Page 1

RCMB300 series

AC/DC sensitive residual current monitoring module

RCMB300 series_D00372_01_Q_XXEN/06.2019

Quick-start guide

EN

Page 2

RCMB300 series

c

ae

e

c

a

a

e

Part of the device documentation in addition to this quick-start guide is the enclosed "Safety

i

instructions for Bender products" and the operating manual. This quick-start guide applies to the

following devices:

Type Supply voltage Response value/variant Order number

RCMB301 DC 24 V (19.2…28.8 V ) 30 mA…3 A/Modbus RTU B74043100

Intended use

The residual current monitoring modules of the RCMB300 series are intended for measuring AC

and DC fault currents in earthed systems (TN and TT systems). The modules are able to measure

residual currents up to I

= 20 A in a frequency range of DC…100 kHz.

Δ

Any other use than that described in this document is regarded as improper. This quick-start

guide does not replace the operating manual of the device. Download: www.bender.de/manuals

Safety instruction

DANGER of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

I

- An electric shock

- Damage to the electrical installation

- Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-energised. Observe the rules for working on electrical installations.

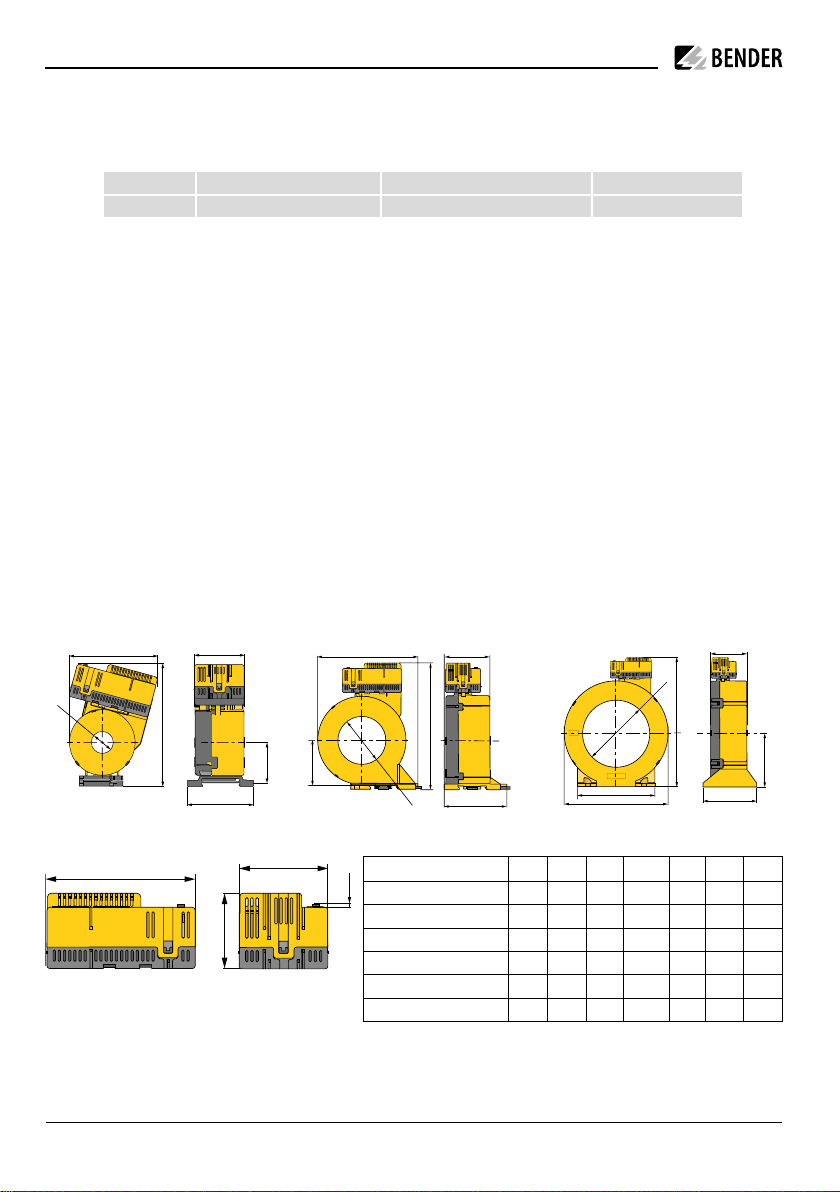

Dimension diagrams RCMB30... + CTBC... (all dimensions in mm, tolerance ±0.5 mm)

d

b

c

f

b

d

f

g

RCMB30… + CTBC20(P)/CTBC35(P) RCMB30… + CTBC60(P) RCMB30… + CTBC120(P)/CTBC210(P)

a

b

RCMB30…

2 RCMB300 series_D00372_01_Q_XXEN/06.2019

d

Type a b c d e f g

RCMB30…-CTBC20(P) 81 112 37 ø 20 46 60

RCMB30…-CTBC35(P) 97 130 47 ø 35 46 61

RCMB30…-CTBC60(P) 126 158 57 ø 60 56 78

RCMB30…-CTBC120(P) 188 232 96 ø 120 65 96 139

RCMB30…-CTBC210(P) 302 346 153 ø 210 67 113 277

RCMB30… 74 37 44 2 4.6

d

b

c

f

Page 3

Dimensions of mountings

34789

RCMB300 series

c

c

Type a b c

CTBC20(P) 31.4 49 2 x ø 5.5

CTBC35(P) 49.8 49 2 x ø 5.5

c

b

a

b

b

a

a

CTBC60(P) 56 66 2 x ø 6.5

CTBC120(P) 103 81 4 x ø 6.5

CTBC210(P) 180 98 4 x ø 5.5

CTBC20(P)/CTBC35(P) CTBC60(P) CTBC120(P)/CTBC210(P)

Assembly

A complete residual current monitoring module consists of the RCMB30… evaluation electronics

and a CTBC20(P)…210(P) series measuring current transformer core. If ordered separately, these

two components must be plugged together and calibrated during commissioning.

Step 1: Place the electronic module on the mark on the

measuring current transformer.

Step 2: Fold the electronic module down onto the

2

3

measuring current transformer.

Step 3: Slide the electronic module onto the plug

1

contacts of the measuring current transformer.

Device view RCMB30…

No. Terminal Meaning

125610

11 12

11 12

K1 K2

21 22 2411 12 14

13 14

1 24 V

2 GND

3 D1

4 DG

5 T/R

6 GND

7 A

8 B

9 X1

10 X2

11 11, 12, 14

12 21, 22, 24

13 –

14 –

Supply voltage U

S

Contact feedback

Connection external test/reset

RS-485 interface

Terminals for cable bridge for connection of the

integrated terminating resistor of the RS-485

interface

Relay K1 (prewarning)

Relay K2 (alarm)

LED: operation "ON" and "Alarm"

Test and reset button "T"

RCMB300 series_D00372_01_Q_XXEN/06.2019 3

Page 4

RCMB300 series

Connection

N

L

F 6 A

RCMB301-CTBC...

21

22 24

21

22 241112 14

3

Refer to the manual for further connection options.

Commissioning - Modbus RTU

24 V

GND

T/R

GND

DC 24 V

AC

DC

SPD

L1

L2

L3

N

The use of a type 2 surge protection de-

i

vice (SPD) is mandatory due to possible

impulse voltages and in order to comply

with normative requirements.

The surge protection device must be connected upstream of the power supply

unit on the supply side.

Features of the surge protection device:

– Nominal discharge current In (8/20 μs): 20 kA

– Response time: 25 ns

– Two-stage: 1 varistor + 1 spark gab

– Alternatively, the power supply unit must be

connected to a CAT II supply without a surge

protection device.

Within an interconnection of devices via

i

the RS-485 interface, the first and the last

device must each be provided with a terminating resistor.

This device-internal resistor can be connected by means of a wire jumper or a

DIP switch.

X1 X2

Wire jumper

RCMB30...

first device

120 Ω

COM465IP

last device

120 Ω

DIP switch

Address setting

Every RCMB3… has a factory-set Modbus address. The address is 1XX, where XX = the last two

i

digits of the serial number. Example: Serial number = 12345678 -> Modbus address = 178

The preset address can be changed via a COMTRAXX gateway, via Modbus or directly on the device.

The address can be changed on the device before installation and offset calibration. The electronic module must not be connected to the measuring current transformer during address setting.

Each address in the bus system may only be assigned once.

4 RCMB300 series_D00372_01_Q_XXEN/06.2019

Page 5

RCMB300 series

LED flashing modes

A

B

medium mode change

C

D

E

once confirmation

slowly error

quickly ready for address modification

very quickly address setting mode

Address modification procedure

Phase Action LED

1 Supply the electronic module with power

Flashes red briey (A, error: no measuring

current transformer)

Flashes red briey (A, error)

Flashes red at medium speed (B, mode

Press and hold "T" until the LED ashes red very quickly; release

2

afterwards

change)

Flashes red quickly (C, ready for address

setting mode)

3 Set address (address setting range: 1…247) Flashes red quickly (D, address setting mode)

Press "T" repeatedly until reaching the desired digit of the

units place

Units

3a

place

Acknowledge the entry: Press and hold "T" until the LED

ashes red; release afterwards

Press "T" repeatedly until reaching the desired digit of the

tens place

Tens

3b

place

Acknowledge the entry: Press and hold "T" until the LED

ashes red; release afterwards

Press "T" repeatedly until reaching the desired digit of the

Hundreds

3c

hundreds place

place

Acknowledge the entry: Press and hold "T" until the LED

ashes red; release afterwards

Check address setting: LED indicates the address by ashing

Each keystroke is conrmed with green (E)

Lights green shortly (E)

LED ashes red briey (C)

Each keystroke is conrmed with green (E)

Lights green shortly (E)

LED ashes red briey (C)

Each keystroke is conrmed with green (E)

Lights green shortly (E)

LED ashes red briey (C)

1)

Digit units place Flashes green for each number (E)

Pause o

4

Digit tens place Flashes green for each number (E)

Pause o

Digit hundreds place Flashes green for each number (E)

Pause o

5 Address set

1)

Example for "Check address setting": flashing pattern after successful setting of address "124" :

E

E

E

Flashes red briey (A, error: no measuring

current transformer)

A

RCMB300 series_D00372_01_Q_XXEN/06.2019 5

Page 6

RCMB300 series

System state LED and output relays

The LED indicates the system state by means of colours and lighting/flashing. The changeover

contacts of the relay outputs K1 and K2 have defined switching positions for each system state.

System state GREEN LED ONRED LED

Notes

Alarm

Device switched o o o Device is de- energised, no monitoring, no

monitoring function

Normal operating state lights o The device is supplied with the specied

voltage and monitors the primary circuit.

No residual current ows which would

lead to tripping.

Prewarning lights ashes

briey

The device is supplied with the specied

voltage and monitors the primary circuit.

A fault current ows which exceeds the

set limit of the prewarning.

Alarm state o lights The device is supplied with the specied

voltage and monitors the primary circuit.

A fault current ows which exceeds the

set limit of the alarm.

Device error o ashes

slowly

The device is supplied with the specied

voltage and monitors the primary circuit.

An error is detected by the periodic self

tests.

Device in calibration

see manual for DC calibration procedure

mode

Device in address mode see manual for procedure

Device signalling Flash quickly in alter-

nation

Modbus register 20006 = 2

Use to detect the device in its environment faster. Is automatically deactivated

after one minute.

Relay K1 Relay K2

de-energised de-energised

energised energised

de-energised energised

de-energised de-energised

de-energised de-energised

de-energised de-energised

6 RCMB300 series_D00372_01_Q_XXEN/06.2019

Page 7

Installation instructions measuring current transformer

PE

*

Do not route any shielded cables through the measuring current transformer.

i

CAUTION! Device damage due to high induction currents! High currents can be induced into

the conductor loop due to the AC/DC sensitive measuring technology used. Do not route pro-

I

tective conductors and low-resistance conductor loops through the measuring current transformer!

CAUTION! Device damage due to interference pulses! The connecting cable (supply, analogue

interface ...) must not be routed directly past the current transformer core.

I

CAUTION! Risk of injury due to accessible live conductors!

The measuring current transformer must be connected to the corresponding evaluator before

I

the first use and before commissioning of the monitored system.

L1

L2

L3

N

*

Never route an existing protective conductor through the measuring current trans-

All current-carrying cables must be routed together through the measuring current

transformer.

The primary conductors may only be bent from the specified minimum distance. The

minimum bending radius specified by the manufacturers must be observed. Distance

to 90° angle = 2 * external diameter

RCMB300 series

The cables must be centred in the measuring current transformer.

Offset calibration and completion of the installation

Before commissioning the system, it is recommended that an offset calibration be carried out on

the RCMB module at the installation site. Note that during the offset calibration the system is

switched off and no current flows through the measuring current transformer. For the CTBC120

and CTBC210 measuring current transformer cores, an offset calibration is mandatory. The offset

calibration procedure is described in the manual.

The installation should be completed with a functional test: Press the "T" button for 1.5…5 s.

RCMB300 series_D00372_01_Q_XXEN/06.2019 7

Page 8

Technical data

ø current

transformers

Type

Art. No.

CTBC20

B98120001

CTBC20P

B98120002

CTBC35

B98120003

CTBC35P

B98120004

CTBC60

B98120005

CTBC60P

B98120006

CTBC120

B98120007

CTBC120P

B98120020

CTBC210

B98120008

CTBC210P

B98120021

4

STEP-PS/1 AC/24 DC/0.5

B94053110

14

STEP-PS/1 AC/24 DC/1.75

B94053111

34

STEP-PS/1 AC/24 DC/4.2

B94053112

Rated voltage .................................................................... 800 V

Overvoltage category ............................................................... III

Nominal supply voltage U

Operating range U

Power consumption ........................................................≤ 2.5 W

...............................................DC 24 V

s

...........................................................±20 %

S

Measuring circuit

Characteristics according to IEC 62020 and IEC/TR 60755

............................................................... AC/DC sensitive, type B

Measuring range ..................................................... 5 mA…20 A

Response value I

......................................................30 mA…3 A

Δn

Prewarning .....................................................50 %…100 % IΔn

Rated current I

n

CTBC20 when IΔn = 30 mA ....................................................40 A

CTBC20 when I

= 300 mA ..................................................63 A

Δn

CTBC20P ................................................................................80 A

CTBC35 when I

CTBC35 when I

= 30 mA ....................................................80 A

Δn

= 300 mA ................................................125 A

Δn

CTBC35P ..............................................................................160 A

CTBC60 when I

CTBC60 when I

= 30 mA ..................................................160 A

Δn

= 300 mA ................................................250 A

Δn

CTBC60P ..............................................................................320 A

CTBC120 when I

CTBC120P when I

CTBC210 when I

CTBC210P when I

CTBC210P when I

= 100 mA ..............................................330 A

Δn

= 100 mA ............................................630 A

Δn

= 300 mA ..............................................630 A

Δn

= 100 mA ............................................630 A

Δn

= 300 mA ..........................................1000 A

Δn

Operating uncertainty ...................................................±17.5 %

Relative uncertainty ................................................... 0…-35 %

Outputs

Outputs .....................................................2 changeover contacts

Operating principle .................... N/C operation or N/O operation

Switching outputs (K1, K2) .........................................250 V, 5 A

Switching capacity .............................................. 1500 VA/144 W

Contact data acc. to IEC 60947-5-1

Rated operational voltage AC.................................. 250 V/250 V

Utilisation category ................................................ AC-13/AC-14

Rated operational current AC ..........................................5 A/3 A

Rated operational voltage DC ............................... 220/110/24 V

Utilisation category ..............................................................DC12

Rated operational current DC .....................................0.1/0.2/1 A

Minimum current ............................................... 10 mA at DC 5 V

Ordering details

Suitable measuring current transformer cores

20 mm

35 mm

60 mm

120 mm

210 mm

System components

max. connected

current transformers

Type Art. No.

Accessories

Type Art. No.

USB to RS-485 interface converter B95012045

Terminal set for RCMB module (spare part) B74043124

Alle Rechte vorbehalten.

Nachdruck und Vervielfältigung

nur mit Genehmigung des Herausgebers.

Bender GmbH & Co. KG

Postfach 1161 • 35301 Grünberg • Deutschland

Londorfer Str. 65 • 35305 Grünberg • Deutschland

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-Mail: info@bender.de • www.bender.de

All rights reserved.

Reprinting and duplicating

only with permission of the publisher.

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Grünberg • Germany

Londorfer Str. 65 • 35305 Grünberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

E-mail: info@bender.de • www.bender.de

RCMB300 series_D00372_01_Q_XXEN/06.2019 / pdf / © Bender GmbH & Co. KG, Germany – Subject to change! The specied standards take into account the edition valid until 06/2019 unless otherwise indicated.

Loading...

Loading...