Page 1

Quick start

PEM330/PEM333

Short instructions

These short instructions do not replace the operating manual. You will find the operating manual on www.bender-de.com

Make sure that the personnel has read this manual and understood all instructions relating to safety.

Intended use

The digital universal measuring device PEM330/PEM333 is suitable

for measuring and displaying electrical parameters of electricity

networks. The device measures current, voltage, energy consumption and power as well as the total harmonic distortion for assessment of the voltage and current quality.

The accuracy of the active energy metering corresponds to class

0.5 S in compliance with the DIN EN 62053-22 (VDE 0418 Part 3-

22):2003-11.

Scope of delivery Safety instruction

● one PEM330 or PEM333

● important safety instructions for Bender Products

● these short instructions

● one sealing frame "IP54"

Danger of electric shock!

Follow the basic safety rules when working with electricity.

Consider the data on the rated voltage and supply voltage as

specified in the technical data!

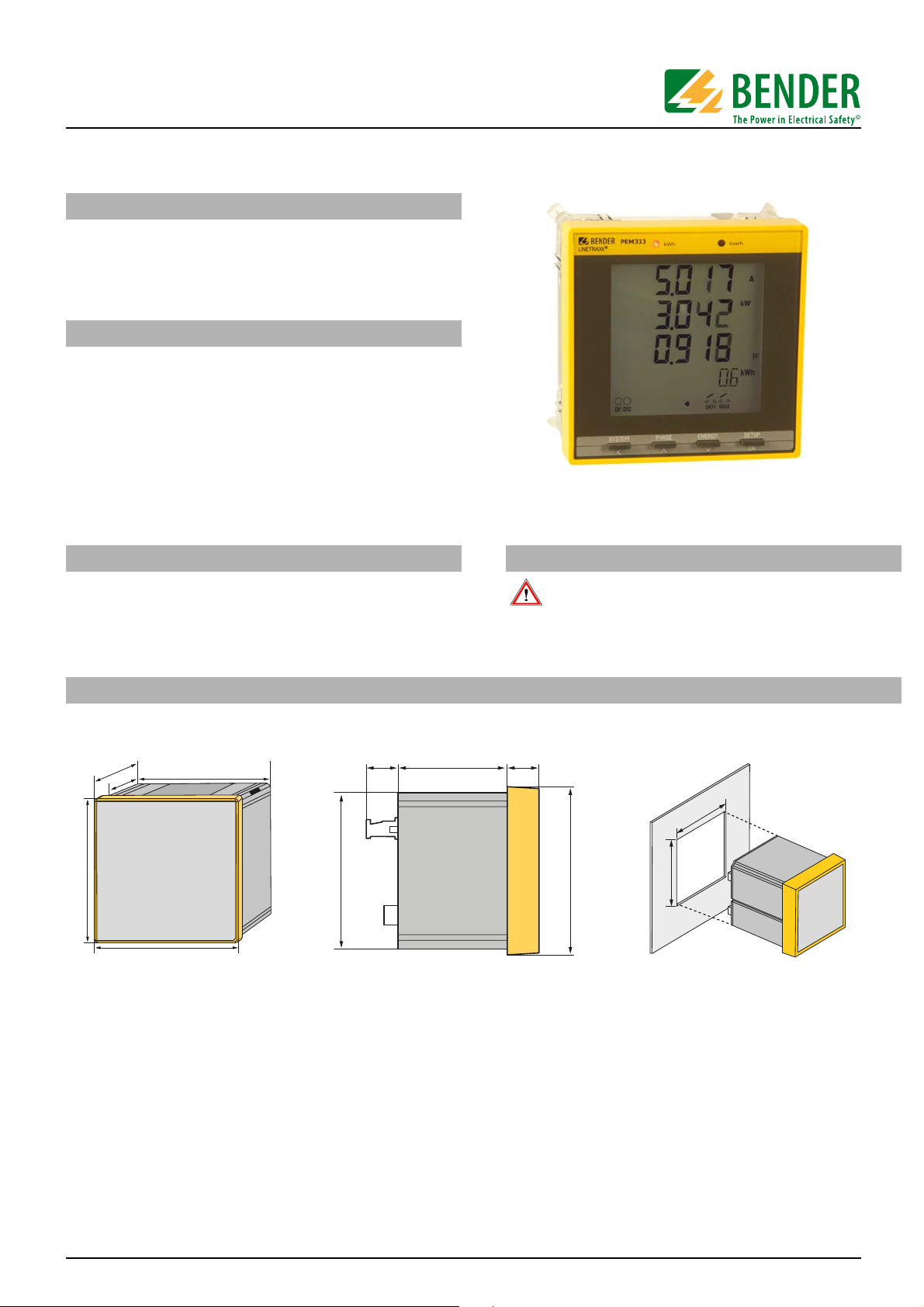

Installing the device

Front panel mounting (front view, side view, panel cut-out)

80

62

96

91

96

A front panel cutout of 92 mm x 92 mm is required for the device.

1. Fit the device through the cut-out in the front panel.

2. Put the 4 transparent mounting brackets from behind on the edges of the device.

3. Push the clips tightly against the panel to secure the device.

4. Check the device to ensure that it is firmly installed in the front panel.

18 1862

9691

92

92

PEM330-333_D00004_00_Q_XXEN/03.2013

1

Page 2

Quick start PEM330/PEM333

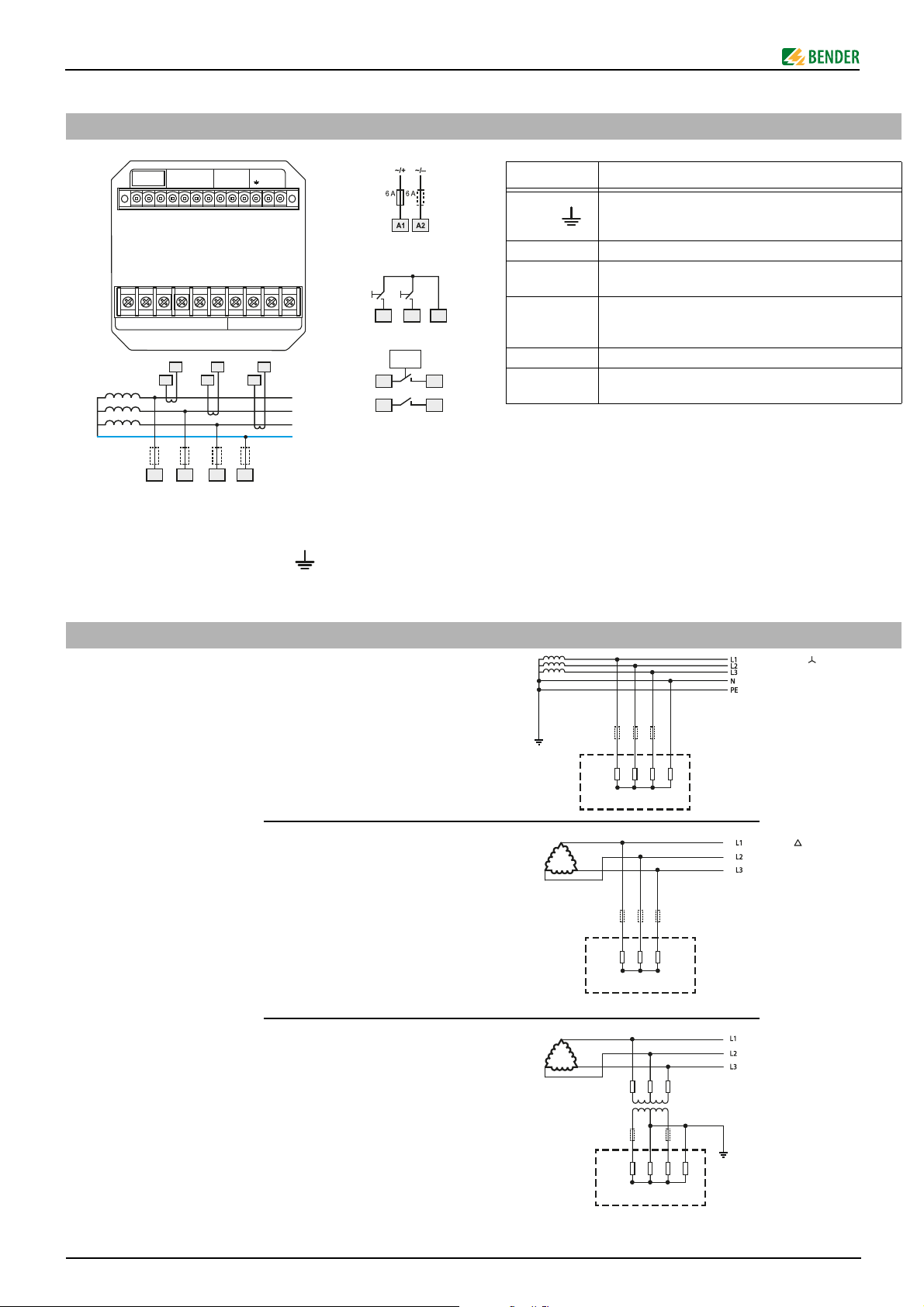

Terminal Description

A1, A2,

Supply voltage. Power protection by a 6 A fuse, quick response. If being supplied from an IT system, both lines

have to be protected by a fuse.

DI1, DI2, DIC Digital inputs (PEM333 only)

DO13, DO14,

DO23, DO24

Digital outputs (N/O contacts) (PEM333 only)

I11, I12,

I21, I22,

I31, I32

Connection to the system to be monitored

D+, D-, SH Connection RS-485 bus (PEM333 only)

L1, L2, L3, N

Measuring voltage inputs: The measuring leads should

be protected with appropriate fuses.

V

Connection of the device

Wiring diagram

D-SH

DO

13

DO14DO

23

24 DI1 DI2

DIC

P1(RS-485) DO

D+

• l11 l12 l22 l32 L1 L2 N• l21 • l31

A1/

A2/

+

-

U

S

DI

L3

DI1 DI2 DIC

I12

I11

L1

I22

I21

L2L2L3L3N

I32

I31

L1

N

DO

DO13 DO14

DO23 DO24

Connection

1. The connecting terminals are located on the rear. Connect

the PEM330/PEM333 to the supply voltage (terminals A1 and

A2 resp. +/-). Connect terminal " " to the protective conductor.

Connection diagram voltage inputs

Three-phase 4-wire system (TN, TT, IT systems)

The PEM can be used in three-phase 4-wire systems, independent of

the type of distribution system (TN, TT, IT system).

2. Power protection by a 6 A fuse, quick response. If being supplied from an IT system, both lines have to be protected by a

fuse.

3. Connection to the RS-485-Bus is made via the terminals D+,

D- and SH. Up to 32 devices can be connected to the bus. The

maximum cable length for the bus connection of all devices

is 1200 m.

AC 400 V / 230 V

PEM

L1L2L3

R

i

N

Three-phase 3-wire system

The PEM can be used in three-phase 3-wire systems.

The line-to-line voltage must not exceed AC 400 V.

Connection via voltage transformers

The coupling via measuring voltage transformers allows the use of

a measuring device in medium and high voltage systems. The transformation ratio in PEM330/PEM333 can be adjusted (1…2200).

2

AC 400 V

L1L2L3

R

i

PEM

LV / MV / H

PEM

L1L2L3

R

i

N

PEM330-333_D00004_00_Q_XXEN/03.2013

Page 3

Commissioning

Check proper connection

During installation and connection, abide by the relevant standards

and regulations and follow the operating manuals for the device.

Before switching on

1. Before switching on think carefully about these questions:

2. Does the connected supply voltage US correspond to the

nameplates information?

3. Is the nominal system voltage of the measuring current

transformer not exceeded?

4. Does the measuring current transformer's maximum current

correspond to the nameplate information of the connected

device?

Getting to know the operating elements

Quick start PEM330/PEM333

Switching on

After switching on, proceed as follows:

1. Connect the supply voltage.

2. Set the bus address/IP address.

3. Set the CT transformer ratio (for each channel).

4. Change the measuring current transformer's counting direction, if required.

5. Set the nominal voltage.

6. Select wye connection or delta connection.

Legend

LED "kWh" and LED "kvarh": Pulse output

"SYSTEM" button: Display mean value and total value (current, vol-

tage); in the menu: in case of numerical values: move the cursor

one position to the left

"PHASE" button: Display line-conductor related measured quanti-

ties; in the menu: go up one entry;in case of numerical values: increasing the value

"ENERGY" button: Display measured values: Active and reactive

energy import/active and reactive energy export (line 4); in

the menu: move down one entry; in case of numerical values: reduce the value

"SETUP" button: Press > 3 s: switching between setup menu and

standard display; in the menu: selection of the parameter to

be edited; confirm entry

Data display

"SYSTEM" button

Column

left

LL V

Ln V

I

4

U

I

D

M

D

D

M

D

Column

right

First

line

A

WPFØ I

Ø U

kvar

Hz

kW

kvar

kVA

A

kW

A I4

%

%

A

A

A

kW

kvar

kVA

LL

P

ges

Wye connection:

Ø U

LN

Delta connection:

Ø U

LL

Unbalance UUnbalance

Demand I

Demand P Demand Q Demand S

Second

line

P

ges

Q

ges

Q

ges

Ø I

I

Demand I2Demand I

1

Power

factor λ

F

S

ges

P

ges

Third

line

Button "ENERGY"

Parameters in the fourth line:

Column left Column right Value

kWh Active energy import

-- kWh Active energy export

kvarh Reactive energy import

-- kvarh Reactive energy export

S Apparent energy

3

PEM330-333_D00004_00_Q_XXEN/03.2013

3

Page 4

Quick start PEM330/PEM333

"PHASE" button

Column

left

Ln

Ln

Ln

LL

LL

LL

D

U

U

P

F

K

F

Column

First line Second line Third line

right

A

AAI1 I2 I3

V

V

V

*

U

L1

V

U

V

L1L2

V

kW

kW

kW

var

var

var

kVA

kVA

kVA

PF

PF

PF

PF

PF

PF

*

P

L1

*

Q

L1

*

S

L1

*

λ

L1

Displacement

factor

*

cos (φ)

L1

%

THD U

%

%

t

%

I

%

%

t

L1

THD I

1

k-factor I

1

Phase angle

U

L1

I

Phase angle I

*

U

L2

U

L2L3

*

P

L2

*

Q

L2

*

S

L2

*

λ

L2

Displacement

factor

*

cos (φ)

L2

THD U

L2

THD I

2

k-factor I

2

Phase angle

U

L2

Phase angle I2Phase angle I

1

*

U

L3

U

L3L1

*

P

L3

*

Q

L3

*

S

L3

*

λ

L3

Displacement

factor

cos (φ)

THD U

THD I

3

k-factor I

Phase angle

U

L3

Note:

* In "delta connection" mode the display shows "– ".

"SETUP" button

Press the "SETUP" button for more than 3 s to access the setup

mode.

Press the "SETUP" button again to return to the default display

screen.

To be able to change parameters, you must first enter

the password. (factory setting: 0)

The following diagram will help you to familiarise yourself with

the menu:

Serial number of device

info INFO

set backlight time out BLTO SET

choose CT direction CT REV

* set DO triggered mode DO CTRL

clear SOE CLR SOE

*

L3

L3

3

3

clear peak demand CLR DMD

clear energy CLR ENGY

set energy pulse constant EN CONST

enable energy pulse EN PULSE

set demand DMD SET

set energy values SET ENGY

set clock CLK

set date DATE

* set conguration parity bit CONFIG

* set baud rate BAUD

* set address for measuring device ID

choose kVA calcuation method KVA SET

choose power factor convention PF SET

select current transformer ratio CT

select transformer ratio for the voltage transformer PT

set wiring mode TYPE

change password SET PASS

enter password PASSWORD

OK

OK

OK

OK

OK

OK

Date of software update UPDATE

Protocol version PRO VER

Software Version SW-VER

CT polarity I3 REV

set I

3

CT polarity I2 REV

set I

2

CT polarity I1 REV

set I

1

set DO2 control mode DO2

set DO1 control mode DO1

set no. of sliding windows NUM

set demand period PERIOD

set apparent energy kVAh

set reactive energy export -kvarh

set reactive energy import kvarh

set active energy export -kWh

set active energy import kWh

enter new password NEW PASS

OK

PROGRAMMING

Setup menu

OK

* PEM333 only

Button

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

D0000400QXXEN

© Bender GmbH & Co. KG

Bender GmbH & Co. KG Tel.: +49 6401 807-0 E-Mail: info@bender-de.com

Londorfer Str. 65

Postfach 1161

4

• 35305 Gruenberg • Germany Fax: +49 6401 807-259 Web: http://www.bender-de.com

• 35301 Gruenberg • Germany

PEM330-333_D00004_00_Q_XXEN/03.2013

Loading...

Loading...