Page 1

T M

Document NAE2028450 • 11.2012 • © Bender Inc. • Page 1/1 • Side 1/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / medical@bender.org • Canada: 800.243.2438 / 905.602.9990 / info@bender-ca.com • www.bender.org

MK2000CBM

Installation Bulletin / Reference Guide

This document is intended as a reference guide to installing and setting an MK2000CBM series remote

indicator. This document includes installation instructions and typical front plate display indications

of the device. For complete details, including installation, setup, settings, and troubleshooting, refer to

the LIM2010 user manual, document NAE2025010.

Only qualied maintenance personnel shall operate or service this equipment. These instructions

should not be viewed as sucient for those who are not otherwise qualied to operate or service

this equipment. This document is intended to provide accurate information only. No responsibility

is assumed by BENDER for any consequences arising from use of this document. This device series is

intended for use only with the BENDER LIM2010 Line Isolation Monitor.

Installation

Mounting

Two-gang plates provide four holes (Two at the top, two at the bottom) for screw mounting.

Use the provided screws for mounting. Refer to gure 1 for dimensions.

Figure 1 - Two-gang wall plate dimensions in inches (mm)

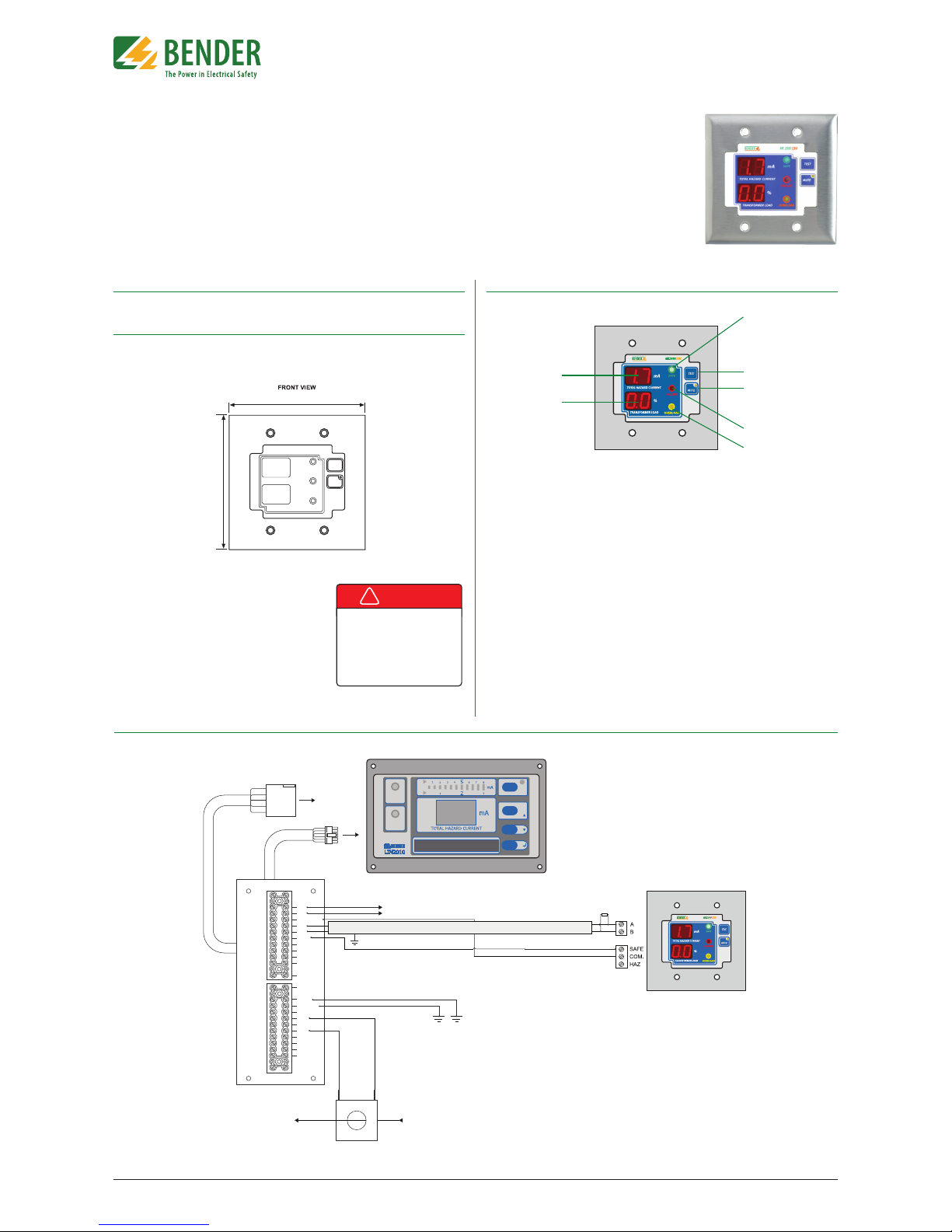

Front Panel Display

1. Green “SAFE” LED. Illuminates when the

connected LIM2010 is in the normal

condition.

2. Yellow “HAZARD” LED. Illuminates

when the connected LIM2010 is in the

alarm condition.

3. Yellow “OVERLOAD” LED. Illuminates

when the connected LIM2010’s transformer overload alarm is active.

4. TEST button. Initiates a self-test of the

connected LIM2010.

5. MUTE button with amber LED. Mutes

the audible alarm when in the alarm

condition. The amber LED indicates that

the audible alarm has been muted.

6. THC Digital Display. Shows the Total

Hazard Current in real-time.

7. Overload Digital Display. Shows the

transformer overload percentage in real-time.

1

4

5

2

3

6

7

Figure 3 - MK2000CBM diagram

Figure 2: Wiring Diagram, MK2000CBM

STW3 / STW4

CP-LIM2010

Connector Plate

L1 from

transformer

secondary

L1 to

load center

To load center

RS-485 cable: twisted, shielded pair

MK2000CBM

120 Ω

Termination

Resistor

SAFE

HAZARD

MUTE

ESC

TEST

RESET

MENU

LIM2010

To panel

ground bus

L1

L2

12VDC CM

A

B

RI1

K1/NC

K1/COM

K1/NO

SAFE

HAZARD

RI2

LIMGND

TEST

1S1

Z1/M+

1S2

Z2/MK2/COM

K2/NC

K2/NO

GND2

4.6“ (116.8)

4.55“ (115.6)

Wiring

MK2000CBM series remotes connect to a connector

plate assembly utilizing a two-wire RS-485 connection.

Ensure that the LIM2010 and corresponding connector

plate have already been installed.

Refer to gure 2 below for wiring diagram. The

MK2000CBM may only be used with type LIM2010 line

isolation monitor.

!

DANGER

• Disconnect all power before servicing.

• Reference NFPA 99 / CSA Z32 for

Installation Standard.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

Applicable Devices

This document applies to MK2000CBM remote indicators only.

Page 2

T M

Document NAE2028450 • 11.2012 • © Bender Inc. • Page 1/1 • Side 2/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / medical@bender.org • Canada: 800.243.2438 / 905.602.9990 / info@bender-ca.com • www.bender.org

MK2000CBM

Installation Bulletin / Reference Guide

Connecting Multiple Remotes to a Single LIM2010

Up to two (2) MK2000CBM remotes may be connected to a single LIM2010. MK2000CBM series

remotes utilize a special RS-485 protocol for communication. Each remote must be assigned

a unique bus address for proper operation. Follow the procedure below to change the address for each remote indicator.

NOTE: The connected LIM2010 will be assigned address 1. A single connected MK2000CBM

will be assigned address 2. This is the factory default and will not require the below procedure.

An additionally connected remote must be assigned address 3 and will require the following

procedure.

Step 2: Changing the Address of the MK2000CBM

Follow the below procedure for changing the communication address of the MK2000CBM.

Step 1: Wiring Modifications

All remotes and LIM2010 are wired in series with each other via each device’s “A” and “B” terminals. ONLY devices at the beginning and the end of the chain require the termination resistor.

For the LIM2010, this resistor is activated via a switch on the device. For MK2000CBM remotes,

a 120 Ω resistor must be wired across the remote’s “A” and “B” terminals. Refer to Figure 4 for a

sample layout.

1) Hold the TEST and MUTE buttons simultaneously for at

least four (4) seconds. “SP” will display on both screens.

2) Push the TEST button until “Ad” is displayed in the top

screen, and two numbers (factory default “02”) is displayed

in the bottom screen. This number is the communication

address of the MK2000CBM remote.

3) Press the MUTE button. Press the TEST button until the

desired address is displayed on the screen. Press the MUTE

button to conrm this value.

4) Press the TEST button. “Ar” will display on the top screen,

and two numbers (factory default “01”) will display on

the bottom screen. This is the address of the connected

LIM2010 device. In most applications, this value will not

need to be changed. If so, skip to step 5. Otherwise, press

the MUTE button. Press the TEST button until the desired

LIM2010 address appears, and press MUTE again to conrm this value.

5) Cycle power to the MK2000CBM to nish.

Technical Data

Operating voltage 12V DC or 12V AC

Max. current 100 mA

Operation class continuous operation

Ambient temperature

when operating 0º C to +50ºC

when stored -25º C to +70º C

Connection screw terminal block

Conductor size AWG 30…12

Tightening torque 5…7 lb-in.

Mounting by screws

Weight 150 g

Figure 4 - Example communication bus layout

Loading...

Loading...