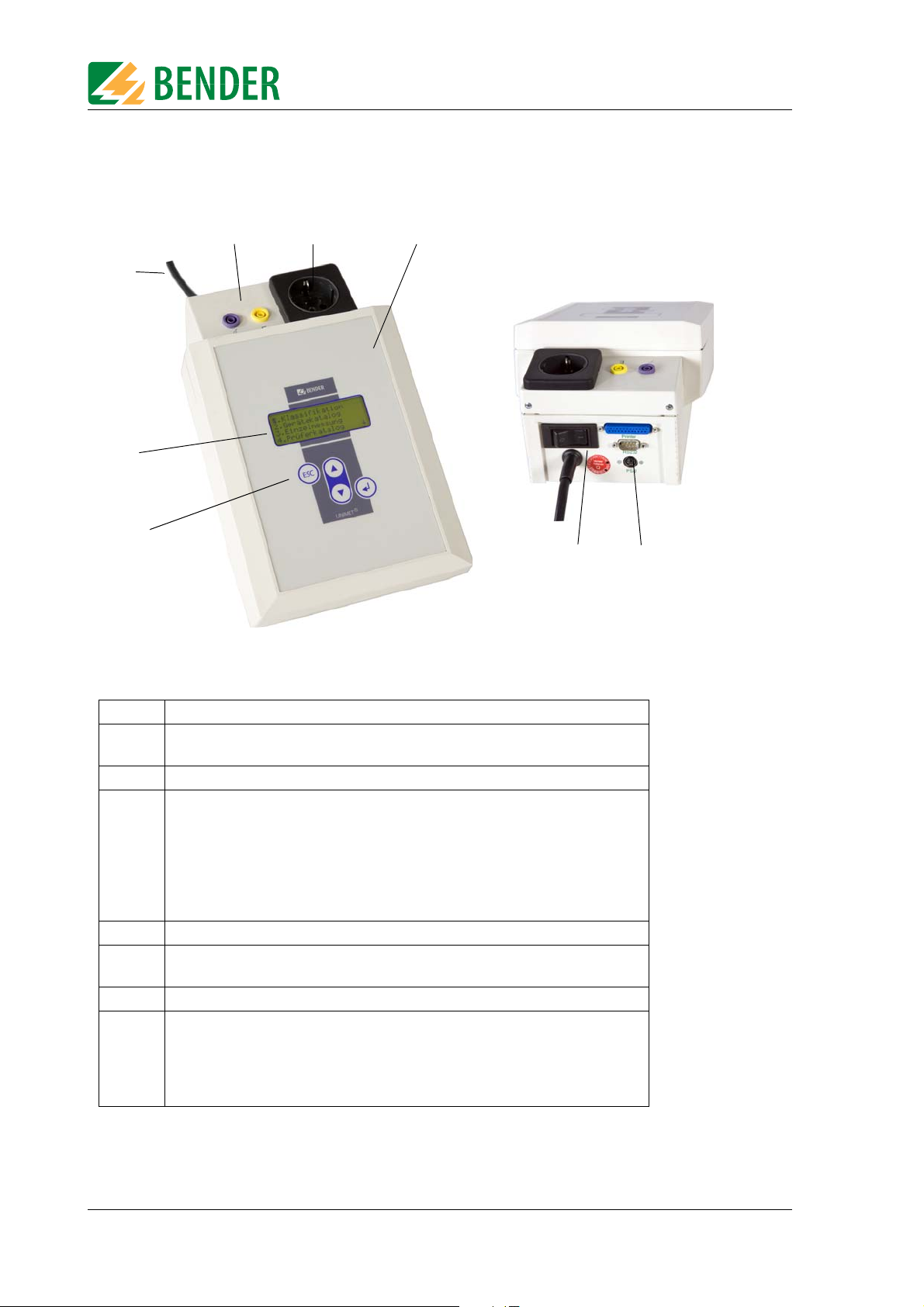

3.4 Controls

2

8

7

6

5

4

3

1

System description

1 Control buttons

2 Backlit LCD for displaying the user menu and the measurement results. Four

lines of 20 characters each.

3 Permanently attached power cable for connection to the supply voltage.

4Sockets

- violet: Connection for test probe for testing accessible parts of the

device under test.

- yellow (E): for a second measuring lead when the low-resistance continuity

5 Test socket: This is where the DUT's power supply cable is plugged in.

6 Durable plastic enclosure, with pushbuttons for safe storage in the carrying

bag.

7 Power switch with thermo-magnetic circuit-breaker.

8Interfaces

- RS-232 interface, 9-pin, galvanically isolated, for connection to a PC

- Centronics interface for connection to a printer

- PS/2 port for connection to an external standard keyboard and a barcode

reading wand or scanner.

of the PE conductor is to be measured between two points (e.g.,

on single-phase, permanently installed devices or extension

cables).

12

TGH1365en/10.2012

Page 13

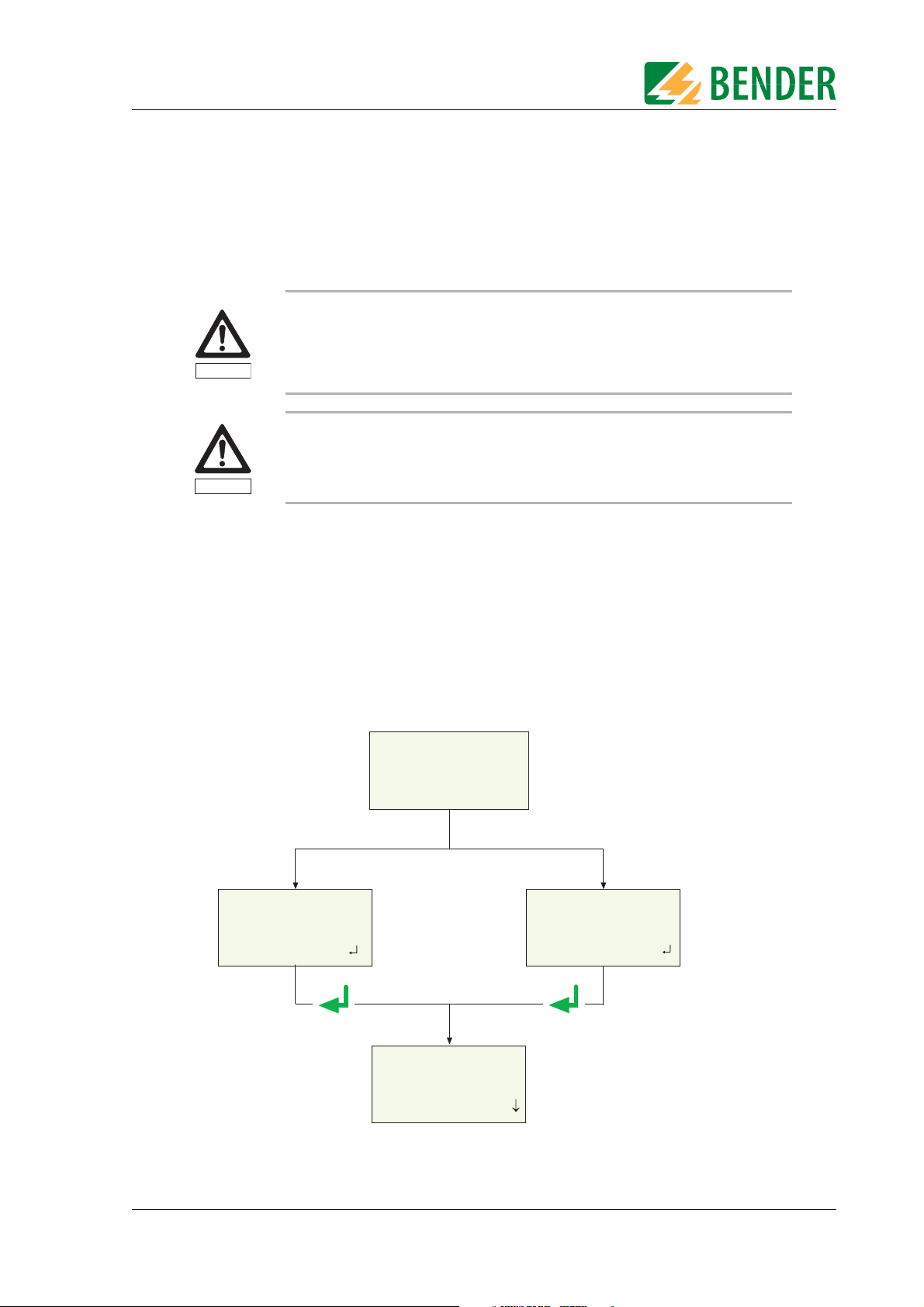

4. Operation and configuration

Warning

Caution

-----------------------------Test eng. logged on:

Hofmann

Next:

** WARNiNG **

No test engineer

logged on!

Next:

UNIMET300ST

Test system for

electrical safety

BENDER GMBH & CO.KG

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

If no test engineer

has logged on yet

If a test engineer has

already logged on

Main menu

Press the ENTER key

or wait 3 seconds

leads to main menu

4.1 Commissioning

Inspect UNIMET® 300ST, its supply cable and measuring leads connected to it for

visible damage on the outside. Do not operate equipment showing any visible

damage.

The UNIMET® 300ST must always be connected to the supply voltage indicated

on the nameplate. Failure to observe this requirement may damage the test system and any device under test connected to it.

1. Lay the UNIMET® 300ST down on an even surface with the coloured edges of the bag facing

up. Open the two covers (Velcro fasteners).

2. Connect the UNIMET® 300ST to the supply voltage using the permanently attached power

cable.

3. Switch on the device using the power switch.

The test system logs on with a beep (only when the buzzer is switched on) and displays the welcome

text:

The test system is now ready for operation. The main menu appears.

TGH1365en/10.2012

13

Page 14

Operation and configuration

Caution

4.1.1 Connecting a printer

Earthed printers can affect the measurements. Therefore, during the measurements, make sure that either

- the Centronics interface is not connected to an earthed printer or

- the Centronics interface is electrically isolated via a suitable component.

A printer can be connected to print out the test results. Providing that:

The printer used has an IBM 8-bit character set

The printer is set to IBM emulation

®

GDI printers (GDI = Graphic Device Interface) are not suitable for the UNIMET

300ST.

You need a standard printer cable (25-pole D-Sub plug to Centronics) to connect the printer. This cable is not included with the equipment.

4.1.2 Connecting the keyboard and barcode scanner

A keyboard and/or barcode reading wand or barcode scanner can be used to make it easier to input

the ID numbers and names of test engineers. UNIMET® 300ST supports the PS/2 interface to which

either a standard keybboard, a PS/2 barcode-pen reader or PS/2 barcode scanner can be connected.

If an AR100 barcode-pen reader is connected to a PS/2 keyboard switch cable (see “Ordering data”

auf Seite 57.), it can be connected to a keyboard at the same time. If no keyboard is connected, then

plug the keyboard simulator supplied with the AR100 barcode-pen reader to this port.

The keyboard and barcode pen reader or barcode scanner can be plugged in and unplugged during

operation. Adjustments on the UNIMET are not necessary. The keyboard and barcode pen reader

must not be connected before switching on the UNIMET. This increases flexibility during testing.

When the UNIMET detects a PS/2 keyboard, then the "Num-Lock" LED lights up. The LED indicates

that the keyboard is ready.

4.2 Principle of operation

4.2.1 Operating the device

All the functions of the UNIMET® 300ST are controlled using the four control keys and the displays on

the screen. The current position on the menus is indicated by a flashing marker (cursor).

ESC The ESC button enables you to leave functions without making

Use the arrow buttons to move the cursor up or down on the menus.

Use the Enter button to confirm selection of the current menu item.

changes. It also enables you to return to the main menu.

14

TGH1365en/10.2012

Page 15

Operation and configuration

4.2.2 Operation via the keyboard

An external keyboard makes it easy to enter the names and ID numbers of the test engineers. You

can also operate the UNIMET entirely via the keyboard. The Cursor block " ", " ", " " "ENTER"

and "ESC" keys have the same function as the buttons on the front of the UNIMET.

Note when entering text:

The text entry cannot be longer than 20 characters. The UNIMET will truncate longer entries to

20 characters.

You can enter all characters which can be selected directly on UNIMET.

Upper and lower case is available but not umlauts.

The numeric keypad can only be used to enter digits. The LED "Num-Lock" therefore lights up

constantly.

When entering text, the following keys can be used to edit the text:

" ", " " (Cursor block), " " (Backspace), Del, Home.

Entries via the keyboard can also be combined with texts read in from the barcode scanner and

barcode reading wand.

Save the entry after entering the last character by

– by holding down the Enter button " " on the UNIMET for approx. 3 seconds

– or by pressing the " " ENTER key on the keyboard once.

4.2.3 Reading in with the barcode reader

Refer to the operating instructions for the barcode reading wand or barcode scanner.

The AR100 barcode reading wand (see “Ordering data” auf Seite 57.) reads more reliably by sweeping it quickly over the barcode. Also follow the instructions for the barcode reading wand. Barcodes

can be read both forwards and backwards.

The data string which is read in can be up to 20 characters long. The UNIMET will truncate longer entries to 20 characters.

When reading in the names and ID numbers of new test engineers, the input screen will remain

open. This allows you to check the entry and change or replace it if necessary. .

You can delete the entry and go to the previous menu by holding down

– the "ESC" button on the UNIMET for approx. 3 seconds

– or by pressing the "ESC" key on the external keyboard once.

Save the entry by holding down

– the Enter button " " on the UNIMET for approx. 3 seconds

– or by pressing the " " Enter key on the external keyboard once.

You can use the barcode scanner or barcode reading wand to call up tests from the device catalogue

again using the ID number. In this case, after successfully reading in the barcode, it will immediately

switch to the next screen of the operating process.

TGH1365en/10.2012

15

Page 16

Operation and configuration

Main menu

1. Select "Test eng. catalog."

ESC

- Select and log on test engineer

- Enter and log on new test engineer

- Delete existing test engineer

2. select required function:

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog.

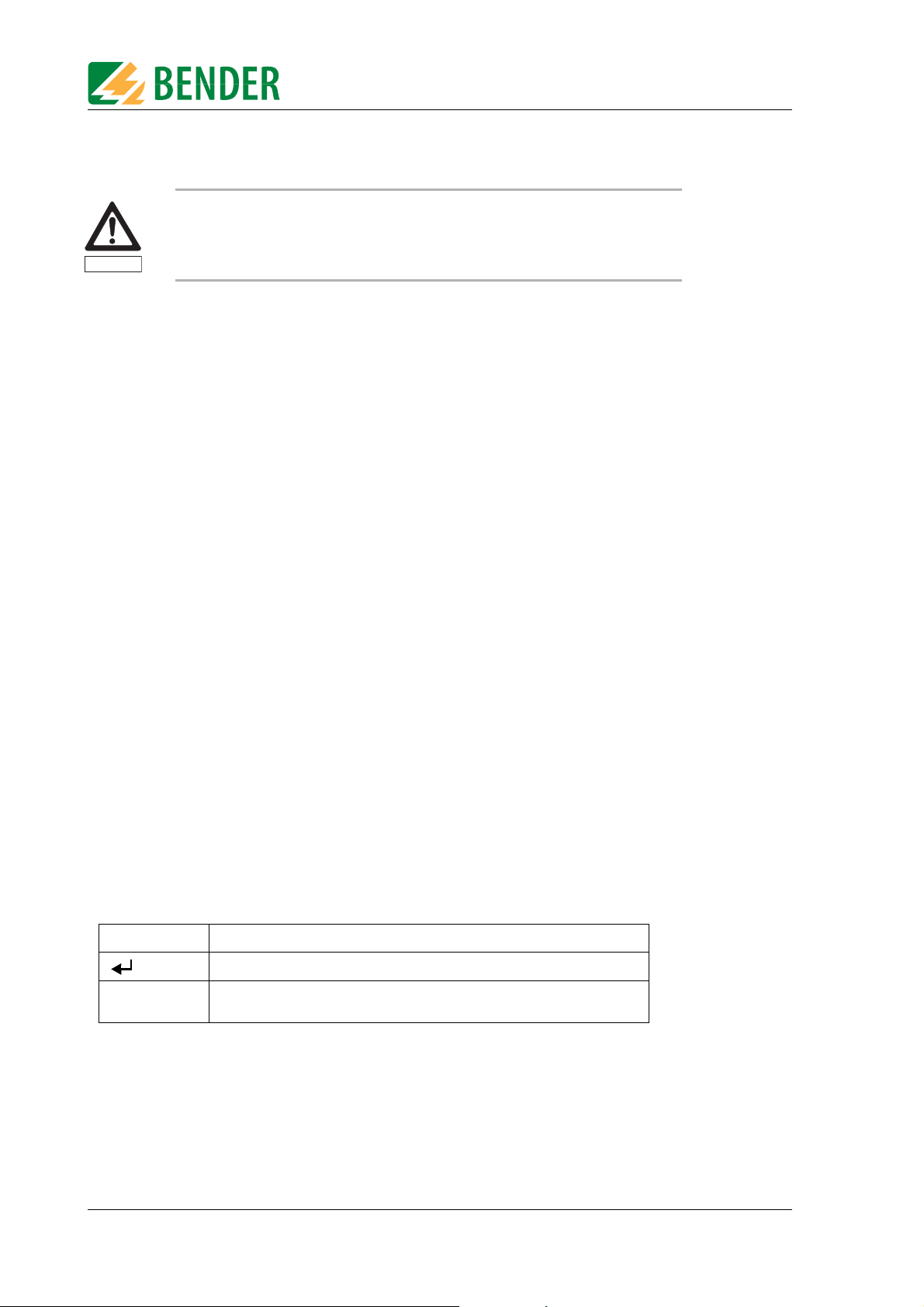

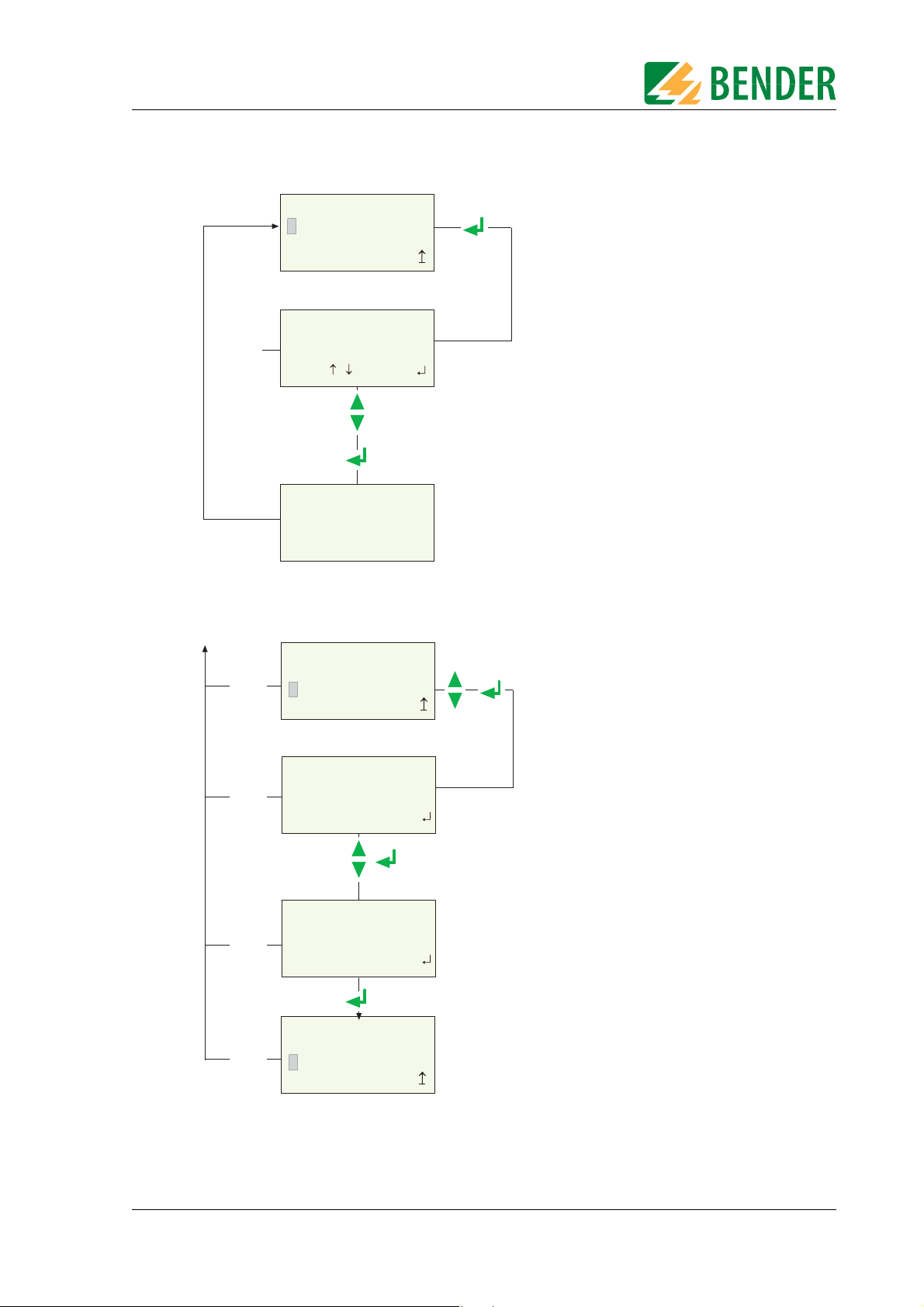

4.3 Main menu

All UNIMET® 300ST functions and submenus can be accessed from the main menu.

Menu item Function Page

1. Classification Answer the questions that appear on the screen. The

test system will identify the required test steps and

limits to be observed. The assisted test sequence will

guide you through all necessary steps to be taken.

2. Device catalogue The test results, tests and limits of the device tested by

the test system are stored in the device catalogue.

3. Single test Test steps can be called up in the form of single tests

and repeated as often as required.

4. Test engineer

catalogue

5. Device setting Settings for test probe, type query, warm-up period,

6. Info Provides information about the device names,

Select test engineer, enter new test engineer, delete

test engineer

company name, clock, RS-232 interface, buzzer,

language and update

software version and serial number of the device.

29

41

49

16

19

28

Each submenu is accessed by selecting it with the arrow buttons and confirming by pressing the

" " button.

4.4 Test engineer catalogue

The names of the test engineers are stored in the "Test engineer catalogue". The test engineer whose

name appears in the test protocol is also logged on here. You should therefore set the name of the

test engineer before carrying out the first test.

The test catalogue can be particularly beneficial if more than one person is working with the test system. Test engineers already registered on the system are simply selected from the test catalogue using the arrow buttons. There is no need to re-enter the name of the test engineer.

A name of a test engineer cannot be longer than twenty characters. The names of up to ten test

engineers can be stored.

16

TGH1365en/10.2012

Page 17

Operation and configuration

ENTER TEST ENG. NAME:

_

Char.: A-Z, 0-9, -. /

Exit: ESC Next:

1. Select “Enter new test eng”

2. Use the arrow keys to select the first characters

and then press the ENTER key

4. After entering the last character,

press and hold down the

ENTER key for approx. 3 seconds.

3. Select all the remaining characters also

Briefly press the ESC key

= edit previous character

Press and hold down the ESC key

= Exit menu without making changes

The new test engineer is

saved and logged on

3 s

ENTER TEST ENG. NAME:

JOHN MEYER

Char.: A-Z, 0-9, -. /

Exit: ESC Next:

ESC

ESC

ESC

ESC

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

Select the name of a test engineer (log on) as follows:

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

SELECT TEST ENGINEER

ESC

Test engin.: ( 3/ 4)

HENRY STONE

Select: , Confirm:

----------------------------Test eng. logged on:

HENRY STONE

-----------------------------

To enter the name of a new test engineer:

1. Call up

“Select test eng.” function

2. Use the arrow keys to select

the test engineer

3. Confirm with ENTER key

Selected test engineer is

displayed for approx. 3 seconds

TGH1365en/10.2012

17

Page 18

To delete the name of a test engineer:

1. Call up “Delete test eng.”

function

2. Use the arrow keys to select

the test engineer

3. Confirm with ENTER key

Confirmation is displayed

for approx. 3 seconds

The selected test

eng. will be deleted

from the catalogue.

Please wait!

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

SELECT TEST ENGINEER

Test engin.: ( 3/ 4)

PETER MILLER

Select: , Confirm:

ESC

Operation and configuration

18

TGH1365en/10.2012

Page 19

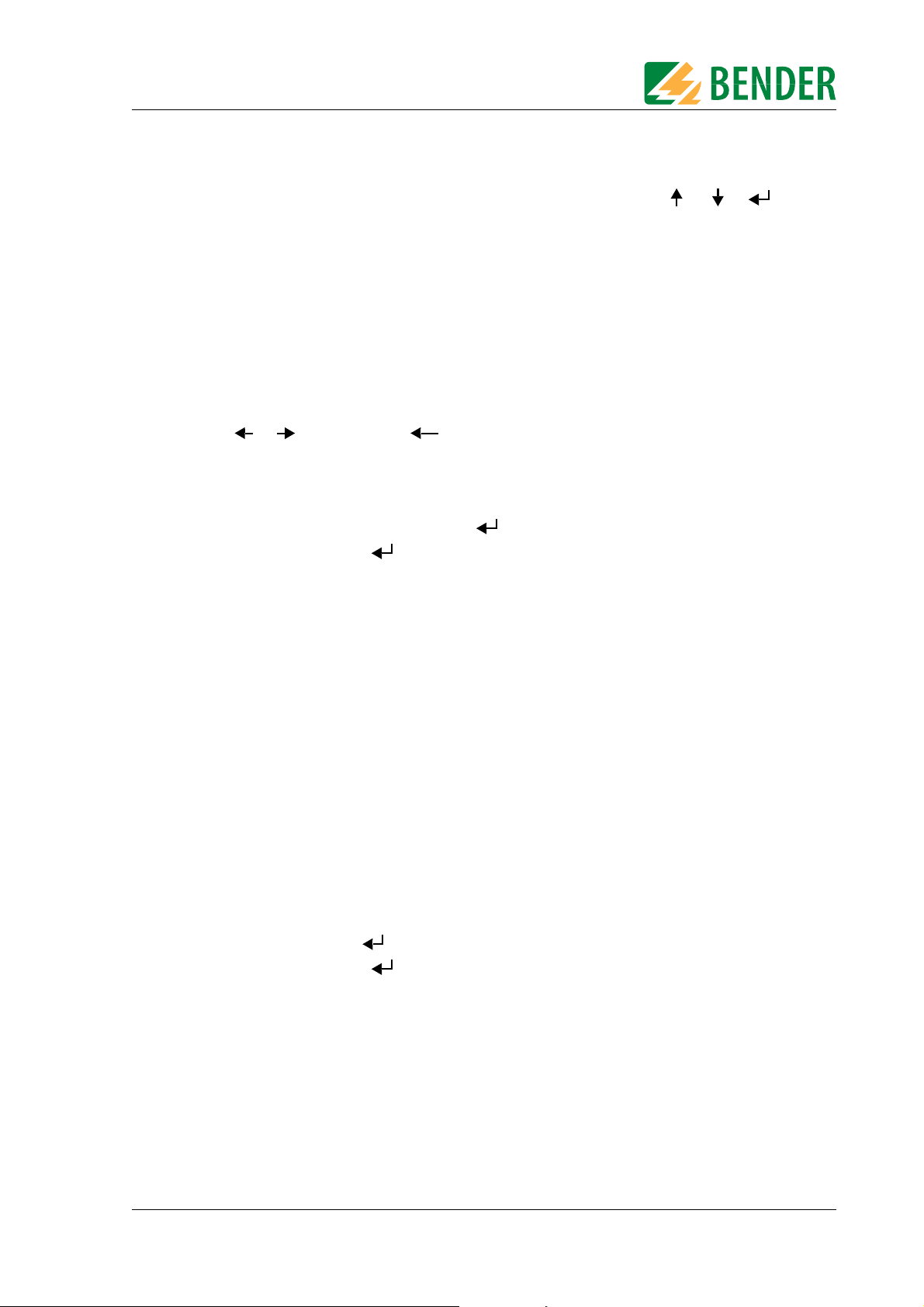

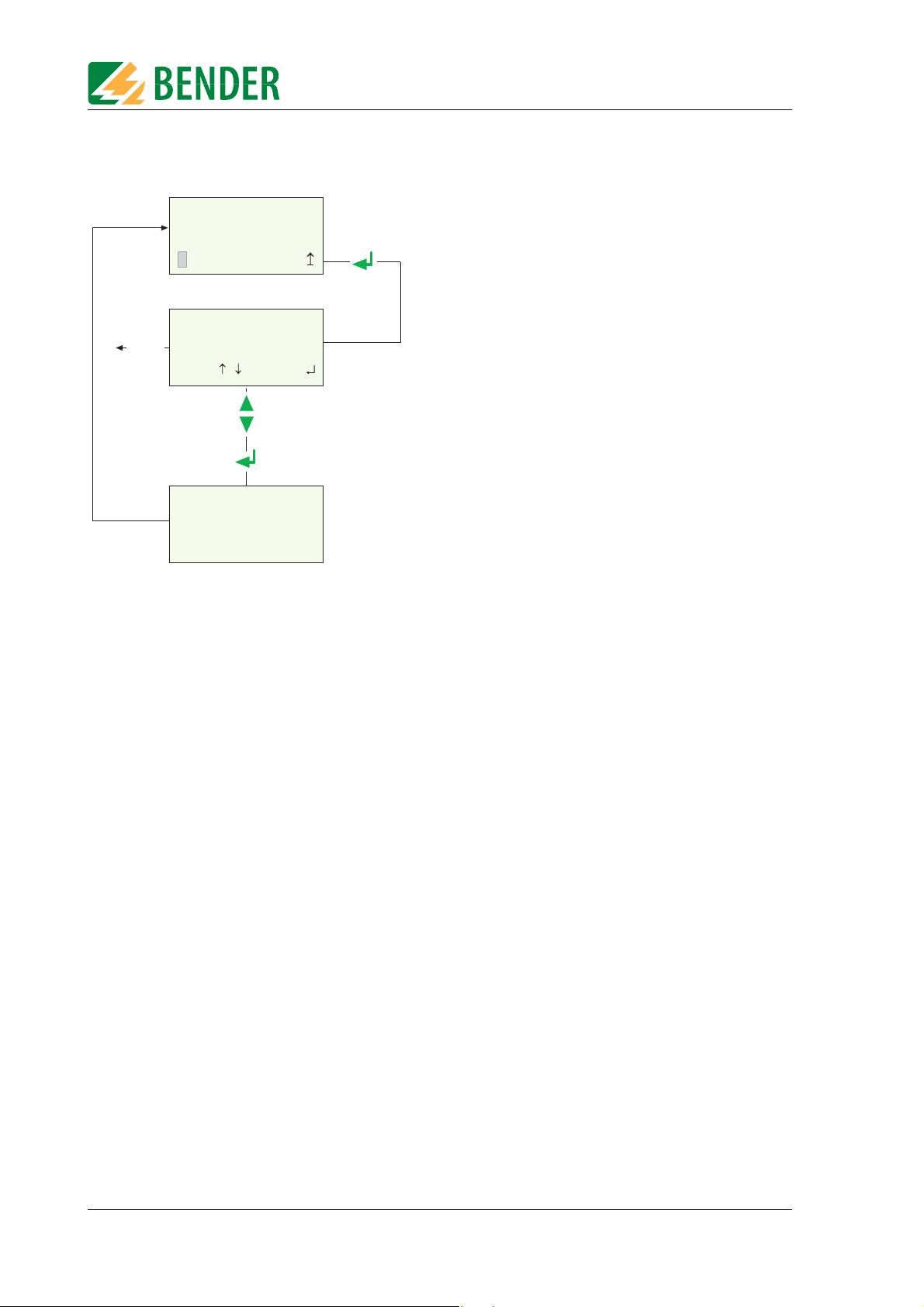

Operation and configuration

Main menu

1. Select “Device setting”

ESC

2. Select required function

1. Exit

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

2. Device catalogue

3. Single test

4. Test eng. catalog.

5. Device setting

4.5 Device settings

Some of the following settings are used in generating reports to record the test

results. You should therefore check these settings before carrying out the first test.

Menu item Function Page

1. Exit Returns to the main menu

2. Test probe calibration Zero calibration test probe

3. Device type query This is where you determine whether another device type

is to be queried and stored in addition to the device ID.

4. Warm-up/cool-down Setting for devices which require a warm-up period before

the test and cool-down period after the test.

5. Change comp. name The company name entered here will appear on the

printout of the test report and after switching on the

device on line 4 of the welcome menu.

6. Time/date Set system time and date

7. RS-232 parameters Set data transfer speed

8. Buzzer On/Off Switch buzzer on or off

9. Summer/wintertime Automatic switchover from summer time to winter time

10. Language/Sprache Select German or English for user menus and protocol

text. Activate settings for use in Austria.

11. Firmware update Load new version of operating software

-

20

21

21

22

22

23

24

24

25

25

To access the device settings:

TGH1365en/10.2012

19

Page 20

Operation and configuration

4.5.1 Test probe calibration

Zero balance must be carried out for the UNIMET® 300ST test probe. As with an ohmmeter, this ensures that the ohmic resistance of the test probe will not affect the PE conductor test result.

Recalibrate each time after connecting

– another test probe,

– another measuring lead,

– or a three-phase adapter

to the test system.

Proceed as follows to calibrate the test probe:

ESC

1. Exit

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

*** CALIBRATION ***

Insert test probe

and contact PE of

socket outl. Next:

Device setting

1.Select “Test probe calibr.”

2. Hold the test probe on the earth contact

of the test socket

*)

.

Make sure that the test probe

remains there during the entire

calibration process.

3. Start calibration.

*** CALIBRATION ***

Testprobe/Cable

Please wait !

*)

With permanently connected Protection class I devices or extension cables also, the low resistance continuity of the PE conductor can be tested. The measurement is carried out between the test probe and the measuring lead connected to

the yellow socket E.

Before the test, a single zero calibration must be carried out with the test probe

and the measuring lead.

Carry out a zero calibration again if you want to run the PE conductor test with

the test probe on equipment with Schuko plug.

Failure to follow these instructions may lead to false test results.

20

TGH1365en/10.2012

Page 21

Operation and configuration

Device setting

1.Select “Warm-up/cool-down”

2. “Off” - not hot or cooling-off phase

“On” - After switching on the device

under test warm-up phase, before

switching off the device under test

cooling-off phase.

1. Exit

2. Warm-up/cool-down

period: On

1. Exit

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

ESC

4.5.2 Device type query

Test results are often stored in the PC software. If the device to be tested is to be sorted in the

software according to type, the type name can be entered in the UNIMET when carrying out the test.

In this case, select "Device type query: On". The setting applies until it is changed again.

1. Exit

2. Test probe calibr.

ESC

3. Device type query

4. Warm-up/cool-down

1. Exit

2. Device type: Off

Enter device type

before entering ID

1.Select “Device type query”

2. The following is asked when saving a test:

"Off" - device ID only

"On" - device ID and device type

4.5.3 Warm-up and cool-down period

Once they have been switched on, an increasing number of DUTs need to complete a self-test and

warm-up period, followed by a cool-down period prior to shutting down. Examples include computers, processor-controlled devices and laser equipment. For these devices, the UNIMET® ST may only

start the measurements once the DUT has warmed up or "booted up". Otherwise, there is a risk that

the parts of the device to be tested will only have switched on partially or not at all, and therefore

will not be tested.

Once the measurements are complete, the UNIMET may only shut down the DUT once it has shut

down or cooled down. Otherwise, on laser equipment, there is the risk of overheating or, on a computer, of sectors of the hard disk becoming unusable.

Device setting

Select "Warm-up/cool-down period: On".

The settings selected for the "Warm-up/cool-down period" applies to all devices

under test for which the test has been put in operation. The settings remains until

it has been changed again.

TGH1365en/10.2012

21

Page 22

Operation and configuration

4.5.4 Changing the company name

The company name must consist of no more than 20 characters. It is printed as a header on the test

report.

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

5. Change comp. name

ENTER COMPANY NAME:

ESC

MEIER GMBH&CO.KG

Char.: A-Z, 0-9, &-. /

Exit: ESC Next:

4.5.5 Time/date

Proceed as follows to set the time and date:

Device setting

1.Select “Change comp. name”

2. Use the arrow keys to change the first

characters and then press the ENTER key

3. Select all the remaining characters also

Briefly press the ESC key

= edit previous characters

Press and hold down the ESC key

= Exit menu without making changes

4. After entering the last character or

holding down ENTER key for

approx. 3 seconds, the entry is saved

and the settings menu exited.

The new company name is saved.

3. Device type query

4. Warm-up/cool-down

5. Change comp. name

6. Time/date

1. Exit

ESC

ESC

The UNIMET

2. Time: 14: 49

3. Date: 30. 09. 11

(Summer time/CEST)

1. Exit

2. Time: 14: 49

3. Date: 30. 09. 11

(Summer time/CEST)

®

300ST clock is powered by a battery with a service life of approximately four years (see

also chapter "6.2 Changing the battery").

Device setting

1. Select “Time/date”

2. Select “Time”

3. Use the arrow keys to select hours and

then confirm with the ENTER key

4.Use the arrow keys to select minutes and

then confirm with the ENTER key

5. Set the “Date” in the same way

22

TGH1365en/10.2012

Page 23

Operation and configuration

On the submenu 7 (see chapter "4.5.8 Summer time/winter time") you can also set whether the

switchover from summer time to winter time is to be automatic. If the note on the 4th line of the

"Time/Date" setting refers to the current date: If the automatic switchover is enabled and the following appears during the summer: 'Summer/ CEST' and during the winter 'Wintert/CET'.

CEST = Central European Summer Time

CET = Central European Time

4.5.6 RS-232 parameters

The UNIMET® 300ST can be connected to a PC via the RS-232 interface. The baud rate gives the data

transfer rate in bits per second.

The baud rate on the test system and the PC (or in the PC software) must always

be set to the same value! Data transfer can only be performed if the two settings

match.

Proceed as follows to adjust the parameters of the RS-232 interface:

Device setting

1. Select “RS-232 parameters”

2. Select the “Baud rate” setting

3. Use the arrow keys to set baud rate

and then confirm with the ENTER key

ESC

ESC

4. Warm-up/cool-down

5. Change comp. name

6. Time/date

7. RS-232 parameters

1. Exit

2. Baud rate: 9600

1. Exit

2. Baud rate: 9600

The following baud rates are available for the setting: 9600, 19200, 38400, 57600 baud

The other parameters of the RS-232 interface are fixed as follows:

Data bit 7

Stop bit 1

Parity even

TGH1365en/10.2012

23

Page 24

Operation and configuration

Caution

Device setting

1. Select “Buzzer On/Off”

2. Select setting for “Buzzer”

1. Exit

2. Buzzer: On

5. Change comp. name

6. Time/date

7. RS-232 parameters

8. Buzzer On/Off

ESC

Device setting

1. Select “Summer/wintertime”

3. Select “On” or “Off”

2. Select “Auto. switchover

from summer to winter

time”

1. Exit

2. Auto. switchover

from summer to

winter time: On

1. Exit

2. Auto. switchover

from summer to

winter time: On

6. Time/date

7. RS-232 parameters

8. Buzzer On/Off

9. Summer/wintertime

ESC

ESC

The interface cable supplied (null modem cable or USB1.1-RS-232 converter) is required for the data

transfer. The data transfer is always initiated by the PC software. No operation is required on the test

system for this to happen. For further information, please see the instruction manual for the PC

software.

The data transfer may not start if just one measurement or single test is carried

out.

Failure to observe this requirement may damage the UNIMET

®

300ST and any de-

vice under test connected to it.

4.5.7 Buzzer On/Off

Proceed as follows to turn the UNIMET® 300ST buzzer on or off:

4.5.8 Summer time/winter time

Proceed as follows to select whether the switchover from summer time to winter time should occur

automatically:

Automatic switchover from summer time to winter time applies to most European countries

(exceptions are e.g. England). Turn off the automatic switchover when using the test system in areas

where this time change does not apply.

24

TGH1365en/10.2012

Page 25

Operation and configuration

1.Select “Language/Sprache”

2. Select German or English.

German (Austria) is required for use in Austria

Standards then appear in Austrian spelling

on the display and the printout.

Device setting

1. Exit

2. German/Deutsch

3. English/Englisch

4. German(Austria)

7. RS-232 parameters

8. Buzzer On/Off

9. Summer/wintertime

10. Language/Sprache

ESC

4.5.9 Language/Sprache

User menus and printouts of the test report ma y be in Ger ma n or Engl is h. Proce ed as foll ow s to sele ct

the language:

4.5.10 Firmware update

UNIMET® 300ST is controlled by an operating software (firmware). New versions are available online

at www.bentron.de. The update is provided as a file with the extension ".hex".

To transfer the updates from the PC to the UNIMET, you will need the PC software

UNIData300.

To prepare the update:

1. UNIData300 is on the CD supplied with the device. It is designed to operate on PCs with

2. Copy the update file (e.g. UPD162 Vxxx.hex) to the hard drive of your PC.

3. Connect the interface cable supplied for data transfer (null-modem cable or USB1.1-RS-232

An update will not delete data saved in the device catalogue. However, we

strongly recommend making a backup copy before updating the device

catalogue on a PC! Other information is available in the chapter "Backing up the

device catalogue" on page 43.

From version 3.00 onwards, UNIMET® 300ST devices are equipped with a new

hardware. When trying to install the operating software 3.00 on an older device,

it cancels the update.

Windows

®

2000 (with Service Pack 3) or higher.

– If the version of the program on your PC is older, first uninstall the older UNIData300 version.

– Open the folder UNIData300 and install the software by executing the file

"UNIData300_Vxxx.exe" on your PC.

converter) to the PC and UNIMET

®

300ST.

TGH1365en/10.2012

25

Page 26

Operation and configuration

Proceed as follows to carry out the update:

1. Start the UNIData300 software ("Start -> Program -> UNIMET®300ST -> UNIData300").

2. Select "Extras -> Firmware-Update UNIMET".

3. Click on the icon (Open folder) to select the update file.

4. Select the update file "UPD162 Vxxx.hex" and click on "Open".

26

TGH1365en/10.2012

Page 27

Operation and configuration

Caution

5. Information must be read from the UNIMET for the update. Click on "Read parameters" button:

6. The information read out is displayed (device info). Click on the "Update program" button. The

UNIMET flash memory is deleted, re-programmed and then checked (verified). The progress of

the update is displayed.

7. Wait until the update is finished. UNIMET restarts and then displays the main menu.

TGH1365en/10.2012

The data transfer takes about 3 minutes. Allow the data transfer to complete

undisturbed. If the data transfer is interrupted, UNIMET

®

300ST no longer has any

operational operating software. The device must then receive a new operating

software from Bender for installation.

UNIData300 confirms that the update has been successful with the following message:

27

Page 28

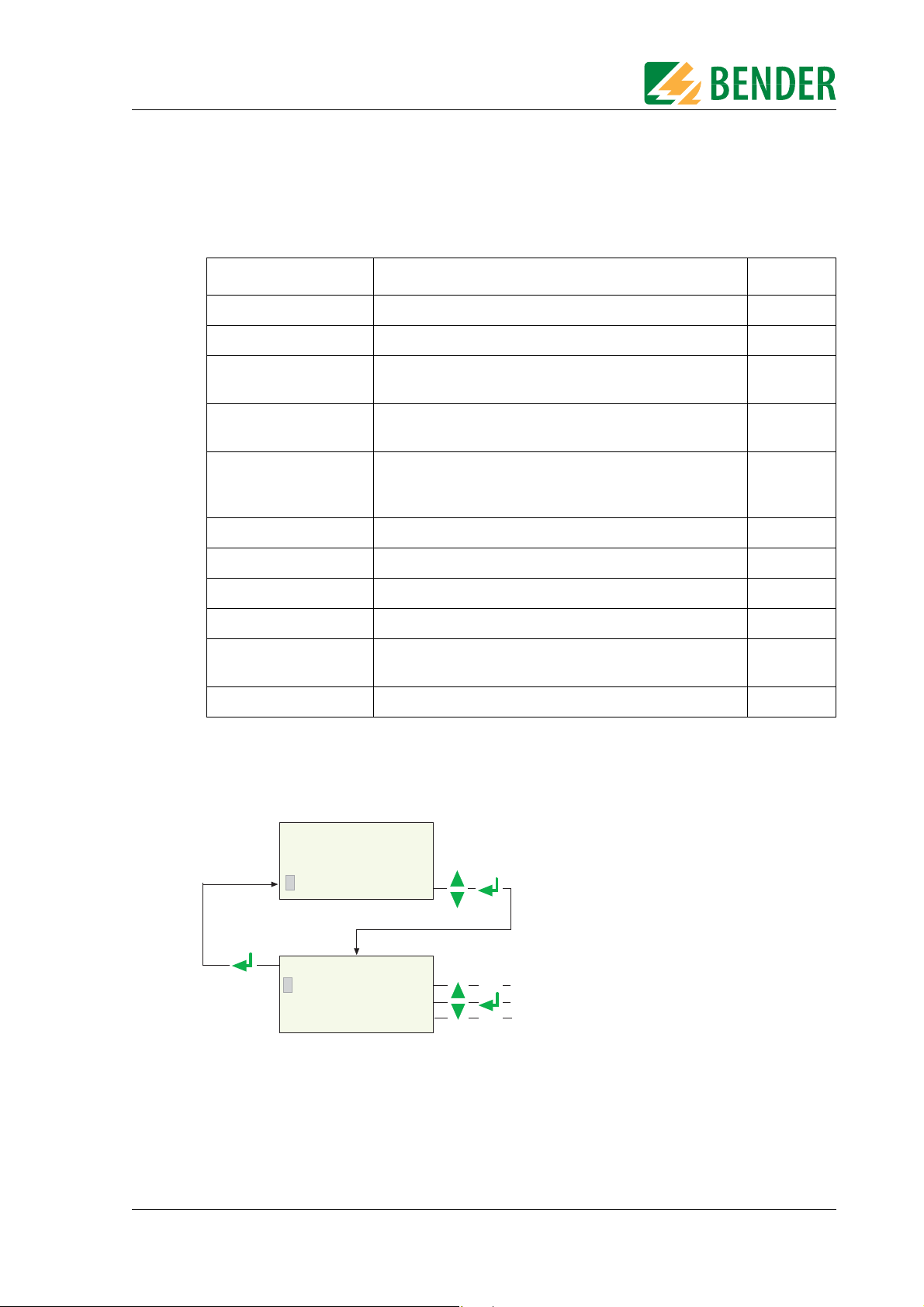

4.6 Information

Main menu

1. Select “Info”

2. The test system then gives information about:

- its device name (in this case, Unimet300ST)

- the version of the internal operating software

- and its serial number

1.Exit

Device:UNIMET300ST

SW: V3.33/05.10.11

Ser-no.: 0123456789

3. Single test

4. Test eng. catalog.

5. Device setting

6. Info

ESC

The menu item "Info" on the main menu gives you the following information:

Operation and configuration

28

TGH1365en/10.2012

Page 29

5. Testing and measuring

Main menu

1. Select “Classification”

2. Select the applicable test standard

e.g. "VDE0701-0702".

3. Select appropriate device type

and safety class,

e.g. “Class I”.

4. Select applicable cable length,

e.g. “Cable length <= 5 m”

5. Select appropriate device type,

e.g. “Standard equipment”.

Next to following page.

1. Exit

2. IEC62353:2007-05

3. VDE0701-0702:08-06

1. Exit

2. Class I

3. Class II

4. Class III

5. 3ph devices CI

6. 3ph devices CII

7. Extension cable

1. Exit

2. Cable length <=5mtr

3. Cable length > 5mtr

1. Exit

2. Standard equipment

3. EE w. heat. circ.

4. EE perm. installed

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

ESC

ESC

ESC

ESC

5.1 Testing via classification

5.1.1 Classification

Answer the questions that appear on the screen. The test system will identify the required tests and

limits to be observed. The guided test sequence will guide you through all the necessary steps to be

taken. In addition to electrical tests, the test sequence also contains a visual and functional test.

Example 1:

Classification of electrical equipment (e.g. angle grinders) according to DIN VDE 0701-0702 with the

UNIMET

®

300ST:

TGH1365en/10.2012

29

Page 30

Testing and measuring

6. Select the measurement method

for determining the leakage current,

e.g. “Direct measurement”.

7. Select other settings for the test.

Label selected setting with “

”.

Then select menu item “5. Next”

and confirm with the ENTER key.

1. Exit

2. Direct measurement

3. Differential meas.

4. Alternative meas.

1. Exit

2.

R-ISO ?

3. Disconn.not poss.

4.

Conduct.parts->PE

5. Next

ESC

ESC

8. Select automatic or manual test

1. Exit

2. Test automatic

3. Test manual

ESC

R-ISO?

(Carry out R-ISO?)

During insulation measurement, a voltage of 500 V is applied between

the active conductor and earth. Insulation testing may damage sensitive

devices. Only activate insulation measurement if permitted by the

manufacturer's instructions provided with the DUT.

Note: If the setting "Disconn. not poss." is selected, the insulation

measurement cannot be selected.

Disconnection not

Choose this setting if the device cannot be disconnected from the mains.

possible

Conduct. parts >PE All accessible conductive parts are connected to PE. This setting can be

used if you know that all metal accessible parts of the enclosure are

connected to the PE conductor. During device testing, the test probe then

only has to be brought into contact with one metal point on the

enclosure.

If not all metal parts of the enclosure are connected to PE, deactivate this

function. During device testing, an additional equipment leakage current

test resp. touch current test (Class II) is carried out. In this case, the manual

test will be selected automatically.

During device testing, proceed as follows:

During PE conductor testing, use the test probe to scan all parts of the

enclosure connected to PE. During equipment leakage current testing or

touch current testing (Class II), test all parts not connected to PE.

30

TGH1365en/10.2012

Page 31

Testing and measuring

Main menu

1. Select “Classification”

2. Select test standard

"IEC62353:2007-05".

3. Select applicable test,

e.g. “Hosp.bed test CI”.

4. Select automatic or manual test.

1. Exit

2. Hosp.bed test CI

3. Hosp.bed test CII

4. Class I

5. Class II

6. Class III

7. 3Ph devices Cl

8. 3Ph devices ClI

1. Exit

2. IEC62353:2007-05

3. VDE0701-0702:08-06

1. Exit

2. Test automatic

3. Test manual

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

ESC

ESC

ESC

R-PE

Value: 0.004

Ω

Limit: 0.300 Ω

Repeat: Next:

Example 2:

Classification of an electric hospital or care bed with the UNIMET

®

300ST:

Manual or automatic test

The test sequence can be carried out automatically or manually for each device under test.

Automatic testing

During automatic testing, the test probe or test terminal comes into contact with one point of the

DUT. The test sequence then runs through all the test steps automatically.

Manual testing

During manual testing, it is possible to repeat each test step as often as required and bring the test

probe into contact with a number of accessible parts on the DUT consecutively.

UNIMET

the PE conductor resistance, this is the highest measured value; when measuring the insulation

resistance, this is the lowest measured value.

®

300ST saves the "worst" measurement in each case. When measuring leakage currents and

TGH1365en/10.2012

31

Page 32

Testing and measuring

R-ISO CI

Value: 200.97 M

Ω

Limit: 2.00 MΩ

--- Measuring ---

R-ISO CI

Value: 200.97 M

Ω

Limit: 2.00 MΩ

Next:

Manual testing of hospital and care beds (UNIMET® 300ST)

The manual test is basically carried out the same way. However, manual measurements where the

bed is in operation (e.g. leakage currents) and the measuring of the insulation resistance are

different. These measurements are carried out as follows:

With leakage currents, the supply voltage to the bed is uninterrupted; with the insulation meas-

urement, the measuring voltage is uninterrupted.

With the measurement where the bed is supplied with voltage, the head and footboard are

operated along with other electrically actuated adjustment devices. The adjustment devices

are operated until their limit switch responds.

Various accessible metal parts of the bed can be scanned with the test probe.

The measurement is repeated until the ENTER button " " is pressed.

In this way, changes in the measured values caused by operating the adjustment devices on the bed

are reliably detected.

The display alternates as follows:

32

TGH1365en/10.2012

Page 33

Testing and measuring

Caution

Caution

Caution

Caution

Caution

5.1.2 Tests

The test system must not be used for testing electrical installations. It is exclusively intended for testing devices and systems listed under "System description" on

page 9.

During insulation measurements, a direct current of 500 V is applied. Touching

faulty DUTs when the test probe is in direct contact may expose personnel to the

danger of electric shock. The touch current is limited to 2.5 mA. .

During alternative measurements of the leakage current, an alternating current

of 250 V is applied. Touching faulty DUTs when the test probe is in direct contact

may expose personnel to the danger of electric shock. The test current is limited

to 3.5 mA.

The current flowing on faulty DUTs during a test may cause unwanted tripping

of a residual current protective device (RCD).

For testing equipment leakage currents with equipment in operational condition, the device under test must be installed in an insulated state to prevent leakage currents from flowing via accidental earth connections.

Exposed conductive parts and the measuring leads of the device under test may

be live and therefore must not be touched.

TGH1365en/10.2012

33

Page 34

Testing and measuring

E

LNPE

Device

under test

Connect the DUT to the test system.

1. To connect hospital beds, care beds and electrical equipment using a plug-in connector:

2. Connecting single-phase permanently installed equipment to the test system

– Switch off the power to the device

– Disconnect the power supply connection.

34

TGH1365en/10.2012

Page 35

Testing and measuring

3. Testing the extension cables

- Connect connecting cables and extensions as follows:

TGH1365en/10.2012

35

Page 36

Follow the instructions on the UNIMET® 300ST display:

Testing and measuring

VISUAL INSP. ERROR

Continue test

anyway?

Cancel:ESC Next:

ESC

The test results

are evaluated

ESC

ESC

not passed

** Note **

Connect DUT to

Unimet a. switch on!

Start:

VISUAL INSPECTION

1. Passed

2. Failed

R-PE

Value: 0.004

Limit: 0.300 Ω

- - - Measuring - - -

Start the electrical tests

Ω

1. Connect device under test

then start test

2. Carry out

and evaluate

visual inspection

3. If visual inspection

not passed:

decide whether

passed

the test should

proceed anyway

During the PE conductor test, the low-resistance continuity of the PE conductor

is tested with a high current (> 2 A). This produces heat energy.

If the PE conductor test is repeated very often and without breaks during manual

testing or single tests, the test system will prevent overheating by aborting the

test. A message will appear:

**Danger**

Test will be stopped

Transformer overheat

(Measur. Time > 2 min)

After the test is terminated, testing the PE conductor is permitted again within a

few seconds.

36

TGH1365en/10.2012

Page 37

Testing and measuring

After the visual inspection, the following tests are carried out for the "Hosp. bed test CI" example:

** WARNING **

Load current <= 5 mA

DUT switched on?

Next:

R-PE

Value: 0.004

Limit: 0.300 Ω

- - - Measuring - - -

R-ISO CI

Value: > 300.00 M

Limit: 2.00 MΩ

- - - Measuring - - -

** ATTENTION! **

Mains voltage at the

socket outlet

Next:

LOAD CURRENT

Value : 25 mA

Limit: --------

- - - Measuring - - -

Ω

yes

Load current

< 5 mA ?

no

Ω

4. Confirm message

If applicable:

Switch on device and

then press ENTER key

Please note that only DUTs with a power consumption of up to 3700 VA may be supplied

with power via the UNIMET® 300ST test socket. If DUTs with higher power consumptions

are connected, the thermomagnetic circuit-breaker integrated into the UNIMET® 300ST

power switch will trip. Once the DUT has been removed, the test system can be switched

on after a few seconds.

MAINS VOLTAGE

Value: 230 V

Limit: --------

- - - Measuring - - -

POWER CONSUMPTION

Value: 6 VA

Limit: --------

- - - Measuring - - -

The leakage current test is carried out

TGH1365en/10.2012

37

Page 38

Testing and measuring

WARM-UP PERIOD:

Boot up DUT!

Next:

COOL-DOWN PERIOD:

Shut down DUT!

Next:

Test sequence with warm-up and cool-down period

If "warm-up and cool-down period" is activated on the device settings, UNIMET waits until the DUT

is powered up or ready for operation. Once the DUT has been connected to the mains supply, the

following message appears:

Wait until the DUT is powered up and then confirm by pressing the ENTER button " ".

After the last test step carried out at this phase position, UNIMET will wait for the DUT to shut down.

Wait until the DUT is powered down and then confirm by pressing the ENTER button " ".

With all test sequences which put the DUT into operation, a test is carried out with the phase position

reversed. In this case, the DUT is powered up and powered down one more time.

38

TGH1365en/10.2012

Page 39

Testing and measuring

** ATTENTION! **

Limit for R-PE

exeeded!

Abort: ESC Repeat:

** Danger! **

Leak.current > 20 mA

Test finished

Continue:

¿

Now, the leakage current test is carried out:

I-ELC CI Diff.

Value: 0.04 mA

Limit: 0.50 mA

- - - Measuring - - -

I-ELC CI Diff. Ph-r

Value: 0.04 mA

Limit: 0.50 mA

- - - Measuring - - -

The function test is carried out

Checking the limits

UNIMET

®

300ST monitors whether the limits are kept to throughout the test sequence.

If a limit is violated when measuring the PE conductor resistance, the test engineer can decide

whether to abort the test or continue to its completion:

With all the other measurements during which the limit has not been kept to, the test is continued.

However, the test system does not permit any hazardous currents:

Faulty DUTs can exhibit dangerous leakage currents. During all leakage current

measurements, testing is aborted immediately if a measured value >20 mA is

reached. UNIMET

®

300ST then shows:

TGH1365en/10.2012

39

Page 40

Testing and measuring

ESC

Save,

Print,

Save and print

ESC short = Edit previous characters

ESC long = Exit menu without making change

short = Accept characters

long = Accept result, carry out

selected action and exit menu

ENTER DEVICE-ID:

Char.: A-Z,0-9,-, /

Exit:ESC Next:

TEST-RESULTS

Total result:

PASSED

Select: , Cont.:

View

result

Discard

test

,

= select next or previous test step

= back to previous menu

1. Save

2. Print

3. Save and print

4. View result

5. Cancel test

On completion of the test sequence, the functional test is carried out. Here, the DUT is put into

operation via the test socket on the test system.

5. Start function test and

then evaluate result

passed

Volt. at sock.outlet

***************************

TEST NOT PASSED!

***************************

Next:

not passed

Message appears when

at least one test step

has not been passed.

5.1.3 Evaluating the test result

FUNCTIONAL TEST

1. Passed

2. Failed

3. Start Funct. test

1. Save

2. Print

3. Save and print

4. View result

5. Cancel test

All

test steps

no

***************************

***************************

Next:

passed

?

TEST PASSED!

6. Evaluate test result

yes

If "Device type query" in the device settings is enabled, this is entered before the device ID.

40

TGH1365en/10.2012

Page 41

Testing and measuring

5.2 Recurrent test and device catalogue

The test results, tests and limits of the device tested by UNIMET® 300ST can be stored in the device

catalogue. In the case of recurrent tests, the devices are simply called up in the device catalogue and

tested again. Other functions are print report, display results, delete device or delete entire catalogue.

The content of the device catalogue can be transferred to a PC program. Similarly, data records selected in the PC program can be transferred to the device catalogue. These functions are described

in the PC software guide.

Proceed as follows to use the device catalogue:

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

Main menu

1. Select “Device catalogue”

Test device

1. Exit

2. Select device

3. Collective print

4. Delete catalogue

----- ID SELECTION -----

ID: ( 1/ 5)

ESC

XY47123456

Select: , Confirm:

ESC

1. Exit

2. Test device

3. Print test report

4. View result

5. Delete device

6. Change dev. type

2. Select required function:

- Select device

- Print out all test logs

- Delete catalog:

after the prompt, all entries

are deleted

3. Select ID No.

,

select next or previous device

Confirm selection

( 1/ 5)

*1

*2

View resultsPrint test report Delete device

shows the position

in the memory and

the number of devices

4. Select action

Unimet a. switch on!

Start:

*1 If "device type query" in the device settings is enabled, then the device type is displayed

*2 If "device type query" in the device settings is enabled, an additional menu item "Change

TGH1365en/10.2012

** Note **

Connect DUT to

Test starts

Test results

are printed

Please wait !

TEST-RESULTS

Total result:

PASS

Select: , Cont.:

,

select next

or previous

test step

back to

previous menu

The selected ID

will be deleted from

the catalogue

Please wait !

on the last line for approximately 2 seconds when scrolling in the device catalogue.

device type" will also appear.

41

Page 42

Testing and measuring

5.2.1 Collective printout

Each DUT stored in the test system can be printed out as a measurement report. Select either all the

reports or only the reports for a desired period.

ESC

ESC

1. Exit

2. Select device

3. Collective print

4. Delete catalogue

1. Exit

2. All data records

3. Select by date

1. Exit

2. All data records

3. Select by date

01.01.10--31.12.10

Device catalogue

1. Select “Collective print”

2. Select required function:

- Print out all test records

- Select the period from which

the test log is printed.

3. The first number for changing the period

(from-to) flashes.

Set the relevant day, month and year

for the start and end of the period as follows

- Use the arrow keys to select number (start day)

and then confirm with the ENTER key

- the next place flashes. Use the arrow keys

to select number (start month) and then

confirm with the ENTER key

- Also change all remaining numbers

ESC

Collective print

Data record 1 / 10

Abord: ESC

The printout starts when the last number

(last month) has been confirmed with ENTER

4. The data records for the selected period are

printed out.

The printout can be aborted with the ESC key.

42

TGH1365en/10.2012

Page 43

Testing and measuring

5.2.2 Backing up the device catalogue

The device catalogue contains the ID numbers, the test results and the classification of tested

devices for the recurrent test. These data can be backed up on a PC with the Bender-PC software

UNIData300.

Proceed as follows to start UNIData300:

1. UNIData300 is on the CD supplied with the device. It is designed to operate on PCs with

Windows

– If the version of the program on your PC is older, first uninstall the older UNIData300 version.

– Open the folder UNIData300 and install the software by executing the file

"UNIData300_Vxxx.exe" on your PC.

2. Connect the interface cable supplied for the data transfer (null-modem cable or USB1.1-RS-232

converter) to the PC and UNIMET

3. Switch on UNIMET.

4. Start the UNIData300 software ("Start -> Program -> UNIMET

UNIData300 adapts itself to the required interface (e.g. COM1) and to the baud rate set on the

UNIMET. The settings for imports and exports appear at the bottom edge of the screen.

The following pages provide a brief introduction to the software UNIData300.

The UNIData300 software Help menu provides a detailed description.

®

2000 (with Service Pack 3) or higher.

®

300ST.

®

300ST -> UNIData300").

To import data to the PC:

1. Select "Data" -> "Import" to import the data from the UNIMET to the PC software

UNIData300 reports when the data have been imported successfully:

TGH1365en/10.2012

43

Page 44

2. Now select the data to be saved in the UNIData300 device database.

1

2

3

4

Testing and measuring

1 Select the data to be stored:

- Click on the individual data in the left window, or

- Select according to test standard and enable the import filter. Once all the standards

are activated, all the data will be selected for saving.

2 Decide whether the device catalogue in the UNIMET is to be deleted.

3 Start the import. UNIData300 shows the progress of data transfer.

Wait until the data are stored.

4Close the Import window.

44

TGH1365en/10.2012

Page 45

Testing and measuring

1

4

3

2

5

6

7

To use the data read in on the PC:

Select "Device catalogue" -> "Open".

The device catalogue data stored on the PC are displayed:

The following functions are available:

1 Use the arrow buttons to select a device. All the known data for this device will be displayed.

Only the fields "Test interval (months)" and "Device name/type" can be changed.

2 After clicking on this tab, you will see the results for the current device.

3 Enter a test interval. This allows you (after updating) to select the devices to export which are

due for testing.

4 "Update" accepts your entries in the fields "Device name/type" and "Test interval (months)" in

the device database. Once the field "Test interval (months)" is full, UNIData300 updates the

field "Next test".

5 The current device is deleted.

TGH1365en/10.2012

45

Page 46

6 A print preview will appear:

-Click on to print.

-Click on to export the test report.

Formats: PDF, MS-Word, Excel, RTF, HTML 4.0.

-In the menu "Extra -> Protocol settings", you can enter the company name (4 lines max.)

and insert the company logo for the report.

7 Click on "Close" to leave the Program window.

Testing and measuring

To delete the device database of UNIData300:

Select "Device catalogue" -> "Delete".

Confirm the confirmation prompt "Delete all". The device database of UNIData300 will be deleted.

To export data from the PC to UNIMET:

1. Select "Data" -> "Export" to transfer the data stored in the PC software to the device catalogue

of the UNIMET.

UNIData300 makes the stored data available and reports:

46

TGH1365en/10.2012

Page 47

Testing and measuring

1

2

3

4

2. Now select the data to be exported. Select the individual data or click on "Select all". Export the

selected data with "Start export".

1 Select the data to be exported:

- Click on the individual data in the left window, or

- Select according to test standard and enable the export filter.

2 If all the data are to be exported, just click on "Select All".

3

4 Close the Export window.

Start the export. UNIData300 shows the progress of data transfer.

Wait until the data are transferred.

TGH1365en/10.2012

47

Page 48

Testing and measuring

To end UNIData300:

Select "Device catalogue"-> "Exit".

To save a copy of the device database of UNIData300:

The menu "Extra -> Database utilities -> Backup database" enables you to back up the database on

the hard drive of your PC.

The copy of the database can be found in the folder "C:\Documents and Settings\All

Users\Application Data\UNIData300\DB_BACKUP".

To back up the original device database of UNIData300:

The hard disk of the PC is not an absolutely secure storage location for data. With a backup copy of

the device database, you will avoid loss of data.

The original device database "u300.mdb_xx" can be found in the folder "C:\Documents and

Settings\All Users\Application Data\UNIData300\Database". Regularly backup the device database

on another data medium.

48

TGH1365en/10.2012

Page 49

Testing and measuring

**Danger**

Test will be stopped

Transformer overheat

(Measur. Time > 2 min)

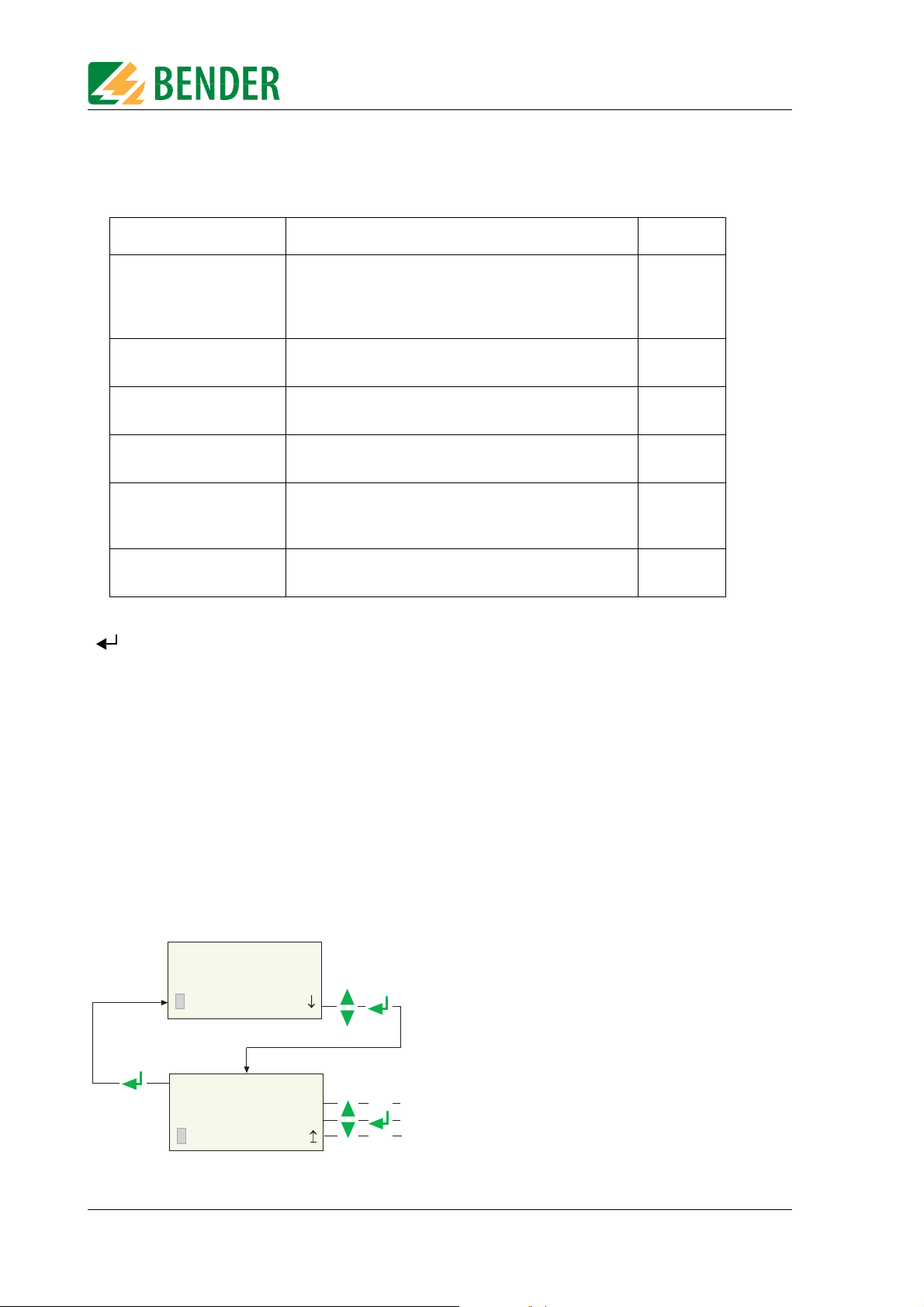

5.3 Single test

Test steps can be called up in the form of single tests and repeated as often as required. For example, if a limit

value is not complied with during a classified test sequence, the test step concerned can be examined in more

detail using a single test.

ESC

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

1. Exit

2. Mains volt. #081

3. Load current #080

4. Power cons. #082

5. R-PE #003

6. R-PE perm.c. #003

7. R-ISO

8. I-ELC A

9. I-PE

10. I-TC

11. I-ELC CI

12. I-ELC CII

Main menu

1. Select “Single test”

2. Select required measurement

ESC

ESC

Option I-ELC CI

1. Direct #210

2. Direct Ph-r #211

3. Diff. meas. #212

4. Diff. Ph-r #213

5. Diff. 3Ph #078

6. Exit

3. Select details for measurement

(e.g. phase position when measuring

device leakage, PE conductor

and touch current)

4. Read off measured value

---- SINGLE TEST----I-ELC CI Direct

Meas. value: 0,04 mA

-- Abort: ESC --

During the PE conductor test, the low-resistance continuity of the PE conductor

is tested with a high current (>2 A). This produces heat energy.

If the PE conductor test is repeated very often and without breaks during manual

testing or single tests, the test system will prevent overheating by aborting the

test. A message will appear:

TGH1365en/10.2012

After the test is terminated, testing the PE conductor is permitted again within a

few seconds.

49

Page 50

Testing and measuring

50

TGH1365en/10.2012

Page 51

6. Maintenance and calibration

** Battery flat! **

Change the battery

Set time/date

Next:

** ERROR **

xxxxx

Contact Service!

Next:

6.1 Calibration

Like any other test instrument, the UNIMET® 300ST requires a regular measured values check. The

calibration interval is 36 months. The test system can only be calibrated and adjusted by Bender or

a centre approved by Bender.

6.2 Changing the battery

The UNIMET® 300ST clock is powered by a battery with a battery life of approximately four years (see

also chapter "4.5.5 Time/date"). If the battery voltage is too low, the following message appears after

switching on the test system:

The test system battery can only be changed by Bender or a centre approved by Bender.

The battery is always replaced by Bender as part of the calibration procedure.

6.3 Error messages

The UNIMET® 300ST continuously monitors its device functions. In the unlikely event on an error

occurring, a message will appear on the display:

xxxxxx stands for the type of error given out. There are the following different types of errors:

Type of fault Meaning

I2C bus (Code 002) Hardware error internal bus

RT clock (Code 004) Device-real-time clock is not running

Cal. values (code 016) Errors in memory for the calibration values. In certain cases,

can be eliminated by correcting the calibration values in the

UNIMET® 300ST database

TGH1365en/10.2012

51

Page 52

Maintenance and calibration

Type of fault Meaning

Database (Code 032) This error appears when a bad data record which cannot be

corrected is detected in the device database.

The error can be eliminated if the data record where this error occurs

is deleted.

Firmware (Code 128) With a UNIMET® 300ST, the firmware of a UNIMET® 301ST has been

installed or vice versa

If several errors occur simultaneously, a different error code is given out.

Proceed as follows:

1. Shut down the UNIMET® 300ST and remove the mains connector.

2. Make a note of what happened prior to the error: operator inputs, type of DUT, ambient

conditions etc.

3. Keep the device serial number to hand.

4. Call Bender technical support and describe the type of error and the error code.

6.4 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask your supplier

if you are not sure how to dispose of the old equipment.

Directive 2002/96/EG on waste electrical and electronic equipment and Directive 2002/95/EG on the

restriction of certain hazardous substances in electrical and electronic equipment apply in the European Community.

In Germany, these policies are implemented through the "Electrical and Electronic Equipment Act"

of 16 March 2005. According to this, the following applies:

Electric and electronic equipment are not to be included in household waste. This is indicated

by the symbol:

Batteries and accumulators are not to be included in household waste but must be disposed of

in accordance with the regulations.

Old electrical and electronic equipment (WEEE) from users other than private households

which was introduced to the market after 13th August 2005 must be taken back by the manufacturer and disposed of properly.

52

TGH1365en/10.2012

Page 53

7. Data

7.1 Standards

7.1.1 Application standards

The UNIMET® 300ST carries out measurements and tests according to the following standards:

DIN EN 62353 (VDE 0751-1):2008-08

DIN VDE 0701-0702 (VDE 0701-0702):2008-06

7.1.2 Design standards

The requirements of the following standards were taken into account in the design of the UNIMET®

300ST:

DIN VDE 0404-1 (VDE 0404-1):2002-05

DIN VDE 0404-2 (VDE 0404-2):2002-05

DIN VDE 0404-3 (VDE 0404-3):2005-04