Page 1

Manual

EN

TM800

Alarm indicator and operator panel

Software version: 4.0x

TM800_D00165_00_M_XXEN/06.2015

Page 2

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Straße 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-mail: info@bender.de • www.bender.de

Photos: Bender archives.

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. How to get the most out of this manual ............................................................. 7

1.1 How to use this manual ......................................................................................................... 7

1.2 Explanation of symbols and notes ..................................................................................... 7

2. Safety instructions .................................................................................................. 9

2.1 Intended use .............................................................................................................................. 9

2.2 Qualified personnel ................................................................................................................. 9

2.3 General safety instructions ................................................................................................... 9

2.4 Delivery conditions, warranty and liability .................................................................. 10

3. System description .............................................................................................. 11

3.1 MEDICS® ................................................................................................................................... 11

3.2 TM800 features ...................................................................................................................... 12

3.3 Functionality of the TM800 ............................................................................................... 13

3.3.1 LC display ................................................................................................................................. 13

3.3.2 Programmable messages .................................................................................................. 14

3.3.3 History memory ..................................................................................................................... 14

3.3.4 Interfaces .................................................................................................................................. 14

3.3.4.1 BMS bus ............................................................................................................................. 14

3.3.4.2 USB interface .................................................................................................................... 15

3.3.5 Programming and reading the TM800 ......................................................................... 15

3.3.5.1 Connection of the personal computer ................................................................... 15

3.3.5.2 Optional software .......................................................................................................... 15

3.3.6 Firmware versions ................................................................................................................. 15

3.4 Mechanical design ................................................................................................................ 16

3.4.1 Module overview .................................................................................................................. 16

3.4.2 BM800 and BM400 modules ............................................................................................. 16

3.4.2.1 BM800 ................................................................................................................................ 16

3.4.2.2 BM400 ................................................................................................................................ 16

3.4.3 Operating and display modules ..................................................................................... 16

3.4.4 Inputs and outputs ............................................................................................................... 17

3.4.4.1 Digital output 1 ............................................................................................................... 17

3.4.4.2 I/O modules ...................................................................................................................... 17

3.4.5 Individual internal components ...................................................................................... 18

TM800_D00165_00_M_XXEN/06.2015

3

Page 4

Table of Contents

4. Installation and connection ............................................................................... 19

4.1 Installation ................................................................................................................................ 19

4.1.1 Overview of enclosure variants ........................................................................................ 19

4.1.2 Unpacking ................................................................................................................................ 20

4.1.3 Installing the flush-mounting type enclosure with bezel frame (UPB) .............. 21

4.1.4 Installing the flush-mounting enclosure with mounting frame (UPE) ............... 22

4.1.5 Mounting the front plate .................................................................................................... 24

4.1.5.1 Flush-mounting type enclosure with bezel frame (UPB) ................................. 24

4.1.5.2 Flush-mounting type enclosure with mounting frame (UPE) ........................ 25

4.1.6 Installation of the surface-mounting enclosure (AP) ................................................ 26

4.1.7 Opening the front plate ...................................................................................................... 27

4.2 Connection ............................................................................................................................... 28

4.2.1 Connection details ................................................................................................................ 28

4.2.2 Modules and connections of the TM800 (connection example) .......................... 29

4.2.3 BMS-bus connection ............................................................................................................ 31

4.2.3.1 Terminating resistor ....................................................................................................... 31

4.3 Examples for connection and address assignment .................................................. 32

4.3.1 Address settings and their meaning ............................................................................... 35

5. Commissioning and testing ............................................................................... 37

5.1 Tests before switching on ................................................................................................... 38

5.2 Tests after switching on ...................................................................................................... 39

5.3 Make settings (parameterisation) .................................................................................... 39

5.3.1 Settings at the TM800 .......................................................................................................... 40

5.3.2 Settings using the TMK-SET software ............................................................................. 41

5.3.3 Tests after parameter setting ........................................................................................... 42

5.4 Periodic verification and service ...................................................................................... 43

5.4.1 Periodic verification .............................................................................................................. 43

5.4.2 Service ........................................................................................................................................ 44

5.4.3 Maintenance ............................................................................................................................ 44

6. Troubleshooting ................................................................................................... 45

6.1 Error messages ........................................................................................................................ 45

6.2 Malfunctions ............................................................................................................................ 46

6.3 Replace flash memory .......................................................................................................... 48

7. Operation ............................................................................................................... 49

7.1 Operator control and display elements ......................................................................... 49

7.2 Quick reference guide .......................................................................................................... 50

4

TM800_D00165_00_M_XXEN/06.2015

Page 5

Table of Contents

7.2.1 Display under normal operating condition ................................................................. 50

7.2.2 Display during fault condition ......................................................................................... 51

7.2.3 Test function ........................................................................................................................... 52

8. Menu mode: Operation and setting ................................................................. 55

8.1 Switching on and calling the main menu .................................................................... 55

8.2 Menu overview diagram .................................................................................................... 56

8.3 Main menu functions ........................................................................................................... 57

8.4 The main menu ...................................................................................................................... 57

8.4.1 Exit .............................................................................................................................................. 57

8.4.2 Menu2: Values ........................................................................................................................ 57

8.4.3 Menu 3: History ...................................................................................................................... 57

8.4.4 Menu 4: Settings .................................................................................................................... 59

8.4.4.1 Exit ....................................................................................................................................... 59

8.4.4.2 Settings menu 2: Alarm addresses ........................................................................... 59

8.4.4.3 Settings menu 3: Test addresses .............................................................................. 60

8.4.4.4 Settings menu 4: Measurement addresses ........................................................... 61

8.4.4.5 Settings menu 5: Digital inputs ................................................................................. 61

8.4.4.6 Settings menu 6: Buzzer (and LED) .......................................................................... 63

8.4.4.7 Settings menu 7: Common reset .............................................................................. 63

8.4.4.8 Settings menu 8: Clock ................................................................................................. 63

8.4.4.9 Settings menu 9: Language ........................................................................................ 64

8.4.4.10 Settings menu 10: Interface ....................................................................................... 65

8.4.4.11 Settings menu 11: Relays ............................................................................................ 65

8.4.4.12 Settings menu 12: Password ...................................................................................... 66

8.4.4.13 Settings menu 13: Service menu .............................................................................. 66

8.4.5 Menu 5: Control ..................................................................................................................... 67

8.4.5.1 Exit ....................................................................................................................................... 67

8.4.5.2 Control menu 2: Reset (AlarmClear) ........................................................................ 67

8.4.5.3 Control menu 3: EDS Start/Stop ............................................................................... 67

8.4.5.4 Control menu 4: Test communication .................................................................... 68

8.4.5.5 Control menu Reset mode .......................................................................................... 68

8.4.6 Menu 6: External devices .................................................................................................... 68

8.4.7 Menu 7: Info ............................................................................................................................ 70

8.5 Overview of setting options .............................................................................................. 71

9. Technical data ....................................................................................................... 73

9.1 Technical data BM800/BM400 modules ....................................................................... 73

9.1.1 Standards, approvals and certifications ........................................................................ 74

9.2 Dimensions ............................................................................................................................. 75

TM800_D00165_00_M_XXEN/06.2015

5

Page 6

Table of Contents

9.2.1 Surface-mounting enclosure, aluminium, silver matt anodised .......................... 76

9.3 Ordering details ...................................................................................................................... 76

10. Internal components and modules ................................................................ 77

10.1 BM800 and BM400 module ................................................................................................ 77

10.1.1 BM800 and BM400 dimensions ........................................................................................ 77

10.2 Operating and display module BI800S .......................................................................... 78

10.2.1 BI800S dimensions ................................................................................................................ 78

10.2.2 Wiring diagram BI800S ........................................................................................................ 78

10.2.3 Technical data BI800S ......................................................................................................... 78

10.2.4 Ordering information BI800S ............................................................................................ 79

10.3 Operating and display module BI71S ............................................................................. 80

10.3.1 BI71S dimensions ................................................................................................................... 80

10.3.2 Wiring diagram BI71S ........................................................................................................... 80

10.3.3 Technical data BI71S ............................................................................................................. 81

10.3.4 Ordering information BI71S ............................................................................................... 81

10.4 Operating and display module BI72S ............................................................................. 82

10.4.1 BI72S dimensions ................................................................................................................... 82

10.4.2 Wiring diagram BI72S ........................................................................................................... 82

10.4.3 Technical data BI72S ............................................................................................................. 83

10.4.4 Ordering information BI72S ............................................................................................... 83

10.5 I/O module BMI8/8 ................................................................................................................ 84

10.5.1 BMI8/8 dimensions ............................................................................................................... 84

10.5.2 Wiring diagram BMI8/8 ........................................................................................................ 84

10.5.3 Technical data BMI8/8 .......................................................................................................... 85

10.6 I/O module BMI8/4 and BMI0/4 ........................................................................................ 86

10.6.1 BMI8/4 and BMI0/4 dimensions ....................................................................................... 86

10.6.2 Wiring diagram BMI8/4 and BMI0/4 ............................................................................... 86

10.6.3 Technical data BMI8/4 and BMI0/4 .................................................................................. 87

INDEX ...........................................................................................................................89

6

TM800_D00165_00_M_XXEN/06.2015

Page 7

1. How to get the most out of this manual

DANGER

WARNING

CAUTION

1.1 How to use this manual

This operating manual describes the TM800 alarm indicator and operator panel with the software

version specified on the title page. The functions and processes described may vary from those featured in other versions. This manual is intended for qualified personnel working in electrical engineering and electronics and in particular for those designing, installing and operating electrical

equipment in medical locations.

Chapter "Operation" on page 49 can also be used as a quick reference guide by medical personnel.

Before using the devices, please read this operating manual, the supplement entitled "Important

safety instructions for Bender Products" and the instruction leaflets supplied with the individual system components. Keep this document in an easily accessible location near to the devices.

Should you have any further questions, please contact our Technical Sales department. We are also

happy to provide on-site service. Contact our Service Department for more information.

Although great care has been taken in the drafting of this operating manual, it may nevertheless

contain errors and mistakes. Bender cannot accept any liability for injury to persons or damage to

property resulting from errors or mistakes in this manual.

1.2 Explanation of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documentation:

The signal word indicates that there is a high risk of danger that will result in

death or serious injury if not avoided

This signal word indicates a medium risk of danger that can lead to death or serious injury, if not avoided.

This signal word indicates a low level risk that can result in minor or moderate

injury or damage to property, if not avoided.

This symbol denotes information intended to assist the user in making optimum

use of the product.

TM800_D00165_00_M_XXEN/06.2015

7

Page 8

How to get the most out of this manual

8

TM800_D00165_00_M_XXEN/06.2015

Page 9

2. Safety instructions

2.1 Intended use

In terms of human/machine interface, alarm indicator and operator panels play a crucial role. Their

task is to take system information and transform it into clear instructions, particularly in the event of

critical operating situations. The flexible TM800 alarm indicator and operator panels provide solutions that meet the requirements of modern medical facilities as well as industrial and functional

buildings. They are used for

the display and visualisation of operating status, warning and alarm messages

central operation and parameterisation of BMS bus devices (BMS = Bender Measuring Device

Interface)

the output of visual and audible warning messages

the display of measured values from Bender monitoring systems with BMS interface, such as

MEDICS®, RCMS or EDS

In addition, they are used for the display, control and operation of

operating theatre tables

equipment for supplying medical gases

battery-supported central power supply systems (BSV systems)

air conditioning and ventilation systems

room lighting

communication equipment

and third-party systems.

All technical devices installed in one alarm indicator and operator panel constitute a technology centre in the relevant room.

Please heed the limits of the area of application indicated in the technical specifications. Use which

deviates from or is beyond the scope of these technical specifications is considered non-compliant.

Use for the intended purpose also includes:

Device-specific settings compliant with local equipment and operating conditions.

The observation of all information in the operating manual.

Compliance with test intervals.

2.2 Qualified personnel

Only appropriately qualified personnel may work with the Bender devices. Personnel who are familiar with the installation, commissioning and operation of the equipment and have undergone appropriate training are considered qualified. Personnel must have read this manual and understood

all instructions relating to safety.

2.3 General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in

respect of technical safety. However, the use of such devices may introduce risks to the life and limb

of the user or third parties and/or result in damage to Bender devices or other property. Only use

TM800_D00165_00_M_XXEN/06.2015

9

Page 10

Safety instructions

Bender devices:

–As intended

– In perfect working order

– In compliance with the accident prevention regulations and guidelines applicable at the

location of use

Eliminate all faults immediately which may endanger safety.

Do not make any unauthorised changes and only use replacement parts and optional accesso-

ries purchased from or recommended by the manufacturer of the devices. Failure to observe

this requirement can result in fire, electric shock and injury.

Reference signs must always be clearly legible. Replace damaged or illegible signs immediately.

Make sure that the dimensions of the BSV (battery-supported safety power supply), the genera-

tor set and the whole wiring are adequate. The applicable national and international standards

must be observed here. Only in this way selective operation of safety devices can be achieved

and a high degree of safety in case of overload and short circuit can be ensured.

2.4 Delivery conditions, warranty and liability

The conditions of sale and delivery set out by Bender apply. Conditions of sale and delivery can be

obtained from Bender in printed or electronic format.

10

TM800_D00165_00_M_XXEN/06.2015

Page 11

3. System description

3.1 MEDICS®

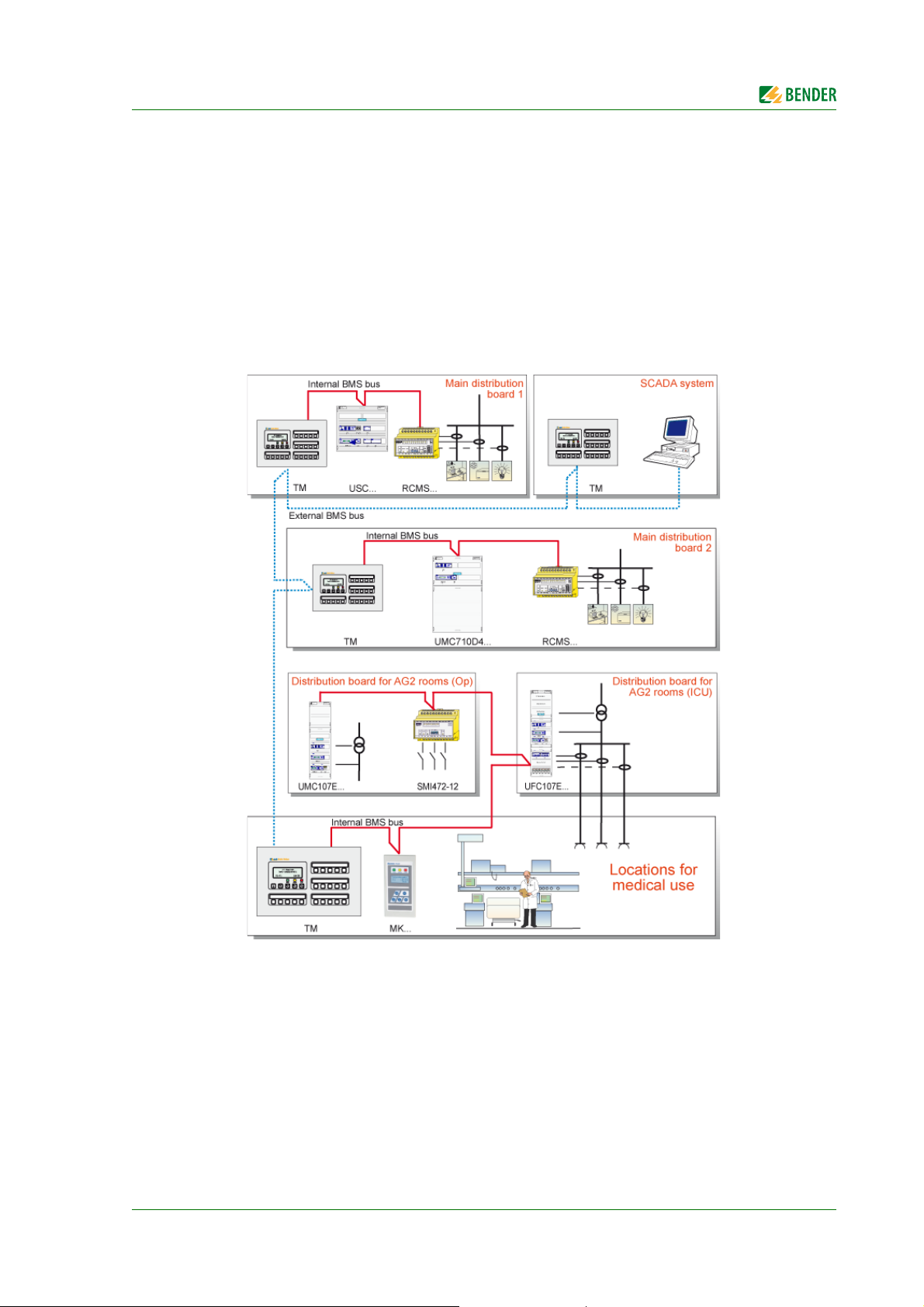

The TM800 alarm indicator and operator panel is an integral component of the MEDICS® system.

MEDICS

Example of a section of a hospital with the MEDICS

®

is an intelligent system that guarantees safe power supply in medical locations.

®

system

Legend to the illustration above

MK… Alarm indicator and test combination

RCMS… Residual current monitoring system for TN-S systems

SMI472 Signal converter for third-party technical equipment (e.g. med. gases, BSV (battery-

supported systems)

TM… Alarm indicator and operator panel

UFC107E… Changeover and monitoring module for IT systems with EDS insulation fault location system

UMC107E… Changeover and monitoring module for IT systems

UMC710D… Changeover module for main distribution boards

USC710D… Control module for changeover modules (preferably in main distribution boards)

SCADA system (Supervisory Control and Data Acquisition)

TM800_D00165_00_M_XXEN/06.2015

11

Page 12

System description

MEDICS® includes:

Single and three-phase monitoring modules. MEDICS

®

system modules are, for example:

UMC…, USC…, UFC… and/or EDS… insulation fault location systems

Display and operating units such as TM… alarm indicator and operator panels or MK… alarm

indicator and test combinations

Communication between these components via the BMS bus (two-wire connection).

The connection of third-party technical systems by means of protocol converters (gateways) or

via digital inputs and relay outputs.

The real strength of MEDICS

®

is to be foun d i n commun ic ation between all involved components and

the resulting information provided to the user. The functionality of the equipment is continuously

monitored. Operating states, irregularities, faults and equipment failures are displayed. This means

high operational reliability of the installation for the user.

3.2 TM800 features

On its backlit LC display, the TM800 displays messages from all BMS-bus devices and digital inputs

assigned via alarm addresses. As well as being used as a standalone indicator, the TM800 also supports parallel indication in different rooms. In the event of an alarm message, the yellow LED "WARNING" or the red LED "ALARM" lights up and the message appears on the LC display in plain text

format. At the same time there is an audible signal (can be acknowledged/muted). If a second message is received whilst the first is still pending, the audible signal will sound again and the messages

will appear alternately on the LC display. The address of the device triggering the alarm can also be

called up. The audible signal sounds again once a configurable period of time has elapsed (repetition

can be deactivated). Illuminated pushbuttons can be programmed to signal alarms and operating

states or for programming operating information. Operator actions or messages can be output via

digital outputs.

Internal device parameters (alarm addresses, test addresses…) and the parameter setting of EDSand RCMS systems can be accessed via the menu system. TM800 can be also be used as a master device in installations with a number of IT and EDS systems.

The test button can be used to check the function of the associated devices such as insulation monitoring devices, LIM (Line Isolation Monitors) or GFCI (Ground Fault Circuit interrupters). The message

is output only on the TM800 on which the test button "TEST" was pressed. The test and its individual

evaluations are carried out sequentially. Finally, a message appears indicating either a successful test

or a fault.

TM800 features:

Display, control and operation of Bender monitoring systems and third-party systems

Backlit clear LC text display (4 x 20 characters, 8 mm)

Additional text with specific information for technical and medical personnel can be displayed

LEDs in traffic light colours: 3 LEDs for optical differentiation of messages

Predetermined standard texts in 21 languages for Bender MEDICS® systems

1000 freely programmable message texts (with TMK-SET PC software)

Audible alarm (can be acknowledged or muted)

Easy parameterisation:

– with a personal computer (USB interface, BMS bus): TM800, MK800, EDS46x, EDS47x,

EDS49x, RCMS460, RCMS470, RCMS490

– via menu: TM800 basic parameters

12

TM800_D00165_00_M_XXEN/06.2015

Page 13

System description

Betrieb Warnung Störung

History memory with real-time clock to store 1000 warning and alarm messages

Variable operator and display modules with a freely programmable function

Easy integration with third-party systems, because operating theatre table controls, medical

gases, intercom systems are behind a closed foil surface

Control of third-party systems by flexible I/O modules with galvanic separation

Alarm LED at each input/output for fast diagnosis

Functions can be easily extended by adding I/O modules

Clearly defined structure thanks to an external and internal bus

Non-reflecting, multi-coloured foil surface

Optionally available with an antibacterial foil surface

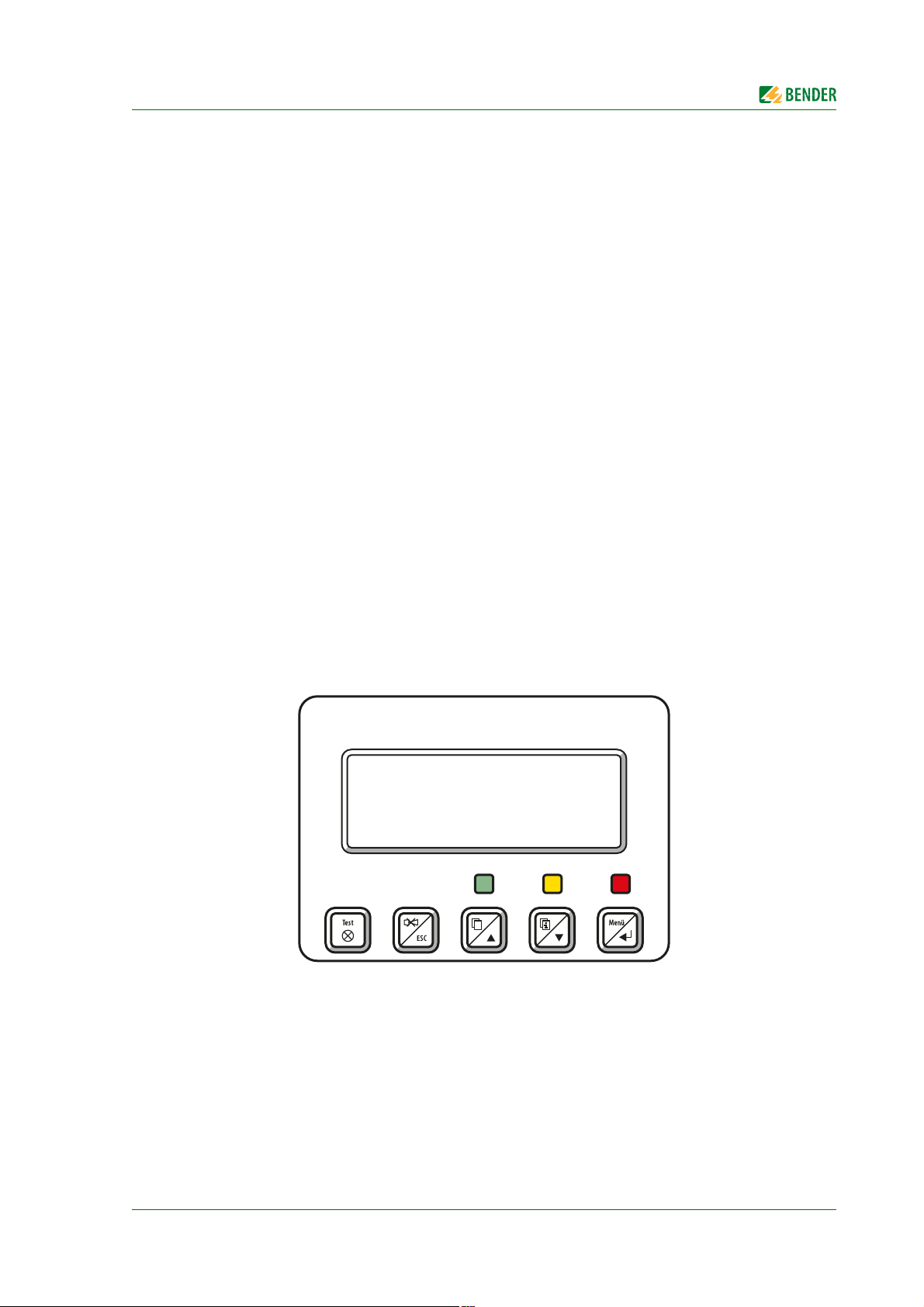

3.3 Functionality of the TM800

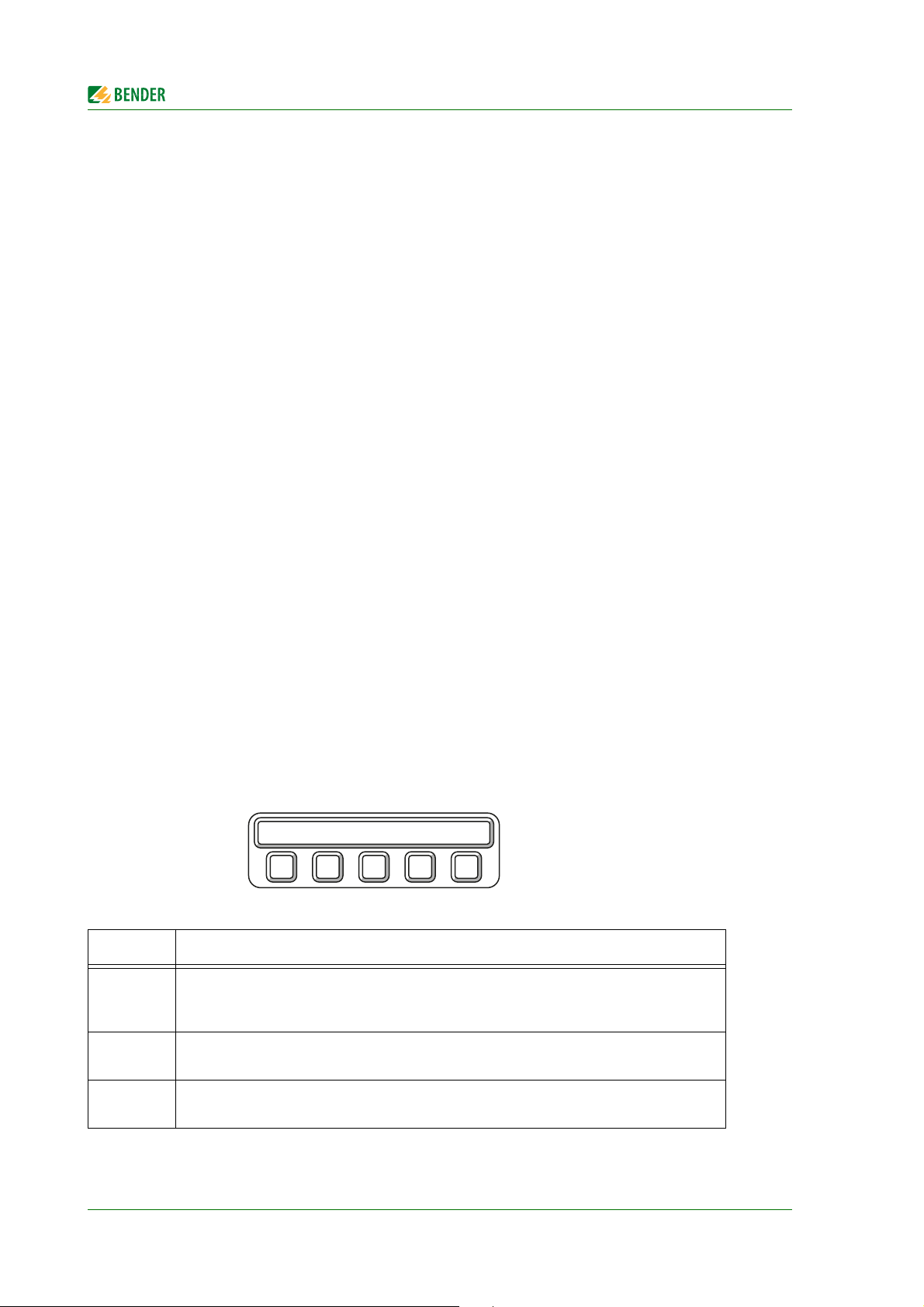

3.3.1 LC display

The backlit features four lines of 20 characters. It assists medical and technical personnel during the

decision-making process with information that is always clear and unambiguous. Every alarm message comprises three lines which appear spontaneously and three additional lines which can be displayed at the touch of a button. The fourth line contains status information (the number of

messages, test procedures, menu information).

Below the text display, three LEDs are arranged. They indicate: normal operation (green), warning

(yellow) or alarm messages (red).

Five buttons are available to acknowledge or to mute alarm and warning messages, for testing the

assigned devices and for the menu system.

TM800_D00165_00_M_XXEN/06.2015

13

Page 14

System description

3.3.2 Programmable messages

Standard message texts can be activated by enabling alarm addresses. These texts are available in

21 national languages. Alarm addresses can be enabled via the device menu system (without personal computer). Individual message texts, each comprising 6 lines à 20 characters can be programmed with the TMK-SET software. Up to three outputs can be assigned to each alarm.

An LED (yellow or red) and an audible signal can be assigned to each message. For this purpose, the

PC is connected to the USB interface or BMS bus (RS-485). In addition to the buzzer, a relay can be

activated that enables, for example, an alarm horn sound in a loud environment.

3.3.3 History memory

Warnings and alarms with date and time stamp are automatically written to the history memory.

1000 text messages can be stored. Each subsequent message overwrites the oldest message in the

history memory (message 1001 will overwrite message 1 etc.). The history memory can be read out

via the operating menu or the TMK-history PC software.

3.3.4 Interfaces

Alarm indicator and operator panels feature different interfaces, for communication with third-party

systems and/or MEDICS

–Internal BMS bus

–External BMS bus

–USB interface

®

components:

3.3.4.1 BMS bus

The BMS bus system (BMS=Bender Measuring Device Interface) guarantees high operational reliability:

Based on the tried and tested industrial standard RS-485

A self-contained system - not influenced by third-party systems

Redundant master function and data transmission (internal and external bus)

Mutual device monitoring

Open, thanks to defined interfaces, e.g. OPC server

Internal BMS bus

The internal BMS bus is used for communication with BMS bus devices,

– e.g. modules like UMC…, UMA…, UFA…, UFC…, LFC…, ATICS®

– or devices like RCMS…, EDS…, SMI…, SMO…, MK800…, TM800

Up to 30 devices can be connected to each internal bus line (in combination with the DI-1PSM repeater up to 150). One address is assigned to each bus device. Address 1 is assigned to the TM800

alarm indicator and operator panel which represents the master on the internal bus.

If the external BMS bus is switched off, addresses 2…150 (slave) can be selected on the internal bus.

14

TM800_D00165_00_M_XXEN/06.2015

Page 15

System description

External BMS bus

The external BMS bus enables communication with other TM800 alarm indicator and operator panels, SMI472-12 or BMS-OPC servers. The master function is cyclically passed to the subsequent master on the external bus. The TM800, with address 1, however, takes over some special tasks:

– As a "master clock", it synchronises the time of all devices on the internal BMS bus

– It ensures that the required supply voltage is available on the external BMS bus.

Messages can be displayed on any TM800 alarm indicator and operator panel via the external BMS

bus. The PC software TMK-SET is used to assign the messages accordingly.

A personal computer is recommended to be connected via the external BMS bus to the TM800 alarm

indicator and operator panel. Any information of the TM800 panels connected to the external BMS

bus can be displayed and set at a central point. If the personal computer does not feature an RS-485

interface, an RS-232/RS-485 converter DI-2 or a USB/RS-485 converter DI-2USB will be required.

3.3.4.2 USB interface

A personal computer can also be connected to the TM800 via the USB interface using a standard-USB

device cable (type A/type B). To access the USB interface plug, open the front plate.

Only the connected TM800 can be read out and set via the USB interface.

3.3.5 Programming and reading the TM800

3.3.5.1 Connection of the personal computer

Connect the TM800 to a personal computer:

directly via the USB interface or

via an RS-232/RS-485 converter DI-2 or a USB/RS-485 converter DI-2USB to the internal or exter-

nal BMS bus.

3.3.5.2 Optional software

You can use the PC software TMK-SET to read, display and change the TM800 settings.

You can use the PC software TMK-History to read the history memory of the TM800 (download

from http://www.bender-de.com).

BMS-OPC server

3.3.6 Firmware versions

The TM800 is controlled by an internal software (firmware).

All devices sharing one external BMS bus must be equipped with compatible

software versions. The following software versions are required:

TM V 4.0 or higher

SMI472 V 2.03 or higher

TM800_D00165_00_M_XXEN/06.2015

All devices must be set to the same baud rate.

15

Page 16

System description

3.4 Mechanical design

3.4.1 Module overview

The TM800 alarm indicator and operator panels are based on a modular design. The appropriate

combination of modules will be made by Bender so that the user is not unnecessarily burdened with

planning details. This chapter provides a summary of the applicable modules:

BM800 Module for TM800 alarm indicator and operator panel

BM400 module like BM800, but without an LC display and control buttons

BI… operating and display modules each with five illuminated pushbuttons

BMI… I/O modules (digital inputs, relay outputs, open collector outputs)

Individual components (remote operating table control, intercom systems…)

3.4.2 BM800 and BM400 modules

3.4.2.1 BM800

Module for a TM800 alarm indicator and operator panel with LC display. BM800 features:

– LC display (without a front foil, because this is included already in the front plate of TM800)

– one operating LED, warning and alarm LED each as common alarm LEDs

– 5 control buttons

– Interfaces 2 x RS-485, 1 x USB, 2 x I²C

–Buzzer

3.4.2.2 BM400

BM400 is a module similar to BM800, but without LC display and control buttons. These operating

and display modules together with digital I/O modules can be configured to form indicator and operator panels.

3.4.3 Operating and display modules

The operating and display modules consist of 5 elements. Depending on the panel type, different

numbers of modules are available (also see "Internal components and modules" on page 77ff).

Type Characteristics

BI800S Operating and display elements to expand the BM800/BM400 modules. 16 BI800S

modules can be controlled via I²C bus. One individual function (switch, button, LED etc.)

can be assigned to each element.

BI71S Operating and display elements without an I²C bus:

5 illuminated pushbuttons, 5 potential free changeover contacts, max. AC 250 V/8 A.

BI72S Operating and display elements without an I²C bus:

5 illuminated pushbuttons, 5 potential free changeover contacts, max. AC 24 V/0.9 A

16

TM800_D00165_00_M_XXEN/06.2015

Page 17

System description

3.4.4 Inputs and outputs

Digital inputs and outputs as well as relay outputs are available for the control and indication of different technical equipment. The I/O modules are controlled via I²C bus.

The digital inputs are designed for a voltage of AC/DC 0…30 V (HIGH=10…30 V; LOW=0…2 V). In

practice, these digital inputs are controlled via an internal or external voltage and potential-free contacts (N/C or N/O operation, selectable). The voltage required for these inputs can be supplied by the

built-in power supply unit. The behaviour of the alarm contact at the digital input (N/O contact or N/

C contact) can be assigned via this PC software. That means that the hardware of the alarm indicator

and operator panel does not need to be changed in case of subsequent changes of the contact behaviour.

Digital inputs or outputs (potential free relay contacts or open collector outputs) are controlled by

warning or alarm messages, via operating and display modules or the digital inputs. A message, a

digital input or an illuminated pushbutton can be assigned to a relay output via the PC software

TMK-SET.

The I/O modules are snapped on a DIN rail in the flush-mounting box separately from the display and

the pushbutton panels. So the system can easily be expanded. Each input and output provides an

alarm LED so that the status is visible at a glance for the technical staff.

3.4.4.1 Digital output 1

When an I/O module BMI8/8, BMI8/4 or BMI0/4 is built in, the first output can be programmed individually. It can be used for system functions (see "Settings menu 11: Relays" on page 65). The output

switches when:

– an internal TM800 device error is recognised

– the test button is pressed (relay will be activated for approx. 1.5 s)

– a device failure is recognised on the BMS bus,

– any warning or alarm message occurs (common alarm)

– the buzzer sounds (relay is activated when buzzer sounding)

The output can also be programmed via TMK-SET like all other outputs.

TM800 alarm indicator and operator panels offer safe separation according to

IEC 60664 between the relay contacts and the electronics, interface outputs, digital inputs and among each other.

3.4.4.2 I/O modules

Type Characteristics

BMI8/8 8 digital inputs, 8 open collector outputs

The open collector outputs are capable of driving a load of up to 15 W at an operating

voltage of 24 V. They feature flyback diodes for the connection of relays.

TM800_D00165_00_M_XXEN/06.2015

17

Page 18

System description

Type Characteristics

BMI8/4 8 digital inputs, 4 relay outputs

The digital outputs correspond to those of the BI8/8 module. The potential-free output

relays feature one changeover contact eachAC 250 V, 5 A (AC1).

BMI0/4 Expansion for BMI8/4 by 4 relay outputs. The module BMI0/4 can only be used in com-

bination with the BMI8/4 module. The potential-free output relays feature one changeover contact each AC 250 V, 5 A (AC1).

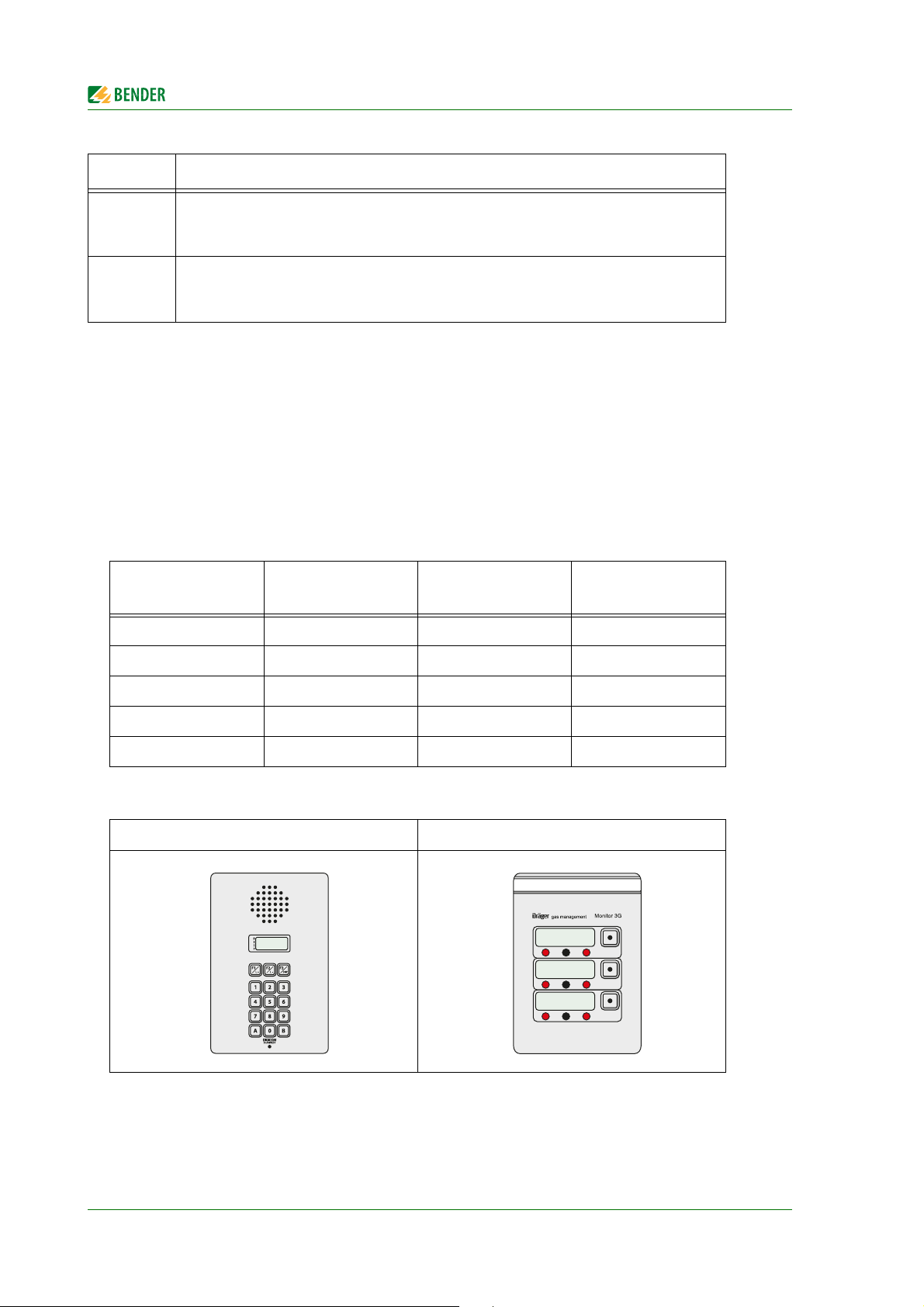

3.4.5 Individual internal components

In addition to the operating functions activated via operating and display modules, often complete

operating units from a third-party manufacturer are integrated into the alarm indicator and operator

panel. Typical examples are operating table controls or intercom systems. These modules are integrated in the alarm indicator and operator panels by Bender so that an aesthetically attractive functional solution is available, documented by the official release of the manufacturer. The required

connections are made in accordance with the specifications of the respective manufacturer.

Typical examples of third-party systems used in medical locations

Med. gases Intercom systems

Dräger Digicom-Scanvest ALM Maquet

Gehrke Berchtold Trumpf

Schneider Dräger

Stentofon Haraeus

Telecom Behnke

Operating theatre

light

Operating theatre

table

Intercom system – Digicom Dräger Monitor 3G

18

TM800_D00165_00_M_XXEN/06.2015

Page 19

4. Installation and connection

4.1 Installation

4.1.1 Overview of enclosure variants

The design of the alarm indicator and operator panels is based on the individual customer requirements in terms of interior design and the architect's and constructor's needs. In addition to the basic

versions also room-high stainless-steel alarm indicator and operator panels or other versions are

available.

The foil surface is completely closed, i.e. there are no screws needed for fixing the front plate. The

panel is easy to clean so that a high standard of hygiene is guaranteed. For additional protection, the

front panel surface can also be delivered with antibacterial surface.

Flush-mounting type enclosure with bezel frame (UPB)

A gap of up to 12 mm between the flush-mounted enclosure and the wall can be concealed by a bezel frame made of anodised aluminium. This version is recommended to be used for wallpapered

walls or walls with non-standard tiles, for example.

Flush-mounting type enclosure with mounting frame (UPE)

The mounting frame permits accurate and close wall mounting. The mounting frame is made of anodised aluminium. The mounting frame version is preferably used where the enclosure is required

to fit exactly the dimension of the tiles.

TM800_D00165_00_M_XXEN/06.2015

19

Page 20

Installation and connection

WARNING

WARNING

Surface-mounting enclosure (AP)

The anodised surface-mounting enclosure is suitable for both pure surface-mounting and for partially recessed mounting. The enclosures can be supplied with a depth of 90, 150 and 210 mm.

The support frame inside the flush-mounted or surface-mounted case is fitted with a long-term elastic seal in order to avoid the ingress of cleaning agents into the panel. Depending on the size, the

front plate is connected to the flush mounting or surface mounting enclosure by two or more stable

hinges. This guarantees easy installation of the alarm indicator and operator panel.

All necessary modules and display elements are permanently fixed to the front plate using threaded

bolts or mounting frames. The front plate is connected with the mounting plate via a flexible spiral

hose that is fixed on both sides with cable clips. The technical equipment and systems are connected

to a terminal board that is fixed on a mounting plate. The power supply unit for the alarm indicator

and operator panel is also located on this mounting plate. The mounting plate can easily be dismantled. That allows the flush-mounting or surface-mounting enclosure to be installed prior to the final

assembly stage. Cable connections between the front plate and the terminal board also do not need

to be disconnected.

With the exception of the mounting plate no other components are fixed to the baseplate of the

flush-mounting/surface-mounting enclosure, allowing sufficient room for installation.

4.1.2 Unpacking

Unpack all the parts supplied with the system. Do not use sharp-edged tools that may damage the

content of the packaging.

Compare your order with our delivery note to check that you have received all products in full. The

article numbers printed on the nameplates simplifies the identification of the devices.

Check all parts supplied for any evidence of damage in transit. Devices damaged

in transit must not be used. If a device is damaged, please contact Bender. Details

of who to contact are indicated on the delivery document.

Before using devices that have been stored at low temperates: Leave the devices

to stand for 3 to 4 hours at room temperature before connecting the power supply. A change in temperature from cold to warm will result in condensation on all

device components. Putting damp devices into operation risks damaging electrical components and there is a danger of electric shock on contact.

20

TM800_D00165_00_M_XXEN/06.2015

Page 21

Installation and connection

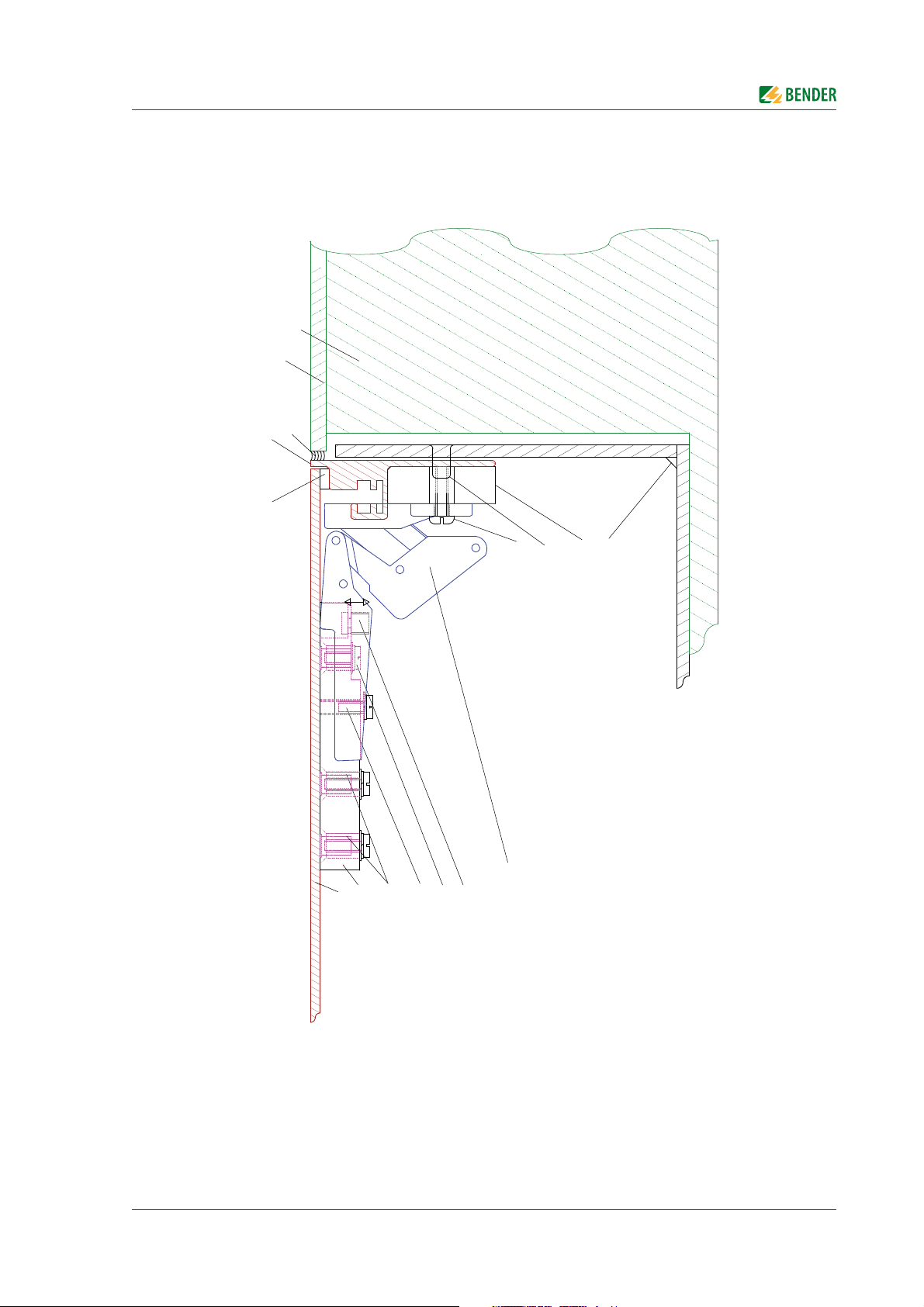

Drawing no.: 9800267

4.1.3 Installing the flush-mounting type enclosure with bezel frame (UPB)

Note: Do not remove the plaster cover and the fixing brackets during the installation to protect the

wall-mounting enclosure!

1. Before inserting the cables remove the knockouts. Guide the power supply cables into the

enclosure.

2. Install the flush-mounting enclosure in a way that the enclosure (and thus the plaster cover)

are approximately 2 mm below the finished surface of the wall.

3. After installing the enclosure securely, remove the plaster cover and the fixing brackets. Then

install the bezel frame into the flush mounting enclosure.

TM800_D00165_00_M_XXEN/06.2015

21

Page 22

Installation and connection

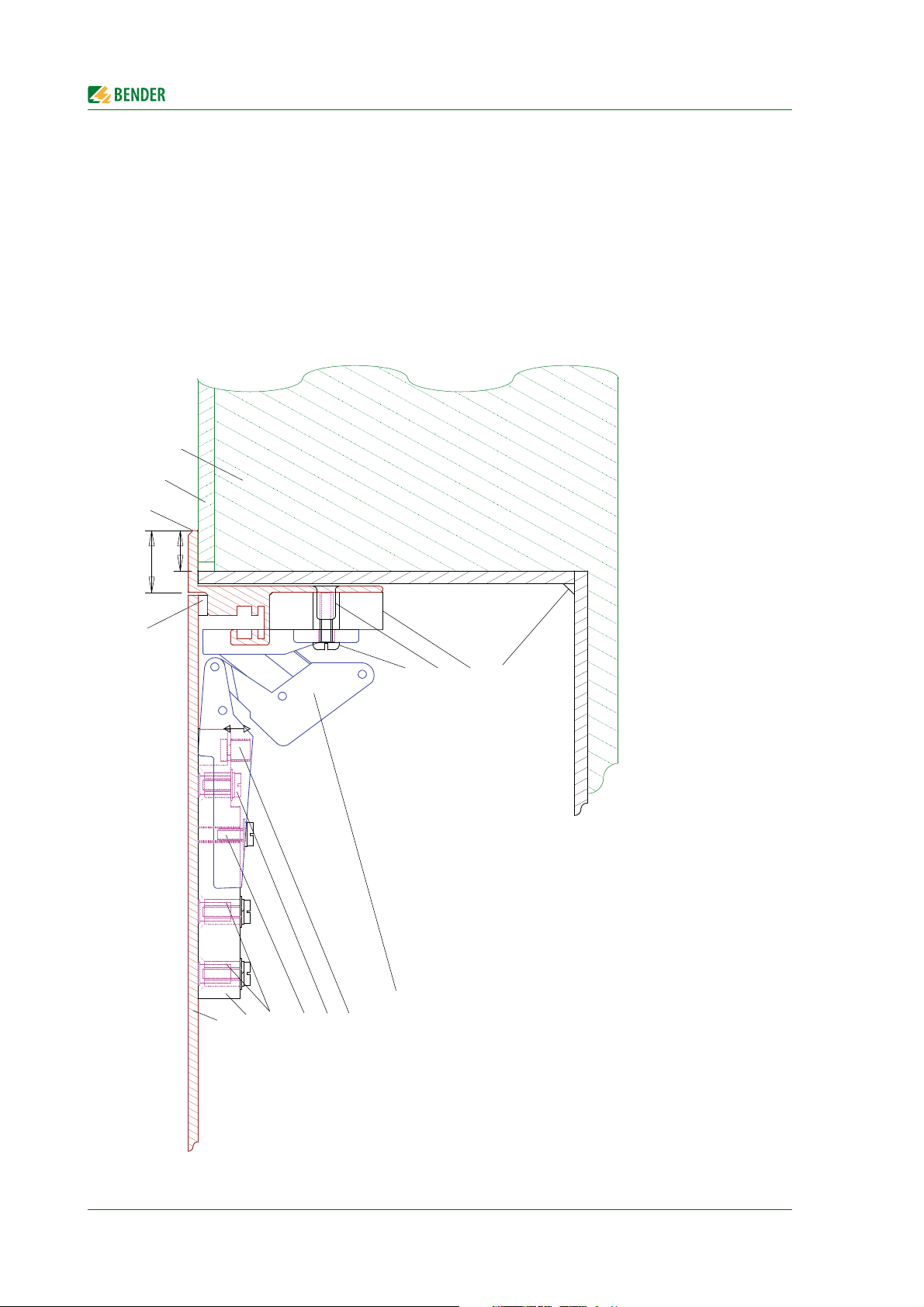

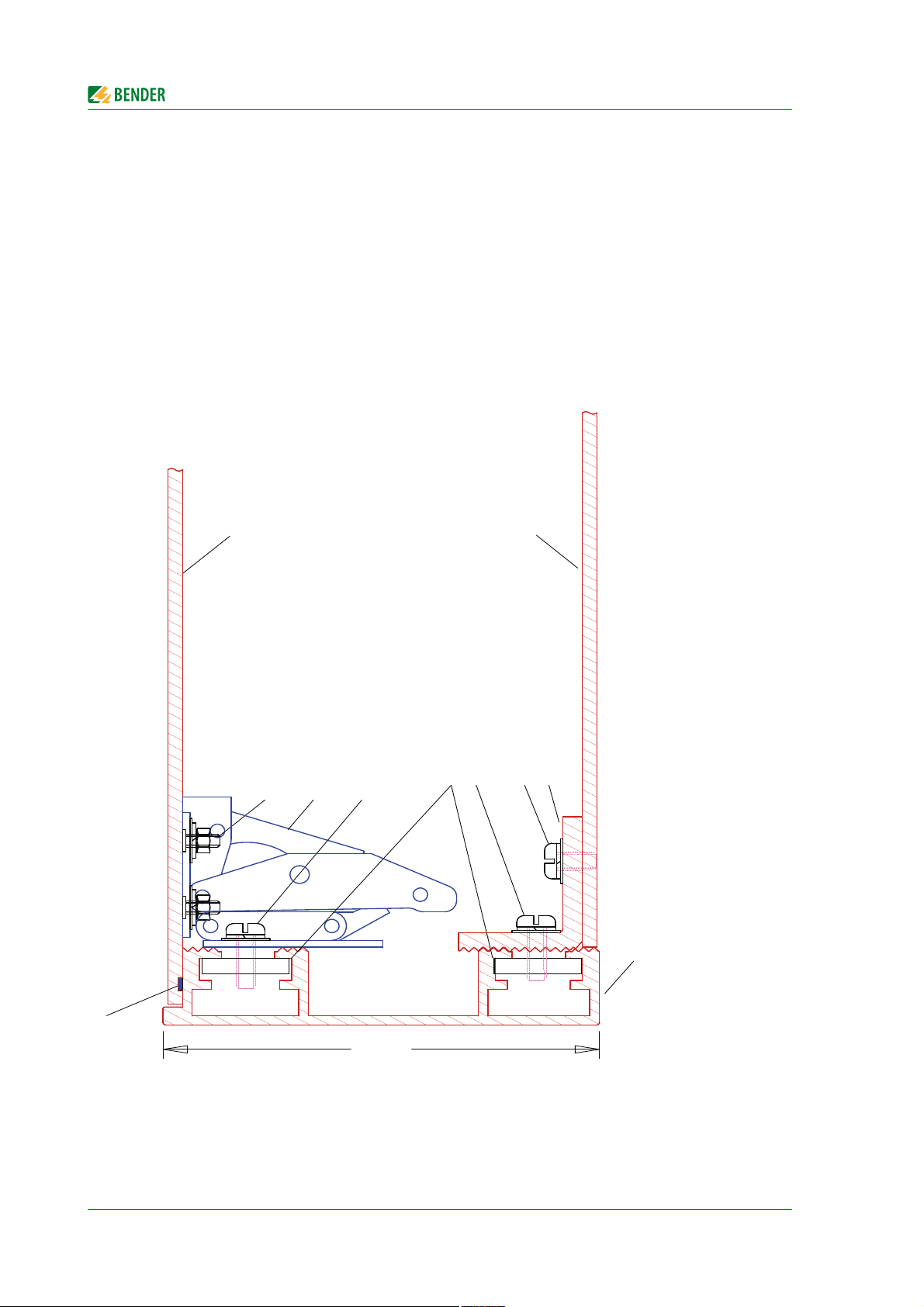

4.1.4 Installing the flush-mounting enclosure with mounting frame (UPE)

The front plates are fitted into the wall-mounting enclosure and identified by a number identical to

the number of the enclosure. The front plate number must be identical to the enclosure number!

Note: Do not remove the plaster cover during the installation to protect the wall-mounting enclosure!

1. Before inserting the cables remove the knockouts. Lead the power supply cables into the

enclosure.

2. Install the mounting frame and the wall-mounting enclosure (UPE) deeper than the finished

wall surface (i.e. tile thickness plus adhesive thickness). Note: The wall-mounting enclosure is

partially covered by the wall surface (e.g. tile)

3. Once the enclosure is firmly installed and the joints are filled, the plaster cover can be

removed.

Size of the panel and flush-mounting enclosure

Typical tile grid

150 mm tile grid= 147 mm tile + 3 mm joint

153 mm tile grid= 150 mm tile + 3 mm joint

Calculation of the panel size

Panel dimension = number of tiles x tile grid - one joint width

Example:

Panel dimension = 2 x 150 mm - 3 mm

Panel dimension = 297 mm

Calculation of the flush-mounting enclosure size

Flush-mounting enclosure dimension= Number of tiles x tile grid - one joint width + 10 mm

Example:

Flush-mounting enclosure dimension= 2 x 150 mm - 3 mm + 10 mm

Flush-mounting enclosure dimension= 307 mm

22

TM800_D00165_00_M_XXEN/06.2015

Page 23

Installation and connection

wall surface, tiles

inside mounted plaster frame, anodized alum-profile, 2mm

brick wall

slotted oval head screw, M4x20mm

with washer and nut

mounting lid

seal

backbox, 4mm

depth as specified

p

l

a

s

t

e

r

3

m

m

297.0

mounting lid

1

4

7

.

0

Drawing no9800268

TM800_D00165_00_M_XXEN/06.2015

23

Page 24

Installation and connection

Drawing no.: 9800269

4.1.5 Mounting the front plate

The front plates are fitted into the flush-mounting enclosure and are marked with a number that is

identical to the number of the enclosure. The front plate number must be identical to the enclosure

number!

Install the hinges of the front plate as described in the drawing below:

4.1.5.1 Flush-mounting type enclosure with bezel frame (UPB)

brick wall

wall surface

adjustable height max. 20mm

bezel/cover frame + alum.-profile, 3mm

20.0

seal

13.0

rivet nut M4

backbox, 4mm

depth as specified

spacer WxHxD 52x35x12

slotted pan head machine screw,M4x16mm

24

frontplate, 3mm, Alum.

hinge

hinge

hinge fixing

+ M4x12 screw

Alum. mountingplate

welded stud M4x5x6x8

horizontal adjustment

hinge fixing

screw M4x8

vertical adjustment

Fixing instructions see on dwg# 9800373EA+B

Mounting instructions see on dwg# 9800267E

Optional: spring catch, see dwg# 9800266E

TM800_D00165_00_M_XXEN/06.2015

Page 25

Installation and connection

in side mouted plaster frame, anodized alum-profile, 2mm

adjustable in depth by 15mm

wall surface, tiles

brick wall

seal

plaster, 3mm

slotted pan head machine screw,M4x16mm

frontplate, 3mm, Alum.

Alum. mountingplate

welded stud M4x5x6x8

+ M4x12 screw

hinge fixing

horizontal adjustment

screw M4x8

hinge fixing

vertical adjustment

Hinge

spacer WxHxD 42x35x6

depth as specified

Fixing instruction see on dwg# 9800374EA+B

Mounting instructions see on dwg# 9800268E

Optional: spring catch, see dwg# 9800266E

rivet nut M4

backbox, 4mm

Drawing no.: 9800272

4.1.5.2 Flush-mounting type enclosure with mounting frame (UPE)

TM800_D00165_00_M_XXEN/06.2015

25

Page 26

Installation and connection

Threaded bolt

T

Threaded bolt M3x12 mm

Hinge

Screw M4x12 mm

Slide nut M4

Screw M4x12 mm

Screw M4x10 mm

Fastening angle for base plate

Base plate, aluminium, 3 mm

Front plate, aluminium, 3 mm

Profile enclosure made of anodized aluminium

T = depth: 90, 150 mm (210 mm on request)

Drawing no.: 9800274

4.1.6 Installation of the surface-mounting enclosure (AP)

1. Open the front plate as described in chapter "4.1.7 Opening the front plate".

2. Drill holes into the enclosure for wall mounting and cable entries. The holes are not pre-drilled

so that local conditions can be considered. However, you must ensure that the cables are positioned in such a way that there is enough space left for the circuit-boards when the frontplate

is closed.

3. Fix the enclosure to the wall using stainless screws.

4. Lead the power supply cables into the enclosure.

26

TM800_D00165_00_M_XXEN/06.2015

Page 27

Installation and connection

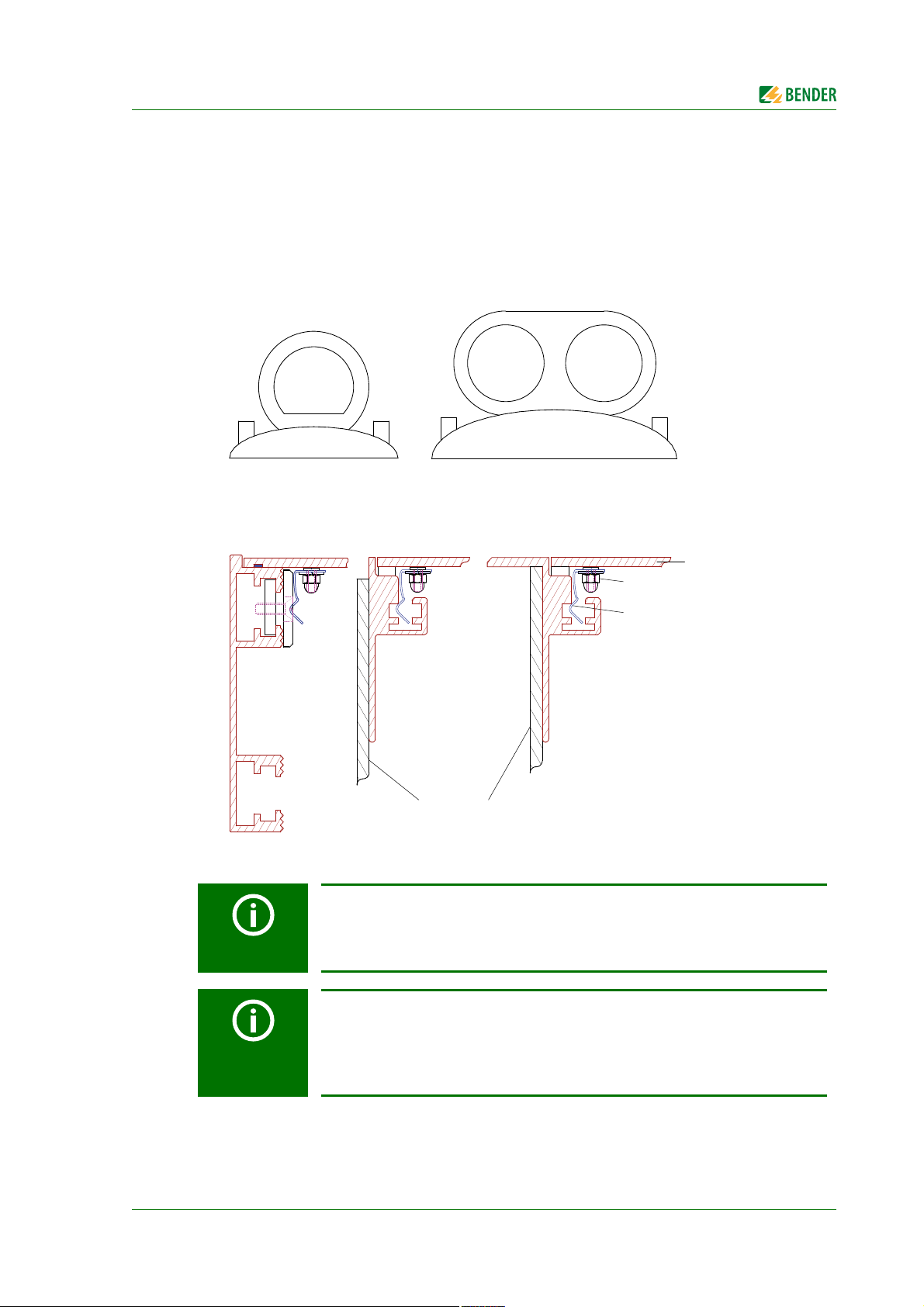

Suction cup d=80 mm

or

Suction cup d=55 mm

Art. No. 102851

Art. No. 102850

steel C75 - H&H

spring catch, 12.5mm

welded stud,

front plate, 3 mm, alum.

M3x6 mm

For following wallboxes:

surface-mounting frame

(AP)

(UPE)

mounting frame

(UPB)

bezel frame

backbox, 4 mm

Drawing no.: 9800266

4.1.7 Opening the front plate

It should only be possible to open the enclosure with a keys or a tool (as, for example a suction cup,

screw driver). This is required by the following standards:

VDE 0660, part 500, chapter 7.4.2.2.3. a)

EN 60439-1, chapter 7.4.2.2.3. a)

IEC 60439-1, chapter 7.4.2.2.3. a)

TM800_D00165_00_M_XXEN/06.2015

Factory-delivered, TM800 panels come with a textile lug that protrudes between

the frame and the front plate. This allows the front plate to be opened for commissioning without the use of a tool. Make sure this textile lug no longer protrudes from the enclosure after commissioning.

Components protruding from the front plate (such as socket-outlets, remote operating theatre table control) which could enable the user to hold on to them

and to open the alarm indicator and operator panel are secured by means of a

screw located in the middle of the side opposite the hinges:

Raised countersunk head screw, M4x10 with rosette.

27

Page 28

4.2 Connection

DANGER

DANGER

CAUTION

CAUTION

CAUTION

Risk of electric shock!

Before fitting the enclosure and working on the device connections, make sure

that the power supply has been disconnected.

Failure to comply with this requirement will expose personnel to the risk of an

electric shock. Furthermore, the electrical installation may be damaged and the

device destroyed beyond repair.

Connect the TM800 alarm indicator and operator panel exclusively according to

the wiring diagram supplied with the device. Do not make any changes to the

internal wiring. Wiring not conforming to the accompanying diagram or unauthorised modifications may result in the TM800 malfunctioning or completely

failing to operate.

If inductive loads and the TM800 share a common voltage source, it is absolutely

necessary to use flyback diodes directly at the inductive load. Always use a separate power supply for the operation of impulse relays in order to avoid interferences.

Installation and connection

Make sure that the power supply of the TM800 is isolated against PE. If this is

not taken into account and a personal computer is connected to the USB interface the TM800 or the personal computer may be damaged.

The device contains components that can be damaged by electrostatic dis-

charges (ESD). If work requires the opening of the device, the safety precautions

concerning the dissipation of electrostatic electricity have to be observed.

4.2.1 Connection details

The following connections are available on modules installed in the lower part of the enclosure:

Connect the supply voltage to the terminals 0 and 230 V of the TM800's power supply unit. The

standard supply voltage is AC 230 V.

The terminals for the digital inputs, the open collector outputs and the relay outputs are availa-

ble on the associated I/O modules BMI8/8, BMI8/4, BMI0/4. Use cables with a cable cross section

of at least 0.75 mm

length per connection is 500 m.

A terminal board allows the connection to the internal and external BMS bus (internal bus = ter-

minals iA/iB, external bus = terminals eA/eB).

Connect the BMS bus according to the instructions in chapter "4.2.3 BMS-bus connection" and

in the "BMS bus" leaflet. Use a shielded cable of at least mm or 0.8 mm cross section for the

interface line (e.g. J-Y(St)Y n x 2x0.8). The terminals iS resp. eS are used to connect the shield of

the respective BMS bus. The shield must be connected to earth at one end. The shield may in no

circumstances be earthed at several points.

2

for the connection of digital inputs and relay outputs. The maximum cable

28

TM800_D00165_00_M_XXEN/06.2015

Page 29

Installation and connection

eA eB eS iA iB iS

eA

eBeSiA

iB

iS

BI800

BI800

BI800

BI800

BM800

A

B

1

D

6

2

345

978

C

4.2.2 Modules and connections of the TM800 (connection example)

TM800_D00165_00_M_XXEN/06.2015

29

Page 30

Legend to wiring diagram

A Back of the front plate

B Mounting plate, installed in the bottom part of the enclosure.

Installation and connection

C

2

C bus, is used for communication between the modules BM800 (resp. BM400) and the

I

operating and display modules BI800S. The terminals of the two I

2

C buses must not be

interchanged!

D

2

C bus, is used for communication between the modules BM800 (or BM400) and the I/O

I

modules BMI8/8, BMI8/4 and BMI0/4. The terminals of the two I

2

C buses must not be inter-

changed!

1 Terminal board for connection to the internal and external BMS bus

internal bus = terminals iA, iB, iS, external bus = terminals eA, eB, eS)

(

2 Digital inputs of the I/O module BMI8/4, or BMI8/8

3 Open collector outputs of the I/O module BMI8/8

4 Relay outputs of the I/O module BMI8/4

5 Relay outputs of the I/O module BMI0/4

6 Connection of the supply voltage U

to the terminals 0 and 230 V of the power supply unit.

S

The standard supply voltage is AC 230 V.

7 Switch S1 to terminate the external BMS bus.

8 Switch S2 to terminate the internal BMS bus.

9 USB connection for programming purposes. Cable: Type A plug on type B plug.

TM800 modules

BM800 Module

BI800S Operating and displaying module to expand each BM800/BM400 module by five pushbut-

tons

BMI8/8 8 digital inputs, 8 open collector outputs.

The open collector outputs are capable of driving a load of up to 15 W, at an operating voltage of 24 V. They feature flyback diodes for the connection of relays.

BMI8/4 8 digital inputs, 4 relay outputs

The digital outputs correspond to those of the BMI8/8 module. The potential-free output

relays feature one changeover contact of AC 250 V, 5 A (AC1) each.

BMI0/4 Expansion for BMI8/4 by 4 additional relay outputs. The

BMI0/4 module can only be used in conjunction with BMI8/4. The potential-free output

relays feature one changeover contact of AC 250 V, 5 A (AC1) each.

Mains

Power supply unit of the TM800 alarm indicator and operator panel.

Part

30

TM800_D00165_00_M_XXEN/06.2015

Page 31

Installation and connection

4.2.3 BMS-bus connection

Communication between the TM800 alarm indicator and operator panel and other system components takes place via two serial interfaces (internal and external BMS bus). These interfaces cables are

of two-wire design. See "BMS bus" instruction leaflet for more details about the BMS bus.

The number of bus devices is limited to 30. Install a DI-1PSM repeater if you want to use more devices

on the BMS bus. A DI-1PSM also is required when the BMS bus segment of 1200 m is exceeded.

4.2.3.1 Terminating resistor

The BMS bus must be terminated at both ends with terminating resistors of 120 Ω (0.4 W). One terminating resistor is installed in each TM800 for the internal and external bus.

If several TM800 alarm indicator and operator panels are connected via the BMS bus, the terminating

resistors of the TM800 alarm indicator and operator panels which are not installed at the end of the

bus have to be switched off. The same applies to all other devices and modules that are not installed

at the end of the bus.

Missing or incorrectly installed terminating resistors (e.g. in the middle of the

bus) will cause bus instability.

Use the DIP switches S1 and S2 to set the terminating resistor for the internal and external BMS bus:

S1 = external BMS bus; S2 = internal BMS bus. Factory setting: S1 and S2: off. The DIP switches are

located on the BM800 module adjacent to the interface terminals. Use the DIP switch to select on or

off position.

BMS-bus addresses

Be sure that the addresses of all devices connected to the bus are correctly assigned. Never assign

one address twice. Assign the addresses consecutively without any gaps. Bear in mind that each bus

requires one master. A device becomes a master by assigning address 1 to it. Address assignment

can be carried out via the menu of the TM800 alarm indicator and operator panel (see "Settings

menu 10: Interface" on page 65) or via the basic settings in the TMK-SET software.

Internal BMS bus

Select an address between 1 and 150 for the internal bus of the alarm indicator and operator panel

(factory setting: 1). The addresses 100…103 are reserved for special tasks (e.g. programming). This

setting can only be changed when the external bus has been switched off before. On the internal

BMS bus the baud rate is set to a fixed value of 9600 bits/s.

External BMS bus

Select an address between 1 and 99 for the BMS bus of the TM800 alarm indicator and operator panel.

The external bus is primarily used for the connection of several TM800 alarm indicator and operator

panels. But also MK800 alarm indicator and test combinations and SMI472-12 signal converters can

be connected. Up to 99 devices can be connected.

The following applies to the external bus:

When the TM800 alarm indicator and operator panel is the only control device in the system,

address 1 (Master) is assigned to it.

TM800_D00165_00_M_XXEN/06.2015

31

Page 32

Installation and connection

CAUTION

On the external bus, the Master function can be cyclically passed from one address to the next

higher one.

The addresses are consecutively assigned to additional TM800 alarm indicator

and operator panels (2, 3 etc.). Only when there are no gaps between the addresses, reliable function can be ensured.

All devices on the external bus must be equipped with compatible software versions (see chapter "3.3.6 ").

All devices must be set to the same baud rate.

4.3 Examples for connection and address assignment

Example Devices on the internal bus

Changeover and monitoring module UMC107E-… with alarm indicator and operator panel TM800 and

3 alarm indicator and test combinations MK2430. All components are connected to the TM800 via the internal RS-485 interface.

32

TM800_D00165_00_M_XXEN/06.2015

Page 33

Installation and connection

Example 2: Parallel operator panel

Changeover and monitoring module UMC107E-… with an alarm indicator and operator panel TM800 in

an operating theatre, a "higher-level" alarm indicator and operator panel TM800 in the technical control

room and a personal computer to evaluate the history memory of the alarm indicator and operator panels. If the personal computer does not have an RS-485 interface, an RS-232/RS-485 converter DI-2 or a

USB/RS-485 converter DI-2USB will be required.

TM800_D00165_00_M_XXEN/06.2015

33

Page 34

Example 3: Central devices on the BMS bus

Installation and connection

A three or four-pole changeover module UMC710D- with two changeover and monitoring modules

UMC107E downstream and messages from the UPS (battery-supported safety power supply) system.

Each UMC107E is connected to "its" alarm indicator and operator panel TM800 via the internal BMS bus.

The TM800 panels are connected with each other and also to a "higher-level" TM800 in the technical

room, to the SMI472-12 converter module and to a personal computer for the evaluation of the history

memory via the external BMS bus. If the personal computer does not have an RS-485 interface, an RS-232/

RS-485 converter DI-2 or a USB/RS-485 converter DI-2USB will be required.

34

TM800_D00165_00_M_XXEN/06.2015

Page 35

Installation and connection

4.3.1 Address settings and their meaning

Display

Meaning

External address Internal address

0 (ext. bus on) 0 -- -- --

0 (ext. bus on) 1 TM/MK itself -- dig. IN*

0 (ext. bus off ) M = own addr. TM/MK itself -- dig. IN*

0 (ext. bus off) M <> own addr Device M on the

int. bus of the

own device

N = own addr. 0 Device N on the

external bus

N = own addr. 1 TM/MK itself -- dig. IN*

N = own addr. M > 1 Device M on the

int. bus of the

own device

N <> own addr. 0 Device N on the

external bus

N <> own addr. 1 Device N on the

external bus

Setting

on TM/MK800

ext: 0/int: M int. bus: int M

-- dig. IN*

-- int. bus: int M

ext: N/int: 0 ext. bus: ext: N,

-- ext. bus: ext: N,

Setting

on TMK-SET

int: 0

int: 0

N <> own addr. M > 1 Device M on the

int. bus of device

N

ext: N/int: M ext. bus: ext: N,

int: M

TM800_D00165_00_M_XXEN/06.2015

35

Page 36

Installation and connection

Explanatory note to the digital inputs (*)

Alarm messages from digital inputs on TM/MK800 are always displayed on the device itself regardless of whether an individual message has been programmed or not (Exception:

channel is deactivated).

An entry into the alarm address table is not required.

If no individual message is programmed, the standard text will be displayed.

An alarm message can also be programmed to be displayed without text/LED/buzzer (silent

message).

Note: Flashing alarm messages are not allowed!

In principle, all alarm messages are stored in the history memory (Exception: channel is deactivated):

If no individual message is programmed, the standard text will be displayed resp. will be stored

in the history memory.

If the message has been programmed without a text (silent message), its source (DigIn resp.

address and channel No.) will be stored in the history memory (no individual text possible!).

Test messages are only stored in the history memory of the device that triggered the message.

Transmission via BMS bus:

All alarm messages are actively sent (i.e. as a new message) via the external or internal BMS.

Operating messages are actively sent via the external BMS bus and are not stored in the history

memory.

Note: Flashing messages must be avoided, where possible, and on no account be sent via the

int./ext. BMS bus!

The first 16 digital inputs can be configured as "flashing" and in this case are not signalled via

the external BMS. This is only permissible for messages with a flashing frequency of 0.5 Hz!

Inputs that are assigned to operating messages or switching commands are not displayed with a text

message or stored into the history memory.

36

TM800_D00165_00_M_XXEN/06.2015

Page 37

5. Commissioning and testing

Start commissioning according to the following commissioning pattern:

1. Tests before switching on

2. Tests after switching on

3. Set parameters (parameterisation)

4. Settings at the TM800

5. Settings in the TMK-SET software

6. Tests after parameter setting

Write down all settings and keep it together with the device and installation documentation.

When setting the TM800 with the configuration softwareTMK-SET, a project file

will be created. Save this file. Create a backup copy of this file and keep it in a safe

place.

TM800_D00165_00_M_XXEN/06.2015

37

Page 38

5.1 Tests before switching on

Is the power supply

connected correctly?

Does the supply voltage

match the information on

the TM800 nameplate?

Are terminating resistors

installed resp. switched

oncorrectly at the beginning

and end of the BMS bus?

no

Provide the appropriate

operating voltage

Connect the supply voltage

correctly

Is the BMS bus (int./ext.)

connected correctly?

no

Connect the supply voltage

correctly. Check polarity of

the terminals A/B!

Install/connect the

terminating resistors

correctly (at TM800 by

means of DIP switch "Term"

on/off)

yes

yes

yes

TM800 with BMI8/8 resp.

BMI8/4 only: Are the digital

inputs connected correctly

and do they have the right

potential?

Make corrections

yes

yes

no

no

no

TM800 with BMI8/4 resp.

BMI0/4 only: Are the relay

outputs connected

correctly?

Make corrections

yes

no

no

Are the other devices

connected correctly?

Make corrections

yes

Are all BMS bus device

addresses set according to

the plan?

Make corrections, first

check that the supply

voltage is switched on.

yes

Have all rules specified

in the "BMS bus" instruction

leaflet been observed?

Make corrections

yes

Is the software and

hardware of all devices in

the system up to date?

Update older devices

yes

Switch voltage supply on.

Then proceed with "tests

after switching on"

no

no

no

Commissioning and testing

Continue with chapter "Tests after switching on" on page 39.

38

TM800_D00165_00_M_XXEN/06.2015

Page 39

Commissioning and testing

Measure the supply voltage

of TM800 (terminals 0,

230 V). Voltage OK?

no

Make corrections

yes

Close the TM800's front

plate

Power supply or TM800

failure? - Remedy fault!

Does one of the three LEDs

below the display light up

and does anything appear

on the TM800's display?

no

Does TM800 indicate a

fault?

Make a note of the

message. Adapt the

signalling device to the

system or remedy the fault.

yes

yes

no

Call up menu "6. External

devices". Are addresses

and software versions of the

connected devices OK?

no

Correct the address settings

of the external devices.

yes

Optional: Use the TMK-SET

software to connect the PC

to the BMS bus of the

TM800. Call up the TMKSET function "Scan bus".

Are addresses and software

versions of the connected

devices OK?

no

Correct address settings of

the external devices.

yes

Test the system. Functions

OK?

no

Change the parameter

settings of TM800.

TM800 is ready for

operation

yes

5.2 Tests after switching on

TM800_D00165_00_M_XXEN/06.2015

Continue with chapter "Make settings (parameterisation)" on page 39.

5.3 Make settings (parameterisation)

All settings can be carried out using the TMK-SET software. Alternatively, some

settings can be carried out via the TM800 menu (see diagrams).

39

Page 40

Commissioning and testing

Set language

Set BMS bus addresses

(int./ ext.)

Set alarm addresses and

system numbers

Set test addresses and

types of Isometers

TM800 with BMI8/8 resp.

BMI8/4 ?

Use of standard assignment

for medical gases/UPS

systems?

Can the buzzer sound be

differentiated from other

device signals?

Common

acknowledgement on/off

yes

Set time/date

Use of standard texts?

Use TMK-SET for

parameterisation (refer to

5.3.2)

no

Setting "medical"

Wiring acc. to specifications!

Relay: Set function and

switching behaviour

no

Adapt buzzer settings

Set and enable password

no

Relay or pushbutton

parameterisation?

yes

yes

5.3.1 Settings at the TM800

The following settings can optionally be carried out via the function buttons at the TM800 or the

TMK-SET software. Make a note of the modified settings (setting table).

Continue with chapter "Tests after parameter setting" on page 42.

40

TM800_D00165_00_M_XXEN/06.2015

Page 41

Set language

Set password

Set buzzer

Common

acknowledgement on/off

TM800 with BMI8/8 resp.

BMI8/4?

Digital inputs: Set function

and operating mode

Relay: Set function and

operating mode

Set device address

Standard display: enter the

appropriate test

Program alarm addresses

for standard alarm

messages.

Enter system numbers or

system designation

yes

yes

Enter individual alarm

messages for the required

channels

If applicable, use semi-automatic mode.

Enter test addresses

Save parameter settings to

project file and print, if

required

Default setting, send

messages and alarms to

TM800

Adapt the Isometer type to

the test addresses

yes

Use of standard assignment

for medical gases/UPS?

Setting "medical"

Wiring acc. to specifications!

yes

no

Operating messages?

Program operating

messages

yes

Switching commands?

Program switching

commands

yes

Commissioning and testing

5.3.2 Settings using the TMK-SET software

TM800_D00165_00_M_XXEN/06.2015

Continue with chapter "Tests after parameter setting" on page 42.

41

Page 42

5.3.3 Tests after parameter setting

Select "External devices"

from the menu. Are all

external device settings

OK?

no

Make corrections

Simulate error messages

(e.g. device failure,

insulation fault). Create an

error directly or select the

"test communication" (*)

function. Is the error

correctly being signalled by

the TM800?

yes

no

yes

TM800 is ready for

operation

Make corrections

Does the TM800 react

correctly to pressed

pushbuttons or to

messages at the digital

inputs?

no

Make corrections

Save modified parameter

settings to project file and

make a print-out, if required.

Send modified default

settings, messages and

alarms to TM800.

Commissioning and testing

(*) Messages which can be created by a BMS device are simulated.

42

TM800_D00165_00_M_XXEN/06.2015

Page 43

Commissioning and testing

5.4 Periodic verification and service

5.4.1 Periodic verification

The following periodic verifications of electrical installations have to be carried out according to the

local or national standards effective at the time of installation. For your Bender products, we recommend:

Task By Interval

Functional test of IT system monitoring

(insulation, load current, transformer temperature and connection monitoring) by pressing the test button on the alarm indicator and test combination or on the alarm indicator and

operator panel.

Functional test of the transfer switching device*:

Functional test of the automatic transfer switching device. Follow the instructions in chapter "Testing of the transfer switching device!

Functional test of the IT system monitoring (insulation, load

current, transformer temperature and connection monitoring)

on the insulation monitoring device.

Test of the setting values and the changeover periods Electrically

Test of the transfer switching device, the IT system monitoring,

and the connection to the SCADA system (Supervisory Control

and Data Acquisition) (if applicable) and the interaction

between the components in the system.

The test includes the following:

- Inspection:

Marking, display elements, mechanical components,

wiring, parameterisation, connection of

third-party equipment, evaluation of the fault memory

- Measurement:

Internal/external supply voltages/potentials,

bus voltage, bus protocol, bus scan

- Testing:

Device function, device communication.

- Documentation:

Test results, recommendations for elimination of defects.

Medical

personnel

Electrically

skilled person

Electrically

skilled person

skilled person

Bender-Service Once every 24

Once every

working day

Once every six

months

Once every six

months

Once every 12

months

months

* This test must only be performed by an authorised electrically skilled person in agreement with the

medical locations concerned.

Before carrying out the tests, please refer to the instructions relating to the functional tests in the

check list. If no national directives apply, you should perform the tests recommended by IEC 603647-710: 2002-11, section 710.62 and DIN VDE 0100-710 (VDE 0100 Part 710):

TM800_D00165_00_M_XXEN/06.2015

43

Page 44

Commissioning and testing

5.4.2 Service

For technical support, commissioning, troubleshooting and periodic verification

Bender offers:

First Level Support

Technical support by phone or e-mail for all Bender products: