Bender MEDICS UMC107E-25, MEDICS UMC107E-40, MEDICS UMC107E-65, MEDICS UMC107E-80 Operating Manual

Page 1

Operating Manual

Power in electrical safety

MEDICS® UMC107E-..

Two-pole

changeover and monitoring modules

for medical locations

TGH1322en/06.2009

Page 2

Dipl.-Ing. W. Bender GmbH & Co.KG

Londorfer Str. 65 • 35305 Grünberg • Germany

Postfach 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-mail: info@bender-de.com

Web: http://www.bender-de.com

© Dipl.-Ing. W. Bender GmbH & Co.KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Page 3

Table of Contents

1. How to use this operating manual effectively ................................................... 5

1.1 How to use this manual ......................................................................................................... 5

1.2 Explanations of symbols and notes ................................................................................... 5

2. Safety instructions .................................................................................................. 7

2.1 Intended use .............................................................................................................................. 7

2.2 Skilled persons .......................................................................................................................... 7

2.3 Device-specific safety information .................................................................................... 8

2.4 General safety instructions ................................................................................................... 8

2.5 Delivery conditions, guarantee, warranty and liability .............................................. 8

3. System description ................................................................................................. 9

3.1 MEDICS® ...................................................................................................................................... 9

3.2 UMC107E.. features .............................................................................................................. 10

3.3 Functionality UMC107E-.. ................................................................................................... 11

3.3.1 The UMC107E-... changeover and monitoring module .......................................... 11

3.3.2 IT system monitoring ........................................................................................................... 11

3.3.3 Monitoring the device functions ..................................................................................... 12

3.3.4 Power supply .......................................................................................................................... 12

3.4 System components ............................................................................................................12

3.5 Front view UMC107E-.. .......................................................................................................13

3.6 UMC107E-.. design plan ...................................................................................................... 14

4. Installation and connection ............................................................................... 15

4.1 Fuses .......................................................................................................................................... 15

4.1.1 Selecting a fuse with only one load ............................................................................... 15

4.1.2 Selecting a fuse with several loads ................................................................................. 16

4.2 Changeover and monitoring module ........................................................................... 17

4.2.1 Typical connection ............................................................................................................... 17

4.2.2 Wiring diagram ...................................................................................................................... 18

4.2.3 Circuit diagram ...................................................................................................................... 19

4.3 Instructions for connection ............................................................................................... 20

4.3.1 Temperature sensor ............................................................................................................. 20

4.3.2 Alarm indicator and test combination .......................................................................... 20

TGH1322en/06.2009

3

Page 4

Table of Contents

4.3.3 SCADA system (Supervisory Control And Data Acquisition) ................................. 20

5. Commissioning, settings and testing ............................................................... 21

5.1 Setting and testing according to the checklist ........................................................... 21

5.1.1 Avoiding errors ....................................................................................................................... 21

5.2 Assigning addresses-examples ........................................................................................ 22

6. Trouble shooting .................................................................................................. 23

6.1 PRC487 error messages ....................................................................................................... 23

6.2 Fuses F1...F11 ........................................................................................................................... 24

7. Periodic verification and service ....................................................................... 25

7.1 Periodic verification .............................................................................................................. 25

7.1.1 Testing the changeover module ...................................................................................... 26

7.2 Service ........................................................................................................................................ 26

7.3 Maintenance ............................................................................................................................ 26

8. Data ......................................................................................................................... 27

8.1 TÜV-test report ....................................................................................................................... 27

8.2 Standards .................................................................................................................................. 28

8.3 Manufacturer's certificate ...................................................................................................28

8.4 Technical data ......................................................................................................................... 28

8.4.1 Dimension and weights ......................................................................................................30

8.5 Ordering information ........................................................................................................... 30

9. Manufacturer's certificate, checklist, circuit documentation ..................... 31

4

TGH1322en/06.2009

Page 5

How to use this operating manual effectively

1. How to use this operating manual effectively

1.1 How to use this manual

This operating manual describes how to operate the UMC107E-... changeover and monitoring

module. It is designed for skilled persons working in electrical engineering and electronics;

and in particular for those designing, installing and operating electrical equipment in the

medical sector.

Before using the equipment, please read this operating manual, the supplement entitled "Important safety instructions for Bender Products" and the instruction leaflets supplied with the

individual system components. This document must be kept in an easily accessible location

near to the equipment.

Should you have any further questions, please contact our Technical Sales Department. We

are also happy to provide on-site service. Please contact our Service Department for more

information.

In this manual, the two redundant supplies for the power supply will be designated "preferred supply" or "line 1" and "second supply" or "line 2". Devices with displays use the terms

"line 1" and "line 2" in the text they indicate.

This manual has been compiled with great care. Nevertheless errors and omissions cannot

be entirely excluded. The Bender Group cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this operating manual.

1.2 Explanations of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documentation:

This symbol indicates an immediate risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions

will result in death, severe bodily injury or substantial damage to property.

Danger!

This symbol indicates a potential risk to life and limb.

Failure to observe these warnings and take appropriate precautions may result

in death, severe bodily injury or substantial damage to property.

Warning

This symbol indicates a potentially dangerous situation.

Failure to observe the associated instructions and take appropriate precautions

may result in minor bodily injury or damage to property.

Caution

TGH1322en/06.2009

5

Page 6

How to use this operating manual effectively

This symbol indicates important information about the correct use of the equipment purchased.

Failure to observe the associated instructions can result in equipment malfunctioning or cause problems in the environment in which it is being used.

This symbol indicates tips for using the equipment and particularly useful information. This type of information will help you to optimise your use of the equipment.

6

TGH1322en/06.2009

Page 7

Safety instructions

2. Safety instructions

2.1 Intended use

The UMC107E-.. changeover and monitoring module is a two-pole, automatic changeover

module for distribution systems used in medical locations group 1 and 2, in accordance with

IEC 60364-7 710: 2002-11, section 710.313.1 and DIN VDE 0100-710 (VDE 0100 Part

710):2002-11, section 710.537.6.2 extended by the IT system monitoring functions in accordance with IEC 60364-7-710:2002-11, section 710.413.1.5 and DIN VDE 0100-710 (VDE 0100

part 710):2002-11, section 710.531.3.1.

It is used in medical locations and monitors the power supply using two independent singlephase supply sources and the AC IT system.

The UMC107E-.. module

z detects whether the preferred supply has failed and automatically performs a two-pole

changeover to the second supply source.

z monitors the insulation resistance in the downstream IT system.

z monitors the load current and temperature of isolating transformers for the IT system.

Customised parameter settings must be made on the equipment for the purpose of adapting

it to local equipment and operating conditions, in order to meet the requirements of applicable standards.

The equipment can also be used in non-medical areas provided that the intended application

has been cleared with Bender in advance.

Please note the limits of the area of application indicated in the technical data.

Use deviating from or beyond the scope of this is considered non-compliant.

Intended use also implies:

z Device-specific settings in accordance with IEC 60364-7-710:2002-11, sections 556.5.2.2, 556.7,

556.8 and DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.537.6.2 (changeover

periods) and for the IT system.

z The observation of all information in the operating manual.

z Compliance with test intervals.

2.2 Skilled persons

Only electrically skilled persons may work on Bender products. Skilled means, persons who

are familiar with the assembly, commissioning and operation of the equipment and have undergone appropriate training. Such persons must have read this manual and understood all

instructions relating to safety.

TGH1322en/06.2009

7

Page 8

Safety instructions

2.3 Device-specific safety information

Device-specific settings are required in order to adapt the MEDICS® module to

the existing equipment. To this end, refer to the instructions in chapter "5. Commissioning, settings and testing", page 21ff.

Warning

2.4 General safety instructions

Bender equipment is designed and built in accordance with the state of the art and accepted

rules in respect of technical safety. However, the use of such devices may introduce risks to

the life and limb of the user or third parties and/or result in damage to Bender equipment

or other property.

z Only use Bender equipment:

–as intended

– in perfect working order

– in compliance with the accident prevention regulations and guidelines applicable in the

location of use

z Rectify any faults that may impair safety immediately.

z Do not make any unauthorised changes and only use replacement parts and optional accesso-

ries purchased from or recommended by the manufacturer of the equipment. Failure to

observe this requirement can result in fire, electric shock and injury.

z Reference plates must always be clearly legible. Replace damaged or illegible plates immedi-

ately.

z Make sure that the dimensioning of the UPS (special safety power supply source), the generator

system and the whole wiring is adequate. Observe the applicable national and international

standards within this context. Only in this way, selective operation of safety devices can be

achieved and a high degree of safety in case of overload and short circuit can be ensured.

2. 1 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender shall apply.

Conditions of sale and delivery can be obtained from Bender in printed and electronic format.

8

TGH1322en/06.2009

Page 9

System description

3. System description

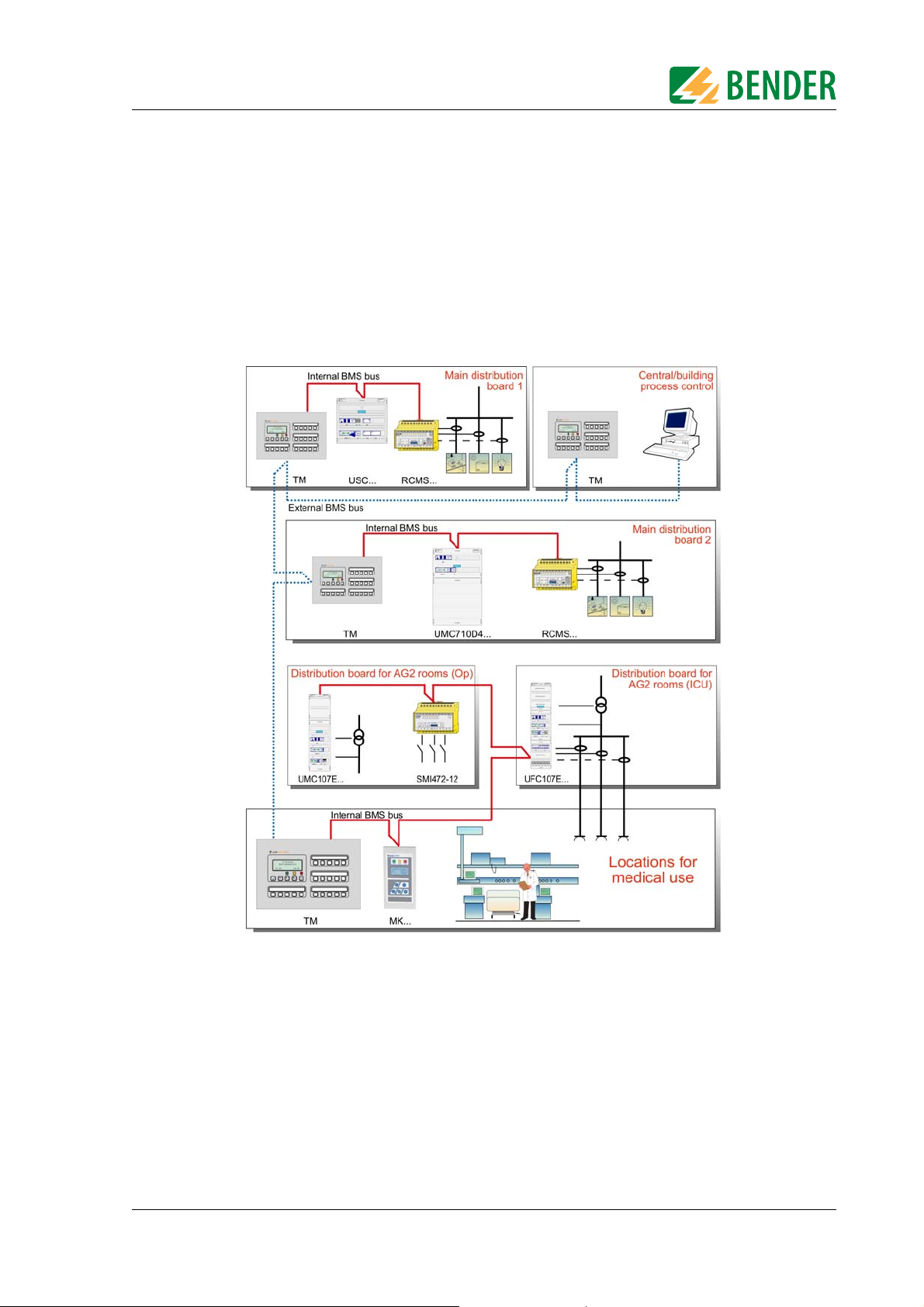

3.1 MEDICS

The UMC107E-.. changeover and monitoring module is a part of the MEDICS® system.

MEDICS

supplies in medical locations.

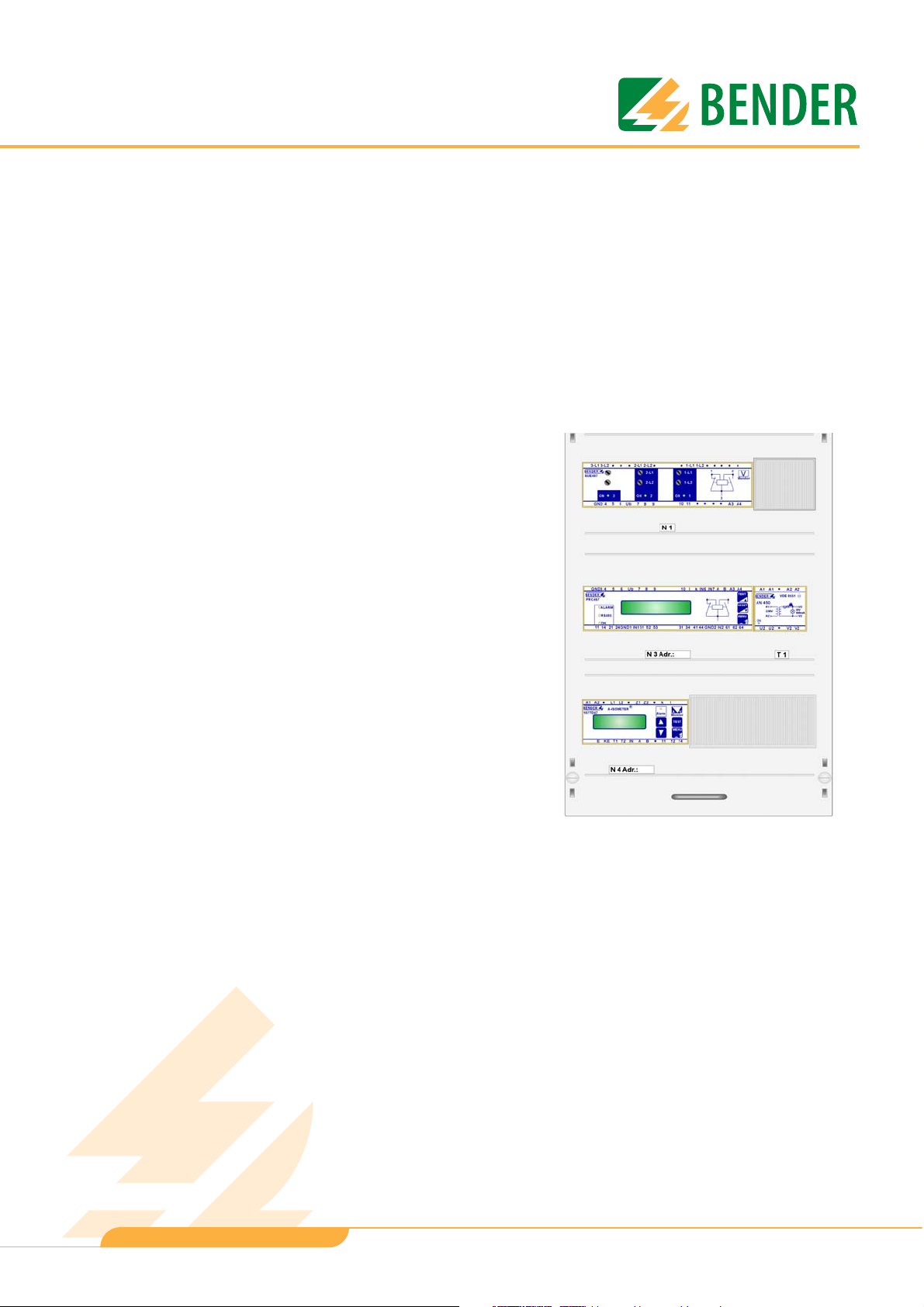

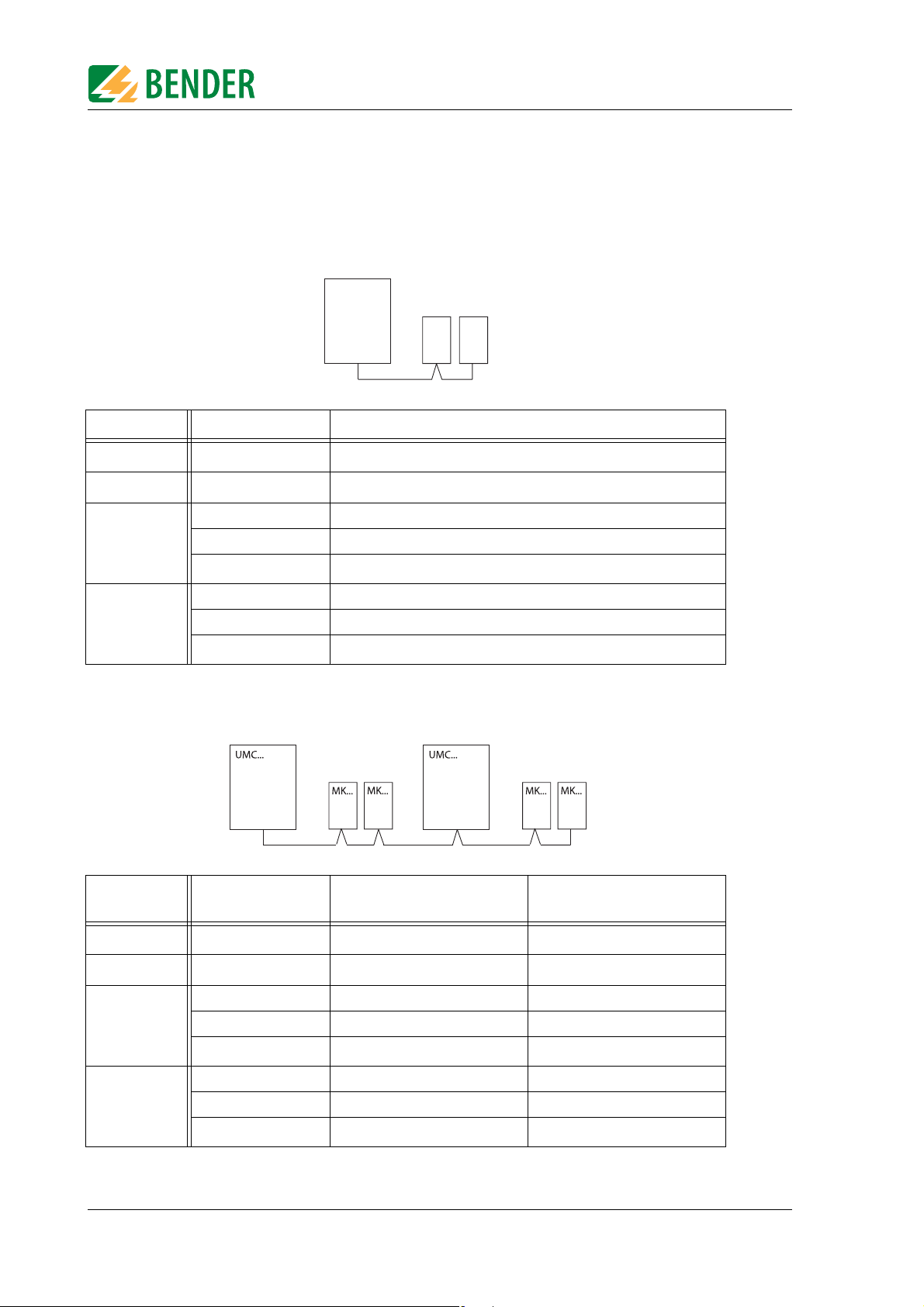

Example of a section of a hospital with the MEDICS®system

®

does not refer to a single product, but rather an intelligent system for safe power

®

Key for example

MK... Alarm indicator and test combination

RCMS... Residual current monitoring system for TN-S systems

SMI472 Signal converter for third-party technical equipment (e.g. med. gases, UPS)

TM Alarm indicator and operator panel

UFC107E... Changeover and monitoring module for IT systems with EDS... insulation fault

UMC107E... Changeover and monitoring module for IT systems

UMC710D... Changeover module for main distribution boards

USC710D... Control module for changeover modules (preferably in main distribution

TGH1322en/06.2009

location system

boards)

9

Page 10

System description

MEDICS® includes:

z AC and 3(N)AC changeover and monitoring modules. Examples of modules in the MEDICS

®

sys-

tem include UMC..., USC..., UFC... and EDS.... insulation fault location systems.

z Display and operating units such as alarm indicator and operator panels or alarm indicator and

test combinations.

z Communication between these components takes place via the BMS bus (two-wire connec-

tion).

z The connection of third-party technical equipment by means of protocol converters (gate-

ways), via digital inputs and relay outputs.

The real strength of MEDICS

®

is to be found in communication between all involved components and the resulting information provided to the user. Readiness for operation is monitored continuously. Operating states, irregularities, faults and equipment failures are

displayed. From the user's point of view, this means high operational reliability.

3.2 UMC107E.. features

The UMC107E-.. changeover and monitoring module has the following features:

z Two-pole changeover with contactors. Both contactors have a mechanical latching.

z Voltage monitoring on the preferred supply (line 1)

z Voltage monitoring on the second supply (line 2)

z Voltage monitoring at the output of the changeover and monitoring module (line 3)

z Monitoring of the switching elements to ensure that they are in the correct switching state and

for wire breaks (connecting wires, contactor coil, coil for latching module)

z Internal functional testing including checking of the changeover times

z Monitoring of the insulation resistance in the IT system

z Monitoring of the IT system transformer load current

z Monitoring of the IT system transformer load temperature

z Monitoring of the A-ISOMETER® 107TD47 connecting wires

z Communication of components with one another via BMS bus

z Communication with remote alarm indicator and test combinations and TM alarm indicator

and operator panels via BMS bus

z Possibility to set the time delay for the changeover in 50 ms increments for adaptation to the

total off-time acc. to DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.537.6.2k

z Can be used in systems in accordance with IEC 60364-7-710:2002-11, sections 556.5.2.2, 556.7

and 556.8 and DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.564.6 with a changeover period = 15 s or = 0.5 s

Warning

10

®

The MEDICS

module is a configured unit and is only certified and tested in this

assembly. Do not make any changes to the components, their password-protected settings or the wiring without consulting Bender first.

In each case you shou ld ma ke th e sett ings that are required for adaptation to the

application case in question and local conditions.

TGH1322en/06.2009

Page 11

System description

3.3 Functionality UMC107E-..

3.3.1 The UMC107E-... changeover and monitoring module

If the preferred supply should fail, the UMC107E-.. ensures safe changeover of the

power supply:

1. In normal condition (fault-free condition), the preferred supply (line 1) is connected via contactor K1 and mechanically latched. This makes it impossible for the IT supply to fail on account of

defective contactor coils, torn lines to the contactor coil, or a failure of the control voltage.

2. If the voltage at the end of the preferred supply falls below the set value or exceeds a value of

115 % x U

response time t(off) has elapsed, K1 is disconnected and, following the set idle time t(K1-2), K2

is connected and latched.

3. On voltage recovery, switching back to the preferred supply source occurs automatically after

the set return transfer time t(on) has elapsed: K2 is disconnected and, following the set idle

time t(K1-2), K1 is connected and latched.

Warning

, the module automatically changes over to the second supply (line 2): Once the set

n

The response time t(off), the idle time t(K1-2) and the return transfer time t(on) of

the UMC107E-.. can be set and must be adjusted according to the requirements

of the specific application case, the short-circuit calculation and the requirements of IEC 60364-7-710:2002-11, sections 556.5.2.2, 556.7 and 556.8 and DIN

VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.537.6 (automatic

changeover modules) (see chapter 5. "Commissioning, settings and testing").

The settings made at the factory ensure a changeover period of t = 0.5 seconds and switching

back within five seconds on voltage recovery on the preferred supply. Therefore, the

UMC107E-.. can also be used in IT systems with a requirement for a changeover period t =

0.5 seconds (IT systems with operating theatre lighting circuits, endoscopic field illumination

in operating theatres, or other essential sources of light, etc.).

If the control device detects a supply line failure or a fault, a message appears in the LC display, the "ALARM" LED lights up, the alarm relay switches, and this alarm is transmitted to

other Bender devices (such as alarm indicator and test combinations) via the BMS bus.

3.3.2 IT system monitoring

Insulation monitoring

The insulation monitoring device measures the insulation resistance in AC IT systems which

may also contain DC circuits. The adaptation to the system leakage capacitances takes place

automatically.

Load current measurement

The load current is measured via the measuring current transformer STW2.

Temperature measurement

The temperature in the transformer winding is measured via PTC thermistors.

Evaluation

If any of the measured values does not fall within the limits, an alarm (common alarm) is

triggered. The "ALARM" LED lights up, the alarm relay switches and a message appears in

the LC display of the insulation monitoring device. This alarm is transmitted to other Bender

devices (such as an alarm indicator and test combination) via the BMS bus.

TGH1322en/06.2009

11

Page 12

System description

3.3.3 Monitoring the device functions

The control circuits are constructed in such a way that even if a particular fault will almost

certainly occur, it cannot cause the power supply at the output of the automatic changeover

and monitoring module to fail. Examples: Failure of the control voltage, operation of a protective device, a short-circuit to exposed-conductive part or an earth fault, and an open circuit.

In addition to this, the module continuously monitors:

z The control circuit that is required for the next changeover process (coil, control contacts, con-

nections)

z Important connecting wires, such as

– the insulation monitoring mains/PE

– measuring current transformer

– temperature sensor

z For alarm indicator and test combinations, and alarm indicator and operator panels, device fail-

ure monitoring can also be programmed via the BMS bus.

Thanks to the redundant hardware design of the changeover module, it is guaranteed to

function safely even if the microcontroller should fail.

3.3.4 Power supply

SUE487 provides the power supply for the PRC487 control device and the AN450 power supply unit, as well as the control voltage for the contactors from line 2, (or from line 1 if line

2 fails). The 107TD47 insulation monitoring device is supplied by the IT system.

The AN450 power supply unit supplies power to a maximum of 3 MK2418 or 2 MK2430

alarm indicator and test combinations.

3.4 System components

In chapter "9. Manufacturer's certificate, checklist, circuit documentation" of this operating

manual, you will find instruction leaflets containing detailed information about the following

system components:

PRC487 Control device for changeover modules

SUE487, SUD487 Voltage relay

A-ISOMETER®107TD47 Insulation monitoring device with transformer

monitoring

BMS bus Bender Measuring Device Interface

AN450 Power supply unit

STW2 Measuring current transformer

12

TGH1322en/06.2009

Page 13

System description

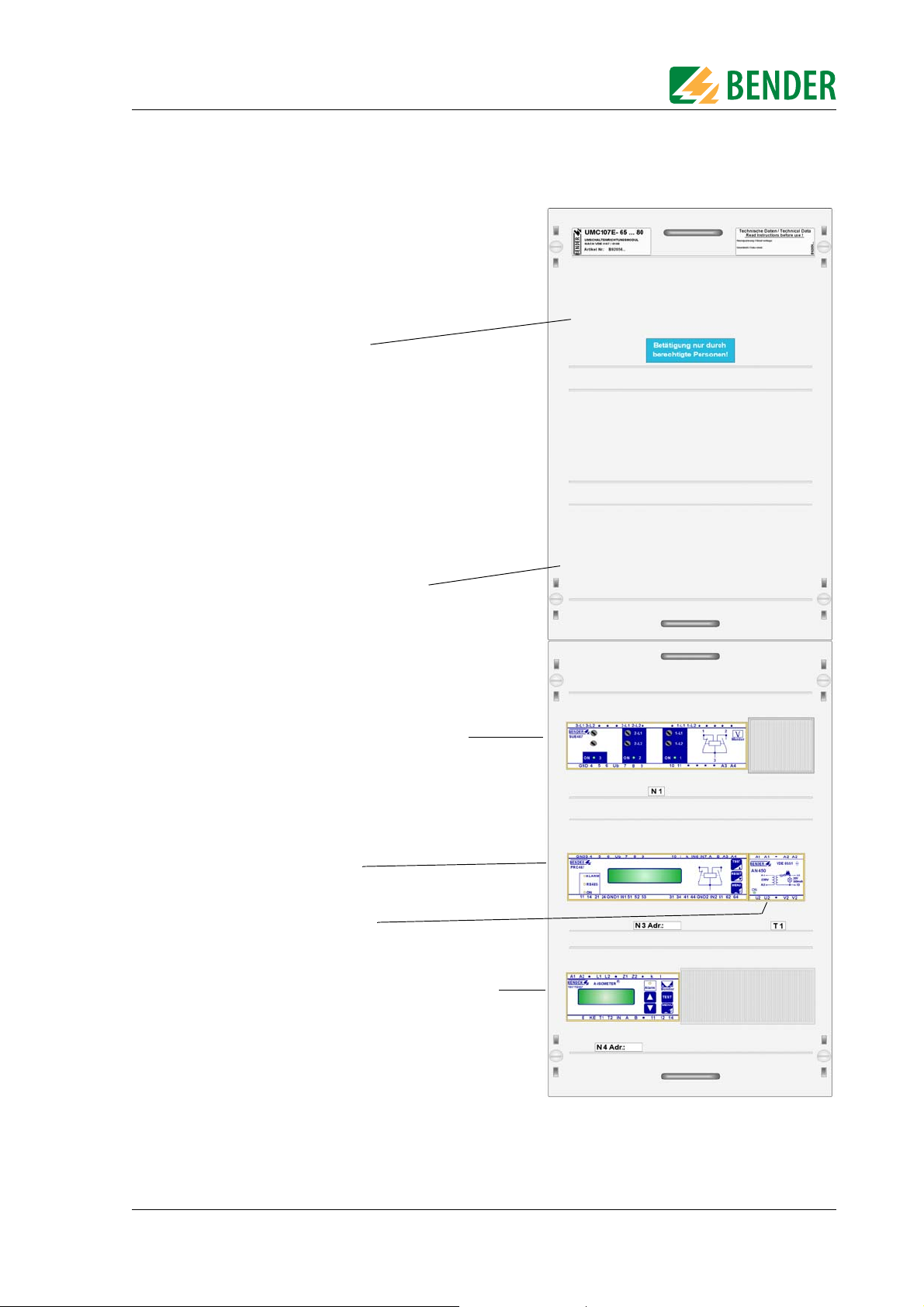

3.5 Front view UMC107E-..

Terminal compartment

Contactor with latching module

SUE487 voltage monitoring device

Control device PRC487

Power supply unit AN450

107TD47 A-ISOMETER® to monitor the insulation resistance, as well as transformer load

and temperature

Example: UMC107E-... front view on a Striebel & John equipment rack.

TGH1322en/06.2009

13

Page 14

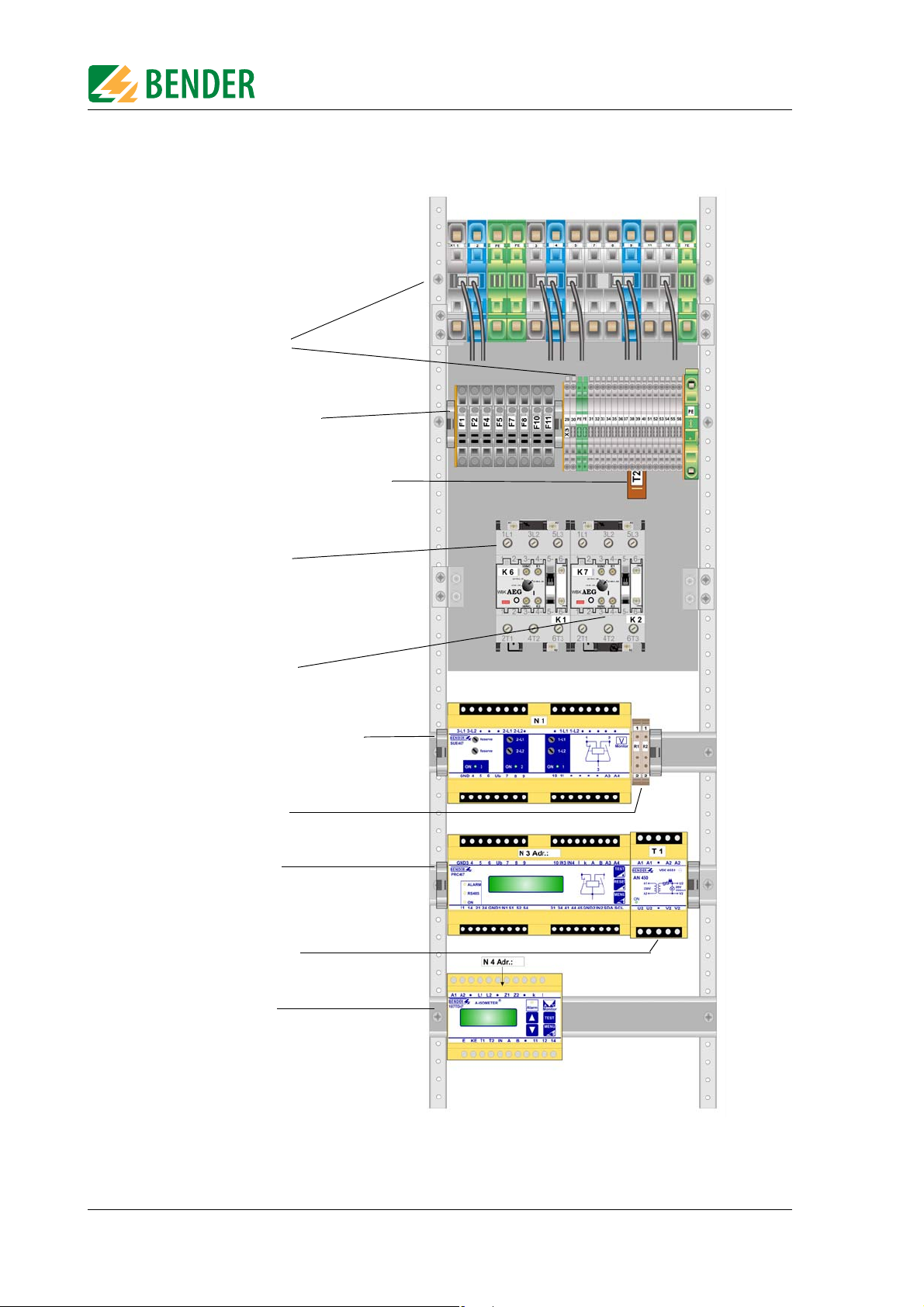

3.6 UMC107E-.. design plan

X1, X2, X3: Terminal strips

F1...F11: Fuses see "chapter 6.2"

T2: STW2 measuring current transformer for

load current measurement

System description

K1: Contactor for line 1 with

K6: latching module

K2: Contactor for line 2 with

K7: latching module

N1: SUE487 voltage monitoring device

R1, R2: Resistors 30 kΩ, 2 W

N3: Control device PRC487

T1: Power supply unit AN450

N4: A-ISOMETER®107TD47

Example: Design plan UMC107E-... on a Striebel & John equipment rack.

14

TGH1322en/06.2009

Page 15

Installation and connection

4. Installation and connection

4.1 Fuses

Please observe the requirements of IEC 60364-7-710:2002-11 and DIN VDE 0100-710 (VDE

0100 Part 710) when selecting fuses for the supply cables and outgoing circuits of the

changeover modules:

z Section: 710.512.1.6.2 (VDE), sections 710.5.3.1, 710.512.1.6 (IEC), Transformers for the IT system:

Where transformers, their primary supply conductor and secondary outgoing line are concerned, overcurrent protective devices are only permitted for short-circuit protection. The

transformer supply cable from the changeover module and the transformer outgoing cable to

the next distribution board section should be laid so that they are short-circuit proof and earthfault proof.

z Section: 710.53.2 (VDE), section 710.413.1 (IEC), Protection of the cable system in Group 2 loca-

tions: The choice of protective devices must ensure that when the anticipated short-circuit current occur, the protective device upstream of a fault will selectively trip the protective devices

that are further upstream.

z Section 710.537.6.2. (VDE), section 710.413.1.1 (IEC), Connecting several load groups down-

stream of a changeover module must not lead to all the load groups failing in the event of a

fault.

As a result, the choice of fuses F should ensure both short-circuit protection for the transformer and selectivity for the overcurrent devices connected downstream in the IT systems.

When selecting fuses, please observe both the maximum permissible values laid down by

the guidelines that apply to the location of use and national and international standards, in

order to ensure that the contactor contacts cannot weld. The considerations presented below

are based on the standard DIN VDE 0100-710 (VDE 0100 Part 710): 2002-11, section

710.537.6.

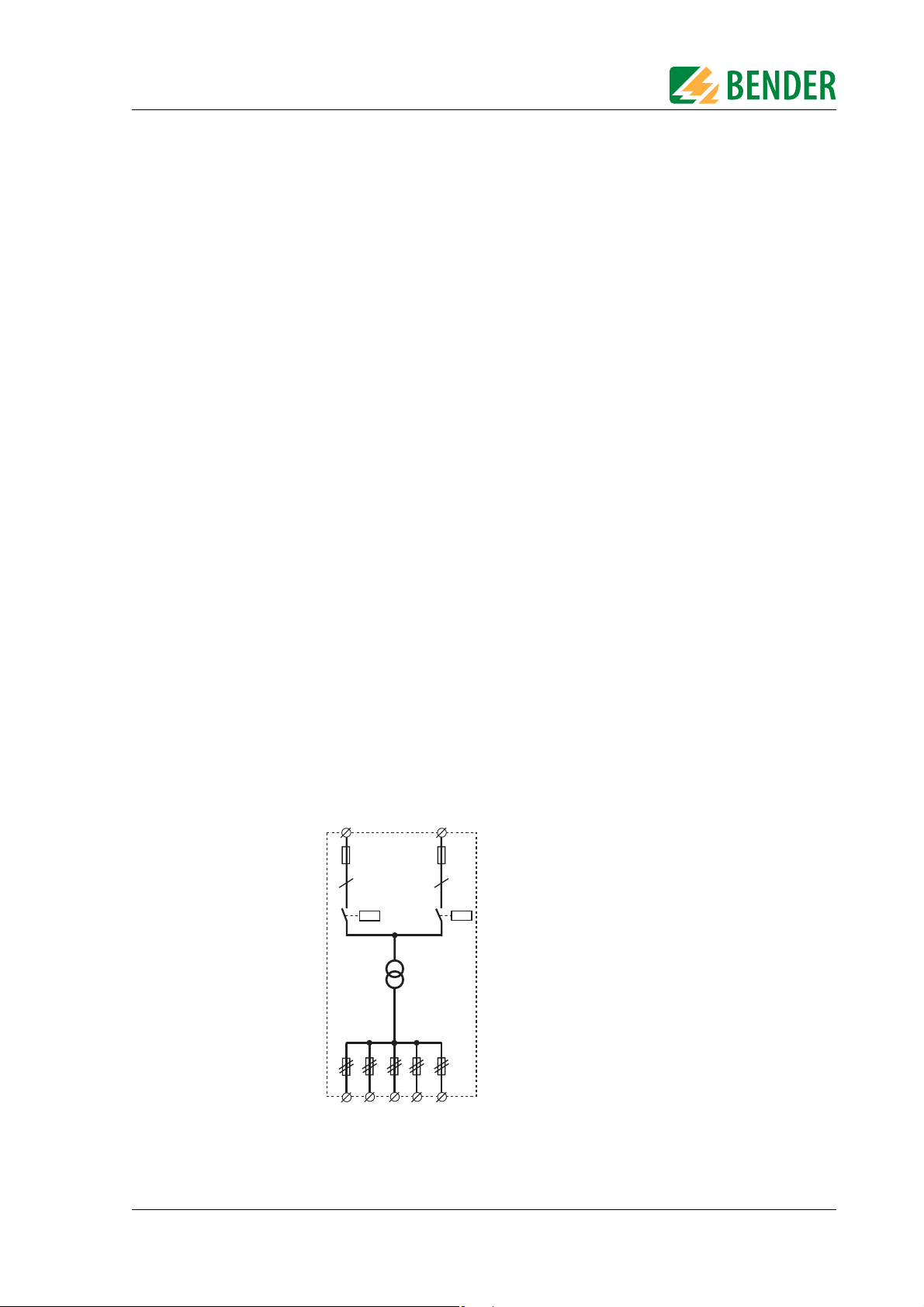

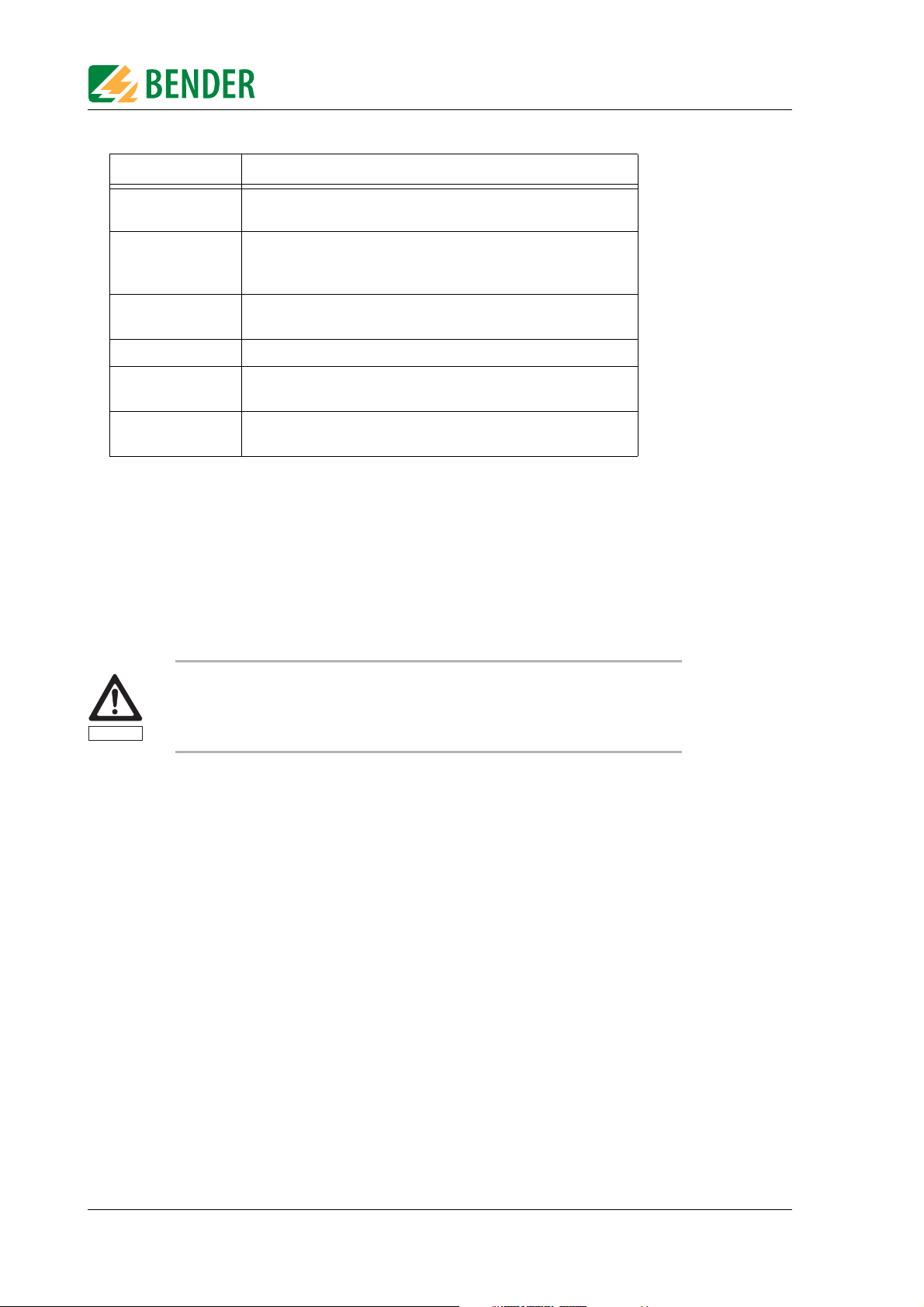

4.1.1 Selecting a fuse with only one load

F1 F2

2

2

Changeover module

Contactors with latching

TGH1322en/06.2009

Circuit breaker

15

Page 16

Installation and connection

The circuit only has one load: the IT system transformer. Taking into consideration the explanation in section 710.537.6 as well as the manufacturer's technical data for the contactor,

the maximum possible fuse (F1 or F2) for the contactor can be calculated as follows:

= Manufacturer's technical data regarding max. fuse x 0.45

I

v

The fuse must match the fuse specified by the manufacturer of the selected IT system transformer.

The rated operational current I

= Manufacturer's technical data for the switching contact with consideration of

I

e

of the changeover module is calculated as follows:

e

AC-3 conditions x 0.45

This rated operational current must be greater than the rated operational current of the IT

system transformer.

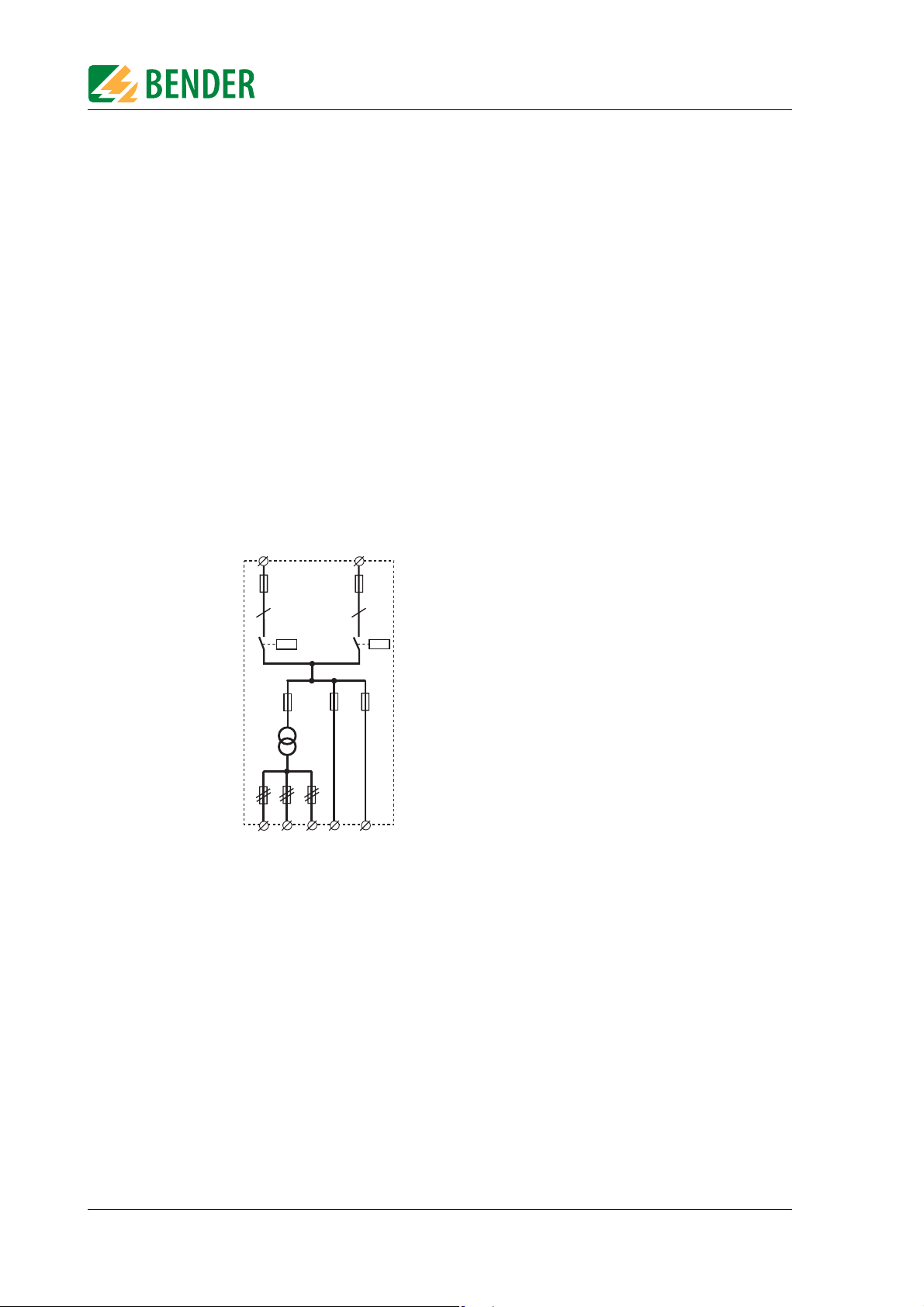

4.1.2 Selecting a fuse with several loads

F1 F2

2

F3 F4

2

Changeover module

Contactors with latching

F5

Circuit breaker

This circuit branches into several load groups. The result is that every fuse of every load

group is moved downstream of the changeover module. Regardless of this, the maximum

possible fuse is calculated in the same way as described above.

The rating of this fuse (F1 or F2) must be coordinated with the rating of fuse F3 (and of

course F4 and F5) so that selective shutdown is ensured. The fuse specified by the manufacturer for the IT system transformer must therefore be at least two stages smaller in rating

than the fuse calculated using the formula above for the changeover module. Of course, the

total nominal current for the changeover module must be calculated from the sum and simultaneity factor of all load groups connected, and the required or minimum rated current calculated according to the formula above.

The values listed in the ordering information apply for the changeover modules.

16

TGH1322en/06.2009

Page 17

Installation and connection

4.2 Changeover and monitoring module

The power supply of Group 2 location is supplied via an isolating transformer. For protection

against indirect contact, one of the following measures is to be used for the transformer:

z Protective insulation according to DIN VDE 0100-410 (VDE 0100 Part 410):2007-06, 413.2 (Use of

a protection class II transformer)

z Protection by non-conductive location according to DIN VDE 0100-410 (VDE 0100 Part

410):2007-06, section 413.3

z Protection by a local, earth-free equipotential bonding according to DIN VDE 0100-410 (VDE

0100 Part 410):2007-06, section 413.4

z Protection by special installation. For this measure, please note the following:

– The protection class I transformer must be installed isolated and must not be connected to

the PE conductor. In Bender's ES710 range of transformers, the fixing angles are isolated

from the transformer core.

– A warning label is to be affixed to the transformer and its cover as follows:

Warning! Accessible parts of the transformer may

be live. You must always verify that there is no

voltage present before touching parts of it.

– The transformer is to be installed behind a cover, which can only be opened using a tool or a

special key. It must only be accessed by skilled persons.

– The shield winding can be connected to the PE conductor. It must be ensured that the con-

necting wire is installed so that it is short-circuit proof and earth-fault proof.

4.2.1 Typical connection

Connect your changeover module to the supply sources as follows:

Preferred supply (line 1) Terminals X1:1 and X1:2

Second supply (line 2) Terminals X1:3 and X1:4

z Connect the primary winding of the transformer to the terminals X1:5 and X1:9 and the second-

ary winding to terminals X1:7 and X1:11. A cross section that conforms to DIN VDE 0100 Part

430 must be selected.

TGH1322en/06.2009

17

Page 18

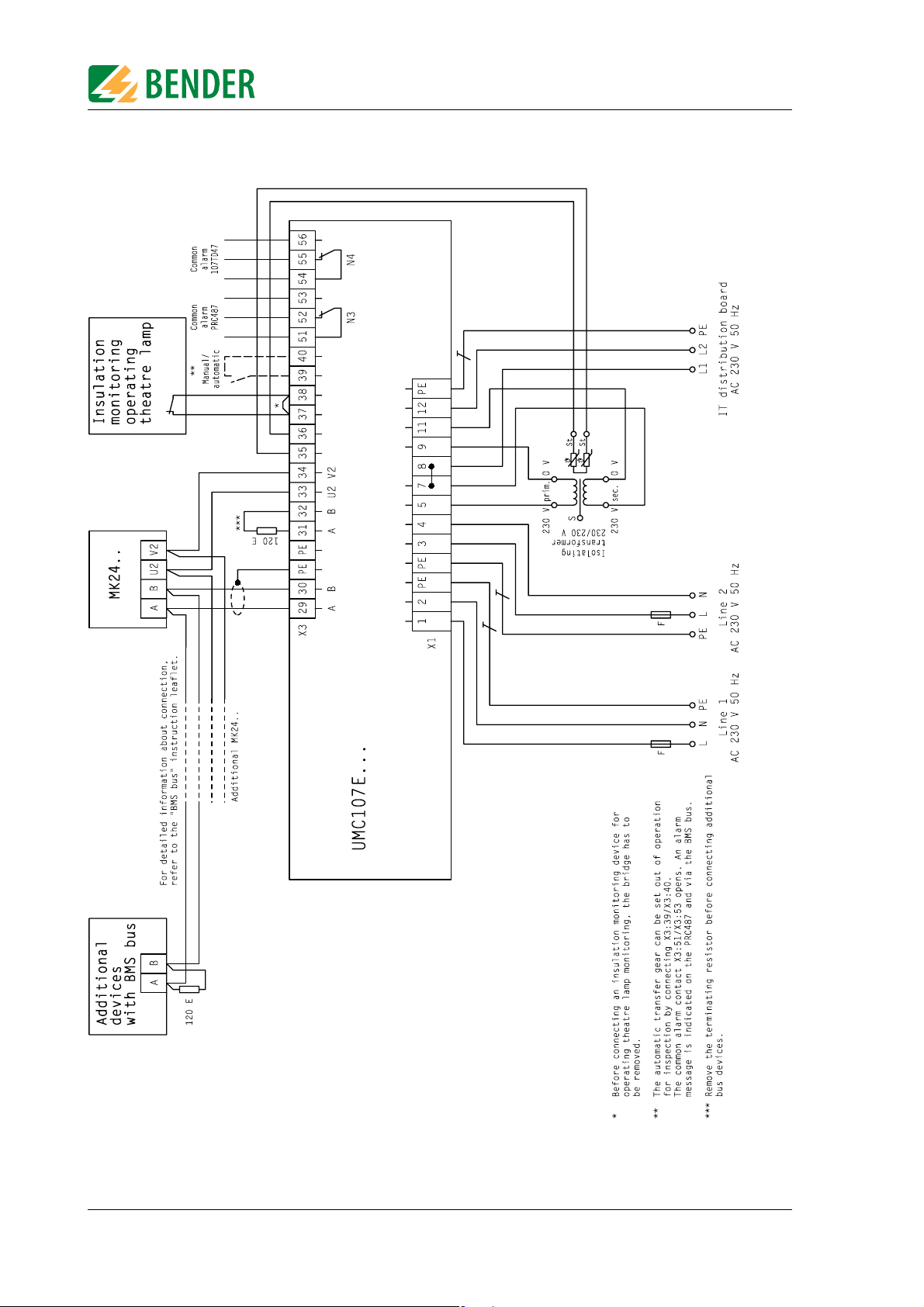

4.2.2 Wiring diagram

Installation and connection

18

Fig. 4.1: Wiring diagram UMC107E-...

TGH1322en/06.2009

Page 19

Installation and connection

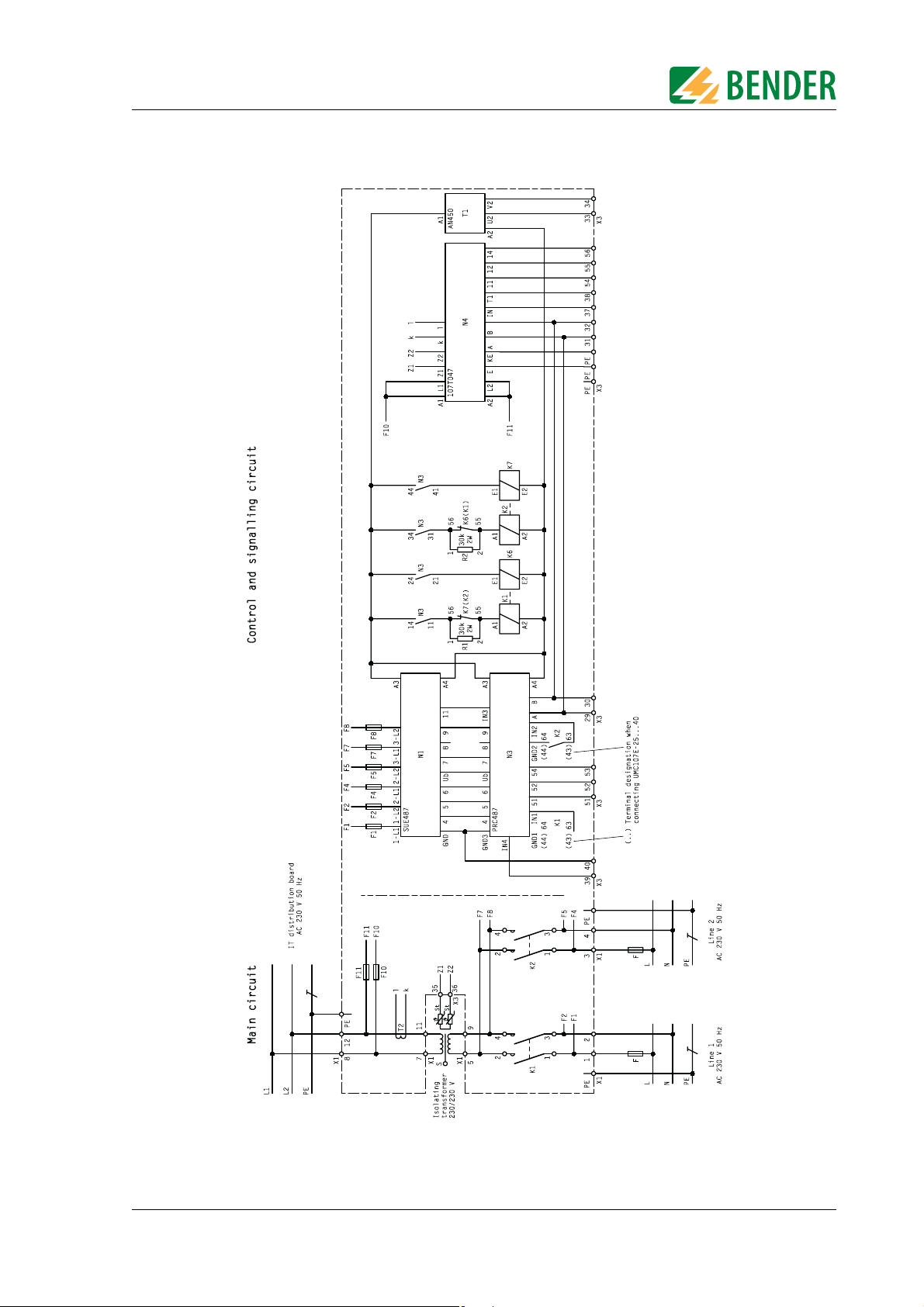

4.2.3 Circuit diagram

TGH1322en/06.2009

Fig. 4.2: Circuit diagram UMC107E-...

19

Page 20

Installation and connection

4.3 Instructions for connection

4.3.1 Temperature sensor

Bender IT system transformers are equipped with the temperature sensors required according to their insulation class. These temperature sensors (maximum of 6 sensors connected in

series) are connected to terminals X3:35 and X3:36.

4.3.2 Alarm indicator and test combination

Ex works, the following pairs of terminals are provided for the connection of BMS bus devices:

X3:29 and X3:30 (A/B)

X3:31 and X3:32 (A/B terminals are terminated with 120 Ω at the factory)

Alarm indicator and test combinations, panels and other Bender-BMS-bus devices can be

connected.

1. A BMS device or an existing BMS bus with several devices is connected to terminals X3:29 and

X3:30:

The last device at the other end of the bus must be terminated with 120 Ω.

Terminals X3:31 and X3:32 remain terminated.

2. An existing BMS bus that has already been terminated on both ends, is disconnected; one

open branch is connected to terminals X3:29 and X3:30, while the other one is connected to

terminals X3:31 and X3:32:

The 120 Ω resistor, provided ex works, must be removed and the open bus branches must be

connected to the specified terminals.

Please read the information on cable routing in the "BMS bus" instruction leaflet.

The AN450 power supply unit can supply power to a maximum of 3 MK2418 or 2 MK2430

alarm indicator and test combinations via the terminals X3:33 and X3:34. In this respect,

please refer to the documentation for the relevant devices. The AN450 is not suitable for supplying power to TM... operator panels.

4.3.3 SCADA system (Supervisory Control And Data Acquisition)

If messages from the UFC107E-.. changeover and monitoring module are to be transmitted

to a SCADA system, you have the following options:

z Protocol converter (gateways)

z OPC server

z Common alarm via the relay outputs of the 107TD47 A-ISOMETER® and the PRC487 control

device

z Conversion between BMS bus and digital inputs and outputs by means of alarm indicator and

operator panels (TM...) or signal converters (SMO480-12, SMO482-12, SMI 472-12).

20

TGH1322en/06.2009

Page 21

Commissioning, settings and testing

5. Commissioning, settings and testing

5.1 Setting and testing according to the checklist

A total changeover time of t ≤ 0.5 s and switching back within five seconds to the preferred

supply on voltage recovery is factory set.

The response time t(off), the idle time t(K1-2) and the return transfer time t(on) of the

UMC107E-.. can be set and must be adjusted in line with the requirements of the specific

application, the short-circuit calculation and the requirements of IEC 60364-7-710:2002-11,

sections 556.5.2.2, 556.7 and 556.8 and DIN VDE 0100-710 (VDE 0100 Part 710):2002-11, section 710.537.6 (automatic changeover modules).

z The total off time permitted to occur (from the point at which the fault occurs until the arc in

the overcurrent protective device is cleared) must be less than the minimum time delay for the

changeover process of the automatic changeover module. Setting: Response time t(off)

z If several changeover modules are connected in series in a power supply system, it is recom-

mended that they be time-graded. Setting: Response time t(off), idle time t(K1-2) and return

transfer time t(on).

z As part of the response delay (to be custom-set), you must, at the very least, take into account

the periods of time when the circuit experiences short interruptions, and the response times of

the short-circuit protective device connected upstream or downstream. Regardless of this, the

idle time for the changeover process corresponding to the place of installation must be considered to prevent switching overvoltages.

Setting: Response time t(off) and idle time t(K1-2).

For this purpose, please consult the changeover time lapse diagram in the instruction leaflet

for the PRC487 control device and make the settings required according to the description.

You will find a checklist in chapter "9. Manufacturer's certificate, checklist, circuit documentation". This list details the factory settings and the system-specific settings for the MEDICS

module. Please carry out all the work outlined in the list and log each test step.

The checklist contains:

z Visual inspection

z Commissioning, settings, factory settings

z Functional test

Keep this checklist with this manual in a location that is close to the MEDICS

®

module.

5.1.1 Avoiding errors

Communication via the BMS bus can only be guaranteed when there is only one

terminating resistor at the beginning and the end of the BMS bus. Additional terminating resistors can lead to malfunctions and therefore must not be used.

Please also note the information in the "BMS bus" instruction leaflet.

®

TGH1322en/06.2009

21

Page 22

Commissioning, settings and testing

5.2 Assigning addresses-examples

Please also note the information in the "BMS bus" instruction leaflet. * The settings for the

alarm addresses marked with an asterisk (*) refer to reciprocal monitoring of MK... alarm indicator and test combinations.

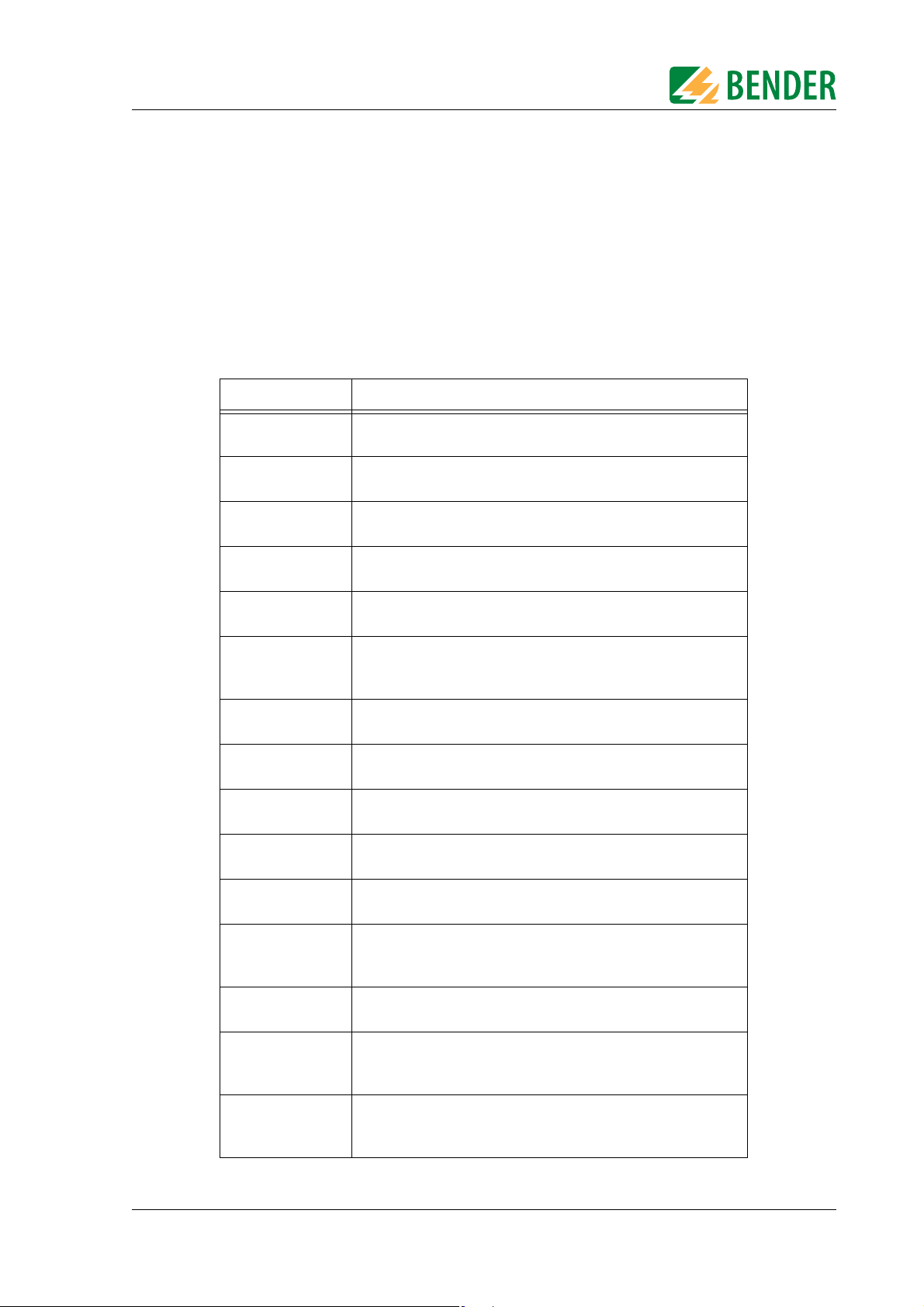

A changeover and monitoring module with two alarm indicator and test combinations:

UMC...

MK...

MK...

Device Parameters Address settings for a changeover module

107TD47

PRC487

First MK...

Bus address 3

Address 4

Address 1

Test address 3

3, 4, 2

*

Second MK...

Alarm address

Address 2

Test address 3

Alarm address

3, 4, 1

*

Two changeover and monitoring modules, with two alarm indicator and test combinations each:

Device Parameters Address settings for the first

changeover module

Address settings for the

second changeover module

107TD47

PRC487

First MK...

Second MK...

22

Bus address 5 7

Address 6 8

Address 1 3

Test address 5 7

Alarm address

5, 6, 2

*

Address 2 4

Test address 5 7

Alarm address

5, 6, 1

*

7, 8, 4

7, 8, 3

*

*

TGH1322en/06.2009

Page 23

Trouble shooting

6. Trouble shooting

6.1 PRC487 error messages

If a fault occurs, the MEDICS® system messages will enable you to narrow down the possible

causes. Some messages can have several causes. The following possible errors are indicated

by messages in the PRC487 display.

If you cannot trigger a test function on the PRC487, an alarm message may already be pending, or there may be an open circuit at terminal 9-Ub of the PRC487.

PRC message Possible causes

Failure line 1 Power supply failure on line 1. SUE487 failure. Open circuit, ter-

minal 6-GND3. Defective fuse 1-L1, 1-L2.

Failure line 2 Power supply failure on line 2. SUE487 failure. Open circuit, ter-

minal 5-GND3. Defective fuse 2-L1, 2-L2.

Failure distribution

board

Failure K3 Failure of the internal relay K3 (SUD487). Open circuit terminal

K1/2 manual mode Contactor control has been changed to manual mode. Auto-

Short-circuit distribution board

Wire break K1 on Open circuit when controlling K1 via terminals 11/14 of the

Wire break K1 off Open circuit when controlling K1 via terminals 21/24 of the

Wire break K2 on Open-circuit when controlling K2 via terminals 31/34, auxiliary

Wire break K2 off Open circuit when controlling K2 via terminals 41/44 of the

Fault K1 on K1 cannot be activated. K1 is jammed. Open circuit, auxiliary

Fault K1 off K1 cannot be switched off via latching module. K1 is jammed.

Power supply failure downstream of the changeover module.

SUE487 failure. Open circuit terminal 4-GND3

IN3-GND3

matic changeover will no longer be performed!

Short-circuit downstream of changeover module. Following a

failure on line 1 and changeover to line 2, line 2 drops out and

voltage is present on line 1 again.

PRC487, auxiliary contact K2 or resistor R1.

PRC487 for the purpose of shutting down the latching module.

contact K1 or resistor R2.

PRC487 for the purpose of shutting down the latching module.

contact at terminal GND1 or IN1 of PRC487.

Open circuit, auxiliary contact at terminal GND1 or IN1 of

PRC487.

TGH1322en/06.2009

Fault K2 on K2 cannot be activated. K2 is jammed. Open circuit, auxiliary

contact at terminal GND2 or IN2 of PRC487.

Fault K2 off K2 cannot be deactivated via latching module. K2 is jammed.

Open circuit, auxiliary contact at terminal GND2 or IN2 of

PRC487.

Failure K1 K1 on, but no voltage downstream of K1. Open circuit, main

contacts K1 or line upstream or downstream of K1. SUE487 failure.

23

Page 24

PRC message Possible causes

Failure K2 K2 on, but no voltage downstream of K2. Open circuit, main

contacts K2. SUE487 failure. Open circuit terminal 4-GND3.

RS-485 fault Undefined characters on the BMS bus. There is more than one

master in the network. More than one slave has the same

address. Interface (A,B) polarity is incorrect.

No MASTER There is no master. No alarm indicator and test combination or

operator panel connected. Bus line interrupted.

EEPROM fault Defective EEPROM or impermissible value stored in EEPROM.

CV460 fault Settings made in SETUP OPTION menu, even though no CV460

is connected.

RK474 fault Settings carried out in the SETUP OPTION menu, although no

RK474 was connected.

Trouble shooting

You can find additional information on messages in the instruction leaflets for the "PRC487

®

control device" and "107TD47 A-ISOMETER

" in chapter "9. Manufacturer's certificate, check-

list, circuit documentation" of this operating manual.

6.2 Fuses F1...F11

If fuses F1 to F11 are tripped, there may be a defect in the changeover module.

These fuses should only be replaced following consultation with Bender.

Caution

Data for fuses F1 to F11

Tripping current......................................................................................................................................... .......4 A, time lag

Breaking capacity ........................................................................................................................................................ 10 kA

ELU type ................................................................................................................................................................... 189140

Dimensions.....................................................................................................................................................6.25 x 32 mm

24

TGH1322en/06.2009

Page 25

Periodic verification and service

7. Periodic verification and service

7.1 Periodic verification

The following periodic verification must be performed on electrical installations in compliance with the local or national regulations that apply. We recommend for your Bender products:

Test To be

performed by

Functional test of IT system monitoring

(insulation, load current, transformer temperature and connection monitoring) by pressing the TEST button on the alarm

indicator and test combination or on the alarm indicator and

operator panel.

Functional test of the changeover module*:

Test of the automatic changeover modules.

Please observe the information in chapter "Testing the changeover module"!

Functional test of the IT system monitoring (insulation, load

current, transformer temperature and connection monitoring)

on the insulation monitoring device.

Testing the set values and the changeover periods Skilled person every 12

Testing of the changeover module, the IT system monitoring,

the connection to the SCADA system (Supervisory Control And

Data Acquisition) (if applicable) and the interaction of the components in the system.

This test includes the following services:

- Inspection:

Marking, display elements, mechanical components,

wiring, parameterisation, connection of

third-party equipment, evaluation of fault memory

- Measurement:

Internal/external supply voltages/potentials,

bus voltage, bus protocol, bus scan

- Practice test:

Device function, device communication

- Documentation:

Test results, recommendations for remedial action

Medical

personnel

Skilled person every 6 months

Skilled person every 6 months

Bender Service every 24

Interval

once every

working day

months

months

* This test must only be performed by an electrically skilled person who has been commissioned to do

so in agreement with the person responsible for the medical location.

Before carrying out the tests, please refer to the instructions relating to the functional tests

in the checklist. If no national directives apply, you should perform the tests recommended

by IEC 60364-7-710:2002-11, section 710.62 and DIN VDE 0100-710 (VDE 0100 Part

710):2002-11, section 710.62.

TGH1322en/06.2009

25

Page 26

Periodic verification and service

7.1.1 Testing the changeover module

Step Response

Disconnect line 1:

1. Disconnect the fuse switch disconnector or

fuse or

2. Remove fuse F1 or

3. Remove the microfuse on the SUE487/SUD487

Reconnect line 1 1. Changeover to line 1 after delay time t(on).

Disconnect line 2 1. Alarm message "Failure line 2"*

Reconnect line 2 1. Alarm message "Failure line 2"* goes out

1. Changeover to line 2

2. Alarm message "Failure line 1"

3. Message on PRC487: "K1off, K2on"

2. Alarm message "Failure line 1"* goes out

3. Message on PRC487: "K1on, K2off"

Exception:

If an automatic switching back interlocking function is active, the changeover module remains on

line 2 and displays the message "interlocking". To

clear the switching back interlocking function,

interrupt the connection between contacts X3:40

and X3:57.

2. Message on PRC487: "K1on, K2off"

2. Message on PRC487: "K1on, K2off"

TEST on PRC487:

Press the TEST button, RESET button and MENU

button in sequence

To return to the standard display,

press the MENU button

1. Changeover to line 2.

Display: "** TEST **"

2. Changeover to line 1 after t(on).

3. Display of changeover period "t 1->2:

xxxxms" **

Message on PRC487: "K1on, K2off"

* Or corresponding parameterised text. Alarm messages are also transferred via bus or

alarm contacts to TMs, MKs or the building services control system. Test, if necessary.

** Up to a maximum of 15 s; above this no indication possible.

7.2 Service

Bender would be delighted to provide on-site service for commissioning and periodic verification. Please contact our Service Department for more information:

Service-Hotline:

0700-BenderHelp (Telephone and Fax)

Carl-Benz-Straße 10 • 35305 Grünberg • Germany

Tel: +49 6401 807-760 • Fax: +49 6401 807-629

E-Mail: info@bender-service.com • www.bender-de.com

7.3 Maintenance

The MEDICS® module does not contain any parts that require maintenance. Despite this, the

intervals specified for periodic verification should be adhered to.

26

TGH1322en/06.2009

Page 27

Data

8. Data

8.1 TÜV-test report

In 2003, the TÜV Süddeutschland, Bau und Betrieb GmbH, based in Munich, Germany, tested the changeover and monitoring modules in the MEDICS

®

system range.

The complete test report is available at Bender.

TGH1322en/06.2009

27

Page 28

8.2 Standards

The changeover and monitoring module conforms to the following standards:

z DIN VDE 0100-710 (VDE 0100 Part 710): 2002-11

z DIN VDE 0100-725 (VDE 0100 Part 725): 1991-11

z DIN VDE 0100-718 (VDE 0100-718):2005-10

z ÖVE/ÖNORM E8007: 2007-12

z IEC 60364-7-710: 2002-11

z DIN EN 61557-8 (VDE 0413 Part 8):2007-12

z IEC 61557-8:2007-01

z EN 61557-8:2007-07

z DIN EN 60439-1 (VDE 0660 Part 500):2005-01

8.3 Manufacturer's certificate

As part of the scope of supply for the changeover and monitoring module, you will find a

manufacturer's certificate in chapter "9. Manufacturer's certificate, checklist, circuit documentation" of this manual.

Data

8.4 Technical data

Insulation coordination acc. to IEC 60664-1

Rated insulation voltage ........................................................................................................................................AC 250 V

Rated impulse voltage/pollution degree ..................................................................................................................4 kV/3

Voltage ranges

Nominal system voltage U

Nominal frequency f

Supply voltage U

Operating range of U

Frequency range of US......................................................................................................................................... 50...60 Hz

Power section/switching elements

Switching elements ............................................................................................................................... latched contactors

Adjustable changeover period......................................................................................................................... < 0.5... 20 s

Rated operational current I

Rated operational voltage U

Frequency of U

................................................................................................................................................. 50 ... 60 Hz

e

Operating range of U

Voltage monitoring

Adjustable undervoltage response value ......................................................................................................0.7 ... 0.9 x U

Response value overvoltage ..................................................................................................................................1.15 x U

Response time tan........................................................................................................................................... 50 ... 250 ms

Response time t(off) can be set in 50 ms increments.................................................................................... 0 ... 9950 ms

Return transfer time t(on) can be set in 1 s increments ......................................................................................0 ... 249 s

Idle time, can be set in 50 ms increments...................................................................................................... 0 ... 9950 ms

...................................................................................................................................AC 230 V

n

....................................................................................................................................DC, 50...60 Hz

n

...................................................................................................................................................AC 230 V

S

................................................................................................................................... 0.8...1.15 x U

S

..................................................................................................................... see ordering data

e

.................................................................................................................................AC 230 V

e

................................................................................................................................... 0.8...1.15 x Ue

e

S

e

e

28

TGH1322en/06.2009

Page 29

Data

Insulation monitoring

Response value R

, adjustable......................................................................................................................50 ... 500 kΩ

an

Hysteresis................................................................................................................................................................. < 25 %

Response time t

Max. permissible system leakage capacitance C

Measuring voltage U

Measuring current Im max. (where R

Internal DC resistance R

Impedance Z

Max. permissible extraneous DC voltage U

where RF = 0.5 x Ran and Ce = 1 μF ............................................................................................ < 3 s

an

.................................................................................................................................................. 12 V

m

..................................................................................................................................... > 240 kΩ

i

at 50 Hz........................................................................................................................................ > 200 kΩ

i

= 0 Ω).................................................................................................... < 50 μA

F

.................................................................................................... < 5 μF

e

........................................................................................................ DC 375 V

fg

Overload monitoring

Adjustable response value .....................................................................................................................................5 ... 50 A

Hysteresis........................................................................................................................................................................4 %

Temperature influence .................................................................................................................................. < 0.15 % / °C

Overtemperature monitoring

Response value ........................................................................................................................................................... 4 kΩ

Release value ............................................................................................................................................................ 1.6 kΩ

PTC resistors acc. to DIN 44081................................................................................................................... max. 6 in series

Interfaces

Interface/protocol............................................................................................................................................ RS-485/BMS

Connection..................................................................................................................................................... terminals A/B

Max. cable length ............................................................................................................................................... ≤ 1200 m

Recommended cable (shielded, shield connected to PE at one end) ..........................................at least J-Y(St)Y 2 x 0.6

Terminating resistor ................................................................................................................................. 120 Ω (0.25 W)

Switching elements

Switching elements ........................................................................................................................... changeover contacts

Operating principle.......................................................................................................... adjustable N/C or N/O operation

Electrical service life, number of cycles...................................................................................................................... 12000

Rated contact voltage............................................................................................................................AC 250 V/DC 300 V

Making capacity .................................................................................................................................................. AC/DC 5 A

Breaking capacity ....................................................................................................................... 2 A, AC 230 V, cos phi 0.4

.............................................................................................................................................. 0.2 A, DC 220 V, L/R = 0.04 s

General data

EMC immunity ................................................................................................................................. acc. to EN 61000-6-2

EMC emission .................................................................................................................................. acc. to EN 61000-6-4

Shock resistance IEC 60068-2-27 (device in operation).................................................................................. 15 g/11 ms

Bumping IEC 60068-2-29 (during transport) .................................................................................................... 40 g/6 ms

Vibration resistance IEC 60068-2-6 (device in operation)....................................................................... 1 g / 10...150 Hz

Vibration resistance IEC 60068-2-6 (device not in operation).............................................................. 2 g /

10 ... 150 Hz

Ambient temperature during operation.................................................................................................... -10 °C...+50 °C

Ambient temperature for storage.............................................................................................................. -40 °C...+70 °C

Climatic class acc. to DIN IEC 60721-3-3 ...................................................................................................................... 3K5

Operating mode ............................................................................................................................... continuous operation

Mounting position.................................................................................................................................................... vertical

Connection..............................................................................................................................................modular terminals

Power section connection type

Cage-clamp spring terminal (at I

< 65 A, AC3) ................................................................... 1.5 ... 16 mm2 (AWG 16-6)

e

Tightening torque............................................................................................................... 0.5 ... 0.6 Nm (4.3 ... 5.3 lb-in)

Cage-clamp spring terminal (at I

≥ 65 A, AC3).................................................................... 6 ... 35 mm2 (AWG 28-12)

e

Tightening torque............................................................................................................... 0.5 ... 0.6 Nm (4.3 ... 5.3 lb-in)

TGH1322en/06.2009

29

Page 30

Data

Control section connection type

Cage-clamp spring terminal ......................................................................................................................0.08 ... 2.5 mm

Degree of protection, internal components (IEC 60529)............................................................................................. IP30

Degree of protection, terminals (IEC 60529)............................................................................................................... IP 20

Mounting into standard distribution panels ............................................................see table "Dimensions and weights"

Flammability class.................................................................................................................................................. UL94V-0

Protection class ...........................................................................................................................................................Class I

Power consumption.....................................................................................................................see ordering information

Approximate weight ................................................................................................. see table "Dimensions and weights"

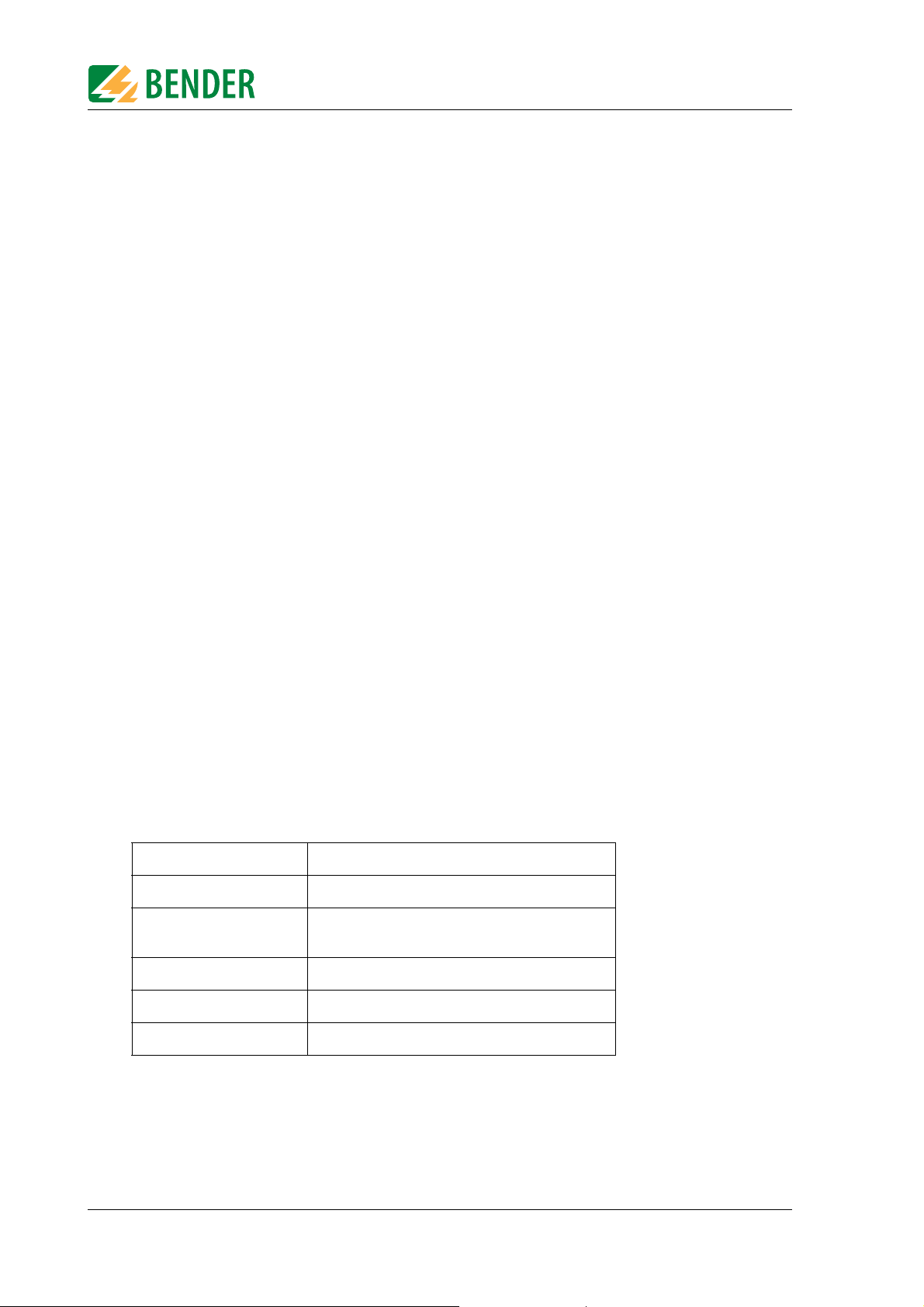

8.4.1 Dimension and weights

2

Type Pan els/ rows Di mensi ons

in mm

Width (W) Height (H) Depth (T) mm kg

Recommended

cabinet depth

Wei ght

approx.

UMC107E-25 1/6 250 900 220 300 13

UMC107E-40 1/6 250 900 220 300 13

UMC107E-65 1/6 250 900 220 300 14

UMC107E-80 1/6 250 900 220 300 15

The height of one row is 150 mm. The width of one panel is 250 mm.

8.5 Ordering information

Type Nom inal

current (AC-3)

of the

UMC107E-..

UMC107E-25 25 A 18 A 50 A gL/gG 3.15 kVA 18 W B92056000

UMC107E-40 40 A 18 A 50 A gL/gG 3.15 kVA 18 W B92056001

Max.

permissible

current acc. to

DIN VDE

0100-710

Max.

permissible

fuse

Recommended

transformer

power

Power

consumption

max.

Art. No.

UMC107E-65 65 A 29 A 80 A gL/gG 3.15 ... 6.3

19 W B92056002

kVA

UMC107E-80 80 A 42 A 100 A gL/gG 8 kVA 19 W B92056003

30

TGH1322en/06.2009

Page 31

Manufacturer's certificate, checklist, circuit documentation

9. Manufacturer's certificate, checklist, circuit documentation

The individual documents compiled for your MEDICS®module consist of:

z Manufacturer's certificate

z Commissioning checklist

z If necessary:

– Connection diagrams

– Circuit diagrams

This manual contains the instruction leaflets for the individual MEDICS

components.

®

module

TGH1322en/06.2009

31

Page 32

Manufacturer's certificate, checklist, circuit documentation

32

TGH1322en/06.2009

Page 33

INDEX

A

assigning addresses -examples 22

B

BMS bus 10

C

changeover module 11

checklist 21

commissioning 21

common alarm 11

connection 17

D

device-specific safety information

8

F

factory settings 21

functional test 25

fuse 30

fuses 15

G

gateway 10

monitoring 11

O

operating theatre light 11

ordering information 30

P

periodic verification 25

persons 7

power supply 12, 17

protocol converter 10, 20

R

relay outputs 10

response time 21

S

SCADA system 20

selectivity 15

service 26

settings 10, 21

short-circuit protection 15

supply

- preferred

- second 10

system components 5, 12

11

I

insulation monitoring 11

intended use 7

isolating transformer 17

L

latching 10

line 3 10

load 16

load current measurement 11

M

maintenance 26

MEDICS® 9

messages 23

TGH1322en/06.2009

T

technical data 28

temperature sensor 20

test report 27

total off-time 10

transformers for the IT system 15

trouble shooting 23

W

warning label 17

Page 34

INDEX

TGH1322en/06.2009

Page 35

Page 36

Dipl.-Ing. W. Bender GmbH & Co.KG

Londorfer Str. 65 • 35305 Grünberg • Germany

Postfach 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-Mail: info@bender-de.com

Web: http://www.bender-de.com

Page 37

PRC487

Steuergerät für

Deutsch English

Umschalteinrichtungen

Bestimmungsgemäße Verwendung

Das Steuergerät PRC487 dient zur zentralen Steuerung von Medics-Modulen der Baureihen UMC..., USC... und UFC... Medics-Module sind besonders geeignet zur Überwachung und

Umschaltung der Stromversorgung von medizinisch genutzten

Räumen nach DIN VDE 0100-710: 2002-11.

Diese Anleitung beschreibt PRC487 mit der eingebauten Softwareversion 1.92.

Sicherheitshinweise allgemein

Montage, Anschluss und Inbetriebnahme nur durch Elektrofachkraft!

Beachten Sie unbedingt:

● die bestehenden Sicherheitsvorschriften und

● das beiliegende Blatt "Wichtige sicherheitstechnische Hin-

weise für BENDER-Produkte".

Funktionsbeschreibung

Das PRC487 steuert die Schaltorgane und überwacht sie auf

Drahtbruch und Schaltzustand.

Control device for switchover modules

Intended use

The intended use of the control device PRC487 is the central control of MEDICS modules, such as UMC..., USC... and UFC...

MEDICS modules are designed to monitor and switchover power

supplies in medically used rooms according to IEC 60364-7-710.

This instruction leaflet describes the PRC487 with integrated software version 1.92.

Safety information

Installation, connection and commissioning of electrical equipment shall only be carried out by qualified electricians:

Particular attention shall be paid to:

● current safety regulations and

● the enclosed sheet "Important safety instructions for

BENDER products".

Function

The PRC487 controls the switching elements and monitors them

for open circuit and switching condition.

Die elementaren Funktionen des PRC487 sind doppelt vorhanden: Zum einen als elektronische Schaltung innerhalb der Systemkomponenten und zum anderen als Funktionen der

Firmware. Dadurch werden undefinierte Schaltzustände verhindert. Das Steuergerät PRC487 kommuniziert direkt mit dem

Spannungsüberwachungsgerät SUE487 (einphasige Systeme)

bzw. SUD487 (dreiphasige Systeme).

Status- und Fehlermeldungen des Medics-Moduls werden im Display des PRC487 angezeigt. Diese Meldungen werden über den

BMS-Bus zur angeschlossenen Melde- und Prüfkombination

MK24.. oder zum TM-Bedientableau übertragen und dort ebenfalls angezeigt.

Über die Bedienmenüs des PRC487 werden alle Parameter für das

Medics-Modul eingestellt. Ein Teil der Einstellungen ist mit einem

Passwort geschützt.

Bedienelemente

The essential functions of the PRC487 are provided within the system components as hard-wired electronic and also as firmware

functions. That avoids undefined switching conditions. The control device PRC487 communicates directly with the voltage monitoring device SUE487 (single-phase systems) respectively

SUD487 the (three-phase systems).

Status and fault messages from the Medics module are shown on

the display of the PRC487. These messages are transmitted to the

connected alarm indicator and test combination MK24.. or the

TM operator panel via the BMS bus and are also displayed on this.

All the parameters for the Medics module are set via the operating menus on the PRC487. Essential settings are protected by a

password.

Operating elements

TBP204003deen / 04.2008

Abb. 1: Bedienelemente

Figure 1: Operating elements

1

Page 38

PRC487

Legende der Bedienelemente

1 Beleuchtete Text-Anzeige (2 x 16 Zeichen).

2 LED „ALARM“ (gelb) leuchtet wenn ein Ansprechwert

überschritten wurde oder ein Fehler erkannt wurde.

3 LED „RS485“ (gelb) informiert über Aktivitäten auf dem

BMS-Bus.

4 LED „ON“ (grün) leuchtet, wenn Gerät im Betrieb ist.

5 Im Anzeige-Modus: Öffnet das TEST-Menü, in dem eine

Umschaltung von Leitung 1 auf Leitung 2 ausgelöst wer-

den kann.

Im Menü-Modus: Pfeiltaste zur Navigation innerhalb der

Menüs und zum Ändern von Parametern.

6 Im Anzeige-Modus: Zum Rücksetzen (RESET) von be-

stimmten Alarmmeldungen.

Im Menü-Modus: Pfeiltaste zur Navigation innerhalb der

Menüs und zum Ändern von Parametern.

7 MENÜ-Taste zum Wechsel vom Anzeige-Modus in den

Menü-Modus.

Im Menü-Modus: ENTER-Taste zur Bestätigung der ange-

wählten Menüpunkte bzw. zur Bestätigung der ausge-

wählten Parameter.

Montage und Anschluss

Stellen Sie vor Einbau des Gerätes und vor Arbeiten an den Anschlüssen des Gerätes sicher, dass

die Anlage spannungsfrei ist.

Wird dies nicht beachtet, so besteht für das Personal die Gefahr eines elektrischen Schlages.

Außerdem drohen Sachschäden an der elektrischen Anlage und die Zerstörung des Gerätes.

Legend to operating elements

1 Illuminated text display (2 x 16 characters) .

2 “ALARM“ LED (yellow) lights up when the response value

has been exceeded or a fault has been detected.

3 LED "RS485" (yellow) signals activities on the BMS bus.

4 "ON" LED (green) lights up when the device is in opera-

tion.

5 In the display mode: to start the TEST menu. Pressing

causes a switchover from line 1 to line 2.

In the Menu mode: arrow key for navigation within the

menus and to change the parameters.

6 In the display mode: to reset alarm messages.

In the Menu mode: arrow key for navigation within the

menus and to change parameters.

7 Menu key to change from the display mode to the Menu

mode.

In the Menu mode: ENTER key to confirm the selected

menu items or to confirm the selected parameters.

Installation and connection

Prior to installation and before any work is carried

out on the connecting cables, make sure that the

mains power is disconnected.

Failure to comply with this safety information

may cause electric shock to personnel.

Substantial damages to the electrical installation

and destruction of the device may occur.

Montage

Das Gerät ist für folgende Einbauarten geeignet:

● Installationsverteiler nach DIN 43 871 oder

●

Schnellmontage auf Hutprofilschiene nach IEC 60715:1995-10

● oder Schraubmontage.

Maßbild

Abb. 2: alle Maße in mm

Installation

The device is suited for:

●

mounting into standard distribution panels acc. to DIN 43 871

● DIN rail mounting in compliance with IEC 60715:1995-10

● or screw mounting.

Dimension diagram

Figure 2: all dimensions in mm

2

TBP204003deen / 04.2008

Page 39

PRC487

Anschluss

Schließen Sie das Gerät entsprechend dem Anschlussplan in der

Anleitung des Medics-Moduls an. Beachten Sie dabei das Anzugsdrehmoment für die Klemmschrauben (siehe Technische Daten).

Anschlüsse

GND3 Masse,

gemeinsamer Eingang der Klemmen 4, 5, 6, IN3, IN4,

SDA, SCL

4 Eingang Leitung 3

high oder offen = Ausfall Leitung 3

5 Eingang Leitung 2

high oder offen = Ausfall Leitung 2

6 Eingang Leitung 1

high oder offen = Ausfall Leitung 1

Ub Ausgang + 12 V

7 PWM-Open-Collector Ausgang Ansprechwert Unter-

spannung

Low = oberer Ansprechwert

high = unterer Wert

8 Dieser Kontakt hat keine Funktion

9 Open-Collector Ausgang Test-Relais

0V = Relais ein, TEST

10 Dieser Kontakt hat keine Funktion

IN3 Eingang Hilfsschütz: High oder offen = Ausfall K3

IN4 Eingang Handbetrieb: Low = Handbetrieb

k, l Anschluss Stromwandler für N-Leiterüberwachung

A, B BMS-Bus

A3, A4 Versorgungsspannung U

GND1 Masse des Eingangs IN1

IN1 Eingang Schaltzustand Schaltorgan K1: Low = K1 ein

GND2 Masse des Eingangs IN2

IN2 Eingang Schaltzustand Schaltorgan K2: Low = K2 ein

11,14 Relaiskontakt zur Ansteuerung des Einschaltens von

K1 (K1on) mit Drahtbruchüberwachung

21, 24 Relaiskontakt zur Ansteuerung des Ausschaltens von

K1 (K1off) mit Drahtbruchüberwachung

31,34 Relaiskontakt zur Ansteuerung des Einschaltens von

K2 (K2on) mit Drahtbruchüberwachung

41, 44 Relaiskontakt zur Ansteuerung des Ausschaltens von

K2 (K2off) mit Drahtbruchüberwachung

51, 52, 54 Potentialfreier Wechsler als Sammelstörmeldung.

45 Drahtbruchüberwachung

SDA, SCL I²C-Bus. Interne serielle Schnittstelle zur Kommunika-

tion mit Drahtbruch-Überwachung CV460 bzw. Re-

laisbaustein RK4xx.

s

Connection

Connect the RCM according to the wiring diagram described in

the operating instructions of the Medics module. Please observe

the tightening torque for the terminal screws (see technical data).

Connections

GND3 Ground,

common input for the terminals 4, 5, 6, IN3, IN4, SDA,

SCL

4 Input line 3

high or open = failure line 3

5 Input line 2

high or open = failure line 2

6 Input line 1

high or open = failure line 1

Ub Output + 12 V

7 Analogue output: setpoint selection undervoltage for

SUE487/SUD487

Low = upper response value

High = lower value

8 Contact without function

9 Open-collector output test relay

0 V = relay On, TEST

10 Contact without function

IN3 Input contactor relay: High or open = failure K3

IN4 Input manual operation: Low = manual operation

k, l Connection current transformer for N conductor mo-

nitoring

A, B BMS bus

A3, A4 Supply voltage U

GND1 Ground of the input IN1

IN1 Input state of switching element K1: Low = K1 On

GND2 Ground of the input IN2

IN2 Input status of switching element K2: Low = K2 On

11, 14 Relay contact to activate K1 (K1 on) with open-circuit

monitoring.

21, 24 Relay contact to deactivate K1 (K1off) with open-cir-

cuit monitoring.

31, 34 Relay contact to activate K2 (K2on) with open-circuit

monitoring.

41, 44 Relay contact to deactivate K2 (K2off). with open-cir-

cuit monitoring.

51,52,54 Potential free changeover contact for collective alarm

message.

45 Open-circuit monitoring

SDA, SCL PC bus. Internal serial interface for communication

with open-circuit monitoring device CV460 or relay

module RK4xx.

S

TBP204003deen / 04.2008

3

Page 40

PRC487

Inbetriebnahme

Kontrollieren Sie vor der Inbetriebnahme den ordnungsgemäßen

Anschluss des Gerätes

Das PRC487 ist Bestandteil eines Medics-Moduls.

Führen Sie die Inbetriebnahme entsprechend den

Hinweisen in der Anleitung des Medics-Moduls durch.

.

Bedienen und Einstellen

Während des Betriebes befindet sich das PRC487 im Anzeige-Modus. Durch Betätigen der MENU-Taste wird in den Menü-Modus

gewechselt. Hier erfolgt die Einstellung aller Parameter für die

Umschaltung.

Meldungen im Anzeigemodus

Im normalen und fehlerfreien Betrieb zeigt die Anzeige:

K1:on K2:off

K1:on Das Schaltorgan K1 ist angezogen;

die Versorgung erfolgt über die bevorzugte Leitung 1.

K1:off Das Schaltorgan K2 ist abgefallen;

es erfolgt keine Versorgung über die zweite Leitung.

Commissioning

Prior to commissioning, check proper connection of the device.

The PRC487 is a component of the Medics module.

For commissioning please refer to the operating instructions of the Medics module.

Operation and setting

During operation, the PRC487 is in the display mode. Pressing the

MENU key changes to the Menu mode. All the parameters for the

switchover can be set in this mode.

Messages in the display mode

During normal and fault-free operation the display indicates:

K1:on The switching element K1 is energized;

the supply source is the preferred supply (line 1).

K1:off The switching element K2 is deenergized;

no supply from the second supply line.

Alarmmeldungen

Erkennt das PRC487 einen Alarm, so zeigt es den entsprechenden

Alarmtext im Display an. Die Alarmmeldung wird auf dem BMSBus gesendet. Dabei können sich mehrere ähnliche Alarmmeldungen einen Kanal teilen.

Die mit * markierten Alarmmeldungen bleiben erhalten, bis sie

mit der Taste „RESET“ gelöscht werden.

Alarmtextanzeige des

PRC487

Ausfall Leitung 1

Ausfall Leitung 2

Ausfall Verteiler

Ausfall N-Leiter Ausfall oder Unterbrechung des Neutral-Leiters 4

Störung K1 on Störung in der Ansteuerung von K1 5

Störung K1 off Störung in der Ansteuerung zum Abfallen von K1 5

Drahtbruch K1 on Drahtbruch in der Ansteuerung von K1 bzw. K11 5

Drahtbruch K1 off

Drahtbruch K1 ON Drahtbruch in der Ansteuerung von K1 (Hauptschütz) 5

Drahtbruch K1 OFF

Ausfall K1 *

Störung K2 on Störung in der Ansteuerung von K2 6

Störung K2 off Störung in der Ansteuerung zum Abfallen von K2 6

Drahtbruch K2 on Drahtbruch in der Ansteuerung von K2 bzw. K12 6

Bedeutung

Spannungsausfall (Unterspannung oder Überspannung) auf Leitung 1

Spannungsausfall (Unterspannung oder Überspannung) auf Leitung 2

Spannungsausfall (Unterspannung oder Überspannung) hinter der Umschalteinrichtung

Drahtbruch in der Ansteuerung zum Abfallen von K1

bzw. K13

Drahtbruch in der Ansteuerung zum Abfallen von K1

(Hauptschütz)

Ausfall des Schützes für Leitung 1 (Schütz eingeschaltet, dennoch keine Spannung am Verteiler)

Kanal

1

2

3

5

5

5

Alarm messages

If a PRC487 recognizes an alarm, the respective alarm message

appears on the display. The alarm message is provided at the BMS