Page 1

Manual

EN

RCMS460 and RCMS490

Residual current monitors

Software version: D233 V2.5x

D216/D256/D339/D403 V2.3x

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 2

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Gruenberg • Germany

P. O. Box 1161 • 35301 Gruenberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

Email: info@bender.de

www.bender.de

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Photos: Bender archives

Page 3

Table of Contents

1. Important information .................................................................................... 7

1.1 How to use this manual ................................................................................. 7

1.2 Technical support: service and support ................................................... 8

1.2.1 First level support ............................................................................................. 8

1.2.2 Repair service ..................................................................................................... 8

1.2.3 Field service ........................................................................................................ 9

1.3 Training courses ............................................................................................. 10

1.4 Delivery conditions ....................................................................................... 10

1.5 Inspection, transport and storage ........................................................... 10

1.6 Warranty and liability ................................................................................... 11

1.7 Disposal ............................................................................................................ 12

2. Safety instructions ......................................................................................... 13

2.1 General safety instructions ........................................................................ 13

2.2 Work activities on electrical installations ............................................. 13

2.3 Intended use ................................................................................................... 14

3. System description ........................................................................................ 17

3.1 Typical applications ...................................................................................... 17

3.2 Description of function ............................................................................... 18

3.3 Device variants ............................................................................................... 19

4. Installation and connection ......................................................................... 21

4.1 Unpacking ........................................................................................................ 21

4.2 Fuses, max. voltage, cable lengths ......................................................... 22

4.3 Installation instructions .............................................................................. 22

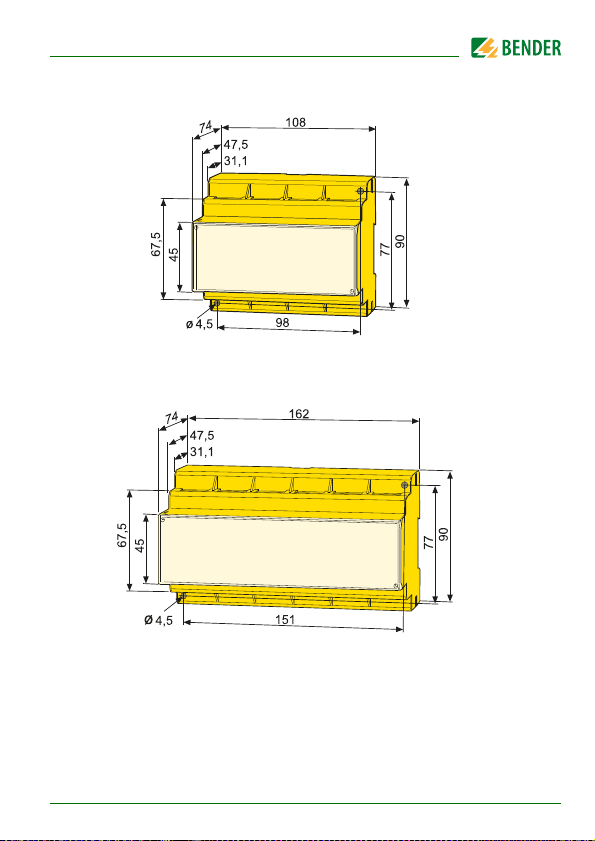

4.3.1 Dimension diagram RCMS460-… ........................................................... 23

4.3.2 Dimension diagram RCMS490-… ........................................................... 23

RCMS460-490_D00067_03_M_XXEN/12.2017

3

Page 4

Table of Contents

4.4 Connection ...................................................................................................... 24

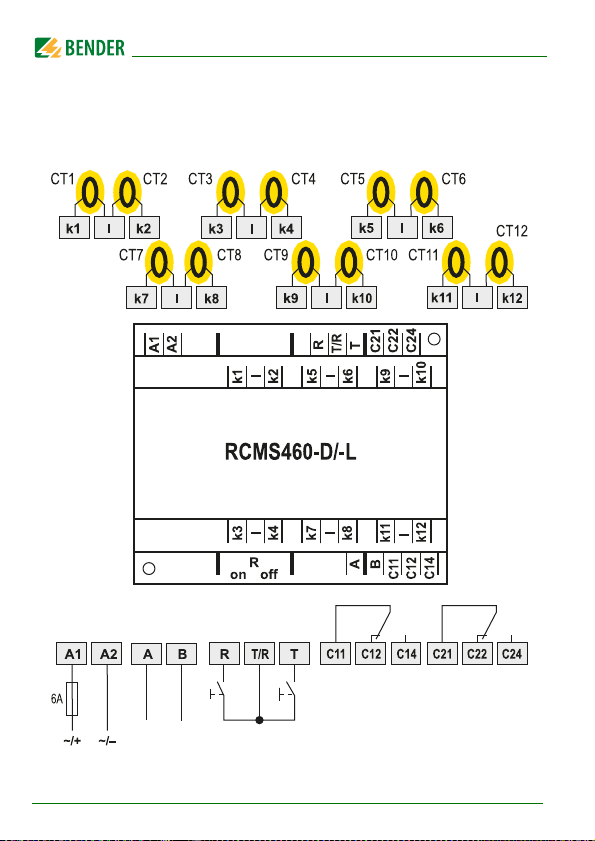

4.4.1 Wiring diagram RCMS460-… .................................................................... 24

4.4.2 Wiring diagram RCMS490-… .................................................................... 26

4.4.3 Connection of W…, WR…, WS… series measuring current

transformers .................................................................................................... 28

4.4.4 Connection W…AB series measuring current transformers

(AC/DC current sensitive) ........................................................................... 29

4.4.5 Connection WF… series measuring current transformers ............. 31

4.4.6 Example for a system design – minimum system consisting of an

RCMS460-D and 12 measuring points ................................................... 32

4.4.7 Example for a standard system design consisting of an RCMS460-D

and RCMS460-L and a protocol converter COM460IP ..................... 33

4.4.8 Connection digital input ............................................................................. 34

5. Commissioning .............................................................................................. 35

5.1 Before switching on ...................................................................................... 35

5.2 Switching on ................................................................................................... 36

6. Operation ........................................................................................................ 37

6.1 Operating and display elements RCMS460…-D ................................ 37

6.2 Operating and display elements RCMS…-L ........................................ 38

6.3 Working in operating mode ...................................................................... 39

6.3.1 Standard display ............................................................................................ 39

6.3.2 Alarm and its effect ....................................................................................... 39

6.3.3 Test procedure ............................................................................................... 41

6.3.4 Resetting saved alarm messages (RESET) ............................................. 42

6.3.5 Displaying standard information ............................................................. 43

6.4 Setting the RCMS…-L… ............................................................................. 44

6.5 Operation and setting of the RCMS…-D… ......................................... 44

6.5.1 Opening the main menu ............................................................................ 45

6.5.2 Menu overview diagram ............................................................................. 46

6.5.3 Main menu functions ................................................................................... 47

4

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 5

Table of Contents

6.6 The main menu .............................................................................................. 49

6.6.1 Menu 1: Alarm/meas. values ..................................................................... 49

6.6.2 Menu 2: % Bar graph .................................................................................... 49

6.6.3 Menu 3: History .............................................................................................. 50

6.6.4 Menu 4: Harmonics ....................................................................................... 51

6.6.5 Menu 5: Data logger ..................................................................................... 52

6.6.6 Menu 6: Settings ............................................................................................ 53

6.6.6.1 Settings menu 1: General .................................................................. 54

6.6.6.2 Settings menu 2: PRESET ................................................................... 56

6.6.6.3 Settings menu 3: Channel ................................................................. 58

6.6.6.4 Settings menu 4: Relay ....................................................................... 68

6.6.6.5 Settings menu 5: History .................................................................... 70

6.6.6.6 Settings menu 6: Data logger .......................................................... 70

6.6.6.7 Settings menu 7: Language .............................................................. 71

6.6.6.8 Settings menu 8: Interface ................................................................ 71

6.6.6.9 Settings menu 9: Alarm addresses ................................................. 71

6.6.6.10 Settings menu 10: Clock ..................................................................... 72

6.6.6.11 Settings menu 11: Password ............................................................ 73

6.6.6.12 Settings menu 12: Factory settings ................................................ 73

6.6.6.13 Settings menu 13: Service ................................................................. 73

6.6.7 Menu 7: Control ............................................................................................. 74

6.6.7.1 Control menu 1: TEST .......................................................................... 74

6.6.7.2 Control menu 2: RESET ....................................................................... 74

6.6.7.3 Control menu 3: Test communication .......................................... 74

6.6.8 Menu 8: External devices ............................................................................ 76

6.6.9 Menu 9: Info .................................................................................................... 79

7. Tests, service, troubleshooting .................................................................. 81

7.1 Periodic verification ...................................................................................... 81

7.2 Maintenance and service ........................................................................... 81

7.3 Troubleshooting ............................................................................................ 82

7.3.1 Display device error ...................................................................................... 82

RCMS460-490_D00067_03_M_XXEN/12.2017

5

Page 6

Table of Contents

7.3.2 Device error display (channel-related) .................................................. 83

7.3.3 CT connection fault display (channel-related) ................................... 84

7.3.4 External alarm ................................................................................................. 84

8. Data .................................................................................................................. 85

8.1 Standards ......................................................................................................... 85

8.2 Approvals and certifications ..................................................................... 85

8.3 Technical data ................................................................................................ 86

8.4 Ordering information .................................................................................. 91

INDEX ................................................................................................................... 101

RCMS460-490_D00067_03_M_XXEN/12.2017

6

Page 7

1. Important information

1.1 How to use this manual

This manual is intended for qualified personnel working in

electrical engineering and electronics!

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this manual, we have used symbols to identify important instructions and information.

The meaning of these symbols is explained below:

This signal word indicates that there is a high risk of danger

that will result in electrocution or serious injury if not

avoided.

This signal word indicates a medium risk of danger that

can lead to death or serious injury if not avoided.

This signal word indicates a low level risk that can result in

minor or moderate injury or damage to property if not

avoided.

This symbol denotes information intended to assist the user

in making optimum use of the product.

This manual has been compiled with great care. It might nevertheless contain

errors and mistakes. Bender cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

RCMS460-490_D00067_03_M_XXEN/12.2017

7

Page 8

Important information

1.2 Technical support: service and support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all Bender products

Questions concerning specific customer applications

Commissioning

Troubleshooting

Telephone: +49 6401 807-760*

Fax: +49 6401 807-259

In Germany only: 0700BenderHelp (Tel. and Fax)

E-mail: support@bender-service.de

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

Repairing, calibrating, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices in the event of faulty or incorrectly

delivered Bender devices

Extended guarantee for Bender devices, which includes an in-house

repair service or replacement devices at no extra cost

Telephone: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (sales)

Fax: +49 6401 807-789

E-mail: repair@bender-service.de

Please send the devices for repair to the following address:

Bender GmbH, Repair-Service,

Londorfer Str. 65,

35305 Grünberg

8

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 9

Important information

1.2.3 Field service

On-site service for all Bender products

Commissioning, configuring, maintenance, troubleshooting of Bender

products

Analysis of the electrical installation in the building (power quality test,

EMC test, thermography)

Training courses for customers

Telephone: +49 6401 807-752**, -762 **(technical issues)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Internet: www.bender-de.com

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m

+49 6401 807-753** (sales)

RCMS460-490_D00067_03_M_XXEN/12.2017

9

Page 10

Important information

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment.

The dates of training courses and workshops can be found on the Internet at

www.bender-de.com -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

For software products the "Softwareklausel zur Überlassung von StandardSoftware als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen

Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie"

(software clause in respect of the licensing of standard software as part of deliveries, modifications and changes to general delivery conditions for products and services in the electrical industry) set out by the ZVEI (Zentralverband

Elektrotechnik- und Elektronikindustrie e. V.) (German Electrical and Electronic Manufacturer's Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or electronic format.

1.5 Inspection, transport and storage

Inspect the dispatch and equipment packaging for damage, and compare the

contents of the package with the delivery documents. In the event of damage

in transit, please contact Bender immediately.

The devices must only be stored in areas where they are protected from dust,

damp, and spray and dripping water, and in which the specified storage temperatures can be ensured.

10

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 11

Important information

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to

property are excluded if they can be attributed to one or more of the following causes:

Improper use of the device.

Incorrect mounting, commissioning, operation and maintenance of the

device.

Failure to observe the instructions in this operating manual regarding

transport, commissioning, operation and maintenance of the device.

Unauthorised changes to the device made by parties other than the

manufacturer.

Non-observance of technical data.

Repairs carried out incorrectly and the use of replacement parts or

accessories not approved by the manufacturer.

Catastrophes caused by external influences and force majeure.

Mounting and installation with device combinations not recom-

mended by the manufacturer.

This operating manual, especially the safety instructions,

must be observed by all personnel working on the device. Furthermore,

the rules and regulations that apply for accident prevention at the place of use

must be observed.

RCMS460-490_D00067_03_M_XXEN/12.2017

11

Page 12

Important information

1.7 Disposal

Abide by the national regulations and laws governing the disposal of this device. Ask your supplier if you are not sure how to dispose of the old equipment.

The directive on waste electrical and electronic equipment (WEEE directive)

and the directive on the restriction of certain hazardous substances in electrical and electronic equipment (RoHS directive) apply in the European Community. In Germany, these policies are implemented through the "Electrical and

Electronic Equipment Act" (ElektroG). According to this, the following applies:

Electrical and electronic equipment are not part of household waste.

Batteries and accumulators are not part of household waste and must

be disposed of in accordance with the regulations.

Old electrical and electronic equipment from users other than private

households which was introduced to the market after 13 August 2005

must be taken back by the manufacturer and disposed of properly.

For more information on the disposal of Bender devices, refer to our

homepage at www.bender-de.com -> Service & support.

12

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 13

2. Safety instructions

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed

"Safety instructions for Bender products".

2.2 Work activities on electrical installations

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

If the device is used outside the Federal Republic of Germany, the applicable

local standards and regulations must be complied with. The European standard EN 50110 can be used as a guide.

RCMS460-490_D00067_03_M_XXEN/12.2017

13

Page 14

Safety instructions

2.3 Intended use

The RCMS460 or RCMS490 residual current monitor is designed for measuring

residual and operating currents TT and TN-S systems (measuring range see

"Chapter 8.3 Technical data", paragraph "measuring circuit"). Alternatively, digital inputs can be scanned and evaluated.

The RCMS system consi sts of one or m ore RCMS460- D/-L or RCMS490-D/-L residual current monitors, which are able to detect and evaluate fault, residual

and operating currents in earthed power supplies via the related measuring

current transformers. The maximum voltage of the system to be monitored

depends on the nominal insulation voltage of the measuring current transformer used in the case of busbar systems, resp. depend on the cables or conductors that are routed through.

To measure AC/DC sensitive residual currents (according to IEC/TR 60755:

Type B) closed W…AB series measuring current transformers are required.

Six W…AB series measuring current transformers require one AN420 or

AN110 power supply unit.

For alternating and pulsating currents (according to IEC/TR 60755: Type A

W… (closed), WR… (rectangular), WS… (split-core) and WF… (flexible) series

measuring current transformers are used.

Any combination of the various measuring current transformer series can be

connected to the evaluator measuring channels.

Each RCMS460-D/-L and RCMS490-D/-L has 12 measuring channels. Up to 90

residual current monitors can be connected via a BMS bus (RS-485 interface

with BMS protocol), thereby up to 1080 measuring channels (sub-circuits) can

be monitored.

If this product is used for personnel protection, fire or plant protection, the frequency response can be set accordingly. The measured currents can be analysed

for harmonics. The THF can be determined too (THF =

T

otal Harmonic Factor).

The product must be adapted to local equipment and operating conditions

by making individual parameter settings, in order to meet the requirements

of applicable standards and to attain the protection goals.

14

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 15

Safety instructions

In order to meet the requirements of the applicable stan dards, customised parameter settings must be made on the equipment in order to adapt it to local

equipment and operating conditions. Please heed the limits of the range of

application indicated in the technical data.

Any use other than that described in this manual is regarded as improper.

RCMS460-490_D00067_03_M_XXEN/12.2017

15

Page 16

Safety instructions

16

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 17

3. System description

In buildings and industrial installations, a fault or failure of the power supply

involves high costs. In installations which require a high fault tolerance and

good safety, an RCMS system should constantly monitor the TN-S system for

insulation deterioration to ensure that the system is "clean" and electromagnetically compatible.

3.1 Typical applications

Measuring and evaluating residual, fault and rated currents of loads

and installations in the frequency range of 0…2000 Hz (W…, WR…,

WS…, WF… series measuring current transformers, 42…2000 Hz (W…,

WR…, WS…, WF… series measuring current transformers) (measuring

range see "Chapter 8.3 Technical data").

Monitoring of currents which can cause fires in flammable atmos-

pheres.

EMC monitoring of TN-S systems for "stray currents" and additional N-

PE connections.

Monitoring of N conductors for overload caused by harmonics

Monitoring of PE and equipotentional bonding conductors to ensure

they are free of current.

Residual current monitoring of stationary electrical equipment and sys-

tems to determine test intervals which meet practical requirements in

compliance with the accident prevention regulations BGV A3 (Ger-

many).

Personnel protection and protection against fire by rapid disconnec-

tion.

Monitoring of digital inputs.

RCMS460-490_D00067_03_M_XXEN/12.2017

17

Page 18

System description

3.2 Description of function

The currents are detected and evaluated as true r.m.s. value s in the fr equenc y

range of 0 (42)…2000 Hz. All channels are scanned simultaneously so that the

maximum scanning time for all channels is ≤180 ms if 1 x the response value

is exceeded and ≤ 30 ms if 5 x the response value is exceeded.

The latest current values of all channels are shown on the LC display in bar

graph format. If one of the two set response values is exceeded, the response

delay t

begins. Once the response delay has elapsed, the common alarm re-

on

lays "K1/K2" switch and the alarm LEDs 1/2 light up.

Two response values/common alarm relays, which can be set separately, allow a distinction to be made between prewarning and alarm. The faulty channel(s) and the associated measured value are indicated on the LC display. If

the current falls below the release value (response value plus hysteresis), the

release delay "toff“ t

mon alarm relays switch back to their initial state.

If the fault memory is enabled, the common alarm relays remain in the alarm

state until the reset button is pressed or a reset command is sent via the BMS

bus. The device function can be tested using the test button. Parameters are

assigned to the device via the LC display and the control buttons on the front

panel of one of the connected RCMS…-D devices or via connected panels,

Ethernet gateways (z. B. COM460IP) and Condition Monitors (z. B. COMTRAXX

CP700). With the adjustable preset function the response values can set for all

channels taking the latest measured value for each channel into account.

Digital input

Each individual channel can be used for one of the following monitoring functions:

– As digital input using a potential-free contact 1/0

– Or for current or residual current monitoring in combination with

measuring current transformers.

begins. When the release delay has elapsed, the com-

off

18

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 19

System description

History memory in RCMS460-D, RCMS490-D

The device utilises a history memory for failsafe storing of up to 300 data records (date, time, channel, event code, measured value), so that all data about

an outgoing circuit or an area can be traced back at any time (what happened

when).

Analysis of harmonics

The analysis of the harmonics of the measured currents can be selected via a

menu item in RCMS460-D, RCMS490-D. There, the DC component, the THF

and the current value of the harmonics (1…40 at 50/60 Hz, 1…5 at 400 Hz) is

displayed numerically and graphically.

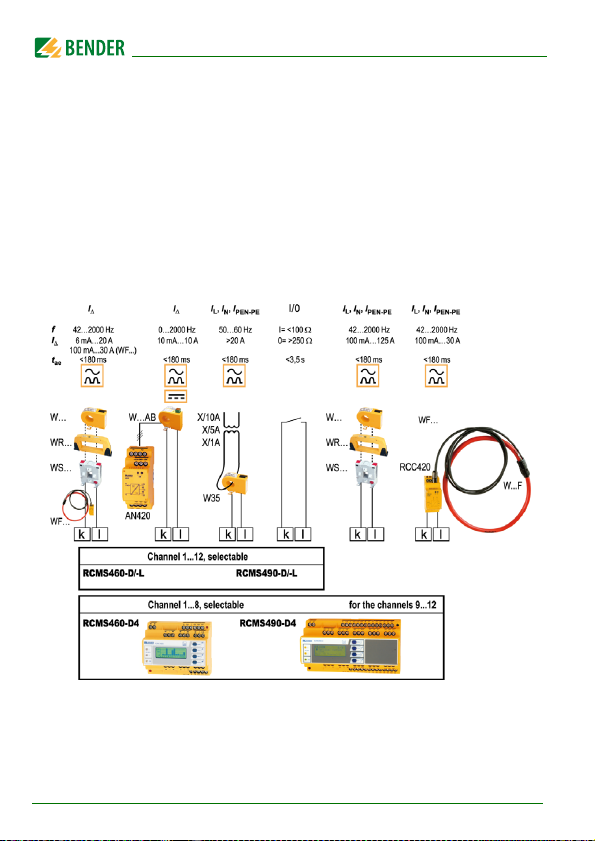

3.3 Device variants

RCMS residual current monitoring systems differ depending on the residual current monitor version used, RCMS460… or RCMS490….

RCMS460-D

Device version RCMS460-D utilises a backlit graphical display. This version is

used for local display of detailed information about all devices connected to the

bus in the control cabinet. This device can be used to parameterise all RCMS devices connected to the BMS bus and to display all measurement details. Several

RCMS-D devices can be used within one system.

RCMS460-L

Device version RCMS460-L utilises a two-digit 7-segment display where the

address of this device is displayed within the BMS bus. The alarm LEDs indicate

in which measuring channel the response value has been exceeded. Parameters

can be set via an RCMS…D, an

tion Monitor (z. B. COMTRAXX CP700).

Ethernet gateway (z. B. COM460IP) or a Condi-

RCMS490-D/RCMS490-L

The function of the device versions RCMS490-D/RCMS490-L corresponds to

the function described above. In addition, a galvanically isolated alarm contact (N/O contact) is available, e.g. for triggering a circuit breaker in this subcircuit when a response value is exceeded.

RCMS460-490_D00067_03_M_XXEN/12.2017

19

Page 20

System description

RCMS…-D4/RCMS…-L4

The function of device version RCMS…-D4/RCMS…-L4 corresponds to the

function described before. The functions of measuring channels k9 … k12

vary from those described before. They are exclusively designed for current

measurements with type A measuring current transformers (measuring range 100 mA … 125 A). For that reason, the measuring channels k9…k12 cannot

be used in c ombi nat ion w ith W…AB ser ies measuring current transformers or

as digital inputs.

Choice of RCMS and measuring channels

20

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 21

4. Installation and connection

4.1 Unpacking

Unpack all the parts supplied with the system. Avoid sharp-edged tools

that may damage the content of the packaging.

Compare

received all products in full. The article numbers and type designation

printed on the nameplates provides an easy means of uniquely identifying

each device.

Check all parts supplied for any evidence of damage in transit. Equip-

ment damaged in transit must not be used. If a device has sustained

damage, please contact Bender. Details of who to contact are indicated

on the delivery documents.

When storing the devices in a cold environment as it is in winter, note

the following: Leave the devices to stand for 3 to 4 hours at room tem-

perature before connecting the power supply. When the devices are

moved from a cold to a warm environment, condensation will be evi-

dent on all parts. Putting damp devices into operation can result in

damage to electrical components and electric shock in case of contact.

your order with our delivery note to check that you have

RCMS460-490_D00067_03_M_XXEN/12.2017

21

Page 22

Installation and connection

4.2 Fuses, max. voltage, cable lengths

Equip the supply voltage of all system components with fuses.

IEC 60364-4-473 requires protective devices to be used to protect the

component in the event of a short circuit. We recommend the use of 6

A fuses.

When using busbar systems, please note: The maximum voltage of the

system being monitored must not exceed the nominal insulation voltage of the measuring current transformers used in the RCMS system.

Select the cables and cable lengths according to the technical data on

page 86ff. If you use cables that are longer than those specified here,

Bender cannot guarantee that the equipment will function safely.

For UL application:

– Use at least 60/70 °C copper lines!

4.3 Installation instructions

Danger of electric shock!

Before fitting the device and prior to working on the device

connections, make sure that the power supply has been

disconnected and the system is dead.

Furthermore, the electrical installation may sustain damage

and the device be destroyed beyond repair.

The devices are suitable for the following installation methods:

Distribution panels according to DIN 43871 or

DIN rail mounting according to IEC 60715 or

Screw mounting using M4 screws.

Mount the measuring current transformers in accordance with the notes in the

"Transformer installation“ technical information. When connecting the measuring current transformers, it is essential that you observe the maximum cable

lengths, the conductor cross section and that you use shielded cables.

22

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 23

Installation and connection

4.3.1 Dimension diagram RCMS460-…

4.3.2 Dimension diagram RCMS490-…

Dimensions in mm

RCMS460-490_D00067_03_M_XXEN/12.2017

23

Page 24

4.4 Connection

4.4.1 Wiring diagram RCMS460-…

Installation and connection

24

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 25

Installation and connection

Legend to wiring diagram RCMS460-…

A1, A2 Connection of supply voltage US (see ordering informa-

tion):we recommend the use of 6 A fuses.

k1, l …

k12, l

A, B BMS bus (RS-485 interface with BMS protocol)

R, T/R External reset button (N/O contact). The external reset but-

T, T/R External test button (N/O contact). The external test buttons

C11, C12,

C14

C21, C22,

C24

R

on/off

CT Measuring current transformers (W…, WR…, WS…, WF…,

Connection to measuring current transformers CT1…CT12.

Either type A (W…, WR…, WS…, WF… series) or type B

(W…AB series) measuring current transformers can be selected for each measuring channel. When using up to six type B

measuring current transformers, an AN420-2 or AN110

power supply unit is required (for connections see page 29).

The channels k9…k12 of the device versions RCMS460-D4/L4 require the connection of type A measuring current

transformers.

tons of several devices must not be connected to one another.

of several devices must not be connected to one another.

Common alarm relay K1: Alarm 1, common message for

alarm, prewarning, device error.

Common alarm relay K2: ALARM 2, common message for

alarm, prewarning, device error.

Activate or deactivate the terminating resistor of the BMS

bus (120 Ω).

W…AB series)

RCMS460-490_D00067_03_M_XXEN/12.2017

25

Page 26

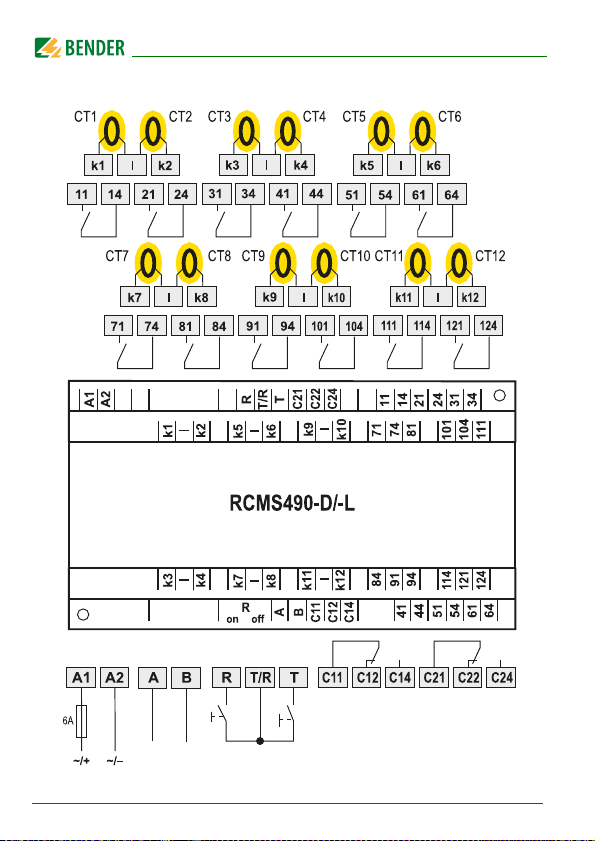

4.4.2 Wiring diagram RCMS490-…

Installation and connection

26

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 27

Installation and connection

Legend to wiring diagram RCMS490-…

A1, A2 Connection of supply voltage US (see ordering information),

we recommend a 6 A fuse

k1, l …

k12, l

A, B BMS bus (RS-485 interface with BMS protocol)

R, T/R External reset button (N/O contact). The external reset but-

T, T/R External test button (N/O contact). The external test buttons

C11, C12,

C14

C21, C22,

C24

R

on/off

11, 14 …

121, 124

CT Measuring current transformers (W…, WR…, WS…, WF…,

Connection to measuring current transformers CT1…CT12.

Either type A (W…, WR…, WS…, WF… series) or type B

(W…AB series) measuring current transformers can be selected for each measuring channel. When using up to six type B

measuring current transformers, an AN420-2 or AN110

power supply unit is required (for connections see page 29).

The channels k9…k12 of the device versions RCMS490-D4/L4 require the connection of type A measuring current transformers.

tons of several devices must not be connected to one another.

of several devices must not be connected to one another.

Common alarm relay K1: Alarm 1, common message for

alarm, prewarning, device error.

Common alarm relay K2: Alarm 2, common message for

alarm, prewarning, device error.

Activate or deactivate the terminating resistor of the BMS

bus (120 Ω )

Alarm relay per channel: One N/O contact per measuring

channel (e.g. N/O contacts 11,14 for channel 1).

W…AB series)

RCMS460-490_D00067_03_M_XXEN/12.2017

27

Page 28

Installation and connection

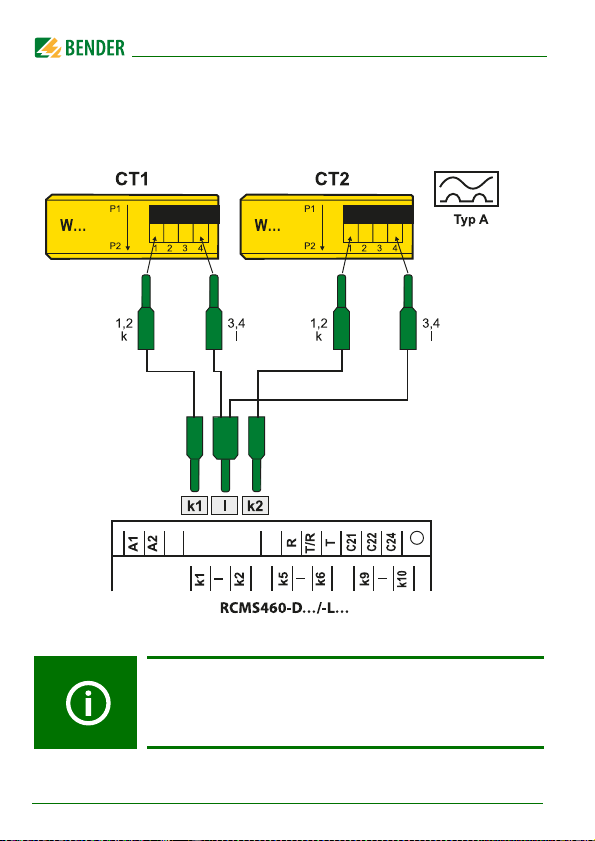

4.4.3 Connection of W…, WR…, WS… series measuring current transformers

Example: Connection W… series measuring current transformers

28

The terminals 1/2 as well as the terminals 3/4 are bridged

internally.

The connections k and l at the residual current monitor must

not be interchanged.

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 29

Installation and connection

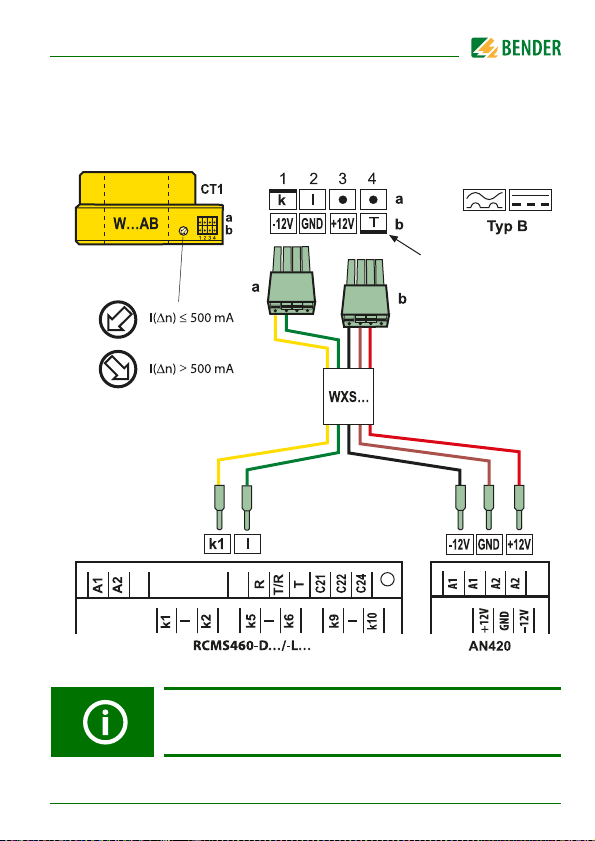

4.4.4 Connection W…AB series measuring current transformers (AC/DC current sensitive)

Coding

(not for W20AB)

The connections k and l at the residual current monitor must

not be interchanged.

RCMS460-490_D00067_03_M_XXEN/12.2017

29

Page 30

Installation and connection

Legend to W…AB series measuring current transformer

connection

W…AB AC/DC sensitive W…AB series measuring current transfor-

mers. Always adapt the measuring current transformers to

the maximum response value I(dn) (see wiring diagram).

WXS… Prefabricated connecting cable.

Colour code:

kyellow

l green

12 V black

GND brown

+ 12 V red

AN420 Power supply unit for supplying up to six W…AB series

measuring current transformers. Alternatively, an AN110

power supply unit can also be used.

Only if these notes are observed will you obtain a true

measurement result.

You must ensure that all live conductors are routed

through the measuring current transformer.

Do not use shielded conductors.

Do not route any PE conductors through the meas-

uring current transformer!

Commercial measuring current transformers are

not suitable for direct connection to the RCMS460/

RCMS490 systems and must not be used.

Additional information is available in our "Transformer

installation" manual.

30

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 31

Installation and connection

4.4.5 Connection WF… series measuring current transformers

The connections k and l at the residual current monitor must

not be interchanged.

RCMS460-490_D00067_03_M_XXEN/12.2017

31

Page 32

Installation and connection

Legend to W…AB series measuring current transformer

connection

W…F Flexible WF… series measuring current transformers

RCC420 Signal converter

Commercial measuring current transformers are not

suitable for direct connection to the RCMS system and must

not be used.

Additional information is available in our "Transformer

installation" manual.

Only if these notes are observed will you obtain a true

measurement result.

4.4.6 Example for a system design – minimum system consisting of an RCMS460-D and 12 measuring points

Measuring current transformer

AC/DC sensitive (0...2000 Hz)

series

W...AB

series

W...AB

series

W...AB

series

W...AB

TN-S-System

Measuring current transformer

pulsed DC sensitive (42...2000 Hz)

distribution

board

series

W..., WR...,

WS..., WF...

series

W..., WR...,

WS...,

series

W..., WR...,

WS..., WF...

32

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 33

Installation and connection

4.4.7 Example for a standard system design consisting of an RCMS460-D and RCMS460-L and a protocol converter COM460IP

COM465IP

COMTRAXX®

ON

ETHERNET/IP

MODBUS/RTU

BMS

RCMS460-D

RCMS460-L

AN420

COM465IP

U

S

AC 85…260 V

NL

DI-1DL

B/N A/P

B/N A/P

Legend to connection example

RCMS… Residual current monitors

AN420 When AC/DC sensitive W…AB series measuring current

transformers are used, an AN420 or AN110 power supply

unit is required that supplies up to six measuring current

transformers of this type. When the supply voltage of

AN110-1 is < 30 V, the output power decreases, so that only

five measuring current transformers can be connected.

COM460IP Protocol converter for connecting the BMS bus (Bender

measuring device interface) with a TCP/IP (Transmission

Control Protocol/Internet Protocol) network via Ethernet.

RCMS460-490_D00067_03_M_XXEN/12.2017

33

Page 34

Installation and connection

CT

a

b

DI-1DL The DI-1DL repeater only is required when the length of the

cable exceeds 1200 m or when more than 32 devices are

connected to the bus.

CT W…, WR…, WS…, WF…, W…AB series measuring current

transformers.

4.4.8 Connection digital input

a Potential-free contact

Status Resistance between k and l

0: > 250 Ω

1: < 100 Ω

b Measuring current transformer

34

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 35

5. Commissioning

5.1 Before switching on

Note on opening the transparent front panel cover:

Take hold of the cover at the bottom edge and swivel it

upwards. The cover can also be removed completely. Once

the adjustments have been completed, the front panel cover

must be refitted.

1. Does the connected supply voltage U

on the device nameplates?

2. Only when busbar systems are used: Has the maximum permissible nominal insulation voltage of the measuring current transformers been observed?

3. Are you sure that the PE conductor has not been routed

through the measuring current transformer at any point?

4. In mounting the measuring current transformers, have any magnetic fields that are nearby and could cause interference been

taken into account?

5. Has the maximum permissible cable length for the measuring

current transformers been observed?

6. Is a 120-Ω resistor connected at the beginning and end of the

BMS bus?

7. Have the maximum permissible interface cable length (1200 m)

and number of BMS bus nodes (32) been observed?

8. Is address 001 and therefore the master function, assigned?

9. In respect of the BMS bus node address settings, has each

address only been assigned once?

RCMS460-490_D00067_03_M_XXEN/12.2017

match the information

S

35

Page 36

Commissioning

5.2 Switching on

1. Connect the supply voltage of all devices connected to the BMS bus.

Initially, the "ON" LED flashes on the RCMS… and the RCMS460…-D

graphic display shows the (Bender) welcome screen. The "ON" LED

then lights up permanently.

2. Set the BMS bus addresses. Never assign one address twice. Check, if

address 001 and thus the master function has been assigned.

3. Select the language (see page 71).

4. Set the CT type for each channel (page 66).

5. Start the preset function (see page 56).

6. Switch off unassigned measuring channels to avoid device errors (see

page 63).

7. Fault messages may be caused by measuring current transformers not

being connected. Check the measuring current transformer connections. Switch off the CT monitoring of the measuring channels not currently used (see page 67).

8. Eliminate insulation faults and the associated fault messages. If a response value is exceeded or device error messages occur, this is indicated on the RCMS… by means of the alarm LEDs lighting up and an

associated message appearing on the graphic display (RCMS…-D

only).

– You can find information about the alarms on the RCMS460…-D in

the "Alarm/Meas. values" menu. Information on the RCMS…-L can

be displayed via the BMS master.

– Eliminate the insulation faults detected by the RCMS. Check whe-

ther the set response values are correct and practical for this system. If you want to readjust all response values, use the preset

function of the device.

– The RCMS…-D displays any device errors that have occurred. The

RCMS…-L… displays an error code. If a device error continues to

exist after a reset has been carried out, the RCMS… has to be

replaced.

36

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 37

6. Operation

1

2

3

6

5

4

7

8

6.1 Operating and display elements RCMS460…-D

LINETRAXX®

1

2

3

4

5

6

7

8

RCMS460-490_D00067_03_M_XXEN/12.2017

RCMS460-D

The "ALARM 2“ LED lights up if the measured value falls below or

exceeds the "Alarm" response value in a measuring channel or

until an error is indicated by the digital input.

The "ALARM 1" LED lights up if the measured value falls below or

exceeds the "prewarning" response value in a measuring channel

or in case of a device error.

LED "ON“ lights up when the device is switched on and

switching on.

"INFO" button: to call up standard information

ESC button: to exit the menu function without changing

"TEST" button: to call up automatic test

Up button: to change parameters, scroll

"RESET" button: to acknowledge alarm and fault messages

Down button: to change parameters, scroll

"MENU" button: to toggle between the standard display, menu

and alarm display

Enter button: to confirm parameter changes

Illuminated graphic LCD

flashes until the device is ready for operation during

parameters

RCMS490-D

37

Page 38

6.2 Operating and display elements RCMS…-L

1

2

3

6

5

4

7

8

9

Operation

LINETRAXX®

1 The "ALARM 2“ LED lights up if the measured value falls below or

2 The "ALARM 1" LED lights up if the measured value falls below or

3 LED "ON“ lights up when the device is switched on and flashes until

4 ESC button: to exit the menu function without changing parameters

5 "TEST" button: to call up automatic test

6 "RESET" button: to acknowledge alarm and fault messages

7 "SET" button: to set the BMS address

8 Alarm-LEDs "1…12“ light up if an insulation fault has been detected

9 Digital display for device address and error codes.

RCMS460-L

exceeds the "Alarm" response value in a measuring channel or until

an error is indicated by the digital input.

exceeds the "prewarning" response value in a measuring channel or

in case of a device error.

the device is ready for operation during switching on.

Up button: to change parameters, scroll

Down button: to change parameters, scroll

"ENTER" button: to confirm parameter changes

in the relevant measuring channel

or flash if there is a fault with the measuring current transformer.

RCMS490-L

38

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 39

Operation

100%

50%

k 1 2 3 4 5 6 7 8 9

10 11

12

0%

Channel disabled

Channel enabled

Channel enabled,

current is flowing

(height ≥ 2 graduation m

(height = 1 graduation m

6.3 Working in operating mode

6.3.1 Standard display

In operating mode, you will see a bar graph on the RCMS460…-D display. For

each of the 12 measuring channels, it shows what percentage of the set alarm

value I

For digital inputs 100 % = 1 and 0 % = 0.

The RCMS…-L shows its BMS bus address (e.g. 02). Only the green "Power ON"

LED is lit.

6.3.2 Alarm and its effect

Possible causes of alarm messages:

The value falls below or exceeds the set response value or the prewarn-

Digital input closed resp. open

Fault measuring current transformer or CT connection fault

Device error (see „Display device error“ on page 82)

(alarm) and I

Δn2

(prewarning) has been reached.

Δn1

ing threshold during current or residual current measurement.

The RCMS460… signals prewarning and/or alarm:

LED "ALARM 1" (prewarning) and/or LED "ALARM 2" (alarm) light

depending on the type of alarm.

Associated common alarm relays (C…) switch.

RCMS490… only: Alarm relays of the individual channel switch.

An alarm message is being sent on the BMS bus.

RCMS460-490_D00067_03_M_XXEN/12.2017

39

Page 40

Operation

ALARM 1/1

Residual current

130 mA

Addr.: 2 Chan.: 12

An entry is made in the history memory.

An entry is made in the history memory.

RCMS…-D…: An alarm message is shown on the display.

Line 1: ALARM, PREWARNING or FAULT

Alarm 1 of 1 pending alarms

Line 2: Alarm status and alarm text: (e.g. residual current, digital in-

put, no Master, CT connection).

No alarm

Prewarning

Alarm, fault

Line 3: r.m.s. value

Line 4: BMS bus address of the RCMS and measuring channel on

which the alarm has occurred.

RCMS…-L…: The alarm LED of the affected measuring channel lights

up.

40

RCMS…-D4/-L4 only (channels 9…12):

When measuring the load current, a prewarning is indicated

in case of overcurrent only. In case of undercurrent a

prewarning is not indicated.

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 41

Operation

Auto test

TEST 12/12

Residual current

100 mA

Addr.: 2 Chan.: 12

6.3.3 Test procedure

A test serves to check the device function (hardware components) of the

RCMS. A test can be activated as follows:

Select standard display and then press the "TEST" button on the RCMS

front panel for at least one second.

Press an external test button connected to the RCMS…

Send a test command via the BMS bus.

RCMS…-D… only: Select "TEST" from the control menu.

The RCMS… responds as follows:

"ALARM 1" and "ALARM 2" LEDs light up.

All alarm relays switch (this function can be deactivated, refer to

page 68).

An alarm message is sent on the BMS bus.

An entry is stored in the history memory with the suffix "TEST".

RCMS…-D…: The progress of the test is indicated on the display.

The RCMS460…-D then displays the set response value for the highest

functioning measuring channel.

Press the "" button several times to display the correct functioning of

the other measuring channels.

RCMS460-490_D00067_03_M_XXEN/12.2017

41

Page 42

Operation

RCMS…-L…: All alarm LEDs light for approx. 10 seconds.

After successful testing, all LEDs must go out again, with the exception of the

LED "ON" and the alarm relays must return to their initial position.

6.3.4 Resetting saved alarm messages (RESET)

If the fault memory is enabled, the alarm status will remain, even after the

cause of the fault has been eliminated, until a "RESET" is carried out.

RCMS…-D… only: First press the "ESC" button to exit the display of the current alarm message. The "RESET" button cannot be pressed before the standard display appears (bar chart).

A reset can be carried out in the following way:

Select standard display and then press the "RESET" button on the RCMS

front panel for at least one second.

Press an external reset button connected to the RCMS…

Send a reset command via the BMS bus.

RCMS…-D… only: Call the "RESET" function in the Control menu.

Saved alarm messages that are no longer pending are deleted. The alarm relay

drops out, the alarm LEDs go out and there are no longer any alarm messages

on the BMS bus.

42

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 43

Operation

RESET

RCMS460-D

10.03.16 12:59

Address :2

Software: D233V2.50

The RCMS…-D shows the progress of the reset operation.

6.3.5 Displaying standard information

This function is only available in RCMS…-D. Press the "INFO" button. You will

now see information relating to the device and software on the RCMS…-D display. Use the "" arrow button to scroll all the information. Please have this

information to hand if you should need to contact us for assistance by telephone.

Line 1: Device type

Line 2: Date, time

Line 3: BMS bus address of the RCMS

Line 4: Software version D233V… for measuring technology proc-

esses

Line 5: Date of the measurement technique software version

Line 6: Software version D216/D256/D339/D403… for

communication processes

Line 7: Date of communication software version

Line 8…10: Bender address, homepage

Line 11: Exit. Exit standard information.

RCMS460-490_D00067_03_M_XXEN/12.2017

43

Page 44

Operation

6.4 Setting the RCMS…-L…

RCMS…-L has a 7-segment LED display. Operation and setting can be carried

out via an RCMS…-D or using the following devices: MK2430, MK800,

COM460IP or CP700. The harmonics analysis and the preset function can only

be carried out in conjunction with an RCMS…-D. Only the BMS bus address

can be set directly on the RCMS…-L.

The following functions and settings are not included in the RCMS…-L :

– Language – Time/date

– Data logger – Interface menu

– History memory – Password

Setting the BMS bus address of the RCMS…-L

1. Press the "SET" button for approximately two seconds to open the

main menu. The BMS bus address flashes.

2. Use the arrow buttons ", " to select the required address.

3. Press the Enter button "↵" to confirm this setting.

4. If you wish to exit the setting without making a change, press the "ESC"

button.

6.5 Operation and setting of the RCMS…-D…

This chapter describes the RCMS…-D menu mode.

The RCMS…-L only has some of these functions available (see „Setting the

RCMS…-L…“ on page 44). This also applies if an RCMS…-D is used to operate

and set an RCMS…-L.

44

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 45

Operation

Exit

1.Alarm/meas.values

2.% Bar graph

3.History

Enter

password:

0 0 0

6.5.1 Opening the main menu

Press the "MENU" button to open the main menu.

In the main menu, use the following buttons:

ESC Exit this function without storing or go up one menu level.

, Select menu items

↵ Confirm selected menu item (Enter).

The menu mode is exited automatically if no button is

pressed for longer than five minutes. Exceptions: The "Test"

and "Test communication" functions.

Settings can be password protected. When an attempt is

made to change settings, the password entry screen appears

automatically:

Details see “Settings menu 11: Password” on page 73.

If you can't remember your password, contact the Bender

Service.

RCMS460-490_D00067_03_M_XXEN/12.2017

45

Page 46

6.5.2 Menu overview diagram

7.Control

8.External devices

9.Info

4.Relay

6.Data logger

7.Language

8.Interface

9.Alarm addresses

10.Clock

11.Password

12.Factory setting

13.Service

Exit

1.TEST

2.RESET

3.Test communication

Exit

Exit

5.History

Exit

1.Alarm/meas.values

3.History

2.% Bar graph

4.Harmonics

5.Data logger

6.Settings

1.General

Exit

2.PRESET

3.Channel

Operation

46

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 47

Operation

6.5.3 Main menu functions

Menu item Function Page

Exit Exit menu mode -

1.Alarm/

meas.values

Displays the following for each measuring

channel, if applicable,: prewarning, alarm,

49

measured value, digital input status, response value, channel disabled, CT connection fault.

2.% Bar graph For each of the 12 measuring channels the

49

reached per cent value of the set alarm

value I

(alarm) and I

Δn2

(prealarm) is indi-

Δn1

cated. In case of digital inputs, the status is

indicated.

3.History Displays the history (300 data records) with

50

information about messages, acknowledgements and associated times. Displays the

minimum and maximum residual current

after an alarm has occurred, with address

and channel.

4.Harmonics Displays the following for the selected

51

measuring channel: measured value, THF

(Total Harmonic Factor) in %; DC component, fundamental oscillation and harmonics in mA.

5.Data logger Displays the recorded measured values (300

52

data records) for each measuring channel.

6.Settings Settings for this RCMS… are made here. 53

RCMS460-490_D00067_03_M_XXEN/12.2017

47

Page 48

Operation

Menu item Function Page

7.Control This menu offers various control options,

8. External

devices

9.Info Information on the device. The same display

such as TEST, RESET, Test communication.

Settings on devices externally connected to

the BMS bus

(e.g. RCMS460-D/-L, RCMS490-D/-L).

is obtained by pressing the INFO button in

the operating mode (refer to „Displaying

standard information“ on page 43).

74

76

79

48

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 49

Operation

I(d) I(dn)

1. 4mA 10mA

2. 120mA 20mA

3.

Channel disabled

100%

50%

k 1 2 3 4 5 6 7 8 9

10 11

12

0%

Channel switched off

Channel enabled

Channel enabled,

current is flowing

(height ≥ 2 graduation m

(height = 1 graduation m

6.6 The main menu

6.6.1 Menu 1: Alarm/meas. values

RCMS…-D… displays the following for each measuring channel: alarm, measured value, response value.

Column 1: Channel number 1…12

Column 2: Alarm status:

Column 3: I(d): The currently measured r.m.s. value of the residual cur-

rent I

Column 4: I(dn): Set response value (rated residual operating current)

I

Δn

or "Channel disabled“ or "CT connected“.

6.6.2 Menu 2: % Bar graph

For each of the 12 channels the RCMS…-D… shows the reached response value in per cent and/or the status of the digital inputs.

No alarm

Prewarning

Alarm, fault

, the load current or the status of the digital input.

Δ

, digital input

100 % Response value (alarm) resp. digital input = 1

50 % Prewarning (here set to 50 %)

0 % Channel disabled resp. digital input = 0

RCMS460-490_D00067_03_M_XXEN/12.2017

49

Page 50

Operation

History no. 297

Start:

01.03.16/15:57:00

Ack.:

End:

01.03.16/16:07:03

History no. 297

Residual current

Min. 21mA/Max.198mA

Addr.:2 Chan.:1

6.6.3 Menu 3: History

The failsafe history memory stores up to 300 events (prewarnings, alarms,

tests). If the history memory is full, the oldest entry will be deleted in each case

in the event of an alarm, to create space for the new entry.

For details about erasing the entire history memory refer to „Settings menu 5:

History“ on page 70.

Line 1: Event number (if applicable): TEST.

Line 2: Event start: Date/time

Line 3: Event acknowledgement (e.g. by pressing

"Buzzer off" at TM…, MK2430, MK800):

Line 4: Event end: Date/time

1. If you are searching for an event that occurred at a specific time, use

the arrow buttons to navigate to the required entry.

2. Press the "↵" button to call up details about the current entry in the history memory.

Date/time

Line 1: Data record number

Line 2:

50

Alarm status and alarm text (e.g. residual current, digital input,

overcurrent at k9…k12 (RCMS…-D4/-L4 only)

No alarm

Prewarning

Alarm, fault

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 51

Operation

Channel:1

1

21mA

THF 3%

DC 3mA

1.

85mA

Line 3: Minimum and maximum measured value after an alarm has

Line 4: Address and measuring channel of the device sending the

occurred.

message.

6.6.4 Menu 4: Harmonics

The analysis of the harmonics of the measured currents is displayed as a bar

and a current value. Harmonics are multiples of the rated frequency.

Example: Rated frequency = 50 Hz, 2nd Harmonics = 100 Hz.

The RCMS…-D… can only determine the harmonics currents correctly if the

selected rated frequency in menu "6. Settings-> General-> Rated frequ." suits

the current being monitored.

At 50 o r 60 Hz, the cur ren t v alu e of harmonics 1…40 is displayed; at 400 Hz the

current value of harmonics 1…5 is displayed.

THF: The total harmonic factor (THF) specifies the ratio of the har-

monics r.m.s value of an alternating quantity to the fundamental r.m.s. value. The smaller the THF, the more sinusoidal

the current signal.

If 50 or 60 Hz are selected in the "Cut-off frequency" menu

(see page 65) the THF cannot be determined. The display

indicates „- - -“ .

An analysis of the harmonics cannot be carried out in

disabled channels or channels with digital input. The display

indicates „- - -“ .

RCMS460-490_D00067_03_M_XXEN/12.2017

51

Page 52

Operation

Exit

1.Data logger

2.Data logger

3.Data logger

Column 1: Identifies the THF, DC component and harmonics number.

Column 2: Bar graph indication of the THF (% of the r.m.s. value),

Column 3: Current r.m.s. value, THF/residual current of this measuring

Select a measuring channel for displaying the harmonics:

– Use the "" button to go to the measuring channel setting. Press

– Use the Up/Down buttons to select a measuring channel. Press "↵"

3. You can use the Up/Down buttons to browse the harmonics current

values of this measuring channel.

bar graph of the current value.

channel. Harmonics current values are updated in order. Updating all harmonics takes up to 15 seconds.

the "↵" button.

to confirm your selection.

6.6.5 Menu 5: Data logger

Up to 300 data records can be recorded for each of the 12 measuring channels. A new measured value is saved if it differs from the previous measured

value by a defined percentage. You define this percentage in the menu "6.

Settings-> 5. Data logger -> Change". You also make settings for overwriting

and deleting measured values here.

52

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 53

Operation

271 01.04.16 15:57:03 35mA

270 01.04.16 15:40:10 51mA

269 01.04.16 15:37:15 36mA

268 01.04.16 15:35:01 70mA

1. Use the Up/Down buttons to select the required measuring channel

(measuring channel number k1…k12). Press the "↵" button.

2. You can use the Up/Down buttons to browse the recorded data

records of this measuring channel (data record number, date, time,

measured value or digital input).

6.6.6 Menu 6: Settings

The following menu items are available for configuring the RCMS:

Menu item Function Page

Exit Exit settings -

1.General Set the fault memory, prewarning, hysteresis, frequency and start-up delay.

2.PRESET Default setting of all response values to a

specified factor and offset value. In case of

digital inputs the current status (0/1) will be

reversed.

3.Channel Set for each measuring channel: factor, response value, function (overcurrent/ undercurrent), digital input or channel "off",

response delay, release delay, cut-off fre-

RCMS460-490_D00067_03_M_XXEN/12.2017

quency, CT type and transformer monitoring.

54

56

58

53

Page 54

Operation

Menu item Function Page

4.Relay Set the relay mode of operation and type of

5.History Delete the history memory. 70

6.Data logger Set change in %, activate/deactivate over-

7.Language Select the language for menu and alarm

8.Interface Set the RCMS…-D own BMS bus address. 71

9.Alarm

addresses

10.Clock Set date format, date, time and summer

11.Password Changing and activating the password. 73

12.Factory setting

13.Service For Bender service employees only. 73

fault that you wish to cause a switching operation for the common alarm relay.

write data, delete data.

texts.

Setting of bus addresses for devices whose

alarm messages are to be displayed on this

RCMS…-D.

time changeover.

Resets all settings to factory settings. 73

68

70

71

71

72

6.6.6.1 Settings menu 1: General

In this menu you make settings that apply to this device and therefore to all

measuring channels.

54

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 55

Operation

1. Fault memory

Faults that only occur temporarily can be saved.

on After eliminating the cause of fault all alarm messages remain

off RCMS… exits the alarm mode as soon as the cause of fault is

stored until a reset is carried out.

eliminated.

2. Prewarning

Setting as a percentage of the response value. Setting range: 10…100 %,

resolution of setting 1%.

3. Hysteresis

If the measured value were to oscillate around the response value, the

RCMS… would constantly change from alarm to normal status and back

again. If a hysteresis of 20 % is set, the alarm status is not exited until the measured value is 20 % below resp. above the response value.

Setting range: 2…40 %, resolution of setting 1%.

4. Frequency

Select the rated frequency of the monitored current. Only if the setting is correct, can the RCMS… determine the harmonics currents properly.

Setting options: DC, 50 Hz, 60 Hz, 400 Hz.

RCMS460-490_D00067_03_M_XXEN/12.2017

55

Page 56

Operation

Exit

1.Factor: *3

2.Offset: 30 mA

3.PRESET

5. Start-up delay t

Time delay after the RCMS… is switched on.

No alarm messages are generated during this period. This time delay is required if the RCMS…-D and the monitored system are switched on simultaneously. Currents caused by switching actions are ignored.

Setting range: 0…99 s. Resolution of settings as follows:

Setting range Resolution of setting

0…50 ms 5 ms

60…200 ms 10 ms

250…500 ms 50 ms

600 ms …2 s 100 ms

2.5…5 s 0.5 s

6…20 s 1 s

25…50 s 5 s

60…99 s 10 s

6.6.6.2 Settings menu 2: PRESET

Default setting of all response values to a specified factor and offset value. This

default setting facilitates commissioning of new installa tions. Alarm messages

as a result of not previously set response values can be avoided. The new response value is determined as follows:

1. The currently measured value is multiplied by the appropriate factor.

2. The specified offset value is added.

Displayed by a formula:

Response value = (currently measured value x factor) + Offset

56

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 57

Operation

1. Factor (for PRESET)

Set the multiplication factor for the latest measured value. Setting range:

1…99 %, resolution of setting 1 %.

Recommended setting (factory setting): Factor 3

2. Offset (for PRESET)

Set the offset value that is to be added to the product of the "current measured value x factor". Setting range: 0…20 A, resolution of setting:

Setting range Resolution of setting

0…20 mA 1 mA

25…50 mA 5 mA

60…200 mA 10 mA

250…500 mA 50 mA

600 mA… 2 A 100 mA

2.5 A…5 A 0.5 A

6 A…20 A 1.0 A

Recommended setting (factory setting): Offset 30 mA

3. PRESET

If the RCMS… is used as a means of protection to ensure

personnel and fire protection, the PRESET function must

not be used!

There is the risk that the selected response values are too

high.

Make sure that all existing insulation faults are eliminated

before using the preset function!

There is the risk that the selected response values are too

high.

RCMS460-490_D00067_03_M_XXEN/12.2017

57

Page 58

Operation

Chan.: 1

Exit

1.Factor: *1

2.Resp. val.:100mA

Setting an

individual channel:

Chan.: 1..12

Exit

1.Factor: --

2.Resp. val..:--

Setting

all channels:

Presetting is carried out for all measuring channels on this device.

Exceptions:

When a channel is disabled, the set response value does not change.

When the current measured value is 0 mA, the smallest possible

response value is set:

– Type A measuring current transformer : 6 mA

– Type B measuring current transformer : 10 mA

If the PRESET routine determines a value that exceeds the maximum

response value (type A: 20 A, type B: 10 A) the highest possible

response value is set.

For digital inputs the current status (0/1) will be reversed.

To prevent unwanted execution of this function, the entry must be confirmed

once more.

6.6.6.3 Settings menu 3: Channel

You make the measuring channel settings in this menu (either individually or

for all channels (1…12) simultaneously). Selecting a measuring channel:

1. Use the "" button to go to the measuring channel setting. Press the

"↵" button.

2. Use the Up/Down buttons to select a single measuring channel (e.g. 1)

or all measuring channels (1…12). Press "↵" to confirm your selection.

58

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 59

Operation

If the measuring channel settings only differ slightly, we

recommend to proceed as follows:

- first set all the measuring channels (1…12) to the same

value

- then modify the setting of an individual measuring channel.

1. Factor (for measuring current transformers)

Setting of a factor to adapt the RCMS… to connected measuring current

transformers. The following factor setting ranges are available depending on

the CT type and the application. When the channel is disabled, this setting

menu has no function (display: --).

Select:

*1 For Bender measuring current transformers (W…, WR…,

*1 … *250 For measuring current transformers with a different transfor-

/2 … /10 If the conductor to be m onitored is wound through the meas-

WS…, WF…, W…AB).

mation ratio (e.g. if third-party measuring current transformers are connected via a Bender measuring current

transformer).

uring current transformer several times in order to amplify

the signal.

Examples for the factor determination

X = transformation ratio, N = number of turns through the measuring current

transformer (wire up)

Example 1: Bender measuring current transformers with a

transformation ratio of 600/1

Factory setting:

Factor: *1, CT monitoring: on

RCMS460-490_D00067_03_M_XXEN/12.2017

59

Page 60

Operation

Example 2: Connection of external Bender measuring current

transformers

Bender-Messstromwandler

BenderMessstromwandler

Settings:

Factor = (X / N)

Measuring current transformer monitoring: On

= 100/1

= *100

60

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 61

Operation

Example 3:

The wire to be monitored is "wound" several times through the

Bender current transformer in order to amplify the signal

Setting:

Factor: /3

Measuring current transformer monitoring: On

2. Response value

The response value is the value at which an alarm is output. In case of digital

inputs, set the status (0 or 1) at which an alarm is to be signalled.

Tolerances have to be taken into account (measuring current

transformers, RCMS…) whenever measurements are carried

out. The IEC 62020 specifies that the set response value shall

not be exceeded, therefore an RCMS… shall respond when

50…100 % of the set response value are reached.

Prewarning is therefore to be signalled earlier (x % of

50…100 % of the response value).

The current measuring channels k9…k12 of version

RCMS…-D4/-L4 have positive tolerances as regards the

response values.

RCMS460-490_D00067_03_M_XXEN/12.2017

61

Page 62

Operation

Depending on the settings in the "Channel -> Mode" menu and "Channel ->

CT" menu the following response values can be selected:

Type AB 10 mA…10 A (DC…2000 Hz)

Type A 6 mA…20 A (42…2000 Hz)

Flex. 100 mA…30 A (42…2000 Hz)

Digital inputs 0/1

Resolution of setting type AB

(AC/DC sensitive measuring current transformers):

Measuring current transformers W20AB measure residual

currents in the range AC/DC 10…500 mA.

Setting range Resolution of setting

10…20 mA 1 mA

25…50 mA 5 mA

60…200 mA 10 mA

250…500 mA 50 mA

600 mA… 2 A 100 mA

2.5 A…5 A 0.5 A

6 A…10 A 1.0 A

Resolution of settings type A

(pulsating current sensitive measuring current transformers):

Setting range Resolution of setting

6…20 mA 1 mA

25…50 mA 5 mA

60…200 mA 10 mA

250…500 mA 50 mA

600 mA… 2 A 100 mA

2.5 A…5 A 0.5 A

6 A…20 A 1.0 A

62

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 63

Operation

Resolution of settings type A (RCMS…-D4/-L4 only, channels k9…k12):

Setting range Resolution of setting

100…200 mA 10 mA

250…500 mA 50 mA

600 mA… 2 A 100 mA

2.5 A…5 A 0.5 A

6 A…20 A 1.0 A

25 A…50 A 5.0 A

60 A…125 A 10.0 A

Resolution of settings type Flex.: the same as for type A

3. Function

Monitoring the measuring channel for overcurrent or undercurrent. Use of the

measuring channel as digital input. Unused measuring channels have to be

disabled.

> Alarm when the response value is exceeded.

< Alarm when the value falls below the set response value.

0/1 Use of the measuring channel as digital input.

off Measuring channel disabled.

* Scanning time digital inputs < 3.5 s.

Potential-free contact > 250 Ω, LC display indication: "0"

Potential-free contact < 100 Ω LC display indication: "1"

RCMS460-490_D00067_03_M_XXEN/12.2017

63

Page 64

Overview of available functions

Operation

RCMS…-

D4/-L4,

Channel

1…8

Measuring function

(selectable)

I/I

: 6 mA…20 A

Δn

RCMS…-D/-L

Channel

1…12

</>/OFF </>/OFF ---

(42…2000 Hz)

type A

I: 100 mA…125 A

--- --- </>/OFF

(42…2000 Hz)

I/I

: 10 mA…10 A

Δn

</>/OFF </>/OFF ---

(0…2000 Hz)

type B

1/0 1/0/OFF 1/0/OFF ---

4. Response delay t(on)

Response delay starts when a new alarm has been triggered.

Setting range: 0…999 s.

Resolution of settings:

Setting range Resolution of setting

0…50 ms 5 ms

60…200 ms 10 ms

250…500 ms 50 ms

600 ms …2 s 100 ms

2.5…5 s 0.5 s

6…20 s 1 s

25…50 s 5 s

60…200 s 10 s

250…500 s 50 s

600…999 s 100 (99) s

RCMS…-

D4/-L4,

Channel

9…12

64

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 65

Operation

5. . Delay on release t(off)

If the condition that triggered the alarm does not exist anymore, the RCMS…

terminates its alarm once the release delay has elapsed.

Setting range: 0…999 s. Resolution of settings: the same as for response delay

t(on).

6. Cutoff frequency

Set the characteristics for the frequency response of residual current measurement I

The frequency response of the equipment can be set for a linear frequency response (up to the maximum frequency of 2000 Hz) if used for fire protection

or for a frequency response in accordance with IEC 60990 for personnel protection. For plant protection, the residual current is measured up to the rated

system frequency. The figure below shows the corresponding frequency response.

and current measurement I.

Δn

Param. Objective

50 Hz Plant protection: Only evaluates the fundamental compo-

nent of the current measurement.

60 Hz Plant protection: Only evaluates the fundamental compo-

nent of the current measurement.

IEC Personnel protection in accordance with IEC 60990 (touch

None Fire protection: Response factor remains the same over the

current for let-go): Above 200 Hz (approx.), the set response

value increases corresponding to the frequency-dependent

threshold according to IEC 60990.

entire frequency range.

RCMS460-490_D00067_03_M_XXEN/12.2017

65

Page 66

Frequency response

(cut-off frequency)

50 Hz 60 Hz

IEC

none

Response factor

I(d)

I(dn)

Operation

Response factor =

I(d) Residual current I

I(dn) Rated residual operating current I

: r.m.s. value currently measured

Δ

: Set response value

Δn

7. CT

Set the type of measuring current transformer.

Type A Pulsating current sensitive W…, WR…, WS…

series measuring current transformers

Flex. Flexible WF… series measuring current trans-

formers

Type AB AC/DC sensitive W…AB series measuring cur-

rent transformers

66

RCMS460-490_D00067_03_M_XXEN/12.2017

Page 67

Operation

8. CT monitor.

Enable or disable the measuring current transformer connection monitoring.

on Measuring current transformer connection is monitored.

Connection interruption, short-circuit or failure of the power supply

unit generate an alarm message after 20 seconds at the latest (W…AB

series) (Fault: CT connection). The "ALARM 1" LED lights up.

off Measuring current transformer connection is not monitored.

Flexible WF… measuring current transformers only:

CT monitor setting "off" must not be changed. If this is not

taken into account, the device signals a fault: "CT

monitoring".

9. Relay mode (RCMS490-D…/-L… only)